befcbec0bc5d609a9605832f452ce3f7.ppt

- Количество слайдов: 18

HEP Conductor Development Program for Nb 3 Sn and Bi-2212 D. R. Dietderich MAP HTS Magnet Workshop, FNAL May 30 -31, 2012 MAP Workshop, May 30 -31, 2012 D. R. Dietderich

Outline • CDP Advisory Board • Funding • CDP Goals and Plans – Short Term 2 -3 years – Hi-Lumi – Beyond 3 years – MAP, Hi-Energy LHC • Status of on going Nb 3 Sn work at OST • Status of effort Bi-2212 MAP Workshop, May 30 -31, 2012 D. R. Dietderich

CDP Organization • Bruce Strauss – DOE • Daniel Dietderich (manager) – LBNL • CDP Advisory Board – – – – Ken Marken -- DOE Arup Ghosh – BNL Giorgio Ambrosio – FNAL Lance Cooley – FNAL David Larbalestier – FSU Peter Lee – FSU Arno Godeke – LBNL A. D. Mc. Inturff – TAMU • Funds received from DOE • Request proposals: – CDP Management provides Task guidelines – Advisory Board reviews proposals • Tasks deemed most important for HEP are funded • OST delivers wire and reports • Characterization is performed on wire by BNL, LBNL and NIST • Wire available to HEP magnet programs MAP Workshop, May 30 -31, 2012 D. R. Dietderich

Conductor R&D Funding • CDP future funding – Carry Forward – FY 12 (Oct. 2011) – FY 13 (Oct. 2012) – FY 14 (Oct. 2013) – FY 15 (Oct. 2014) – Total ~$200 k $450 k $2, 000 k • Past funding for Bi-2212 – ~$75 k per year for last 4 years MAP Workshop, May 30 -31, 2012 D. R. Dietderich

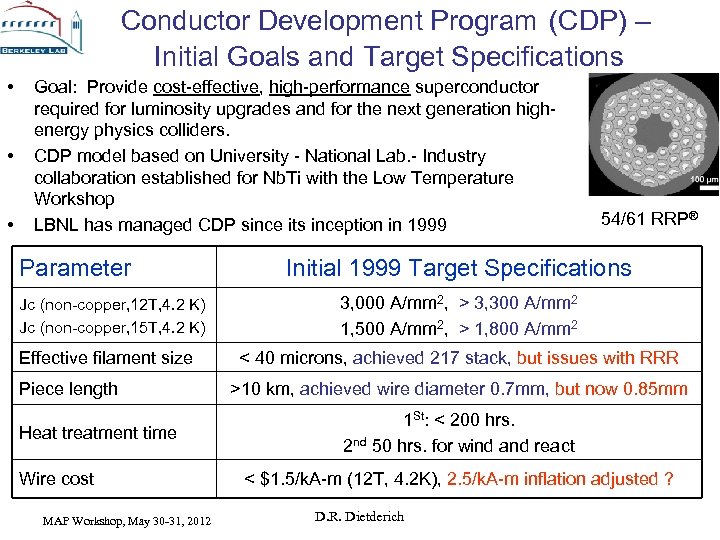

Conductor Development Program (CDP) – Initial Goals and Target Specifications • • • Goal: Provide cost-effective, high-performance superconductor required for luminosity upgrades and for the next generation highenergy physics colliders. CDP model based on University - National Lab. - Industry collaboration established for Nb. Ti with the Low Temperature Workshop LBNL has managed CDP since its inception in 1999 Parameter Jc (non-copper, 12 T, 4. 2 K) Jc (non-copper, 15 T, 4. 2 K) Effective filament size Piece length Heat treatment time Wire cost MAP Workshop, May 30 -31, 2012 54/61 RRP® Initial 1999 Target Specifications 3, 000 A/mm 2, > 3, 300 A/mm 2 1, 500 A/mm 2, > 1, 800 A/mm 2 < 40 microns, achieved 217 stack, but issues with RRR >10 km, achieved wire diameter 0. 7 mm, but now 0. 85 mm 1 St: < 200 hrs. 2 nd 50 hrs. for wind and react < $1. 5/k. A-m (12 T, 4. 2 K), 2. 5/k. A-m inflation adjusted ? D. R. Dietderich

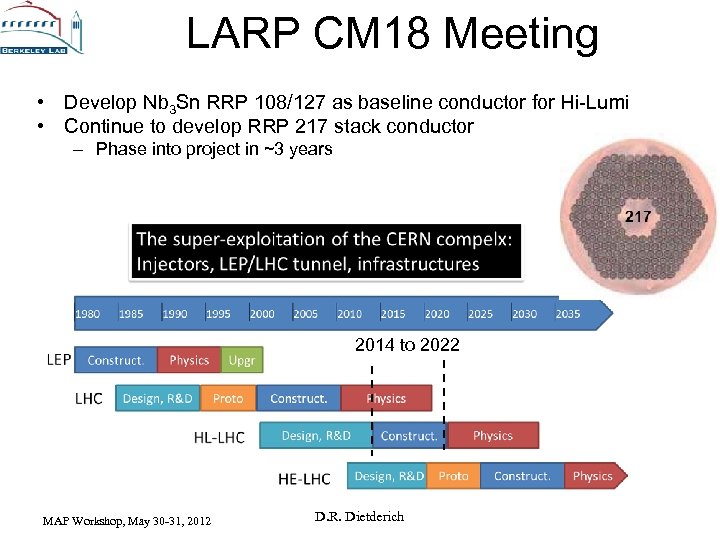

LARP CM 18 Meeting • Develop Nb 3 Sn RRP 108/127 as baseline conductor for Hi-Lumi • Continue to develop RRP 217 stack conductor – Phase into project in ~3 years 2014 to 2022 MAP Workshop, May 30 -31, 2012 D. R. Dietderich

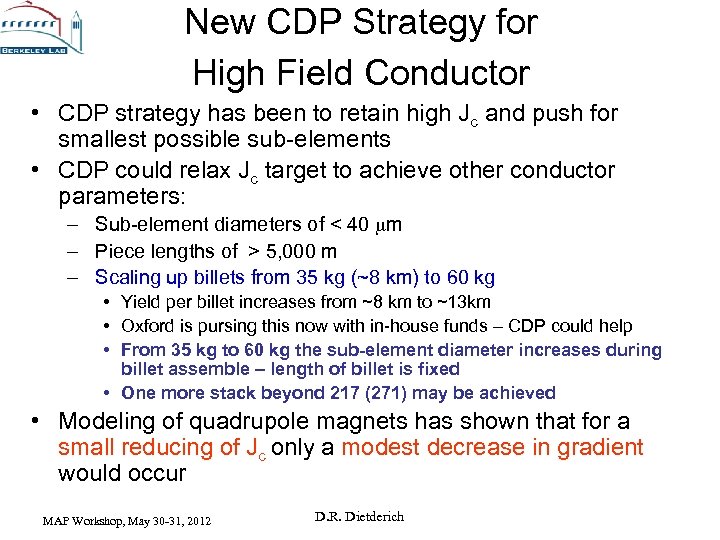

New CDP Strategy for High Field Conductor • CDP strategy has been to retain high Jc and push for smallest possible sub-elements • CDP could relax Jc target to achieve other conductor parameters: – Sub-element diameters of < 40 mm – Piece lengths of > 5, 000 m – Scaling up billets from 35 kg (~8 km) to 60 kg • Yield per billet increases from ~8 km to ~13 km • Oxford is pursing this now with in-house funds – CDP could help • From 35 kg to 60 kg the sub-element diameter increases during billet assemble – length of billet is fixed • One more stack beyond 217 (271) may be achieved • Modeling of quadrupole magnets has shown that for a small reducing of Jc only a modest decrease in gradient would occur MAP Workshop, May 30 -31, 2012 D. R. Dietderich

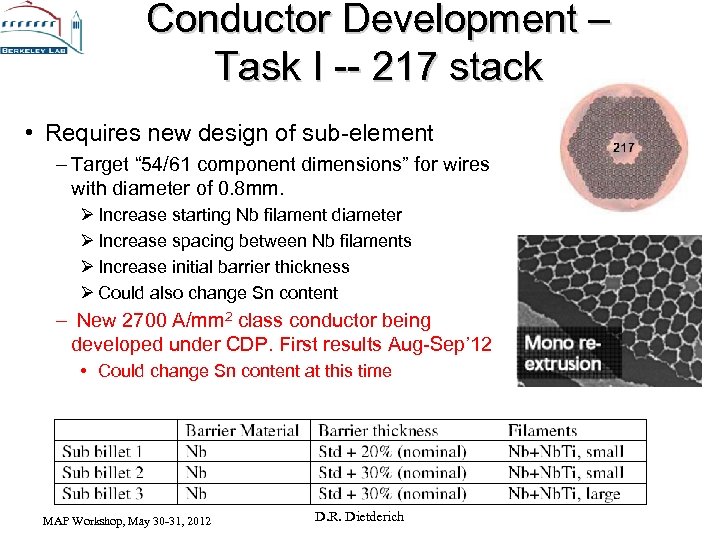

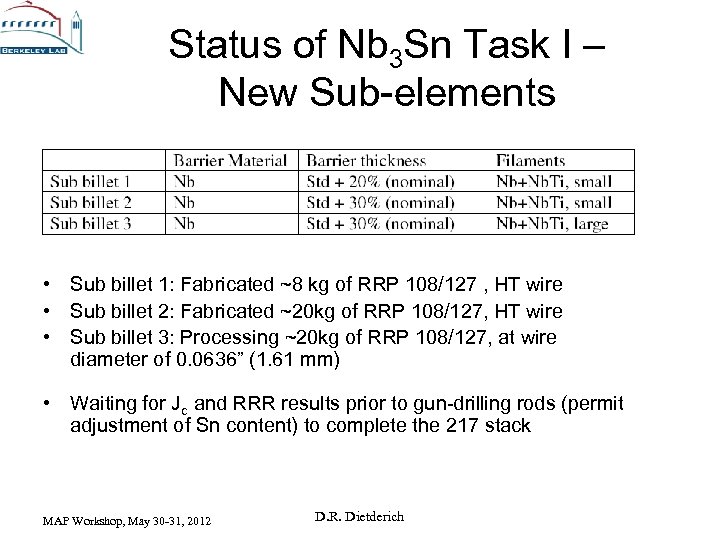

Conductor Development – Task I -- 217 stack • Requires new design of sub-element – Target “ 54/61 component dimensions” for wires with diameter of 0. 8 mm. Ø Increase starting Nb filament diameter Ø Increase spacing between Nb filaments Ø Increase initial barrier thickness Ø Could also change Sn content – New 2700 A/mm 2 class conductor being developed under CDP. First results Aug-Sep’ 12 • Could change Sn content at this time MAP Workshop, May 30 -31, 2012 D. R. Dietderich 8

Status of Nb 3 Sn Task I – New Sub-elements • Sub billet 1: Fabricated ~8 kg of RRP 108/127 , HT wire • Sub billet 2: Fabricated ~20 kg of RRP 108/127, HT wire • Sub billet 3: Processing ~20 kg of RRP 108/127, at wire diameter of 0. 0636” (1. 61 mm) • Waiting for Jc and RRR results prior to gun-drilling rods (permit adjustment of Sn content) to complete the 217 stack MAP Workshop, May 30 -31, 2012 D. R. Dietderich

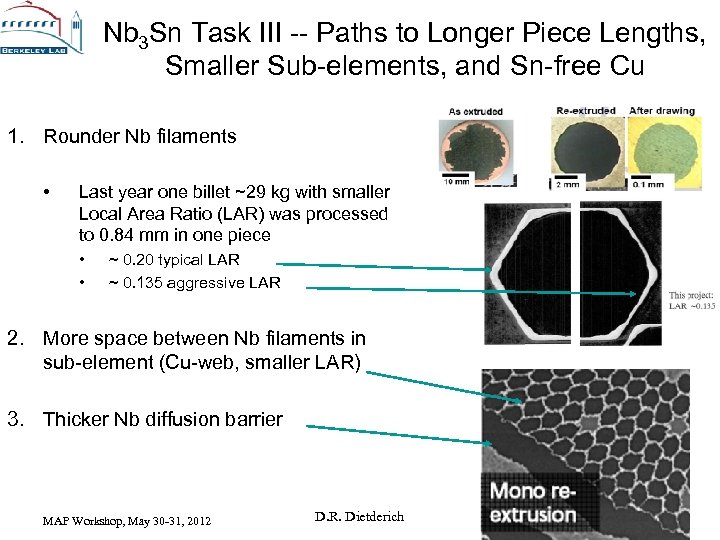

Nb 3 Sn Task III -- Paths to Longer Piece Lengths, Smaller Sub-elements, and Sn-free Cu 1. Rounder Nb filaments • Last year one billet ~29 kg with smaller Local Area Ratio (LAR) was processed to 0. 84 mm in one piece • • ~ 0. 20 typical LAR ~ 0. 135 aggressive LAR 2. More space between Nb filaments in sub-element (Cu-web, smaller LAR) 3. Thicker Nb diffusion barrier MAP Workshop, May 30 -31, 2012 D. R. Dietderich

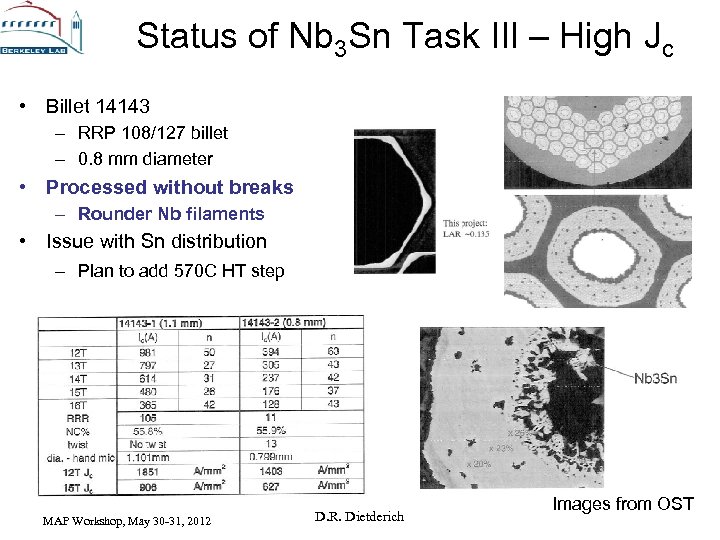

Status of Nb 3 Sn Task III – High Jc • Billet 14143 – RRP 108/127 billet – 0. 8 mm diameter • Processed without breaks – Rounder Nb filaments • Issue with Sn distribution – Plan to add 570 C HT step MAP Workshop, May 30 -31, 2012 D. R. Dietderich Images from OST

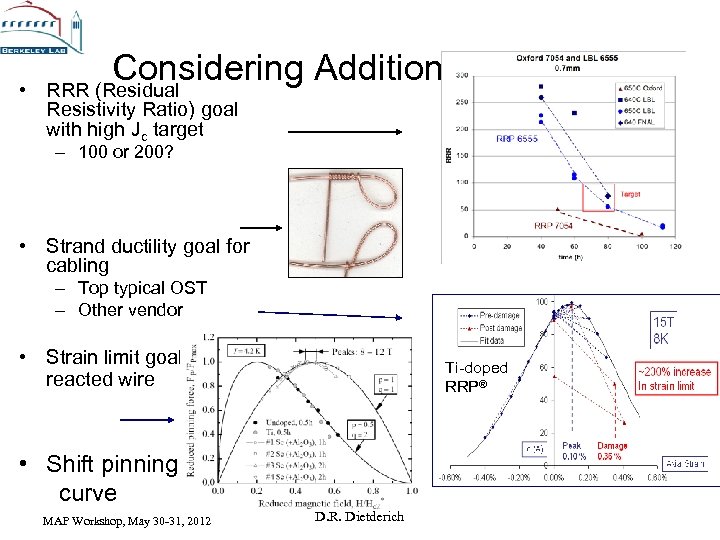

• Considering Additional CDP Goals RRR (Residual Resistivity Ratio) goal with high Jc target – 100 or 200? • Strand ductility goal for cabling – Top typical OST – Other vendor • Strain limit goal for reacted wire Ti-doped RRP® • Shift pinning curve MAP Workshop, May 30 -31, 2012 D. R. Dietderich

Nb 3 Sn Conductor Development Summary • Has transition to all Ti-doped conductor • Better tolerance to tensile strain • Plans to demonstrate 217 stack by end of 2012 • • Results of 3 new sub-element designs – Sept. 2012 Establish the 217 stack RRP® conductor in 2 years, perhaps 3 years. • Production of 3 billets from new sub-elements with best results from R&D billets from above. • Scale-up billets from 35 kg to 60 kg • Longer piece length • Easier to assemble billets • Continue to explore options for higher Jc • Could add more Cu to conductor for the same Ic MAP Workshop, May 30 -31, 2012 D. R. Dietderich

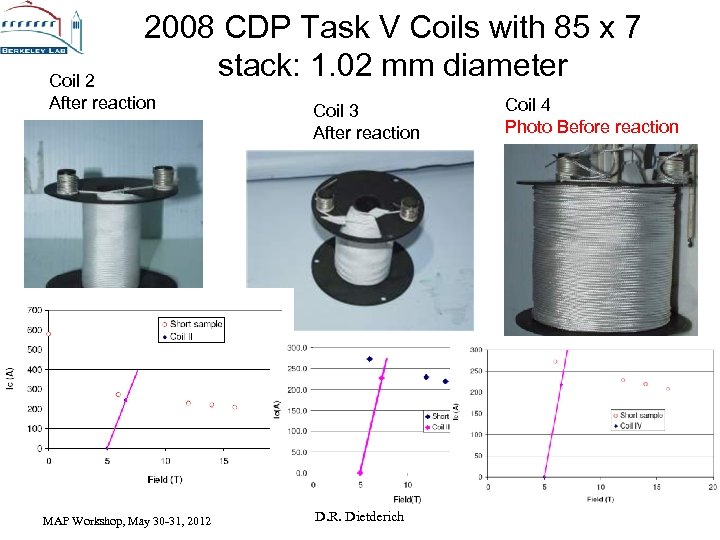

2008 CDP Task V Coils with 85 x 7 stack: 1. 02 mm diameter Coil 2 After reaction MAP Workshop, May 30 -31, 2012 Coil 3 After reaction D. R. Dietderich Coil 4 Photo Before reaction

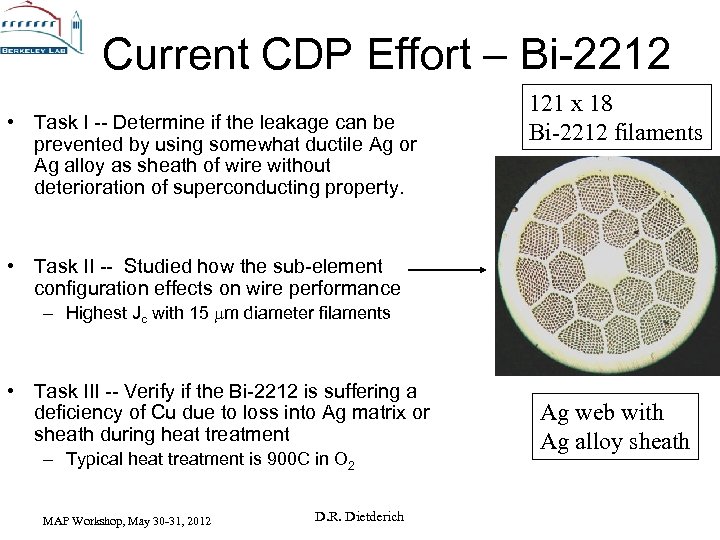

Current CDP Effort – Bi-2212 • Task I -- Determine if the leakage can be prevented by using somewhat ductile Ag or Ag alloy as sheath of wire without deterioration of superconducting property. 121 x 18 Bi-2212 filaments • Task II -- Studied how the sub-element configuration effects on wire performance – Highest Jc with 15 mm diameter filaments • Task III -- Verify if the Bi-2212 is suffering a deficiency of Cu due to loss into Ag matrix or sheath during heat treatment – Typical heat treatment is 900 C in O 2 MAP Workshop, May 30 -31, 2012 D. R. Dietderich Ag web with Ag alloy sheath

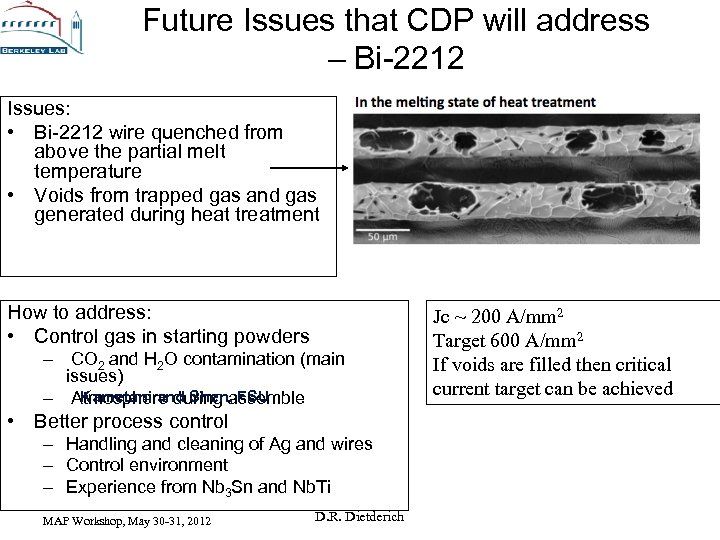

Future Issues that CDP will address – Bi-2212 Issues: • Bi-2212 wire quenched from above the partial melt temperature • Voids from trapped gas and gas generated during heat treatment How to address: • Control gas in starting powders – CO 2 and H 2 O contamination (main issues) Kametani and Shen, FSU – Atmosphere during assemble • Better process control – Handling and cleaning of Ag and wires – Control environment – Experience from Nb 3 Sn and Nb. Ti MAP Workshop, May 30 -31, 2012 D. R. Dietderich Jc ~ 200 A/mm 2 Target 600 A/mm 2 If voids are filled then critical current target can be achieved

Other Bi-2212 Issues • Powder supply – How concerned should we be? – Only Nexans, SCI has stopped production • Twisted Showa wires – About 6 years ago had identical twisted and un-twisted wire – Wires with a 14 mm twist lost 50% of Ic • What stresses can the Bi-2212 conductor tolerate? – Does less porosity help? – Can better Ag alloys help strengthen conductor? MAP Workshop, May 30 -31, 2012 D. R. Dietderich

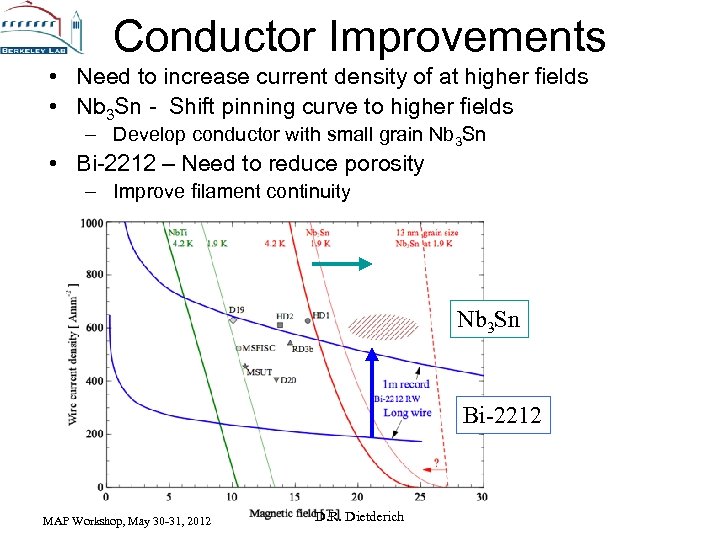

Conductor Improvements • Need to increase current density of at higher fields • Nb 3 Sn - Shift pinning curve to higher fields – Develop conductor with small grain Nb 3 Sn • Bi-2212 – Need to reduce porosity – Improve filament continuity Nb 3 Sn Bi-2212 MAP Workshop, May 30 -31, 2012 D. R. Dietderich

befcbec0bc5d609a9605832f452ce3f7.ppt