721aaea8b69cd1796271bc538578e78d.ppt

- Количество слайдов: 58

Helicopter Risk Mitigation International Association of Oil and Gas Producers Formerly E & P Forum Presentation to Regional IHST Meeting in New Delhi, 12 June 2006 By Bob Sheffield, representing OGP’s Aviation Subcommittee

Helicopter Risk Mitigation International Association of Oil and Gas Producers Formerly E & P Forum Presentation to Regional IHST Meeting in New Delhi, 12 June 2006 By Bob Sheffield, representing OGP’s Aviation Subcommittee

Overview • • • The current problem and the goal for improvement What’s been proven already What remains to achieve the goal Justifying the necessary risk mitigation measures Conclusions and summing up

Overview • • • The current problem and the goal for improvement What’s been proven already What remains to achieve the goal Justifying the necessary risk mitigation measures Conclusions and summing up

Three Main Points • The risk of flying in a helicopter is an order of magnitude greater than in an airliner– we have a problem • Helicopter safety can be improved significantly – we can fix it: – Proven risk mitigations are available for helicopters. – We need new helicopters built to the latest design standards. • To be effective at lowest possible cost requires a combined effort from: – – Regulators Manufacturers Operators Their customers - we need your help

Three Main Points • The risk of flying in a helicopter is an order of magnitude greater than in an airliner– we have a problem • Helicopter safety can be improved significantly – we can fix it: – Proven risk mitigations are available for helicopters. – We need new helicopters built to the latest design standards. • To be effective at lowest possible cost requires a combined effort from: – – Regulators Manufacturers Operators Their customers - we need your help

Oversight and Safety Go Hand In Hand • The best safety records come from those operations where either regulatory oversight or corporate care is highest. • Corporate care is more expensive and less effective when the operators serve customers with different standards. • If everyone in the industry (manufacturers, operators, regulators, and their customers) works together to implement the known, cost-effective solutions, these risk mitigations will be more effective and less costly.

Oversight and Safety Go Hand In Hand • The best safety records come from those operations where either regulatory oversight or corporate care is highest. • Corporate care is more expensive and less effective when the operators serve customers with different standards. • If everyone in the industry (manufacturers, operators, regulators, and their customers) works together to implement the known, cost-effective solutions, these risk mitigations will be more effective and less costly.

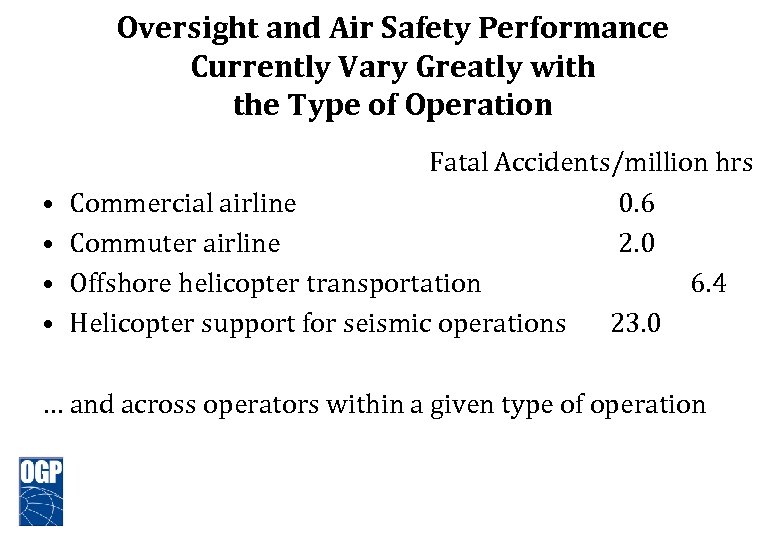

Oversight and Air Safety Performance Currently Vary Greatly with the Type of Operation • • Fatal Accidents/million hrs Commercial airline 0. 6 Commuter airline 2. 0 Offshore helicopter transportation 6. 4 Helicopter support for seismic operations 23. 0 … and across operators within a given type of operation

Oversight and Air Safety Performance Currently Vary Greatly with the Type of Operation • • Fatal Accidents/million hrs Commercial airline 0. 6 Commuter airline 2. 0 Offshore helicopter transportation 6. 4 Helicopter support for seismic operations 23. 0 … and across operators within a given type of operation

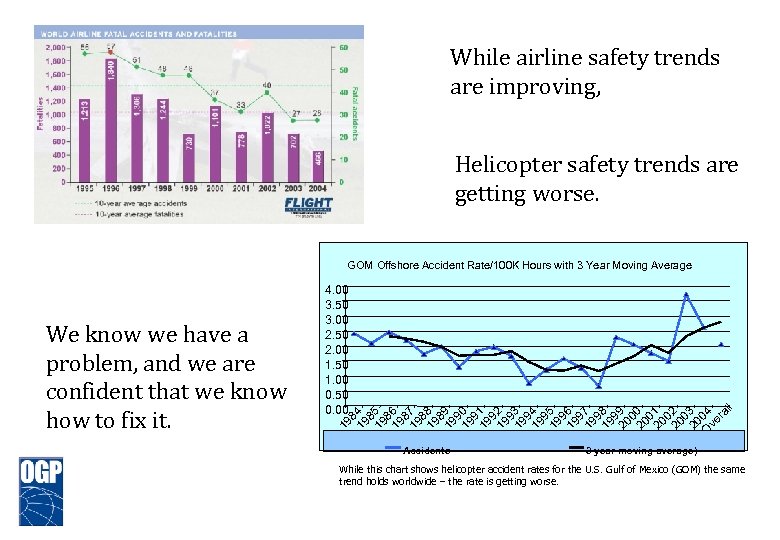

While airline safety trends are improving, Helicopter safety trends are getting worse. GOM Offshore Accident Rate/100 K Hours with 3 Year Moving Average 19 8 19 4 8 19 5 8 19 6 8 19 7 8 19 8 8 19 9 9 19 0 9 19 1 9 19 2 9 19 3 9 19 4 9 19 5 9 19 6 9 19 7 9 19 8 9 20 9 0 20 0 0 20 1 0 20 2 0 20 3 O 04 ve ra ll We know we have a problem, and we are confident that we know how to fix it. 4. 00 3. 50 3. 00 2. 50 2. 00 1. 50 1. 00 0. 50 0. 00 Accidents 3 year moving average) While this chart shows helicopter accident rates for the U. S. Gulf of Mexico (GOM) the same trend holds worldwide – the rate is getting worse.

While airline safety trends are improving, Helicopter safety trends are getting worse. GOM Offshore Accident Rate/100 K Hours with 3 Year Moving Average 19 8 19 4 8 19 5 8 19 6 8 19 7 8 19 8 8 19 9 9 19 0 9 19 1 9 19 2 9 19 3 9 19 4 9 19 5 9 19 6 9 19 7 9 19 8 9 20 9 0 20 0 0 20 1 0 20 2 0 20 3 O 04 ve ra ll We know we have a problem, and we are confident that we know how to fix it. 4. 00 3. 50 3. 00 2. 50 2. 00 1. 50 1. 00 0. 50 0. 00 Accidents 3 year moving average) While this chart shows helicopter accident rates for the U. S. Gulf of Mexico (GOM) the same trend holds worldwide – the rate is getting worse.

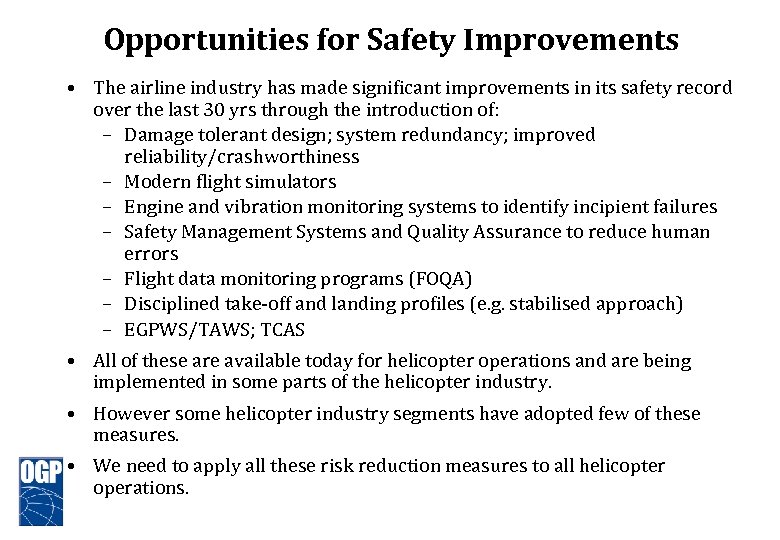

Opportunities for Safety Improvements • The airline industry has made significant improvements in its safety record over the last 30 yrs through the introduction of: – Damage tolerant design; system redundancy; improved reliability/crashworthiness – Modern flight simulators – Engine and vibration monitoring systems to identify incipient failures – Safety Management Systems and Quality Assurance to reduce human errors – Flight data monitoring programs (FOQA) – Disciplined take-off and landing profiles (e. g. stabilised approach) – EGPWS/TAWS; TCAS • All of these are available today for helicopter operations and are being implemented in some parts of the helicopter industry. • However some helicopter industry segments have adopted few of these measures. • We need to apply all these risk reduction measures to all helicopter operations.

Opportunities for Safety Improvements • The airline industry has made significant improvements in its safety record over the last 30 yrs through the introduction of: – Damage tolerant design; system redundancy; improved reliability/crashworthiness – Modern flight simulators – Engine and vibration monitoring systems to identify incipient failures – Safety Management Systems and Quality Assurance to reduce human errors – Flight data monitoring programs (FOQA) – Disciplined take-off and landing profiles (e. g. stabilised approach) – EGPWS/TAWS; TCAS • All of these are available today for helicopter operations and are being implemented in some parts of the helicopter industry. • However some helicopter industry segments have adopted few of these measures. • We need to apply all these risk reduction measures to all helicopter operations.

The Helicopter Safety Goal • OGP Safety Commitment: “The individual risk period of flying exposure for an individual flying on OGP contracted business should be no greater than on the average global airline. ” • This goal coincides with IHST’s goal of reducing the current helicopter accident rate by 80%. • This presentation will show you how this goal can be achieved.

The Helicopter Safety Goal • OGP Safety Commitment: “The individual risk period of flying exposure for an individual flying on OGP contracted business should be no greater than on the average global airline. ” • This goal coincides with IHST’s goal of reducing the current helicopter accident rate by 80%. • This presentation will show you how this goal can be achieved.

Overview • • • The current problem and the goal for improvement What’s been proven already What remains to achieve the goal Justifying the necessary risk mitigation measures Conclusions and summing up

Overview • • • The current problem and the goal for improvement What’s been proven already What remains to achieve the goal Justifying the necessary risk mitigation measures Conclusions and summing up

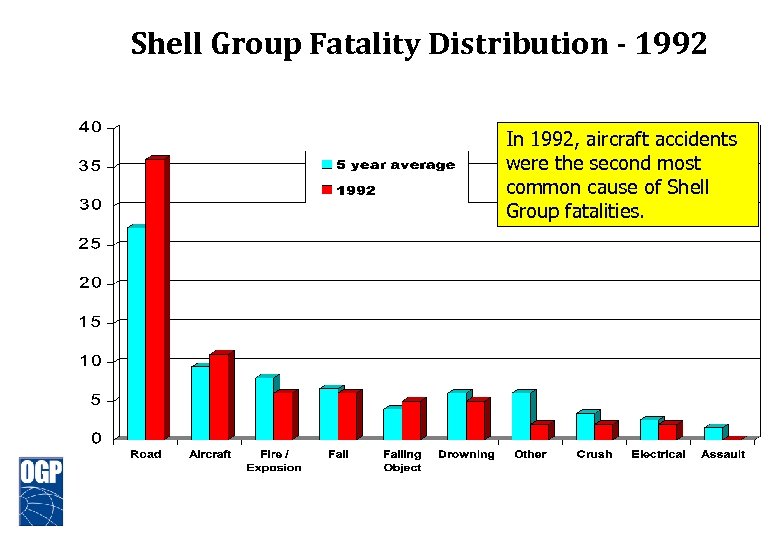

Shell Group Fatality Distribution - 1992 In 1992, aircraft accidents were the second most common cause of Shell Group fatalities.

Shell Group Fatality Distribution - 1992 In 1992, aircraft accidents were the second most common cause of Shell Group fatalities.

Shell Aircraft Responded With: • Development of safety targets and focussed programme • Shell Group Standards for Aircraft Operations – – Aviation Safety Management System (SMS) Aircraft performance standards Pilot, maintenance and passenger training Equipment fit – items that could have prevented half the Go. M fatalities since 1992 – Quality-based maintenance • Approval of aircraft operators and aircraft types • More than $1. 5 million on a range of research programmes – Health & Usage Monitoring Systems (HUMS) – Helicopter Operations Monitoring Program (HOMP) – Underwater escapability trials that led to Helicopter Underwater Escape Training (HUET) – Safety management and safety case concept for aircraft operators – Mathematical modelling of enhanced Performance Class 2 • Influenced industry and regulatory bodies via – OGP, UKOOA, EHOC, CAA, FAA, NTSB, FSF/IFA, IAGSA, HAI, HSAC

Shell Aircraft Responded With: • Development of safety targets and focussed programme • Shell Group Standards for Aircraft Operations – – Aviation Safety Management System (SMS) Aircraft performance standards Pilot, maintenance and passenger training Equipment fit – items that could have prevented half the Go. M fatalities since 1992 – Quality-based maintenance • Approval of aircraft operators and aircraft types • More than $1. 5 million on a range of research programmes – Health & Usage Monitoring Systems (HUMS) – Helicopter Operations Monitoring Program (HOMP) – Underwater escapability trials that led to Helicopter Underwater Escape Training (HUET) – Safety management and safety case concept for aircraft operators – Mathematical modelling of enhanced Performance Class 2 • Influenced industry and regulatory bodies via – OGP, UKOOA, EHOC, CAA, FAA, NTSB, FSF/IFA, IAGSA, HAI, HSAC

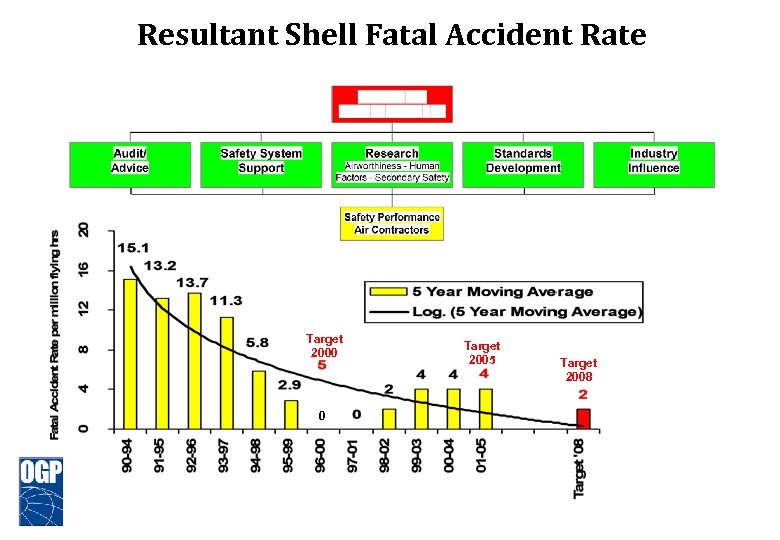

Resultant Shell Fatal Accident Rate Target 2000 0 Target 2005 Target 2008

Resultant Shell Fatal Accident Rate Target 2000 0 Target 2005 Target 2008

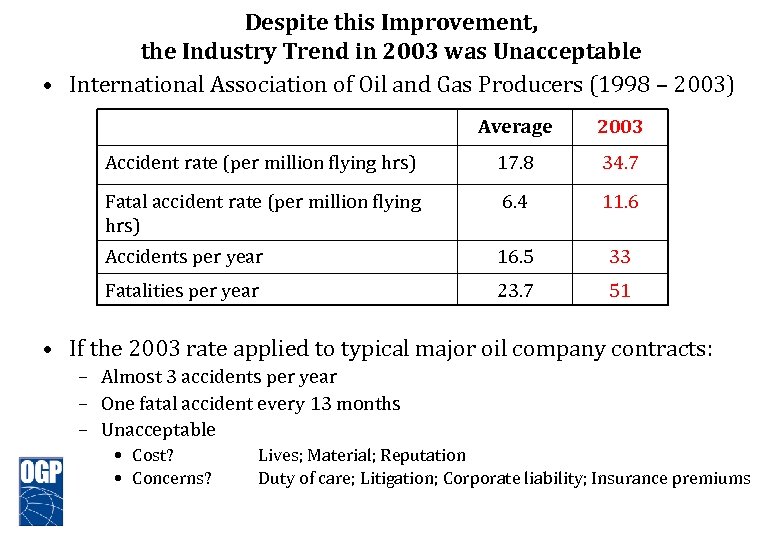

Despite this Improvement, the Industry Trend in 2003 was Unacceptable • International Association of Oil and Gas Producers (1998 – 2003) Average 2003 Accident rate (per million flying hrs) 17. 8 34. 7 Fatal accident rate (per million flying hrs) 6. 4 11. 6 Accidents per year 16. 5 33 Fatalities per year 23. 7 51 • If the 2003 rate applied to typical major oil company contracts: – Almost 3 accidents per year – One fatal accident every 13 months – Unacceptable • Cost? • Concerns? Lives; Material; Reputation Duty of care; Litigation; Corporate liability; Insurance premiums

Despite this Improvement, the Industry Trend in 2003 was Unacceptable • International Association of Oil and Gas Producers (1998 – 2003) Average 2003 Accident rate (per million flying hrs) 17. 8 34. 7 Fatal accident rate (per million flying hrs) 6. 4 11. 6 Accidents per year 16. 5 33 Fatalities per year 23. 7 51 • If the 2003 rate applied to typical major oil company contracts: – Almost 3 accidents per year – One fatal accident every 13 months – Unacceptable • Cost? • Concerns? Lives; Material; Reputation Duty of care; Litigation; Corporate liability; Insurance premiums

Shell Aircraft Analysed Accident Data to Evaluate Potential Risk Mitigations • • OGP published data on offshore accidents – GOM and Worldwide NASA/TM – 2000 -209579 – US Civil Helicopter Accidents 1963 – 1997 Individual NTSB/AAIB Accident Reports Annual Business Turbine Accident Review 1993 through 2003 – Breiling Associates • Design Reviews • FAA Final Rules – 14 CFR Parts 27 and 29 and associated NPRMs – Amendments 12 through 47 (Part 29) – Amendments 11 though 40 (Part 27) • Type Certificate Data Sheets for offshore helicopters • Design certification reviews with Sikorsky and Eurocopter specialists on S 76 and AS 332 • CAA Paper 2003/1 – Helicopter Tail Rotor Failures • UKCAA MORs for S 76 and AS 332 • SINTEF Helicopter Safety Study 2 – Dec 99

Shell Aircraft Analysed Accident Data to Evaluate Potential Risk Mitigations • • OGP published data on offshore accidents – GOM and Worldwide NASA/TM – 2000 -209579 – US Civil Helicopter Accidents 1963 – 1997 Individual NTSB/AAIB Accident Reports Annual Business Turbine Accident Review 1993 through 2003 – Breiling Associates • Design Reviews • FAA Final Rules – 14 CFR Parts 27 and 29 and associated NPRMs – Amendments 12 through 47 (Part 29) – Amendments 11 though 40 (Part 27) • Type Certificate Data Sheets for offshore helicopters • Design certification reviews with Sikorsky and Eurocopter specialists on S 76 and AS 332 • CAA Paper 2003/1 – Helicopter Tail Rotor Failures • UKCAA MORs for S 76 and AS 332 • SINTEF Helicopter Safety Study 2 – Dec 99

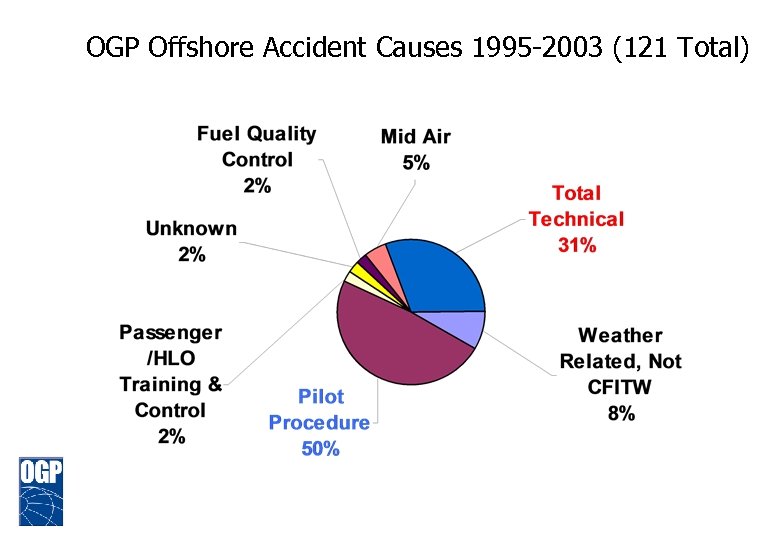

OGP Offshore Accident Causes 1995 -2003 (121 Total)

OGP Offshore Accident Causes 1995 -2003 (121 Total)

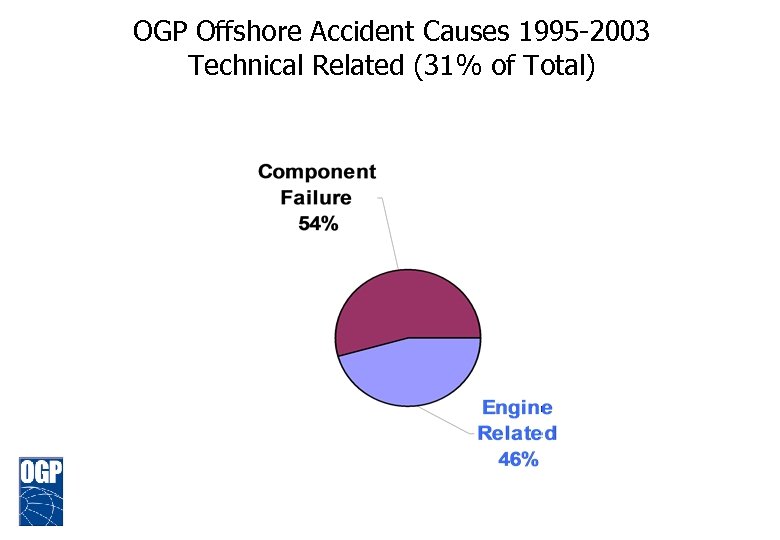

OGP Offshore Accident Causes 1995 -2003 Technical Related (31% of Total)

OGP Offshore Accident Causes 1995 -2003 Technical Related (31% of Total)

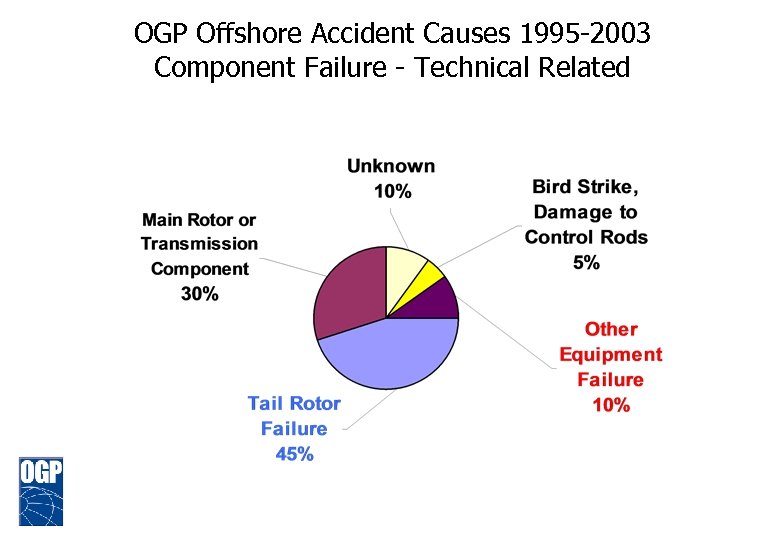

OGP Offshore Accident Causes 1995 -2003 Component Failure - Technical Related

OGP Offshore Accident Causes 1995 -2003 Component Failure - Technical Related

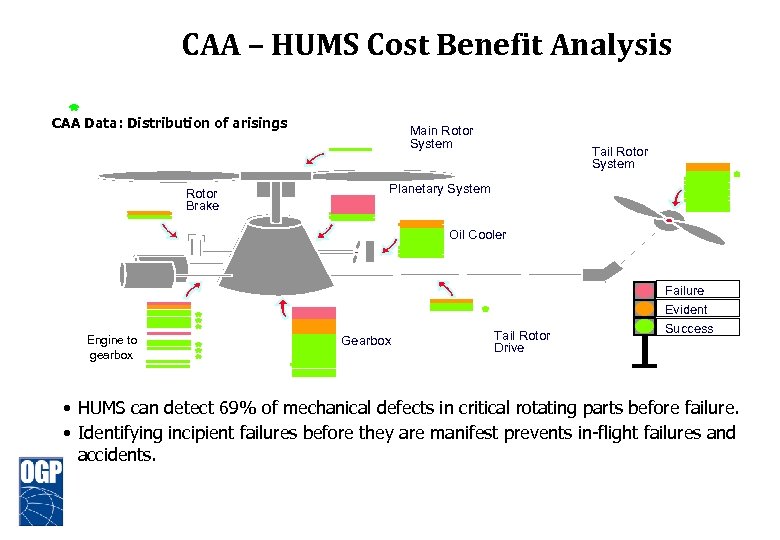

CAA – HUMS Cost Benefit Analysis CAA Data: Distribution of arisings Rotor Brake Main Rotor System Tail Rotor System Planetary System Oil Cooler Engine to gearbox Gearbox Tail Rotor Drive Failure Evident Success • HUMS can detect 69% of mechanical defects in critical rotating parts before failure. • Identifying incipient failures before they are manifest prevents in-flight failures and accidents.

CAA – HUMS Cost Benefit Analysis CAA Data: Distribution of arisings Rotor Brake Main Rotor System Tail Rotor System Planetary System Oil Cooler Engine to gearbox Gearbox Tail Rotor Drive Failure Evident Success • HUMS can detect 69% of mechanical defects in critical rotating parts before failure. • Identifying incipient failures before they are manifest prevents in-flight failures and accidents.

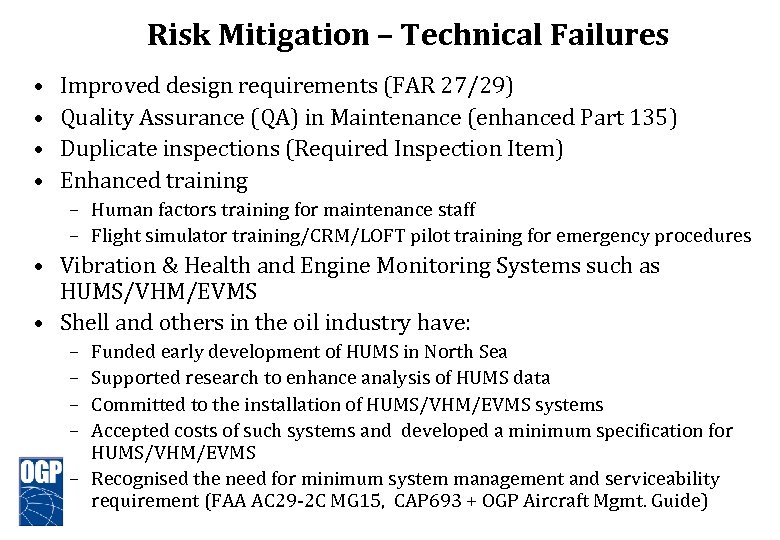

Risk Mitigation – Technical Failures • • Improved design requirements (FAR 27/29) Quality Assurance (QA) in Maintenance (enhanced Part 135) Duplicate inspections (Required Inspection Item) Enhanced training – Human factors training for maintenance staff – Flight simulator training/CRM/LOFT pilot training for emergency procedures • Vibration & Health and Engine Monitoring Systems such as HUMS/VHM/EVMS • Shell and others in the oil industry have: – – Funded early development of HUMS in North Sea Supported research to enhance analysis of HUMS data Committed to the installation of HUMS/VHM/EVMS systems Accepted costs of such systems and developed a minimum specification for HUMS/VHM/EVMS – Recognised the need for minimum system management and serviceability requirement (FAA AC 29 -2 C MG 15, CAP 693 + OGP Aircraft Mgmt. Guide)

Risk Mitigation – Technical Failures • • Improved design requirements (FAR 27/29) Quality Assurance (QA) in Maintenance (enhanced Part 135) Duplicate inspections (Required Inspection Item) Enhanced training – Human factors training for maintenance staff – Flight simulator training/CRM/LOFT pilot training for emergency procedures • Vibration & Health and Engine Monitoring Systems such as HUMS/VHM/EVMS • Shell and others in the oil industry have: – – Funded early development of HUMS in North Sea Supported research to enhance analysis of HUMS data Committed to the installation of HUMS/VHM/EVMS systems Accepted costs of such systems and developed a minimum specification for HUMS/VHM/EVMS – Recognised the need for minimum system management and serviceability requirement (FAA AC 29 -2 C MG 15, CAP 693 + OGP Aircraft Mgmt. Guide)

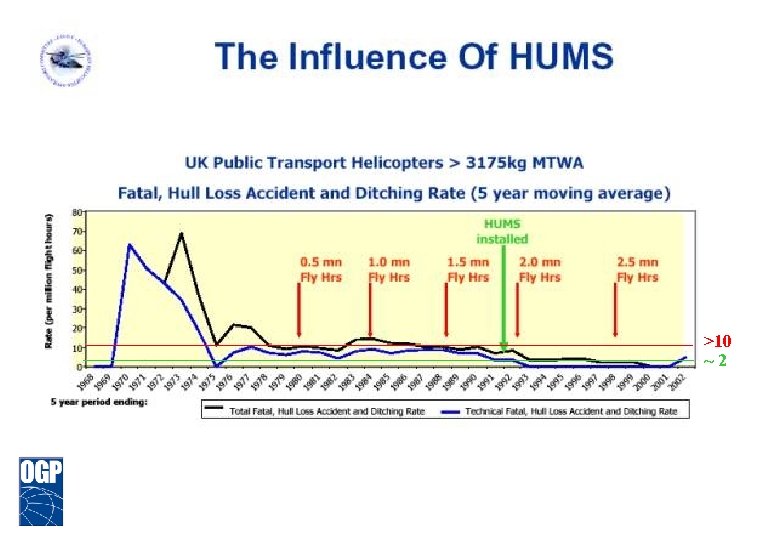

>10 ~2

>10 ~2

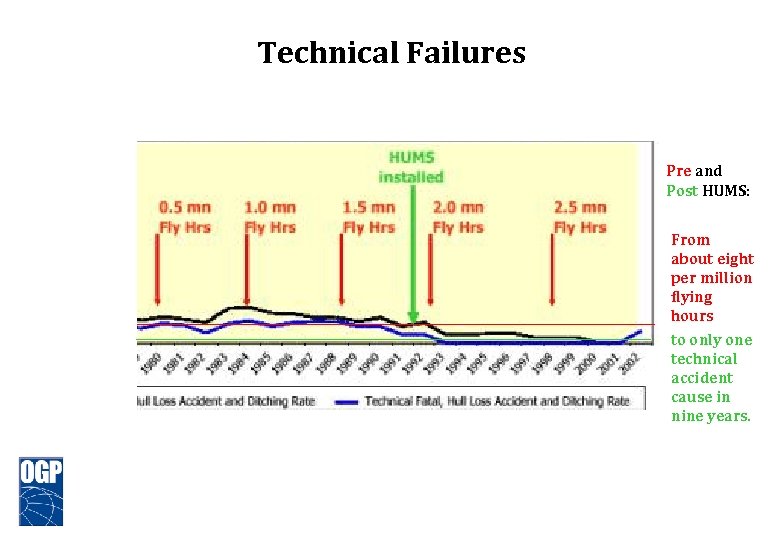

Technical Failures Pre and Post HUMS: From about eight per million flying hours to only one technical accident cause in nine years.

Technical Failures Pre and Post HUMS: From about eight per million flying hours to only one technical accident cause in nine years.

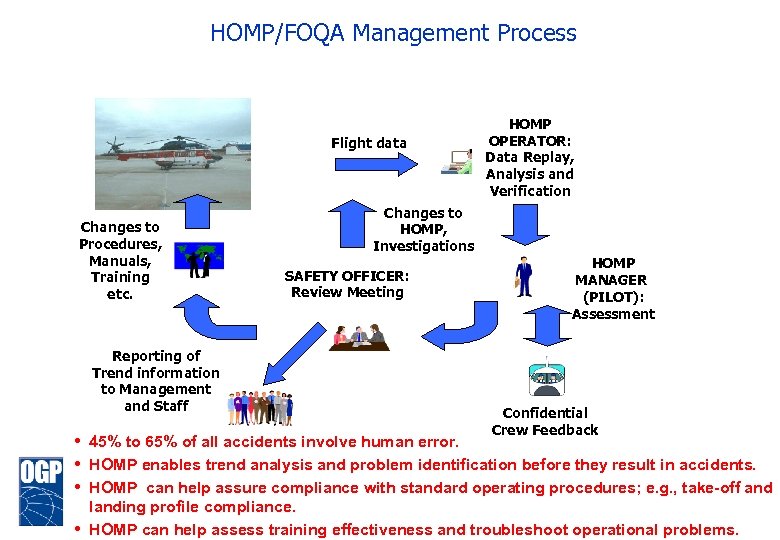

HOMP/FOQA Management Process Flight data Changes to Procedures, Manuals, Training etc. Reporting of Trend information to Management and Staff HOMP OPERATOR: Data Replay, Analysis and Verification Changes to HOMP, Investigations SAFETY OFFICER: Review Meeting HOMP MANAGER (PILOT): Assessment Confidential Crew Feedback • 45% to 65% of all accidents involve human error. • HOMP enables trend analysis and problem identification before they result in accidents. • HOMP can help assure compliance with standard operating procedures; e. g. , take-off and • landing profile compliance. HOMP can help assess training effectiveness and troubleshoot operational problems.

HOMP/FOQA Management Process Flight data Changes to Procedures, Manuals, Training etc. Reporting of Trend information to Management and Staff HOMP OPERATOR: Data Replay, Analysis and Verification Changes to HOMP, Investigations SAFETY OFFICER: Review Meeting HOMP MANAGER (PILOT): Assessment Confidential Crew Feedback • 45% to 65% of all accidents involve human error. • HOMP enables trend analysis and problem identification before they result in accidents. • HOMP can help assure compliance with standard operating procedures; e. g. , take-off and • landing profile compliance. HOMP can help assess training effectiveness and troubleshoot operational problems.

Risk Mitigation – Pilot Human Factors • Flight simulator training in LOFT scenarios emphasising CRM • Improved aircraft performance and disciplined helideck take-off and landing profiles to standardised helidecks • Enhanced management controls within a structured safety management system, including improved helideck management, adequate weather forecasting and communications • Defensive aids such as EGPWS (or AVAD) and TCAS • Helicopter Operations Monitoring Programme (HOMP) • Shell and others in the oil industry have : – – – Funded initial HOMP feasibility studies and development in UK Deployed HOMP on UK North Sea operations on AS 332 L and S 76 A++ Committed to the installation of HOMP systems on contracted helicopters Accepted the costs of such systems and are developing a minimum specification Recognised the need for minimum system management and serviceability requirement (CAP 739 and CAA Papers 2002/02 and 2004/12) – Strongly endorsed initiatives of the ICAO HTSG to add HOMP to ICAO Annex 6 as a Recommended Practice for all helicopters equipped with flight data recorders

Risk Mitigation – Pilot Human Factors • Flight simulator training in LOFT scenarios emphasising CRM • Improved aircraft performance and disciplined helideck take-off and landing profiles to standardised helidecks • Enhanced management controls within a structured safety management system, including improved helideck management, adequate weather forecasting and communications • Defensive aids such as EGPWS (or AVAD) and TCAS • Helicopter Operations Monitoring Programme (HOMP) • Shell and others in the oil industry have : – – – Funded initial HOMP feasibility studies and development in UK Deployed HOMP on UK North Sea operations on AS 332 L and S 76 A++ Committed to the installation of HOMP systems on contracted helicopters Accepted the costs of such systems and are developing a minimum specification Recognised the need for minimum system management and serviceability requirement (CAP 739 and CAA Papers 2002/02 and 2004/12) – Strongly endorsed initiatives of the ICAO HTSG to add HOMP to ICAO Annex 6 as a Recommended Practice for all helicopters equipped with flight data recorders

In Sum - What Have We Learned? • Essential Pre-requisites for Safe Operations – Safety culture supported by Quality and Safety Management systems • Equipment fit – Appropriate to the operation – HUMS/EGPWS/TCAS and cabin egress modifications • Pilot procedures – Helicopter Flight Data Monitoring (HFDM, also known as HOMP or FOQA) – Flight simulator training in LOFT scenarios emphasising CRM – Helideck performance profiles • Helideck management – Helicopter Landing Officer and Helideck Assistant training – Helideck procedures • System failure management – HUMS/VHM/EVMS – Engine monitoring – Flight Simulator training • Human error in maintenance – Human factors training – Duplicate inspections/RIIs – HUMS/VHM/EVMS • All these items are addressed in OGP’s Aircraft Management Guide, and will mitigate risk, but they are unlikely to achieve the long term safety goal.

In Sum - What Have We Learned? • Essential Pre-requisites for Safe Operations – Safety culture supported by Quality and Safety Management systems • Equipment fit – Appropriate to the operation – HUMS/EGPWS/TCAS and cabin egress modifications • Pilot procedures – Helicopter Flight Data Monitoring (HFDM, also known as HOMP or FOQA) – Flight simulator training in LOFT scenarios emphasising CRM – Helideck performance profiles • Helideck management – Helicopter Landing Officer and Helideck Assistant training – Helideck procedures • System failure management – HUMS/VHM/EVMS – Engine monitoring – Flight Simulator training • Human error in maintenance – Human factors training – Duplicate inspections/RIIs – HUMS/VHM/EVMS • All these items are addressed in OGP’s Aircraft Management Guide, and will mitigate risk, but they are unlikely to achieve the long term safety goal.

Overview • The current problem and the goal for improvement • What’s been proven already • What remains to achieve the goal • Justifying the necessary risk mitigation measures • Conclusions and summing up

Overview • The current problem and the goal for improvement • What’s been proven already • What remains to achieve the goal • Justifying the necessary risk mitigation measures • Conclusions and summing up

All But The Latest Helicopters Have Significant Design Gaps • “Most important issues would be to improve helicopter design and continuous airworthiness” - SINTEF • “The evidence that tail rotors were … not meeting the spirit of airworthiness requirements, was stark and compelling” – UK CAA • “. . This means that the helicopter is not considered airworthy without HUMS installed and in function. ” – Norwegian Committee for Review of Helicopter Safety • Typical aircraft in common use today - AS-332 Super Puma, Bell 412, and S-76 were designed to requirements that are now over 25 years old • Latest design requirements offer: – – Improved performance with one engine inoperative Redundant systems with flaw tolerance Fail safe designs Digital flight management systems to reduce pilot workload, improve situational awareness, and help cope with emergencies – Crashworthy airframe, fuel cells, and passenger/crew seats

All But The Latest Helicopters Have Significant Design Gaps • “Most important issues would be to improve helicopter design and continuous airworthiness” - SINTEF • “The evidence that tail rotors were … not meeting the spirit of airworthiness requirements, was stark and compelling” – UK CAA • “. . This means that the helicopter is not considered airworthy without HUMS installed and in function. ” – Norwegian Committee for Review of Helicopter Safety • Typical aircraft in common use today - AS-332 Super Puma, Bell 412, and S-76 were designed to requirements that are now over 25 years old • Latest design requirements offer: – – Improved performance with one engine inoperative Redundant systems with flaw tolerance Fail safe designs Digital flight management systems to reduce pilot workload, improve situational awareness, and help cope with emergencies – Crashworthy airframe, fuel cells, and passenger/crew seats

Old Cars & Vans • How many of you are driving vehicles like these with: – – No seat belts or shoulder harnesses No anti-skid braking system (ABS) No airbags Low power engines with normally aspirated carburettors • How many companies would use such vehicles to transport their workers?

Old Cars & Vans • How many of you are driving vehicles like these with: – – No seat belts or shoulder harnesses No anti-skid braking system (ABS) No airbags Low power engines with normally aspirated carburettors • How many companies would use such vehicles to transport their workers?

Old Helicopters • Yet many helicopter operations still use aircraft such as B 212 and AS 350 that were designed in a similar era (1960/70’s) and to equivalent safety standards. • Whilst certification standards for new design aircraft have changed, these models have continued to be built to old certification standards under “grandfather rights. ”

Old Helicopters • Yet many helicopter operations still use aircraft such as B 212 and AS 350 that were designed in a similar era (1960/70’s) and to equivalent safety standards. • Whilst certification standards for new design aircraft have changed, these models have continued to be built to old certification standards under “grandfather rights. ”

Design Requirements and Airworthiness • Latest design requirements offer: – Improved performance with one engine inoperative – Redundant systems with flaw tolerance – Fail safe designs – Digital flight management systems to reduce pilot workload, improve situational awareness, and help cope with emergencies – Crashworthy airframe, fuel cells, and passenger/crew seats • FAR 29/27 design requirements were reviewed to determine: – How design requirements have changed over the years – Potential safety improvements offered – How far short of the ideal requirements are the helicopters in current use – What impact this has on the achieved safety record of these types

Design Requirements and Airworthiness • Latest design requirements offer: – Improved performance with one engine inoperative – Redundant systems with flaw tolerance – Fail safe designs – Digital flight management systems to reduce pilot workload, improve situational awareness, and help cope with emergencies – Crashworthy airframe, fuel cells, and passenger/crew seats • FAR 29/27 design requirements were reviewed to determine: – How design requirements have changed over the years – Potential safety improvements offered – How far short of the ideal requirements are the helicopters in current use – What impact this has on the achieved safety record of these types

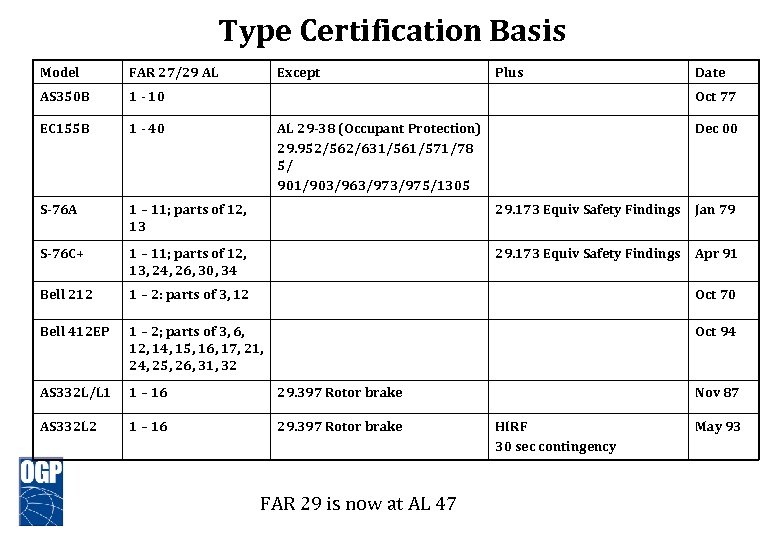

Type Certification Basis Model FAR 27/29 AL Except Plus Date AS 350 B 1 - 10 EC 155 B 1 - 40 S-76 A 1 – 11; parts of 12, 13 29. 173 Equiv Safety Findings Jan 79 S-76 C+ 1 – 11; parts of 12, 13, 24, 26, 30, 34 29. 173 Equiv Safety Findings Apr 91 Bell 212 1 – 2: parts of 3, 12 Oct 70 Bell 412 EP 1 – 2; parts of 3, 6, 12, 14, 15, 16, 17, 21, 24, 25, 26, 31, 32 Oct 94 AS 332 L/L 1 1 – 16 29. 397 Rotor brake AS 332 L 2 1 – 16 29. 397 Rotor brake Oct 77 AL 29 -38 (Occupant Protection) 29. 952/562/631/561/571/78 5/ 901/903/963/975/1305 FAR 29 is now at AL 47 Dec 00 Nov 87 HIRF 30 sec contingency May 93

Type Certification Basis Model FAR 27/29 AL Except Plus Date AS 350 B 1 - 10 EC 155 B 1 - 40 S-76 A 1 – 11; parts of 12, 13 29. 173 Equiv Safety Findings Jan 79 S-76 C+ 1 – 11; parts of 12, 13, 24, 26, 30, 34 29. 173 Equiv Safety Findings Apr 91 Bell 212 1 – 2: parts of 3, 12 Oct 70 Bell 412 EP 1 – 2; parts of 3, 6, 12, 14, 15, 16, 17, 21, 24, 25, 26, 31, 32 Oct 94 AS 332 L/L 1 1 – 16 29. 397 Rotor brake AS 332 L 2 1 – 16 29. 397 Rotor brake Oct 77 AL 29 -38 (Occupant Protection) 29. 952/562/631/561/571/78 5/ 901/903/963/975/1305 FAR 29 is now at AL 47 Dec 00 Nov 87 HIRF 30 sec contingency May 93

Key Design Improvements • FAR 29. 67 Climb: One engine inoperative Amendment 29 -26 (Oct 88) – New continuous OEI rating • FAR 29. 547/29. 917 Main & Tail Rotor Drive System Amendment 29 -40 (Aug 96) – Design assessment and failure analysis of Rotor/drive system • FAR 29. 571 Fatigue Evaluation of Structure Amendment 29 -28 (Nov 89) – Tolerance to flaws and damage • FAR 29. 610 Lightning and static electricity protection Amendment 29 -40 (Aug 96) – Improved protection • FAR 29. 863 Flammable fluid fire protection Amendment 29 -17 (Dec 78) – New requirements • FAR 29. 901/903 Engines Amendment 29 -36 (Jan 96) – Design consideration of effects of uncontained engine rotor burst – Containment and redundancy of key flight essential systems in the burst zone • FAR 29. 1309 Equipment, Systems and Installations Amendment 29 -24 (Dec 84) – Safety analysis with consideration of system interactions and multiple failures • FAR 29. 1529 Instructions for continued airworthiness – Requires substantiation via lightning tests Amendment 29 -20 (Oct 80)

Key Design Improvements • FAR 29. 67 Climb: One engine inoperative Amendment 29 -26 (Oct 88) – New continuous OEI rating • FAR 29. 547/29. 917 Main & Tail Rotor Drive System Amendment 29 -40 (Aug 96) – Design assessment and failure analysis of Rotor/drive system • FAR 29. 571 Fatigue Evaluation of Structure Amendment 29 -28 (Nov 89) – Tolerance to flaws and damage • FAR 29. 610 Lightning and static electricity protection Amendment 29 -40 (Aug 96) – Improved protection • FAR 29. 863 Flammable fluid fire protection Amendment 29 -17 (Dec 78) – New requirements • FAR 29. 901/903 Engines Amendment 29 -36 (Jan 96) – Design consideration of effects of uncontained engine rotor burst – Containment and redundancy of key flight essential systems in the burst zone • FAR 29. 1309 Equipment, Systems and Installations Amendment 29 -24 (Dec 84) – Safety analysis with consideration of system interactions and multiple failures • FAR 29. 1529 Instructions for continued airworthiness – Requires substantiation via lightning tests Amendment 29 -20 (Oct 80)

New Types EC 135 Agusta Bell 139 EC 225 Sikorsky S 92

New Types EC 135 Agusta Bell 139 EC 225 Sikorsky S 92

Overview • The current problem and the goal for improvement • What’s been proven already • What remains to achieve the goal • Justifying the necessary risk mitigation measures • Conclusions and summing up

Overview • The current problem and the goal for improvement • What’s been proven already • What remains to achieve the goal • Justifying the necessary risk mitigation measures • Conclusions and summing up

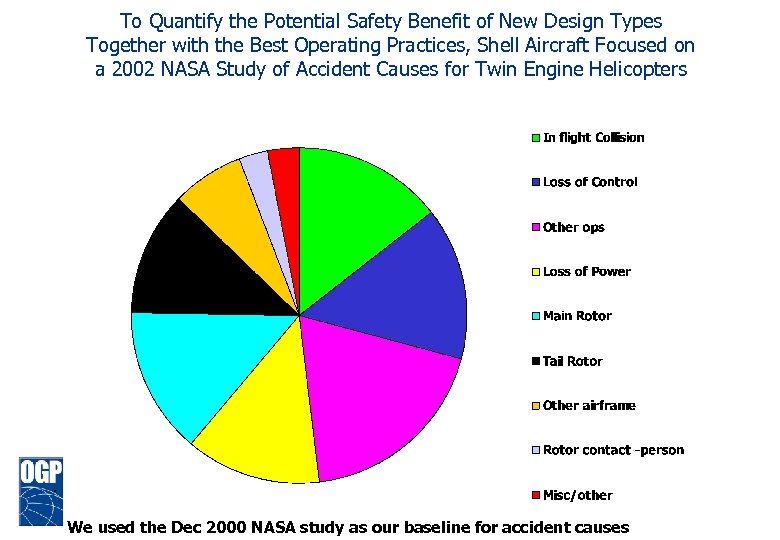

To Quantify the Potential Safety Benefit of New Design Types Together with the Best Operating Practices, Shell Aircraft Focused on a 2002 NASA Study of Accident Causes for Twin Engine Helicopters . We used the Dec 2000 NASA study as our baseline for accident causes

To Quantify the Potential Safety Benefit of New Design Types Together with the Best Operating Practices, Shell Aircraft Focused on a 2002 NASA Study of Accident Causes for Twin Engine Helicopters . We used the Dec 2000 NASA study as our baseline for accident causes

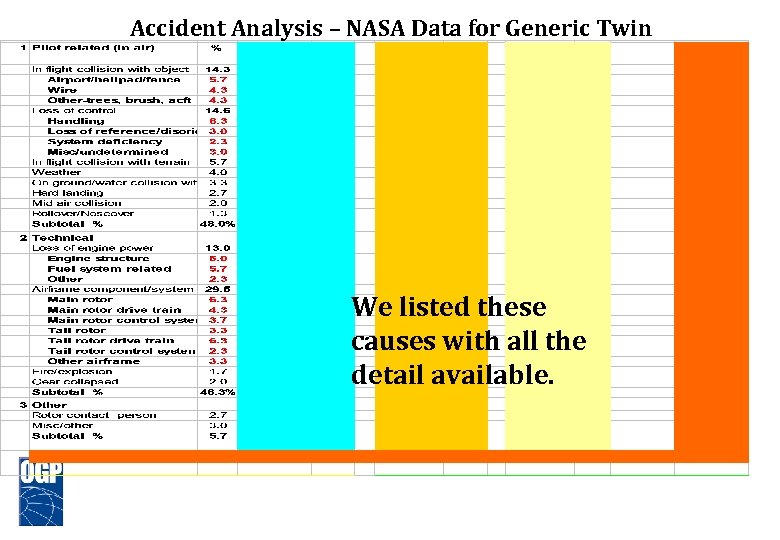

Accident Analysis – NASA Data for Generic Twin We listed these causes with all the detail available.

Accident Analysis – NASA Data for Generic Twin We listed these causes with all the detail available.

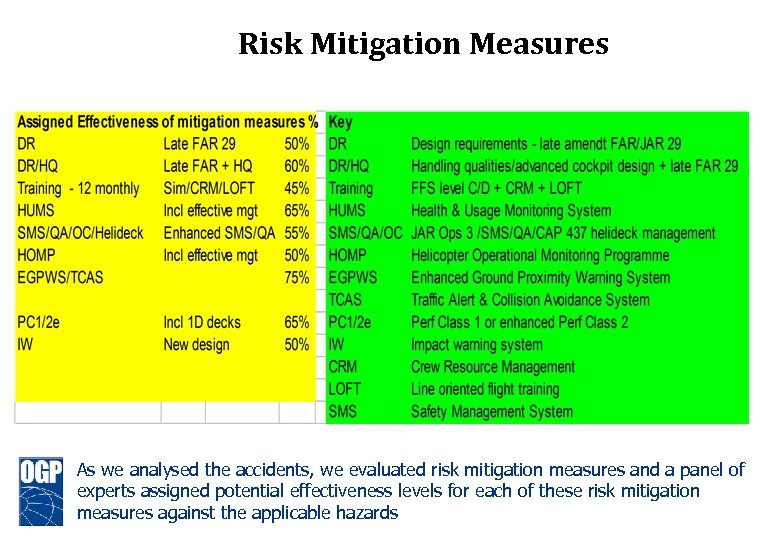

Risk Mitigation Measures As we analysed the accidents, we evaluated risk mitigation measures and a panel of experts assigned potential effectiveness levels for each of these risk mitigation measures against the applicable hazards

Risk Mitigation Measures As we analysed the accidents, we evaluated risk mitigation measures and a panel of experts assigned potential effectiveness levels for each of these risk mitigation measures against the applicable hazards

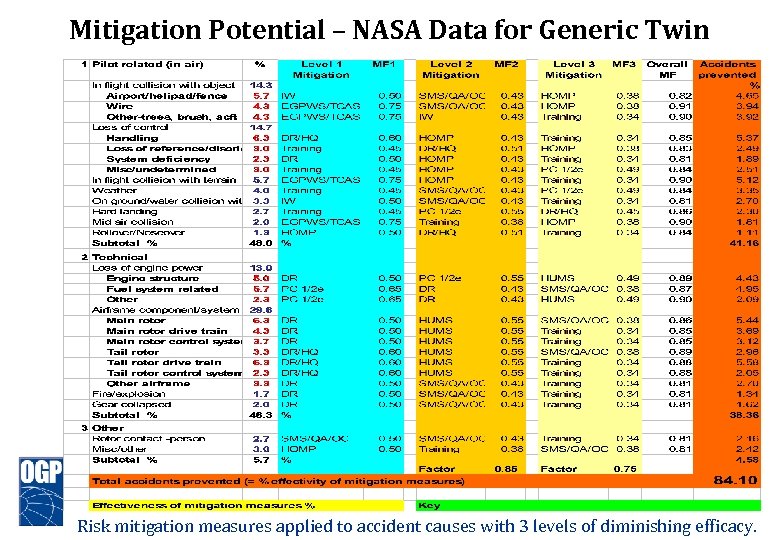

Mitigation Potential – NASA Data for Generic Twin Risk mitigation measures applied to accident causes with 3 levels of diminishing efficacy.

Mitigation Potential – NASA Data for Generic Twin Risk mitigation measures applied to accident causes with 3 levels of diminishing efficacy.

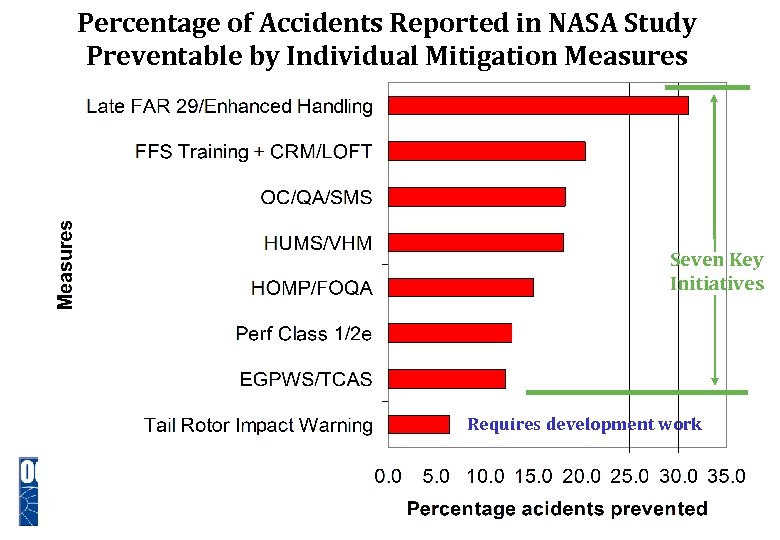

Percentage of Accidents Reported in NASA Study Preventable by Individual Mitigation Measures Seven Key Initiatives Requires development work

Percentage of Accidents Reported in NASA Study Preventable by Individual Mitigation Measures Seven Key Initiatives Requires development work

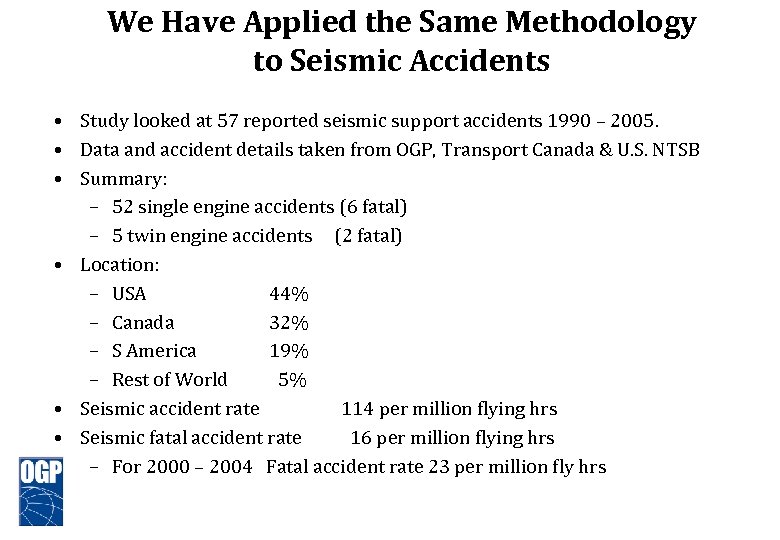

We Have Applied the Same Methodology to Seismic Accidents • Study looked at 57 reported seismic support accidents 1990 – 2005. • Data and accident details taken from OGP, Transport Canada & U. S. NTSB • Summary: – 52 single engine accidents (6 fatal) – 5 twin engine accidents (2 fatal) • Location: – USA 44% – Canada 32% – S America 19% – Rest of World 5% • Seismic accident rate 114 per million flying hrs • Seismic fatal accident rate 16 per million flying hrs – For 2000 – 2004 Fatal accident rate 23 per million fly hrs

We Have Applied the Same Methodology to Seismic Accidents • Study looked at 57 reported seismic support accidents 1990 – 2005. • Data and accident details taken from OGP, Transport Canada & U. S. NTSB • Summary: – 52 single engine accidents (6 fatal) – 5 twin engine accidents (2 fatal) • Location: – USA 44% – Canada 32% – S America 19% – Rest of World 5% • Seismic accident rate 114 per million flying hrs • Seismic fatal accident rate 16 per million flying hrs – For 2000 – 2004 Fatal accident rate 23 per million fly hrs

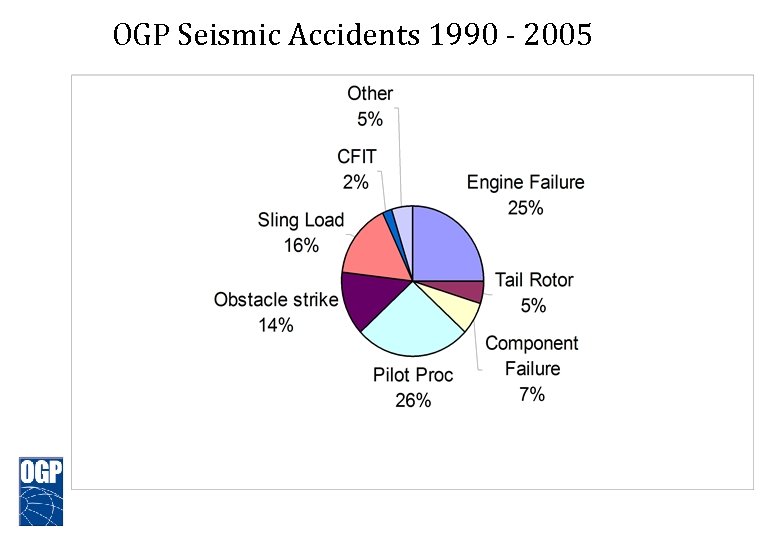

OGP Seismic Accidents 1990 - 2005

OGP Seismic Accidents 1990 - 2005

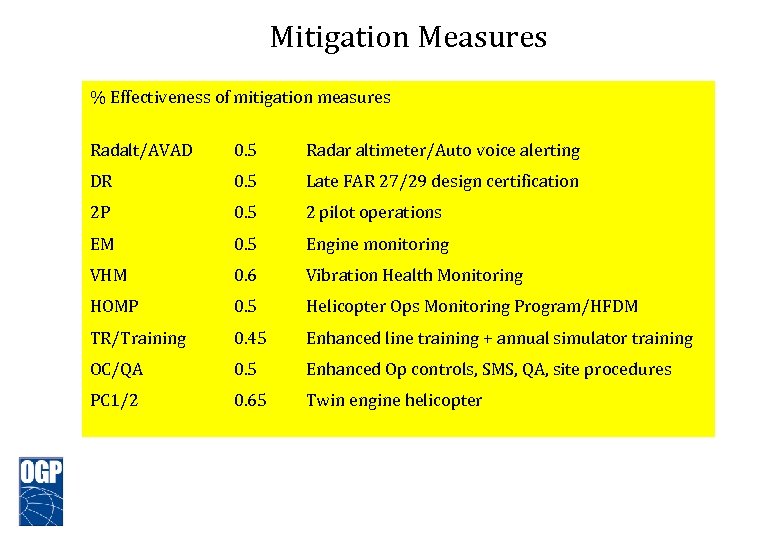

Mitigation Measures % Effectiveness of mitigation measures Radalt/AVAD 0. 5 Radar altimeter/Auto voice alerting DR 0. 5 Late FAR 27/29 design certification 2 P 0. 5 2 pilot operations EM 0. 5 Engine monitoring VHM 0. 6 Vibration Health Monitoring HOMP 0. 5 Helicopter Ops Monitoring Program/HFDM TR/Training 0. 45 Enhanced line training + annual simulator training OC/QA 0. 5 Enhanced Op controls, SMS, QA, site procedures PC 1/2 0. 65 Twin engine helicopter

Mitigation Measures % Effectiveness of mitigation measures Radalt/AVAD 0. 5 Radar altimeter/Auto voice alerting DR 0. 5 Late FAR 27/29 design certification 2 P 0. 5 2 pilot operations EM 0. 5 Engine monitoring VHM 0. 6 Vibration Health Monitoring HOMP 0. 5 Helicopter Ops Monitoring Program/HFDM TR/Training 0. 45 Enhanced line training + annual simulator training OC/QA 0. 5 Enhanced Op controls, SMS, QA, site procedures PC 1/2 0. 65 Twin engine helicopter

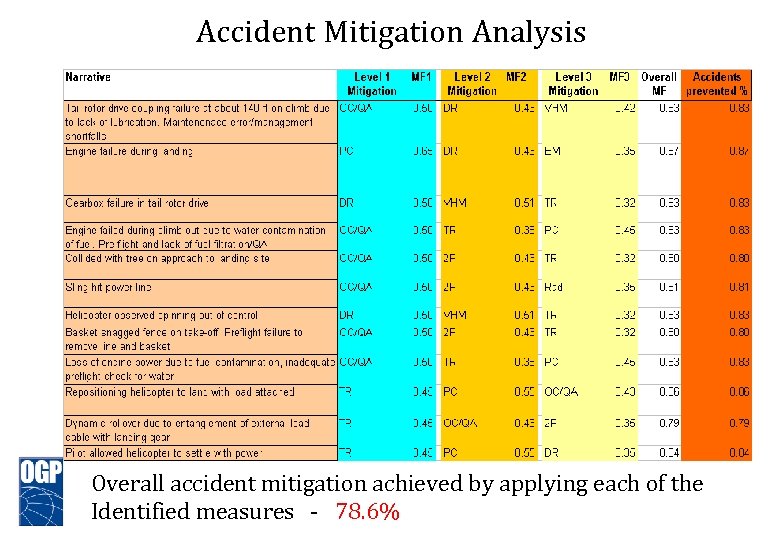

Accident Mitigation Analysis Overall accident mitigation achieved by applying each of the Identified measures - 78. 6%

Accident Mitigation Analysis Overall accident mitigation achieved by applying each of the Identified measures - 78. 6%

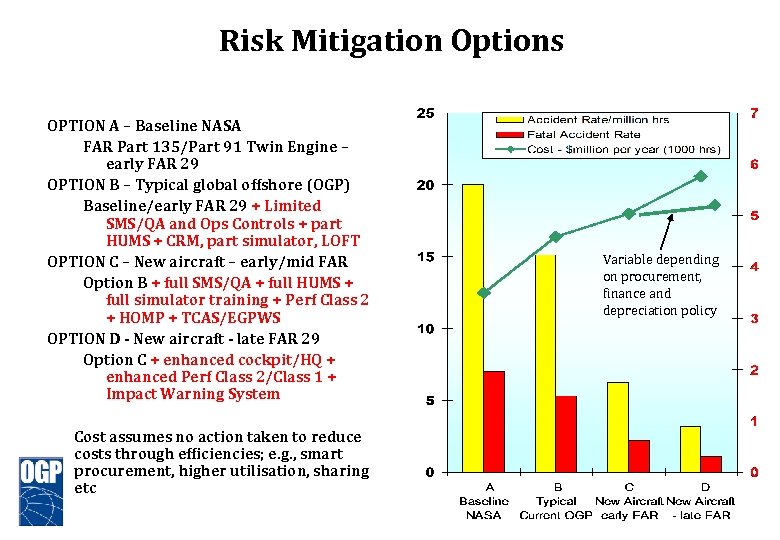

Risk Mitigation Options OPTION A – Baseline NASA FAR Part 135/Part 91 Twin Engine – early FAR 29 OPTION B – Typical global offshore (OGP) Baseline/early FAR 29 + Limited SMS/QA and Ops Controls + part HUMS + CRM, part simulator, LOFT OPTION C – New aircraft – early/mid FAR Option B + full SMS/QA + full HUMS + full simulator training + Perf Class 2 + HOMP + TCAS/EGPWS OPTION D - New aircraft - late FAR 29 Option C + enhanced cockpit/HQ + enhanced Perf Class 2/Class 1 + Impact Warning System Cost assumes no action taken to reduce costs through efficiencies; e. g. , smart procurement, higher utilisation, sharing etc Variable depending on procurement, finance and depreciation policy

Risk Mitigation Options OPTION A – Baseline NASA FAR Part 135/Part 91 Twin Engine – early FAR 29 OPTION B – Typical global offshore (OGP) Baseline/early FAR 29 + Limited SMS/QA and Ops Controls + part HUMS + CRM, part simulator, LOFT OPTION C – New aircraft – early/mid FAR Option B + full SMS/QA + full HUMS + full simulator training + Perf Class 2 + HOMP + TCAS/EGPWS OPTION D - New aircraft - late FAR 29 Option C + enhanced cockpit/HQ + enhanced Perf Class 2/Class 1 + Impact Warning System Cost assumes no action taken to reduce costs through efficiencies; e. g. , smart procurement, higher utilisation, sharing etc Variable depending on procurement, finance and depreciation policy

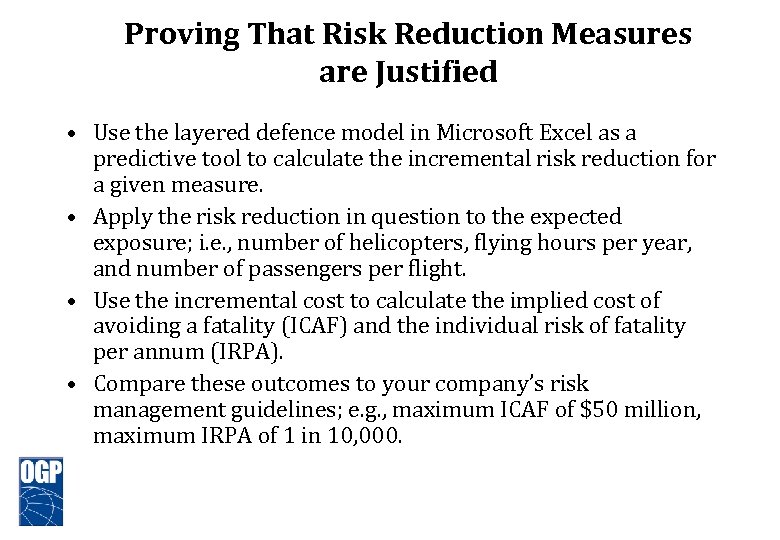

Proving That Risk Reduction Measures are Justified • Use the layered defence model in Microsoft Excel as a predictive tool to calculate the incremental risk reduction for a given measure. • Apply the risk reduction in question to the expected exposure; i. e. , number of helicopters, flying hours per year, and number of passengers per flight. • Use the incremental cost to calculate the implied cost of avoiding a fatality (ICAF) and the individual risk of fatality per annum (IRPA). • Compare these outcomes to your company’s risk management guidelines; e. g. , maximum ICAF of $50 million, maximum IRPA of 1 in 10, 000.

Proving That Risk Reduction Measures are Justified • Use the layered defence model in Microsoft Excel as a predictive tool to calculate the incremental risk reduction for a given measure. • Apply the risk reduction in question to the expected exposure; i. e. , number of helicopters, flying hours per year, and number of passengers per flight. • Use the incremental cost to calculate the implied cost of avoiding a fatality (ICAF) and the individual risk of fatality per annum (IRPA). • Compare these outcomes to your company’s risk management guidelines; e. g. , maximum ICAF of $50 million, maximum IRPA of 1 in 10, 000.

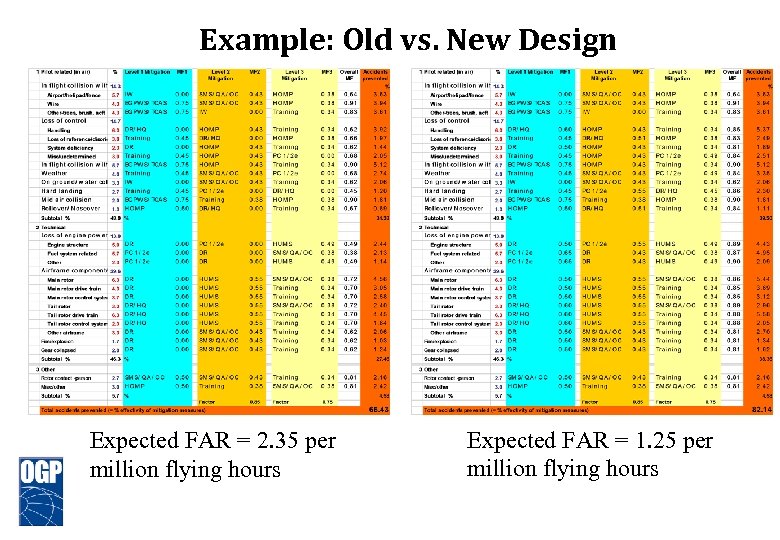

Example: Old vs. New Design Expected FAR = 2. 35 per million flying hours Expected FAR = 1. 25 per million flying hours

Example: Old vs. New Design Expected FAR = 2. 35 per million flying hours Expected FAR = 1. 25 per million flying hours

ICAF and IRPA • ICAF = Incremental Cost per Annum divided by the Incremental Lives Saved per Annum – Incremental Lives Saved per Annum = (Incremental Reduction in Fatal Accident Rate) * (Flying Hours per Annum) * (Average Number of Occupants) * (Average Percentage of Occupants Killed in Fatal Accidents) • IRPA = (Fatal Accident Rate) * (Individual Flying Hours per Annum) * (Average Percentage of Occupants Killed in Fatal Accidents)

ICAF and IRPA • ICAF = Incremental Cost per Annum divided by the Incremental Lives Saved per Annum – Incremental Lives Saved per Annum = (Incremental Reduction in Fatal Accident Rate) * (Flying Hours per Annum) * (Average Number of Occupants) * (Average Percentage of Occupants Killed in Fatal Accidents) • IRPA = (Fatal Accident Rate) * (Individual Flying Hours per Annum) * (Average Percentage of Occupants Killed in Fatal Accidents)

Overview • • • The current problem and the goal for improvement What’s been proven already What remains to achieve the goal Justifying the necessary risk mitigation measures Conclusions and summing up

Overview • • • The current problem and the goal for improvement What’s been proven already What remains to achieve the goal Justifying the necessary risk mitigation measures Conclusions and summing up

How To Achieve the Air Safety Goal • Customers must commit to the goal and contract for higher standards. • Manufacturers must support HUMS/VHM/EVMS, the latest design standards (FAR 29 - 47) and provide affordable solutions for legacy aircraft. • Operators must adopt proven global best practices as their minimum standard • Regulators must support proven global best practices. • All stakeholders must support these initiatives: – Transition to new aircraft built to the latest design standards on new contracts. – Require annual training in flight simulators to practice crew coordination during emergency procedures. – Equip all helicopters with Vibration & Health and Engine Monitoring Systems such as HUMS/VHM/EVMS – Require operators to implement quality and safety management systems. – Require operators to implement HFDM (HOMP). – Require operators to fly profiles that minimize the risks of engine failure. – Equip all helicopters with EGPWS or TAWS and TCAS

How To Achieve the Air Safety Goal • Customers must commit to the goal and contract for higher standards. • Manufacturers must support HUMS/VHM/EVMS, the latest design standards (FAR 29 - 47) and provide affordable solutions for legacy aircraft. • Operators must adopt proven global best practices as their minimum standard • Regulators must support proven global best practices. • All stakeholders must support these initiatives: – Transition to new aircraft built to the latest design standards on new contracts. – Require annual training in flight simulators to practice crew coordination during emergency procedures. – Equip all helicopters with Vibration & Health and Engine Monitoring Systems such as HUMS/VHM/EVMS – Require operators to implement quality and safety management systems. – Require operators to implement HFDM (HOMP). – Require operators to fly profiles that minimize the risks of engine failure. – Equip all helicopters with EGPWS or TAWS and TCAS

We have many imperatives to make these improvements! • Respect for people – the disparity between helicopter safety and airline safety • ALARP – we know what can be done and that the cost is not disproportionate to the benefits to be gained • The Ford Pinto story • The “Red Face” test • Good business sense – safer operations will attract more customers.

We have many imperatives to make these improvements! • Respect for people – the disparity between helicopter safety and airline safety • ALARP – we know what can be done and that the cost is not disproportionate to the benefits to be gained • The Ford Pinto story • The “Red Face” test • Good business sense – safer operations will attract more customers.

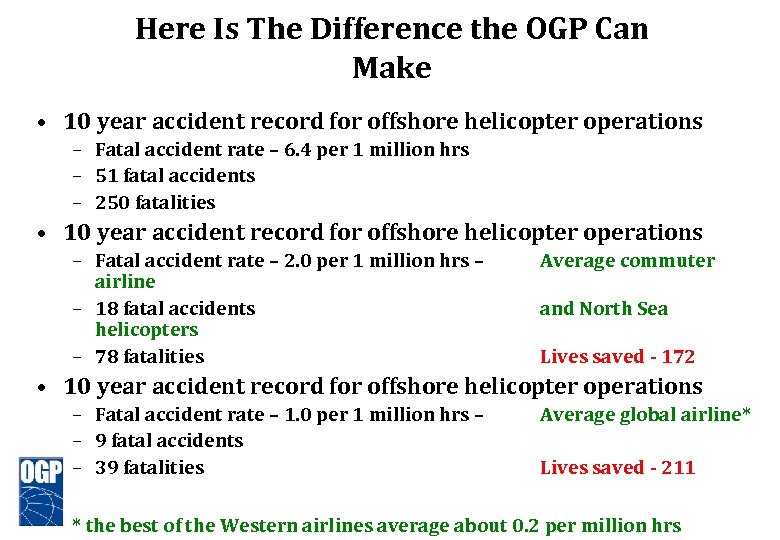

Here Is The Difference the OGP Can Make • 10 year accident record for offshore helicopter operations – Fatal accident rate – 6. 4 per 1 million hrs – 51 fatal accidents – 250 fatalities • 10 year accident record for offshore helicopter operations – Fatal accident rate – 2. 0 per 1 million hrs – airline – 18 fatal accidents helicopters – 78 fatalities Average commuter and North Sea Lives saved - 172 • 10 year accident record for offshore helicopter operations – Fatal accident rate – 1. 0 per 1 million hrs – – 9 fatal accidents – 39 fatalities Average global airline* Lives saved - 211 * the best of the Western airlines average about 0. 2 per million hrs

Here Is The Difference the OGP Can Make • 10 year accident record for offshore helicopter operations – Fatal accident rate – 6. 4 per 1 million hrs – 51 fatal accidents – 250 fatalities • 10 year accident record for offshore helicopter operations – Fatal accident rate – 2. 0 per 1 million hrs – airline – 18 fatal accidents helicopters – 78 fatalities Average commuter and North Sea Lives saved - 172 • 10 year accident record for offshore helicopter operations – Fatal accident rate – 1. 0 per 1 million hrs – – 9 fatal accidents – 39 fatalities Average global airline* Lives saved - 211 * the best of the Western airlines average about 0. 2 per million hrs

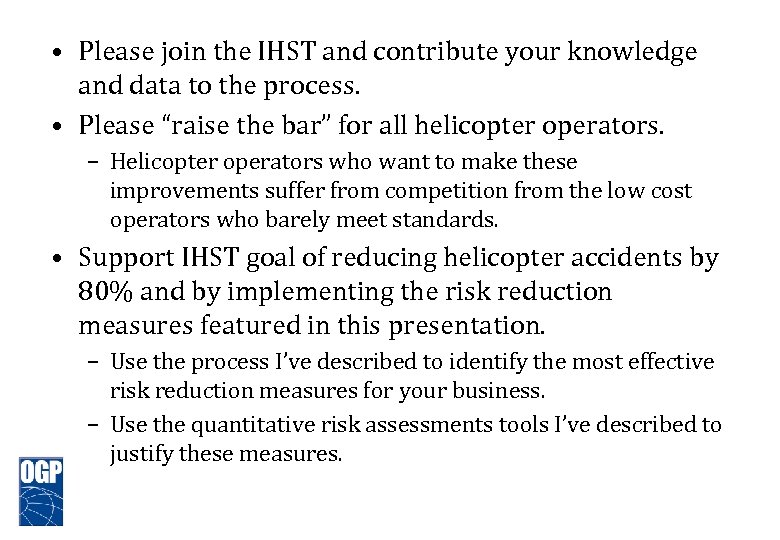

• Please join the IHST and contribute your knowledge and data to the process. • Please “raise the bar” for all helicopter operators. – Helicopter operators who want to make these improvements suffer from competition from the low cost operators who barely meet standards. • Support IHST goal of reducing helicopter accidents by 80% and by implementing the risk reduction measures featured in this presentation. – Use the process I’ve described to identify the most effective risk reduction measures for your business. – Use the quantitative risk assessments tools I’ve described to justify these measures.

• Please join the IHST and contribute your knowledge and data to the process. • Please “raise the bar” for all helicopter operators. – Helicopter operators who want to make these improvements suffer from competition from the low cost operators who barely meet standards. • Support IHST goal of reducing helicopter accidents by 80% and by implementing the risk reduction measures featured in this presentation. – Use the process I’ve described to identify the most effective risk reduction measures for your business. – Use the quantitative risk assessments tools I’ve described to justify these measures.

Questions?

Questions?

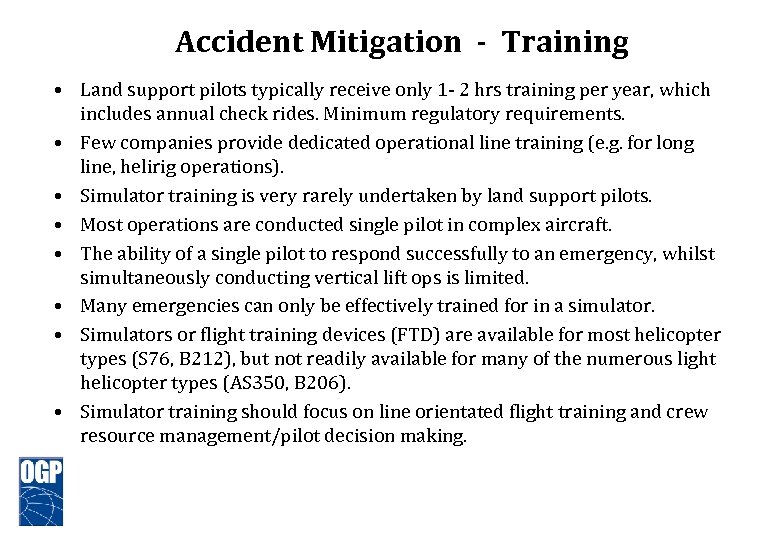

Accident Mitigation - Training • Land support pilots typically receive only 1 - 2 hrs training per year, which includes annual check rides. Minimum regulatory requirements. • Few companies provide dedicated operational line training (e. g. for long line, helirig operations). • Simulator training is very rarely undertaken by land support pilots. • Most operations are conducted single pilot in complex aircraft. • The ability of a single pilot to respond successfully to an emergency, whilst simultaneously conducting vertical lift ops is limited. • Many emergencies can only be effectively trained for in a simulator. • Simulators or flight training devices (FTD) are available for most helicopter types (S 76, B 212), but not readily available for many of the numerous light helicopter types (AS 350, B 206). • Simulator training should focus on line orientated flight training and crew resource management/pilot decision making.

Accident Mitigation - Training • Land support pilots typically receive only 1 - 2 hrs training per year, which includes annual check rides. Minimum regulatory requirements. • Few companies provide dedicated operational line training (e. g. for long line, helirig operations). • Simulator training is very rarely undertaken by land support pilots. • Most operations are conducted single pilot in complex aircraft. • The ability of a single pilot to respond successfully to an emergency, whilst simultaneously conducting vertical lift ops is limited. • Many emergencies can only be effectively trained for in a simulator. • Simulators or flight training devices (FTD) are available for most helicopter types (S 76, B 212), but not readily available for many of the numerous light helicopter types (AS 350, B 206). • Simulator training should focus on line orientated flight training and crew resource management/pilot decision making.

Accident Mitigation Operational Controls, SMS, QA. • An effective safety management system that systematically identifies and assesses the hazards associated with a specific operation and identifies controls to manage those hazards. • Well defined operational procedures that include the controls identified above and would include: – Operational controls to manage pilot fatigue and crew duty hours. – Oversight of maintenance and control of deferred defects. – Weather minimums related to the task, including emergency response. • A quality assurance program that checks that the controls are in place and working. • The implementation of SMS, QA and company procedures at remote sites is a challenge - what procedures do you have in place to assure this?

Accident Mitigation Operational Controls, SMS, QA. • An effective safety management system that systematically identifies and assesses the hazards associated with a specific operation and identifies controls to manage those hazards. • Well defined operational procedures that include the controls identified above and would include: – Operational controls to manage pilot fatigue and crew duty hours. – Oversight of maintenance and control of deferred defects. – Weather minimums related to the task, including emergency response. • A quality assurance program that checks that the controls are in place and working. • The implementation of SMS, QA and company procedures at remote sites is a challenge - what procedures do you have in place to assure this?

Accident Mitigation Twin Engine • Engine failures account for 25% of seismic accidents • Single engine passenger flights should only be flown over terrain that allows a safe forced landing in the event of an engine failure. • Forested areas and mountainous terrain does not allow this, but is often the environment in which seismic and geophysical ops take place.

Accident Mitigation Twin Engine • Engine failures account for 25% of seismic accidents • Single engine passenger flights should only be flown over terrain that allows a safe forced landing in the event of an engine failure. • Forested areas and mountainous terrain does not allow this, but is often the environment in which seismic and geophysical ops take place.

Accident Mitigation Engine and Vibration Health Monitoring • First generation HUMS has been proven to detect 69% of mechanical defects in critical rotating parts before failure. Later generation systems are more effective. • Engine monitoring systems and HUMS are now available for all aircraft types and are becoming widely accepted within the helicopter industry. The more enlightened helicopter manufacturers are fitting them as standard to new designs. • However, no seismic, geophysical operators have yet equipped with HUMS. • HUMS not only provides a safety benefit, but also delivers cost savings through pre-emptive maintenance, component life management and reduced down time.

Accident Mitigation Engine and Vibration Health Monitoring • First generation HUMS has been proven to detect 69% of mechanical defects in critical rotating parts before failure. Later generation systems are more effective. • Engine monitoring systems and HUMS are now available for all aircraft types and are becoming widely accepted within the helicopter industry. The more enlightened helicopter manufacturers are fitting them as standard to new designs. • However, no seismic, geophysical operators have yet equipped with HUMS. • HUMS not only provides a safety benefit, but also delivers cost savings through pre-emptive maintenance, component life management and reduced down time.

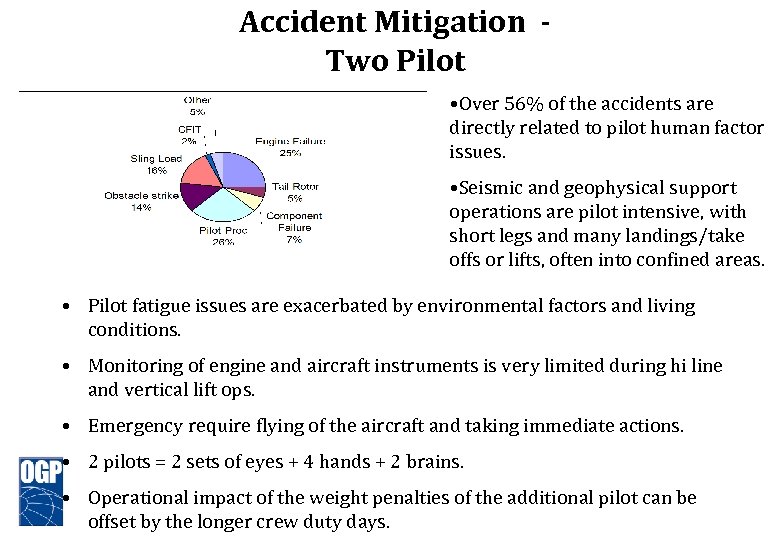

Accident Mitigation Two Pilot • Over 56% of the accidents are directly related to pilot human factor issues. • Seismic and geophysical support operations are pilot intensive, with short legs and many landings/take offs or lifts, often into confined areas. • Pilot fatigue issues are exacerbated by environmental factors and living conditions. • Monitoring of engine and aircraft instruments is very limited during hi line and vertical lift ops. • Emergency require flying of the aircraft and taking immediate actions. • 2 pilots = 2 sets of eyes + 4 hands + 2 brains. • Operational impact of the weight penalties of the additional pilot can be offset by the longer crew duty days.

Accident Mitigation Two Pilot • Over 56% of the accidents are directly related to pilot human factor issues. • Seismic and geophysical support operations are pilot intensive, with short legs and many landings/take offs or lifts, often into confined areas. • Pilot fatigue issues are exacerbated by environmental factors and living conditions. • Monitoring of engine and aircraft instruments is very limited during hi line and vertical lift ops. • Emergency require flying of the aircraft and taking immediate actions. • 2 pilots = 2 sets of eyes + 4 hands + 2 brains. • Operational impact of the weight penalties of the additional pilot can be offset by the longer crew duty days.