6208e28a7d1558de0114cd19cf462316.ppt

- Количество слайдов: 27

HAZARD COMMUNICATIONS OSHA 29 CFR 1910. 1200

HAZARD COMMUNICATIONS OSHA 29 CFR 1910. 1200

• HISTORY u Late 1970’s-- “Right to Know” u Early 1980’s--City Ordinances/State Laws u Late 1980’s--Federal Law

• HISTORY u Late 1970’s-- “Right to Know” u Early 1980’s--City Ordinances/State Laws u Late 1980’s--Federal Law

Goals of Standard u Requires development of information on hazardous materials u Requires a written program addressing employee exposures to hazardous materials

Goals of Standard u Requires development of information on hazardous materials u Requires a written program addressing employee exposures to hazardous materials

Key Points: u Communication u Hazardous Materials vs. Hazardous Chemicals u Performance Standard

Key Points: u Communication u Hazardous Materials vs. Hazardous Chemicals u Performance Standard

Purpose u OSHA CFR 29 1910. 1200 (a)(1)

Purpose u OSHA CFR 29 1910. 1200 (a)(1)

Scope u OSHA CFR 29 1910. 1200 (b)(2)

Scope u OSHA CFR 29 1910. 1200 (b)(2)

Costs and Benefits u Costs: – Requires time and effort to start – Must be maintained u Benefits – Safer work practices – Hazard reduction

Costs and Benefits u Costs: – Requires time and effort to start – Must be maintained u Benefits – Safer work practices – Hazard reduction

How Important is HCS u Latest information on OSHA citations indicates Haz Com-- MOST commonly cited standard.

How Important is HCS u Latest information on OSHA citations indicates Haz Com-- MOST commonly cited standard.

Requirements of the Standard MSDS Labeling Written Program Inventory Training

Requirements of the Standard MSDS Labeling Written Program Inventory Training

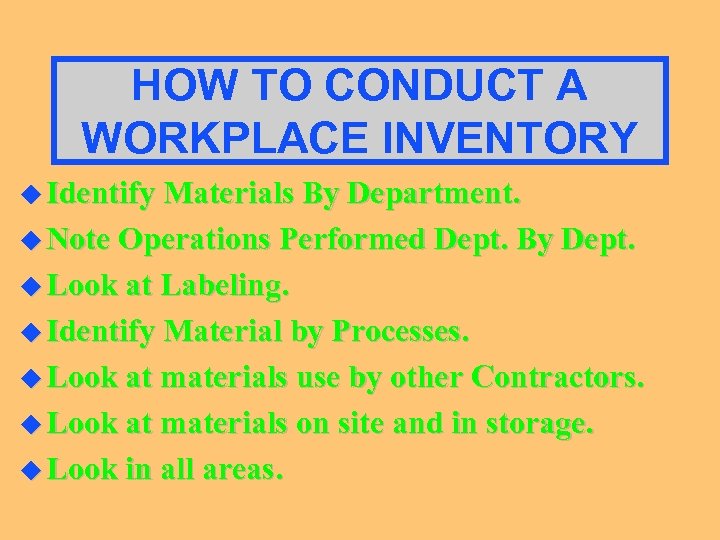

HOW TO CONDUCT A WORKPLACE INVENTORY u Identify Materials By Department. u Note Operations Performed Dept. By Dept. u Look at Labeling. u Identify Material by Processes. u Look at materials use by other Contractors. u Look at materials on site and in storage. u Look in all areas.

HOW TO CONDUCT A WORKPLACE INVENTORY u Identify Materials By Department. u Note Operations Performed Dept. By Dept. u Look at Labeling. u Identify Material by Processes. u Look at materials use by other Contractors. u Look at materials on site and in storage. u Look in all areas.

HAZARDOUS MATERIAL INVENTORY

HAZARDOUS MATERIAL INVENTORY

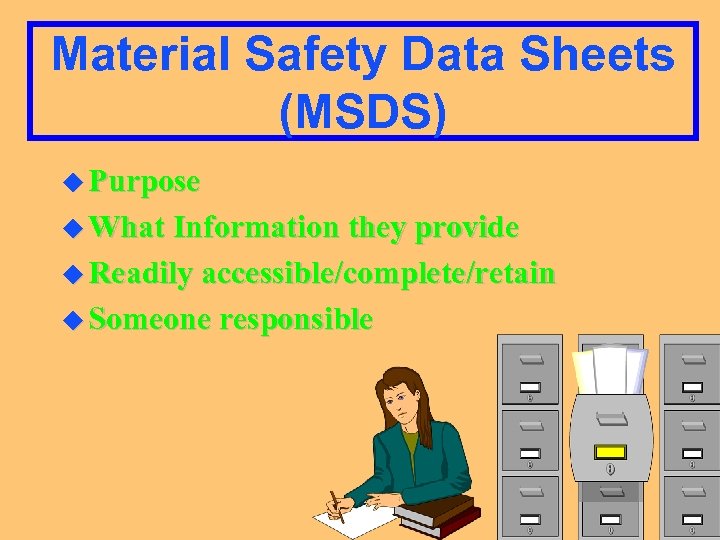

Material Safety Data Sheets (MSDS) u Purpose u What Information they provide u Readily accessible/complete/retain u Someone responsible

Material Safety Data Sheets (MSDS) u Purpose u What Information they provide u Readily accessible/complete/retain u Someone responsible

Labeling u Purpose u What information is required u Accessible/Legible/in English u Types; Mfg. ’s, HMIS, NFPA u Someone responsible Zip Cleaner

Labeling u Purpose u What information is required u Accessible/Legible/in English u Types; Mfg. ’s, HMIS, NFPA u Someone responsible Zip Cleaner

Manufacturers Label Mfg. ’s Name/Address n Product Name n Physical Warnings n Health Hazard Warnings Including Target Organs n Zip Cleaner XYZ Company PO Box 1 Anytown, OH Flammable, Avoid Prolong Breathing

Manufacturers Label Mfg. ’s Name/Address n Product Name n Physical Warnings n Health Hazard Warnings Including Target Organs n Zip Cleaner XYZ Company PO Box 1 Anytown, OH Flammable, Avoid Prolong Breathing

In House Label Product Name n Physical Hazards n Health Hazard Warnings Including Target Organs n Zip Cleaner Flammable, Avoid prolonged breathing.

In House Label Product Name n Physical Hazards n Health Hazard Warnings Including Target Organs n Zip Cleaner Flammable, Avoid prolonged breathing.

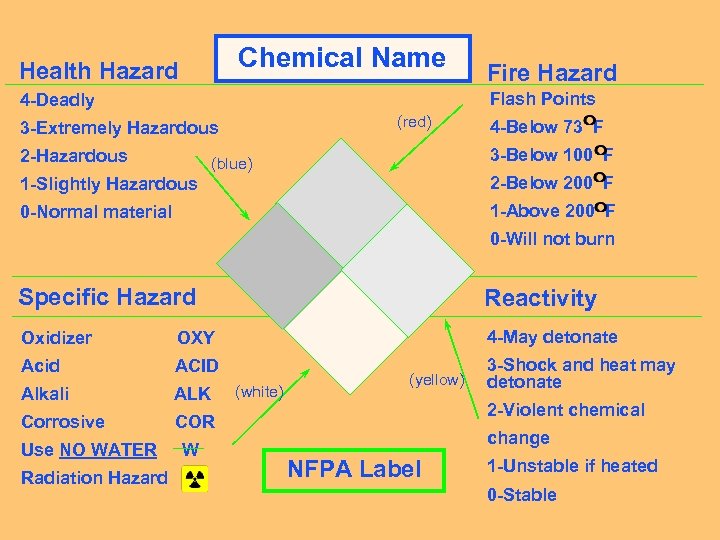

Chemical Name Health Hazard Fire Hazard Flash Points 4 -Deadly (red) 3 -Extremely Hazardous 2 -Hazardous 4 -Below 73 F 3 -Below 100 F (blue) 1 -Slightly Hazardous 2 -Below 200 F 0 -Normal material 1 -Above 200 F 0 -Will not burn Specific Hazard Reactivity Oxidizer OXY 4 -May detonate Acid ACID 3 -Shock and heat may detonate Alkali ALK Corrosive (white) (yellow) COR Use NO WATER Radiation Hazard W 2 -Violent chemical change NFPA Label 1 -Unstable if heated 0 -Stable

Chemical Name Health Hazard Fire Hazard Flash Points 4 -Deadly (red) 3 -Extremely Hazardous 2 -Hazardous 4 -Below 73 F 3 -Below 100 F (blue) 1 -Slightly Hazardous 2 -Below 200 F 0 -Normal material 1 -Above 200 F 0 -Will not burn Specific Hazard Reactivity Oxidizer OXY 4 -May detonate Acid ACID 3 -Shock and heat may detonate Alkali ALK Corrosive (white) (yellow) COR Use NO WATER Radiation Hazard W 2 -Violent chemical change NFPA Label 1 -Unstable if heated 0 -Stable

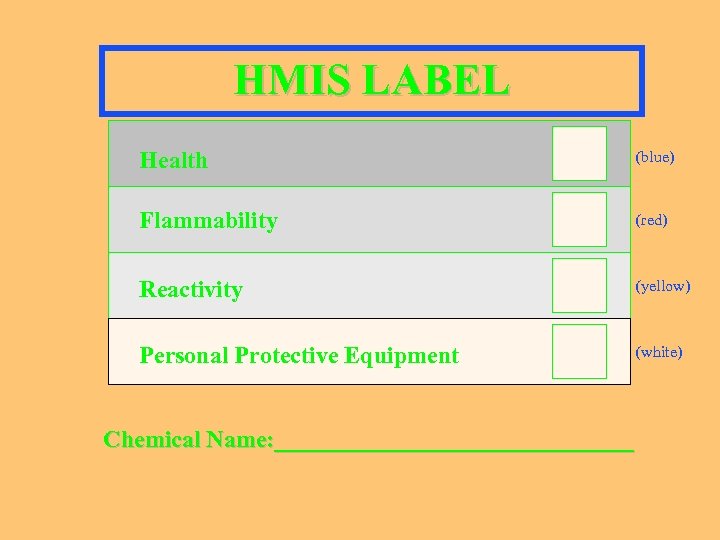

HMIS LABEL Health (blue) Flammability (red) Reactivity (yellow) Personal Protective Equipment (white) Chemical Name: _______________

HMIS LABEL Health (blue) Flammability (red) Reactivity (yellow) Personal Protective Equipment (white) Chemical Name: _______________

Employee Training u General Training u Specific Training

Employee Training u General Training u Specific Training

General Training u Hazard Communication Standard u Employer’s Written Program u Location/Availability Of Written Program & MSDS u How to read labels & MSDS’s

General Training u Hazard Communication Standard u Employer’s Written Program u Location/Availability Of Written Program & MSDS u How to read labels & MSDS’s

Specific Training u Characteristics - How to detect u Health & Safety Hazards u Work practices or SOPs u Emergency action plans u Personal Protective Equipment (PPE) u Non-routine tasks u Industrial Hygiene monitoring results

Specific Training u Characteristics - How to detect u Health & Safety Hazards u Work practices or SOPs u Emergency action plans u Personal Protective Equipment (PPE) u Non-routine tasks u Industrial Hygiene monitoring results

Written Program u Must be developed, implemented & maintained u A blueprint for how the requirements will be met m z. Com u Readily accessible Ha am Progr

Written Program u Must be developed, implemented & maintained u A blueprint for how the requirements will be met m z. Com u Readily accessible Ha am Progr

Written Program u Develop, implement, and maintain at each workplace, a written program that describes: – Labels and other forms of warning – MSDSs – Employee Training and Information – and includes:

Written Program u Develop, implement, and maintain at each workplace, a written program that describes: – Labels and other forms of warning – MSDSs – Employee Training and Information – and includes:

Miscellaneous u. Chemical Inventory u Non-Routine Tasks u Piping Systems u Contractors/ Multi-Employer Worksites

Miscellaneous u. Chemical Inventory u Non-Routine Tasks u Piping Systems u Contractors/ Multi-Employer Worksites

Multi-Employer Workplaces u Use hazardous materials in such a way other employers are exposed – Methods to provide access to MSDS and Written Program – Methods to inform of precautionary measures and labeling system u Intent is met when information on haz. materials at the worksite is available to all

Multi-Employer Workplaces u Use hazardous materials in such a way other employers are exposed – Methods to provide access to MSDS and Written Program – Methods to inform of precautionary measures and labeling system u Intent is met when information on haz. materials at the worksite is available to all

Other Exemptions u By Size? No u By Type of Substance? Does not apply to substances covered by other laws: i. e. -tobacco, wood/wood products, articles u By Extent of Use? Does not apply if substance is used in manner, duration, & frequency as a consumer product

Other Exemptions u By Size? No u By Type of Substance? Does not apply to substances covered by other laws: i. e. -tobacco, wood/wood products, articles u By Extent of Use? Does not apply if substance is used in manner, duration, & frequency as a consumer product

Summary u What is Hazcom? u Why was the Hazcom Standard implemented? u What are the 4 major elements of our written Hazcom program? u Why is a workplace inventory important? u What is the purpose of an MSDS?

Summary u What is Hazcom? u Why was the Hazcom Standard implemented? u What are the 4 major elements of our written Hazcom program? u Why is a workplace inventory important? u What is the purpose of an MSDS?

Summary (continued) u Where do we keep MSDSs & Written Program? u Who is responsible for maintaining MSDS in your area? u What labeling system do we use? u Why do we need MSDS and labeling? u Why do we train on Hazcom? u What’s the difference between General and Specific training?

Summary (continued) u Where do we keep MSDSs & Written Program? u Who is responsible for maintaining MSDS in your area? u What labeling system do we use? u Why do we need MSDS and labeling? u Why do we train on Hazcom? u What’s the difference between General and Specific training?