d0e8b68a8f001312c7aad7af44258027.ppt

- Количество слайдов: 30

Hall C Meeting SHMS Magnets and Support Structure Design and Procurement Status Paul Brindza January 26, 2009

Hall C Meeting SHMS Magnets and Support Structure Design and Procurement Status Paul Brindza January 26, 2009

SHMS Magnets and Support Structure • • • SHMS Spectrometer and Magnets SC Magnet Procurement Status SHMS Magnet Recent Progress SHMS Support Structure Conclusions

SHMS Magnets and Support Structure • • • SHMS Spectrometer and Magnets SC Magnet Procurement Status SHMS Magnet Recent Progress SHMS Support Structure Conclusions

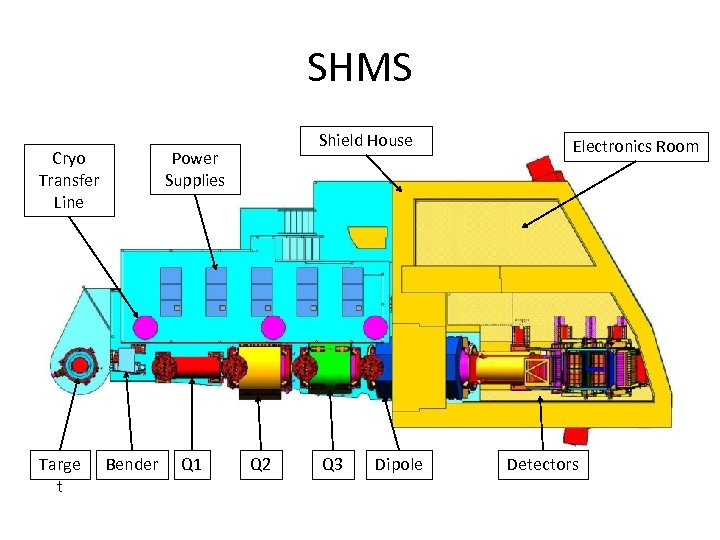

SHMS Cryo Transfer Line Targe t Shield House Power Supplies Bender Q 1 Q 2 Q 3 Dipole Electronics Room Detectors

SHMS Cryo Transfer Line Targe t Shield House Power Supplies Bender Q 1 Q 2 Q 3 Dipole Electronics Room Detectors

SHMS Q 1 Quadrupole Assembly JLAB Cold Iron Quad Design (CIQ) SHMS Q 3 Cosine 2Θ Quadrupole Assembly 60 cm warm bore cryo-stable design SHMS Horizontal Bend Dipole Warm Iron SC “C” Magnet SHMS Cosine Θ Dipole Assembly 60 cm warm bore- cryo-stable design

SHMS Q 1 Quadrupole Assembly JLAB Cold Iron Quad Design (CIQ) SHMS Q 3 Cosine 2Θ Quadrupole Assembly 60 cm warm bore cryo-stable design SHMS Horizontal Bend Dipole Warm Iron SC “C” Magnet SHMS Cosine Θ Dipole Assembly 60 cm warm bore- cryo-stable design

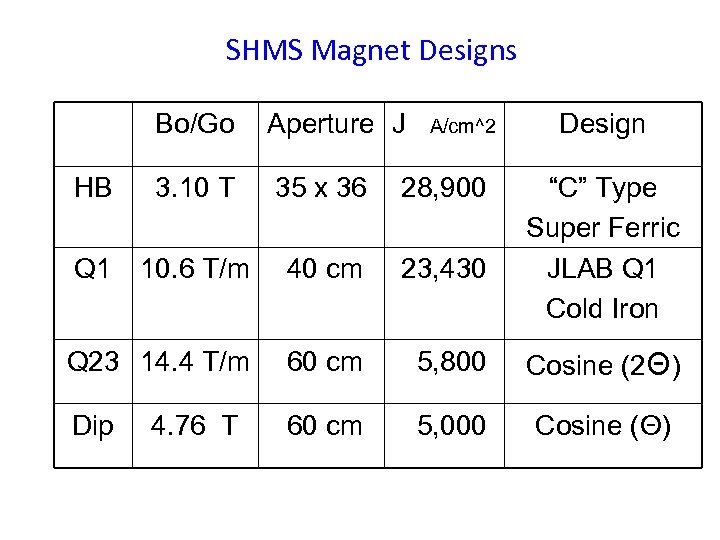

SHMS Magnet Designs Bo/Go Aperture J HB 3. 10 T 35 x 36 28, 900 Q 1 10. 6 T/m 40 cm 23, 430 Q 23 14. 4 T/m 60 cm 5, 800 Cosine (2Θ) Dip 60 cm 5, 000 Cosine (Θ) 4. 76 T A/cm^2 Design “C” Type Super Ferric JLAB Q 1 Cold Iron

SHMS Magnet Designs Bo/Go Aperture J HB 3. 10 T 35 x 36 28, 900 Q 1 10. 6 T/m 40 cm 23, 430 Q 23 14. 4 T/m 60 cm 5, 800 Cosine (2Θ) Dip 60 cm 5, 000 Cosine (Θ) 4. 76 T A/cm^2 Design “C” Type Super Ferric JLAB Q 1 Cold Iron

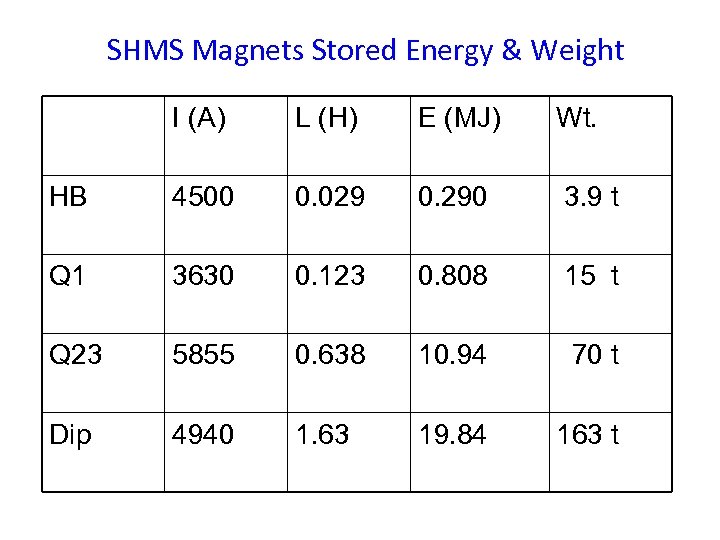

SHMS Magnets Stored Energy & Weight I (A) L (H) E (MJ) Wt. HB 4500 0. 029 0. 290 3. 9 t Q 1 3630 0. 123 0. 808 15 t Q 23 5855 0. 638 10. 94 70 t Dip 4940 1. 63 19. 84 163 t

SHMS Magnets Stored Energy & Weight I (A) L (H) E (MJ) Wt. HB 4500 0. 029 0. 290 3. 9 t Q 1 3630 0. 123 0. 808 15 t Q 23 5855 0. 638 10. 94 70 t Dip 4940 1. 63 19. 84 163 t

SHMS Requirements from Optics and SC Magnet Design Margin Magnet HB dipole TM Q 1 Quad (T/M)M Q 2 Quad (T/M)M Q 3 Quad (T/M)M Dipole TM Optics at 11 Ge. V/c Design Maximum Design Margin 1. 929 2. 345 17. 7% 14. 752 19. 905 25. 9% 19. 429 23. 210 16. 3% 12. 917 23. 210 44. 3% 11. 189 13. 591 17. 7%

SHMS Requirements from Optics and SC Magnet Design Margin Magnet HB dipole TM Q 1 Quad (T/M)M Q 2 Quad (T/M)M Q 3 Quad (T/M)M Dipole TM Optics at 11 Ge. V/c Design Maximum Design Margin 1. 929 2. 345 17. 7% 14. 752 19. 905 25. 9% 19. 429 23. 210 16. 3% 12. 917 23. 210 44. 3% 11. 189 13. 591 17. 7%

SHMS SC Magnet Procurement Strategy • SC Magnets will be built by contractors • In a significant departure from HMS we will provide major SC magnet components – – – Superconductor (SSC surplus) Cryo-Control Reservoir( same as HMS Design) DC Power System( same as HMS) Magnet Control System( Same as HMS) Warm Yoke Steel

SHMS SC Magnet Procurement Strategy • SC Magnets will be built by contractors • In a significant departure from HMS we will provide major SC magnet components – – – Superconductor (SSC surplus) Cryo-Control Reservoir( same as HMS Design) DC Power System( same as HMS) Magnet Control System( Same as HMS) Warm Yoke Steel

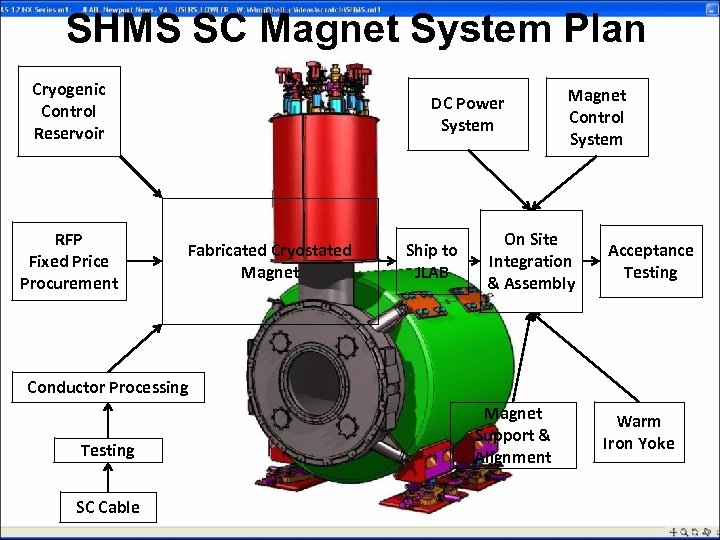

SHMS SC Magnet System Plan Cryogenic Control Reservoir RFP Fixed Price Procurement DC Power System Fabricated Cryostated Magnet Ship to JLAB Magnet Control System On Site Integration & Assembly Acceptance Testing Conductor Processing Testing SC Cable Magnet Support & Alignment Warm Iron Yoke

SHMS SC Magnet System Plan Cryogenic Control Reservoir RFP Fixed Price Procurement DC Power System Fabricated Cryostated Magnet Ship to JLAB Magnet Control System On Site Integration & Assembly Acceptance Testing Conductor Processing Testing SC Cable Magnet Support & Alignment Warm Iron Yoke

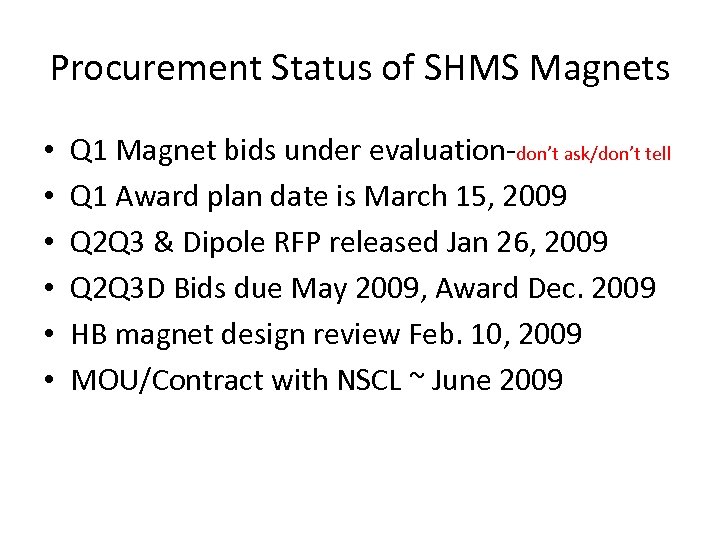

Procurement Status of SHMS Magnets • • • Q 1 Magnet bids under evaluation-don’t ask/don’t tell Q 1 Award plan date is March 15, 2009 Q 2 Q 3 & Dipole RFP released Jan 26, 2009 Q 2 Q 3 D Bids due May 2009, Award Dec. 2009 HB magnet design review Feb. 10, 2009 MOU/Contract with NSCL ~ June 2009

Procurement Status of SHMS Magnets • • • Q 1 Magnet bids under evaluation-don’t ask/don’t tell Q 1 Award plan date is March 15, 2009 Q 2 Q 3 & Dipole RFP released Jan 26, 2009 Q 2 Q 3 D Bids due May 2009, Award Dec. 2009 HB magnet design review Feb. 10, 2009 MOU/Contract with NSCL ~ June 2009

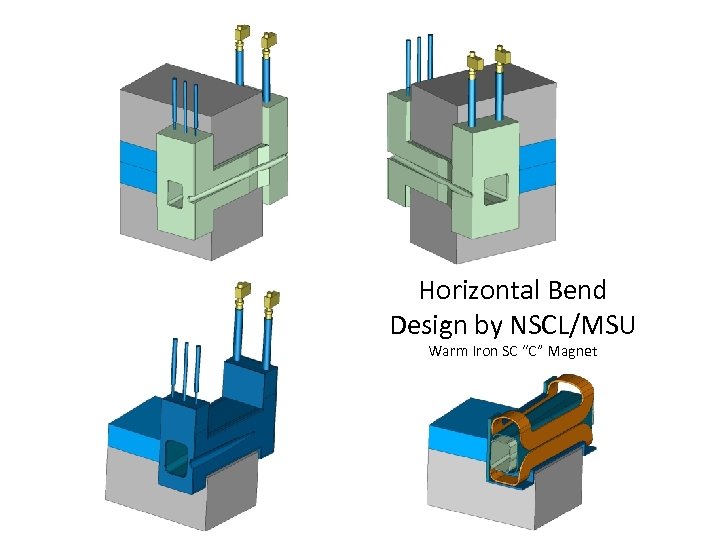

Horizontal Bend Design by NSCL/MSU Warm Iron SC “C” Magnet

Horizontal Bend Design by NSCL/MSU Warm Iron SC “C” Magnet

HB Coil Drawing and 3 D CAD of Winding Tooling

HB Coil Drawing and 3 D CAD of Winding Tooling

HB Coil Winding Tooling

HB Coil Winding Tooling

1 st Full HB Coil – 90 Turns

1 st Full HB Coil – 90 Turns

Q 1 Quad 3 D CAD Model Cold Iron Quad Design like HMS Q 1 Bids are IN!!

Q 1 Quad 3 D CAD Model Cold Iron Quad Design like HMS Q 1 Bids are IN!!

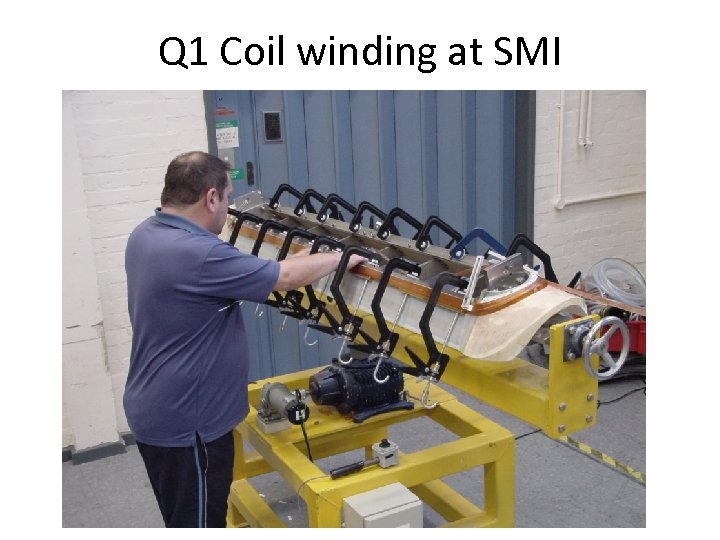

Q 1 Coil winding at SMI

Q 1 Coil winding at SMI

First Phase II Q 1 Coil

First Phase II Q 1 Coil

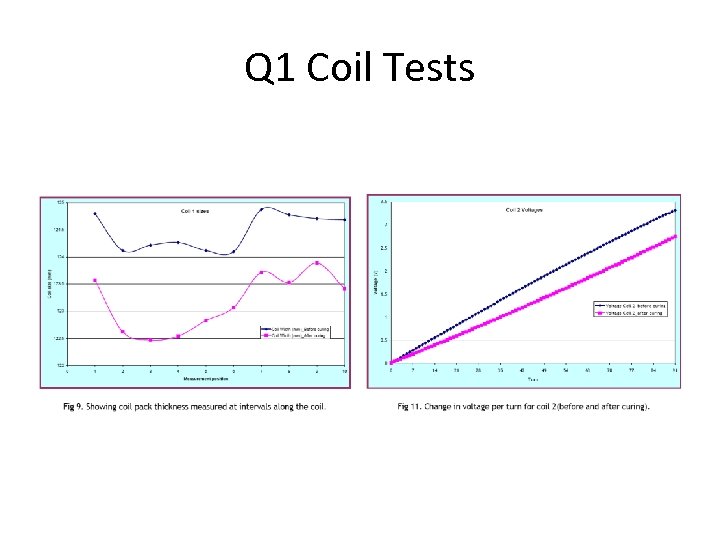

Q 1 Coil Tests

Q 1 Coil Tests

SHMS Support Structure

SHMS Support Structure

Mechanical Requirements • • SHMS Minimum Scattering Angle 5. 5 degrees SHMS-HMS angle 5. 5+12 = 17. 5 degrees HMS Minimum Angle (present) 10. 5 degrees SHMS Max angle 40 degrees HMS Max Angle(present ) 85 degrees Hall C Radius at SHMS max 73 feet Fit to beam pipe at 5. 5 degrees ~ 5 mm Fit to HMS at 17. 5 degrees ~ 1 cm

Mechanical Requirements • • SHMS Minimum Scattering Angle 5. 5 degrees SHMS-HMS angle 5. 5+12 = 17. 5 degrees HMS Minimum Angle (present) 10. 5 degrees SHMS Max angle 40 degrees HMS Max Angle(present ) 85 degrees Hall C Radius at SHMS max 73 feet Fit to beam pipe at 5. 5 degrees ~ 5 mm Fit to HMS at 17. 5 degrees ~ 1 cm

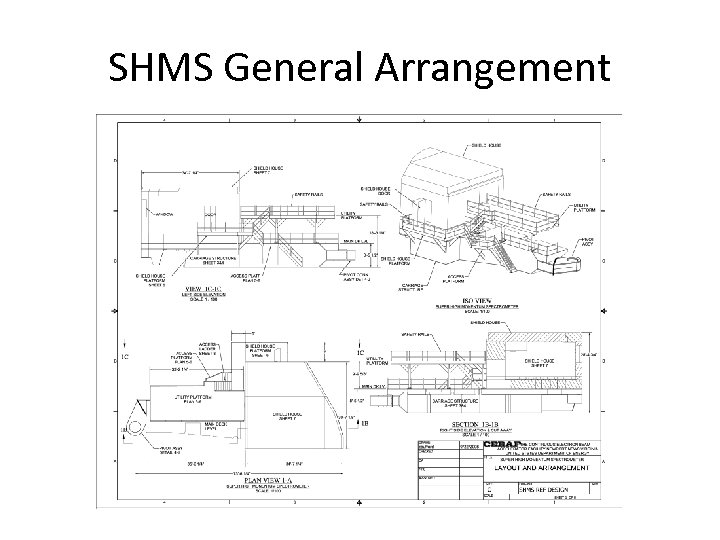

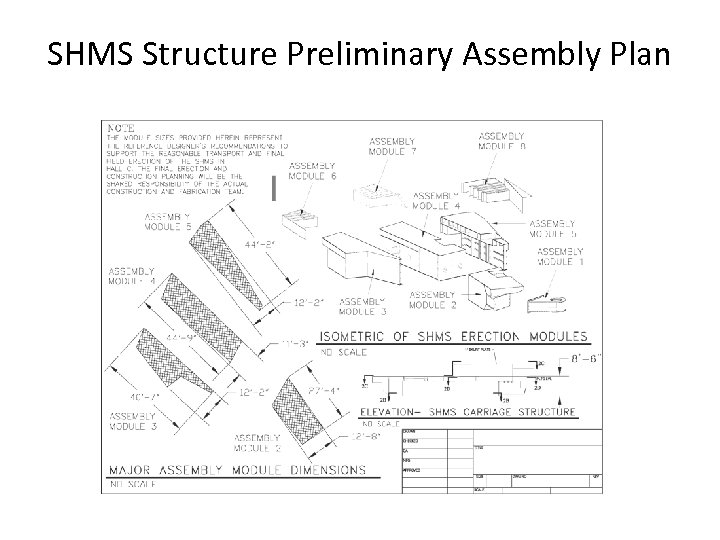

SHMS Support Structure Reference Design • SHMS Support Structure Preliminary Design completed in 2007 by ALION, a local company with experience in large welded steel structures • SHMS Support Structure Reference Design(RD) Completed by ALION January 28, 2009 • RD will be the technical elements for the bid packages for the SHMS support structure. • SHMS Support Structure RD review was held in December 08 at JLAB

SHMS Support Structure Reference Design • SHMS Support Structure Preliminary Design completed in 2007 by ALION, a local company with experience in large welded steel structures • SHMS Support Structure Reference Design(RD) Completed by ALION January 28, 2009 • RD will be the technical elements for the bid packages for the SHMS support structure. • SHMS Support Structure RD review was held in December 08 at JLAB

SHMS General Arrangement

SHMS General Arrangement

SHMS Support Cross Sections

SHMS Support Cross Sections

SHMS Structure Preliminary Assembly Plan

SHMS Structure Preliminary Assembly Plan

Top View SHMS & HMS Spectrometers Dipole Q 3 Q 1 Q 2 Bender Beamline Target HMS Spectrometer

Top View SHMS & HMS Spectrometers Dipole Q 3 Q 1 Q 2 Bender Beamline Target HMS Spectrometer

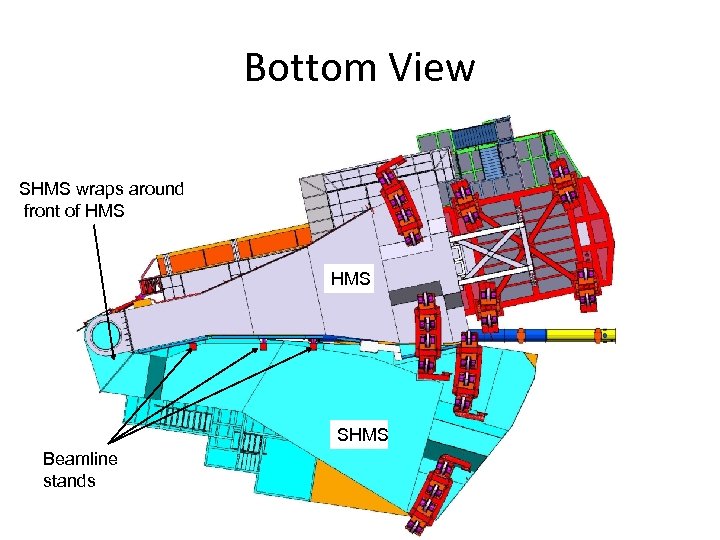

Bottom View SHMS wraps around front of HMS SHMS Beamline stands

Bottom View SHMS wraps around front of HMS SHMS Beamline stands

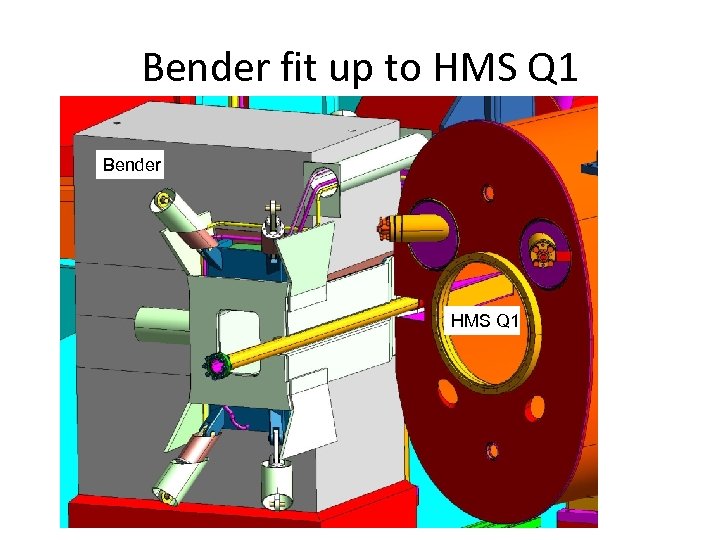

Bender fit up to HMS Q 1 Bender HMS Q 1

Bender fit up to HMS Q 1 Bender HMS Q 1

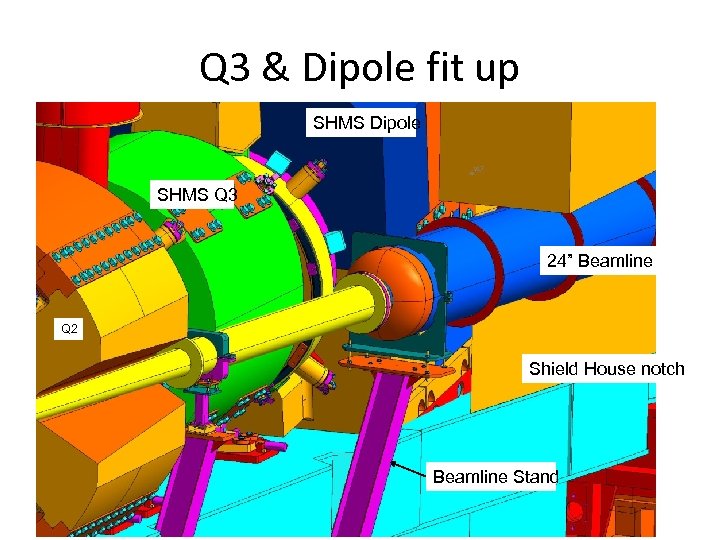

Q 3 & Dipole fit up SHMS Dipole SHMS Q 3 24” Beamline Q 2 Shield House notch Beamline Stand

Q 3 & Dipole fit up SHMS Dipole SHMS Q 3 24” Beamline Q 2 Shield House notch Beamline Stand

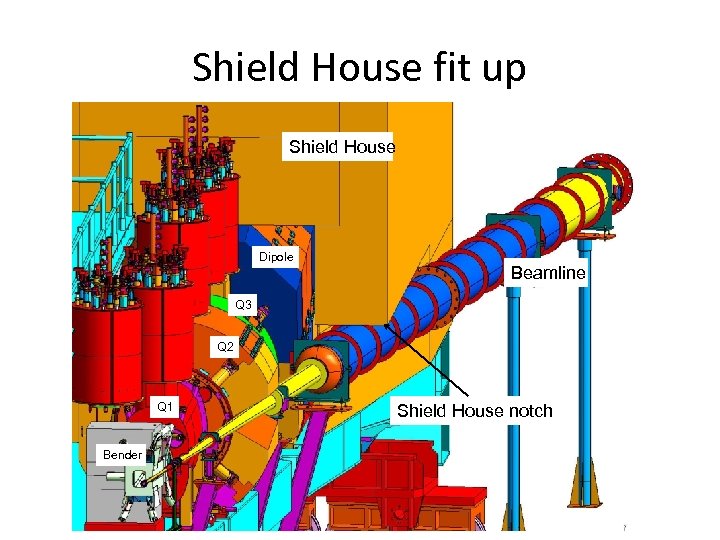

Shield House fit up Shield House Dipole Beamline Q 3 Q 2 Q 1 Bender Shield House notch

Shield House fit up Shield House Dipole Beamline Q 3 Q 2 Q 1 Bender Shield House notch

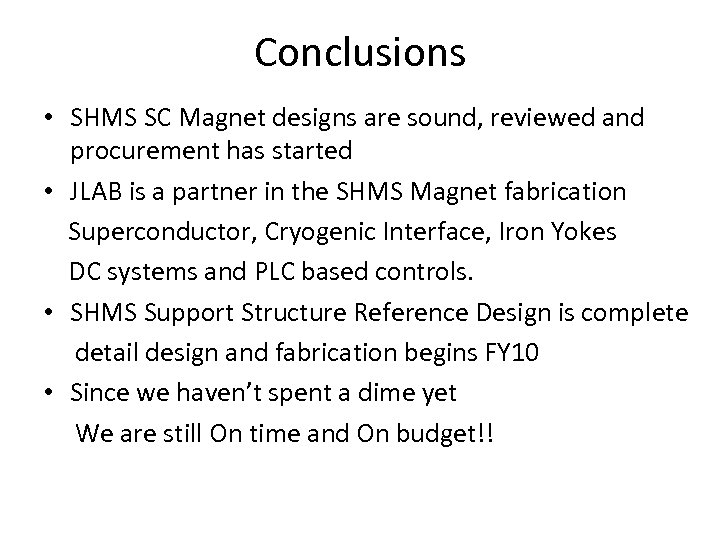

Conclusions • SHMS SC Magnet designs are sound, reviewed and procurement has started • JLAB is a partner in the SHMS Magnet fabrication Superconductor, Cryogenic Interface, Iron Yokes DC systems and PLC based controls. • SHMS Support Structure Reference Design is complete detail design and fabrication begins FY 10 • Since we haven’t spent a dime yet We are still On time and On budget!!

Conclusions • SHMS SC Magnet designs are sound, reviewed and procurement has started • JLAB is a partner in the SHMS Magnet fabrication Superconductor, Cryogenic Interface, Iron Yokes DC systems and PLC based controls. • SHMS Support Structure Reference Design is complete detail design and fabrication begins FY 10 • Since we haven’t spent a dime yet We are still On time and On budget!!