GTK gas cooling system Marco Statera NA 62 - GTK working group meeting 5 -4 -2011

GTK gas cooling system Marco Statera NA 62 - GTK working group meeting 5 -4 -2011

From test bench to final design • TEST BENCH – nitrogen from a bottle cooled by a liquid bath – open system – manual regulation of the flow • FINAL DESIGN – closed circuit of nitrogen – zero boil off – automated regulation of the flow – remote control GTK working group meeting 5 -4 -2011 Marco Statera 1

From test bench to final design • TEST BENCH – nitrogen from a bottle cooled by a liquid bath – open system – manual regulation of the flow • FINAL DESIGN – closed circuit of nitrogen – zero boil off – automated regulation of the flow – remote control GTK working group meeting 5 -4 -2011 Marco Statera 1

The working principle • cold nitrogen gas from a liquid bath The liquid bath keeps the temperature constant (pressure is regulated) and is a gas source • closed circuit: nitrogen gas must be cooled down A cold head reliquefies the returning nitrogen • the driving force of the flow is the pressure of the vessel • a regulating valve controls the flow GTK working group meeting 5 -4 -2011 Marco Statera 2

The working principle • cold nitrogen gas from a liquid bath The liquid bath keeps the temperature constant (pressure is regulated) and is a gas source • closed circuit: nitrogen gas must be cooled down A cold head reliquefies the returning nitrogen • the driving force of the flow is the pressure of the vessel • a regulating valve controls the flow GTK working group meeting 5 -4 -2011 Marco Statera 2

Configuration • One bath and three cooling lines PRO - 1 cryostat CONS - crosstalking of the flows - length of the lines (≈20 m) • Three separate baths and cooling lines PRO CONS - independent cooling flow control - more spare parts - shorter lines (5 m) - flexible configuration GTK working group meeting 5 -4 -2011 Marco Statera 3

Configuration • One bath and three cooling lines PRO - 1 cryostat CONS - crosstalking of the flows - length of the lines (≈20 m) • Three separate baths and cooling lines PRO CONS - independent cooling flow control - more spare parts - shorter lines (5 m) - flexible configuration GTK working group meeting 5 -4 -2011 Marco Statera 3

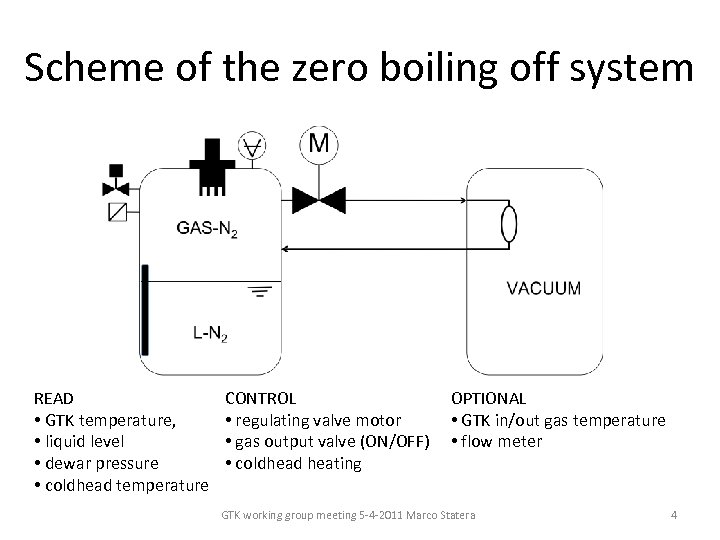

Scheme of the zero boiling off system READ • GTK temperature, • liquid level • dewar pressure • coldhead temperature CONTROL • regulating valve motor • gas output valve (ON/OFF) • coldhead heating OPTIONAL • GTK in/out gas temperature • flow meter GTK working group meeting 5 -4 -2011 Marco Statera 4

Scheme of the zero boiling off system READ • GTK temperature, • liquid level • dewar pressure • coldhead temperature CONTROL • regulating valve motor • gas output valve (ON/OFF) • coldhead heating OPTIONAL • GTK in/out gas temperature • flow meter GTK working group meeting 5 -4 -2011 Marco Statera 4

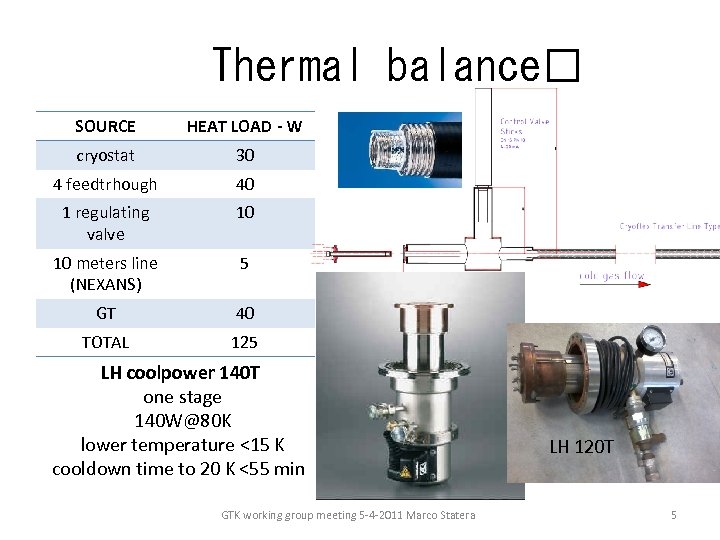

Thermal balance SOURCE HEAT LOAD - W cryostat 30 4 feedtrhough 40 1 regulating valve 10 10 meters line (NEXANS) 5 GT 40 TOTAL 125 LH coolpower 140 T one stage 140 W@80 K lower temperature <15 K cooldown time to 20 K <55 min GTK working group meeting 5 -4 -2011 Marco Statera LH 120 T 5

Thermal balance SOURCE HEAT LOAD - W cryostat 30 4 feedtrhough 40 1 regulating valve 10 10 meters line (NEXANS) 5 GT 40 TOTAL 125 LH coolpower 140 T one stage 140 W@80 K lower temperature <15 K cooldown time to 20 K <55 min GTK working group meeting 5 -4 -2011 Marco Statera LH 120 T 5

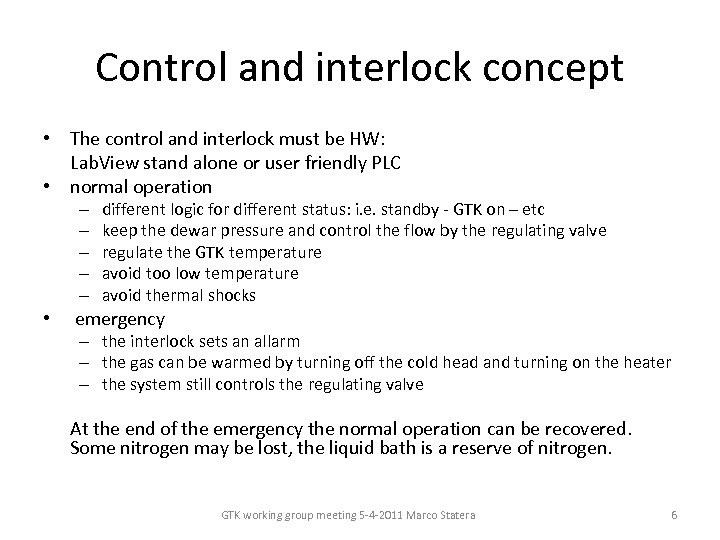

Control and interlock concept • The control and interlock must be HW: Lab. View stand alone or user friendly PLC • normal operation – – – • different logic for different status: i. e. standby - GTK on – etc keep the dewar pressure and control the flow by the regulating valve regulate the GTK temperature avoid too low temperature avoid thermal shocks emergency – the interlock sets an allarm – the gas can be warmed by turning off the cold head and turning on the heater – the system still controls the regulating valve At the end of the emergency the normal operation can be recovered. Some nitrogen may be lost, the liquid bath is a reserve of nitrogen. GTK working group meeting 5 -4 -2011 Marco Statera 6

Control and interlock concept • The control and interlock must be HW: Lab. View stand alone or user friendly PLC • normal operation – – – • different logic for different status: i. e. standby - GTK on – etc keep the dewar pressure and control the flow by the regulating valve regulate the GTK temperature avoid too low temperature avoid thermal shocks emergency – the interlock sets an allarm – the gas can be warmed by turning off the cold head and turning on the heater – the system still controls the regulating valve At the end of the emergency the normal operation can be recovered. Some nitrogen may be lost, the liquid bath is a reserve of nitrogen. GTK working group meeting 5 -4 -2011 Marco Statera 6

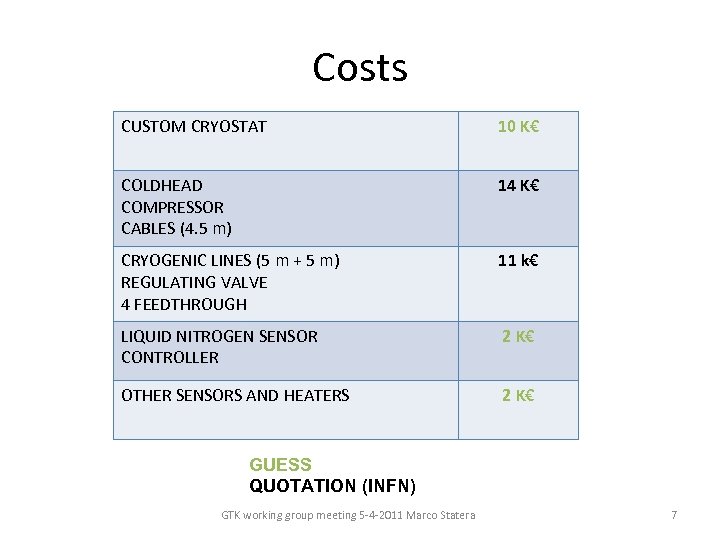

Costs CUSTOM CRYOSTAT 10 K€ COLDHEAD COMPRESSOR CABLES (4. 5 m) 14 K€ CRYOGENIC LINES (5 m + 5 m) REGULATING VALVE 4 FEEDTHROUGH 11 k€ LIQUID NITROGEN SENSOR CONTROLLER 2 K€ OTHER SENSORS AND HEATERS 2 K€ GUESS QUOTATION (INFN) GTK working group meeting 5 -4 -2011 Marco Statera 7

Costs CUSTOM CRYOSTAT 10 K€ COLDHEAD COMPRESSOR CABLES (4. 5 m) 14 K€ CRYOGENIC LINES (5 m + 5 m) REGULATING VALVE 4 FEEDTHROUGH 11 k€ LIQUID NITROGEN SENSOR CONTROLLER 2 K€ OTHER SENSORS AND HEATERS 2 K€ GUESS QUOTATION (INFN) GTK working group meeting 5 -4 -2011 Marco Statera 7

Conclusions • coolig system defined – – three separate systems closed circuit zero boil off control and interlock concept • total costs – 40 k€ per system (plus VAT) – total 120 k€ + 40 k€ (spare) • time schedule – cryostat ≈12 wks – cryogenic line: 8 wks – Installation: tbd GTK working group meeting 5 -4 -2011 Marco Statera 8

Conclusions • coolig system defined – – three separate systems closed circuit zero boil off control and interlock concept • total costs – 40 k€ per system (plus VAT) – total 120 k€ + 40 k€ (spare) • time schedule – cryostat ≈12 wks – cryogenic line: 8 wks – Installation: tbd GTK working group meeting 5 -4 -2011 Marco Statera 8