ccc63e9beb49e0cfc417b80f9d391873.ppt

- Количество слайдов: 71

Hazardous Waste Management: Overview Waste Management

Hazardous Waste Management: Overview Waste Management

Definition of Hazardous Waste A solid or liquid wastes which because of its quantity, concentration or physical, chemical or infectious characteristics, may: 1. Cause increase in mortality or severe illness, 2. Pose a substantial potential hazard to human health or environment, when improperly treated, stored, transported or disposed

Definition of Hazardous Waste A solid or liquid wastes which because of its quantity, concentration or physical, chemical or infectious characteristics, may: 1. Cause increase in mortality or severe illness, 2. Pose a substantial potential hazard to human health or environment, when improperly treated, stored, transported or disposed

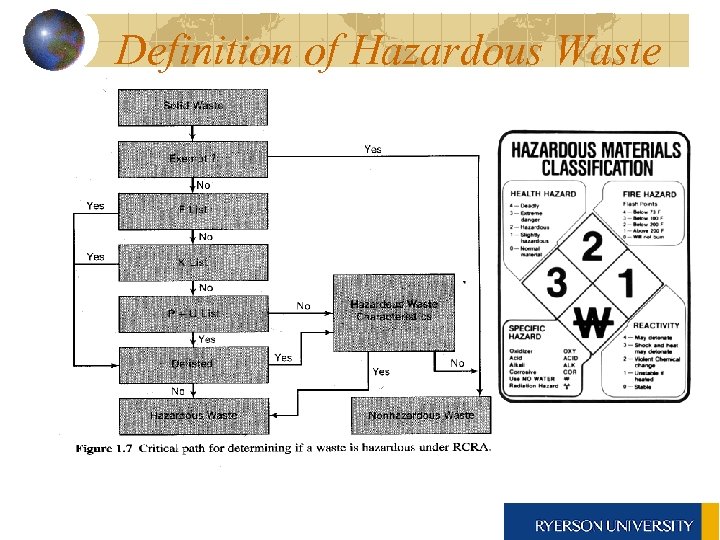

Definition of Hazardous Waste

Definition of Hazardous Waste

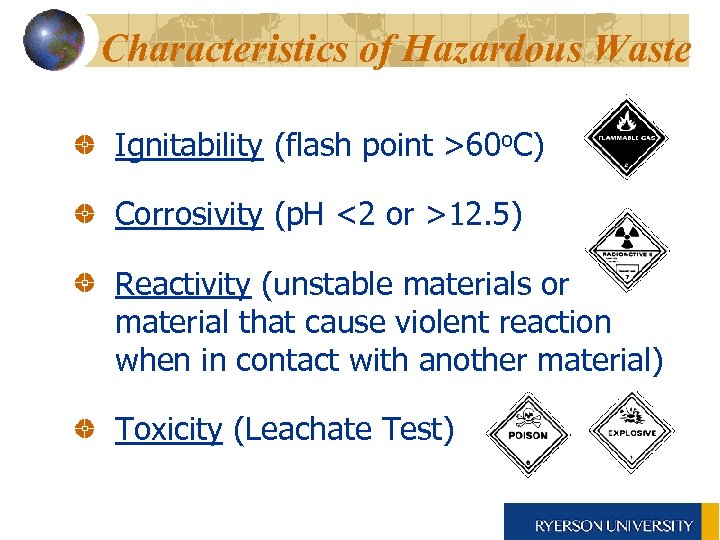

Characteristics of Hazardous Waste Ignitability (flash point >60 o. C) Corrosivity (p. H <2 or >12. 5) Reactivity (unstable materials or material that cause violent reaction when in contact with another material) Toxicity (Leachate Test)

Characteristics of Hazardous Waste Ignitability (flash point >60 o. C) Corrosivity (p. H <2 or >12. 5) Reactivity (unstable materials or material that cause violent reaction when in contact with another material) Toxicity (Leachate Test)

Nature of Hazardous Waste Management Hazardous Waste field is interdisciplinary Requires professionals with diverse background working together to solve the complex issue of hazardous waste management Environmental Impact and Risk Assessment Treatment, Storage and Disposal Waste Minimization, Recycling and Reduction Management and Cost

Nature of Hazardous Waste Management Hazardous Waste field is interdisciplinary Requires professionals with diverse background working together to solve the complex issue of hazardous waste management Environmental Impact and Risk Assessment Treatment, Storage and Disposal Waste Minimization, Recycling and Reduction Management and Cost

Past Disposal Practice Ø Soil Spreading Ø Pits/Ponds/Lagoons Ø Sanitary Landfills Ø Drum Storage Areas Ø Underground Storage Tanks Ø Midnight Dumping Ø Uncontrolled Incineration

Past Disposal Practice Ø Soil Spreading Ø Pits/Ponds/Lagoons Ø Sanitary Landfills Ø Drum Storage Areas Ø Underground Storage Tanks Ø Midnight Dumping Ø Uncontrolled Incineration

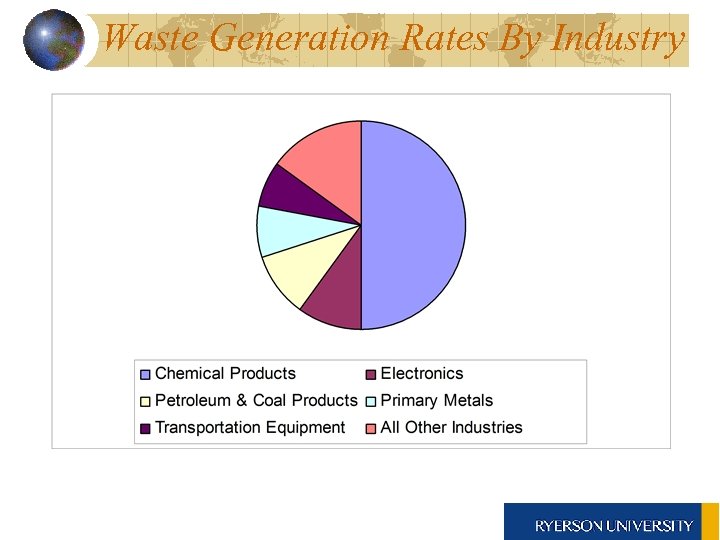

Waste Generation Rates By Industry

Waste Generation Rates By Industry

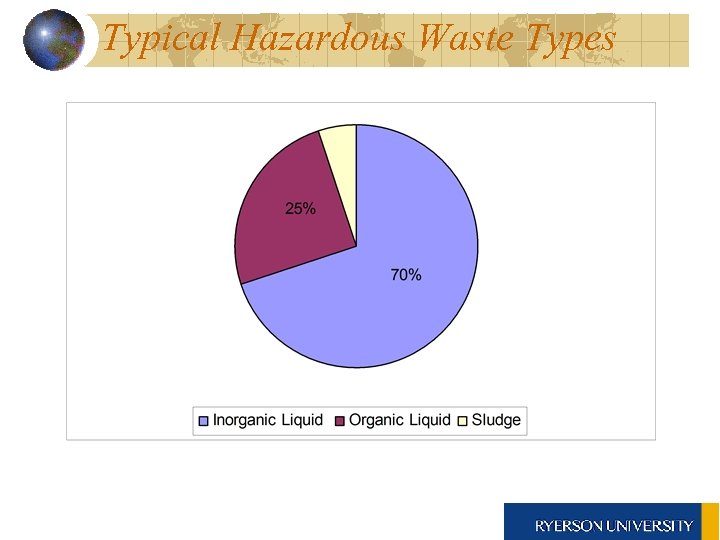

Typical Hazardous Waste Types

Typical Hazardous Waste Types

Why the need for HWTC? Protect public health and the environment Reduce impact of hazardous waste on surface water and ground water Provide the means to enhance: Waste minimization at various industrial operations, and Waste recycling

Why the need for HWTC? Protect public health and the environment Reduce impact of hazardous waste on surface water and ground water Provide the means to enhance: Waste minimization at various industrial operations, and Waste recycling

Objectives of HWTC 1. Avoid and minimize environmental and health pollution risks associated with the generation, storage, collection, transport, handling, recycling, and disposal of hazardous wastes 2. Ensure the movement and disposal practice of hazardous wastes is always controlled and environmentally safe, flexible, and economically sustainable for local conditions

Objectives of HWTC 1. Avoid and minimize environmental and health pollution risks associated with the generation, storage, collection, transport, handling, recycling, and disposal of hazardous wastes 2. Ensure the movement and disposal practice of hazardous wastes is always controlled and environmentally safe, flexible, and economically sustainable for local conditions

Technical Feasibility ü Can the wastes be separated at source to avoid co-mingling and analyzed before shipping to the facility? ü What characteristics are the separated wastes likely to have? ü What quantity of the wastes should be considered as wastewater?

Technical Feasibility ü Can the wastes be separated at source to avoid co-mingling and analyzed before shipping to the facility? ü What characteristics are the separated wastes likely to have? ü What quantity of the wastes should be considered as wastewater?

Market and Economic Feasibility ü Is there a local market for the products of recycling? ü Is there an international market for the products of recycling? ü What scale of disposal fees is to be expected for each category of waste? ü What rate of return would a Private Sector investor expect for providing and operating a Hazardous Waste Recycling Facility?

Market and Economic Feasibility ü Is there a local market for the products of recycling? ü Is there an international market for the products of recycling? ü What scale of disposal fees is to be expected for each category of waste? ü What rate of return would a Private Sector investor expect for providing and operating a Hazardous Waste Recycling Facility?

Materials Disposed in HWTC Liquid organic waste Oily sludge and residue from petroleum industry Spent oil and catalysts Contaminated soil Liquid heavy metals Acidic and basic solids and liquids Liquid ammonia and urea Off-Specification products

Materials Disposed in HWTC Liquid organic waste Oily sludge and residue from petroleum industry Spent oil and catalysts Contaminated soil Liquid heavy metals Acidic and basic solids and liquids Liquid ammonia and urea Off-Specification products

Estimation of Hazardous Wastes Quantities? ? Hazardous Waste Inventory: Estimate the total waste stream quantity Deduct the portion of these wastes that are being recycled or processed at the generator’s own facilities Deduct any co-mingled wastes that are impossible to separate in a cost-effective manner

Estimation of Hazardous Wastes Quantities? ? Hazardous Waste Inventory: Estimate the total waste stream quantity Deduct the portion of these wastes that are being recycled or processed at the generator’s own facilities Deduct any co-mingled wastes that are impossible to separate in a cost-effective manner

Estimation of Hazardous Wastes Quantities (cont. ) Deduct waste quantities being disposed without permit Prepare an integrated treatment system for the remainder with add-on facilities for growth and improvement in anticipation of reducing any unauthorized disposal Propose action as necessary for treatment and disposal facilities for the co-mingled and improperly disposed wastes

Estimation of Hazardous Wastes Quantities (cont. ) Deduct waste quantities being disposed without permit Prepare an integrated treatment system for the remainder with add-on facilities for growth and improvement in anticipation of reducing any unauthorized disposal Propose action as necessary for treatment and disposal facilities for the co-mingled and improperly disposed wastes

HWTC Design Approach 1. A flexible modular design will provide the Project Authority with the opportunity to attract private sector investments and will minimize capital cost in the longterm Focus initially on the major polluters Provide HWTC to treat part of the waste Initiate and monitor

HWTC Design Approach 1. A flexible modular design will provide the Project Authority with the opportunity to attract private sector investments and will minimize capital cost in the longterm Focus initially on the major polluters Provide HWTC to treat part of the waste Initiate and monitor

HWTC Design Approach (cont. ) 2. Due to the nature of the hazardous wastes and their potential to change characteristics and properties over time, the HWTC needs to be properly designed and equipped with facilities that are capable of safely meeting the needs of handling and disposing the hazardous waste

HWTC Design Approach (cont. ) 2. Due to the nature of the hazardous wastes and their potential to change characteristics and properties over time, the HWTC needs to be properly designed and equipped with facilities that are capable of safely meeting the needs of handling and disposing the hazardous waste

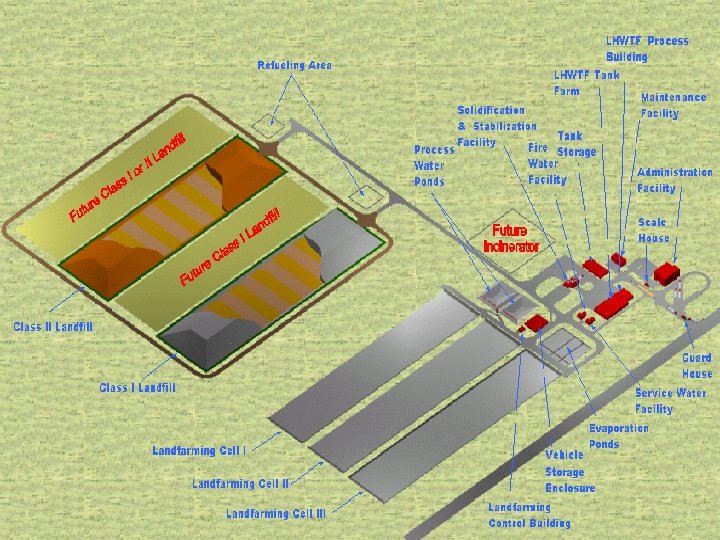

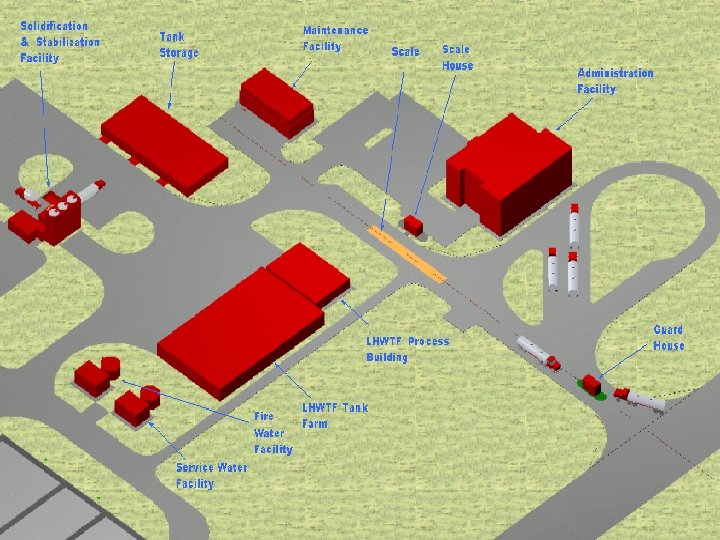

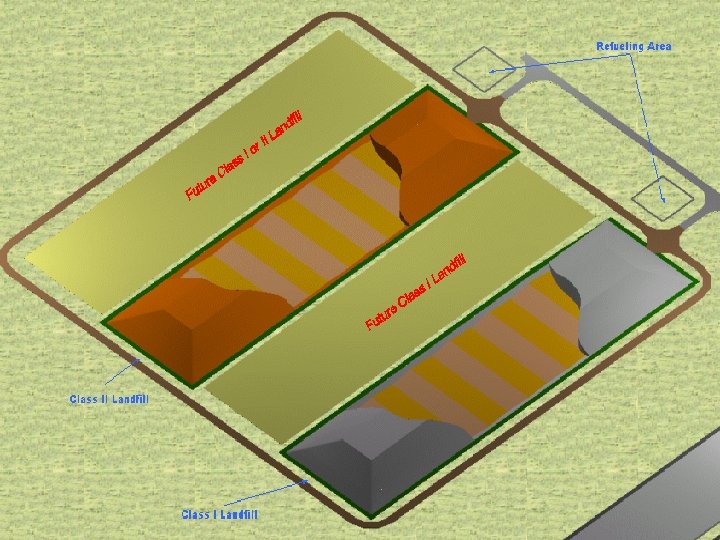

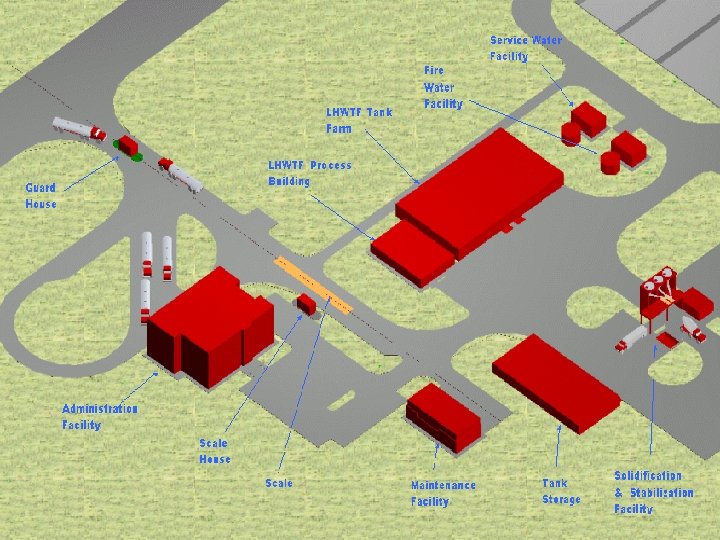

Description of the HWTC Liquid Waste Treatment Facility Land Farming Facility Class I Hazardous Waste Landfill Class II Regular Waste Landfill Solidification and Stabilization Unit Incinerator

Description of the HWTC Liquid Waste Treatment Facility Land Farming Facility Class I Hazardous Waste Landfill Class II Regular Waste Landfill Solidification and Stabilization Unit Incinerator

Important Points The priorities of hazardous Waste management in decreasing order of importance: Minimization/Prevention Treatment/Remediation Disposal

Important Points The priorities of hazardous Waste management in decreasing order of importance: Minimization/Prevention Treatment/Remediation Disposal

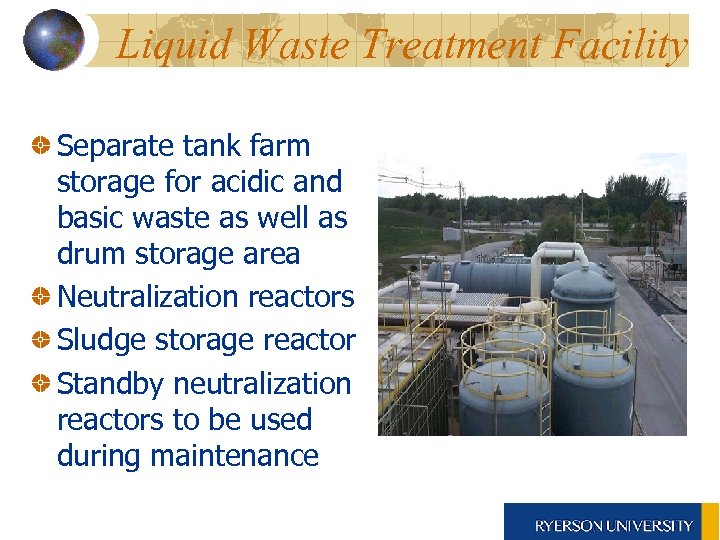

Liquid Waste Treatment Facility Separate tank farm storage for acidic and basic waste as well as drum storage area Neutralization reactors Sludge storage reactor Standby neutralization reactors to be used during maintenance

Liquid Waste Treatment Facility Separate tank farm storage for acidic and basic waste as well as drum storage area Neutralization reactors Sludge storage reactor Standby neutralization reactors to be used during maintenance

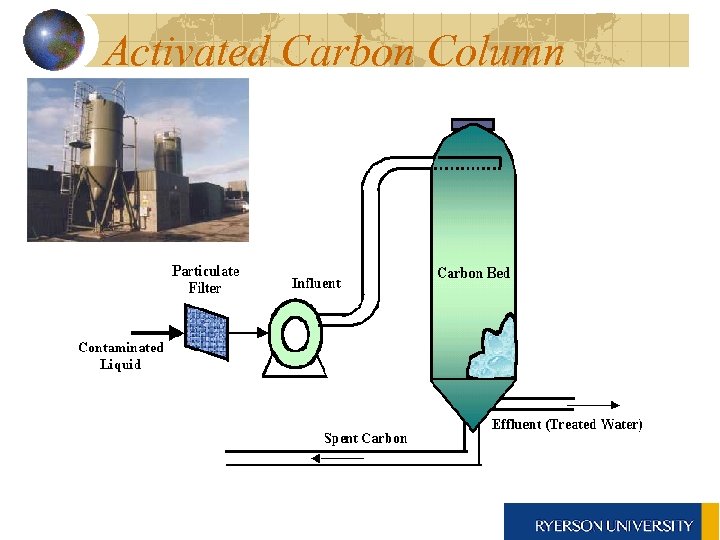

Activated Carbon Column

Activated Carbon Column

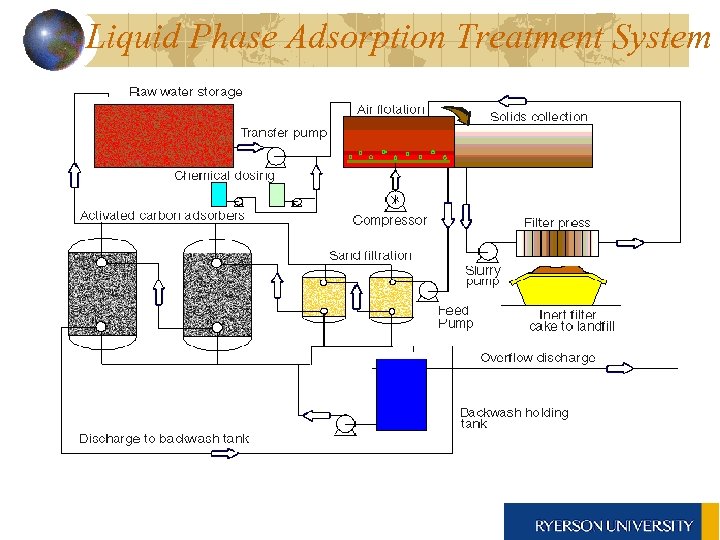

Liquid Phase Adsorption Treatment System

Liquid Phase Adsorption Treatment System

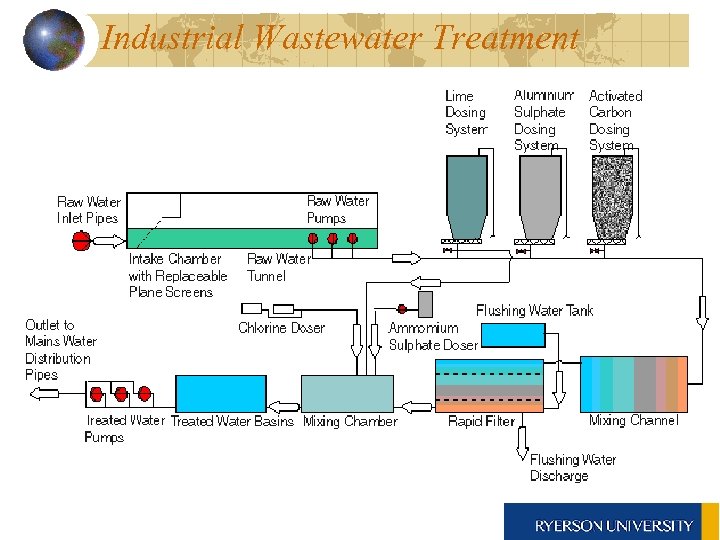

Industrial Wastewater Treatment

Industrial Wastewater Treatment

Chemical Oxidation In general the objective of chemical oxidation is to detoxify waste by adding an oxidizing agent to chemically transform waste components Chemical oxidation is a well established technology that is capable of destroying a wide range of organic molecules, including chlorinated VOCs, phenols and inorganics such as cyanide

Chemical Oxidation In general the objective of chemical oxidation is to detoxify waste by adding an oxidizing agent to chemically transform waste components Chemical oxidation is a well established technology that is capable of destroying a wide range of organic molecules, including chlorinated VOCs, phenols and inorganics such as cyanide

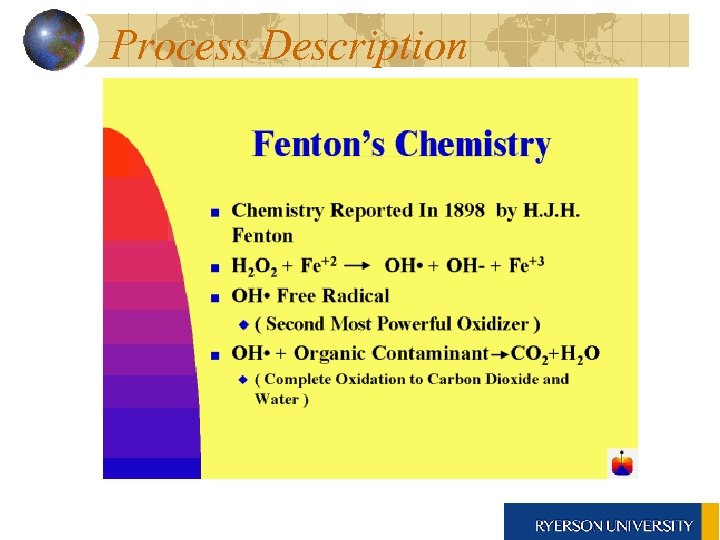

Process Description Chemical Oxidation is based on the delivery of oxidants to contaminated media in order to either destroy the contaminants by converting them to innocuous compounds commonly found in nature The oxidants applied are typically hydrogen peroxide (H 2 O 2), potassium permanganate (KMn. O 2), ozone (O 3)

Process Description Chemical Oxidation is based on the delivery of oxidants to contaminated media in order to either destroy the contaminants by converting them to innocuous compounds commonly found in nature The oxidants applied are typically hydrogen peroxide (H 2 O 2), potassium permanganate (KMn. O 2), ozone (O 3)

Process Description

Process Description

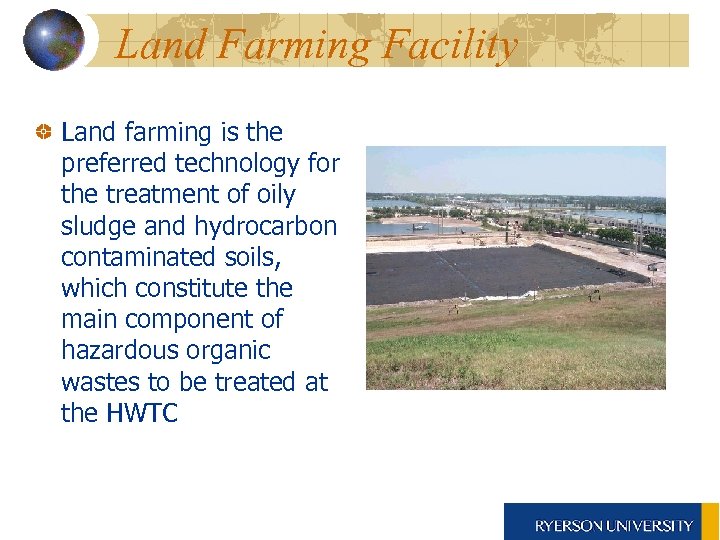

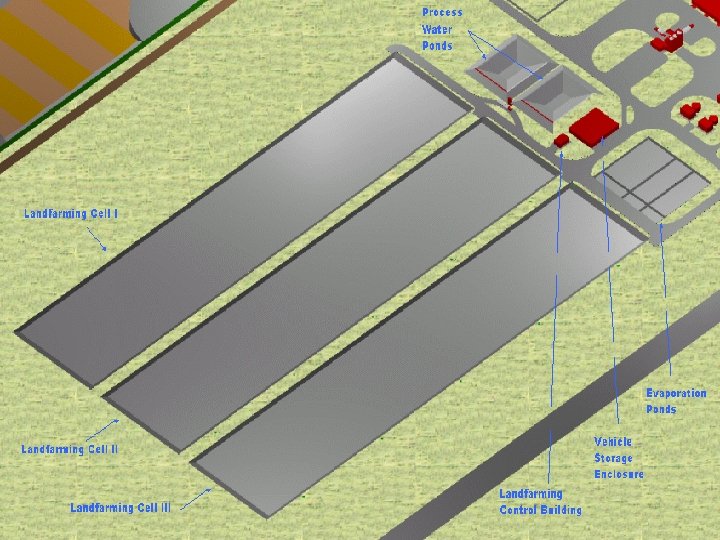

Land Farming Facility Land farming is the preferred technology for the treatment of oily sludge and hydrocarbon contaminated soils, which constitute the main component of hazardous organic wastes to be treated at the HWTC

Land Farming Facility Land farming is the preferred technology for the treatment of oily sludge and hydrocarbon contaminated soils, which constitute the main component of hazardous organic wastes to be treated at the HWTC

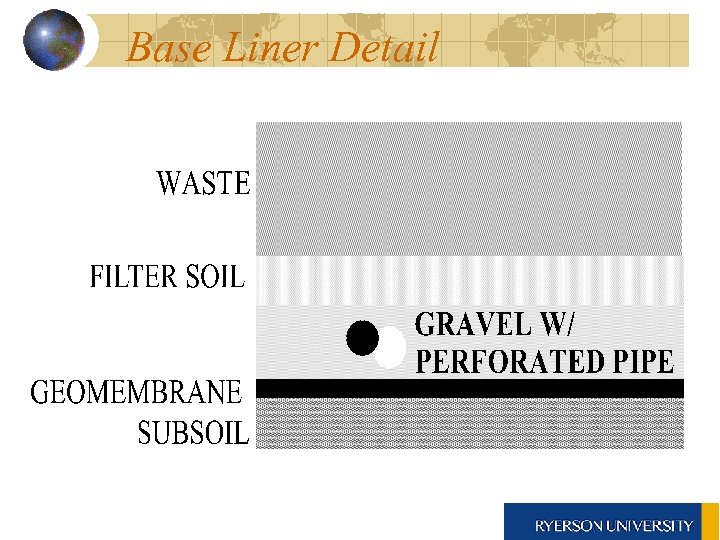

Base Liner Detail

Base Liner Detail

Land Farming Facility (cont’d) Compounds to be treated at the land Farming Facility: Ø Volatile Organic Compounds (VOCs): benzene, ethylbenzene, toluene, xylenes; Ø Semi-Volatile Organic Compounds (SVOCs): phenols, creosol, naphthalene, phennathrene, benzo(a)pyrene, flourrene, anthracene, chrysene; and Ø Heavy Metals: chromium, cyanides, lead and nickel

Land Farming Facility (cont’d) Compounds to be treated at the land Farming Facility: Ø Volatile Organic Compounds (VOCs): benzene, ethylbenzene, toluene, xylenes; Ø Semi-Volatile Organic Compounds (SVOCs): phenols, creosol, naphthalene, phennathrene, benzo(a)pyrene, flourrene, anthracene, chrysene; and Ø Heavy Metals: chromium, cyanides, lead and nickel

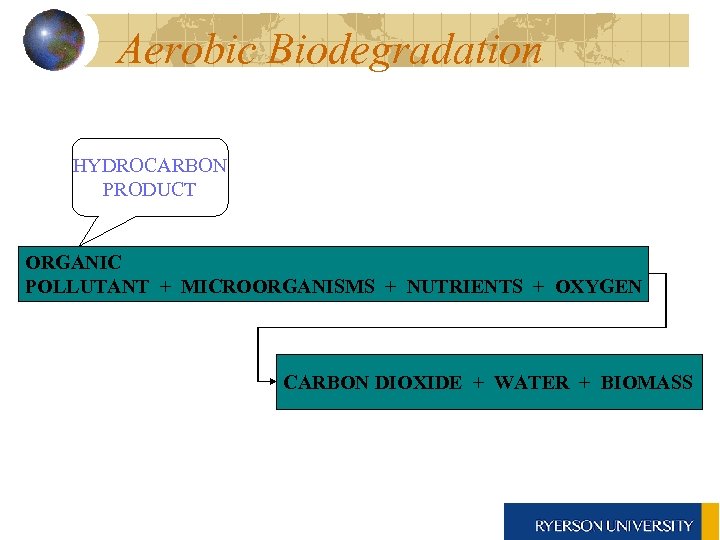

Aerobic Biodegradation HYDROCARBON PRODUCT ORGANIC POLLUTANT + MICROORGANISMS + NUTRIENTS + OXYGEN CARBON DIOXIDE + WATER + BIOMASS

Aerobic Biodegradation HYDROCARBON PRODUCT ORGANIC POLLUTANT + MICROORGANISMS + NUTRIENTS + OXYGEN CARBON DIOXIDE + WATER + BIOMASS

Microorganisms • Regarding the natural breakdown of hydrocarbon products, bacteria are the main microorganism in the bioremediation process • Bacteria act as decomposers and utilize hydrocarbon product as a source of energy

Microorganisms • Regarding the natural breakdown of hydrocarbon products, bacteria are the main microorganism in the bioremediation process • Bacteria act as decomposers and utilize hydrocarbon product as a source of energy

Nutrients Ø Nutrients enhance the biodegradation process by supplying essential elements required for optimal microbial growth and maintenance Ø Nutrients can be supplied in the field through the application of manure or fertilizer Ø C: N: P = (100 -300): 10: 1

Nutrients Ø Nutrients enhance the biodegradation process by supplying essential elements required for optimal microbial growth and maintenance Ø Nutrients can be supplied in the field through the application of manure or fertilizer Ø C: N: P = (100 -300): 10: 1

Requirements for Biodegradation Ø Proper nutrient balance Ø Temperature 15 – 30 o. C Ø Acceptable p. H 5. 5 - 8. 5 Ø Moisture content of 60% - 80% of field capacity Ø Oxygen concentration Ø Presence of toxic heavy metals

Requirements for Biodegradation Ø Proper nutrient balance Ø Temperature 15 – 30 o. C Ø Acceptable p. H 5. 5 - 8. 5 Ø Moisture content of 60% - 80% of field capacity Ø Oxygen concentration Ø Presence of toxic heavy metals

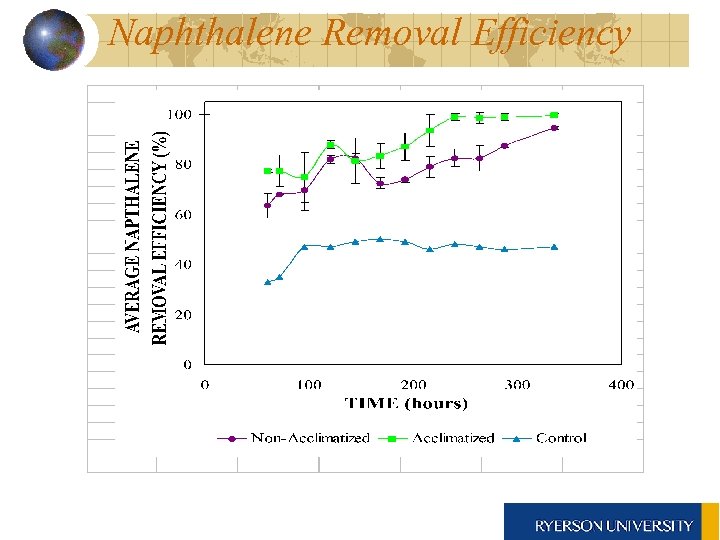

Naphthalene Removal Efficiency

Naphthalene Removal Efficiency

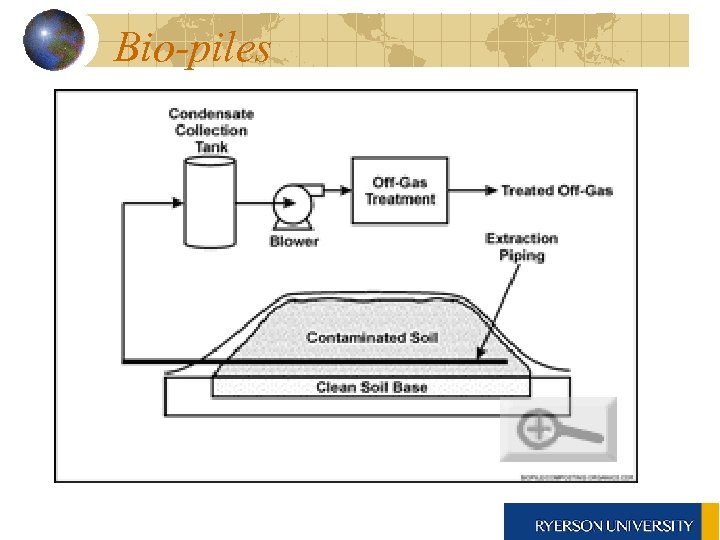

Bio-piles

Bio-piles

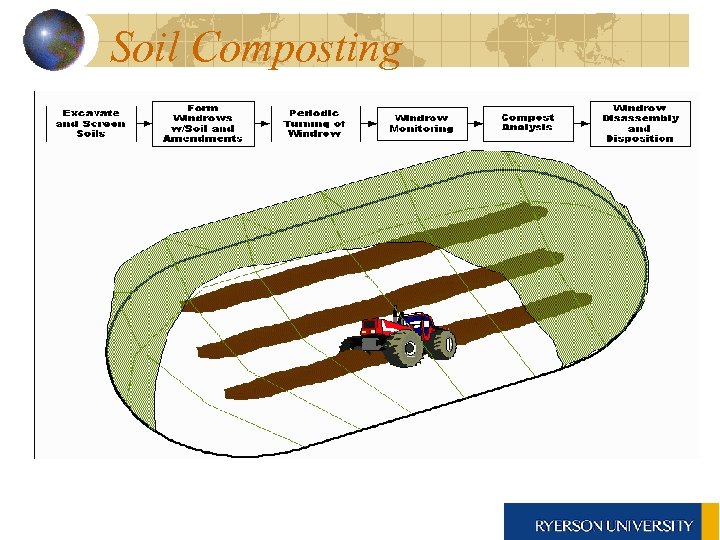

Soil Composting

Soil Composting

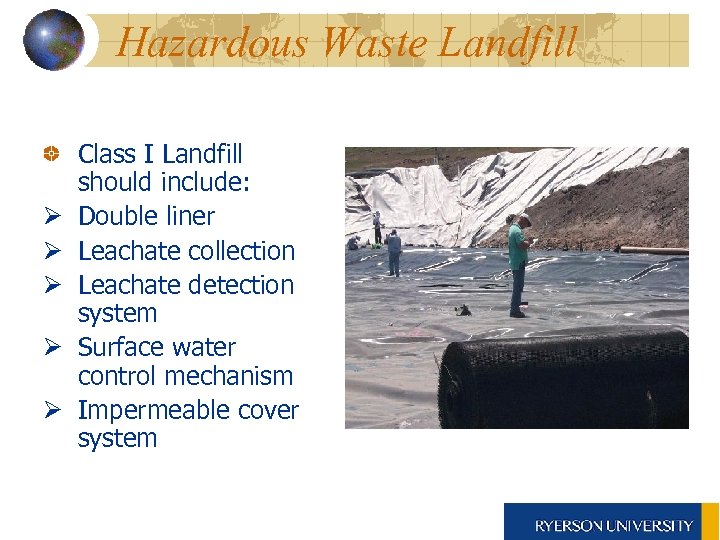

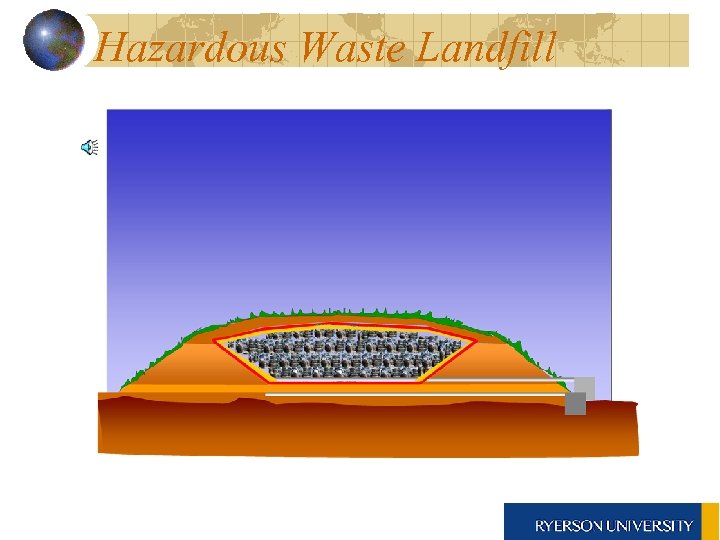

Hazardous Waste Landfill Ø Ø Ø Class I Landfill should include: Double liner Leachate collection Leachate detection system Surface water control mechanism Impermeable cover system

Hazardous Waste Landfill Ø Ø Ø Class I Landfill should include: Double liner Leachate collection Leachate detection system Surface water control mechanism Impermeable cover system

Hazardous Waste Landfill

Hazardous Waste Landfill

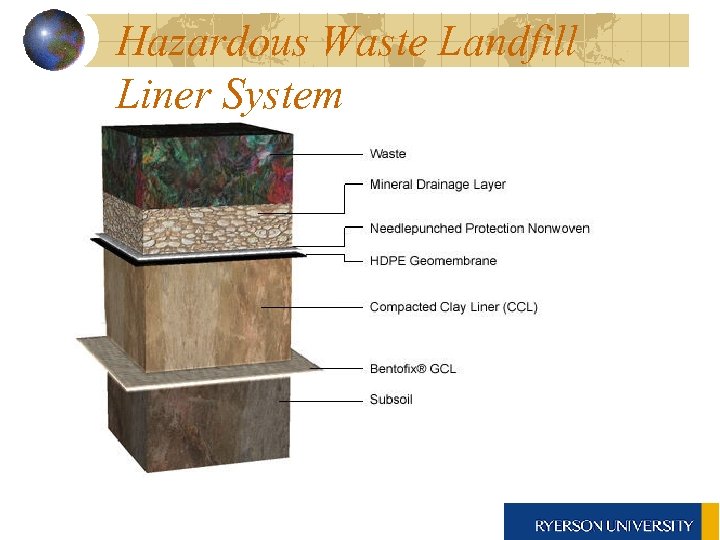

Hazardous Waste Landfill Liner System

Hazardous Waste Landfill Liner System

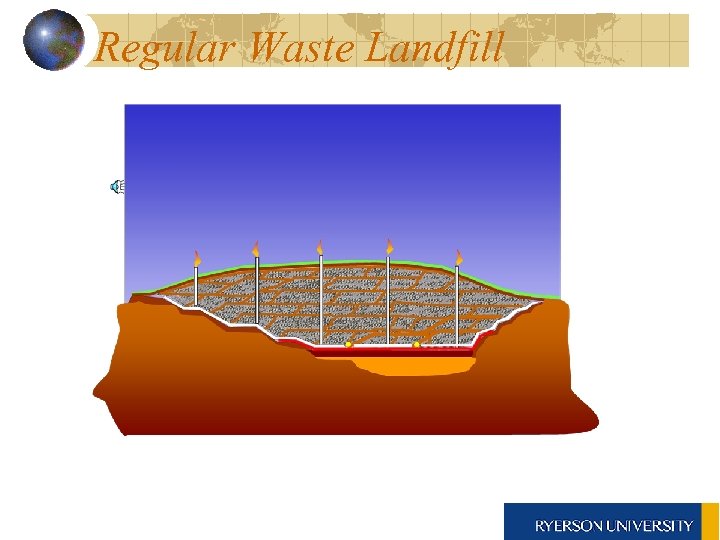

Regular Waste Landfill Ø Ø Class II Landfill should include: Single liner Leachate collection Surface water control mechanism Impermeable cover system

Regular Waste Landfill Ø Ø Class II Landfill should include: Single liner Leachate collection Surface water control mechanism Impermeable cover system

Regular Waste Landfill

Regular Waste Landfill

Solidification and Stabilization The solidification and stabilization facility (SSF) will be designed to inactivate and immobilize contaminants prior to landfilling

Solidification and Stabilization The solidification and stabilization facility (SSF) will be designed to inactivate and immobilize contaminants prior to landfilling

Solidification and Stabilization The following waste will be processed by SSF plant prior to landfilling: Ø Mercury contaminated solid wastes; Ø Solid miscellaneous inorganic sulfur; Ø Semi-solid hazardous waste; and Ø Sludge from Liquid Hazardous Waste Treatment

Solidification and Stabilization The following waste will be processed by SSF plant prior to landfilling: Ø Mercury contaminated solid wastes; Ø Solid miscellaneous inorganic sulfur; Ø Semi-solid hazardous waste; and Ø Sludge from Liquid Hazardous Waste Treatment

Solidification and Stabilization S/S reduces the mobility of hazardous substances and contaminants in the environment through both physical and chemical means S/S seeks to trap or immobilize contaminants within their host medium (i. e. soil, sand binding agent) Leachability testing is usually performed to measure the immobilization of contaminants from the stabilized matrix

Solidification and Stabilization S/S reduces the mobility of hazardous substances and contaminants in the environment through both physical and chemical means S/S seeks to trap or immobilize contaminants within their host medium (i. e. soil, sand binding agent) Leachability testing is usually performed to measure the immobilization of contaminants from the stabilized matrix

Solidification and Stabilization General binding and sorbent materials: Cement Ø Pozzolans Ø Lime Ø Silicates Ø Organically Modified Clays Ø

Solidification and Stabilization General binding and sorbent materials: Cement Ø Pozzolans Ø Lime Ø Silicates Ø Organically Modified Clays Ø

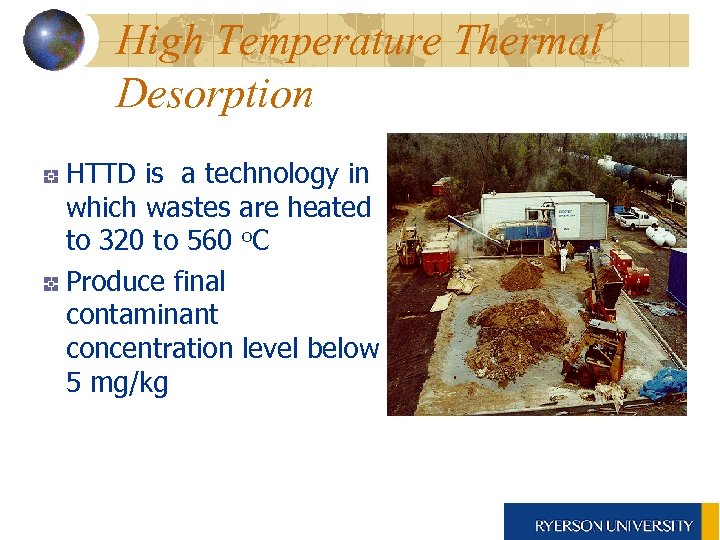

High Temperature Thermal Desorption HTTD is a technology in which wastes are heated to 320 to 560 o. C Produce final contaminant concentration level below 5 mg/kg

High Temperature Thermal Desorption HTTD is a technology in which wastes are heated to 320 to 560 o. C Produce final contaminant concentration level below 5 mg/kg

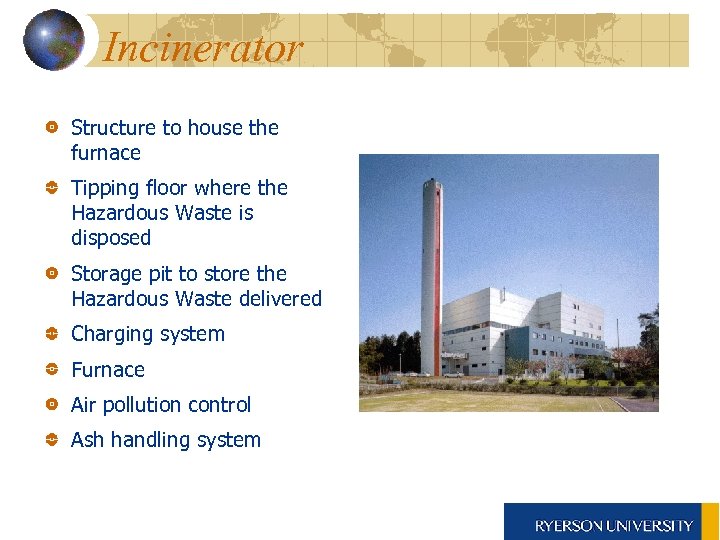

Incinerator Structure to house the furnace Tipping floor where the Hazardous Waste is disposed Storage pit to store the Hazardous Waste delivered Charging system Furnace Air pollution control Ash handling system

Incinerator Structure to house the furnace Tipping floor where the Hazardous Waste is disposed Storage pit to store the Hazardous Waste delivered Charging system Furnace Air pollution control Ash handling system

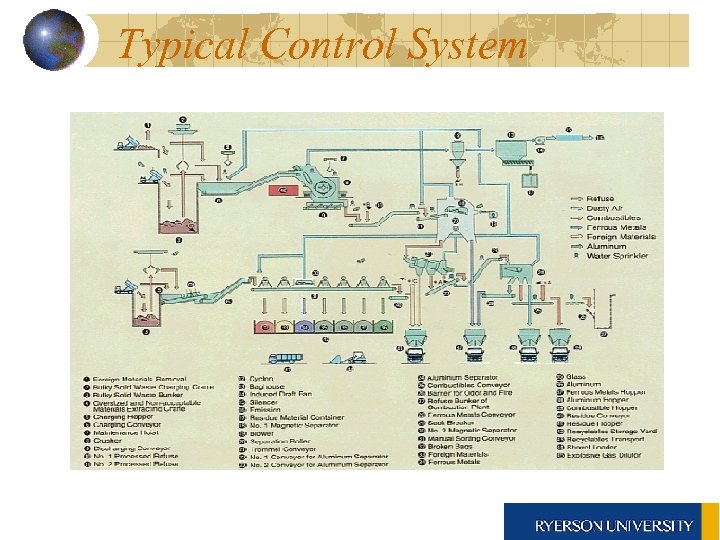

HWTC Control Philosophy Provide a Supervisory Control and Data Acquisition (SCADA). The SCADA system will provide two levels of control: Level 1 control operates equipment directly and bypasses all interlocks. Level 2 is initiated directly by computer programming. Level 2 controls, operates equipment and processes remotely.

HWTC Control Philosophy Provide a Supervisory Control and Data Acquisition (SCADA). The SCADA system will provide two levels of control: Level 1 control operates equipment directly and bypasses all interlocks. Level 2 is initiated directly by computer programming. Level 2 controls, operates equipment and processes remotely.

Typical Control System

Typical Control System

Environmental Monitoring Ø Air Quality Ø Groundwater Quality Ø Surface Water Quality Ø Dust and Noise

Environmental Monitoring Ø Air Quality Ø Groundwater Quality Ø Surface Water Quality Ø Dust and Noise

Environmental Monitoring Ø Selection of the parameters of concern Ø Sampling methodology Ø Quality assurance /quality control plan

Environmental Monitoring Ø Selection of the parameters of concern Ø Sampling methodology Ø Quality assurance /quality control plan

Project Approach Task 1: Review of Existing Data Task 2: Discussion with Project Authority Task 3: Development and Finalization of HWTF Design Task 4: Prepare Final Design Drawings and Design Basis Memorandum

Project Approach Task 1: Review of Existing Data Task 2: Discussion with Project Authority Task 3: Development and Finalization of HWTF Design Task 4: Prepare Final Design Drawings and Design Basis Memorandum

Project Approach (cont. ) Task 5: Design of Liquid Hazardous Waste Treatment Facility Task 6: Class I and II Landfills Design Task 7: Land Framing Facility Design Task 8: Solidification and Stabilization Facility Design

Project Approach (cont. ) Task 5: Design of Liquid Hazardous Waste Treatment Facility Task 6: Class I and II Landfills Design Task 7: Land Framing Facility Design Task 8: Solidification and Stabilization Facility Design

Project Approach (cont. ) Task 9: HWTC Construction Task 10: Facility Commissioning and Operation Task 11: Facility Handing Over

Project Approach (cont. ) Task 9: HWTC Construction Task 10: Facility Commissioning and Operation Task 11: Facility Handing Over

Conclusions 1. Key to proper design of HWTC is system flexibility to adjust to hazardous waste quantities and properties over time 2. Enforcement of environmental law and regulations

Conclusions 1. Key to proper design of HWTC is system flexibility to adjust to hazardous waste quantities and properties over time 2. Enforcement of environmental law and regulations

Leachate Treatment Using Wetlands Department of Environmental Engineering Beijing University of Chemical Technology December 2003

Leachate Treatment Using Wetlands Department of Environmental Engineering Beijing University of Chemical Technology December 2003

Wetlands Ø Wetland is define as land having the water table at, near or above the land surface or which is saturated for long enough period to promote wetland or aquatic processes as indicated by hydric soils, hydrophilic vegetation, and various kinds of biological activity which are adapted to the wet environment.

Wetlands Ø Wetland is define as land having the water table at, near or above the land surface or which is saturated for long enough period to promote wetland or aquatic processes as indicated by hydric soils, hydrophilic vegetation, and various kinds of biological activity which are adapted to the wet environment.

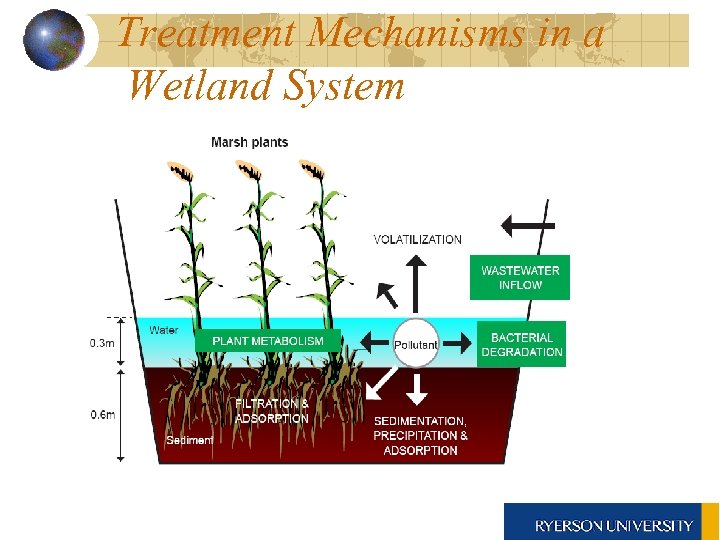

Treatment Mechanisms in a Wetland System

Treatment Mechanisms in a Wetland System

Type of Engineered wetlands Constructed wetland systems are classified into two general types: Ø Horizontal Flow System (HFS) Ø Ø Surface Flow (SF) Sub-surface Flow (SSF) Ø Vertical Flow System (VFS).

Type of Engineered wetlands Constructed wetland systems are classified into two general types: Ø Horizontal Flow System (HFS) Ø Ø Surface Flow (SF) Sub-surface Flow (SSF) Ø Vertical Flow System (VFS).

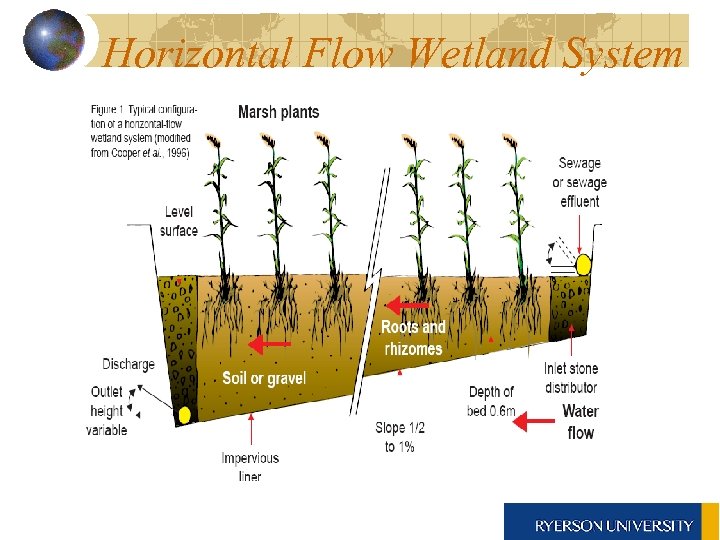

Horizontal Flow Wetland System

Horizontal Flow Wetland System

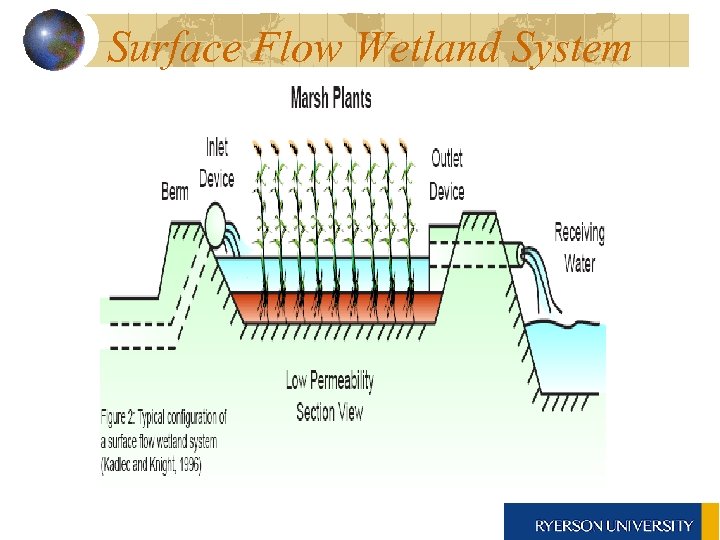

Surface Flow Wetland System

Surface Flow Wetland System

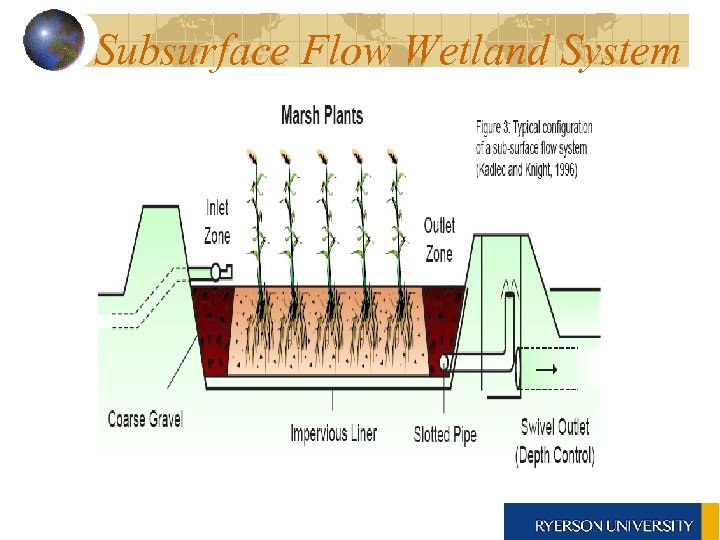

Subsurface Flow Wetland System

Subsurface Flow Wetland System

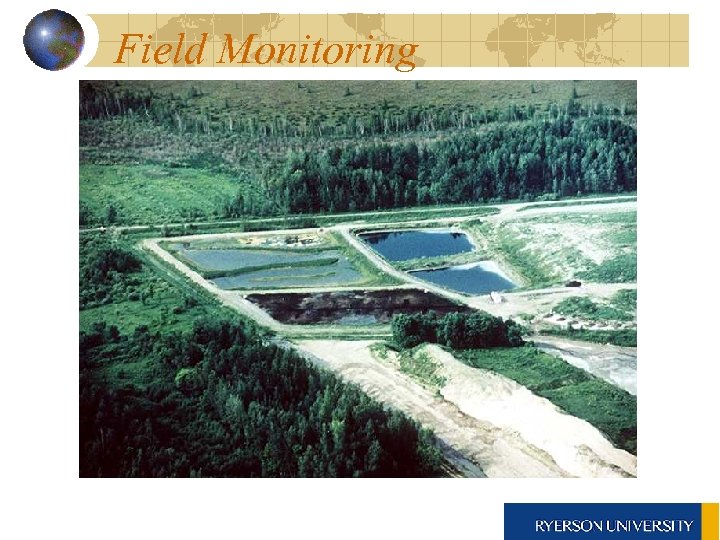

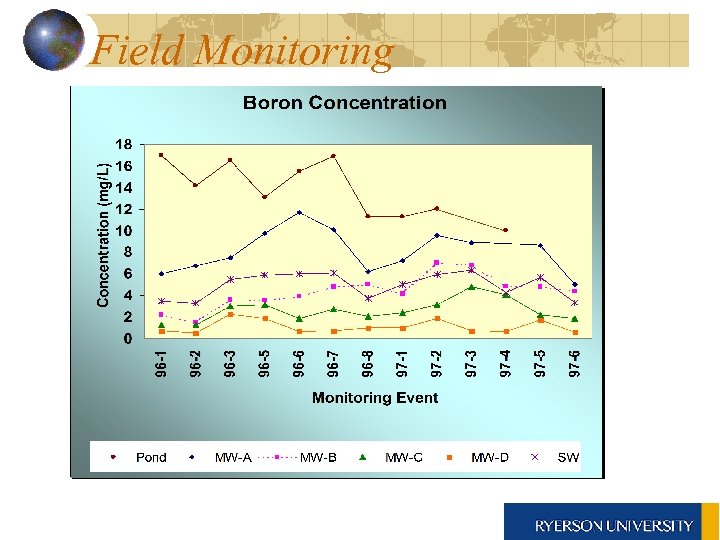

Field Monitoring

Field Monitoring

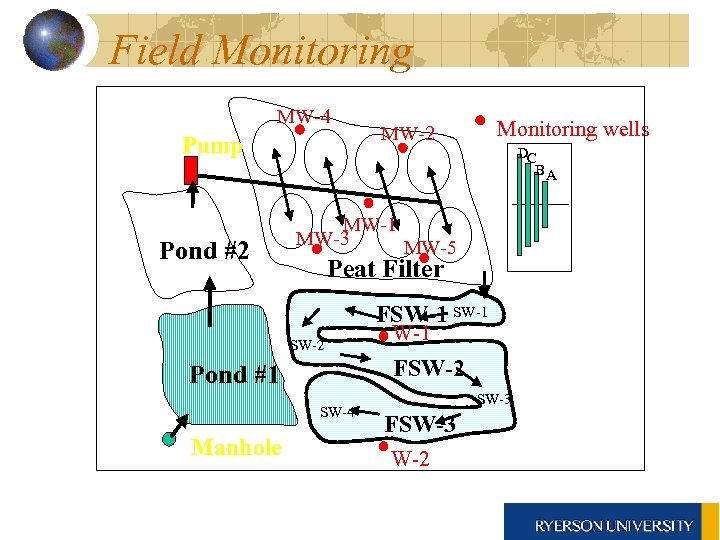

Field Monitoring MW-4 Pump Pond #2 Monitoring wells MW-2 DC BA MW-1 MW-3 MW-5 Peat Filter FSW-1 SW-2 FSW-2 Pond #1 SW-4 Manhole W-1 SW-3 FSW-3 W-2

Field Monitoring MW-4 Pump Pond #2 Monitoring wells MW-2 DC BA MW-1 MW-3 MW-5 Peat Filter FSW-1 SW-2 FSW-2 Pond #1 SW-4 Manhole W-1 SW-3 FSW-3 W-2

Field Monitoring

Field Monitoring

Conclusions Boron adsorption was directly related to organic content Peat filter was effective in treating landfill leachate The adsorption capacity of the peat can be significantly enhanced by lime addition

Conclusions Boron adsorption was directly related to organic content Peat filter was effective in treating landfill leachate The adsorption capacity of the peat can be significantly enhanced by lime addition