e73348099f82b8cfd1873c87762b8bc3.ppt

- Количество слайдов: 51

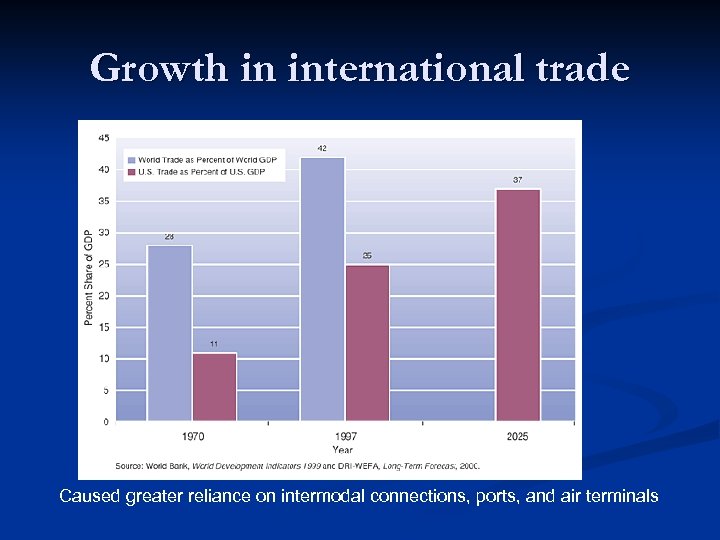

Growth in international trade Caused greater reliance on intermodal connections, ports, and air terminals

Growth in international trade Caused greater reliance on intermodal connections, ports, and air terminals

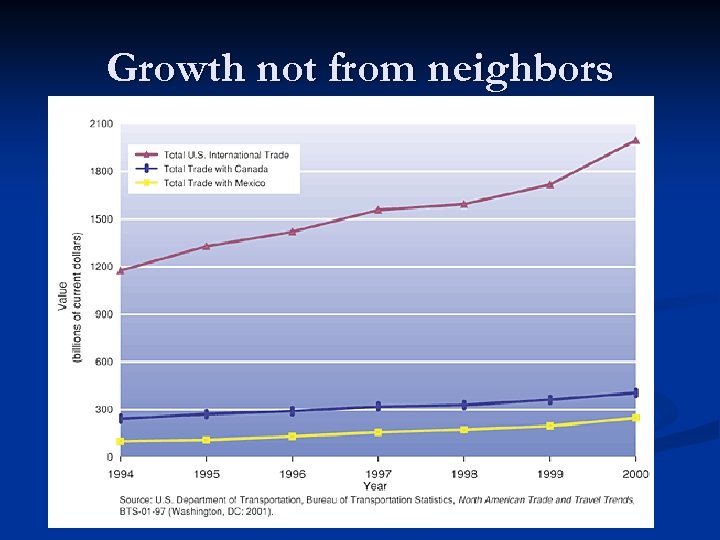

Growth not from neighbors

Growth not from neighbors

Major Gateways

Major Gateways

Logistics Cost Professor Goodchild Spring 09

Logistics Cost Professor Goodchild Spring 09

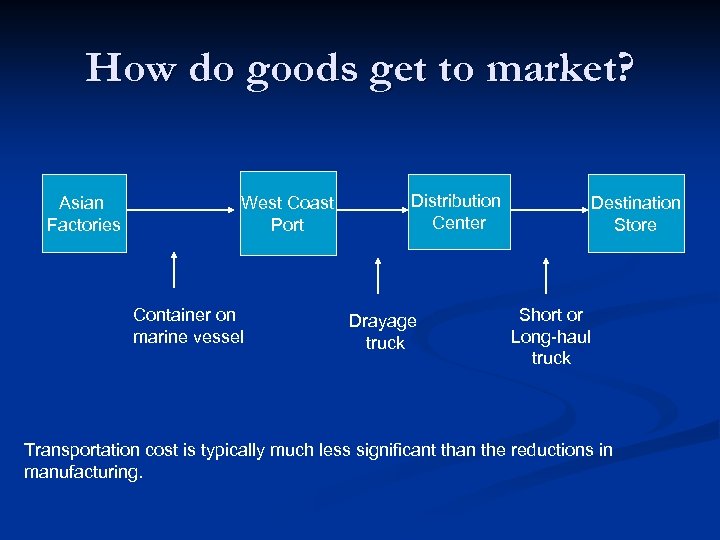

How do goods get to market? Asian Factories West Coast Port Container on marine vessel Distribution Center Drayage truck Destination Store Short or Long-haul truck Transportation cost is typically much less significant than the reductions in manufacturing.

How do goods get to market? Asian Factories West Coast Port Container on marine vessel Distribution Center Drayage truck Destination Store Short or Long-haul truck Transportation cost is typically much less significant than the reductions in manufacturing.

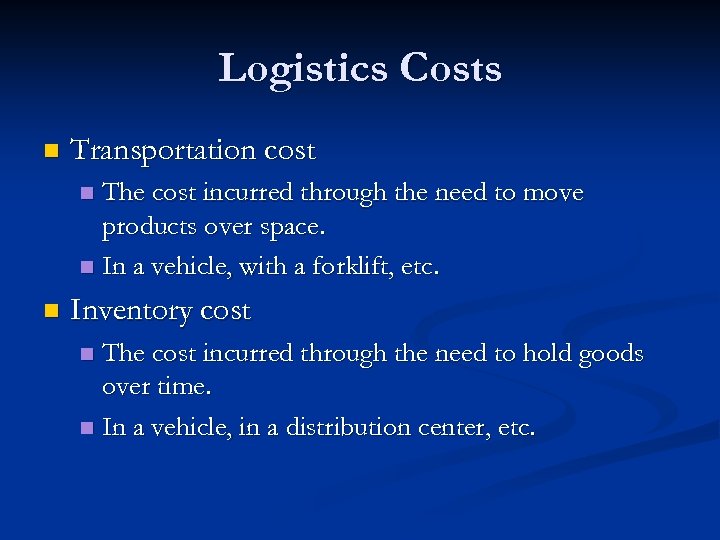

Logistics Costs n Transportation cost The cost incurred through the need to move products over space. n In a vehicle, with a forklift, etc. n n Inventory cost The cost incurred through the need to hold goods over time. n In a vehicle, in a distribution center, etc. n

Logistics Costs n Transportation cost The cost incurred through the need to move products over space. n In a vehicle, with a forklift, etc. n n Inventory cost The cost incurred through the need to hold goods over time. n In a vehicle, in a distribution center, etc. n

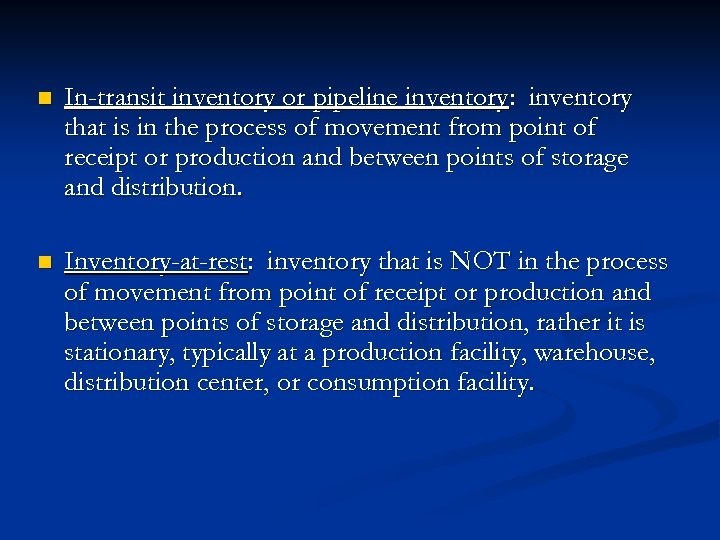

n In-transit inventory or pipeline inventory: inventory that is in the process of movement from point of receipt or production and between points of storage and distribution. n Inventory-at-rest: inventory that is NOT in the process of movement from point of receipt or production and between points of storage and distribution, rather it is stationary, typically at a production facility, warehouse, distribution center, or consumption facility.

n In-transit inventory or pipeline inventory: inventory that is in the process of movement from point of receipt or production and between points of storage and distribution. n Inventory-at-rest: inventory that is NOT in the process of movement from point of receipt or production and between points of storage and distribution, rather it is stationary, typically at a production facility, warehouse, distribution center, or consumption facility.

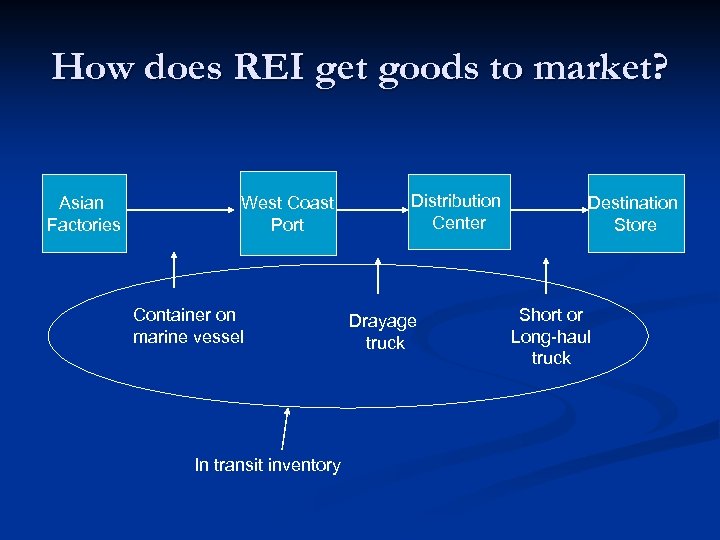

How does REI get goods to market? Asian Factories West Coast Port Container on marine vessel In transit inventory Distribution Center Drayage truck Destination Store Short or Long-haul truck

How does REI get goods to market? Asian Factories West Coast Port Container on marine vessel In transit inventory Distribution Center Drayage truck Destination Store Short or Long-haul truck

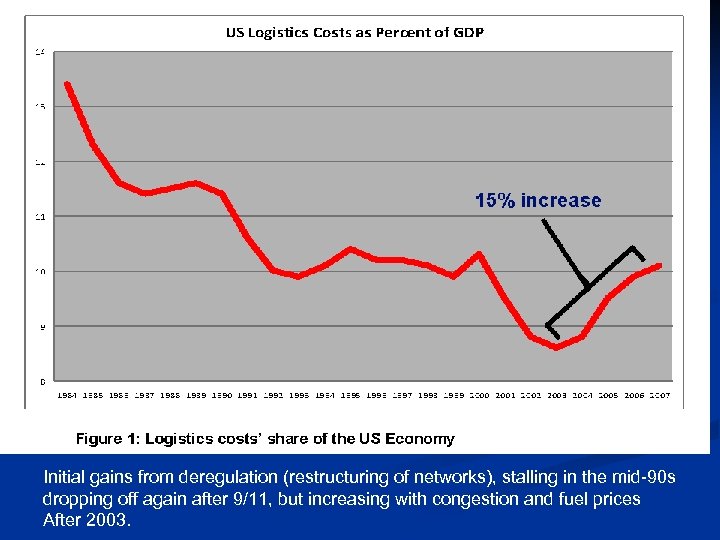

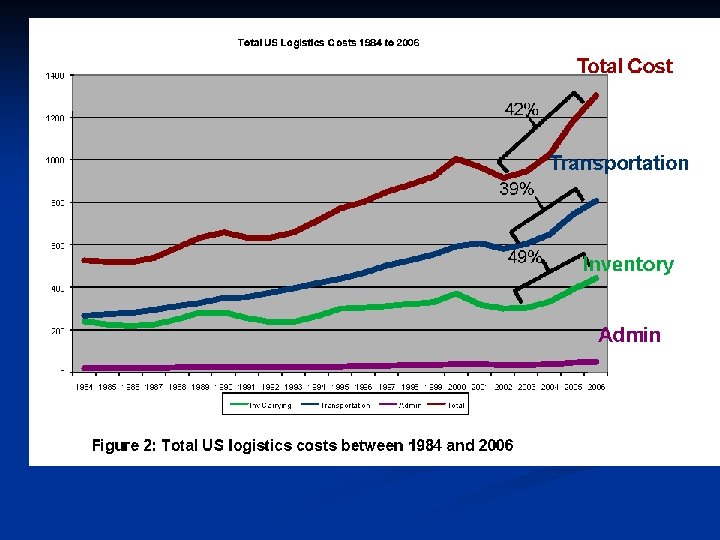

Initial gains from deregulation (restructuring of networks), stalling in the mid-90 s dropping off again after 9/11, but increasing with congestion and fuel prices After 2003.

Initial gains from deregulation (restructuring of networks), stalling in the mid-90 s dropping off again after 9/11, but increasing with congestion and fuel prices After 2003.

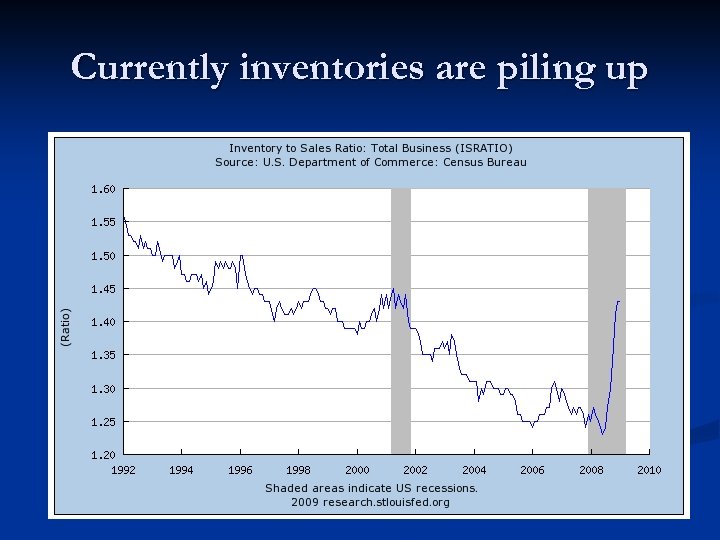

Currently inventories are piling up

Currently inventories are piling up

Follow the path of an item Carried from production area to storage area n Held in temporary storage n Loaded into transport vehicle n Transported to the destination n Unloaded, handled, and held for consumption n

Follow the path of an item Carried from production area to storage area n Held in temporary storage n Loaded into transport vehicle n Transported to the destination n Unloaded, handled, and held for consumption n

What incurs cost? n Overcoming distance (motion): n n n transportation cost (over the road/rail) handling cost (through a terminal, in and out of vehicles) Overcoming time (holding): n holding cost: n n Rent (proportional to D’H) Waiting (value*time*interest rate) n n In transit pipeline How you calculate the value depends on the analysis you are doing (cost or price) We will include all costs, regardless of who pays them (we are designing systems)

What incurs cost? n Overcoming distance (motion): n n n transportation cost (over the road/rail) handling cost (through a terminal, in and out of vehicles) Overcoming time (holding): n holding cost: n n Rent (proportional to D’H) Waiting (value*time*interest rate) n n In transit pipeline How you calculate the value depends on the analysis you are doing (cost or price) We will include all costs, regardless of who pays them (we are designing systems)

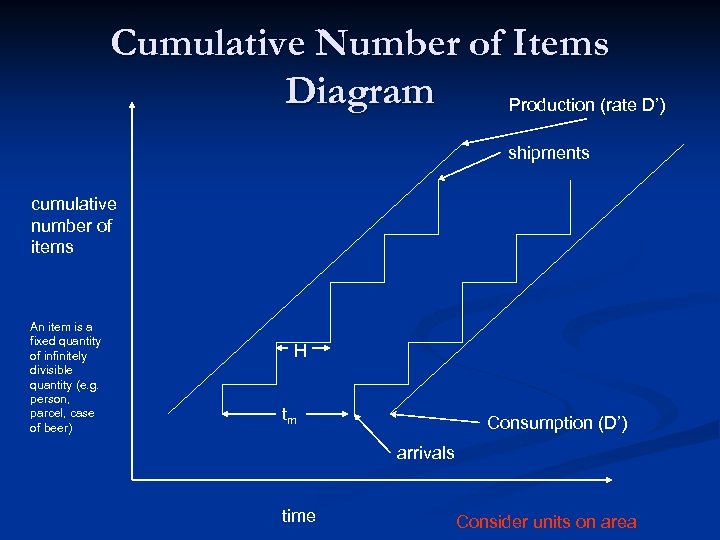

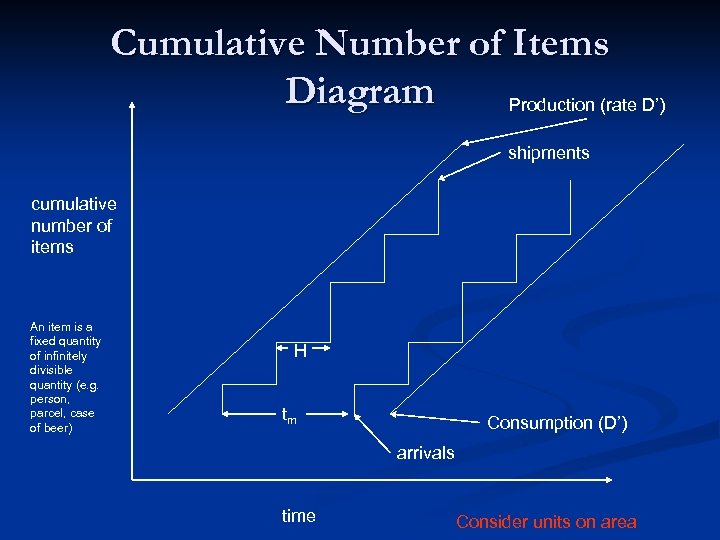

Cumulative Number of Items Diagram Production (rate D’) shipments cumulative number of items An item is a fixed quantity of infinitely divisible quantity (e. g. person, parcel, case of beer) H tm Consumption (D’) arrivals time Consider units on area

Cumulative Number of Items Diagram Production (rate D’) shipments cumulative number of items An item is a fixed quantity of infinitely divisible quantity (e. g. person, parcel, case of beer) H tm Consumption (D’) arrivals time Consider units on area

Queue Discipline n FIFO: First In First Out n LIFO: Last In First Out n Others If LIFO inventory cost is usually underestimated

Queue Discipline n FIFO: First In First Out n LIFO: Last In First Out n Others If LIFO inventory cost is usually underestimated

Holding cost: Rent proportional to max. accumulation n Independent of flow rate, D’ n Proportional to max. time between dispatches n

Holding cost: Rent proportional to max. accumulation n Independent of flow rate, D’ n Proportional to max. time between dispatches n

Holding cost: Waiting Cost associated with delay to items n c i. H i + c it m n Stationary + pipeline inventory n Determining ci is difficult n

Holding cost: Waiting Cost associated with delay to items n c i. H i + c it m n Stationary + pipeline inventory n Determining ci is difficult n

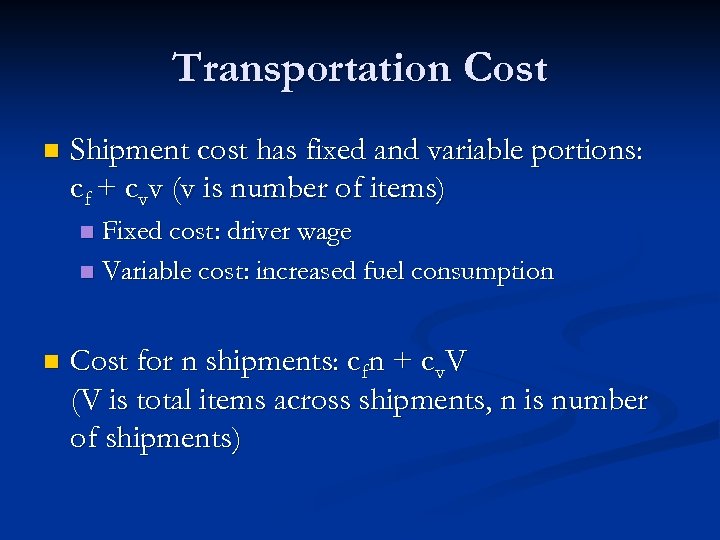

Transportation Cost n Shipment cost has fixed and variable portions: cf + cvv (v is number of items) Fixed cost: driver wage n Variable cost: increased fuel consumption n n Cost for n shipments: cfn + cv. V (V is total items across shipments, n is number of shipments)

Transportation Cost n Shipment cost has fixed and variable portions: cf + cvv (v is number of items) Fixed cost: driver wage n Variable cost: increased fuel consumption n n Cost for n shipments: cfn + cv. V (V is total items across shipments, n is number of shipments)

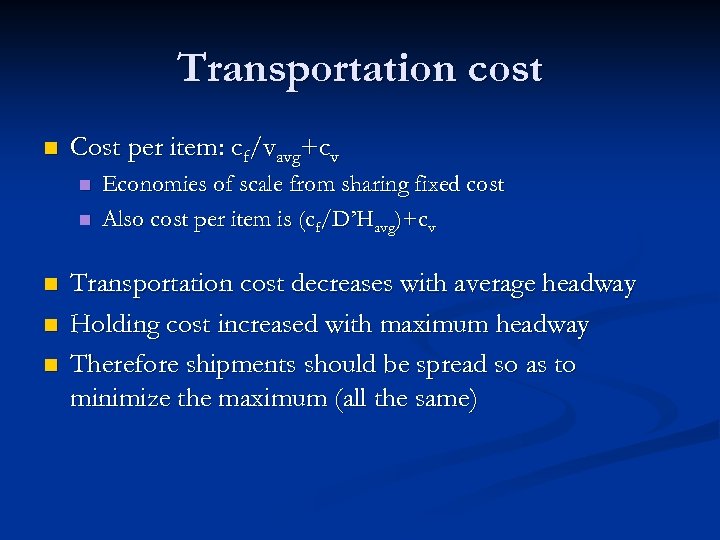

Transportation cost n Cost per item: cf/vavg+cv n n n Economies of scale from sharing fixed cost Also cost per item is (cf/D’Havg)+cv Transportation cost decreases with average headway Holding cost increased with maximum headway Therefore shipments should be spread so as to minimize the maximum (all the same)

Transportation cost n Cost per item: cf/vavg+cv n n n Economies of scale from sharing fixed cost Also cost per item is (cf/D’Havg)+cv Transportation cost decreases with average headway Holding cost increased with maximum headway Therefore shipments should be spread so as to minimize the maximum (all the same)

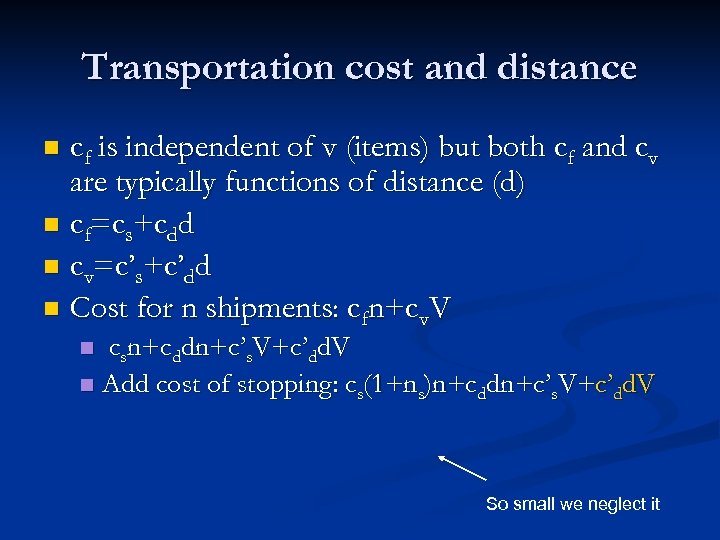

Transportation cost and distance n cf is independent of v (items) but both cf and cv are typically functions of distance (d) n cf=cs+cdd n cv=c’s+c’dd n Cost for n shipments: cfn+cv. V csn+cddn+c’s. V+c’dd. V n Add cost of stopping: cs(1+ns)n+cddn+c’s. V+c’dd. V n So small we neglect it

Transportation cost and distance n cf is independent of v (items) but both cf and cv are typically functions of distance (d) n cf=cs+cdd n cv=c’s+c’dd n Cost for n shipments: cfn+cv. V csn+cddn+c’s. V+c’dd. V n Add cost of stopping: cs(1+ns)n+cddn+c’s. V+c’dd. V n So small we neglect it

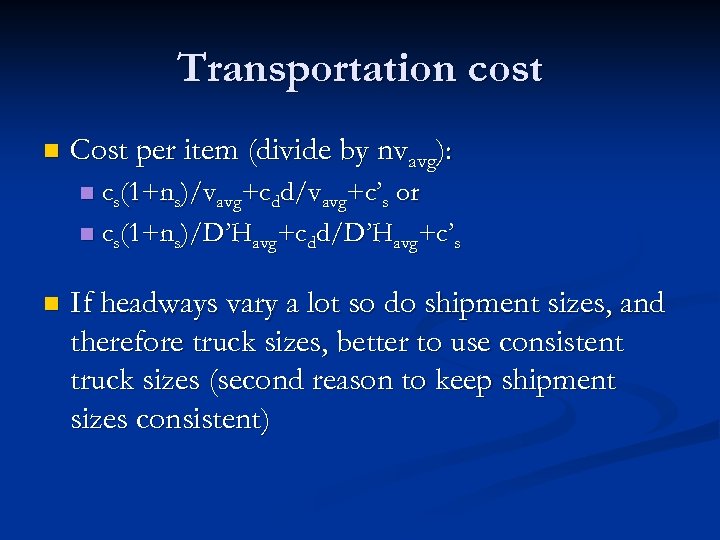

Transportation cost n Cost per item (divide by nvavg): n cs(1+ns)/vavg+cdd/vavg+c’s or n cs(1+ns)/D’Havg+cdd/D’Havg+c’s n If headways vary a lot so do shipment sizes, and therefore truck sizes, better to use consistent truck sizes (second reason to keep shipment sizes consistent)

Transportation cost n Cost per item (divide by nvavg): n cs(1+ns)/vavg+cdd/vavg+c’s or n cs(1+ns)/D’Havg+cdd/D’Havg+c’s n If headways vary a lot so do shipment sizes, and therefore truck sizes, better to use consistent truck sizes (second reason to keep shipment sizes consistent)

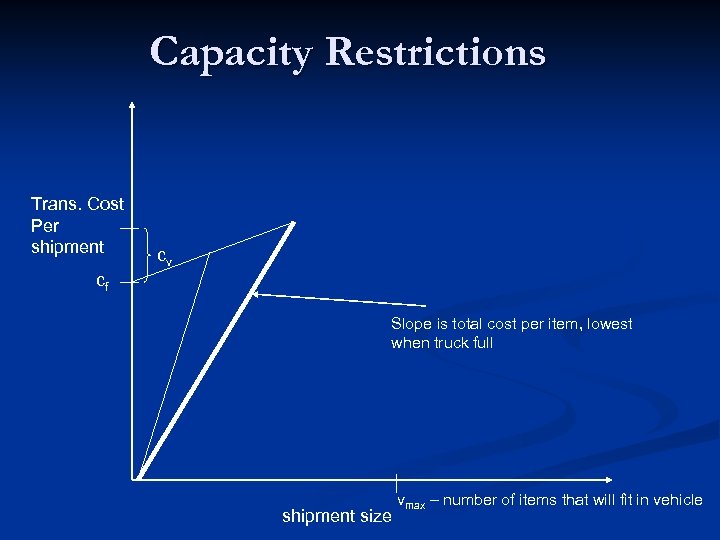

Capacity Restrictions Trans. Cost Per shipment cv cf Slope is total cost per item, lowest when truck full shipment size vmax – number of items that will fit in vehicle

Capacity Restrictions Trans. Cost Per shipment cv cf Slope is total cost per item, lowest when truck full shipment size vmax – number of items that will fit in vehicle

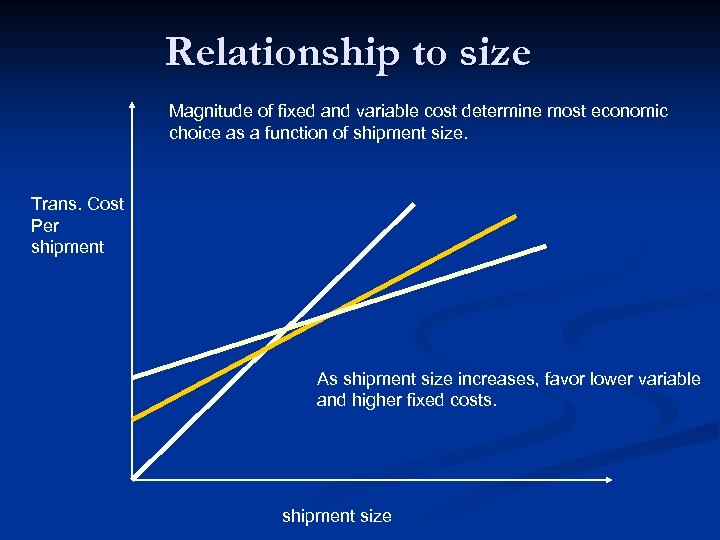

Relationship to size Magnitude of fixed and variable cost determine most economic choice as a function of shipment size. Trans. Cost Per shipment As shipment size increases, favor lower variable and higher fixed costs. shipment size

Relationship to size Magnitude of fixed and variable cost determine most economic choice as a function of shipment size. Trans. Cost Per shipment As shipment size increases, favor lower variable and higher fixed costs. shipment size

Inventory Cost Captures time-value of holding product n Perishability, theft, opportunity cost of cash, insurance, shrinkage, obsolescence n Usually 10 -15% for electronics n n Value of good*interest rate*time

Inventory Cost Captures time-value of holding product n Perishability, theft, opportunity cost of cash, insurance, shrinkage, obsolescence n Usually 10 -15% for electronics n n Value of good*interest rate*time

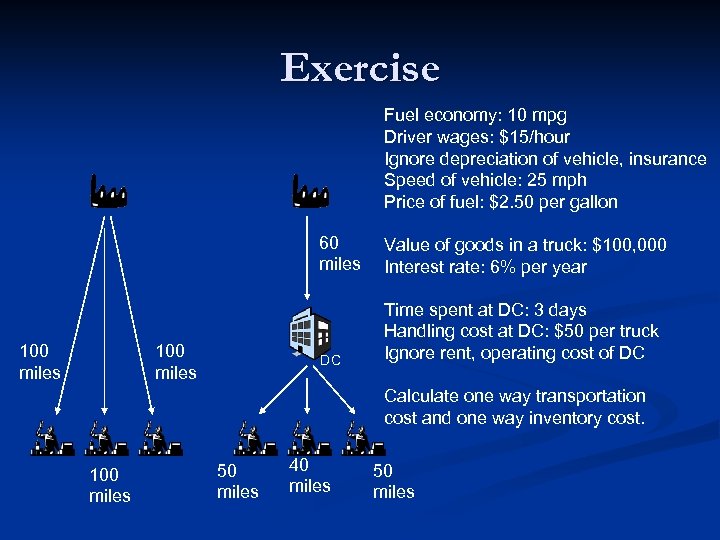

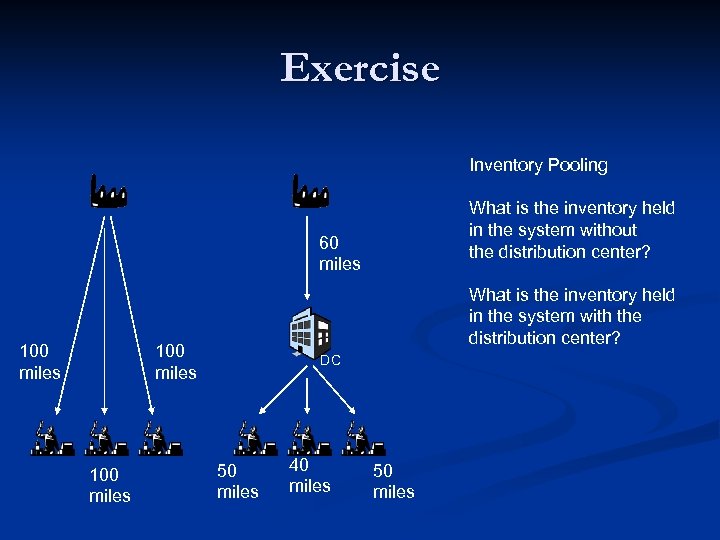

Exercise Fuel economy: 10 mpg Driver wages: $15/hour Ignore depreciation of vehicle, insurance Speed of vehicle: 25 mph Price of fuel: $2. 50 per gallon 60 miles 100 miles DC 100 miles Value of goods in a truck: $100, 000 Interest rate: 6% per year Time spent at DC: 3 days Handling cost at DC: $50 per truck Ignore rent, operating cost of DC Calculate one way transportation cost and one way inventory cost. 100 miles 50 miles 40 miles 50 miles

Exercise Fuel economy: 10 mpg Driver wages: $15/hour Ignore depreciation of vehicle, insurance Speed of vehicle: 25 mph Price of fuel: $2. 50 per gallon 60 miles 100 miles DC 100 miles Value of goods in a truck: $100, 000 Interest rate: 6% per year Time spent at DC: 3 days Handling cost at DC: $50 per truck Ignore rent, operating cost of DC Calculate one way transportation cost and one way inventory cost. 100 miles 50 miles 40 miles 50 miles

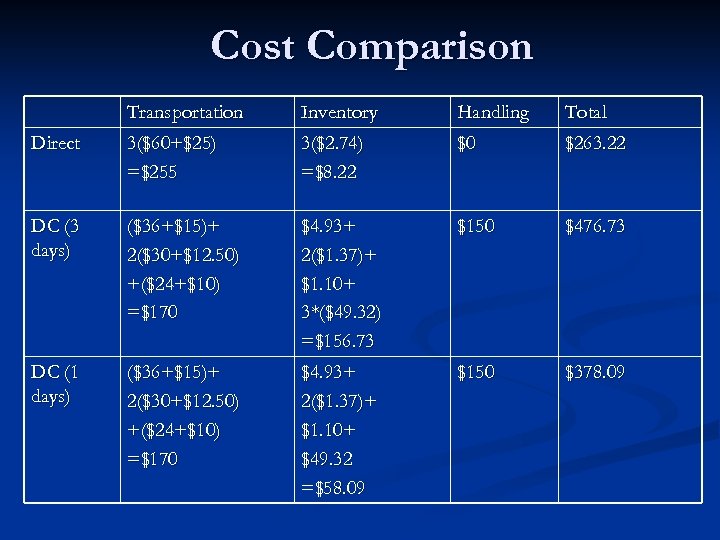

Cost Comparison Transportation Inventory Handling Total Direct 3($60+$25) =$255 3($2. 74) =$8. 22 $0 $263. 22 DC (3 days) ($36+$15)+ 2($30+$12. 50) +($24+$10) =$170 $4. 93+ 2($1. 37)+ $1. 10+ 3*($49. 32) =$156. 73 $150 $476. 73 DC (1 days) ($36+$15)+ 2($30+$12. 50) +($24+$10) =$170 $4. 93+ 2($1. 37)+ $1. 10+ $49. 32 =$58. 09 $150 $378. 09

Cost Comparison Transportation Inventory Handling Total Direct 3($60+$25) =$255 3($2. 74) =$8. 22 $0 $263. 22 DC (3 days) ($36+$15)+ 2($30+$12. 50) +($24+$10) =$170 $4. 93+ 2($1. 37)+ $1. 10+ 3*($49. 32) =$156. 73 $150 $476. 73 DC (1 days) ($36+$15)+ 2($30+$12. 50) +($24+$10) =$170 $4. 93+ 2($1. 37)+ $1. 10+ $49. 32 =$58. 09 $150 $378. 09

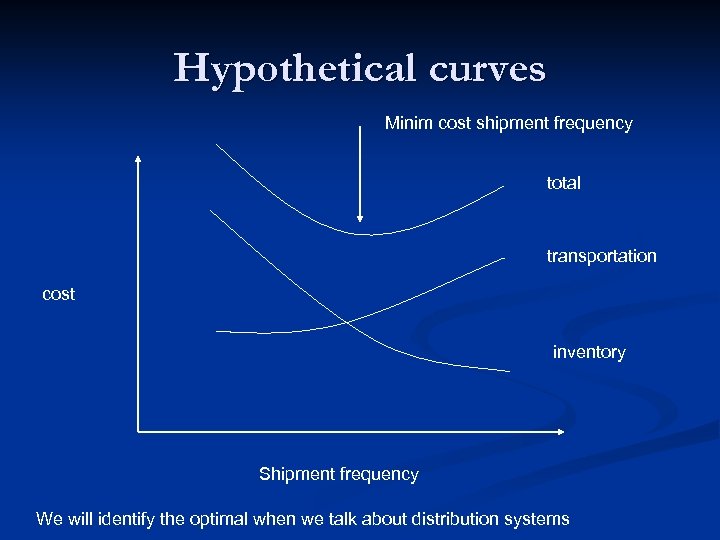

Hypothetical curves Minim cost shipment frequency total transportation cost inventory Shipment frequency We will identify the optimal when we talk about distribution systems

Hypothetical curves Minim cost shipment frequency total transportation cost inventory Shipment frequency We will identify the optimal when we talk about distribution systems

Cumulative Number of Items Diagram Production (rate D’) shipments cumulative number of items An item is a fixed quantity of infinitely divisible quantity (e. g. person, parcel, case of beer) H tm Consumption (D’) arrivals time Consider units on area

Cumulative Number of Items Diagram Production (rate D’) shipments cumulative number of items An item is a fixed quantity of infinitely divisible quantity (e. g. person, parcel, case of beer) H tm Consumption (D’) arrivals time Consider units on area

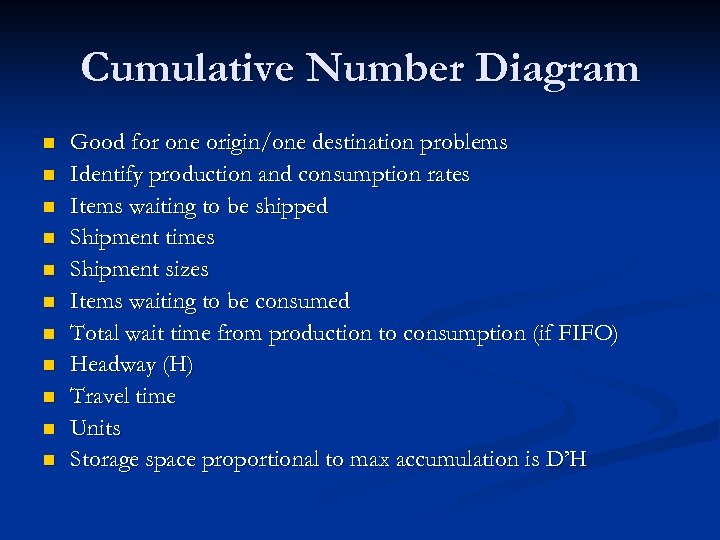

Cumulative Number Diagram n n n Good for one origin/one destination problems Identify production and consumption rates Items waiting to be shipped Shipment times Shipment sizes Items waiting to be consumed Total wait time from production to consumption (if FIFO) Headway (H) Travel time Units Storage space proportional to max accumulation is D’H

Cumulative Number Diagram n n n Good for one origin/one destination problems Identify production and consumption rates Items waiting to be shipped Shipment times Shipment sizes Items waiting to be consumed Total wait time from production to consumption (if FIFO) Headway (H) Travel time Units Storage space proportional to max accumulation is D’H

Network Structures Trade-off inventory cost and transportation cost n Milk-run n Hub and spoke (distribution center) n Direct Shipping n

Network Structures Trade-off inventory cost and transportation cost n Milk-run n Hub and spoke (distribution center) n Direct Shipping n

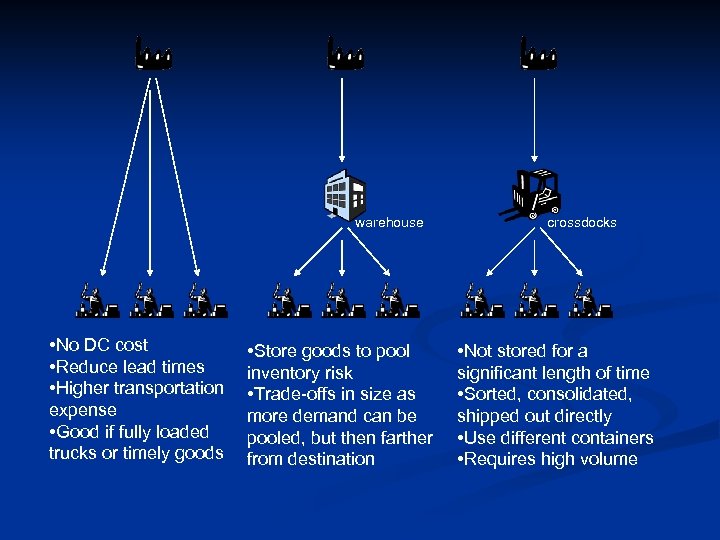

warehouse • No DC cost • Reduce lead times • Higher transportation expense • Good if fully loaded trucks or timely goods • Store goods to pool inventory risk • Trade-offs in size as more demand can be pooled, but then farther from destination crossdocks • Not stored for a significant length of time • Sorted, consolidated, shipped out directly • Use different containers • Requires high volume

warehouse • No DC cost • Reduce lead times • Higher transportation expense • Good if fully loaded trucks or timely goods • Store goods to pool inventory risk • Trade-offs in size as more demand can be pooled, but then farther from destination crossdocks • Not stored for a significant length of time • Sorted, consolidated, shipped out directly • Use different containers • Requires high volume

Exercise Inventory Pooling What is the inventory held in the system without the distribution center? 60 miles 100 miles What is the inventory held in the system with the distribution center? 100 miles DC 50 miles 40 miles 50 miles

Exercise Inventory Pooling What is the inventory held in the system without the distribution center? 60 miles 100 miles What is the inventory held in the system with the distribution center? 100 miles DC 50 miles 40 miles 50 miles

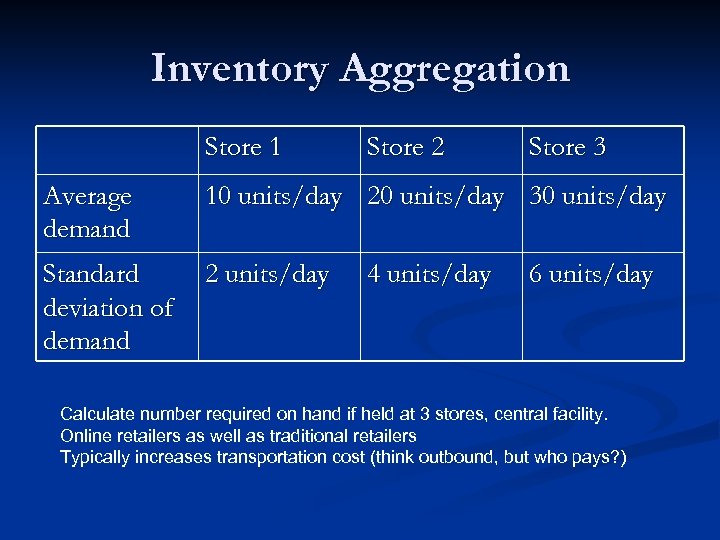

Inventory Aggregation Store 1 Store 2 Store 3 Average demand 10 units/day 20 units/day 30 units/day Standard deviation of demand 2 units/day 4 units/day 6 units/day Calculate number required on hand if held at 3 stores, central facility. Online retailers as well as traditional retailers Typically increases transportation cost (think outbound, but who pays? )

Inventory Aggregation Store 1 Store 2 Store 3 Average demand 10 units/day 20 units/day 30 units/day Standard deviation of demand 2 units/day 4 units/day 6 units/day Calculate number required on hand if held at 3 stores, central facility. Online retailers as well as traditional retailers Typically increases transportation cost (think outbound, but who pays? )

Inventory Management Improve service level n Reduce logistics cost n Cope with randomness and seasonality n Speculate on price n Overcoming inefficiencies in managing the logistics system n

Inventory Management Improve service level n Reduce logistics cost n Cope with randomness and seasonality n Speculate on price n Overcoming inefficiencies in managing the logistics system n

Distribution Systems Prof. Anne Goodchild Spring 2009

Distribution Systems Prof. Anne Goodchild Spring 2009

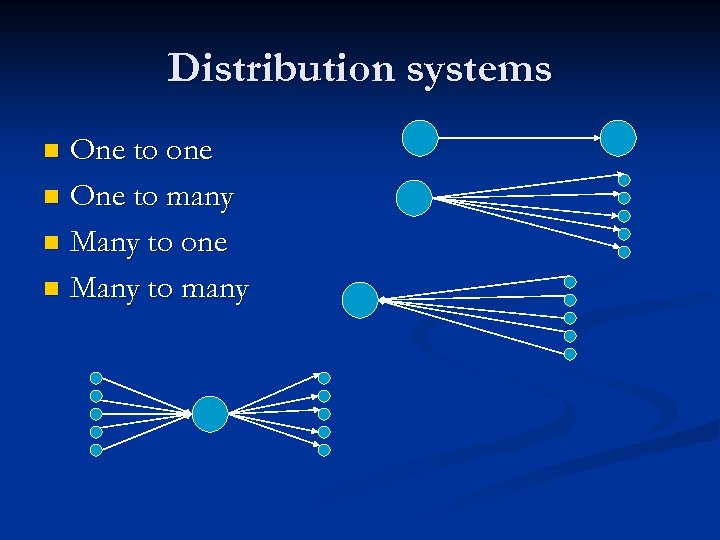

Distribution systems One to one n One to many n Many to one n Many to many n

Distribution systems One to one n One to many n Many to one n Many to many n

1 -1 Distribution Examples Port to rail head drayage n Small in scale and/or scope n n Decisions: Shipment frequency n Route (this is typically a function of the network and travel times) n Shipment times n

1 -1 Distribution Examples Port to rail head drayage n Small in scale and/or scope n n Decisions: Shipment frequency n Route (this is typically a function of the network and travel times) n Shipment times n

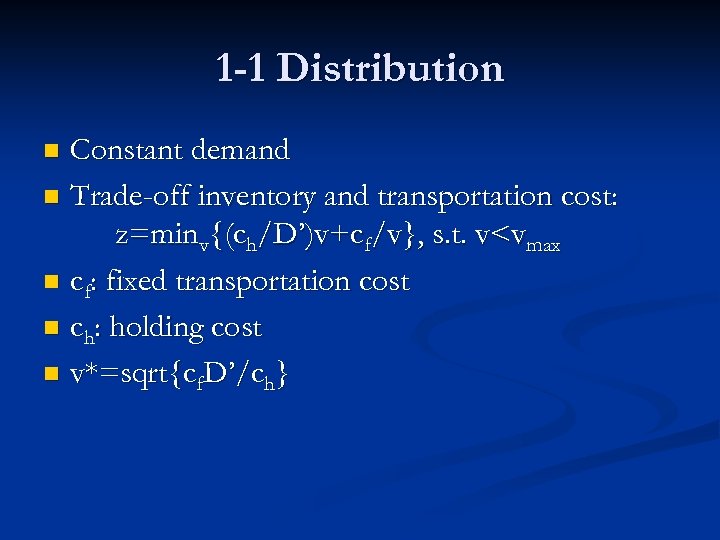

1 -1 Distribution Constant demand n Trade-off inventory and transportation cost: z=minv{(ch/D’)v+cf/v}, s. t. v

1 -1 Distribution Constant demand n Trade-off inventory and transportation cost: z=minv{(ch/D’)v+cf/v}, s. t. v

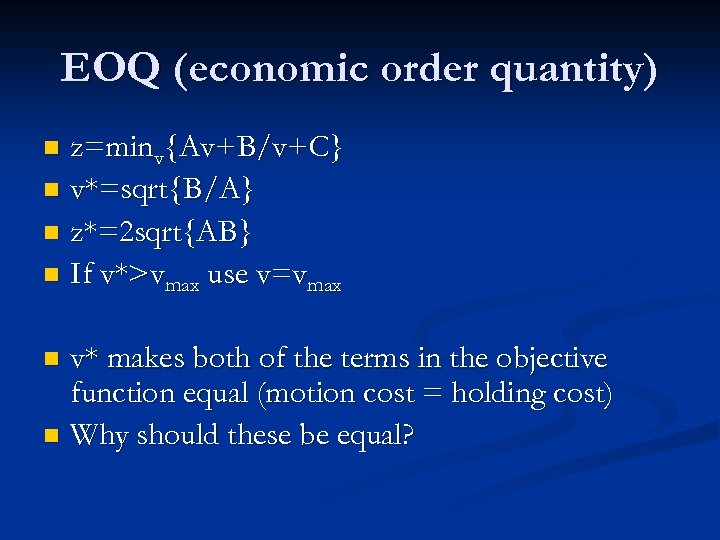

EOQ (economic order quantity) z=minv{Av+B/v+C} n v*=sqrt{B/A} n z*=2 sqrt{AB} n If v*>vmax use v=vmax n v* makes both of the terms in the objective function equal (motion cost = holding cost) n Why should these be equal? n

EOQ (economic order quantity) z=minv{Av+B/v+C} n v*=sqrt{B/A} n z*=2 sqrt{AB} n If v*>vmax use v=vmax n v* makes both of the terms in the objective function equal (motion cost = holding cost) n Why should these be equal? n

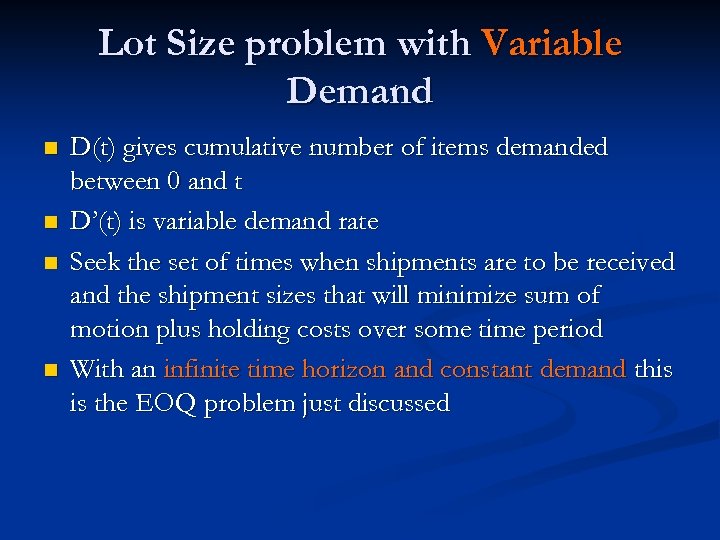

Lot Size problem with Variable Demand n n D(t) gives cumulative number of items demanded between 0 and t D’(t) is variable demand rate Seek the set of times when shipments are to be received and the shipment sizes that will minimize sum of motion plus holding costs over some time period With an infinite time horizon and constant demand this is the EOQ problem just discussed

Lot Size problem with Variable Demand n n D(t) gives cumulative number of items demanded between 0 and t D’(t) is variable demand rate Seek the set of times when shipments are to be received and the shipment sizes that will minimize sum of motion plus holding costs over some time period With an infinite time horizon and constant demand this is the EOQ problem just discussed

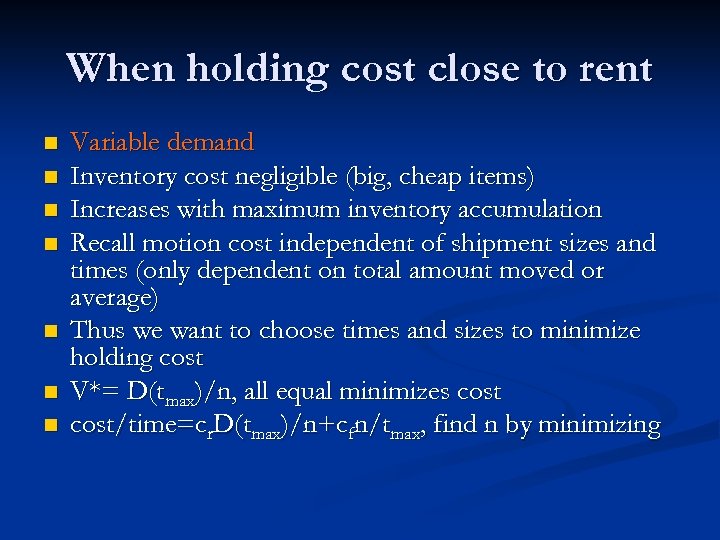

When holding cost close to rent n n n n Variable demand Inventory cost negligible (big, cheap items) Increases with maximum inventory accumulation Recall motion cost independent of shipment sizes and times (only dependent on total amount moved or average) Thus we want to choose times and sizes to minimize holding cost V*= D(tmax)/n, all equal minimizes cost/time=cr. D(tmax)/n+cfn/tmax, find n by minimizing

When holding cost close to rent n n n n Variable demand Inventory cost negligible (big, cheap items) Increases with maximum inventory accumulation Recall motion cost independent of shipment sizes and times (only dependent on total amount moved or average) Thus we want to choose times and sizes to minimize holding cost V*= D(tmax)/n, all equal minimizes cost/time=cr. D(tmax)/n+cfn/tmax, find n by minimizing

When rent is negligible Small, expensive items n Simple expression cannot be obtained unless D(t) varies slowly with t (CA method) n Use numerical solution (e. g. dynamic programming) n

When rent is negligible Small, expensive items n Simple expression cannot be obtained unless D(t) varies slowly with t (CA method) n Use numerical solution (e. g. dynamic programming) n

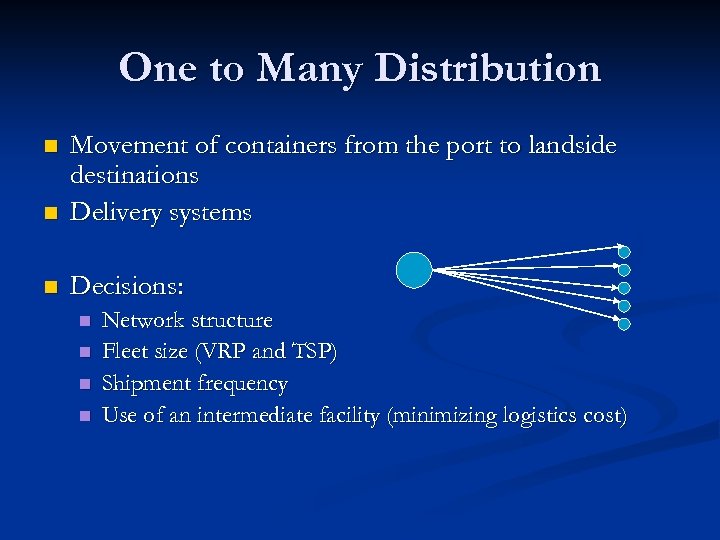

One to Many Distribution n Movement of containers from the port to landside destinations Delivery systems n Decisions: n n n Network structure Fleet size (VRP and TSP) Shipment frequency Use of an intermediate facility (minimizing logistics cost)

One to Many Distribution n Movement of containers from the port to landside destinations Delivery systems n Decisions: n n n Network structure Fleet size (VRP and TSP) Shipment frequency Use of an intermediate facility (minimizing logistics cost)

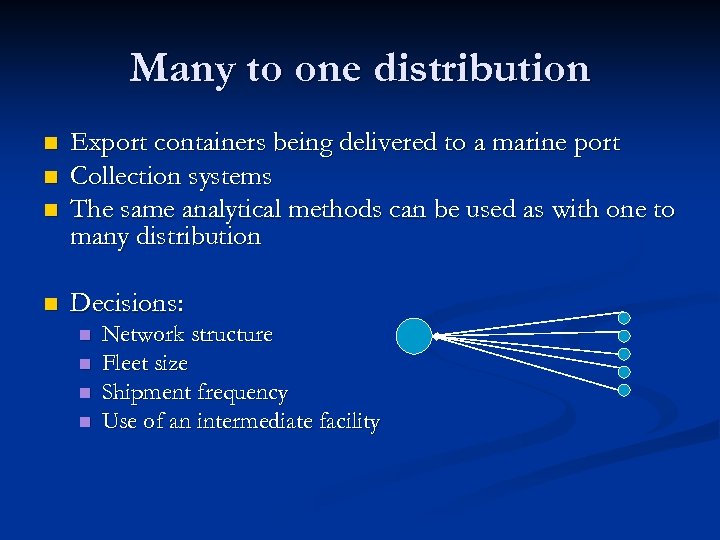

Many to one distribution n n Export containers being delivered to a marine port Collection systems The same analytical methods can be used as with one to many distribution Decisions: n n Network structure Fleet size Shipment frequency Use of an intermediate facility

Many to one distribution n n Export containers being delivered to a marine port Collection systems The same analytical methods can be used as with one to many distribution Decisions: n n Network structure Fleet size Shipment frequency Use of an intermediate facility

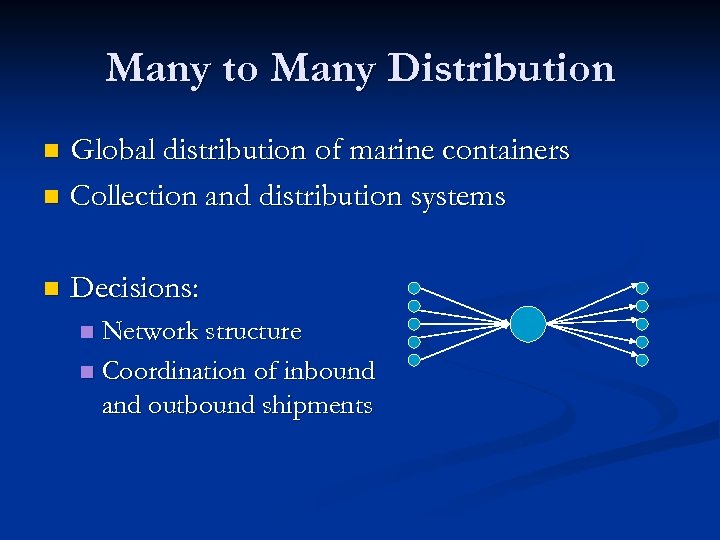

Many to Many Distribution Global distribution of marine containers n Collection and distribution systems n n Decisions: Network structure n Coordination of inbound and outbound shipments n

Many to Many Distribution Global distribution of marine containers n Collection and distribution systems n n Decisions: Network structure n Coordination of inbound and outbound shipments n

Many to many distribution n The problem can often, and should often, be broken down into pieces Inbound logistics (many to one) n Outbound logistics (one to many) n Be mindful of who is responsible for cost within the supply chain n Most supply chains are not operated by the same entity n Use terminals to consolidate some of the flow n

Many to many distribution n The problem can often, and should often, be broken down into pieces Inbound logistics (many to one) n Outbound logistics (one to many) n Be mindful of who is responsible for cost within the supply chain n Most supply chains are not operated by the same entity n Use terminals to consolidate some of the flow n

Transshipment

Transshipment

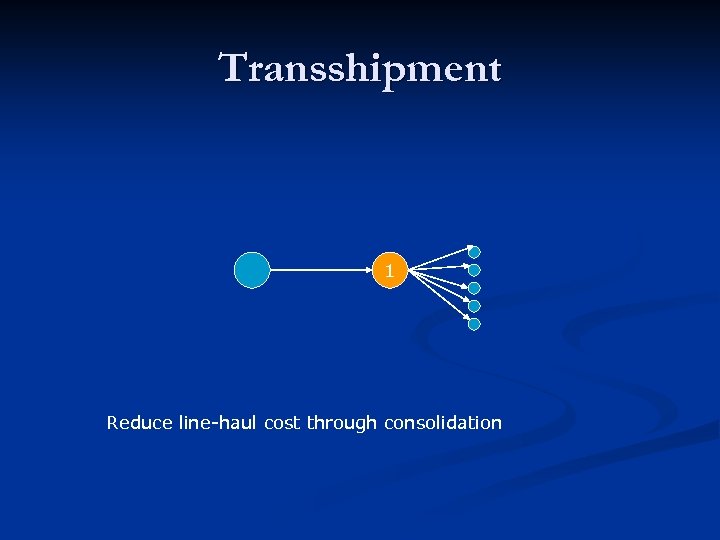

Transshipment 1 Reduce line-haul cost through consolidation

Transshipment 1 Reduce line-haul cost through consolidation

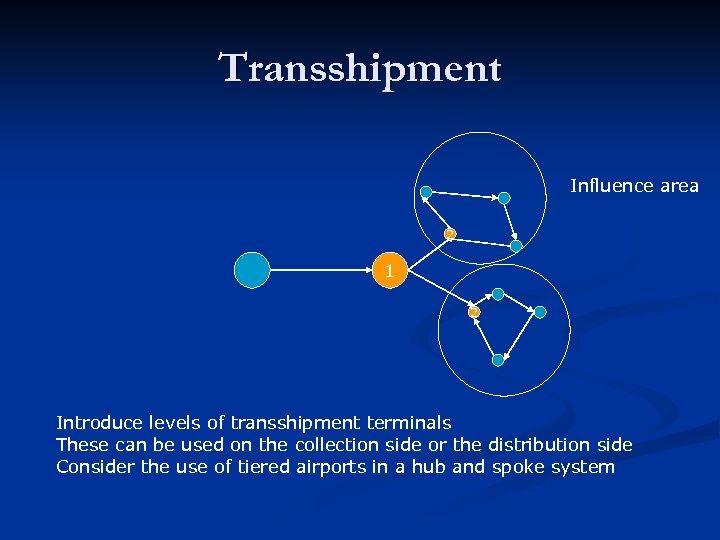

Transshipment Influence area 2 1 2 Introduce levels of transshipment terminals These can be used on the collection side or the distribution side Consider the use of tiered airports in a hub and spoke system

Transshipment Influence area 2 1 2 Introduce levels of transshipment terminals These can be used on the collection side or the distribution side Consider the use of tiered airports in a hub and spoke system

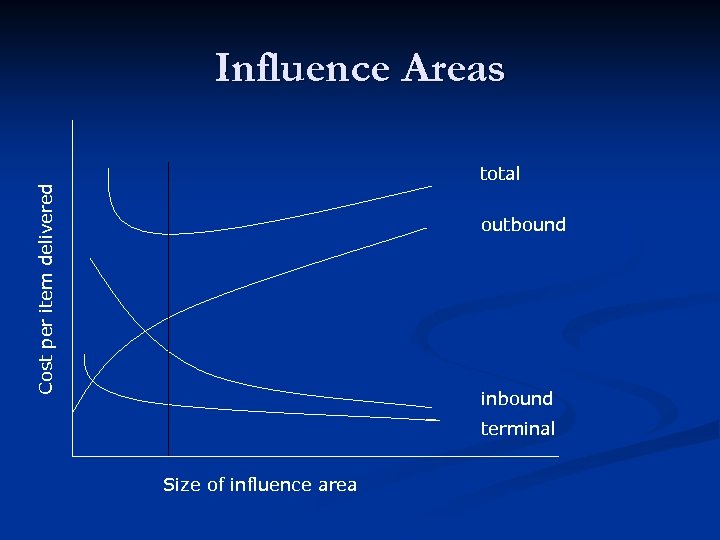

Influence Areas Cost per item delivered total outbound inbound terminal Size of influence area

Influence Areas Cost per item delivered total outbound inbound terminal Size of influence area

Themes n Scale What part of the logistics system will you consider? n Typically determined by ownership and operating units but it depends on your goals n n Consistency n Logistics systems are more manageable

Themes n Scale What part of the logistics system will you consider? n Typically determined by ownership and operating units but it depends on your goals n n Consistency n Logistics systems are more manageable