a3f9d26dd5250650b6e0def94e6d8ea7.ppt

- Количество слайдов: 42

HALE UAV Preliminary Design SAURON AERSP 402 B Spring 2014 Team: NSFW Nisherag Gandhi Thomas Gempp Doug Rohrbaugh Gregory Snyder Steve Stanek Victor Thomas

Mission Statement To design a High Altitude / Long Endurance (HALE) UAV using alternative fuel sources to support homeland security efforts with a concentration in long term border security.

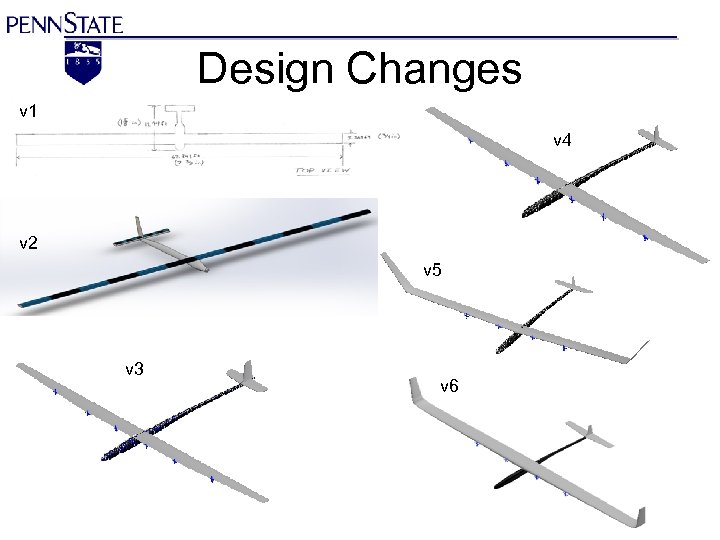

Design Changes v 1 v 4 v 2 v 5 v 3 v 6

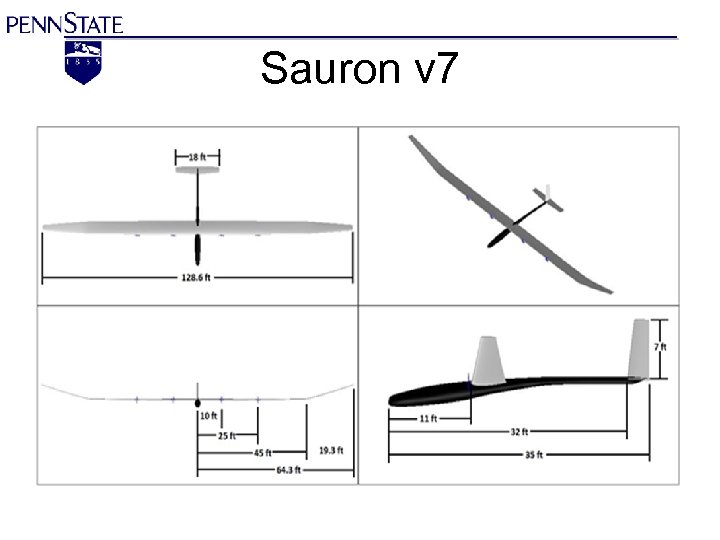

Sauron v 7

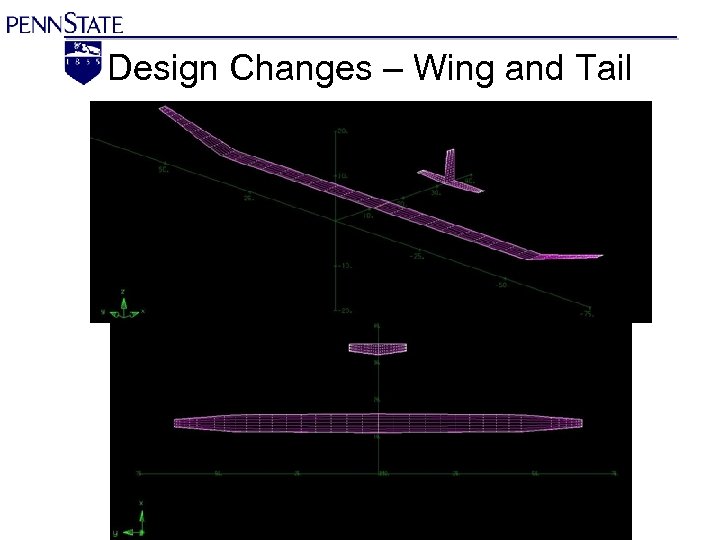

Design Changes – Wing and Tail

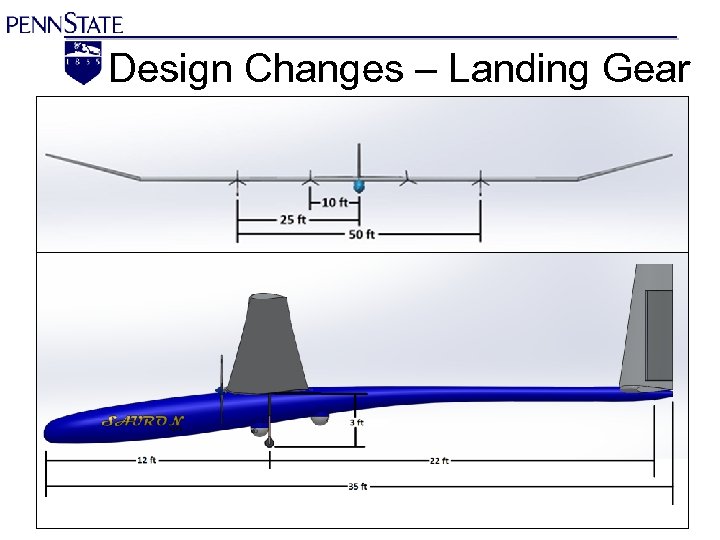

Design Changes – Landing Gear

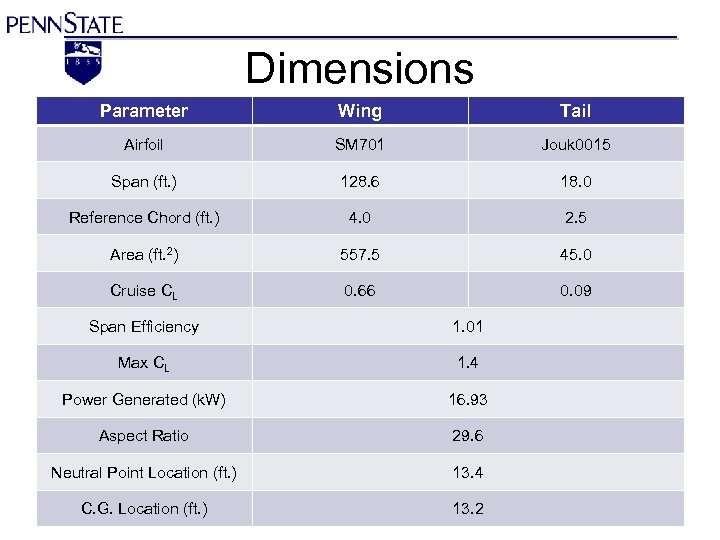

Dimensions Parameter Wing Tail Airfoil SM 701 Jouk 0015 Span (ft. ) 128. 6 18. 0 Reference Chord (ft. ) 4. 0 2. 5 Area (ft. 2) 557. 5 45. 0 Cruise CL 0. 66 0. 09 Span Efficiency 1. 01 Max CL 1. 4 Power Generated (k. W) 16. 93 Aspect Ratio 29. 6 Neutral Point Location (ft. ) 13. 4 C. G. Location (ft. ) 13. 2

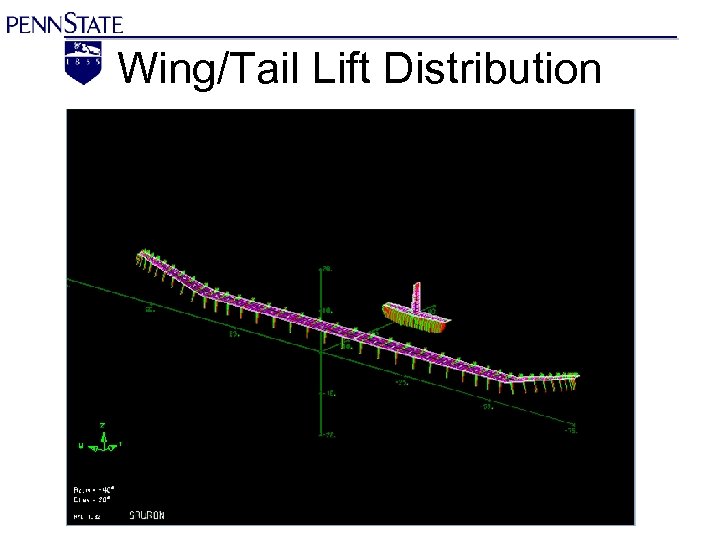

Wing/Tail Lift Distribution

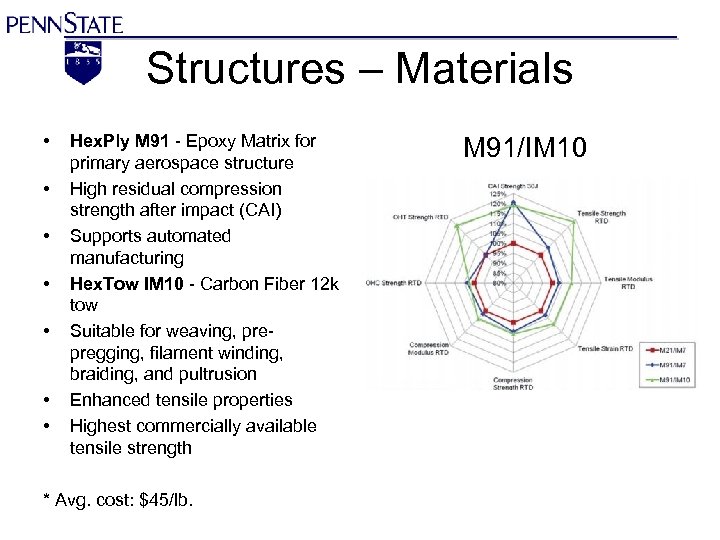

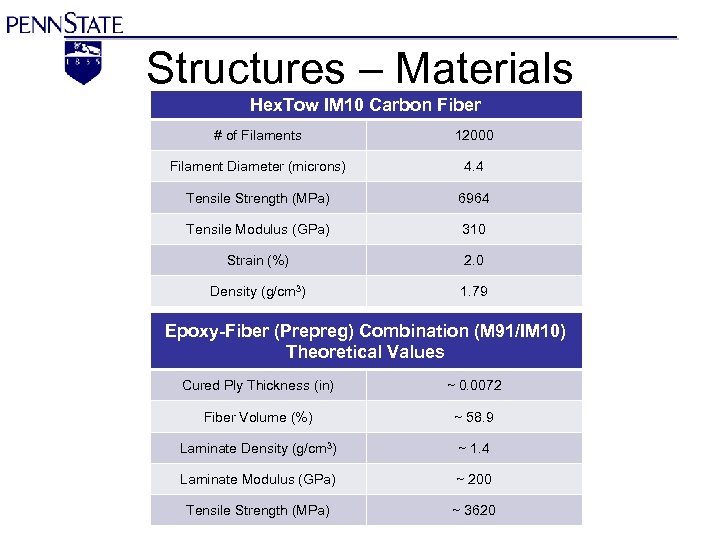

Structures – Materials • • Hex. Ply M 91 - Epoxy Matrix for primary aerospace structure High residual compression strength after impact (CAI) Supports automated manufacturing Hex. Tow IM 10 - Carbon Fiber 12 k tow Suitable for weaving, prepregging, filament winding, braiding, and pultrusion Enhanced tensile properties Highest commercially available tensile strength * Avg. cost: $45/lb. M 91/IM 10

Structures – Materials Hex. Tow IM 10 Carbon Fiber # of Filaments 12000 Filament Diameter (microns) 4. 4 Tensile Strength (MPa) 6964 Tensile Modulus (GPa) 310 Strain (%) 2. 0 Density (g/cm 3) 1. 79 Epoxy-Fiber (Prepreg) Combination (M 91/IM 10) Theoretical Values Cured Ply Thickness (in) ~ 0. 0072 Fiber Volume (%) ~ 58. 9 Laminate Density (g/cm 3) ~ 1. 4 Laminate Modulus (GPa) ~ 200 Tensile Strength (MPa) ~ 3620

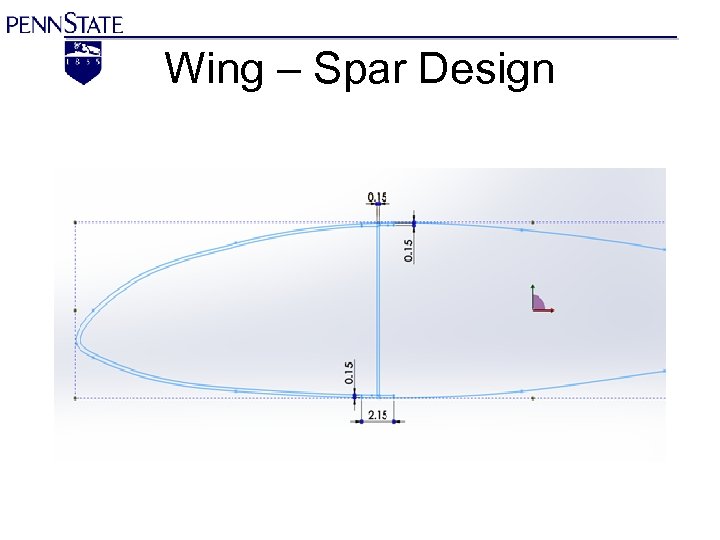

Wing – Spar Design

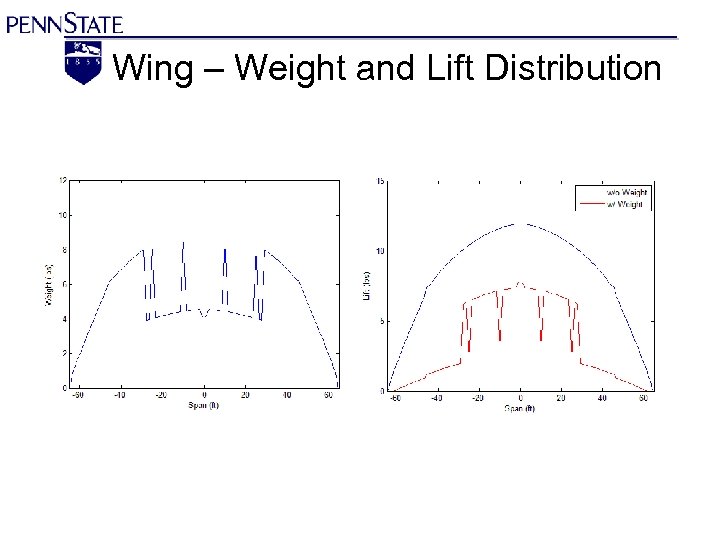

Wing – Weight and Lift Distribution

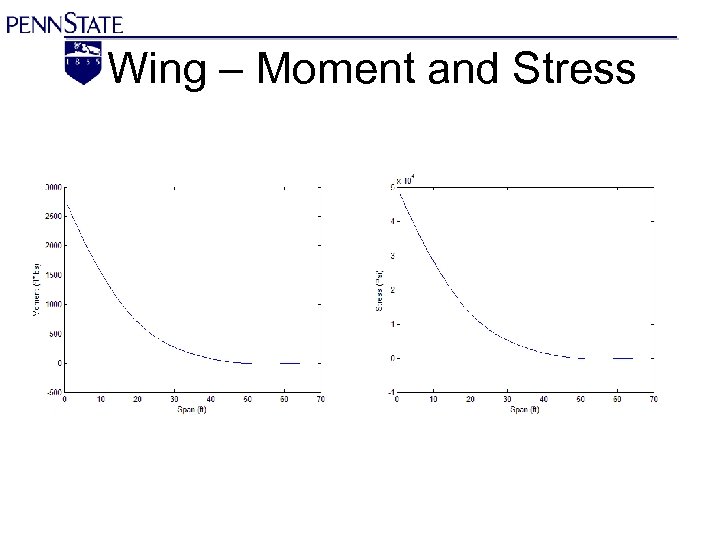

Wing – Moment and Stress

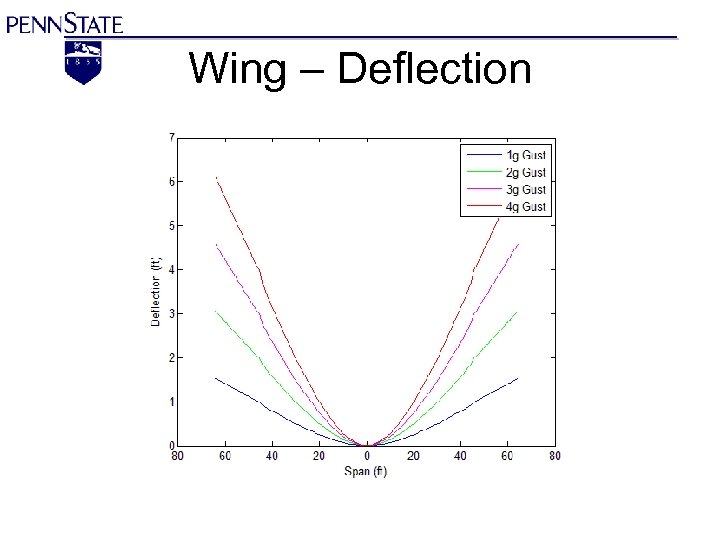

Wing – Deflection

Wing Deflection Analysis

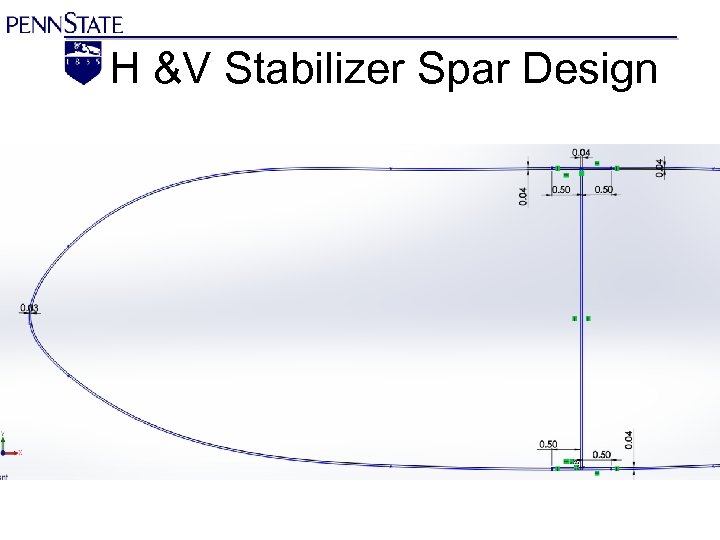

H &V Stabilizer Spar Design

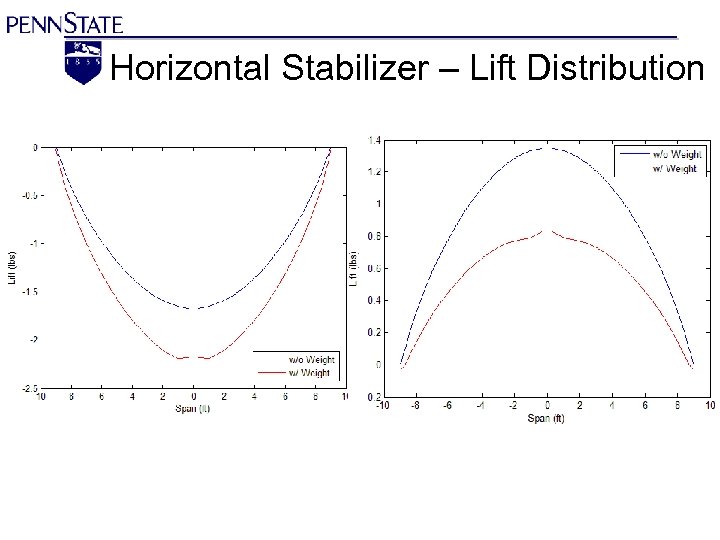

Horizontal Stabilizer – Lift Distribution

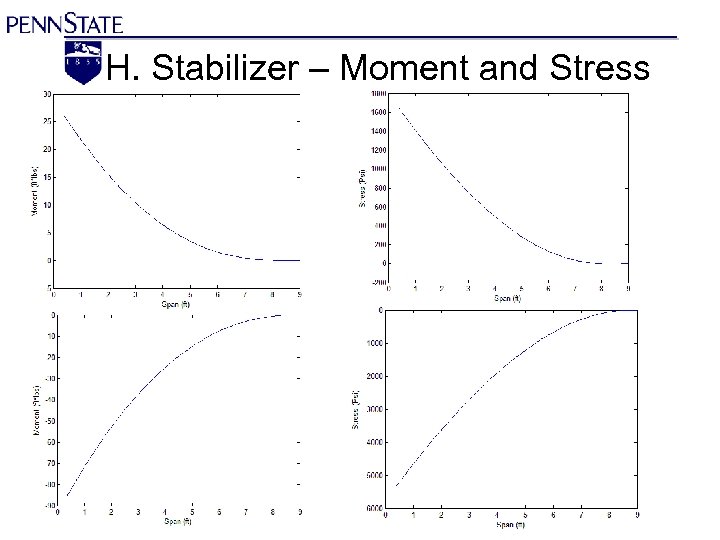

H. Stabilizer – Moment and Stress

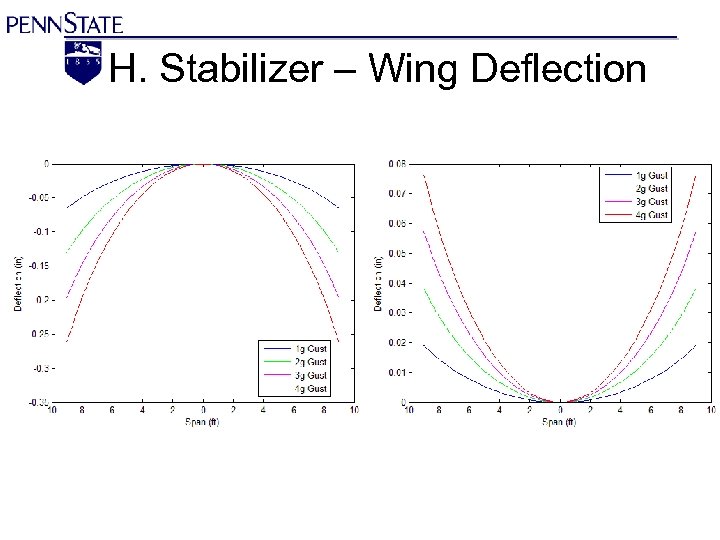

H. Stabilizer – Wing Deflection

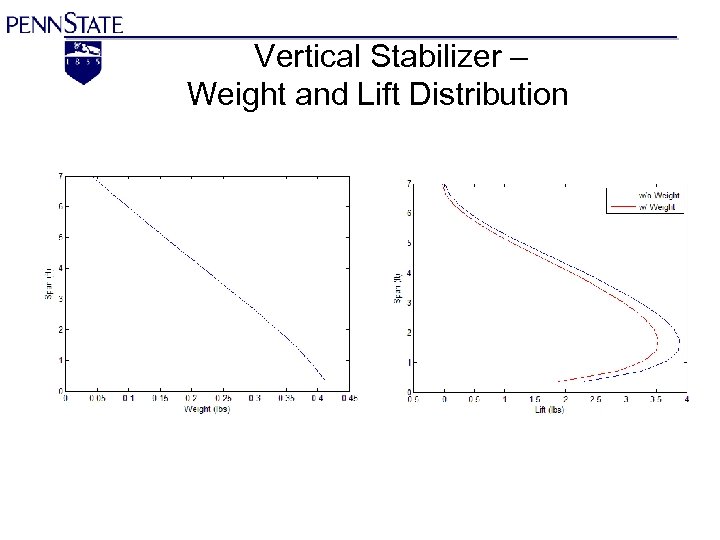

Vertical Stabilizer – Weight and Lift Distribution

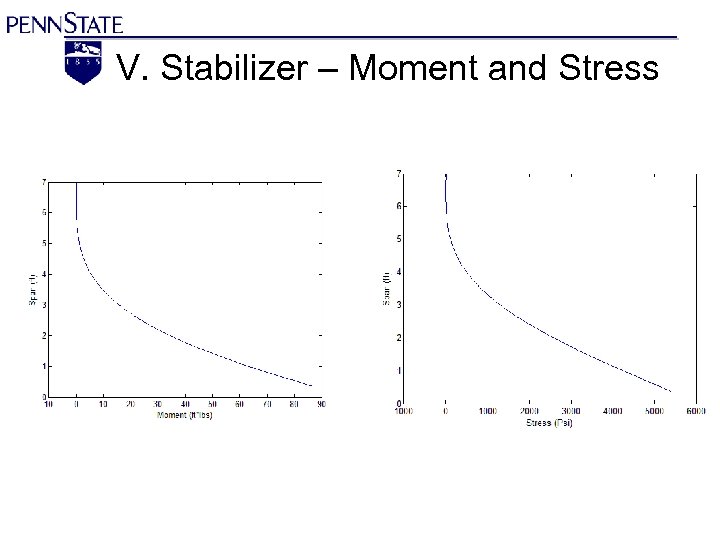

V. Stabilizer – Moment and Stress

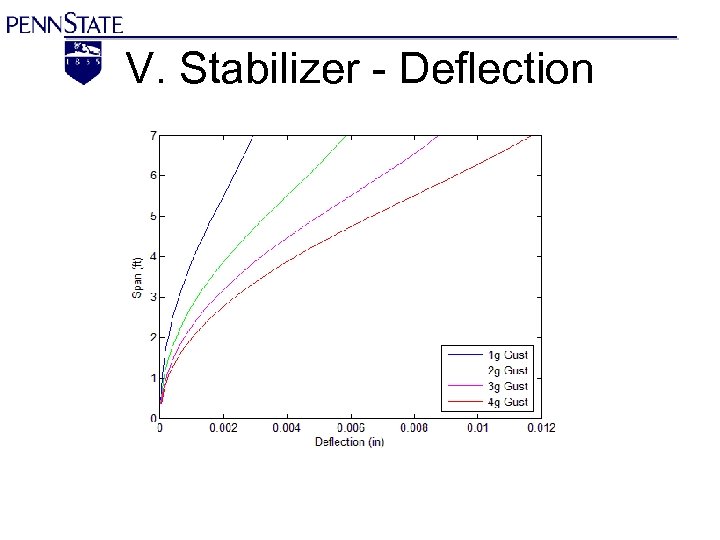

V. Stabilizer - Deflection

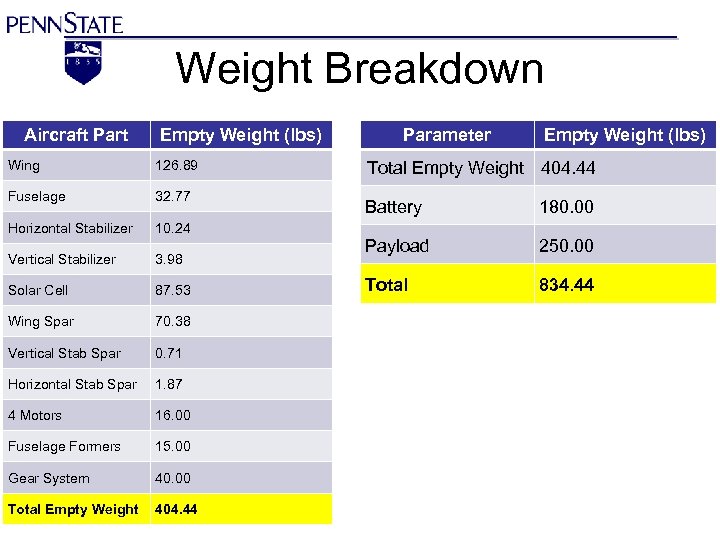

Weight Breakdown Aircraft Part Empty Weight (lbs) Wing 126. 89 Fuselage 32. 77 Horizontal Stabilizer 3. 98 Solar Cell 87. 53 Wing Spar 70. 38 Vertical Stab Spar 0. 71 Horizontal Stab Spar 1. 87 4 Motors 16. 00 Fuselage Formers 15. 00 Gear System 40. 00 Total Empty Weight 404. 44 Empty Weight (lbs) 10. 24 Vertical Stabilizer Parameter Total Empty Weight 404. 44 Battery 180. 00 Payload 250. 00 Total 834. 44

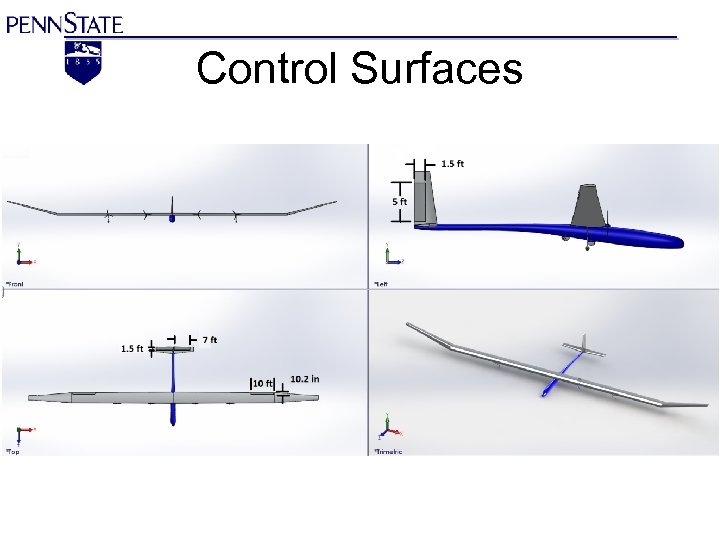

Control Surfaces

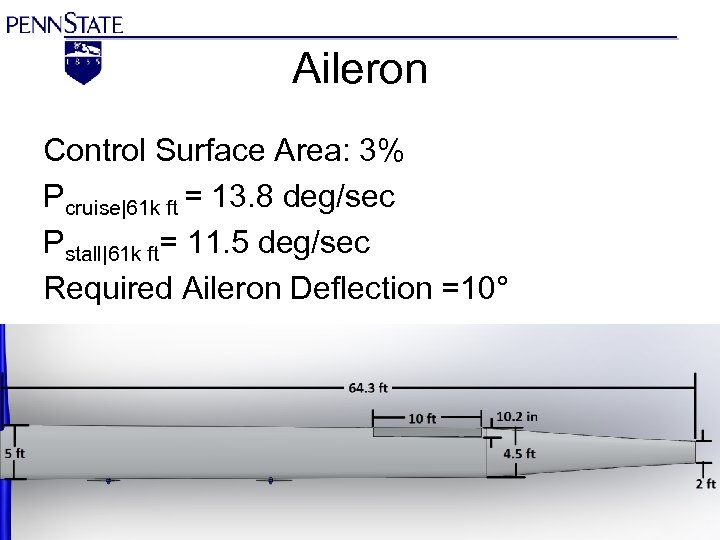

Aileron Control Surface Area: 3% Pcruise|61 k ft = 13. 8 deg/sec Pstall|61 k ft= 11. 5 deg/sec Required Aileron Deflection =10°

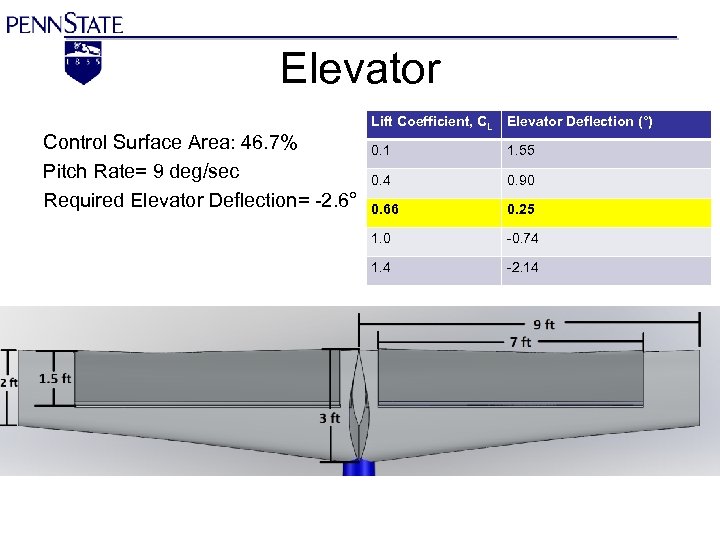

Elevator Control Surface Area: 46. 7% Pitch Rate= 9 deg/sec Required Elevator Deflection= -2. 6° Lift Coefficient, CL Elevator Deflection (°) 0. 1 1. 55 0. 4 0. 90 0. 66 0. 25 1. 0 -0. 74 1. 4 -2. 14

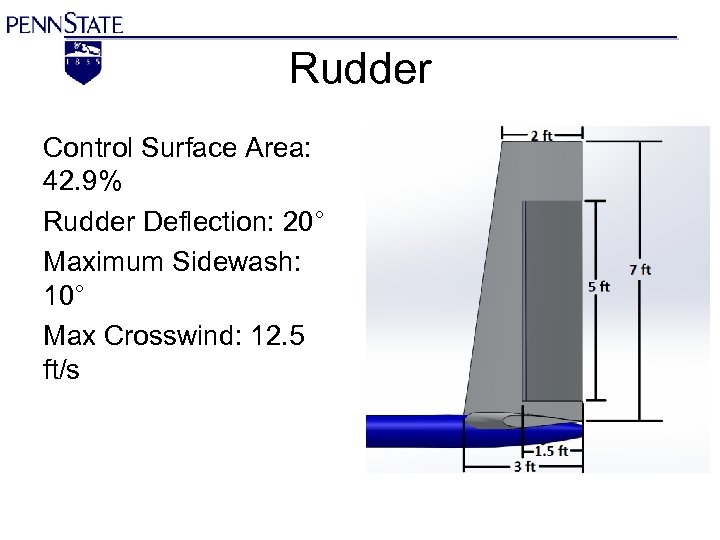

Rudder Control Surface Area: 42. 9% Rudder Deflection: 20° Maximum Sidewash: 10° Max Crosswind: 12. 5 ft/s

Control Surface Demo

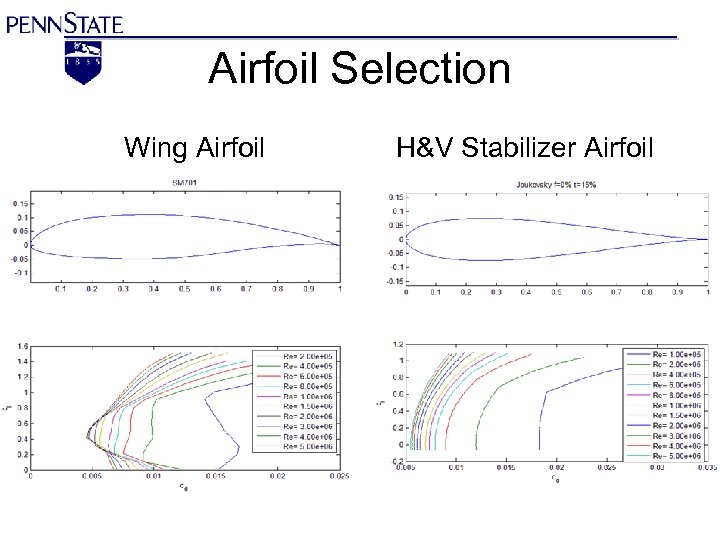

Airfoil Selection Wing Airfoil H&V Stabilizer Airfoil

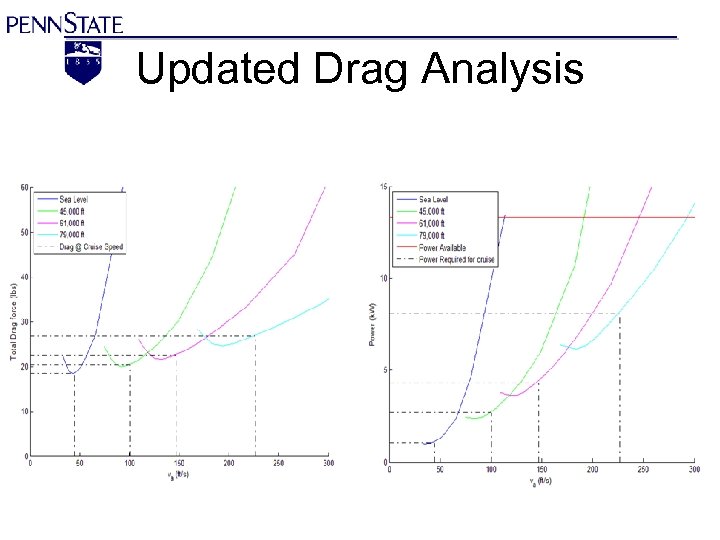

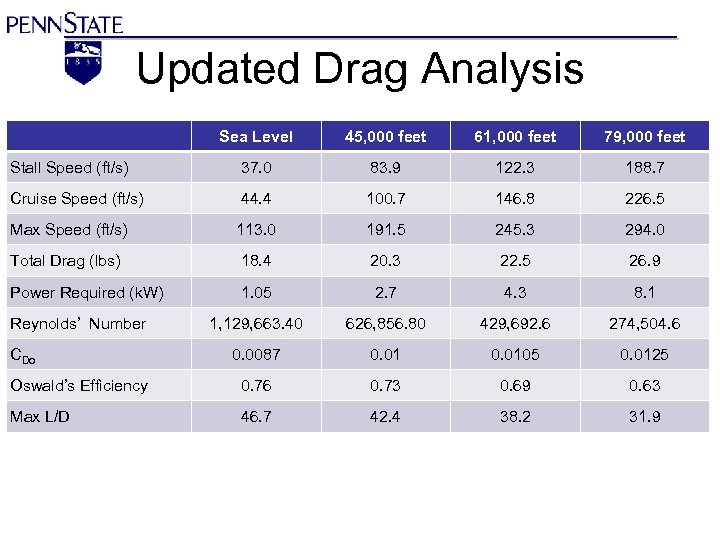

Updated Drag Analysis

Updated Drag Analysis Sea Level 45, 000 feet 61, 000 feet 79, 000 feet Stall Speed (ft/s) 37. 0 83. 9 122. 3 188. 7 Cruise Speed (ft/s) 44. 4 100. 7 146. 8 226. 5 Max Speed (ft/s) 113. 0 191. 5 245. 3 294. 0 Total Drag (lbs) 18. 4 20. 3 22. 5 26. 9 Power Required (k. W) 1. 05 2. 7 4. 3 8. 1 1, 129, 663. 40 626, 856. 80 429, 692. 6 274, 504. 6 0. 0087 0. 0105 0. 0125 Oswald’s Efficiency 0. 76 0. 73 0. 69 0. 63 Max L/D 46. 7 42. 4 38. 2 31. 9 Reynolds’ Number CDo

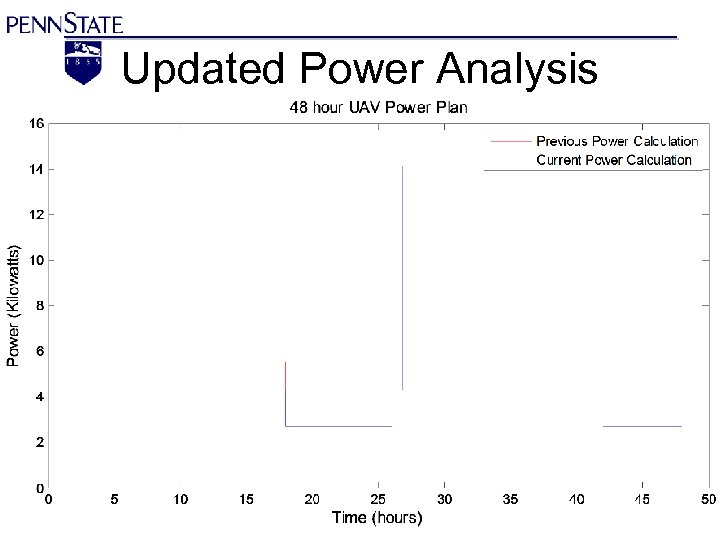

Updated Power Analysis

![Takeoff Parameter Ground Roll [ft] Vtakeoff [ft/s] dab|35 ft [ft] dab|50 ft [ft] Dtotal|35 Takeoff Parameter Ground Roll [ft] Vtakeoff [ft/s] dab|35 ft [ft] dab|50 ft [ft] Dtotal|35](https://present5.com/presentation/a3f9d26dd5250650b6e0def94e6d8ea7/image-33.jpg)

Takeoff Parameter Ground Roll [ft] Vtakeoff [ft/s] dab|35 ft [ft] dab|50 ft [ft] Dtotal|35 ft [ft] Dtotal|50 ft [ft] Thrust [lbs] Sea Level Denver Afghanistan

![Landing Parameter Va [ft/s] γa [deg] Radius [ft] Flare Height [ft] Flare Speed [ft/s] Landing Parameter Va [ft/s] γa [deg] Radius [ft] Flare Height [ft] Flare Speed [ft/s]](https://present5.com/presentation/a3f9d26dd5250650b6e0def94e6d8ea7/image-34.jpg)

Landing Parameter Va [ft/s] γa [deg] Radius [ft] Flare Height [ft] Flare Speed [ft/s] da 35 ft [ft] da 50 ft [ft] df [ft] VTD [ft/s] Thrust [lbs] Sea Level Denver Afghanistan

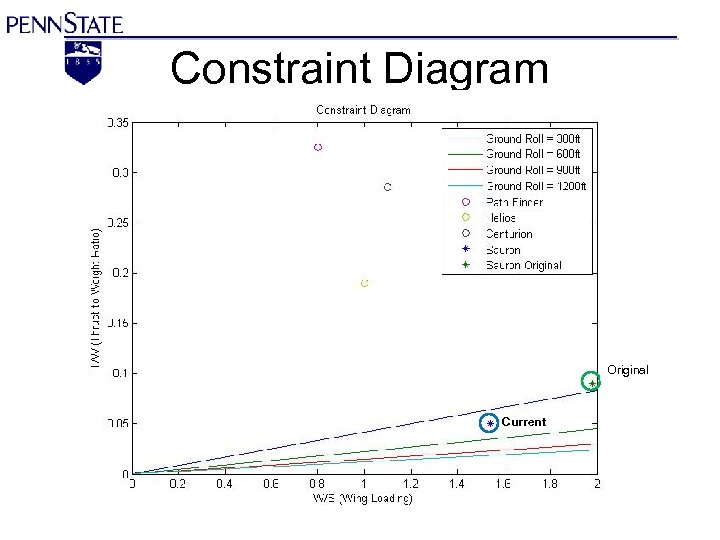

Constraint Diagram Original Current

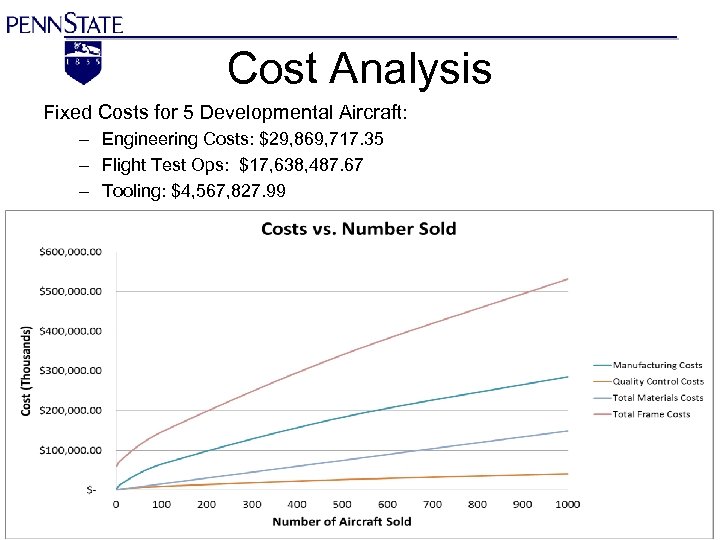

Cost Analysis Fixed Costs for 5 Developmental Aircraft: – Engineering Costs: $29, 869, 717. 35 – Flight Test Ops: $17, 638, 487. 67 – Tooling: $4, 567, 827. 99

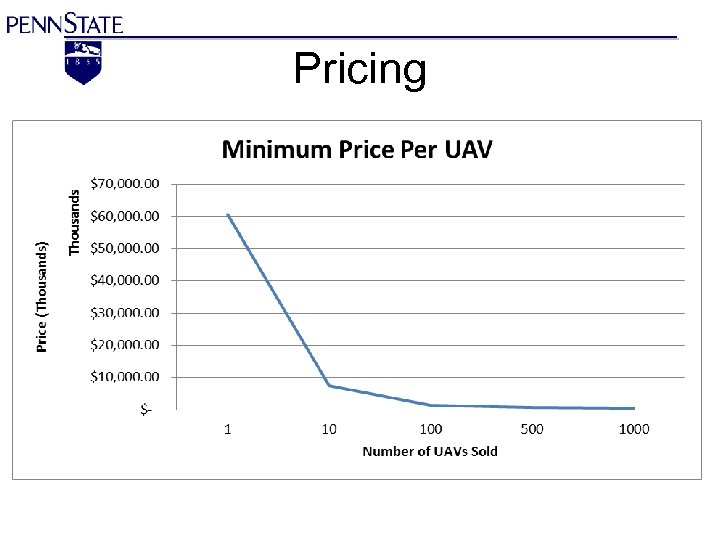

Pricing

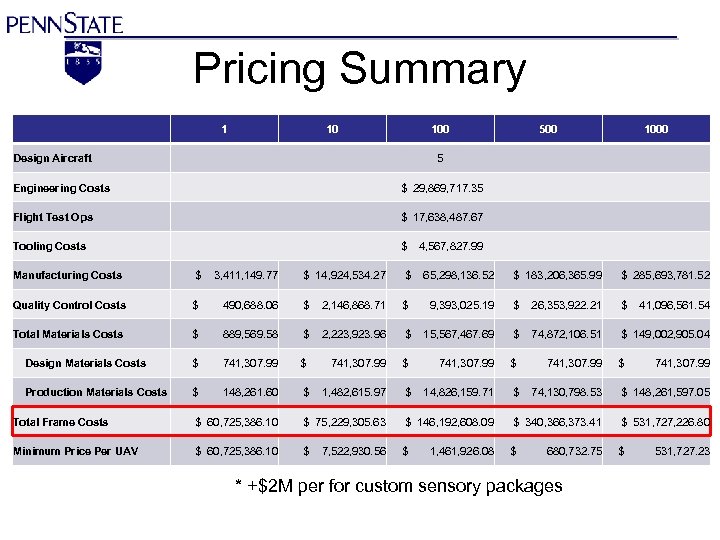

Pricing Summary 1 10 Design Aircraft 100 500 1000 5 Engineering Costs $ 29, 869, 717. 35 Flight Test Ops $ 17, 638, 487. 67 Tooling Costs $ 4, 567, 827. 99 Manufacturing Costs $ 3, 411, 149. 77 $ 14, 924, 534. 27 $ 65, 298, 136. 52 $ 183, 206, 365. 99 $ 285, 693, 781. 52 Quality Control Costs $ 490, 688. 06 $ 2, 146, 868. 71 $ 9, 393, 025. 19 $ 26, 353, 922. 21 $ 41, 096, 561. 54 Total Materials Costs $ 889, 569. 58 $ 2, 223, 923. 96 $ 74, 872, 106. 51 $ 149, 002, 905. 04 Design Materials Costs $ 741, 307. 99 $ 741, 307. 99 Production Materials Costs $ 148, 261. 60 $ 1, 482, 615. 97 $ 14, 826, 159. 71 $ 74, 130, 798. 53 $ 148, 261, 597. 05 Total Frame Costs $ 60, 725, 386. 10 $ 75, 229, 305. 63 $ 146, 192, 608. 09 $ 340, 366, 373. 41 $ 531, 727, 226. 80 Minimum Price Per UAV $ 60, 725, 386. 10 $ 7, 522, 930. 56 $ 1, 461, 926. 08 $ 680, 732. 75 $ 531, 727. 23 $ 15, 567, 467. 69 * +$2 M per for custom sensory packages

Comparison to Competitors • RQ-1/MQ-1 Predator – Unit Cost: $4. 03 M – 360 Built • MQ-9 Reaper – Unit Cost: $16. 9 M – 104 Built • RQ-4 Global Hawk – Unit Cost: $131. 4 M – 42 Built • Solara 50/60 – Unit Cost: $1 -2 M – N/A Built

14 Days ‘Til Graduation Questions?

Double Camera

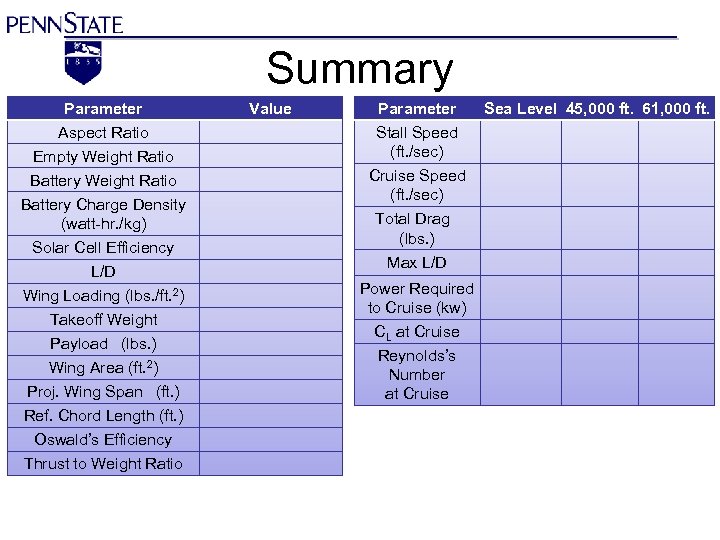

Summary Parameter Aspect Ratio Empty Weight Ratio Battery Charge Density (watt-hr. /kg) Solar Cell Efficiency L/D Wing Loading (lbs. /ft. 2) Takeoff Weight Payload (lbs. ) Wing Area (ft. 2) Proj. Wing Span (ft. ) Ref. Chord Length (ft. ) Oswald’s Efficiency Thrust to Weight Ratio Value Parameter Stall Speed (ft. /sec) Cruise Speed (ft. /sec) Total Drag (lbs. ) Max L/D Power Required to Cruise (kw) CL at Cruise Reynolds’s Number at Cruise Sea Level 45, 000 ft. 61, 000 ft.

a3f9d26dd5250650b6e0def94e6d8ea7.ppt