3115ab0df362bf6ec8e65a3b4e3f9e65.ppt

- Количество слайдов: 47

“Harnessing the Power of Supply Chain Metrics” Alan L. Milliken CFPIM CIRM CSCP BASF Corporation Presented to: West Coast Florida Chapter of APICS February 12, 2008 Advancing Productivity, Innovation, and Competitive Success

“Harnessing the Power of Supply Chain Metrics” Alan L. Milliken CFPIM CIRM CSCP BASF Corporation Presented to: West Coast Florida Chapter of APICS February 12, 2008 Advancing Productivity, Innovation, and Competitive Success

Alan L. Milliken CFPIM CIRM CSCP • 20+ years at major manufacturing sites working in Production, Logistics, Process & Quality Control, Industrial Engineering, Training, and Scheduling • 12+ years as a Supply Chain Consultant and APICS Instructor including two years in Mexico City helping BASF Mexicana improve their supply chain. While there, taught Operations Management as guest professor at University of Panamericana in Mexico City. • Identified by an independent consulting firm as one of three APICS members who best answer the question, “What is a Supply Chain Manager? ” • Served as an SME (Subject Matter Expert) on the team that developed the new Certified Supply Chain Professional (CSCP) program. • Served as an SME on the team that developed the new Certified Forecasting Professional (CFP) for the Institute of Business Forecasting (IBF) • Engineering Degree from Auburn University and MBA from Clemson University Advancing Productivity, Innovation, and Competitive Success

Alan L. Milliken CFPIM CIRM CSCP • 20+ years at major manufacturing sites working in Production, Logistics, Process & Quality Control, Industrial Engineering, Training, and Scheduling • 12+ years as a Supply Chain Consultant and APICS Instructor including two years in Mexico City helping BASF Mexicana improve their supply chain. While there, taught Operations Management as guest professor at University of Panamericana in Mexico City. • Identified by an independent consulting firm as one of three APICS members who best answer the question, “What is a Supply Chain Manager? ” • Served as an SME (Subject Matter Expert) on the team that developed the new Certified Supply Chain Professional (CSCP) program. • Served as an SME on the team that developed the new Certified Forecasting Professional (CFP) for the Institute of Business Forecasting (IBF) • Engineering Degree from Auburn University and MBA from Clemson University Advancing Productivity, Innovation, and Competitive Success

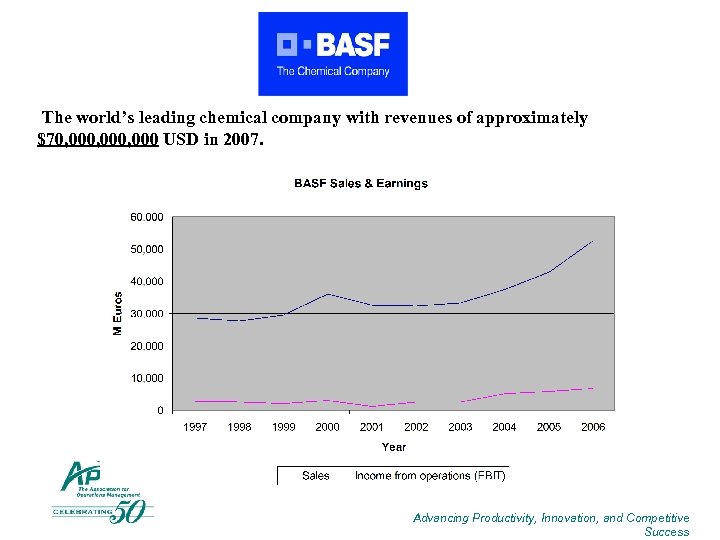

The world’s leading chemical company with revenues of approximately $70, 000, 000 USD in 2007. Advancing Productivity, Innovation, and Competitive Success

The world’s leading chemical company with revenues of approximately $70, 000, 000 USD in 2007. Advancing Productivity, Innovation, and Competitive Success

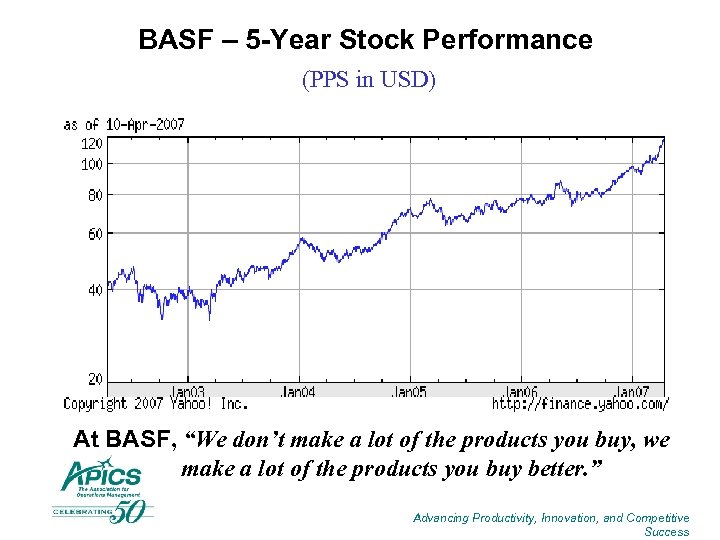

BASF – 5 -Year Stock Performance (PPS in USD) At BASF, “We don’t make a lot of the products you buy, we make a lot of the products you buy better. ” Advancing Productivity, Innovation, and Competitive Success

BASF – 5 -Year Stock Performance (PPS in USD) At BASF, “We don’t make a lot of the products you buy, we make a lot of the products you buy better. ” Advancing Productivity, Innovation, and Competitive Success

Aligning Supply Chain Metrics with Corporate Strategies and Competitive Priorities If you don’t know where you are going, everyway is the wrong way. Advancing Productivity, Innovation, and Competitive Success

Aligning Supply Chain Metrics with Corporate Strategies and Competitive Priorities If you don’t know where you are going, everyway is the wrong way. Advancing Productivity, Innovation, and Competitive Success

Value-Based Management Approach The company’s definition of success will define the contents of the performance management system. Advancing Productivity, Innovation, and Competitive Success

Value-Based Management Approach The company’s definition of success will define the contents of the performance management system. Advancing Productivity, Innovation, and Competitive Success

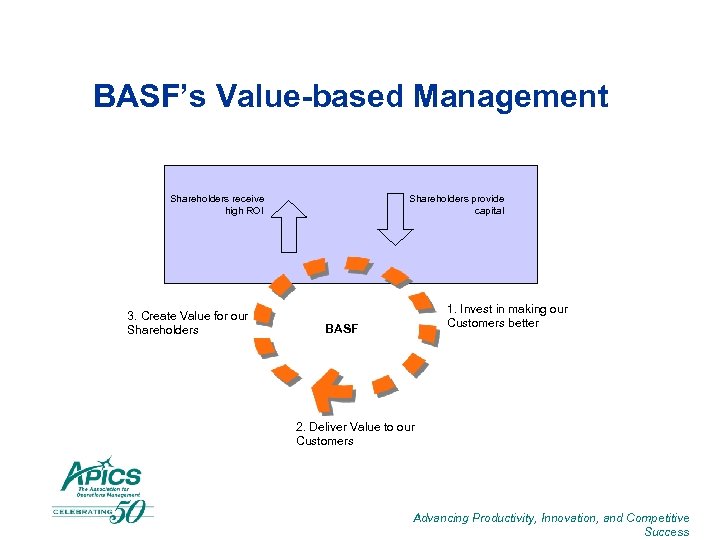

BASF’s Value-based Management Shareholders receive high ROI 3. Create Value for our Shareholders provide capital 1. Invest in making our Customers better BASF 2. Deliver Value to our Customers Advancing Productivity, Innovation, and Competitive Success

BASF’s Value-based Management Shareholders receive high ROI 3. Create Value for our Shareholders provide capital 1. Invest in making our Customers better BASF 2. Deliver Value to our Customers Advancing Productivity, Innovation, and Competitive Success

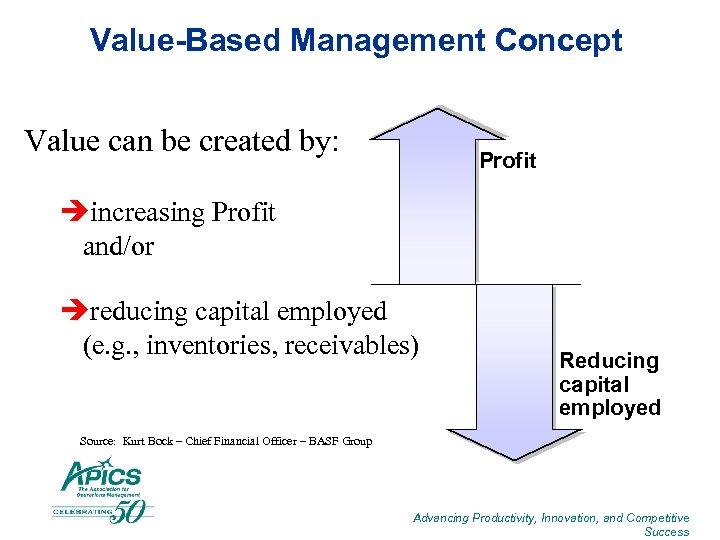

Value-Based Management Concept Value can be created by: Profit èincreasing Profit and/or èreducing capital employed (e. g. , inventories, receivables) Reducing capital employed Source: Kurt Bock – Chief Financial Officer – BASF Group Advancing Productivity, Innovation, and Competitive Success

Value-Based Management Concept Value can be created by: Profit èincreasing Profit and/or èreducing capital employed (e. g. , inventories, receivables) Reducing capital employed Source: Kurt Bock – Chief Financial Officer – BASF Group Advancing Productivity, Innovation, and Competitive Success

Who in the Organization Can Create Value? All employees can create value by optimizing the value drivers in their day-to-day business, e. g. , by: èincreasing sales through higher prices and/or sales volumes èreducing costs èoptimizing inventories and receivables èusing production plants optimally Source: Kurt Bock – Chief Financial Officer – BASF Group Advancing Productivity, Innovation, and Competitive Success

Who in the Organization Can Create Value? All employees can create value by optimizing the value drivers in their day-to-day business, e. g. , by: èincreasing sales through higher prices and/or sales volumes èreducing costs èoptimizing inventories and receivables èusing production plants optimally Source: Kurt Bock – Chief Financial Officer – BASF Group Advancing Productivity, Innovation, and Competitive Success

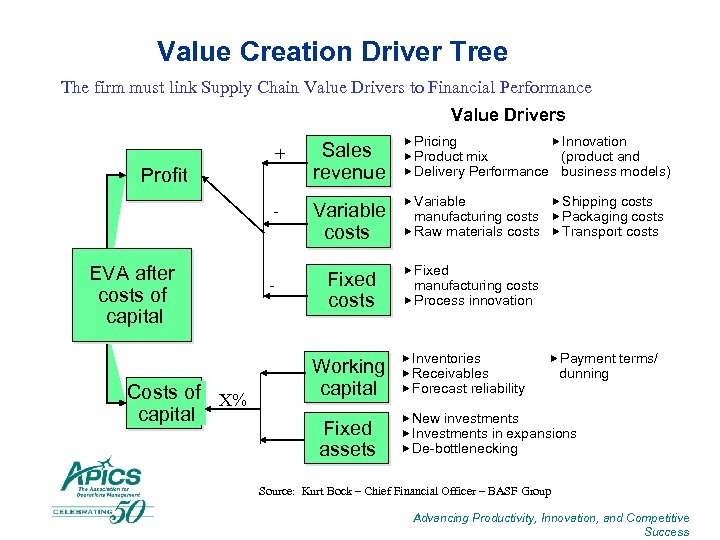

Value Creation Driver Tree The firm must link Supply Chain Value Drivers to Financial Performance Value Drivers + Sales revenue Pricing Innovation Product mix (product and Delivery Performance business models) - Variable costs Variable - Fixed costs Profit EVA after costs of capital Costs of X% capital Working capital Fixed assets Shipping costs manufacturing costs Packaging costs Raw materials costs Transport costs Fixed manufacturing costs Process innovation Inventories Receivables Forecast reliability Payment terms/ dunning New investments Investments in expansions De-bottlenecking Source: Kurt Bock – Chief Financial Officer – BASF Group Advancing Productivity, Innovation, and Competitive Success

Value Creation Driver Tree The firm must link Supply Chain Value Drivers to Financial Performance Value Drivers + Sales revenue Pricing Innovation Product mix (product and Delivery Performance business models) - Variable costs Variable - Fixed costs Profit EVA after costs of capital Costs of X% capital Working capital Fixed assets Shipping costs manufacturing costs Packaging costs Raw materials costs Transport costs Fixed manufacturing costs Process innovation Inventories Receivables Forecast reliability Payment terms/ dunning New investments Investments in expansions De-bottlenecking Source: Kurt Bock – Chief Financial Officer – BASF Group Advancing Productivity, Innovation, and Competitive Success

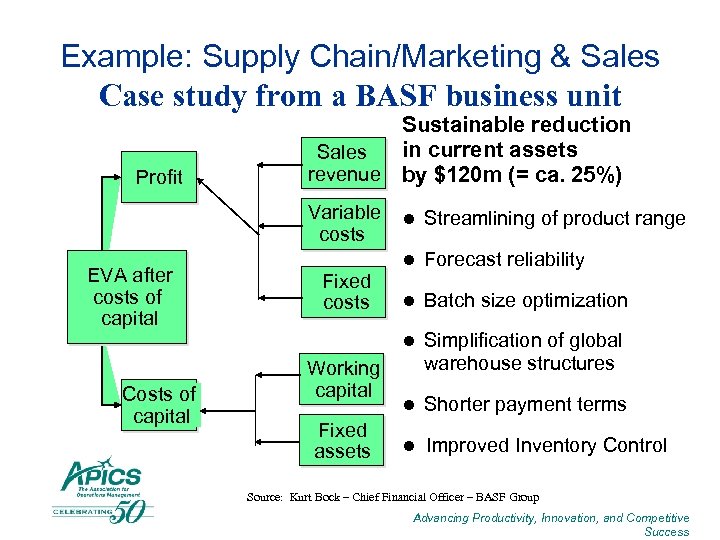

Example: Supply Chain/Marketing & Sales Case study from a BASF business unit Profit Sustainable reduction in current assets Sales revenue by $120 m (= ca. 25%) Variable costs EVA after costs of capital Costs of capital Fixed costs l Streamlining of product range l Forecast reliability l Batch size optimization l Simplification of global Working capital Fixed assets warehouse structures l Shorter payment terms l Improved Inventory Control Source: Kurt Bock – Chief Financial Officer – BASF Group Advancing Productivity, Innovation, and Competitive Success

Example: Supply Chain/Marketing & Sales Case study from a BASF business unit Profit Sustainable reduction in current assets Sales revenue by $120 m (= ca. 25%) Variable costs EVA after costs of capital Costs of capital Fixed costs l Streamlining of product range l Forecast reliability l Batch size optimization l Simplification of global Working capital Fixed assets warehouse structures l Shorter payment terms l Improved Inventory Control Source: Kurt Bock – Chief Financial Officer – BASF Group Advancing Productivity, Innovation, and Competitive Success

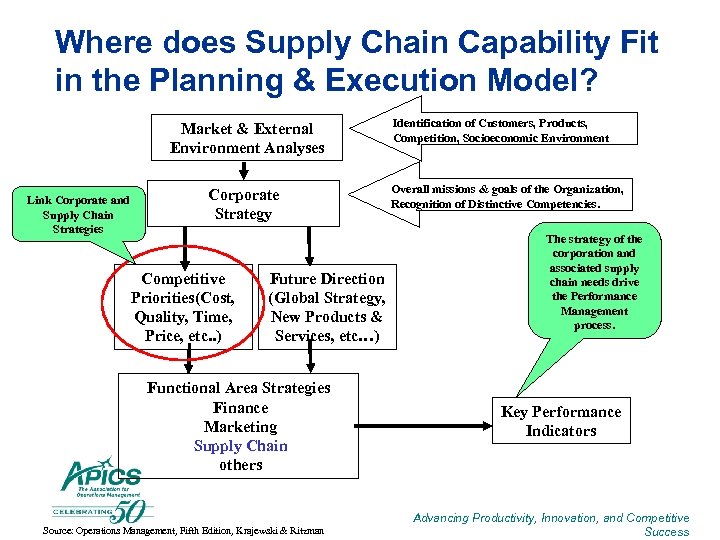

Where does Supply Chain Capability Fit in the Planning & Execution Model? Market & External Environment Analyses Link Corporate and Supply Chain Strategies Corporate Strategy Competitive Priorities(Cost, Quality, Time, Price, etc. . ) Future Direction (Global Strategy, New Products & Services, etc…) Functional Area Strategies Finance Marketing Supply Chain others Source: Operations Management, Fifth Edition, Krajewski & Ritzman Identification of Customers, Products, Competition, Socioeconomic Environment Overall missions & goals of the Organization, Recognition of Distinctive Competencies. The strategy of the corporation and associated supply chain needs drive the Performance Management process. Key Performance Indicators Advancing Productivity, Innovation, and Competitive Success

Where does Supply Chain Capability Fit in the Planning & Execution Model? Market & External Environment Analyses Link Corporate and Supply Chain Strategies Corporate Strategy Competitive Priorities(Cost, Quality, Time, Price, etc. . ) Future Direction (Global Strategy, New Products & Services, etc…) Functional Area Strategies Finance Marketing Supply Chain others Source: Operations Management, Fifth Edition, Krajewski & Ritzman Identification of Customers, Products, Competition, Socioeconomic Environment Overall missions & goals of the Organization, Recognition of Distinctive Competencies. The strategy of the corporation and associated supply chain needs drive the Performance Management process. Key Performance Indicators Advancing Productivity, Innovation, and Competitive Success

The Roles of Supply Chain Metrics Advancing Productivity, Innovation, and Competitive Success

The Roles of Supply Chain Metrics Advancing Productivity, Innovation, and Competitive Success

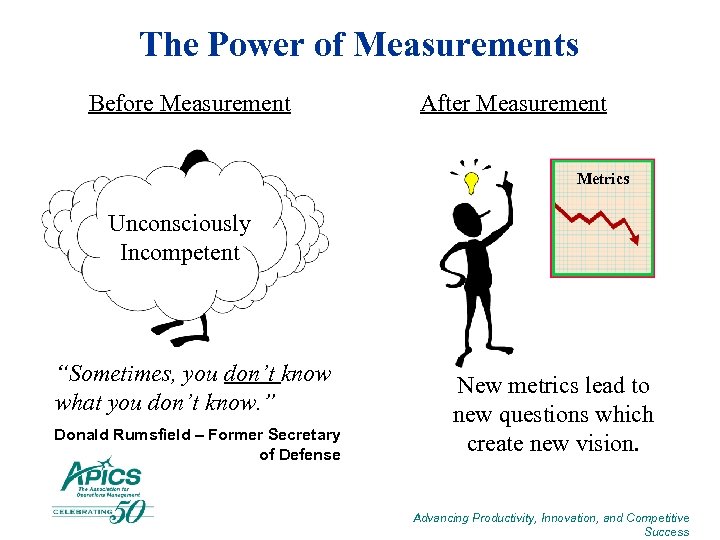

The Power of Measurements Before Measurement After Measurement Metrics Unconsciously Incompetent “Sometimes, you don’t know what you don’t know. ” Donald Rumsfield – Former Secretary of Defense New metrics lead to new questions which create new vision. Advancing Productivity, Innovation, and Competitive Success

The Power of Measurements Before Measurement After Measurement Metrics Unconsciously Incompetent “Sometimes, you don’t know what you don’t know. ” Donald Rumsfield – Former Secretary of Defense New metrics lead to new questions which create new vision. Advancing Productivity, Innovation, and Competitive Success

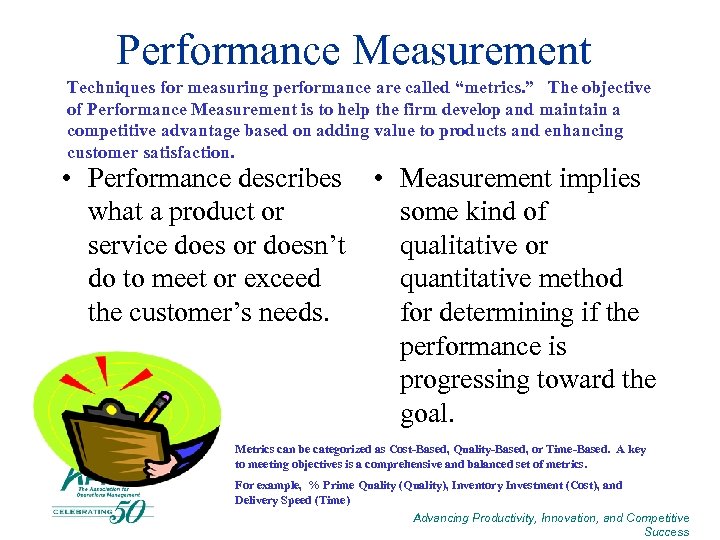

Performance Measurement Techniques for measuring performance are called “metrics. ” The objective of Performance Measurement is to help the firm develop and maintain a competitive advantage based on adding value to products and enhancing customer satisfaction. • Performance describes • Measurement implies what a product or some kind of service does or doesn’t qualitative or do to meet or exceed quantitative method the customer’s needs. for determining if the performance is progressing toward the goal. Metrics can be categorized as Cost-Based, Quality-Based, or Time-Based. A key to meeting objectives is a comprehensive and balanced set of metrics. For example, % Prime Quality (Quality), Inventory Investment (Cost), and Delivery Speed (Time) Advancing Productivity, Innovation, and Competitive Success

Performance Measurement Techniques for measuring performance are called “metrics. ” The objective of Performance Measurement is to help the firm develop and maintain a competitive advantage based on adding value to products and enhancing customer satisfaction. • Performance describes • Measurement implies what a product or some kind of service does or doesn’t qualitative or do to meet or exceed quantitative method the customer’s needs. for determining if the performance is progressing toward the goal. Metrics can be categorized as Cost-Based, Quality-Based, or Time-Based. A key to meeting objectives is a comprehensive and balanced set of metrics. For example, % Prime Quality (Quality), Inventory Investment (Cost), and Delivery Speed (Time) Advancing Productivity, Innovation, and Competitive Success

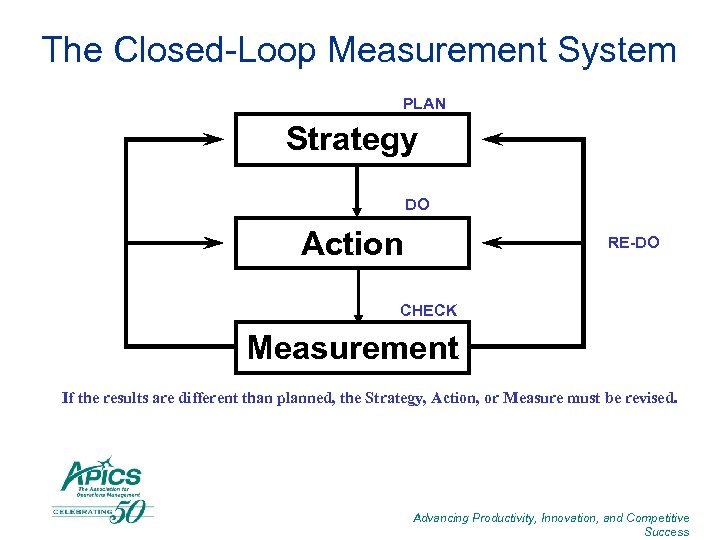

The Closed-Loop Measurement System PLAN Strategy DO Action RE-DO CHECK Measurement If the results are different than planned, the Strategy, Action, or Measure must be revised. Advancing Productivity, Innovation, and Competitive Success

The Closed-Loop Measurement System PLAN Strategy DO Action RE-DO CHECK Measurement If the results are different than planned, the Strategy, Action, or Measure must be revised. Advancing Productivity, Innovation, and Competitive Success

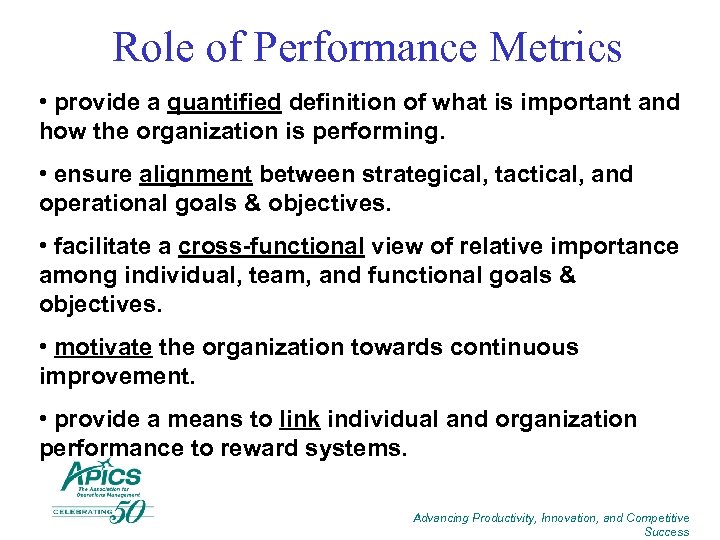

Role of Performance Metrics • provide a quantified definition of what is important and how the organization is performing. • ensure alignment between strategical, tactical, and operational goals & objectives. • facilitate a cross-functional view of relative importance among individual, team, and functional goals & objectives. • motivate the organization towards continuous improvement. • provide a means to link individual and organization performance to reward systems. Advancing Productivity, Innovation, and Competitive Success

Role of Performance Metrics • provide a quantified definition of what is important and how the organization is performing. • ensure alignment between strategical, tactical, and operational goals & objectives. • facilitate a cross-functional view of relative importance among individual, team, and functional goals & objectives. • motivate the organization towards continuous improvement. • provide a means to link individual and organization performance to reward systems. Advancing Productivity, Innovation, and Competitive Success

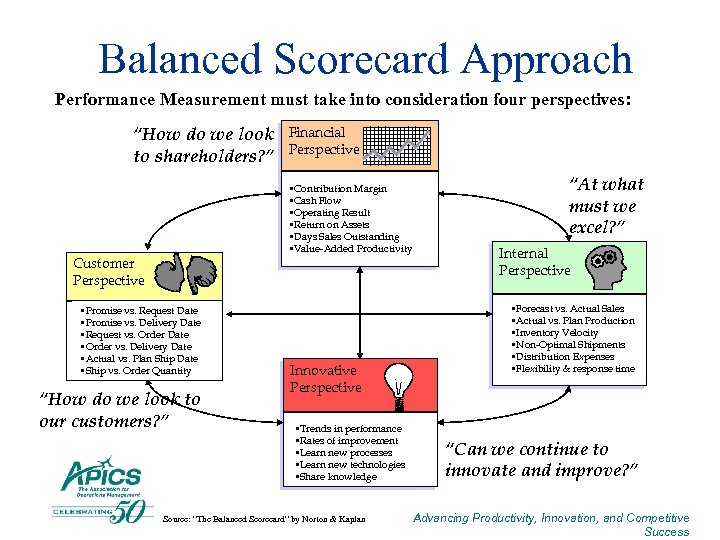

Balanced Scorecard Approach Performance Measurement must take into consideration four perspectives: “How do we look to shareholders? ” Financial Perspective • Contribution Margin • Cash Flow • Operating Result • Return on Assets • Days Sales Outstanding • Value-Added Productivity Customer Perspective • Promise vs. Request Date • Promise vs. Delivery Date • Request vs. Order Date • Order vs. Delivery Date • Actual vs. Plan Ship Date • Ship vs. Order Quantity “How do we look to our customers? ” Innovative Perspective • Trends in performance • Rates of improvement • Learn new processes • Learn new technologies • Share knowledge Source: “The Balanced Scorecard” by Norton & Kaplan “At what must we excel? ” Internal Perspective • Forecast vs. Actual Sales • Actual vs. Plan Production • Inventory Velocity • Non-Optimal Shipments • Distribution Expenses • Flexibility & response time “Can we continue to innovate and improve? ” Advancing Productivity, Innovation, and Competitive Success

Balanced Scorecard Approach Performance Measurement must take into consideration four perspectives: “How do we look to shareholders? ” Financial Perspective • Contribution Margin • Cash Flow • Operating Result • Return on Assets • Days Sales Outstanding • Value-Added Productivity Customer Perspective • Promise vs. Request Date • Promise vs. Delivery Date • Request vs. Order Date • Order vs. Delivery Date • Actual vs. Plan Ship Date • Ship vs. Order Quantity “How do we look to our customers? ” Innovative Perspective • Trends in performance • Rates of improvement • Learn new processes • Learn new technologies • Share knowledge Source: “The Balanced Scorecard” by Norton & Kaplan “At what must we excel? ” Internal Perspective • Forecast vs. Actual Sales • Actual vs. Plan Production • Inventory Velocity • Non-Optimal Shipments • Distribution Expenses • Flexibility & response time “Can we continue to innovate and improve? ” Advancing Productivity, Innovation, and Competitive Success

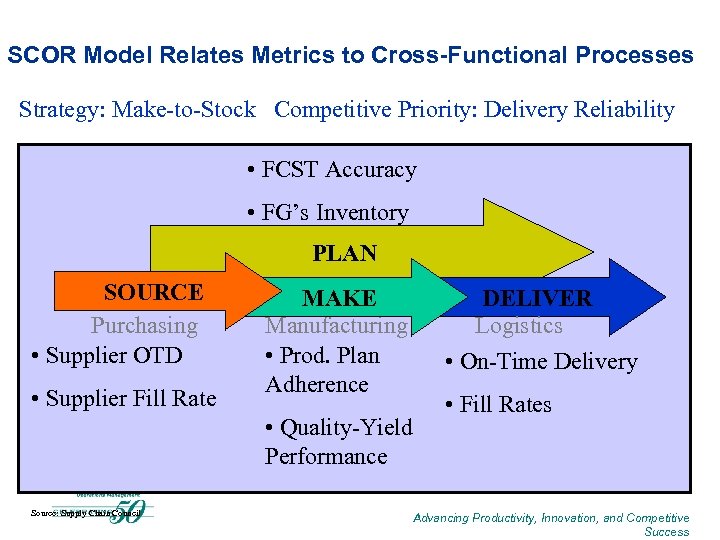

SCOR Model Relates Metrics to Cross-Functional Processes Strategy: Make-to-Stock Competitive Priority: Delivery Reliability • FCST Accuracy • FG’s Inventory PLAN SOURCE Purchasing • Supplier OTD • Supplier Fill Rate MAKE Manufacturing • Prod. Plan Adherence DELIVER Logistics • On-Time Delivery • Quality-Yield Performance Source: Supply Chain Council • Fill Rates Advancing Productivity, Innovation, and Competitive Success

SCOR Model Relates Metrics to Cross-Functional Processes Strategy: Make-to-Stock Competitive Priority: Delivery Reliability • FCST Accuracy • FG’s Inventory PLAN SOURCE Purchasing • Supplier OTD • Supplier Fill Rate MAKE Manufacturing • Prod. Plan Adherence DELIVER Logistics • On-Time Delivery • Quality-Yield Performance Source: Supply Chain Council • Fill Rates Advancing Productivity, Innovation, and Competitive Success

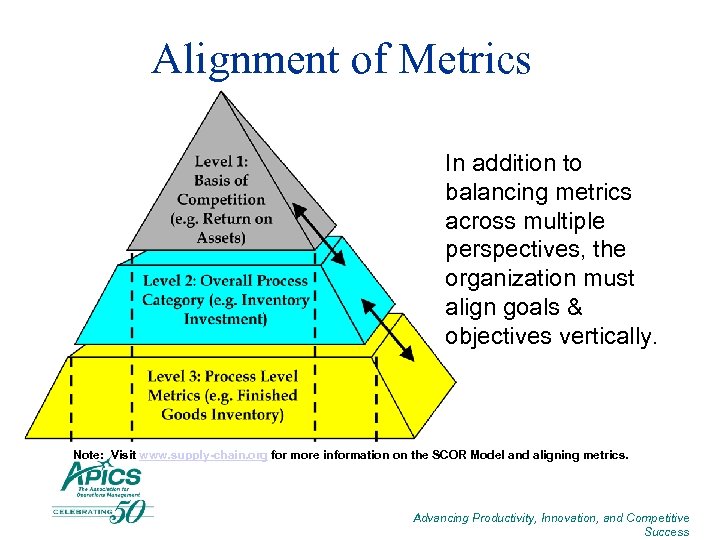

Alignment of Metrics In addition to balancing metrics across multiple perspectives, the organization must align goals & objectives vertically. Note: Visit www. supply-chain. org for more information on the SCOR Model and aligning metrics. Advancing Productivity, Innovation, and Competitive Success

Alignment of Metrics In addition to balancing metrics across multiple perspectives, the organization must align goals & objectives vertically. Note: Visit www. supply-chain. org for more information on the SCOR Model and aligning metrics. Advancing Productivity, Innovation, and Competitive Success

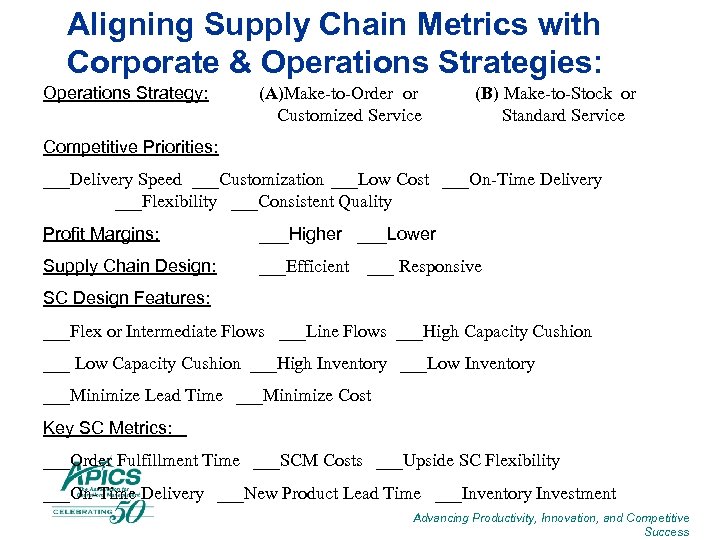

Aligning Supply Chain Metrics with Corporate & Operations Strategies: Operations Strategy: (A)Make-to-Order or Customized Service (B) Make-to-Stock or Standard Service Competitive Priorities: ___Delivery Speed ___Customization ___Low Cost ___On-Time Delivery ___Flexibility ___Consistent Quality Profit Margins: ___Higher ___Lower Supply Chain Design: ___Efficient ___ Responsive SC Design Features: ___Flex or Intermediate Flows ___Line Flows ___High Capacity Cushion ___ Low Capacity Cushion ___High Inventory ___Low Inventory ___Minimize Lead Time ___Minimize Cost Key SC Metrics: ___Order Fulfillment Time ___SCM Costs ___Upside SC Flexibility ___On-Time Delivery ___New Product Lead Time ___Inventory Investment Advancing Productivity, Innovation, and Competitive Success

Aligning Supply Chain Metrics with Corporate & Operations Strategies: Operations Strategy: (A)Make-to-Order or Customized Service (B) Make-to-Stock or Standard Service Competitive Priorities: ___Delivery Speed ___Customization ___Low Cost ___On-Time Delivery ___Flexibility ___Consistent Quality Profit Margins: ___Higher ___Lower Supply Chain Design: ___Efficient ___ Responsive SC Design Features: ___Flex or Intermediate Flows ___Line Flows ___High Capacity Cushion ___ Low Capacity Cushion ___High Inventory ___Low Inventory ___Minimize Lead Time ___Minimize Cost Key SC Metrics: ___Order Fulfillment Time ___SCM Costs ___Upside SC Flexibility ___On-Time Delivery ___New Product Lead Time ___Inventory Investment Advancing Productivity, Innovation, and Competitive Success

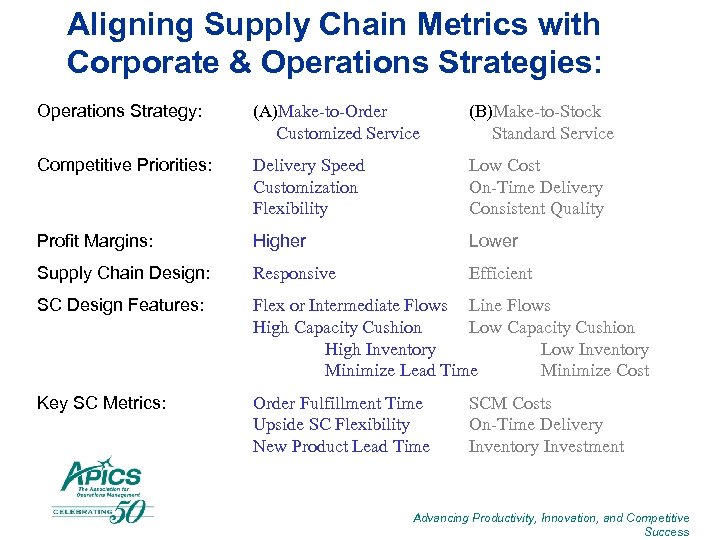

Aligning Supply Chain Metrics with Corporate & Operations Strategies: Operations Strategy: (A)Make-to-Order Customized Service (B)Make-to-Stock Standard Service Competitive Priorities: Delivery Speed Customization Flexibility Low Cost On-Time Delivery Consistent Quality Profit Margins: Higher Lower Supply Chain Design: Responsive Efficient SC Design Features: Flex or Intermediate Flows Line Flows High Capacity Cushion Low Capacity Cushion High Inventory Low Inventory Minimize Lead Time Minimize Cost Key SC Metrics: Order Fulfillment Time Upside SC Flexibility New Product Lead Time SCM Costs On-Time Delivery Inventory Investment Advancing Productivity, Innovation, and Competitive Success

Aligning Supply Chain Metrics with Corporate & Operations Strategies: Operations Strategy: (A)Make-to-Order Customized Service (B)Make-to-Stock Standard Service Competitive Priorities: Delivery Speed Customization Flexibility Low Cost On-Time Delivery Consistent Quality Profit Margins: Higher Lower Supply Chain Design: Responsive Efficient SC Design Features: Flex or Intermediate Flows Line Flows High Capacity Cushion Low Capacity Cushion High Inventory Low Inventory Minimize Lead Time Minimize Cost Key SC Metrics: Order Fulfillment Time Upside SC Flexibility New Product Lead Time SCM Costs On-Time Delivery Inventory Investment Advancing Productivity, Innovation, and Competitive Success

Designing and Implementing KPI’s Advancing Productivity, Innovation, and Competitive Success

Designing and Implementing KPI’s Advancing Productivity, Innovation, and Competitive Success

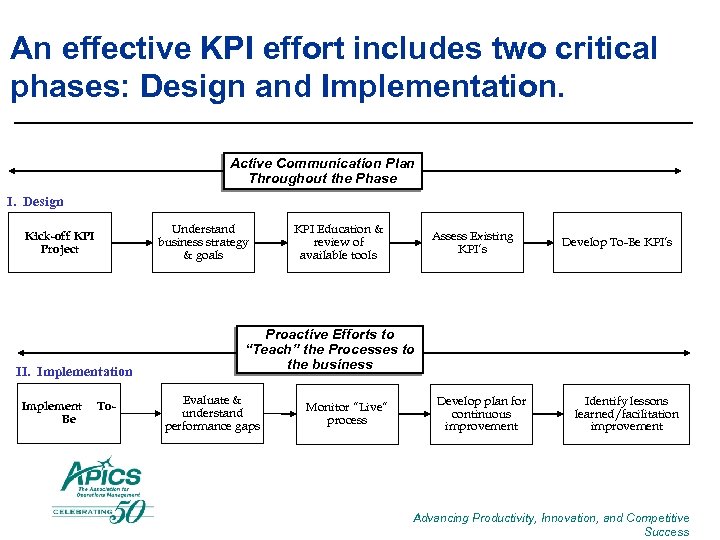

An effective KPI effort includes two critical phases: Design and Implementation. Active Communication Plan Throughout the Phase I. Design Understand business strategy & goals Kick-off KPI Project II. Implementation Implement Be To- KPI Education & review of available tools Assess Existing KPI’s Develop To-Be KPI’s Proactive Efforts to “Teach” the Processes to the business Evaluate & understand performance gaps Monitor “Live” process Develop plan for continuous improvement Identify lessons learned/facilitation improvement Advancing Productivity, Innovation, and Competitive Success

An effective KPI effort includes two critical phases: Design and Implementation. Active Communication Plan Throughout the Phase I. Design Understand business strategy & goals Kick-off KPI Project II. Implementation Implement Be To- KPI Education & review of available tools Assess Existing KPI’s Develop To-Be KPI’s Proactive Efforts to “Teach” the Processes to the business Evaluate & understand performance gaps Monitor “Live” process Develop plan for continuous improvement Identify lessons learned/facilitation improvement Advancing Productivity, Innovation, and Competitive Success

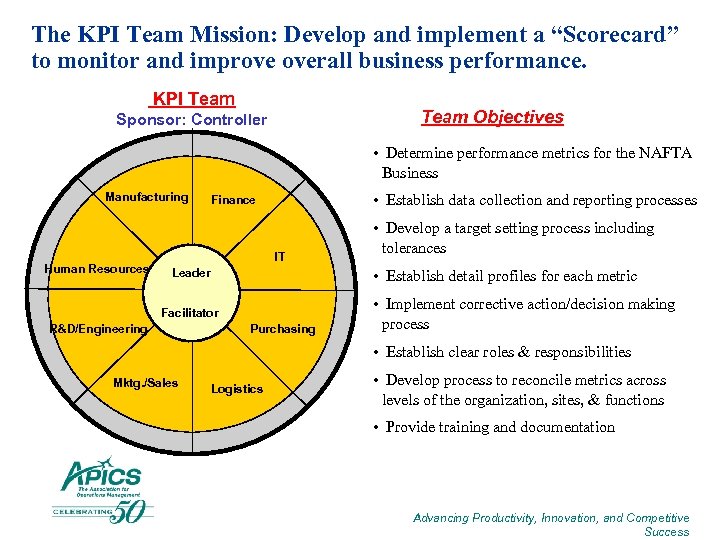

The KPI Team Mission: Develop and implement a “Scorecard” to monitor and improve overall business performance. KPI Team Objectives Sponsor: Controller • Determine performance metrics for the NAFTA Business Manufacturing Human Resources • Establish data collection and reporting processes Finance IT Leader • Establish detail profiles for each metric Facilitator R&D/Engineering • Develop a target setting process including tolerances Purchasing • Implement corrective action/decision making process • Establish clear roles & responsibilities Mktg. /Sales Logistics • Develop process to reconcile metrics across levels of the organization, sites, & functions • Provide training and documentation Advancing Productivity, Innovation, and Competitive Success

The KPI Team Mission: Develop and implement a “Scorecard” to monitor and improve overall business performance. KPI Team Objectives Sponsor: Controller • Determine performance metrics for the NAFTA Business Manufacturing Human Resources • Establish data collection and reporting processes Finance IT Leader • Establish detail profiles for each metric Facilitator R&D/Engineering • Develop a target setting process including tolerances Purchasing • Implement corrective action/decision making process • Establish clear roles & responsibilities Mktg. /Sales Logistics • Develop process to reconcile metrics across levels of the organization, sites, & functions • Provide training and documentation Advancing Productivity, Innovation, and Competitive Success

Develop a High-Level Project Plan “Take care to get what you like, or you will be forced to like what you get. ” George Bernard Shaw Advancing Productivity, Innovation, and Competitive Success

Develop a High-Level Project Plan “Take care to get what you like, or you will be forced to like what you get. ” George Bernard Shaw Advancing Productivity, Innovation, and Competitive Success

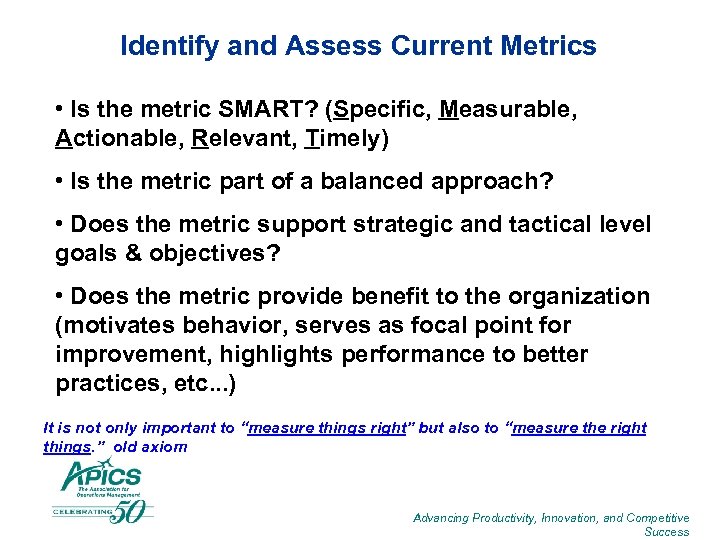

Identify and Assess Current Metrics • Is the metric SMART? (Specific, Measurable, Actionable, Relevant, Timely) • Is the metric part of a balanced approach? • Does the metric support strategic and tactical level goals & objectives? • Does the metric provide benefit to the organization (motivates behavior, serves as focal point for improvement, highlights performance to better practices, etc. . . ) It is not only important to “measure things right” but also to “measure the right things. ” old axiom Advancing Productivity, Innovation, and Competitive Success

Identify and Assess Current Metrics • Is the metric SMART? (Specific, Measurable, Actionable, Relevant, Timely) • Is the metric part of a balanced approach? • Does the metric support strategic and tactical level goals & objectives? • Does the metric provide benefit to the organization (motivates behavior, serves as focal point for improvement, highlights performance to better practices, etc. . . ) It is not only important to “measure things right” but also to “measure the right things. ” old axiom Advancing Productivity, Innovation, and Competitive Success

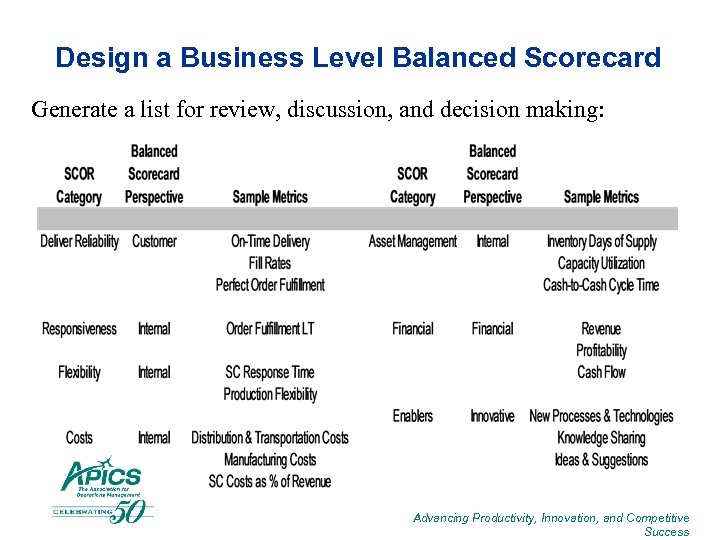

Design a Business Level Balanced Scorecard Generate a list for review, discussion, and decision making: Advancing Productivity, Innovation, and Competitive Success

Design a Business Level Balanced Scorecard Generate a list for review, discussion, and decision making: Advancing Productivity, Innovation, and Competitive Success

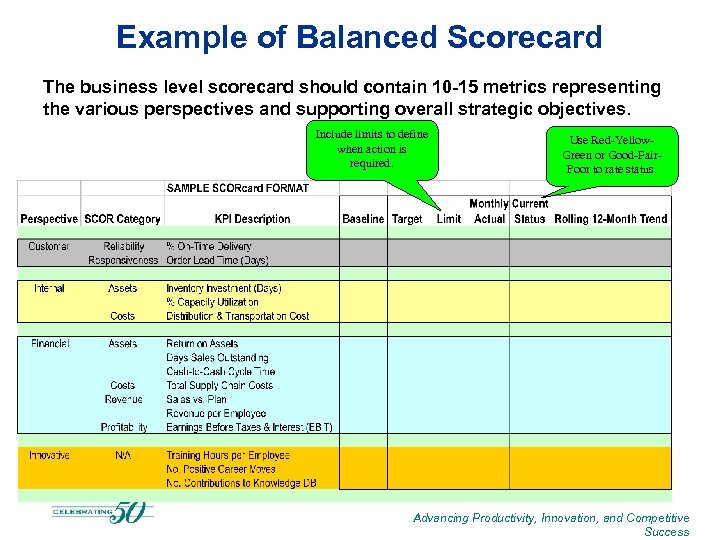

Example of Balanced Scorecard The business level scorecard should contain 10 -15 metrics representing the various perspectives and supporting overall strategic objectives. Include limits to define when action is required. Use Red-Yellow. Green or Good-Fair. Poor to rate status. Advancing Productivity, Innovation, and Competitive Success

Example of Balanced Scorecard The business level scorecard should contain 10 -15 metrics representing the various perspectives and supporting overall strategic objectives. Include limits to define when action is required. Use Red-Yellow. Green or Good-Fair. Poor to rate status. Advancing Productivity, Innovation, and Competitive Success

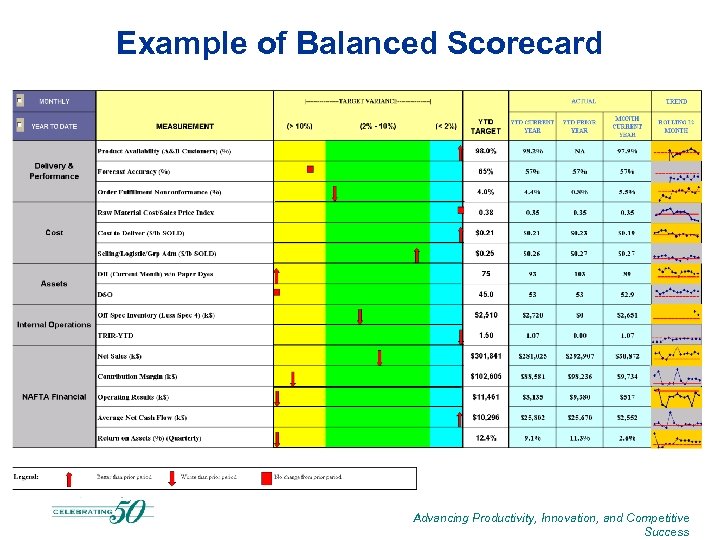

Example of Balanced Scorecard Advancing Productivity, Innovation, and Competitive Success

Example of Balanced Scorecard Advancing Productivity, Innovation, and Competitive Success

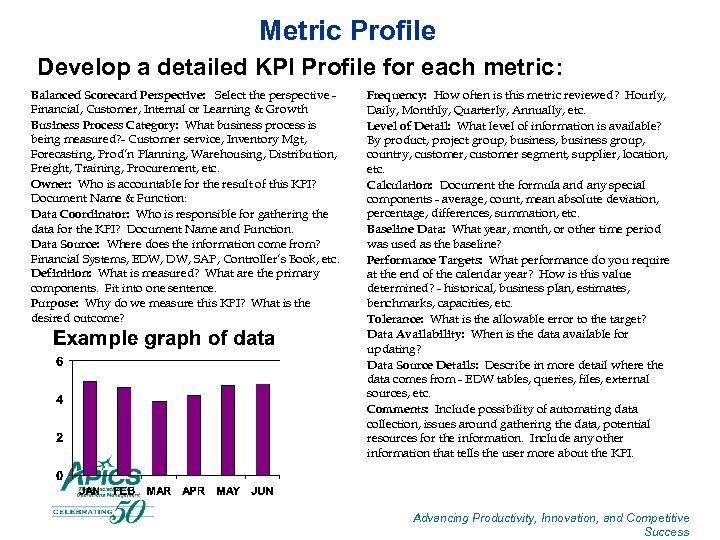

Metric Profile Develop a detailed KPI Profile for each metric: Balanced Scorecard Perspective: Select the perspective Financial, Customer, Internal or Learning & Growth Business Process Category: What business process is being measured? - Customer service, Inventory Mgt, Forecasting, Prod’n Planning, Warehousing, Distribution, Freight, Training, Procurement, etc. Owner: Who is accountable for the result of this KPI? Document Name & Function: Data Coordinator: Who is responsible for gathering the data for the KPI? Document Name and Function. Data Source: Where does the information come from? Financial Systems, EDW, SAP, Controller’s Book, etc. Definition: What is measured? What are the primary components. Fit into one sentence. Purpose: Why do we measure this KPI? What is the desired outcome? Frequency: How often is this metric reviewed? Hourly, Daily, Monthly, Quarterly, Annually, etc. Level of Detail: What level of information is available? By product, project group, business group, country, customer segment, supplier, location, etc. Calculation: Document the formula and any special components - average, count, mean absolute deviation, percentage, differences, summation, etc. Baseline Data: What year, month, or other time period was used as the baseline? Performance Targets: What performance do you require at the end of the calendar year? How is this value determined? - historical, business plan, estimates, benchmarks, capacities, etc. Tolerance: What is the allowable error to the target? Data Availability: When is the data available for updating? Data Source Details: Describe in more detail where the data comes from - EDW tables, queries, files, external sources, etc. Comments: Include possibility of automating data collection, issues around gathering the data, potential resources for the information. Include any other information that tells the user more about the KPI. Advancing Productivity, Innovation, and Competitive Success

Metric Profile Develop a detailed KPI Profile for each metric: Balanced Scorecard Perspective: Select the perspective Financial, Customer, Internal or Learning & Growth Business Process Category: What business process is being measured? - Customer service, Inventory Mgt, Forecasting, Prod’n Planning, Warehousing, Distribution, Freight, Training, Procurement, etc. Owner: Who is accountable for the result of this KPI? Document Name & Function: Data Coordinator: Who is responsible for gathering the data for the KPI? Document Name and Function. Data Source: Where does the information come from? Financial Systems, EDW, SAP, Controller’s Book, etc. Definition: What is measured? What are the primary components. Fit into one sentence. Purpose: Why do we measure this KPI? What is the desired outcome? Frequency: How often is this metric reviewed? Hourly, Daily, Monthly, Quarterly, Annually, etc. Level of Detail: What level of information is available? By product, project group, business group, country, customer segment, supplier, location, etc. Calculation: Document the formula and any special components - average, count, mean absolute deviation, percentage, differences, summation, etc. Baseline Data: What year, month, or other time period was used as the baseline? Performance Targets: What performance do you require at the end of the calendar year? How is this value determined? - historical, business plan, estimates, benchmarks, capacities, etc. Tolerance: What is the allowable error to the target? Data Availability: When is the data available for updating? Data Source Details: Describe in more detail where the data comes from - EDW tables, queries, files, external sources, etc. Comments: Include possibility of automating data collection, issues around gathering the data, potential resources for the information. Include any other information that tells the user more about the KPI. Advancing Productivity, Innovation, and Competitive Success

The Use of Supply Chain Metrics “Sometimes, you do know what you don’t know. ” Donald Rumsfield – Former Secretary of Defense Advancing Productivity, Innovation, and Competitive Success

The Use of Supply Chain Metrics “Sometimes, you do know what you don’t know. ” Donald Rumsfield – Former Secretary of Defense Advancing Productivity, Innovation, and Competitive Success

Uses of Performance Measures – Communicate expectations To ensure all members of the firm are working toward the same goals. – Establish metrics Aligned with focus goals and objectives. – Measure and control key factors Compare actual-to-target and take actions as needed. – Track changes in performance Detect trends and develop plans accordingly. – Control operations To obtain desired behaviors and results. Advancing Productivity, Innovation, and Competitive Success

Uses of Performance Measures – Communicate expectations To ensure all members of the firm are working toward the same goals. – Establish metrics Aligned with focus goals and objectives. – Measure and control key factors Compare actual-to-target and take actions as needed. – Track changes in performance Detect trends and develop plans accordingly. – Control operations To obtain desired behaviors and results. Advancing Productivity, Innovation, and Competitive Success

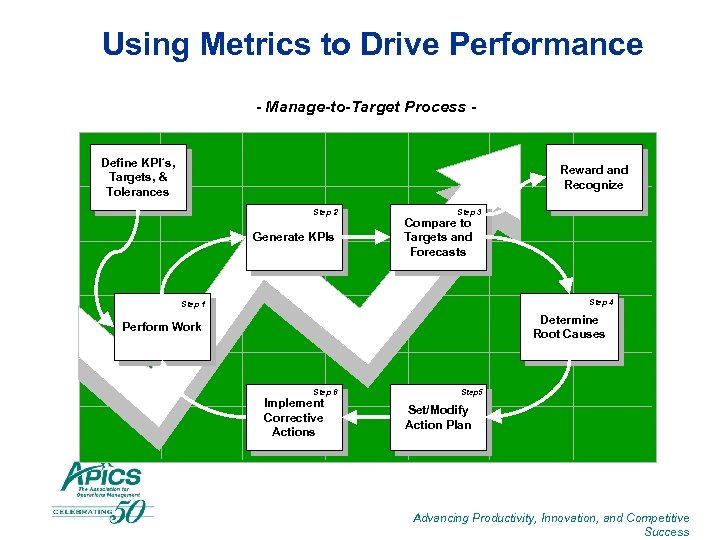

Using Metrics to Drive Performance - Manage-to-Target Process - Define KPI´s, Targets, & Tolerances Reward and Recognize Step 2 Generate KPIs Step 3 Compare to Targets and Forecasts Step 4 Step 1 Determine Root Causes Perform Work Step 6 Implement Corrective Actions Step 5 Set/Modify Action Plan Advancing Productivity, Innovation, and Competitive Success

Using Metrics to Drive Performance - Manage-to-Target Process - Define KPI´s, Targets, & Tolerances Reward and Recognize Step 2 Generate KPIs Step 3 Compare to Targets and Forecasts Step 4 Step 1 Determine Root Causes Perform Work Step 6 Implement Corrective Actions Step 5 Set/Modify Action Plan Advancing Productivity, Innovation, and Competitive Success

Characteristics of Effective Measurement System – Measure more than one function or activity Don’t just measure cost or even revenue, cost, & profit. Include different perspectives such as service, quality, innovation, etc. . . – Can be used for decision-making Include trends as well as absolute measures. – Economical to obtain and apply Leverage automation as much as feasible. Avoid metrics requiring people to write things down or tally manually. – Easy to understand interpret Use KISS principle. Avoid metrics which require interpretation for scorekeeping. – Linked to strategy For example, if focus of strategy is low-cost and delivery reliability, don’t emphasize responsiveness or flexibility. – Inspires the desired response Is progress toward goals being made? Smart-Measurable-Actionable-Relevant-Timely Advancing Productivity, Innovation, and Competitive Success

Characteristics of Effective Measurement System – Measure more than one function or activity Don’t just measure cost or even revenue, cost, & profit. Include different perspectives such as service, quality, innovation, etc. . . – Can be used for decision-making Include trends as well as absolute measures. – Economical to obtain and apply Leverage automation as much as feasible. Avoid metrics requiring people to write things down or tally manually. – Easy to understand interpret Use KISS principle. Avoid metrics which require interpretation for scorekeeping. – Linked to strategy For example, if focus of strategy is low-cost and delivery reliability, don’t emphasize responsiveness or flexibility. – Inspires the desired response Is progress toward goals being made? Smart-Measurable-Actionable-Relevant-Timely Advancing Productivity, Innovation, and Competitive Success

Some General Principles of Measurements – Don’t confuse process measures with people give individual’s measures. For example, don’texpense of quality. productivity goals that encourage throughput at the – People at all levels of the firm do better when they choose their own measures (subject to strategy which they select. checks). People are more enthusiastic and dedicated to metricsassociated goals. They must understand the competitive strategies and – A few well-chosen measures are better than many measures—use Pareto’s Law. Avoid, metric of the week syndrome and conflicting metrics which send confusing signals. – There is a difference between data and information. All firms create a great deal of data. For example, movement data, inventory data, production data, etc…. To convert this data to information the data must be processed into something meaningful and measurable. For example, month-end inventory units are translated to inventory dollars using standard costs and then aggregated and compared with goals. Advancing Productivity, Innovation, and Competitive Success

Some General Principles of Measurements – Don’t confuse process measures with people give individual’s measures. For example, don’texpense of quality. productivity goals that encourage throughput at the – People at all levels of the firm do better when they choose their own measures (subject to strategy which they select. checks). People are more enthusiastic and dedicated to metricsassociated goals. They must understand the competitive strategies and – A few well-chosen measures are better than many measures—use Pareto’s Law. Avoid, metric of the week syndrome and conflicting metrics which send confusing signals. – There is a difference between data and information. All firms create a great deal of data. For example, movement data, inventory data, production data, etc…. To convert this data to information the data must be processed into something meaningful and measurable. For example, month-end inventory units are translated to inventory dollars using standard costs and then aggregated and compared with goals. Advancing Productivity, Innovation, and Competitive Success

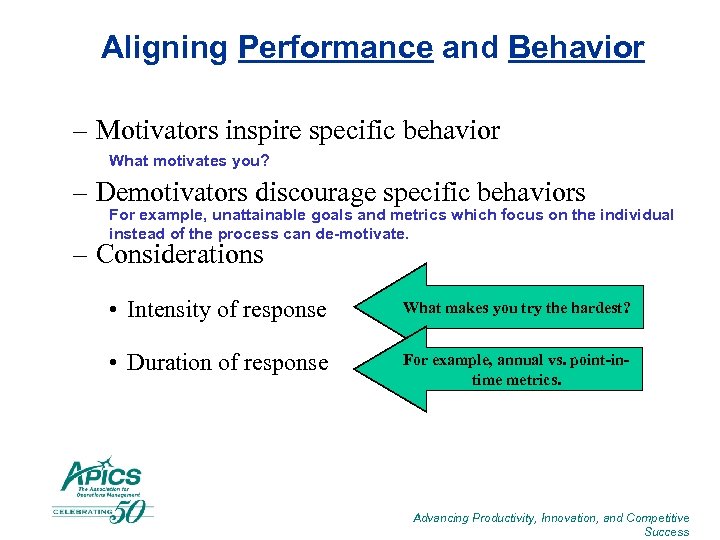

Aligning Performance and Behavior – Motivators inspire specific behavior What motivates you? – Demotivators discourage specific behaviors For example, unattainable goals and metrics which focus on the individual instead of the process can de-motivate. – Considerations • Intensity of response What makes you try the hardest? • Duration of response For example, annual vs. point-intime metrics. Advancing Productivity, Innovation, and Competitive Success

Aligning Performance and Behavior – Motivators inspire specific behavior What motivates you? – Demotivators discourage specific behaviors For example, unattainable goals and metrics which focus on the individual instead of the process can de-motivate. – Considerations • Intensity of response What makes you try the hardest? • Duration of response For example, annual vs. point-intime metrics. Advancing Productivity, Innovation, and Competitive Success

Sample KPI’s Advancing Productivity, Innovation, and Competitive Success

Sample KPI’s Advancing Productivity, Innovation, and Competitive Success

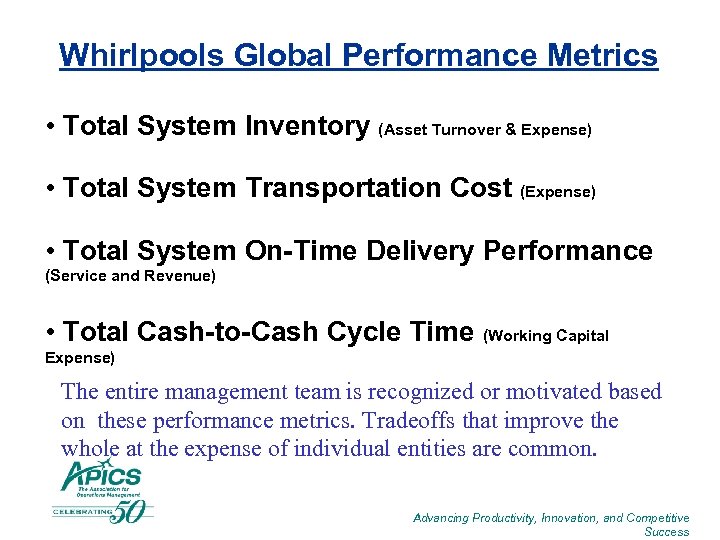

Whirlpools Global Performance Metrics • Total System Inventory (Asset Turnover & Expense) • Total System Transportation Cost (Expense) • Total System On-Time Delivery Performance (Service and Revenue) • Total Cash-to-Cash Cycle Time (Working Capital Expense) The entire management team is recognized or motivated based on these performance metrics. Tradeoffs that improve the whole at the expense of individual entities are common. Advancing Productivity, Innovation, and Competitive Success

Whirlpools Global Performance Metrics • Total System Inventory (Asset Turnover & Expense) • Total System Transportation Cost (Expense) • Total System On-Time Delivery Performance (Service and Revenue) • Total Cash-to-Cash Cycle Time (Working Capital Expense) The entire management team is recognized or motivated based on these performance metrics. Tradeoffs that improve the whole at the expense of individual entities are common. Advancing Productivity, Innovation, and Competitive Success

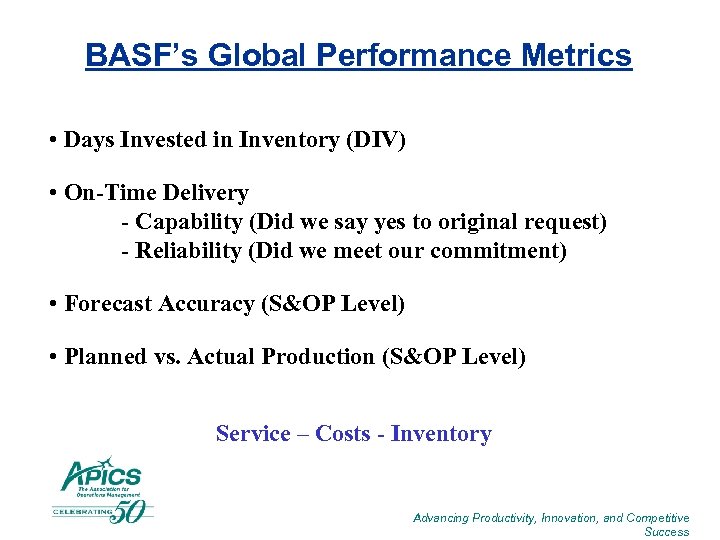

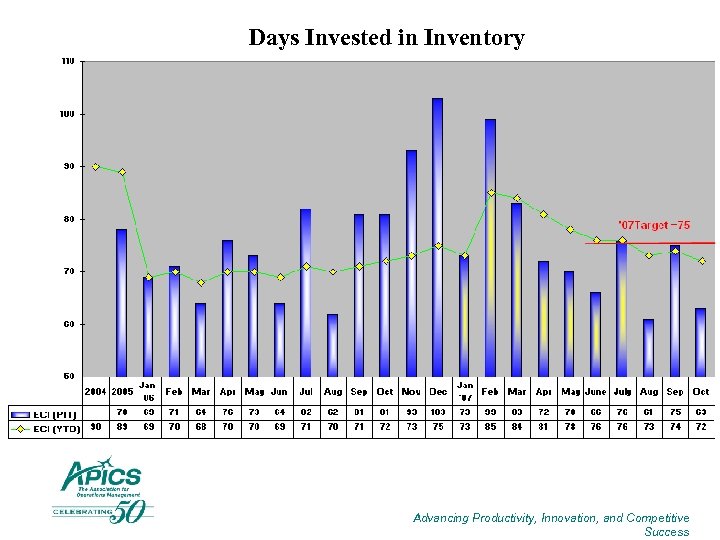

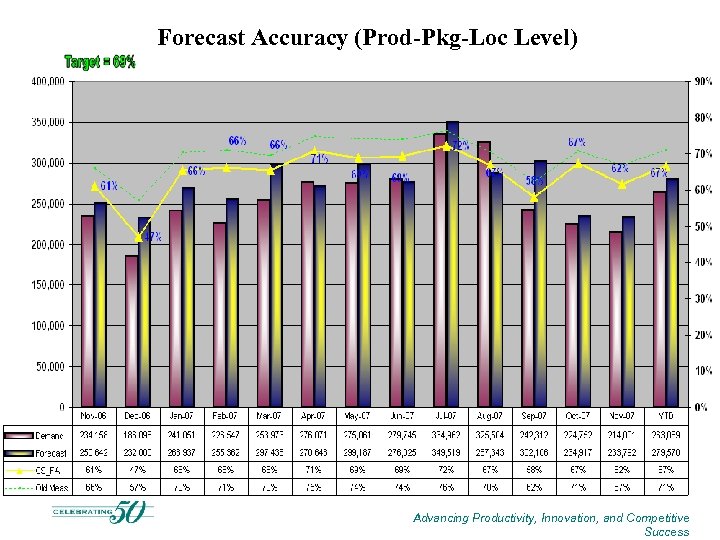

BASF’s Global Performance Metrics • Days Invested in Inventory (DIV) • On-Time Delivery - Capability (Did we say yes to original request) - Reliability (Did we meet our commitment) • Forecast Accuracy (S&OP Level) • Planned vs. Actual Production (S&OP Level) Service – Costs - Inventory Advancing Productivity, Innovation, and Competitive Success

BASF’s Global Performance Metrics • Days Invested in Inventory (DIV) • On-Time Delivery - Capability (Did we say yes to original request) - Reliability (Did we meet our commitment) • Forecast Accuracy (S&OP Level) • Planned vs. Actual Production (S&OP Level) Service – Costs - Inventory Advancing Productivity, Innovation, and Competitive Success

Customer Service Scorecard – BU Level Advancing Productivity, Innovation, and Competitive Success

Customer Service Scorecard – BU Level Advancing Productivity, Innovation, and Competitive Success

Days Invested in Inventory Advancing Productivity, Innovation, and Competitive Success

Days Invested in Inventory Advancing Productivity, Innovation, and Competitive Success

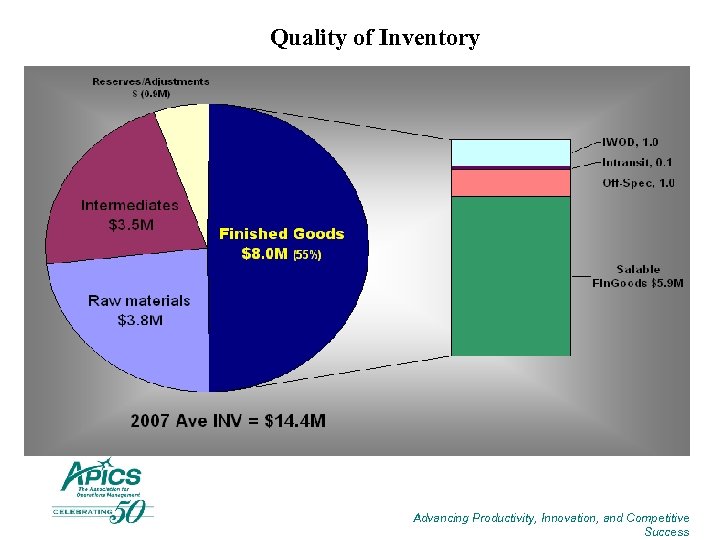

Quality of Inventory Advancing Productivity, Innovation, and Competitive Success

Quality of Inventory Advancing Productivity, Innovation, and Competitive Success

Forecast Accuracy (Prod-Pkg-Loc Level) Advancing Productivity, Innovation, and Competitive Success

Forecast Accuracy (Prod-Pkg-Loc Level) Advancing Productivity, Innovation, and Competitive Success

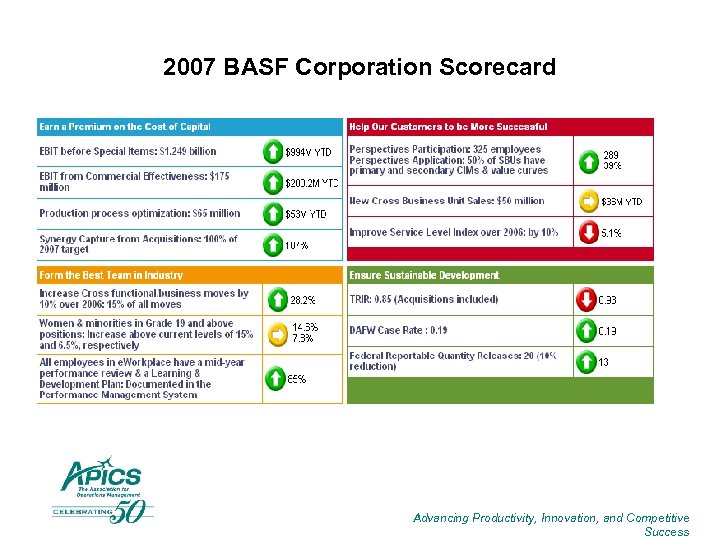

2007 BASF Corporation Scorecard Advancing Productivity, Innovation, and Competitive Success

2007 BASF Corporation Scorecard Advancing Productivity, Innovation, and Competitive Success

“It ain’t what you know, it’s what you think you know that just ain’t so. ” Satchel Paige Advancing Productivity, Innovation, and Competitive Success

“It ain’t what you know, it’s what you think you know that just ain’t so. ” Satchel Paige Advancing Productivity, Innovation, and Competitive Success

Advancing Productivity, Innovation, and Competitive Success

Advancing Productivity, Innovation, and Competitive Success