cd387773ca0eb7534a20f7c8164b9b06.ppt

- Количество слайдов: 32

Heat and Power Integration CHEN 4460 – Process Synthesis, Simulation and Optimization Dr. Mario Richard Eden Department of Chemical Engineering Auburn University Lecture No. 9 – Heat and Power Integration: Targeting October 23, 2012 Contains Material Developed by Dr. Daniel R. Lewin, Technion, Israel

Heat and Power Integration CHEN 4460 – Process Synthesis, Simulation and Optimization Dr. Mario Richard Eden Department of Chemical Engineering Auburn University Lecture No. 9 – Heat and Power Integration: Targeting October 23, 2012 Contains Material Developed by Dr. Daniel R. Lewin, Technion, Israel

Lecture 8 – Objectives Given data on the hot and cold streams of a process, you should be able to: Compute the pinch temperatures Compute the Maximum Energy Recovery (MER) targets using graphical and/or algebraic methods

Lecture 8 – Objectives Given data on the hot and cold streams of a process, you should be able to: Compute the pinch temperatures Compute the Maximum Energy Recovery (MER) targets using graphical and/or algebraic methods

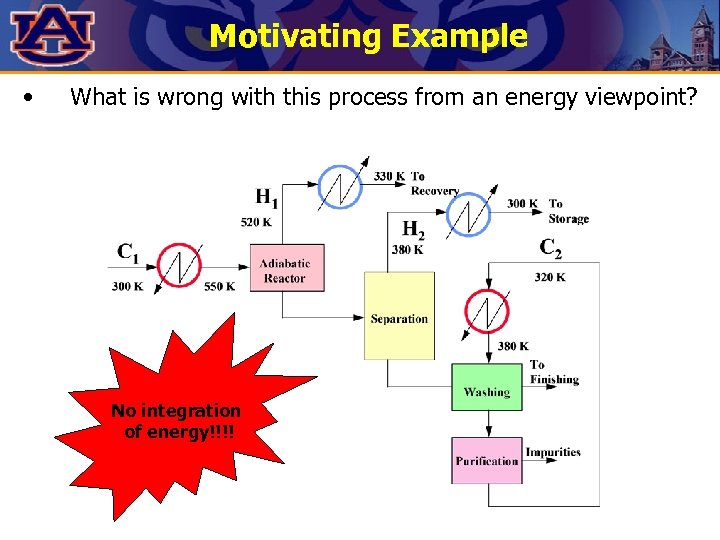

Motivating Example • What is wrong with this process from an energy viewpoint? No integration of energy!!!!

Motivating Example • What is wrong with this process from an energy viewpoint? No integration of energy!!!!

Short Bibliography • Early pioneers – Rudd @ Wisconsin (1968) – Hohmann @ USC (1971) • Central figure – Linnhoff @ ICI/UMIST (1978) – Currently: President, Linnhoff-March • Recommended text – Seider, Seader and Lewin (2004): Product and Process Design Principles, 2 ed. Wiley and Sons, NY – Linnhoff et al. (1982): A User Guide on Process Integration for the Efficient Use of Energy, I. Chem. E. , London • Most comprehensive review: – Gundersen, T. and Naess, L. (1988): The Synthesis of Cost Optimal Heat Exchanger Networks: An Industrial Review of the State of the Art, Comp. Chem. Eng. , 12(6), 503 -530

Short Bibliography • Early pioneers – Rudd @ Wisconsin (1968) – Hohmann @ USC (1971) • Central figure – Linnhoff @ ICI/UMIST (1978) – Currently: President, Linnhoff-March • Recommended text – Seider, Seader and Lewin (2004): Product and Process Design Principles, 2 ed. Wiley and Sons, NY – Linnhoff et al. (1982): A User Guide on Process Integration for the Efficient Use of Energy, I. Chem. E. , London • Most comprehensive review: – Gundersen, T. and Naess, L. (1988): The Synthesis of Cost Optimal Heat Exchanger Networks: An Industrial Review of the State of the Art, Comp. Chem. Eng. , 12(6), 503 -530

Capital vs. Energy 1: 3 • The design of Heat Exchanger Networks (HENs) deals with the following problem: Given: Ø NH hot streams, with given heat capacity flowrate, each having to be cooled from supply temperature THS to targets THT Ø NC cold streams, with given heat capacity flowrate, each having to be heated from supply temperature TCS to targets TCT Design: An optimum network of heat exchangers, connecting between the hot and cold streams and between the streams and cold/hot utilities (furnace, hot-oil, steam, cooling water or refrigerant, depending on the required duty temperature)

Capital vs. Energy 1: 3 • The design of Heat Exchanger Networks (HENs) deals with the following problem: Given: Ø NH hot streams, with given heat capacity flowrate, each having to be cooled from supply temperature THS to targets THT Ø NC cold streams, with given heat capacity flowrate, each having to be heated from supply temperature TCS to targets TCT Design: An optimum network of heat exchangers, connecting between the hot and cold streams and between the streams and cold/hot utilities (furnace, hot-oil, steam, cooling water or refrigerant, depending on the required duty temperature)

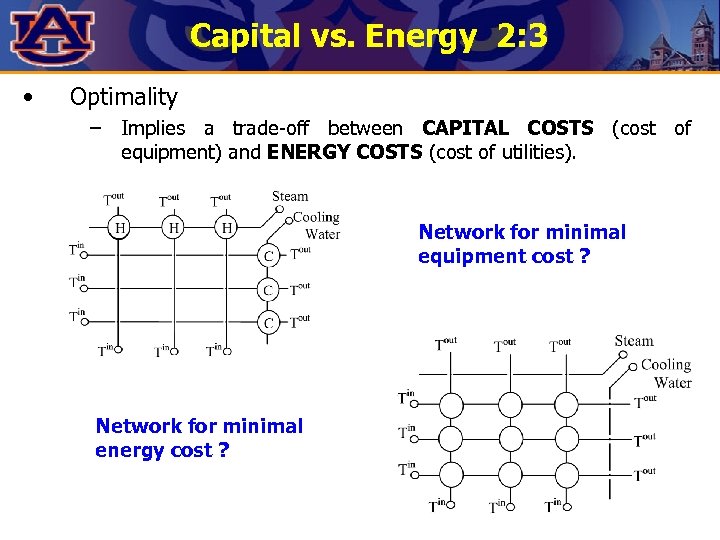

Capital vs. Energy 2: 3 • Optimality – Implies a trade-off between CAPITAL COSTS (cost of equipment) and ENERGY COSTS (cost of utilities). Network for minimal equipment cost ? Network for minimal energy cost ?

Capital vs. Energy 2: 3 • Optimality – Implies a trade-off between CAPITAL COSTS (cost of equipment) and ENERGY COSTS (cost of utilities). Network for minimal equipment cost ? Network for minimal energy cost ?

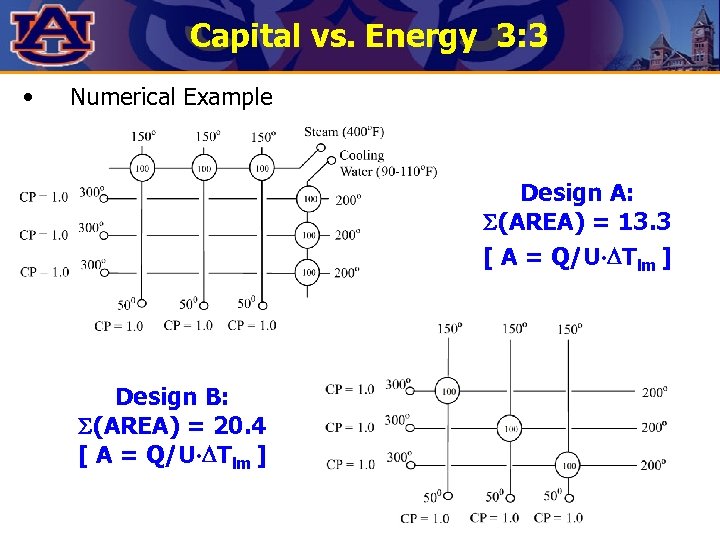

Capital vs. Energy 3: 3 • Numerical Example Design A: (AREA) = 13. 3 [ A = Q/U Tlm ] Design B: (AREA) = 20. 4 [ A = Q/U Tlm ]

Capital vs. Energy 3: 3 • Numerical Example Design A: (AREA) = 13. 3 [ A = Q/U Tlm ] Design B: (AREA) = 20. 4 [ A = Q/U Tlm ]

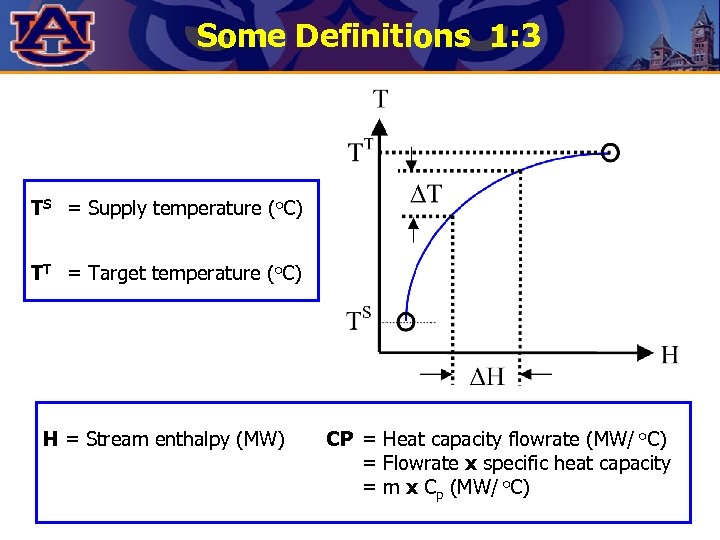

Some Definitions 1: 3 TS = Supply temperature (o. C) TT = Target temperature (o. C) H = Stream enthalpy (MW) CP = Heat capacity flowrate (MW/ o. C) = Flowrate x specific heat capacity = m x Cp (MW/ o. C)

Some Definitions 1: 3 TS = Supply temperature (o. C) TT = Target temperature (o. C) H = Stream enthalpy (MW) CP = Heat capacity flowrate (MW/ o. C) = Flowrate x specific heat capacity = m x Cp (MW/ o. C)

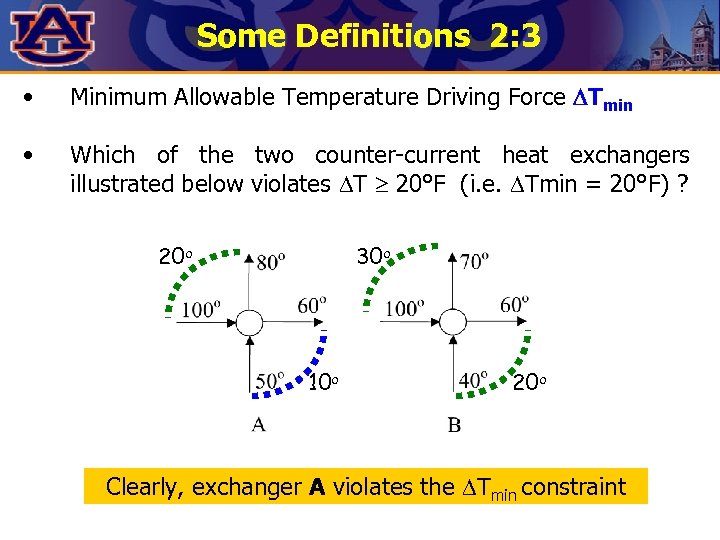

Some Definitions 2: 3 • Minimum Allowable Temperature Driving Force Tmin • Which of the two counter-current heat exchangers illustrated below violates T 20°F (i. e. Tmin = 20°F) ? 20 o 30 o 10 o 20 o Clearly, exchanger A violates the Tmin constraint

Some Definitions 2: 3 • Minimum Allowable Temperature Driving Force Tmin • Which of the two counter-current heat exchangers illustrated below violates T 20°F (i. e. Tmin = 20°F) ? 20 o 30 o 10 o 20 o Clearly, exchanger A violates the Tmin constraint

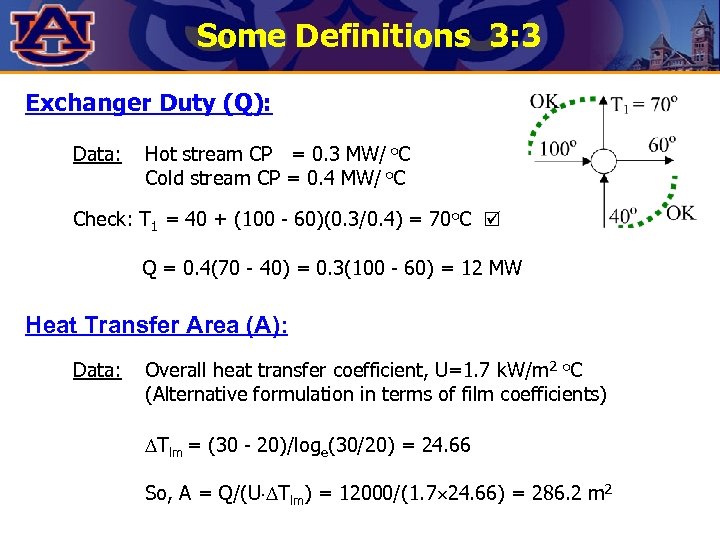

Some Definitions 3: 3 Exchanger Duty (Q): Data: Hot stream CP = 0. 3 MW/ o. C Cold stream CP = 0. 4 MW/ o. C Check: T 1 = 40 + (100 - 60)(0. 3/0. 4) = 70 o. C Q = 0. 4(70 - 40) = 0. 3(100 - 60) = 12 MW Heat Transfer Area (A): Data: Overall heat transfer coefficient, U=1. 7 k. W/m 2 o. C (Alternative formulation in terms of film coefficients) Tlm = (30 - 20)/loge(30/20) = 24. 66 So, A = Q/(U Tlm) = 12000/(1. 7 24. 66) = 286. 2 m 2

Some Definitions 3: 3 Exchanger Duty (Q): Data: Hot stream CP = 0. 3 MW/ o. C Cold stream CP = 0. 4 MW/ o. C Check: T 1 = 40 + (100 - 60)(0. 3/0. 4) = 70 o. C Q = 0. 4(70 - 40) = 0. 3(100 - 60) = 12 MW Heat Transfer Area (A): Data: Overall heat transfer coefficient, U=1. 7 k. W/m 2 o. C (Alternative formulation in terms of film coefficients) Tlm = (30 - 20)/loge(30/20) = 24. 66 So, A = Q/(U Tlm) = 12000/(1. 7 24. 66) = 286. 2 m 2

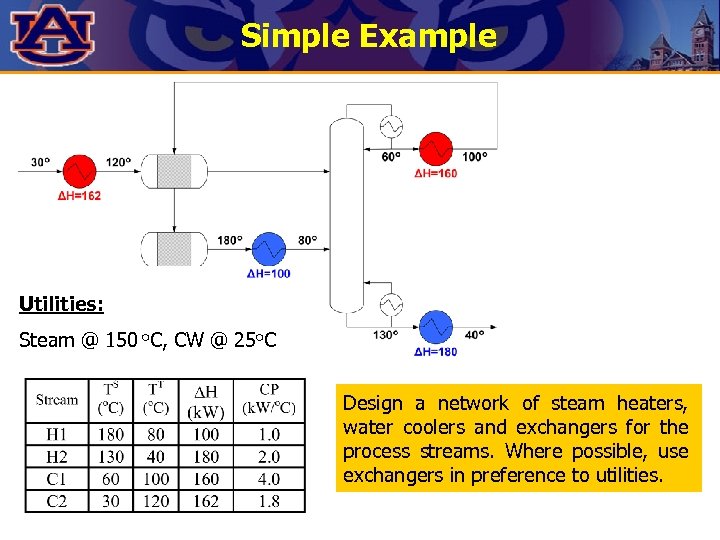

Simple Example Utilities: Steam @ 150 o. C, CW @ 25 o. C Design a network of steam heaters, water coolers and exchangers for the process streams. Where possible, use exchangers in preference to utilities.

Simple Example Utilities: Steam @ 150 o. C, CW @ 25 o. C Design a network of steam heaters, water coolers and exchangers for the process streams. Where possible, use exchangers in preference to utilities.

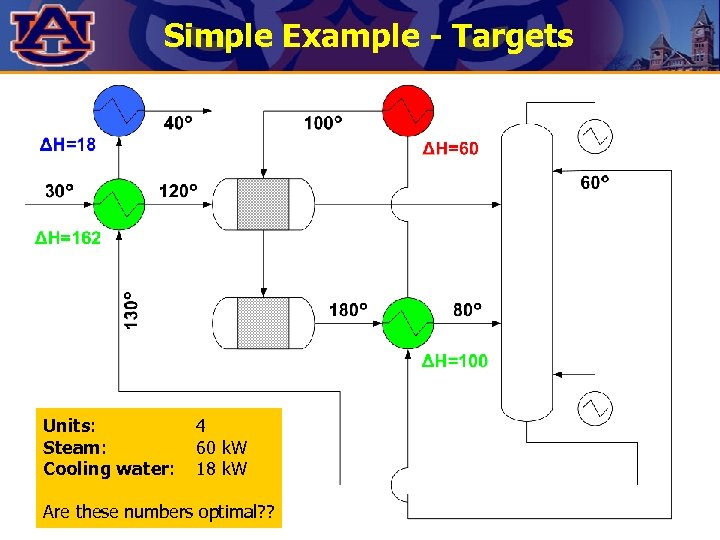

Simple Example - Targets Units: Steam: Cooling water: 4 60 k. W 18 k. W Are these numbers optimal? ?

Simple Example - Targets Units: Steam: Cooling water: 4 60 k. W 18 k. W Are these numbers optimal? ?

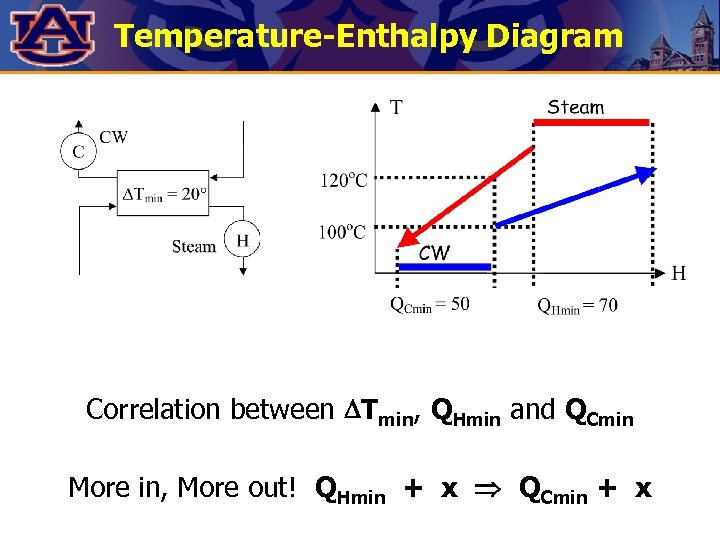

Temperature-Enthalpy Diagram Correlation between Tmin, QHmin and QCmin More in, More out! QHmin + x QCmin + x

Temperature-Enthalpy Diagram Correlation between Tmin, QHmin and QCmin More in, More out! QHmin + x QCmin + x

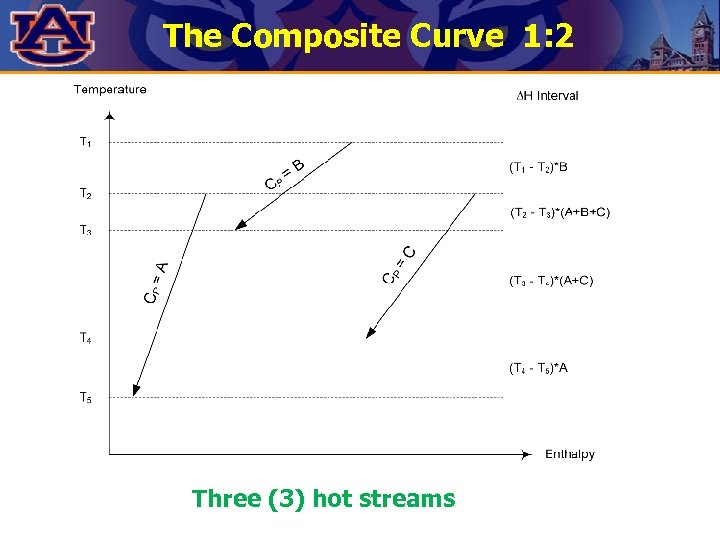

The Composite Curve 1: 2 Three (3) hot streams

The Composite Curve 1: 2 Three (3) hot streams

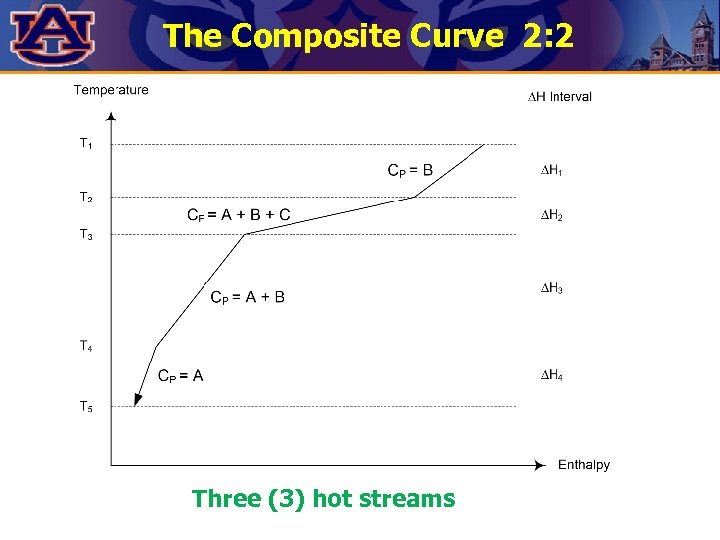

The Composite Curve 2: 2 Three (3) hot streams

The Composite Curve 2: 2 Three (3) hot streams

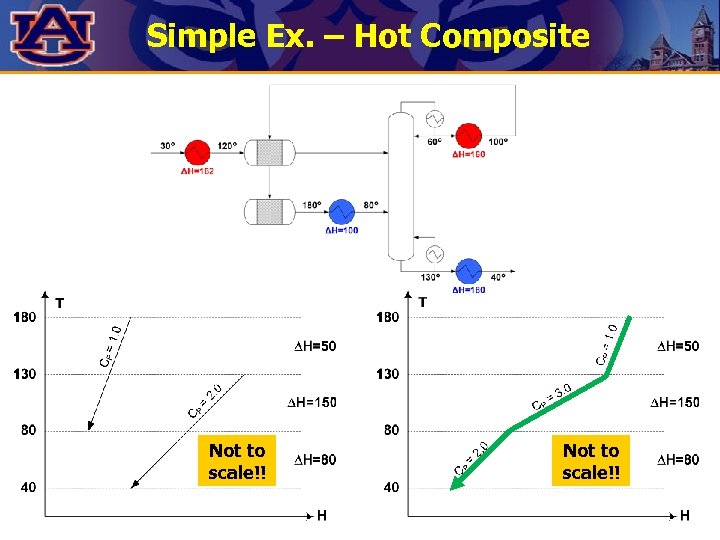

Simple Ex. – Hot Composite Not to scale!!

Simple Ex. – Hot Composite Not to scale!!

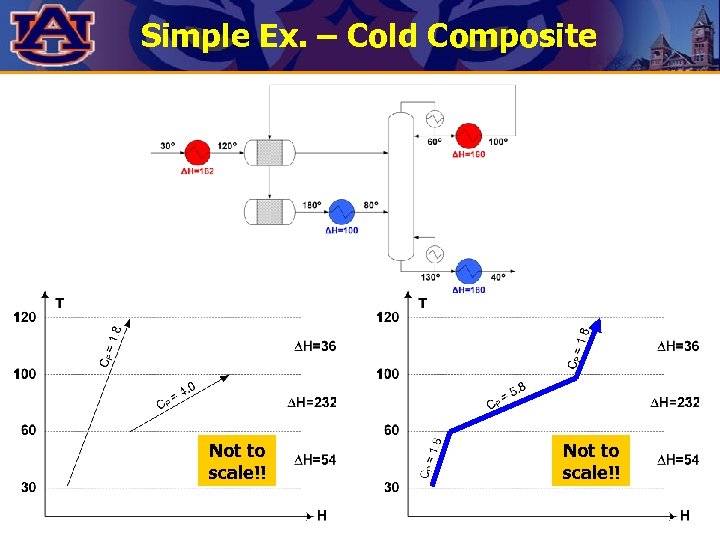

Simple Ex. – Cold Composite Not to scale!!

Simple Ex. – Cold Composite Not to scale!!

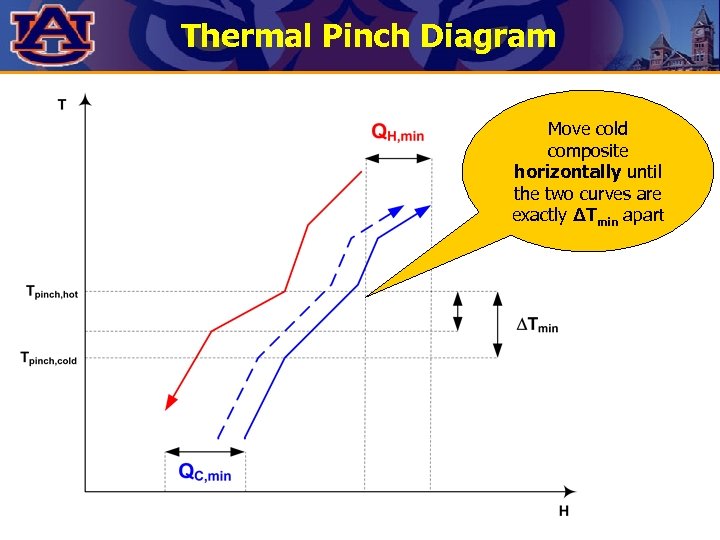

Thermal Pinch Diagram Move cold composite horizontally until the two curves are exactly ΔTmin apart

Thermal Pinch Diagram Move cold composite horizontally until the two curves are exactly ΔTmin apart

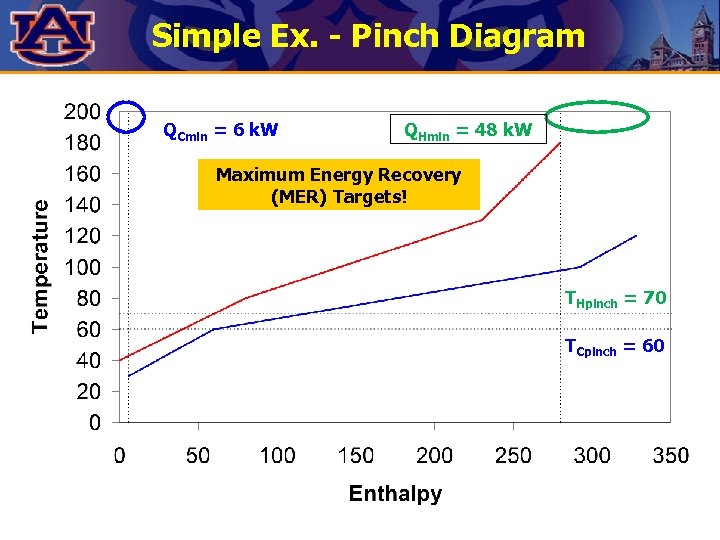

Simple Ex. - Pinch Diagram QCmin = 6 k. W QHmin = 48 k. W Maximum Energy Recovery (MER) Targets! THpinch = 70 TCpinch = 60

Simple Ex. - Pinch Diagram QCmin = 6 k. W QHmin = 48 k. W Maximum Energy Recovery (MER) Targets! THpinch = 70 TCpinch = 60

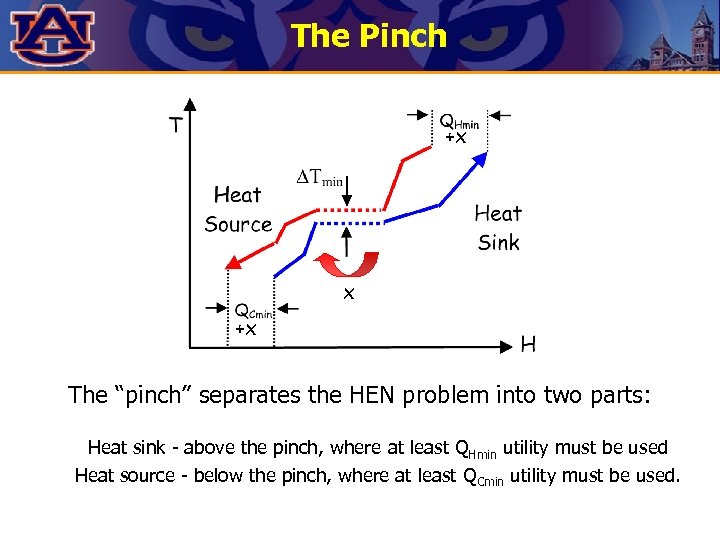

The Pinch +x x +x The “pinch” separates the HEN problem into two parts: Heat sink - above the pinch, where at least QHmin utility must be used Heat source - below the pinch, where at least QCmin utility must be used.

The Pinch +x x +x The “pinch” separates the HEN problem into two parts: Heat sink - above the pinch, where at least QHmin utility must be used Heat source - below the pinch, where at least QCmin utility must be used.

Significance of the Pinch • Do not transfer heat across pinch • Do not use cold utilities above the pinch • Do not use hot utilities below the pinch

Significance of the Pinch • Do not transfer heat across pinch • Do not use cold utilities above the pinch • Do not use hot utilities below the pinch

Algebraic Targeting Method • Temperature scales – Hot stream temperatures (T) – Cold stream temperatures (t) • Thermal equilibrium – Achieved when T = t • Inclusion of temperature driving force ΔTmin – T = t + ΔTmin – Thus substracting ΔTmin from the hot temperatures will ensure thermal feasibility at all times

Algebraic Targeting Method • Temperature scales – Hot stream temperatures (T) – Cold stream temperatures (t) • Thermal equilibrium – Achieved when T = t • Inclusion of temperature driving force ΔTmin – T = t + ΔTmin – Thus substracting ΔTmin from the hot temperatures will ensure thermal feasibility at all times

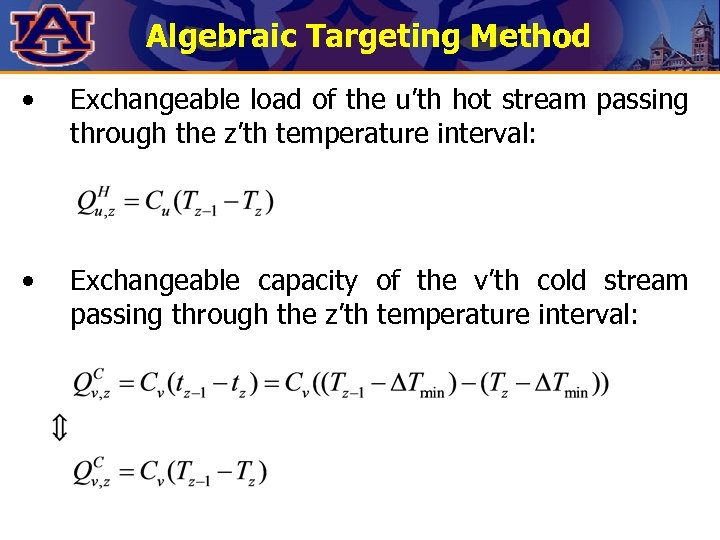

Algebraic Targeting Method • Exchangeable load of the u’th hot stream passing through the z’th temperature interval: • Exchangeable capacity of the v’th cold stream passing through the z’th temperature interval:

Algebraic Targeting Method • Exchangeable load of the u’th hot stream passing through the z’th temperature interval: • Exchangeable capacity of the v’th cold stream passing through the z’th temperature interval:

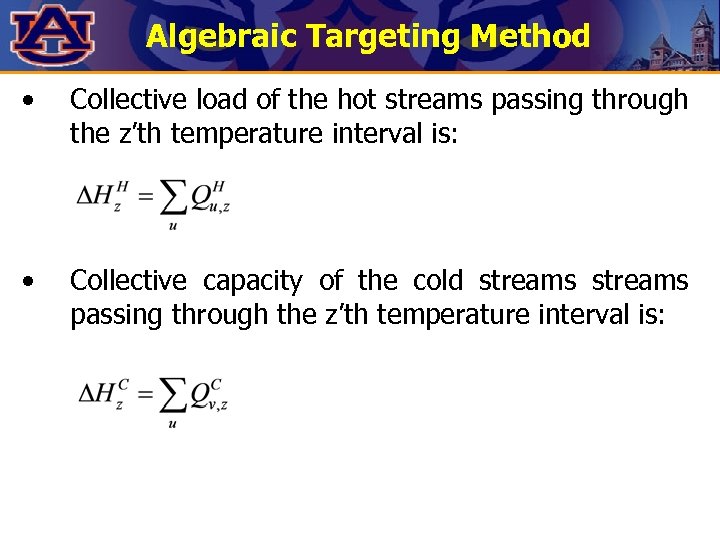

Algebraic Targeting Method • Collective load of the hot streams passing through the z’th temperature interval is: • Collective capacity of the cold streams passing through the z’th temperature interval is:

Algebraic Targeting Method • Collective load of the hot streams passing through the z’th temperature interval is: • Collective capacity of the cold streams passing through the z’th temperature interval is:

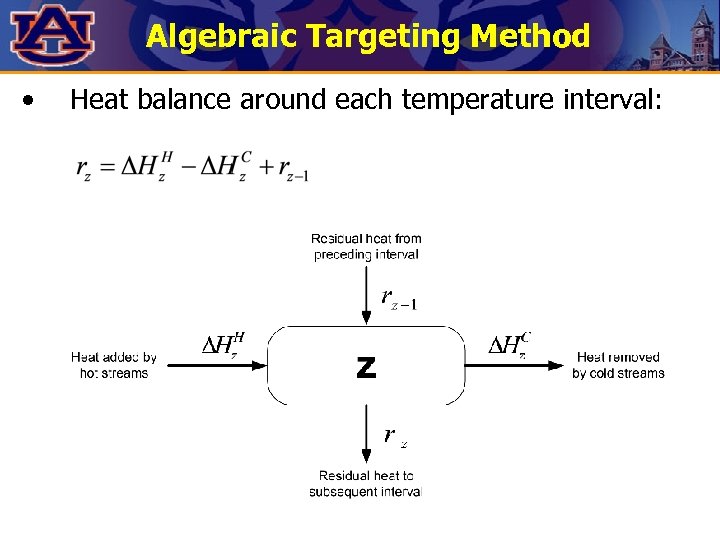

Algebraic Targeting Method • Heat balance around each temperature interval:

Algebraic Targeting Method • Heat balance around each temperature interval:

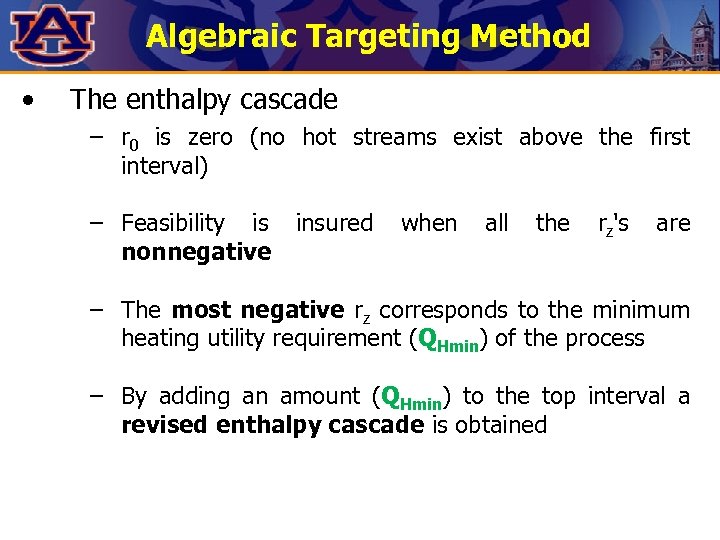

Algebraic Targeting Method • The enthalpy cascade – r 0 is zero (no hot streams exist above the first interval) – Feasibility is nonnegative insured when all the rz's are – The most negative rz corresponds to the minimum heating utility requirement (QHmin) of the process – By adding an amount (QHmin) to the top interval a revised enthalpy cascade is obtained

Algebraic Targeting Method • The enthalpy cascade – r 0 is zero (no hot streams exist above the first interval) – Feasibility is nonnegative insured when all the rz's are – The most negative rz corresponds to the minimum heating utility requirement (QHmin) of the process – By adding an amount (QHmin) to the top interval a revised enthalpy cascade is obtained

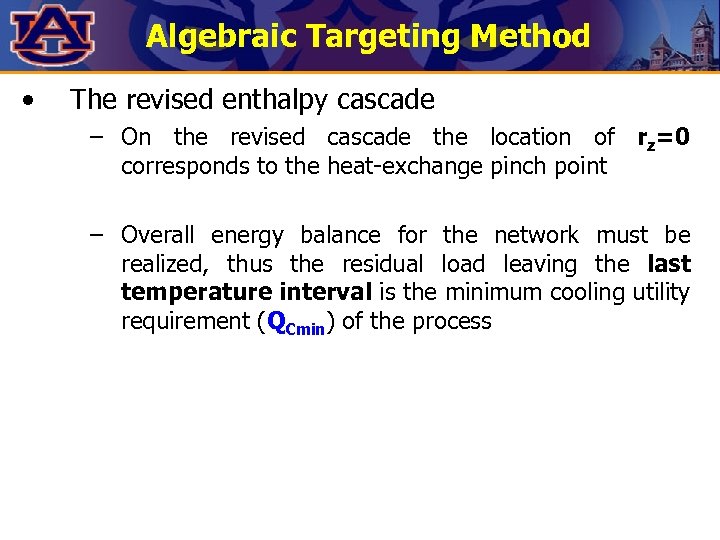

Algebraic Targeting Method • The revised enthalpy cascade – On the revised cascade the location of rz=0 corresponds to the heat-exchange pinch point – Overall energy balance for the network must be realized, thus the residual load leaving the last temperature interval is the minimum cooling utility requirement (QCmin) of the process

Algebraic Targeting Method • The revised enthalpy cascade – On the revised cascade the location of rz=0 corresponds to the heat-exchange pinch point – Overall energy balance for the network must be realized, thus the residual load leaving the last temperature interval is the minimum cooling utility requirement (QCmin) of the process

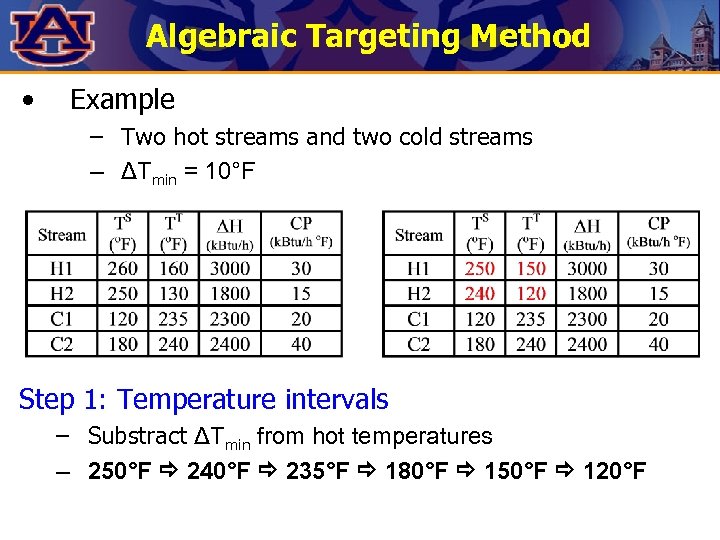

Algebraic Targeting Method • Example – Two hot streams and two cold streams – ΔTmin = 10°F Step 1: Temperature intervals – Substract ΔTmin from hot temperatures – 250°F 240°F 235°F 180°F 150°F 120°F

Algebraic Targeting Method • Example – Two hot streams and two cold streams – ΔTmin = 10°F Step 1: Temperature intervals – Substract ΔTmin from hot temperatures – 250°F 240°F 235°F 180°F 150°F 120°F

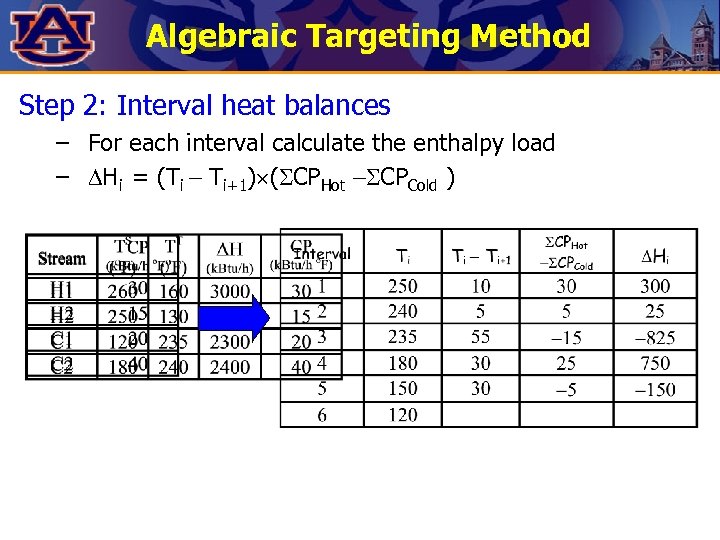

Algebraic Targeting Method Step 2: Interval heat balances – For each interval calculate the enthalpy load – Hi = (Ti Ti+1) ( CPHot CPCold )

Algebraic Targeting Method Step 2: Interval heat balances – For each interval calculate the enthalpy load – Hi = (Ti Ti+1) ( CPHot CPCold )

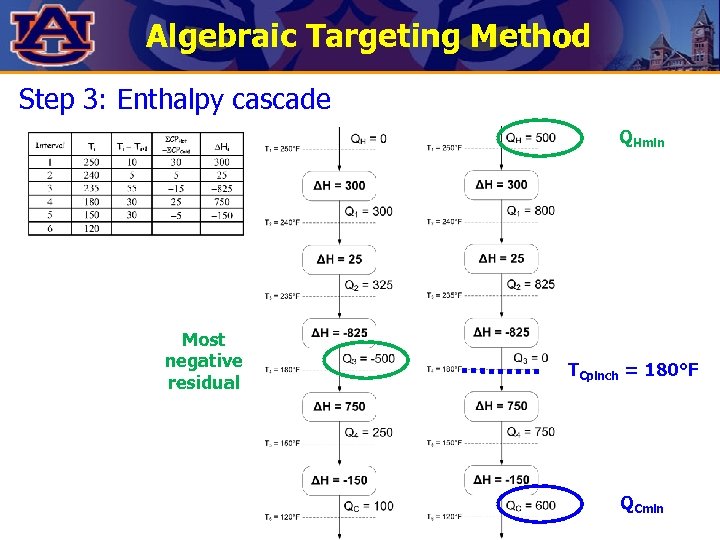

Algebraic Targeting Method Step 3: Enthalpy cascade QHmin Most negative residual TCpinch = 180°F QCmin

Algebraic Targeting Method Step 3: Enthalpy cascade QHmin Most negative residual TCpinch = 180°F QCmin

Summary – Heat Integration On completion of this part, given data on the hot and cold streams of a process, you should be able to: Compute the pinch temperatures Compute the Maximum Energy Recovery (MER) targets using graphical and/or algebraic methods

Summary – Heat Integration On completion of this part, given data on the hot and cold streams of a process, you should be able to: Compute the pinch temperatures Compute the Maximum Energy Recovery (MER) targets using graphical and/or algebraic methods

Other Business • No lecture next week (October 30) – • I will be in Pittsburgh for the AICh. E Annual Meeting Next Lecture – November 6 – Heat and Power Integration: Network Design (SSLW p. 261 -280)

Other Business • No lecture next week (October 30) – • I will be in Pittsburgh for the AICh. E Annual Meeting Next Lecture – November 6 – Heat and Power Integration: Network Design (SSLW p. 261 -280)