abb7029ef544599041a6eb7e7e63e581.ppt

- Количество слайдов: 48

• HCM is an international company supplying high quality Injection Mould Tools to moulding companies in Europe. • Our strength lies in our resolve to represent only the best Toolmakers in the Far East.

• HCM is an international company supplying high quality Injection Mould Tools to moulding companies in Europe. • Our strength lies in our resolve to represent only the best Toolmakers in the Far East.

Portfolio of Excellence • HCM was established to provide European moulders with high quality, short delivery tooling at competitive prices. • Extensive benchmarking in Hong Kong and China over a ten year period has established a portfolio of “best in class” toolmakers.

Portfolio of Excellence • HCM was established to provide European moulders with high quality, short delivery tooling at competitive prices. • Extensive benchmarking in Hong Kong and China over a ten year period has established a portfolio of “best in class” toolmakers.

• Our operations are split between the UK, the Netherlands, Germany & Shenzhen (China). • The company office in Shenzhen employs English speaking Chinese nationals who monitor all tool builds against the required time lines.

• Our operations are split between the UK, the Netherlands, Germany & Shenzhen (China). • The company office in Shenzhen employs English speaking Chinese nationals who monitor all tool builds against the required time lines.

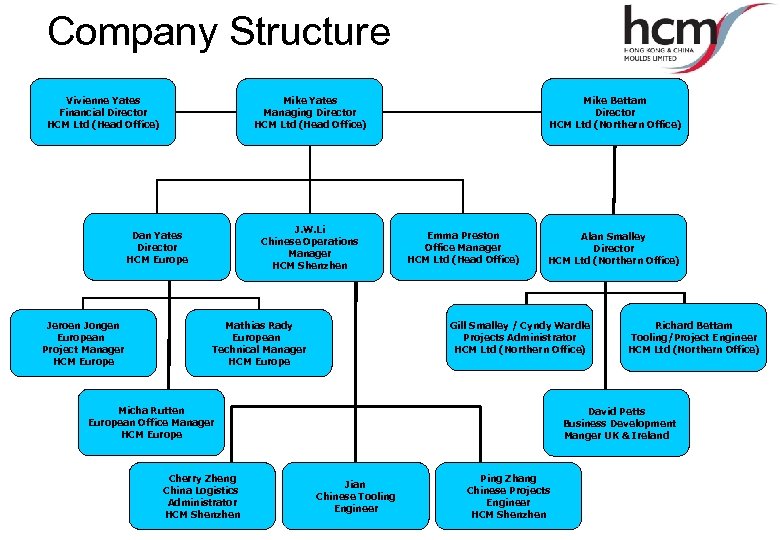

Company Structure Vivienne Yates Financial Director HCM Ltd (Head Office) Mike Yates Managing Director HCM Ltd (Head Office) J. W. Li Chinese Operations Manager HCM Shenzhen Dan Yates Director HCM Europe Jeroen Jongen European Project Manager HCM Europe Mathias Rady European Technical Manager HCM Europe Mike Bettam Director HCM Ltd (Northern Office) Emma Preston Office Manager HCM Ltd (Head Office) Alan Smalley Director HCM Ltd (Northern Office) Gill Smalley / Cyndy Wardle Projects Administrator HCM Ltd (Northern Office) Micha Rutten European Office Manager HCM Europe Cherry Zheng China Logistics Administrator HCM Shenzhen Richard Bettam Tooling/Project Engineer HCM Ltd (Northern Office) David Petts Business Development Manger UK & Ireland Jian Chinese Tooling Engineer Ping Zhang Chinese Projects Engineer HCM Shenzhen

Company Structure Vivienne Yates Financial Director HCM Ltd (Head Office) Mike Yates Managing Director HCM Ltd (Head Office) J. W. Li Chinese Operations Manager HCM Shenzhen Dan Yates Director HCM Europe Jeroen Jongen European Project Manager HCM Europe Mathias Rady European Technical Manager HCM Europe Mike Bettam Director HCM Ltd (Northern Office) Emma Preston Office Manager HCM Ltd (Head Office) Alan Smalley Director HCM Ltd (Northern Office) Gill Smalley / Cyndy Wardle Projects Administrator HCM Ltd (Northern Office) Micha Rutten European Office Manager HCM Europe Cherry Zheng China Logistics Administrator HCM Shenzhen Richard Bettam Tooling/Project Engineer HCM Ltd (Northern Office) David Petts Business Development Manger UK & Ireland Jian Chinese Tooling Engineer Ping Zhang Chinese Projects Engineer HCM Shenzhen

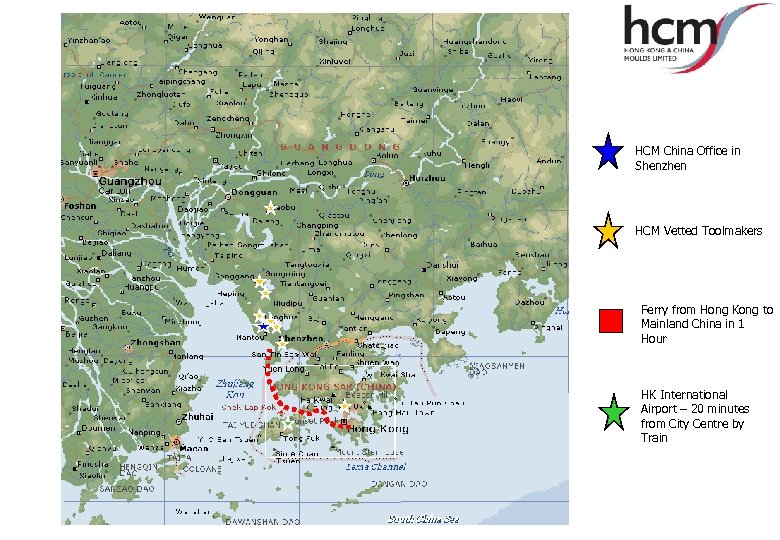

HCM China Office in Shenzhen HCM Vetted Toolmakers Ferry from Hong Kong to Mainland China in 1 Hour HK International Airport – 20 minutes from City Centre by Train

HCM China Office in Shenzhen HCM Vetted Toolmakers Ferry from Hong Kong to Mainland China in 1 Hour HK International Airport – 20 minutes from City Centre by Train

Tooling Technology • Each of our toolmakers has specific areas of specialisation which cover all moulding technologies: • Single & Two shot moulding • Gas Injection • Sequential hot runner moulds • Lens and optical components • Small, medium and large components • Tooling between 25 & 35, 000 Kilos

Tooling Technology • Each of our toolmakers has specific areas of specialisation which cover all moulding technologies: • Single & Two shot moulding • Gas Injection • Sequential hot runner moulds • Lens and optical components • Small, medium and large components • Tooling between 25 & 35, 000 Kilos

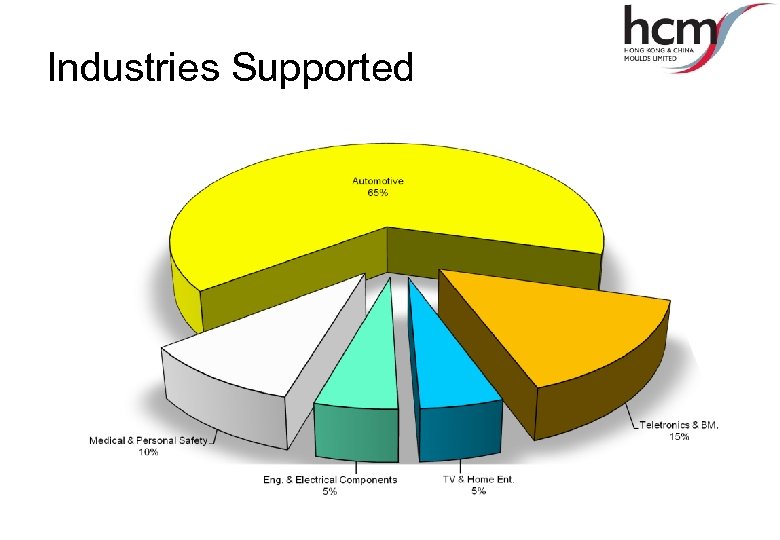

Industries Supported • • Automotive Teletronics & Business Machine Medical & Personal Safety Engineering and Electrical components

Industries Supported • • Automotive Teletronics & Business Machine Medical & Personal Safety Engineering and Electrical components

Industries Supported

Industries Supported

HCM Automotive HCM has supplied tooling to the suppliers of the following OEM’s

HCM Automotive HCM has supplied tooling to the suppliers of the following OEM’s

HCM Automotive Here is a selection of Tear 1 suppliers & Trade Moulders that HCM has supplied tooling for.

HCM Automotive Here is a selection of Tear 1 suppliers & Trade Moulders that HCM has supplied tooling for.

BMW -MINI HCM Tooling Produced These Parts

BMW -MINI HCM Tooling Produced These Parts

Land Rover - Freelander 13

Land Rover - Freelander 13

Range Rover – L 322 14

Range Rover – L 322 14

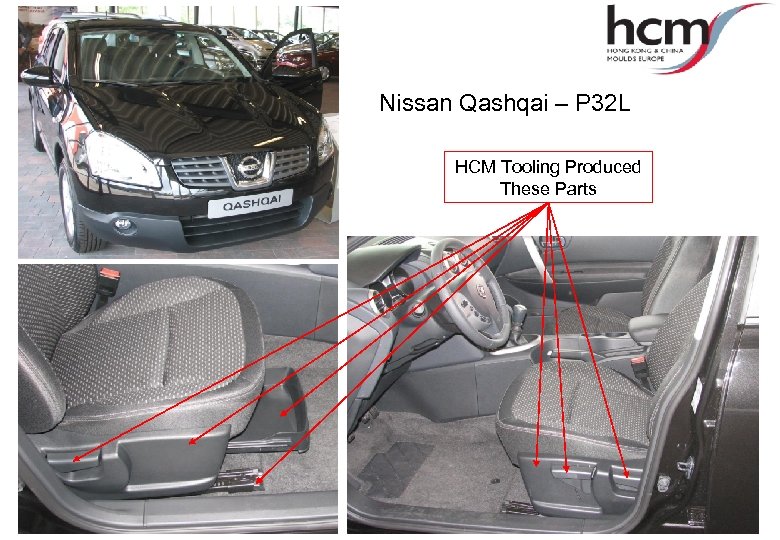

Nissan Qashqai – P 32 L HCM Tooling Produced These Parts 15

Nissan Qashqai – P 32 L HCM Tooling Produced These Parts 15

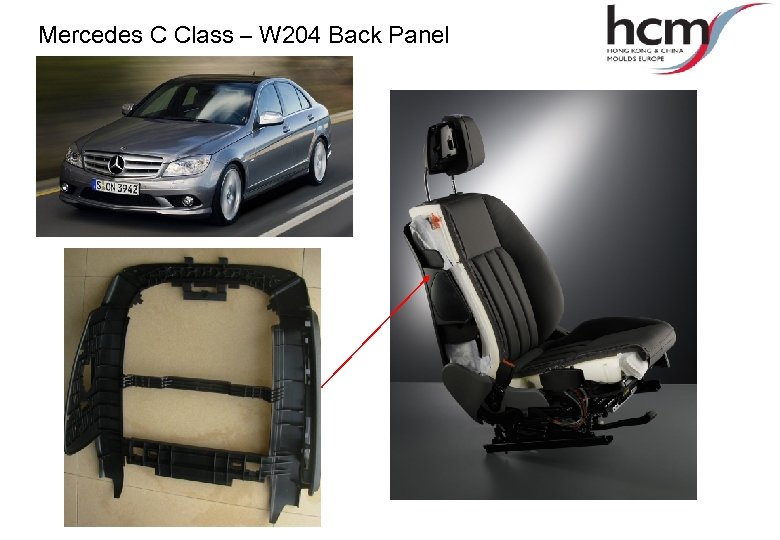

Mercedes C Class – W 204 Back Panel

Mercedes C Class – W 204 Back Panel

Mercedes AMG C 63 – Seat Back 17

Mercedes AMG C 63 – Seat Back 17

Nissan Qashqai + 2 – N 32 L

Nissan Qashqai + 2 – N 32 L

Teletronics & Business Machines

Teletronics & Business Machines

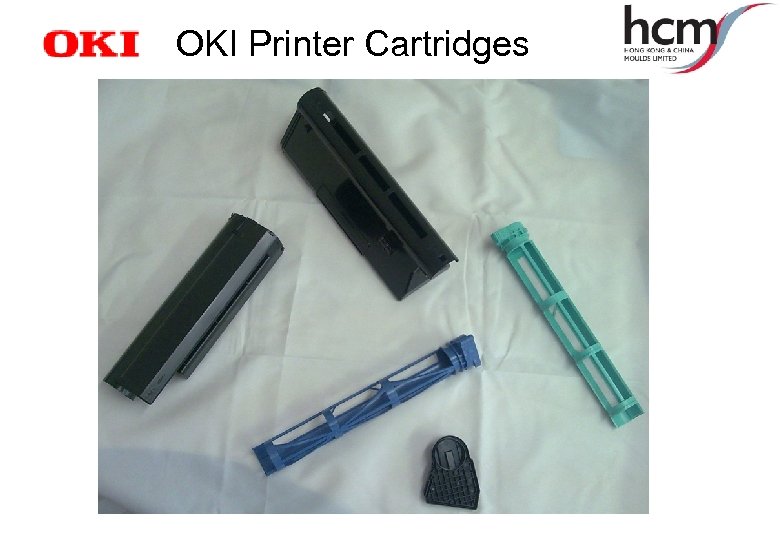

OKI Printer Cartridges

OKI Printer Cartridges

1000 Line Small Character Ink Jet Printer This unit is used in the labeling of products in the following markets: • Food processing • Beverage • Personal care and cosmetics • Pharmaceutical • Extrusion • Chemical This project required 53 Moulds

1000 Line Small Character Ink Jet Printer This unit is used in the labeling of products in the following markets: • Food processing • Beverage • Personal care and cosmetics • Pharmaceutical • Extrusion • Chemical This project required 53 Moulds

Medical & Personal Safety

Medical & Personal Safety

Medical training device for Surgeons, supplied to training hospitals. Specifically for the training of “Key Hole” surgery. 13 Tool Project

Medical training device for Surgeons, supplied to training hospitals. Specifically for the training of “Key Hole” surgery. 13 Tool Project

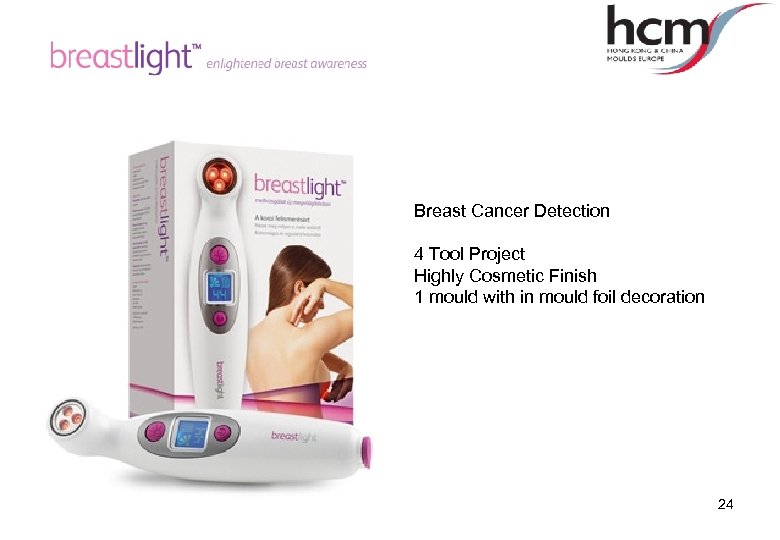

Breast Cancer Detection 4 Tool Project Highly Cosmetic Finish 1 mould with in mould foil decoration 24

Breast Cancer Detection 4 Tool Project Highly Cosmetic Finish 1 mould with in mould foil decoration 24

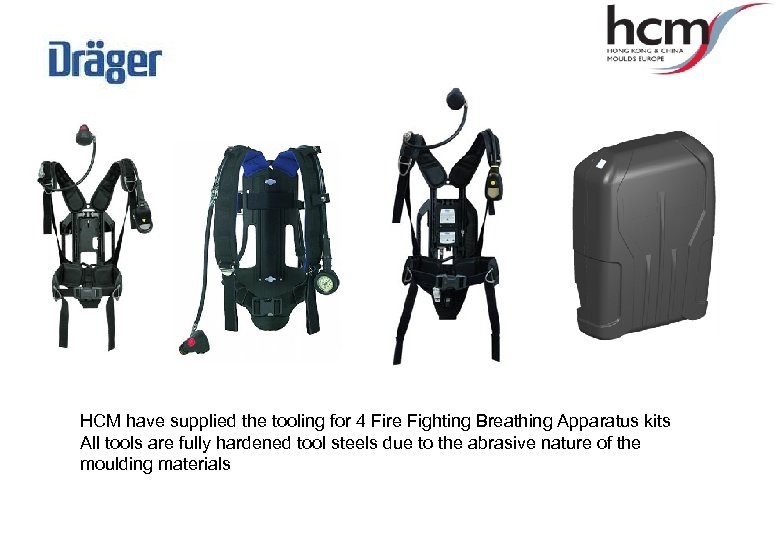

HCM have supplied the tooling for 4 Fire Fighting Breathing Apparatus kits All tools are fully hardened tool steels due to the abrasive nature of the moulding materials

HCM have supplied the tooling for 4 Fire Fighting Breathing Apparatus kits All tools are fully hardened tool steels due to the abrasive nature of the moulding materials

First Aid Kit High Cosmetic Requirement Leaf Hinge feature controlled by Sequential Hotrunner to ensure no weld lines on the Lid

First Aid Kit High Cosmetic Requirement Leaf Hinge feature controlled by Sequential Hotrunner to ensure no weld lines on the Lid

Engineering and Electrical Components

Engineering and Electrical Components

PHS Soap Dispensers Paper Dispensers Hand Dryers Sanitary Disposal Units

PHS Soap Dispensers Paper Dispensers Hand Dryers Sanitary Disposal Units

Thomas Dudley Water Cisterns Internal Mechanisms

Thomas Dudley Water Cisterns Internal Mechanisms

Worcester Bosch Central Heating Boilers Cosmetic Doors & Surrounds Internal Connections

Worcester Bosch Central Heating Boilers Cosmetic Doors & Surrounds Internal Connections

Honeywell - Trend Range of Control Modules 3 sizes to fit a common rail 15 tool project

Honeywell - Trend Range of Control Modules 3 sizes to fit a common rail 15 tool project

2 Shot Tooling

2 Shot Tooling

HCM 2 shot Capability • 3 toolmakers currently making 2 shot tooling • 1 toolmaker making technical tools up to 200 tonne machine size. • 1 toolmaker currently making 2 shot tooling up to 400 tonne machine size for sampling in-house and can sample larger tools at external trial houses. • 1 toolmaker currently making large automotive 2 shot tools up to 1100 tonne machine size

HCM 2 shot Capability • 3 toolmakers currently making 2 shot tooling • 1 toolmaker making technical tools up to 200 tonne machine size. • 1 toolmaker currently making 2 shot tooling up to 400 tonne machine size for sampling in-house and can sample larger tools at external trial houses. • 1 toolmaker currently making large automotive 2 shot tools up to 1100 tonne machine size

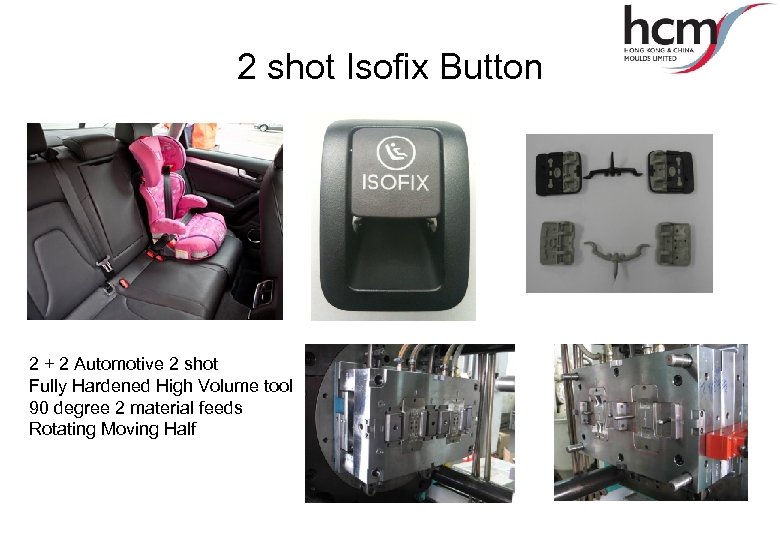

2 shot Isofix Button 2 + 2 Automotive 2 shot Fully Hardened High Volume tool 90 degree 2 material feeds Rotating Moving Half

2 shot Isofix Button 2 + 2 Automotive 2 shot Fully Hardened High Volume tool 90 degree 2 material feeds Rotating Moving Half

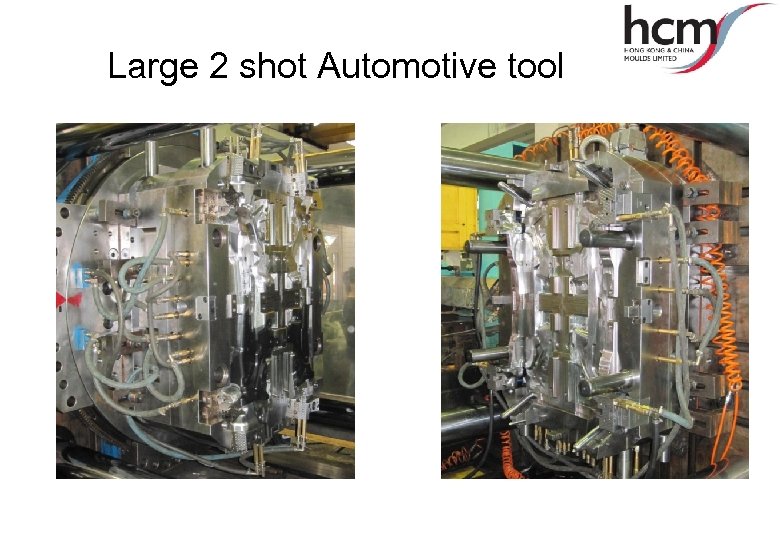

Large 2 shot Automotive tool

Large 2 shot Automotive tool

Technical Capability • All toolmakers represented use advanced CAD/ CAM/CAE technology with high speed machining centres, wire erosion and EDM. They have many years experience in running their own moulding shops giving excellent feedback in tool design technology. • Tool Feasibility • Mold flow on selected components • ISIR’s using CMM & Optical non contact • Full trial facilities, both in-house & via trial houses.

Technical Capability • All toolmakers represented use advanced CAD/ CAM/CAE technology with high speed machining centres, wire erosion and EDM. They have many years experience in running their own moulding shops giving excellent feedback in tool design technology. • Tool Feasibility • Mold flow on selected components • ISIR’s using CMM & Optical non contact • Full trial facilities, both in-house & via trial houses.

Quality Tooling • All tools are made to customer specific requirements as detailed in the RFQ. • Tools are made to European standards using European or Japanese tool steels as requested. • Hasco or DME consumable parts, • Water and Electrical connections as specified. • Non Export tools can be provided to remain in Hong Kong & China.

Quality Tooling • All tools are made to customer specific requirements as detailed in the RFQ. • Tools are made to European standards using European or Japanese tool steels as requested. • Hasco or DME consumable parts, • Water and Electrical connections as specified. • Non Export tools can be provided to remain in Hong Kong & China.

HCM Project Management After providing initial feasibility and split line sketches (showing ejection and feed positions etc…) HCM supplies their customers with detailed data during the mould construction. This data can be given in various formats such as: • HCM’s own “Workbook” Layout • Customers own project management format We can also advise customers on what additional points they should take into consideration when having tooling placed in China. Some of these are: • Chinese Holidays • Methods of transporting material out to Hong Kong • Estimated sea and airfreight duration for shipping parts and moulds • Estimated time for customs clearance and final transportation to the customers site

HCM Project Management After providing initial feasibility and split line sketches (showing ejection and feed positions etc…) HCM supplies their customers with detailed data during the mould construction. This data can be given in various formats such as: • HCM’s own “Workbook” Layout • Customers own project management format We can also advise customers on what additional points they should take into consideration when having tooling placed in China. Some of these are: • Chinese Holidays • Methods of transporting material out to Hong Kong • Estimated sea and airfreight duration for shipping parts and moulds • Estimated time for customs clearance and final transportation to the customers site

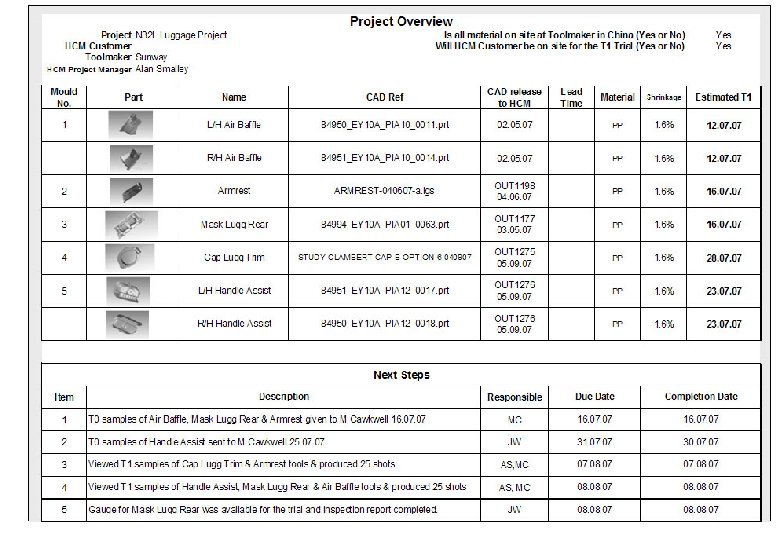

HCM “Workbooks” Over the course of the last several years HCM has learnt that the secret to a successful tooling project revolves around good information. Obtaining on time, accurate information from the customer is key to avoiding unnecessary delays. HCM works with the customer to obtain this information and then passes it onto the HCM toolmakers in a format they understand. To aid with this HCM has developed their own “Workbook” which is compiled in Microsoft Excel format. The “Workbook” includes updated tooling status as well as capturing fundamental details ranging from CAD references all the way to Material types & Shrinkages. HCM supplies a copy of the “Workbook” to the customer and the toolmaker so that everyone has access to the same data and important Next Steps

HCM “Workbooks” Over the course of the last several years HCM has learnt that the secret to a successful tooling project revolves around good information. Obtaining on time, accurate information from the customer is key to avoiding unnecessary delays. HCM works with the customer to obtain this information and then passes it onto the HCM toolmakers in a format they understand. To aid with this HCM has developed their own “Workbook” which is compiled in Microsoft Excel format. The “Workbook” includes updated tooling status as well as capturing fundamental details ranging from CAD references all the way to Material types & Shrinkages. HCM supplies a copy of the “Workbook” to the customer and the toolmaker so that everyone has access to the same data and important Next Steps

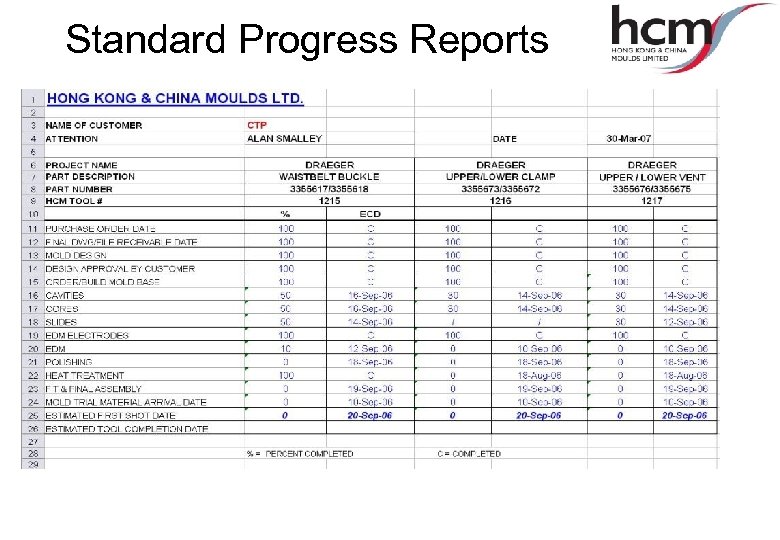

Standard Progress Reports

Standard Progress Reports

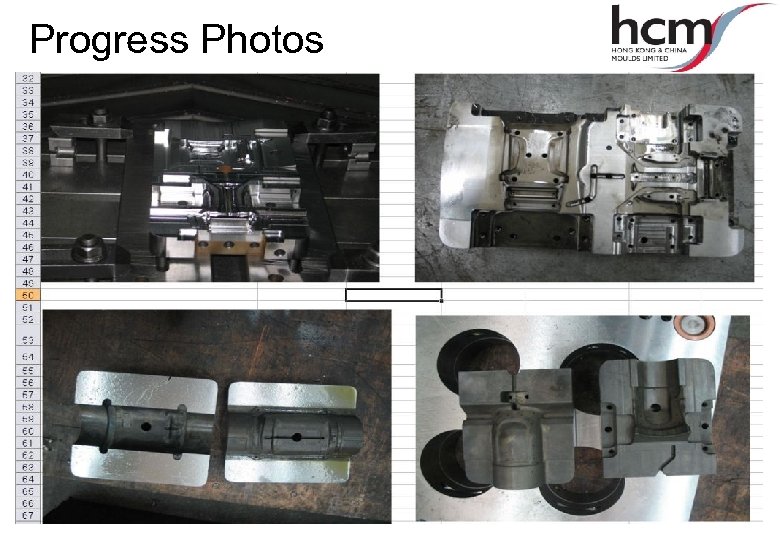

Progress Photos 42

Progress Photos 42

Tool Sampling • Conducted visits are arranged for our customer’s engineers who wish to see tool sampling undertaken. • All our toolmakers have their own sampling facilities or for larger tools will arrange trials at local specialised trial houses • Tools are sampled until the customer approves the parts. • Pilot production runs can be arranged.

Tool Sampling • Conducted visits are arranged for our customer’s engineers who wish to see tool sampling undertaken. • All our toolmakers have their own sampling facilities or for larger tools will arrange trials at local specialised trial houses • Tools are sampled until the customer approves the parts. • Pilot production runs can be arranged.

Tool Transfer • When moulds are despatched we have them protected from corrosion and shipped with a full Tool information pack. • HCM Tooling quotations include “door to door” transportation of moulds by sea. Quotations for the airfreight of moulds can also be supplied upon request.

Tool Transfer • When moulds are despatched we have them protected from corrosion and shipped with a full Tool information pack. • HCM Tooling quotations include “door to door” transportation of moulds by sea. Quotations for the airfreight of moulds can also be supplied upon request.

HCM Tool Information Packs All HCM tools arrive at our customers complete with a tool information pack which is put together by the toolmaker & our own staff prior to Tool Transfer. The tool information packs are comprised from the following items: • Tool Design Drawings (hard copy & 3 D copy) • CAD data for electrodes (actual electrodes available on request) • Inspection reports • Tool trial reports • Copy of the 3 D part data • Samples of last off parts from China

HCM Tool Information Packs All HCM tools arrive at our customers complete with a tool information pack which is put together by the toolmaker & our own staff prior to Tool Transfer. The tool information packs are comprised from the following items: • Tool Design Drawings (hard copy & 3 D copy) • CAD data for electrodes (actual electrodes available on request) • Inspection reports • Tool trial reports • Copy of the 3 D part data • Samples of last off parts from China

HCM Tool Support • HCM has developed relationships with a number of toolmakers throughout the UK and Benelux & Europe to ensure that any modifications can easily be handled and project managed.

HCM Tool Support • HCM has developed relationships with a number of toolmakers throughout the UK and Benelux & Europe to ensure that any modifications can easily be handled and project managed.

Guaranteed Satisfaction • Tools are guaranteed against breakdown for a period of 12 months except where failure is caused by poor maintenance, misuse and accidental damage. Full engineering support is given to ensure that the tooling performs correctly. • Hot runner and Hydraulic components are covered by the manufacturers warranty.

Guaranteed Satisfaction • Tools are guaranteed against breakdown for a period of 12 months except where failure is caused by poor maintenance, misuse and accidental damage. Full engineering support is given to ensure that the tooling performs correctly. • Hot runner and Hydraulic components are covered by the manufacturers warranty.

Full Confidence • We make the decision of placing tooling orders easy with full consultation before, during and after tool build. • For further information, please visit our website at www. hcmmoulds. co. uk

Full Confidence • We make the decision of placing tooling orders easy with full consultation before, during and after tool build. • For further information, please visit our website at www. hcmmoulds. co. uk