6efea461bb0f05882ed83e0eb7271171.ppt

- Количество слайдов: 26

Hardy Process Solutions – New Product Introduction HI 6600 Series – Modular Sensor System • Hardy delivers productivity solutions to manufacturers and processors • Hardy developed the first PLC integrated weighing system • We are a Rockwell Automation Global Encompass Partner • We were founded as Hardy Scales in 1918 • Hardy is part of Roper Industries, a $3. 2 B+ public company 1

Hardy Process Solutions – New Product Introduction HI 6600 Series – Modular Sensor System • Hardy delivers productivity solutions to manufacturers and processors • Hardy developed the first PLC integrated weighing system • We are a Rockwell Automation Global Encompass Partner • We were founded as Hardy Scales in 1918 • Hardy is part of Roper Industries, a $3. 2 B+ public company 1

Available Hardware to Provide “Weight” Into a PLC Transmitter 4 -20 m. A out Weight Indicator w/ Ether. Net/IP Weight Processor w/ Ether. Net/IP & Hardy Core Features • Webserver • Waversaver • C 2 Auto Calibration • Integrated Technician 2

Available Hardware to Provide “Weight” Into a PLC Transmitter 4 -20 m. A out Weight Indicator w/ Ether. Net/IP Weight Processor w/ Ether. Net/IP & Hardy Core Features • Webserver • Waversaver • C 2 Auto Calibration • Integrated Technician 2

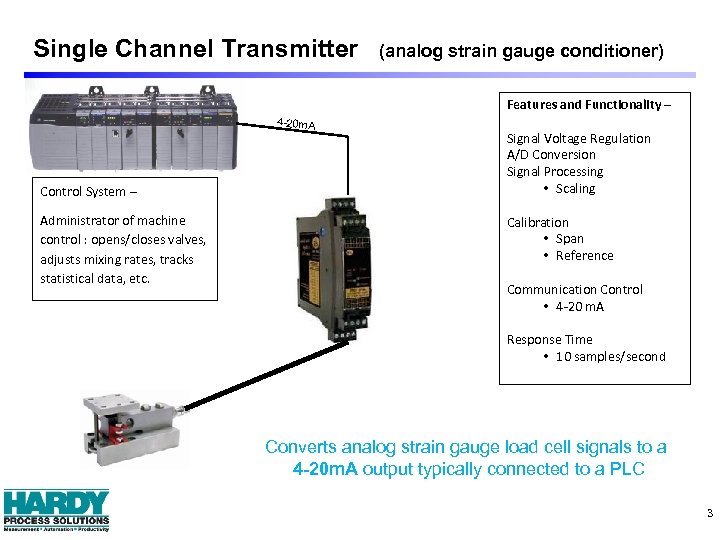

Single Channel Transmitter (analog strain gauge conditioner) Features and Functionality – 4 -20 m. A Control System – Administrator of machine control : opens/closes valves, adjusts mixing rates, tracks statistical data, etc. Signal Voltage Regulation A/D Conversion Signal Processing • Scaling Calibration • Span • Reference Communication Control • 4 -20 m. A Response Time • 10 samples/second Converts analog strain gauge load cell signals to a 4 -20 m. A output typically connected to a PLC 3

Single Channel Transmitter (analog strain gauge conditioner) Features and Functionality – 4 -20 m. A Control System – Administrator of machine control : opens/closes valves, adjusts mixing rates, tracks statistical data, etc. Signal Voltage Regulation A/D Conversion Signal Processing • Scaling Calibration • Span • Reference Communication Control • 4 -20 m. A Response Time • 10 samples/second Converts analog strain gauge load cell signals to a 4 -20 m. A output typically connected to a PLC 3

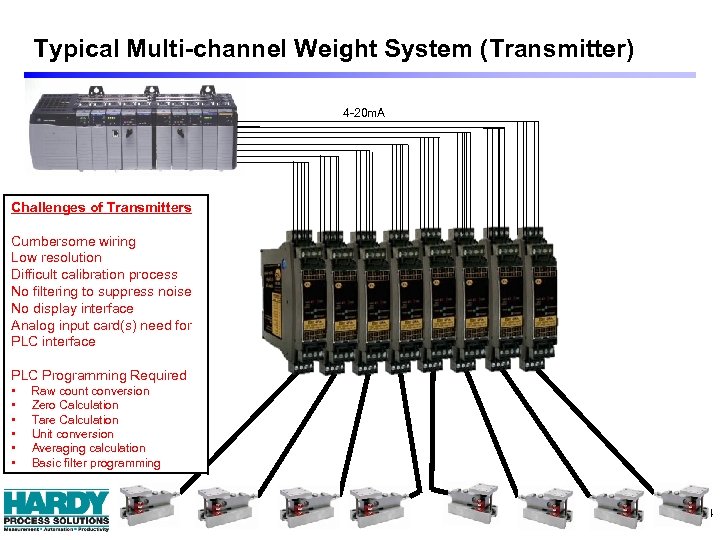

Typical Multi-channel Weight System (Transmitter) 4 -20 m. A Challenges of Transmitters Cumbersome wiring Low resolution Difficult calibration process No filtering to suppress noise No display interface Analog input card(s) need for PLC interface PLC Programming Required • • • Raw count conversion Zero Calculation Tare Calculation Unit conversion Averaging calculation Basic filter programming 4

Typical Multi-channel Weight System (Transmitter) 4 -20 m. A Challenges of Transmitters Cumbersome wiring Low resolution Difficult calibration process No filtering to suppress noise No display interface Analog input card(s) need for PLC interface PLC Programming Required • • • Raw count conversion Zero Calculation Tare Calculation Unit conversion Averaging calculation Basic filter programming 4

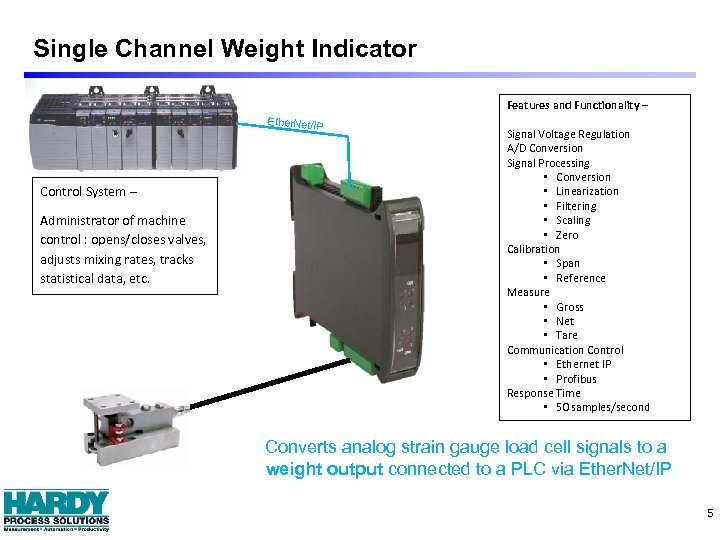

Single Channel Weight Indicator Features and Functionality – Ether. Net/IP Control System – Administrator of machine control : opens/closes valves, adjusts mixing rates, tracks statistical data, etc. Signal Voltage Regulation A/D Conversion Signal Processing • Conversion • Linearization • Filtering • Scaling • Zero Calibration • Span • Reference Measure • Gross • Net • Tare Communication Control • Ethernet IP • Profibus Response Time • 50 samples/second Converts analog strain gauge load cell signals to a weight output connected to a PLC via Ether. Net/IP 5

Single Channel Weight Indicator Features and Functionality – Ether. Net/IP Control System – Administrator of machine control : opens/closes valves, adjusts mixing rates, tracks statistical data, etc. Signal Voltage Regulation A/D Conversion Signal Processing • Conversion • Linearization • Filtering • Scaling • Zero Calibration • Span • Reference Measure • Gross • Net • Tare Communication Control • Ethernet IP • Profibus Response Time • 50 samples/second Converts analog strain gauge load cell signals to a weight output connected to a PLC via Ether. Net/IP 5

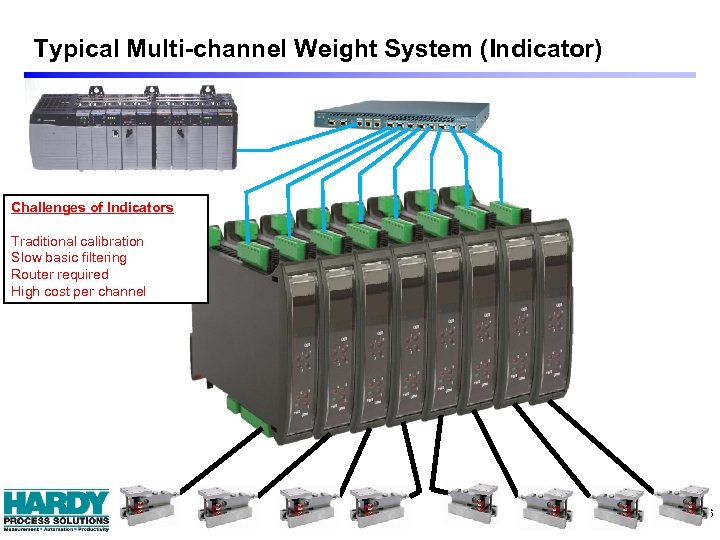

Typical Multi-channel Weight System (Indicator) Challenges of Indicators Traditional calibration Slow basic filtering Router required High cost per channel 6

Typical Multi-channel Weight System (Indicator) Challenges of Indicators Traditional calibration Slow basic filtering Router required High cost per channel 6

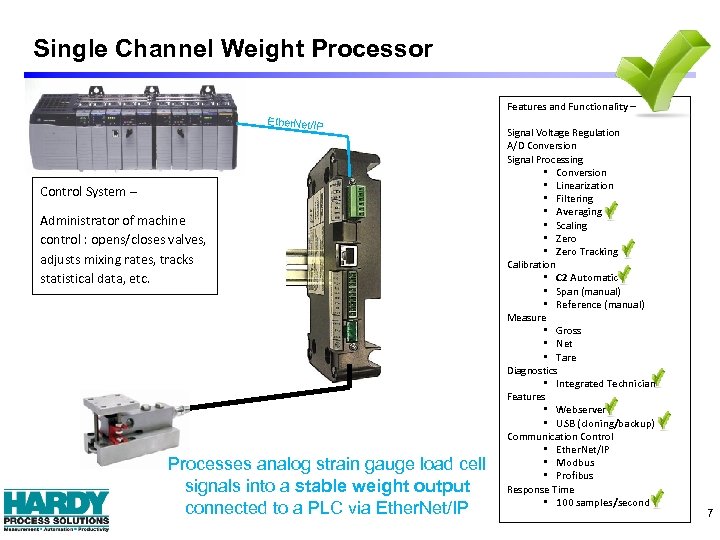

Single Channel Weight Processor Features and Functionality – Ether. Net/IP Control System – Administrator of machine control : opens/closes valves, adjusts mixing rates, tracks statistical data, etc. Processes analog strain gauge load cell signals into a stable weight output connected to a PLC via Ether. Net/IP Signal Voltage Regulation A/D Conversion Signal Processing • Conversion • Linearization • Filtering • Averaging • Scaling • Zero Tracking Calibration • C 2 Automatic • Span (manual) • Reference (manual) Measure • Gross • Net • Tare Diagnostics • Integrated Technician Features • Webserver • USB (cloning/backup) Communication Control • Ether. Net/IP • Modbus • Profibus Response Time • 100 samples/second 7

Single Channel Weight Processor Features and Functionality – Ether. Net/IP Control System – Administrator of machine control : opens/closes valves, adjusts mixing rates, tracks statistical data, etc. Processes analog strain gauge load cell signals into a stable weight output connected to a PLC via Ether. Net/IP Signal Voltage Regulation A/D Conversion Signal Processing • Conversion • Linearization • Filtering • Averaging • Scaling • Zero Tracking Calibration • C 2 Automatic • Span (manual) • Reference (manual) Measure • Gross • Net • Tare Diagnostics • Integrated Technician Features • Webserver • USB (cloning/backup) Communication Control • Ether. Net/IP • Modbus • Profibus Response Time • 100 samples/second 7

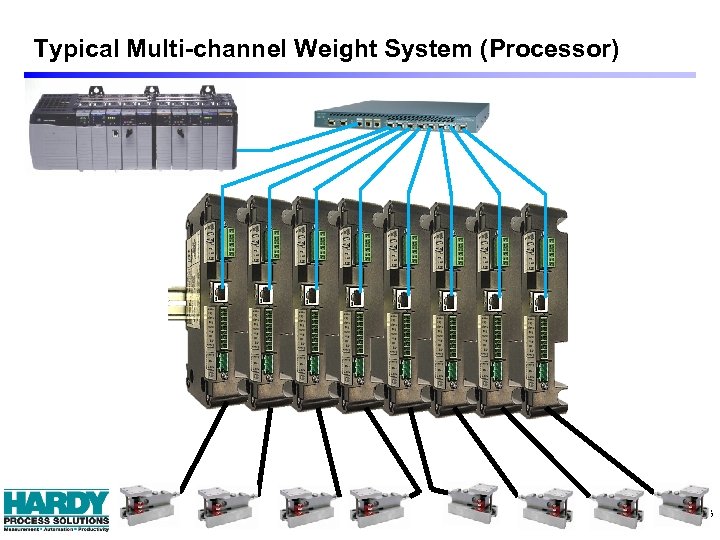

Typical Multi-channel Weight System (Processor) 8

Typical Multi-channel Weight System (Processor) 8

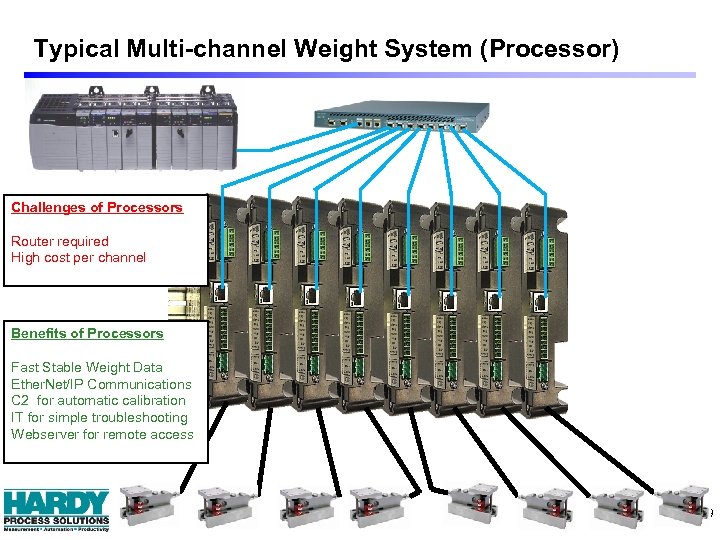

Typical Multi-channel Weight System (Processor) Challenges of Processors Router required High cost per channel Benefits of Processors Fast Stable Weight Data Ether. Net/IP Communications C 2 for automatic calibration IT for simple troubleshooting Webserver for remote access 9

Typical Multi-channel Weight System (Processor) Challenges of Processors Router required High cost per channel Benefits of Processors Fast Stable Weight Data Ether. Net/IP Communications C 2 for automatic calibration IT for simple troubleshooting Webserver for remote access 9

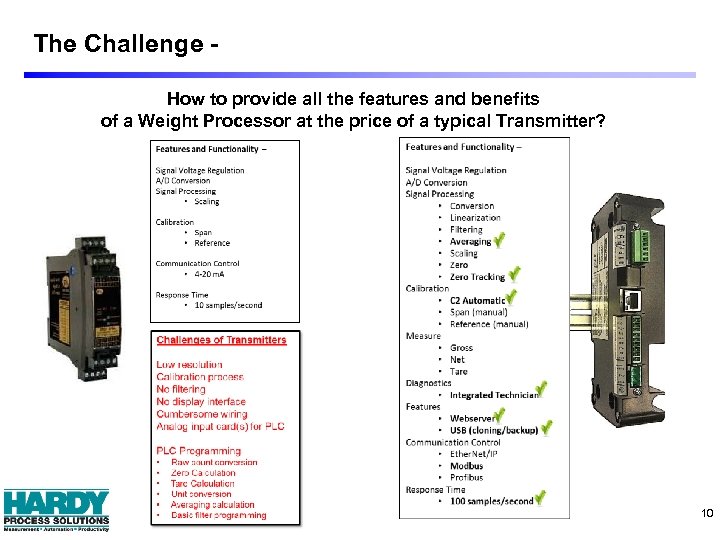

The Challenge - How to provide all the features and benefits of a Weight Processor at the price of a typical Transmitter? 10

The Challenge - How to provide all the features and benefits of a Weight Processor at the price of a typical Transmitter? 10

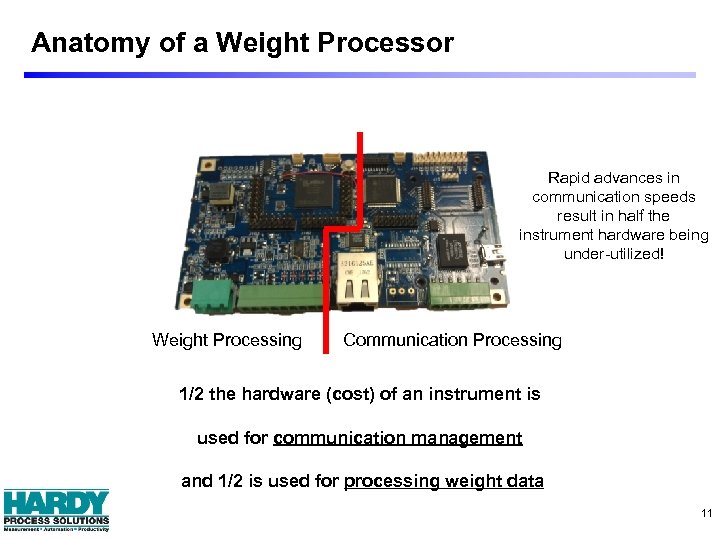

Anatomy of a Weight Processor Rapid advances in communication speeds result in half the instrument hardware being under-utilized! Weight Processing Communication Processing 1/2 the hardware (cost) of an instrument is used for communication management and 1/2 is used for processing weight data 11

Anatomy of a Weight Processor Rapid advances in communication speeds result in half the instrument hardware being under-utilized! Weight Processing Communication Processing 1/2 the hardware (cost) of an instrument is used for communication management and 1/2 is used for processing weight data 11

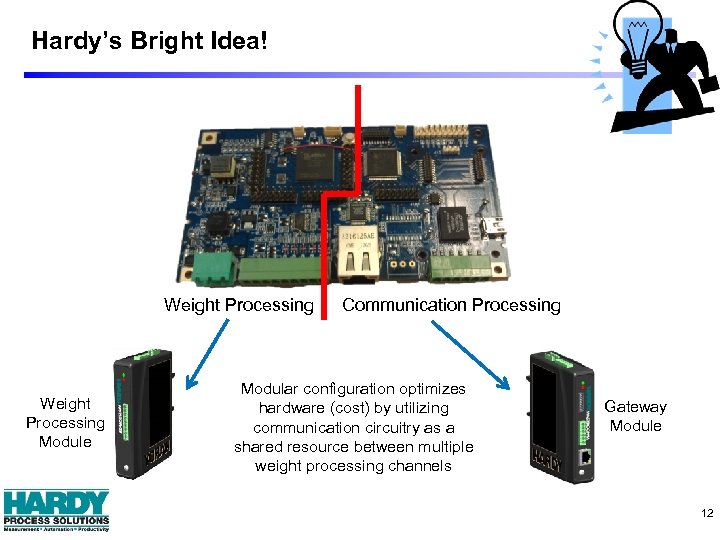

Hardy’s Bright Idea! Weight Processing Module Communication Processing Modular configuration optimizes hardware (cost) by utilizing communication circuitry as a shared resource between multiple weight processing channels Gateway Module 12

Hardy’s Bright Idea! Weight Processing Module Communication Processing Modular configuration optimizes hardware (cost) by utilizing communication circuitry as a shared resource between multiple weight processing channels Gateway Module 12

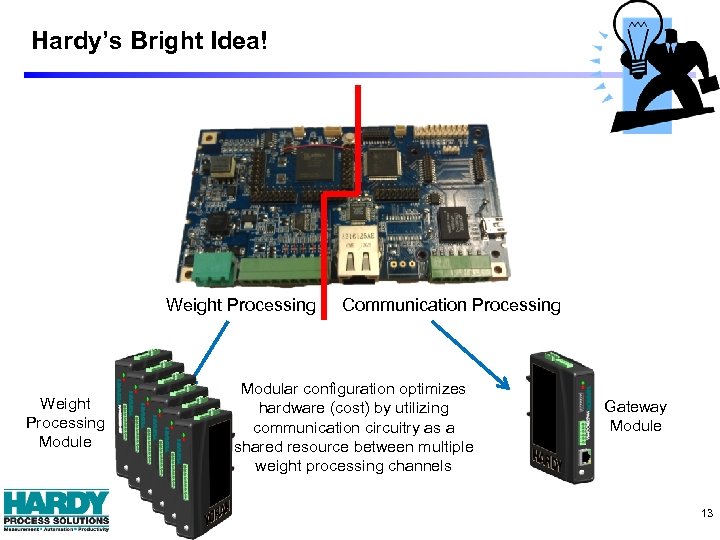

Hardy’s Bright Idea! Weight Processing Module Communication Processing Modular configuration optimizes hardware (cost) by utilizing communication circuitry as a shared resource between multiple weight processing channels Gateway Module 13

Hardy’s Bright Idea! Weight Processing Module Communication Processing Modular configuration optimizes hardware (cost) by utilizing communication circuitry as a shared resource between multiple weight processing channels Gateway Module 13

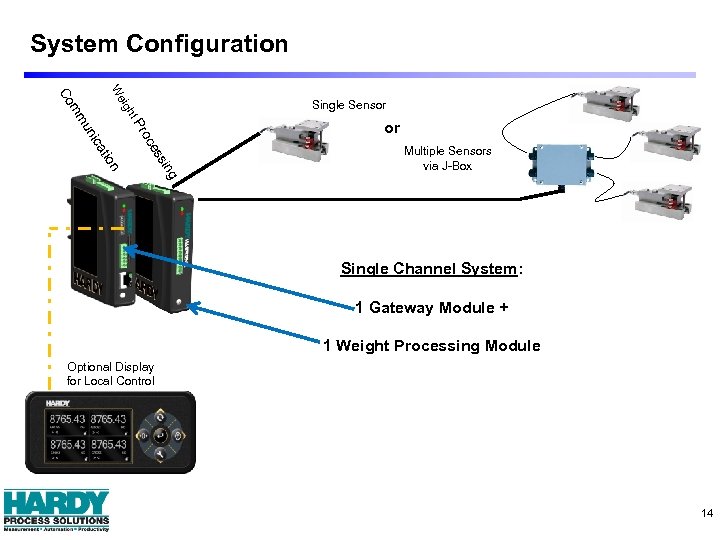

System Configuration W ht or Multiple Sensors via J-Box g sin es oc Pr n tio ica un mm eig Co Single Sensor Single Channel System: 1 Gateway Module + 1 Weight Processing Module Optional Display for Local Control 14

System Configuration W ht or Multiple Sensors via J-Box g sin es oc Pr n tio ica un mm eig Co Single Sensor Single Channel System: 1 Gateway Module + 1 Weight Processing Module Optional Display for Local Control 14

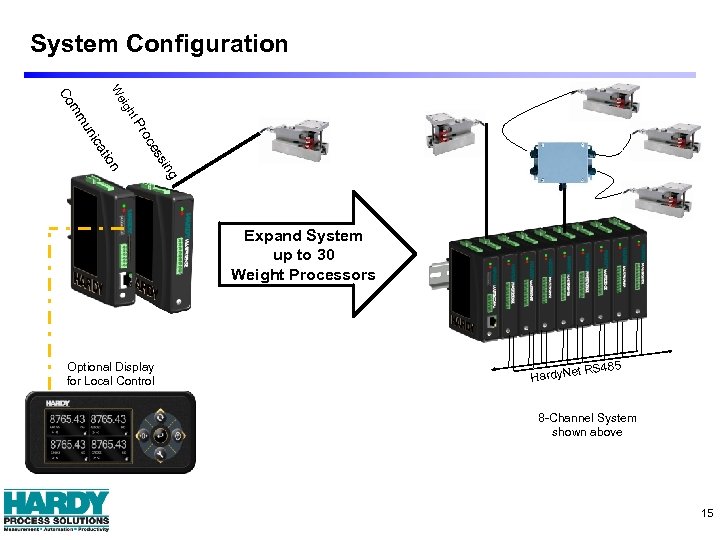

System Configuration W ht g sin es oc Pr n tio ica un mm eig Co Expand System up to 30 Weight Processors Optional Display for Local Control t RS 485 Hardy. Ne 8 -Channel System shown above 15

System Configuration W ht g sin es oc Pr n tio ica un mm eig Co Expand System up to 30 Weight Processors Optional Display for Local Control t RS 485 Hardy. Ne 8 -Channel System shown above 15

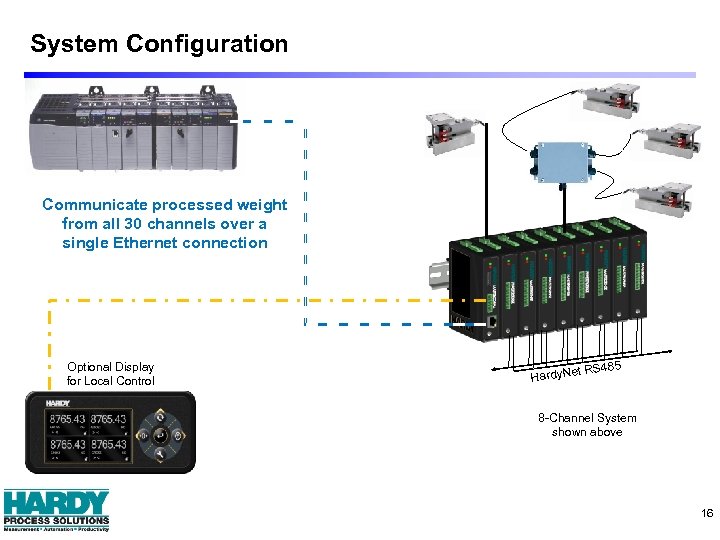

System Configuration Communicate processed weight from all 30 channels over a single Ethernet connection Optional Display for Local Control t RS 485 Hardy. Ne 8 -Channel System shown above 16

System Configuration Communicate processed weight from all 30 channels over a single Ethernet connection Optional Display for Local Control t RS 485 Hardy. Ne 8 -Channel System shown above 16

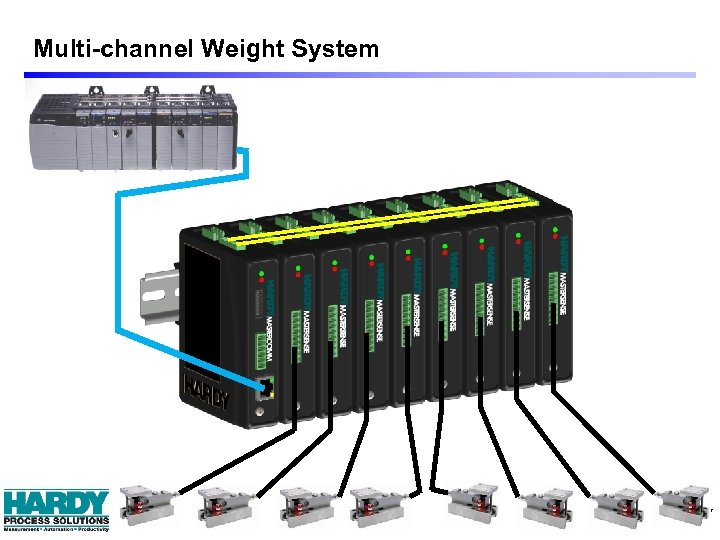

Multi-channel Weight System 17

Multi-channel Weight System 17

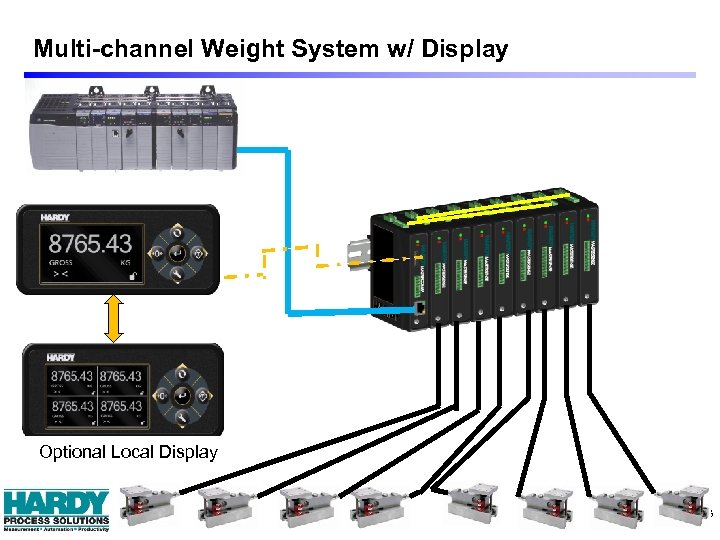

Multi-channel Weight System w/ Display Optional Local Display 18

Multi-channel Weight System w/ Display Optional Local Display 18

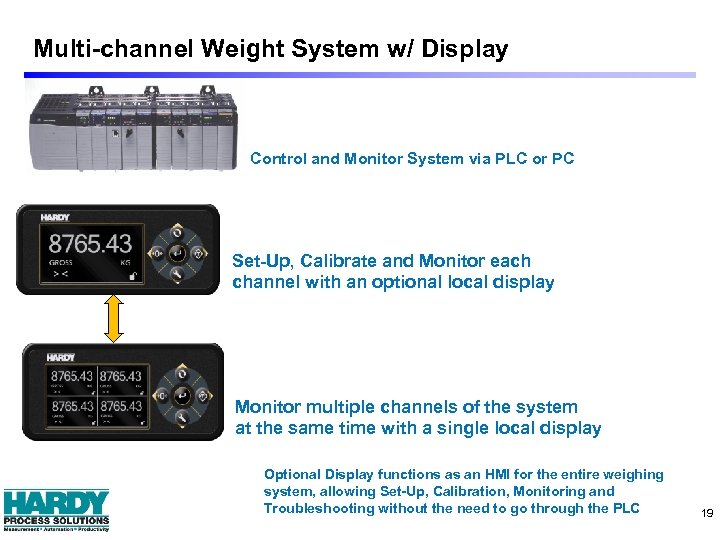

Multi-channel Weight System w/ Display Control and Monitor System via PLC or PC Set-Up, Calibrate and Monitor each channel with an optional local display Monitor multiple channels of the system at the same time with a single local display Optional Display functions as an HMI for the entire weighing system, allowing Set-Up, Calibration, Monitoring and Troubleshooting without the need to go through the PLC 19

Multi-channel Weight System w/ Display Control and Monitor System via PLC or PC Set-Up, Calibrate and Monitor each channel with an optional local display Monitor multiple channels of the system at the same time with a single local display Optional Display functions as an HMI for the entire weighing system, allowing Set-Up, Calibration, Monitoring and Troubleshooting without the need to go through the PLC 19

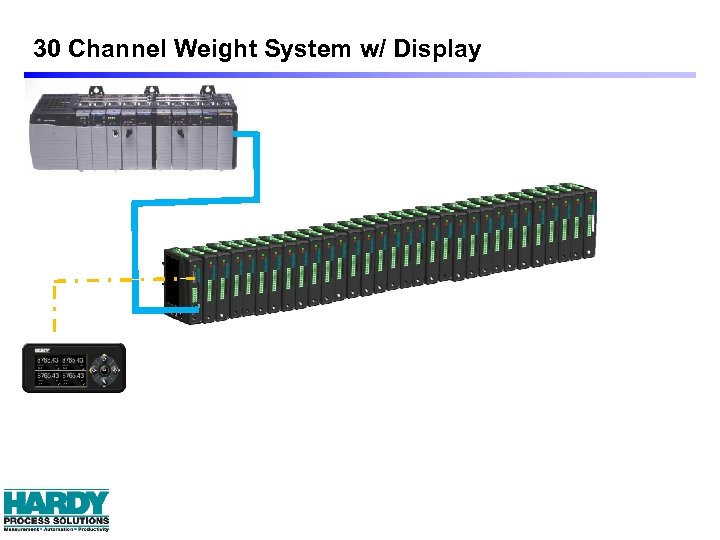

30 Channel Weight System w/ Display

30 Channel Weight System w/ Display

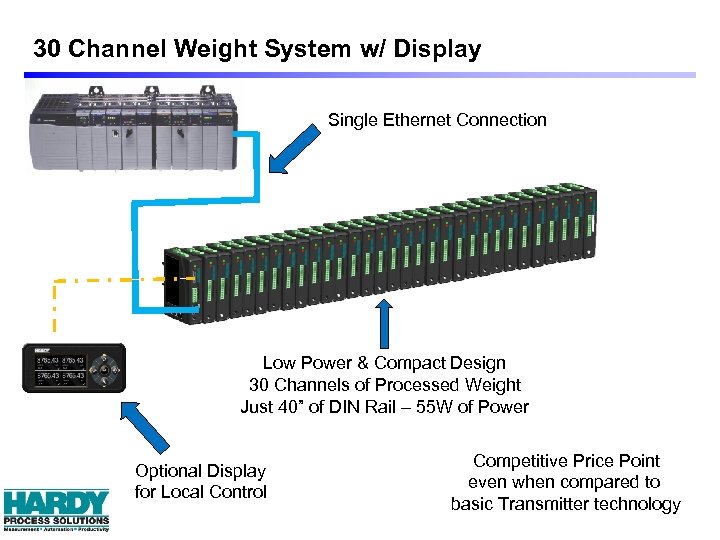

30 Channel Weight System w/ Display Single Ethernet Connection Low Power & Compact Design 30 Channels of Processed Weight Just 40” of DIN Rail – 55 W of Power Optional Display for Local Control Competitive Price Point even when compared to basic Transmitter technology

30 Channel Weight System w/ Display Single Ethernet Connection Low Power & Compact Design 30 Channels of Processed Weight Just 40” of DIN Rail – 55 W of Power Optional Display for Local Control Competitive Price Point even when compared to basic Transmitter technology

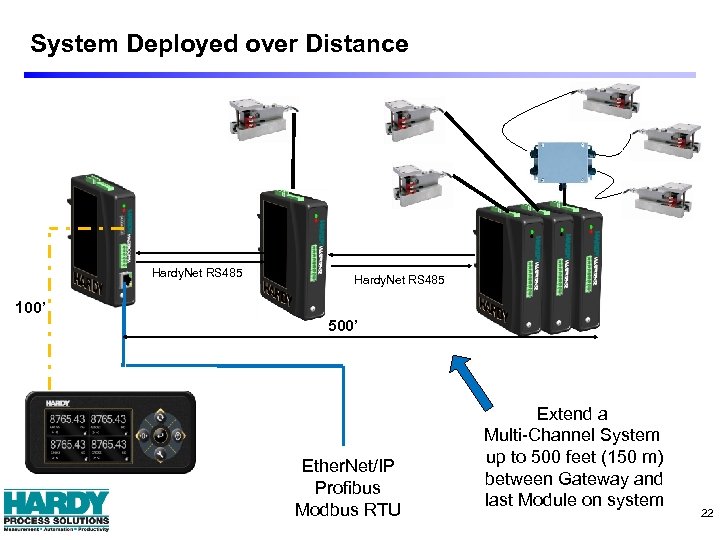

System Deployed over Distance Hardy. Net RS 485 100’ 500’ Ether. Net/IP Profibus Modbus RTU Extend a Multi-Channel System up to 500 feet (150 m) between Gateway and last Module on system 22

System Deployed over Distance Hardy. Net RS 485 100’ 500’ Ether. Net/IP Profibus Modbus RTU Extend a Multi-Channel System up to 500 feet (150 m) between Gateway and last Module on system 22

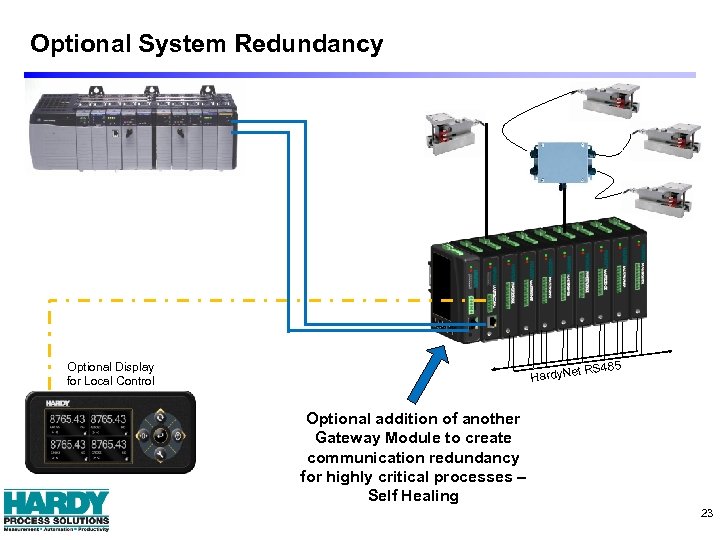

Optional System Redundancy t RS 485 Optional Display for Local Control Hardy. Ne Optional addition of another Gateway Module to create communication redundancy for highly critical processes – Self Healing 23

Optional System Redundancy t RS 485 Optional Display for Local Control Hardy. Ne Optional addition of another Gateway Module to create communication redundancy for highly critical processes – Self Healing 23

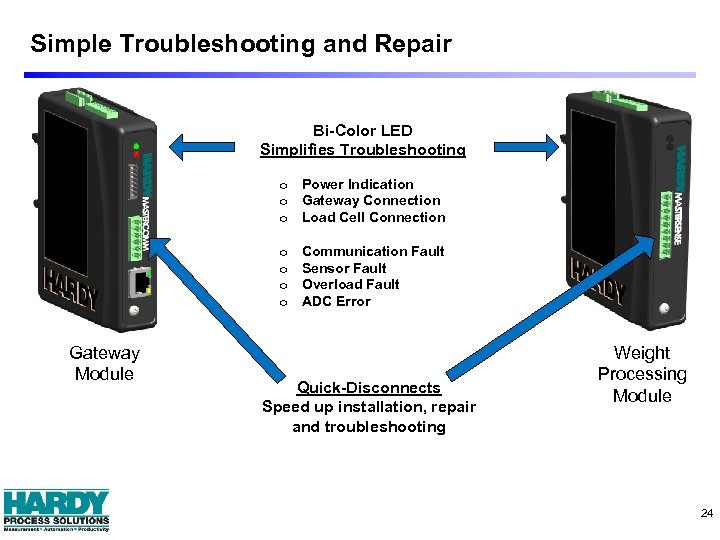

Simple Troubleshooting and Repair Bi-Color LED Simplifies Troubleshooting o Power Indication o Gateway Connection o Load Cell Connection o o Gateway Module Communication Fault Sensor Fault Overload Fault ADC Error Quick-Disconnects Speed up installation, repair and troubleshooting Weight Processing Module 24

Simple Troubleshooting and Repair Bi-Color LED Simplifies Troubleshooting o Power Indication o Gateway Connection o Load Cell Connection o o Gateway Module Communication Fault Sensor Fault Overload Fault ADC Error Quick-Disconnects Speed up installation, repair and troubleshooting Weight Processing Module 24

Where to Use? Stock • Tank Farms • Multiple Feedstock Vessels Make • Batching Systems • Small Ingredient Mixing Pack • Multi-Head Filling Machinery Ship • Dock Scales • Check Points Anywhere multiple channels of Weight are Required

Where to Use? Stock • Tank Farms • Multiple Feedstock Vessels Make • Batching Systems • Small Ingredient Mixing Pack • Multi-Head Filling Machinery Ship • Dock Scales • Check Points Anywhere multiple channels of Weight are Required

We believe that industrial weighing solutions should be EASY to engineer and operate. We believe that simplicity delivers the LOWEST TOTAL COST to own. That’s why our solutions are EASIER to install, integrate, commission, diagnose and maintain. Want MORE PRODUCTIVITY at the LEAST TOTAL COST to own? Call Hardy to discover how Today! 26

We believe that industrial weighing solutions should be EASY to engineer and operate. We believe that simplicity delivers the LOWEST TOTAL COST to own. That’s why our solutions are EASIER to install, integrate, commission, diagnose and maintain. Want MORE PRODUCTIVITY at the LEAST TOTAL COST to own? Call Hardy to discover how Today! 26