Group of companies ITALIAN INSTITUTE OF WELDINGThe Italian

all_iis_group_presentation_2015_astrakhan.ppt

- Количество слайдов: 59

Group of companies ITALIAN INSTITUTE OF WELDING

Group of companies ITALIAN INSTITUTE OF WELDING

The Italian Institute of Welding was founded in 1948 and is a founder member of the International Institute of Welding (IIW) and of the European Welding Federation (EWF): within both organizations it has always held apical appointments. IIS attends or leads various executive, research and standardization European and international committees. The active participation of the Italian Institute of Welding within these bodies results in a strong international activity, originating contacts and synergies with similar institutes of highly developed countries. FOUNDER MEMBER Group of companies ITALIAN INSTITUTE OF WELDING

The Italian Institute of Welding was founded in 1948 and is a founder member of the International Institute of Welding (IIW) and of the European Welding Federation (EWF): within both organizations it has always held apical appointments. IIS attends or leads various executive, research and standardization European and international committees. The active participation of the Italian Institute of Welding within these bodies results in a strong international activity, originating contacts and synergies with similar institutes of highly developed countries. FOUNDER MEMBER Group of companies ITALIAN INSTITUTE OF WELDING

IIS HEADQUARTER Italian Institute of Welding (www.iis.it) is a private non-profit distributing organization, established in 1948. The head office is based in Genoa. Our scientific and technical departments and laboratories are consolidated in an area of 11,000 m2, of which 7,500m2 indoor. Group of companies ITALIAN INSTITUTE OF WELDING

IIS HEADQUARTER Italian Institute of Welding (www.iis.it) is a private non-profit distributing organization, established in 1948. The head office is based in Genoa. Our scientific and technical departments and laboratories are consolidated in an area of 11,000 m2, of which 7,500m2 indoor. Group of companies ITALIAN INSTITUTE OF WELDING

IIS GROUP consists at present of four legally distinct companies: the Italian Institute of Welding, with a legal status of a no - profit distributing association, and three limited companies owned by the Italian Institute of Welding: IIS CERT srl, IIS PROGRESS srl and IIS SERVICE srl. The Group boasts at present nearly 230 employees. 150 are graduate or diploma-holders. Group of companies ITALIAN INSTITUTE OF WELDING

IIS GROUP consists at present of four legally distinct companies: the Italian Institute of Welding, with a legal status of a no - profit distributing association, and three limited companies owned by the Italian Institute of Welding: IIS CERT srl, IIS PROGRESS srl and IIS SERVICE srl. The Group boasts at present nearly 230 employees. 150 are graduate or diploma-holders. Group of companies ITALIAN INSTITUTE OF WELDING

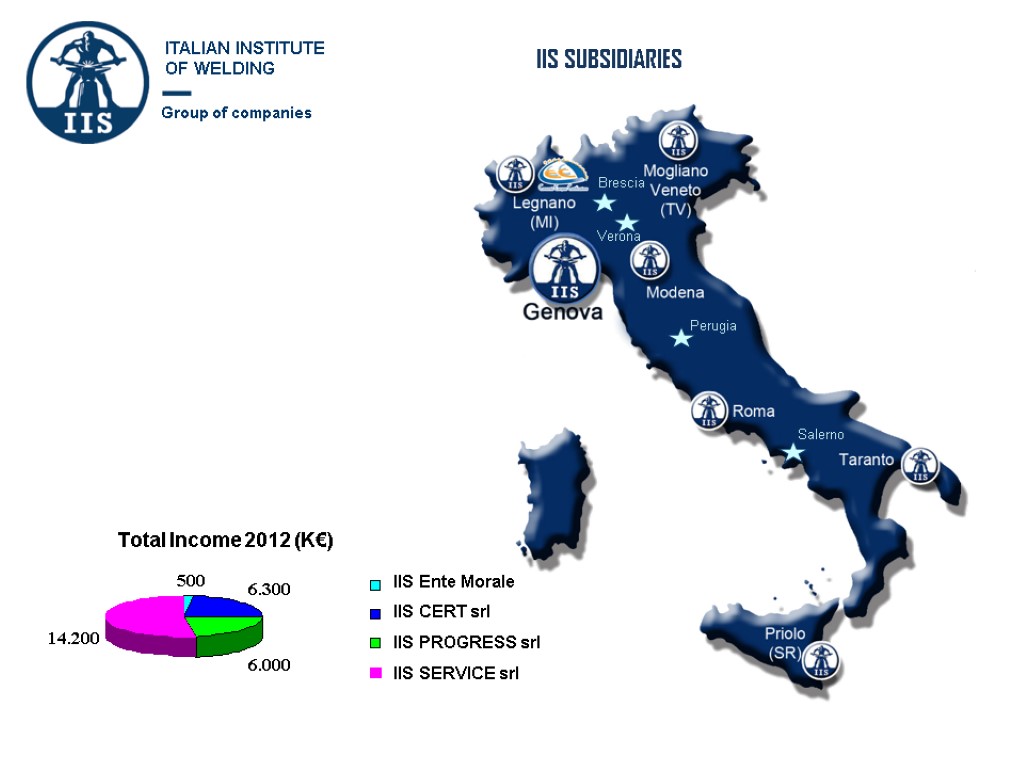

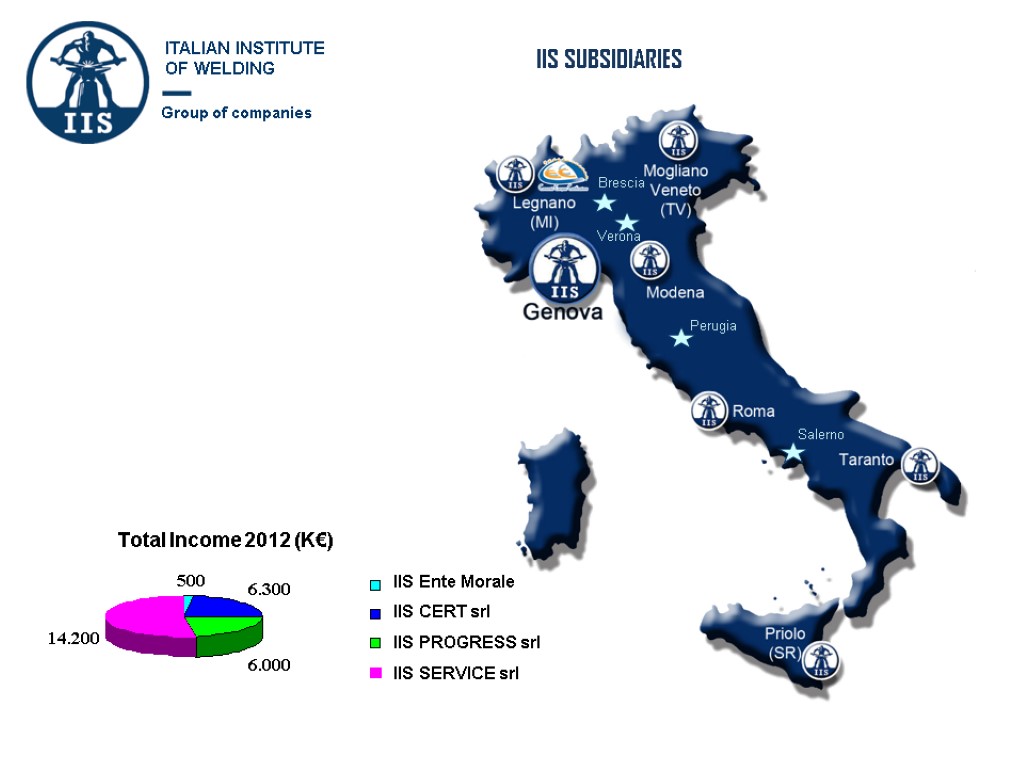

Total Income 2012 (K€) IIS SUBSIDIARIES IIS Ente Morale IIS CERT srl IIS PROGRESS srl IIS SERVICE srl Group of companies ITALIAN INSTITUTE OF WELDING Brescia Verona Perugia Salerno

Total Income 2012 (K€) IIS SUBSIDIARIES IIS Ente Morale IIS CERT srl IIS PROGRESS srl IIS SERVICE srl Group of companies ITALIAN INSTITUTE OF WELDING Brescia Verona Perugia Salerno

…. taking into value being reliable and trustworthy and establishing long-term relationships with clients, employees, suppliers and technical partners. The common mission of the Companies of IIS Group is supplying a wide range of integrated services in the field of technical assistance, certification, education and training, laboratory test addressed to ensure integrity, reliability, availability of structures, components and industrial plants, being recognized as a leader group as far as expertise and technical independence are concerned... Group of companies ITALIAN INSTITUTE OF WELDING

…. taking into value being reliable and trustworthy and establishing long-term relationships with clients, employees, suppliers and technical partners. The common mission of the Companies of IIS Group is supplying a wide range of integrated services in the field of technical assistance, certification, education and training, laboratory test addressed to ensure integrity, reliability, availability of structures, components and industrial plants, being recognized as a leader group as far as expertise and technical independence are concerned... Group of companies ITALIAN INSTITUTE OF WELDING

Technical Assistance Technical Assistance - by IIS SERVICE Group of companies ITALIAN INSTITUTE OF WELDING

Technical Assistance Technical Assistance - by IIS SERVICE Group of companies ITALIAN INSTITUTE OF WELDING

Based upon our in-house know-how we devise new solutions to meet clients needs. Our target is to give the best possible advice involving consultancy, supervision, coaching. Technical Assistance - by IIS SERVICE Group of companies ITALIAN INSTITUTE OF WELDING Our approach is to support Clients offering our services in the fields of: • Engineering: Structural, Process, Materials & Corrosion Engineering • Inspection and survey • Advanced diagnostics A technical third party…

Based upon our in-house know-how we devise new solutions to meet clients needs. Our target is to give the best possible advice involving consultancy, supervision, coaching. Technical Assistance - by IIS SERVICE Group of companies ITALIAN INSTITUTE OF WELDING Our approach is to support Clients offering our services in the fields of: • Engineering: Structural, Process, Materials & Corrosion Engineering • Inspection and survey • Advanced diagnostics A technical third party…

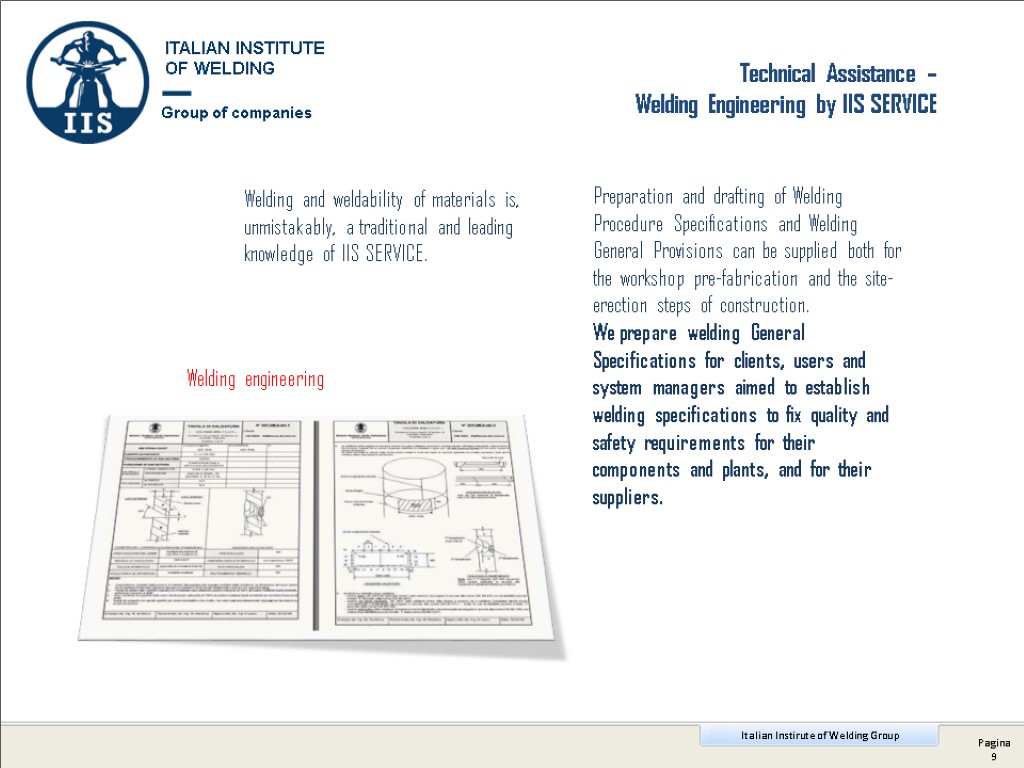

Welding and weldability of materials is, unmistakably, a traditional and leading knowledge of IIS SERVICE. Welding engineering Technical Assistance – Welding Engineering by IIS SERVICE Preparation and drafting of Welding Procedure Specifications and Welding General Provisions can be supplied both for the workshop pre-fabrication and the site-erection steps of construction. We prepare welding General Specifications for clients, users and system managers aimed to establish welding specifications to fix quality and safety requirements for their components and plants, and for their suppliers. Group of companies ITALIAN INSTITUTE OF WELDING

Welding and weldability of materials is, unmistakably, a traditional and leading knowledge of IIS SERVICE. Welding engineering Technical Assistance – Welding Engineering by IIS SERVICE Preparation and drafting of Welding Procedure Specifications and Welding General Provisions can be supplied both for the workshop pre-fabrication and the site-erection steps of construction. We prepare welding General Specifications for clients, users and system managers aimed to establish welding specifications to fix quality and safety requirements for their components and plants, and for their suppliers. Group of companies ITALIAN INSTITUTE OF WELDING

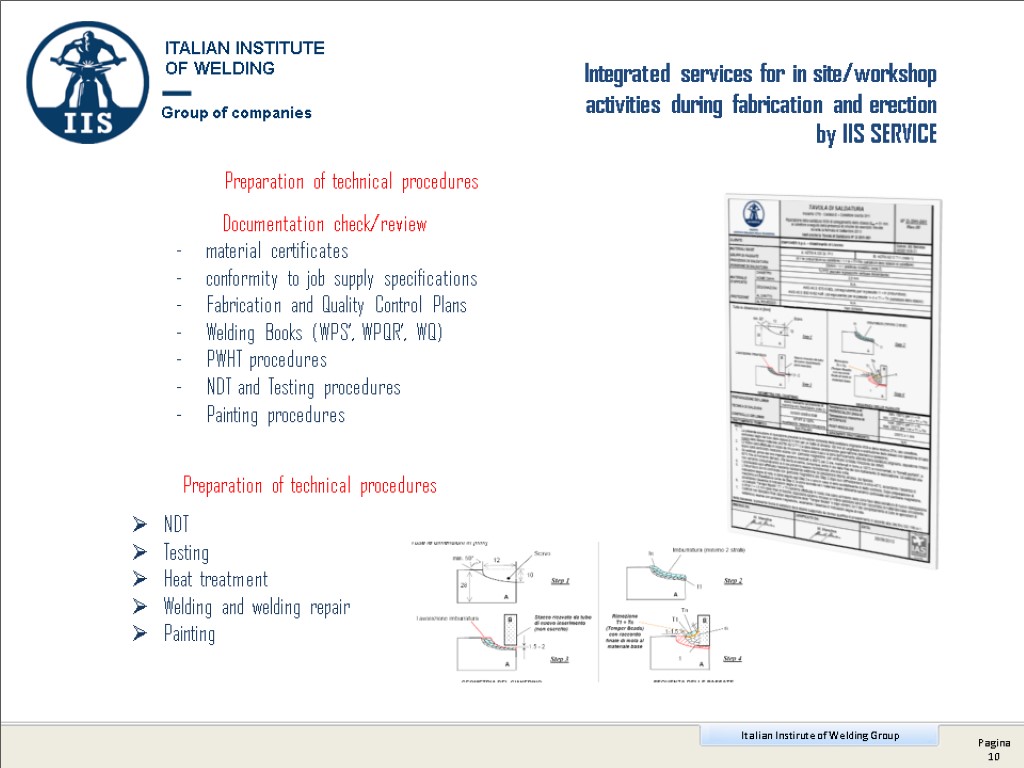

material certificates conformity to job supply specifications Fabrication and Quality Control Plans Welding Books (WPS’, WPQR’, WQ) PWHT procedures NDT and Testing procedures Painting procedures Documentation check/review Integrated services for in site/workshop activities during fabrication and erection by IIS SERVICE Preparation of technical procedures Preparation of technical procedures NDT Testing Heat treatment Welding and welding repair Painting Group of companies ITALIAN INSTITUTE OF WELDING

material certificates conformity to job supply specifications Fabrication and Quality Control Plans Welding Books (WPS’, WPQR’, WQ) PWHT procedures NDT and Testing procedures Painting procedures Documentation check/review Integrated services for in site/workshop activities during fabrication and erection by IIS SERVICE Preparation of technical procedures Preparation of technical procedures NDT Testing Heat treatment Welding and welding repair Painting Group of companies ITALIAN INSTITUTE OF WELDING

“More and more refiners are making Risk-Based Inspection –RBI- an integral part of their plant work process” (E2G - The Equity Engineering Group). IIS SERVICE is the recognized leader in service and support for inspection planning and RBI studies based on API 580-581 approach, in Italy and abroad. Our membership in API-RBI User’s Group dates back to 2001. IIS SERVICE accomplishes RBI analysis by the official software API-RBI. Risk Based Inspection Technical Assistance - by IIS SERVICE Group of companies ITALIAN INSTITUTE OF WELDING

“More and more refiners are making Risk-Based Inspection –RBI- an integral part of their plant work process” (E2G - The Equity Engineering Group). IIS SERVICE is the recognized leader in service and support for inspection planning and RBI studies based on API 580-581 approach, in Italy and abroad. Our membership in API-RBI User’s Group dates back to 2001. IIS SERVICE accomplishes RBI analysis by the official software API-RBI. Risk Based Inspection Technical Assistance - by IIS SERVICE Group of companies ITALIAN INSTITUTE OF WELDING

Tailor made Software Non intrusive inspections Technical Assistance - by IIS SERVICE Group of companies ITALIAN INSTITUTE OF WELDING

Tailor made Software Non intrusive inspections Technical Assistance - by IIS SERVICE Group of companies ITALIAN INSTITUTE OF WELDING

Fitness for Service (FFS) Engineering Critical Assessment (ECA) and the fracture mechanics approach Group of companies ITALIAN INSTITUTE OF WELDING

Fitness for Service (FFS) Engineering Critical Assessment (ECA) and the fracture mechanics approach Group of companies ITALIAN INSTITUTE OF WELDING

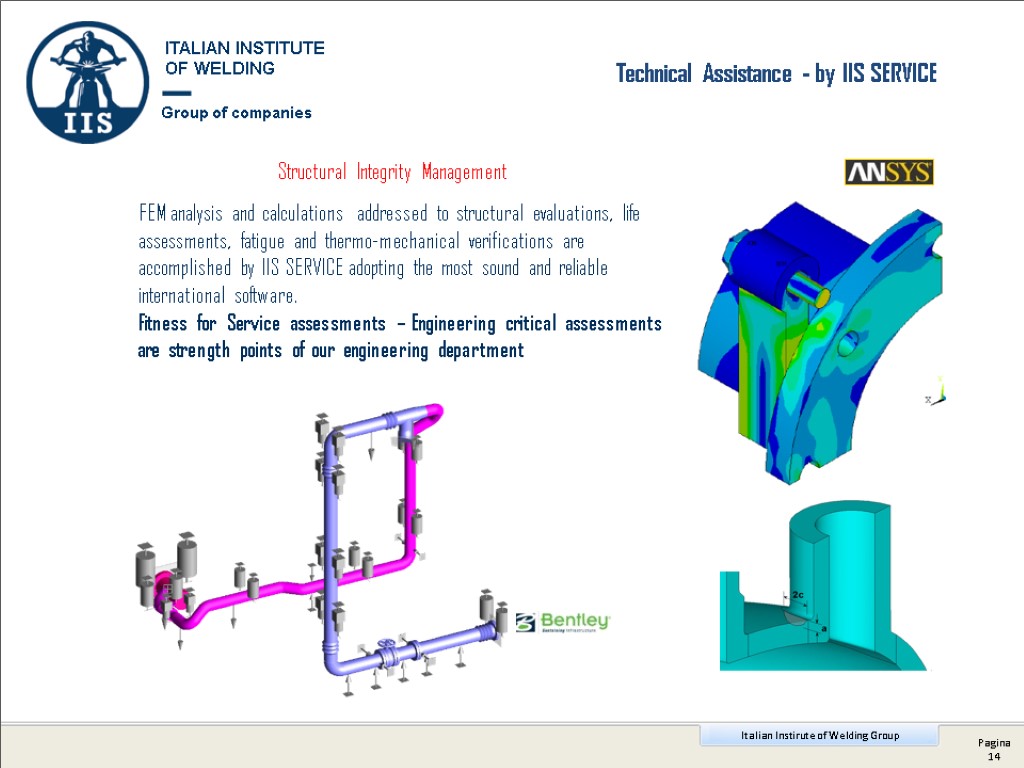

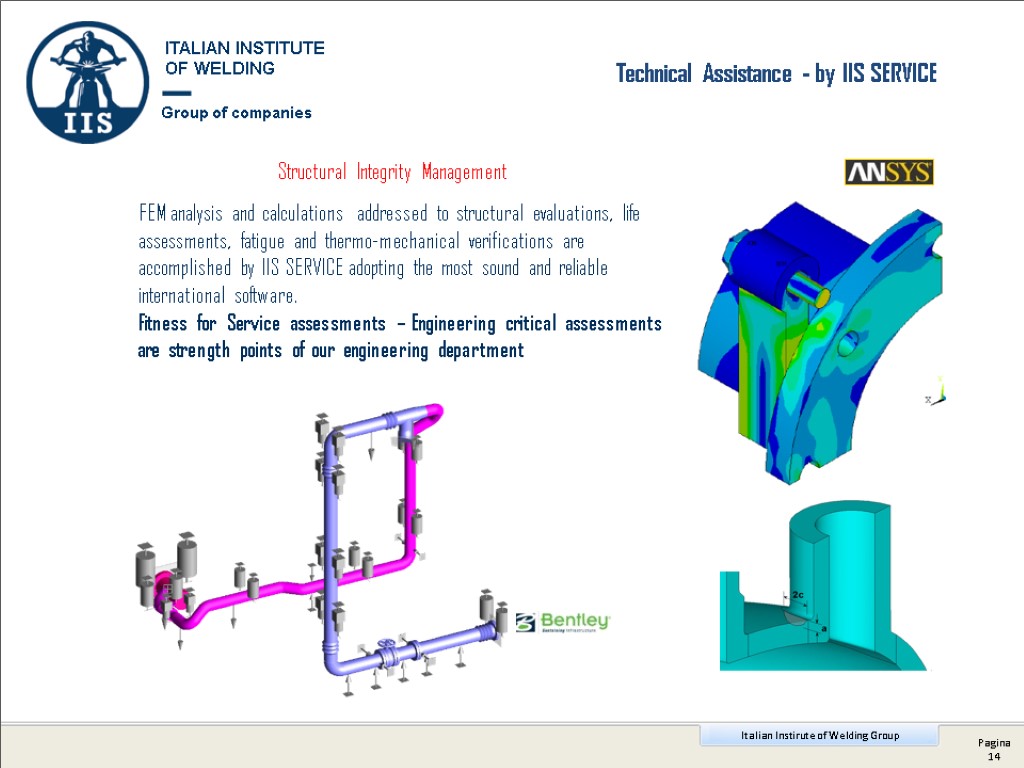

Technical Assistance - by IIS SERVICE FEM analysis and calculations addressed to structural evaluations, life assessments, fatigue and thermo-mechanical verifications are accomplished by IIS SERVICE adopting the most sound and reliable international software. Fitness for Service assessments – Engineering critical assessments are strength points of our engineering department Structural Integrity Management Group of companies ITALIAN INSTITUTE OF WELDING

Technical Assistance - by IIS SERVICE FEM analysis and calculations addressed to structural evaluations, life assessments, fatigue and thermo-mechanical verifications are accomplished by IIS SERVICE adopting the most sound and reliable international software. Fitness for Service assessments – Engineering critical assessments are strength points of our engineering department Structural Integrity Management Group of companies ITALIAN INSTITUTE OF WELDING

ASME SECT. VIII Div. 1/Div. 2 EN 13445 FFS – ECA: Why? Design and Fabrication codes and standards for equipment, structures and components provide rules for the design, fabrication, inspection, and testing of new items. These codes typically do not provide assessment procedures to evaluate degradation due to in-service environmentally-induced damage or from original fabrication that may be found during subsequent inspections. Group of companies ITALIAN INSTITUTE OF WELDING

ASME SECT. VIII Div. 1/Div. 2 EN 13445 FFS – ECA: Why? Design and Fabrication codes and standards for equipment, structures and components provide rules for the design, fabrication, inspection, and testing of new items. These codes typically do not provide assessment procedures to evaluate degradation due to in-service environmentally-induced damage or from original fabrication that may be found during subsequent inspections. Group of companies ITALIAN INSTITUTE OF WELDING

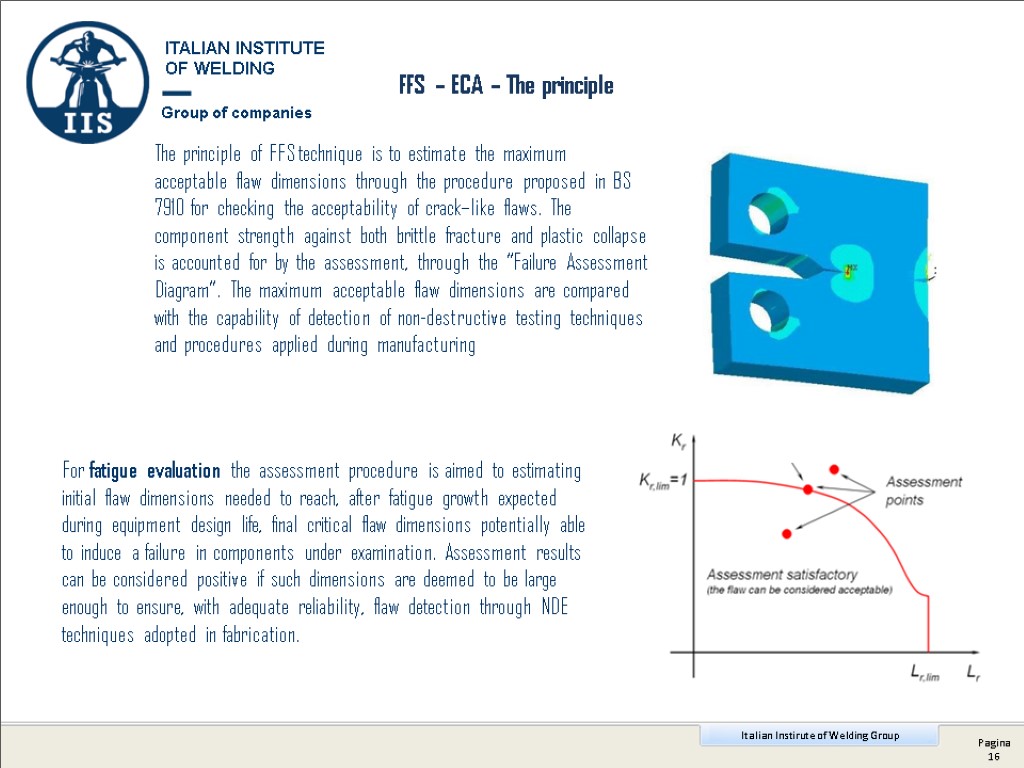

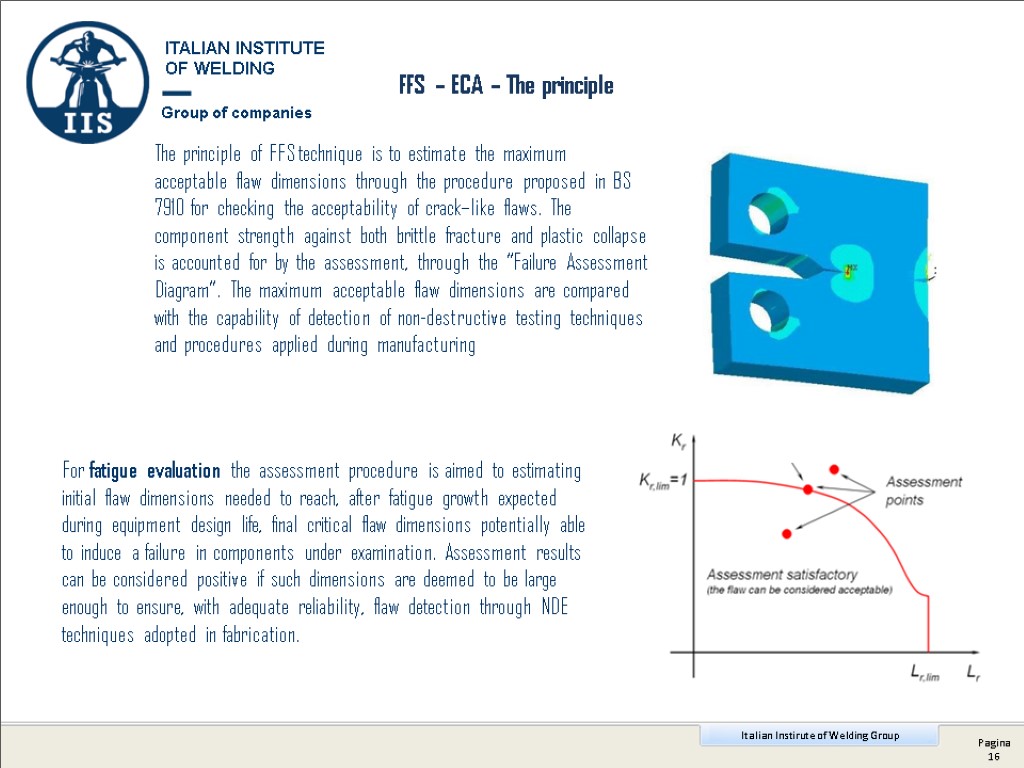

FFS – ECA – The principle The principle of FFS technique is to estimate the maximum acceptable flaw dimensions through the procedure proposed in BS 7910 for checking the acceptability of crack–like flaws. The component strength against both brittle fracture and plastic collapse is accounted for by the assessment, through the “Failure Assessment Diagram”. The maximum acceptable flaw dimensions are compared with the capability of detection of non-destructive testing techniques and procedures applied during manufacturing For fatigue evaluation the assessment procedure is aimed to estimating initial flaw dimensions needed to reach, after fatigue growth expected during equipment design life, final critical flaw dimensions potentially able to induce a failure in components under examination. Assessment results can be considered positive if such dimensions are deemed to be large enough to ensure, with adequate reliability, flaw detection through NDE techniques adopted in fabrication. Group of companies ITALIAN INSTITUTE OF WELDING

FFS – ECA – The principle The principle of FFS technique is to estimate the maximum acceptable flaw dimensions through the procedure proposed in BS 7910 for checking the acceptability of crack–like flaws. The component strength against both brittle fracture and plastic collapse is accounted for by the assessment, through the “Failure Assessment Diagram”. The maximum acceptable flaw dimensions are compared with the capability of detection of non-destructive testing techniques and procedures applied during manufacturing For fatigue evaluation the assessment procedure is aimed to estimating initial flaw dimensions needed to reach, after fatigue growth expected during equipment design life, final critical flaw dimensions potentially able to induce a failure in components under examination. Assessment results can be considered positive if such dimensions are deemed to be large enough to ensure, with adequate reliability, flaw detection through NDE techniques adopted in fabrication. Group of companies ITALIAN INSTITUTE OF WELDING

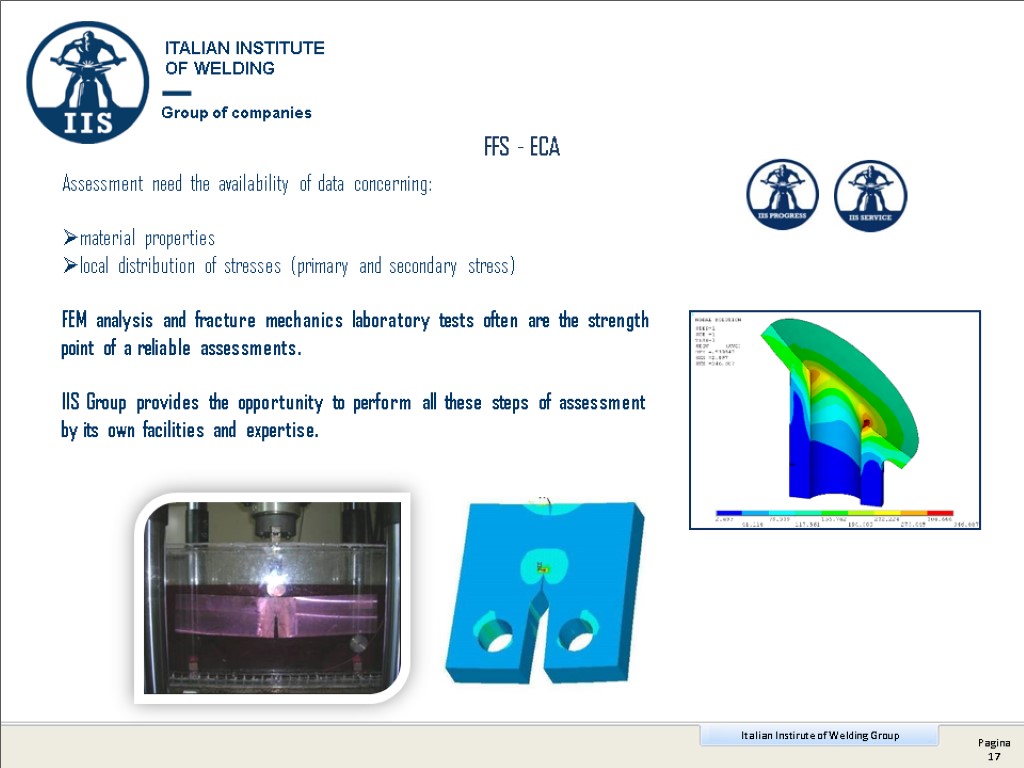

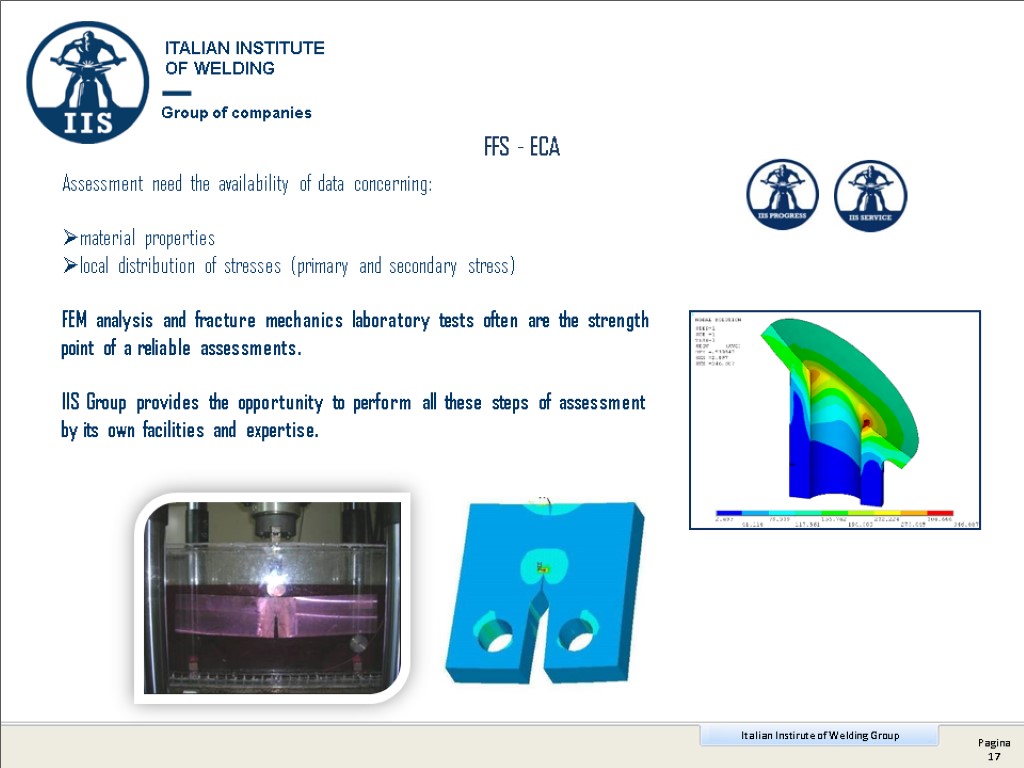

FFS - ECA Group of companies ITALIAN INSTITUTE OF WELDING Assessment need the availability of data concerning: material properties local distribution of stresses (primary and secondary stress) FEM analysis and fracture mechanics laboratory tests often are the strength point of a reliable assessments. IIS Group provides the opportunity to perform all these steps of assessment by its own facilities and expertise.

FFS - ECA Group of companies ITALIAN INSTITUTE OF WELDING Assessment need the availability of data concerning: material properties local distribution of stresses (primary and secondary stress) FEM analysis and fracture mechanics laboratory tests often are the strength point of a reliable assessments. IIS Group provides the opportunity to perform all these steps of assessment by its own facilities and expertise.

Site and workshop inspections Technical Assistance - by IIS SERVICE Group of companies ITALIAN INSTITUTE OF WELDING

Site and workshop inspections Technical Assistance - by IIS SERVICE Group of companies ITALIAN INSTITUTE OF WELDING

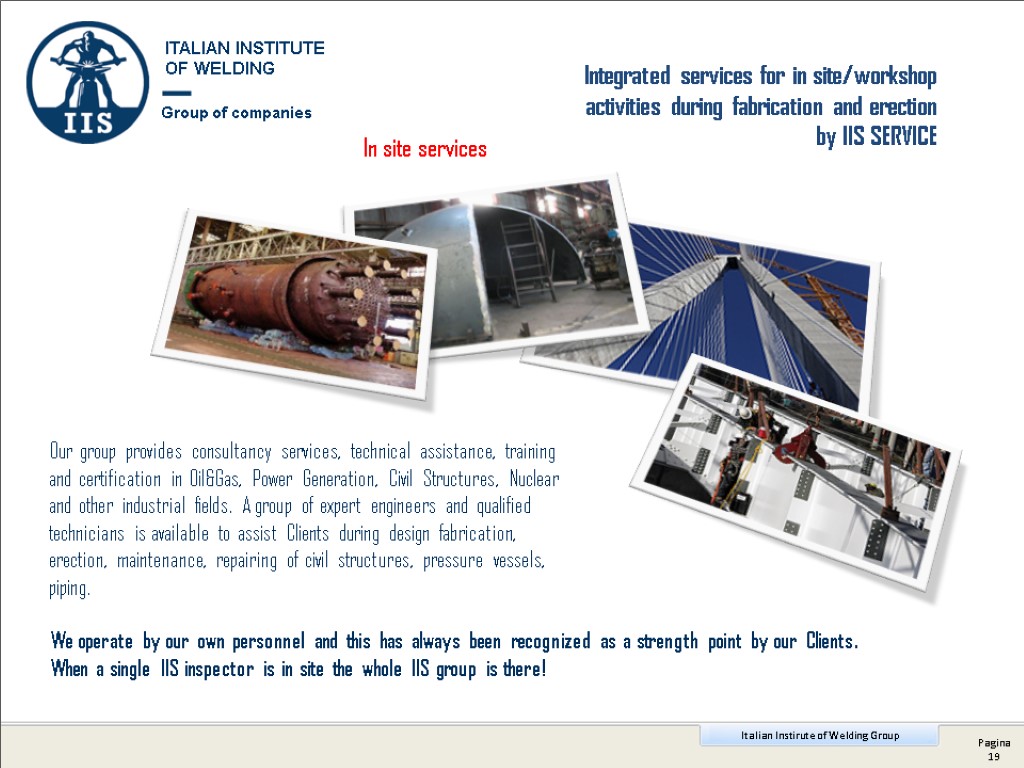

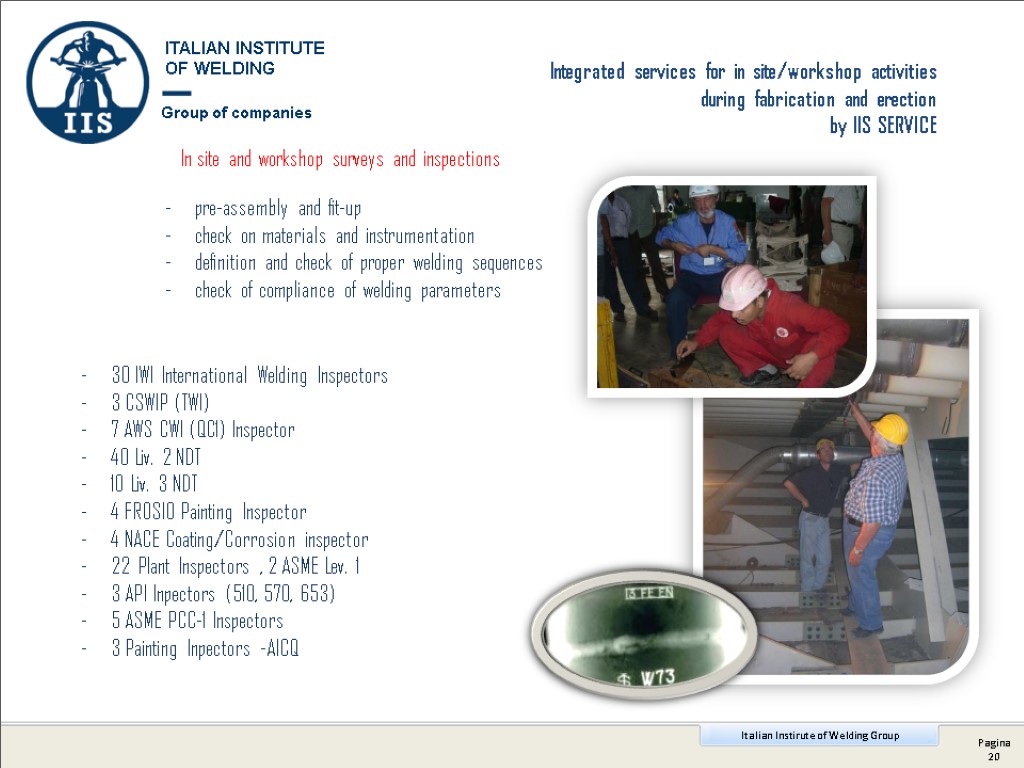

Our group provides consultancy services, technical assistance, training and certification in Oil&Gas, Power Generation, Civil Structures, Nuclear and other industrial fields. A group of expert engineers and qualified technicians is available to assist Clients during design fabrication, erection, maintenance, repairing of civil structures, pressure vessels, piping. Integrated services for in site/workshop activities during fabrication and erection by IIS SERVICE In site services We operate by our own personnel and this has always been recognized as a strength point by our Clients. When a single IIS inspector is in site the whole IIS group is there! Group of companies ITALIAN INSTITUTE OF WELDING

Our group provides consultancy services, technical assistance, training and certification in Oil&Gas, Power Generation, Civil Structures, Nuclear and other industrial fields. A group of expert engineers and qualified technicians is available to assist Clients during design fabrication, erection, maintenance, repairing of civil structures, pressure vessels, piping. Integrated services for in site/workshop activities during fabrication and erection by IIS SERVICE In site services We operate by our own personnel and this has always been recognized as a strength point by our Clients. When a single IIS inspector is in site the whole IIS group is there! Group of companies ITALIAN INSTITUTE OF WELDING

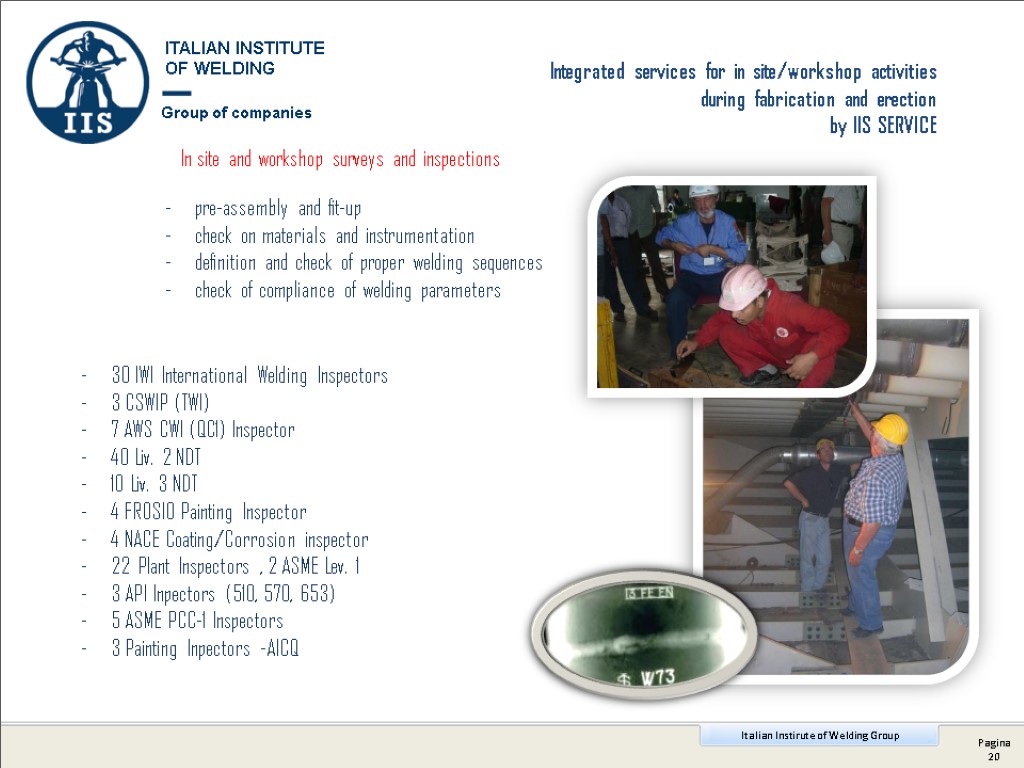

- pre-assembly and fit-up check on materials and instrumentation definition and check of proper welding sequences check of compliance of welding parameters In site and workshop surveys and inspections Integrated services for in site/workshop activities during fabrication and erection by IIS SERVICE 30 IWI International Welding Inspectors 3 CSWIP (TWI) 7 AWS CWI (QC1) Inspector 40 Liv. 2 NDT 10 Liv. 3 NDT 4 FROSIO Painting Inspector 4 NACE Coating/Corrosion inspector 22 Plant Inspectors , 2 ASME Lev. 1 3 API Inpectors (510, 570, 653) 5 ASME PCC-1 Inspectors 3 Painting Inpectors -AICQ Group of companies ITALIAN INSTITUTE OF WELDING

- pre-assembly and fit-up check on materials and instrumentation definition and check of proper welding sequences check of compliance of welding parameters In site and workshop surveys and inspections Integrated services for in site/workshop activities during fabrication and erection by IIS SERVICE 30 IWI International Welding Inspectors 3 CSWIP (TWI) 7 AWS CWI (QC1) Inspector 40 Liv. 2 NDT 10 Liv. 3 NDT 4 FROSIO Painting Inspector 4 NACE Coating/Corrosion inspector 22 Plant Inspectors , 2 ASME Lev. 1 3 API Inpectors (510, 570, 653) 5 ASME PCC-1 Inspectors 3 Painting Inpectors -AICQ Group of companies ITALIAN INSTITUTE OF WELDING

Advanced Diagnostics Automated NDT Technical Assistance - by IIS SERVICE Group of companies ITALIAN INSTITUTE OF WELDING

Advanced Diagnostics Automated NDT Technical Assistance - by IIS SERVICE Group of companies ITALIAN INSTITUTE OF WELDING

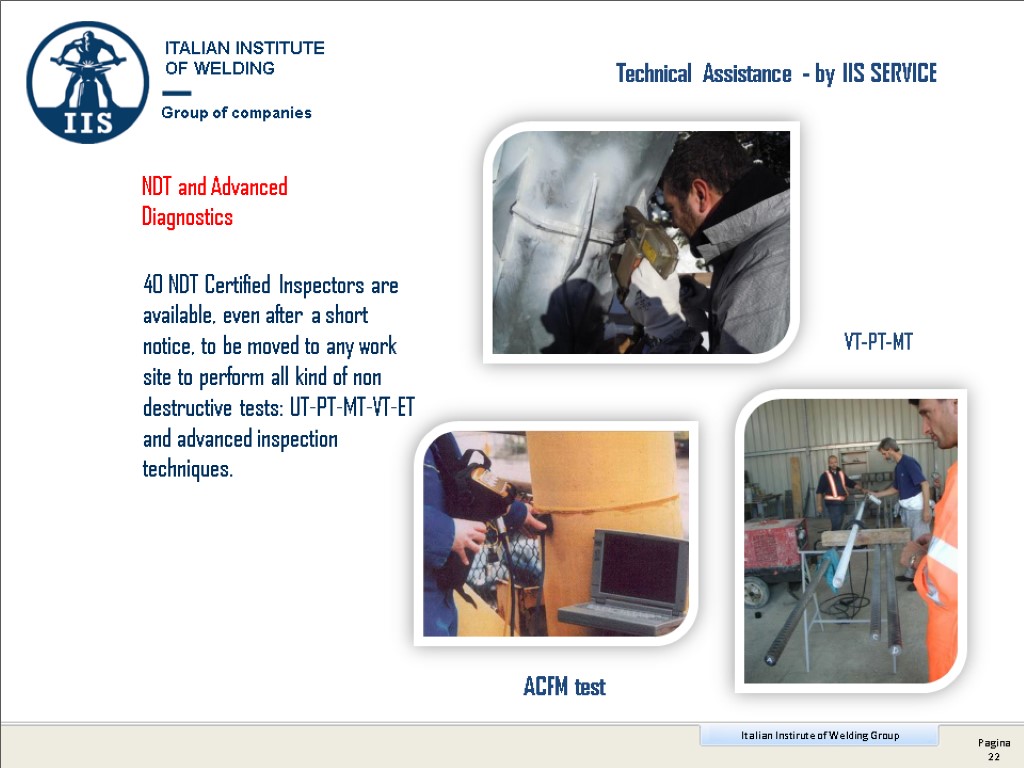

40 NDT Certified Inspectors are available, even after a short notice, to be moved to any work site to perform all kind of non destructive tests: UT-PT-MT-VT-ET and advanced inspection techniques. NDT and Advanced Diagnostics Technical Assistance - by IIS SERVICE ACFM test VT-PT-MT Group of companies ITALIAN INSTITUTE OF WELDING

40 NDT Certified Inspectors are available, even after a short notice, to be moved to any work site to perform all kind of non destructive tests: UT-PT-MT-VT-ET and advanced inspection techniques. NDT and Advanced Diagnostics Technical Assistance - by IIS SERVICE ACFM test VT-PT-MT Group of companies ITALIAN INSTITUTE OF WELDING

Technical Assistance - by IIS SERVICE Manual UT HARDNESS TEST NDT and Advanced Diagnostics Group of companies ITALIAN INSTITUTE OF WELDING

Technical Assistance - by IIS SERVICE Manual UT HARDNESS TEST NDT and Advanced Diagnostics Group of companies ITALIAN INSTITUTE OF WELDING

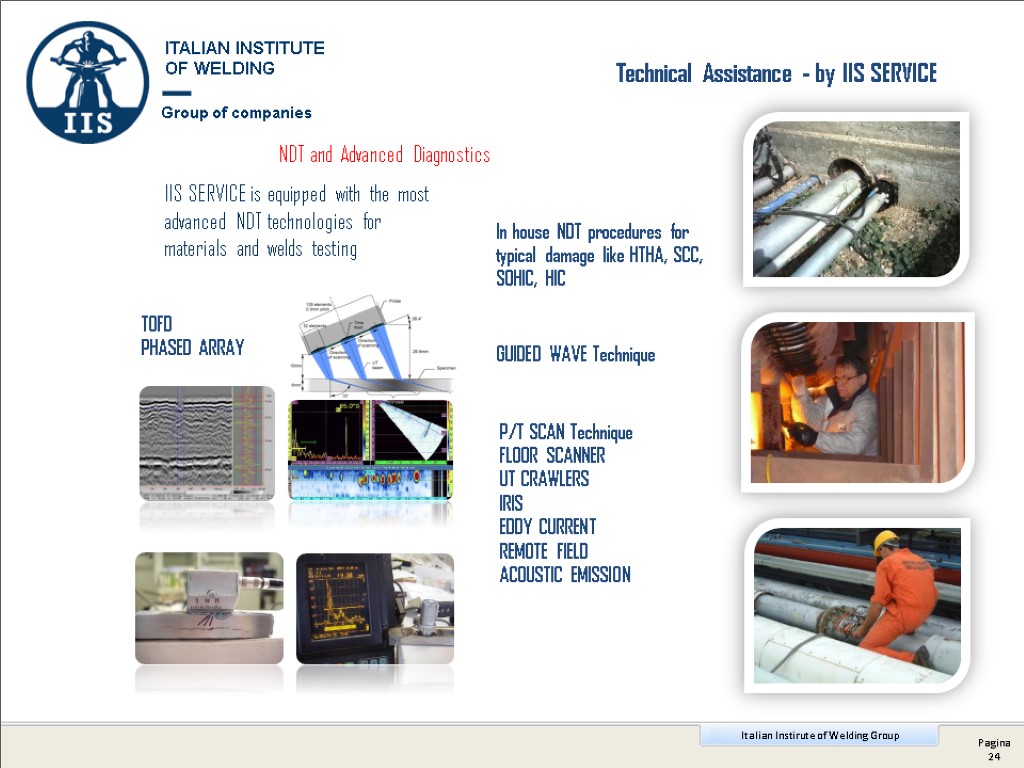

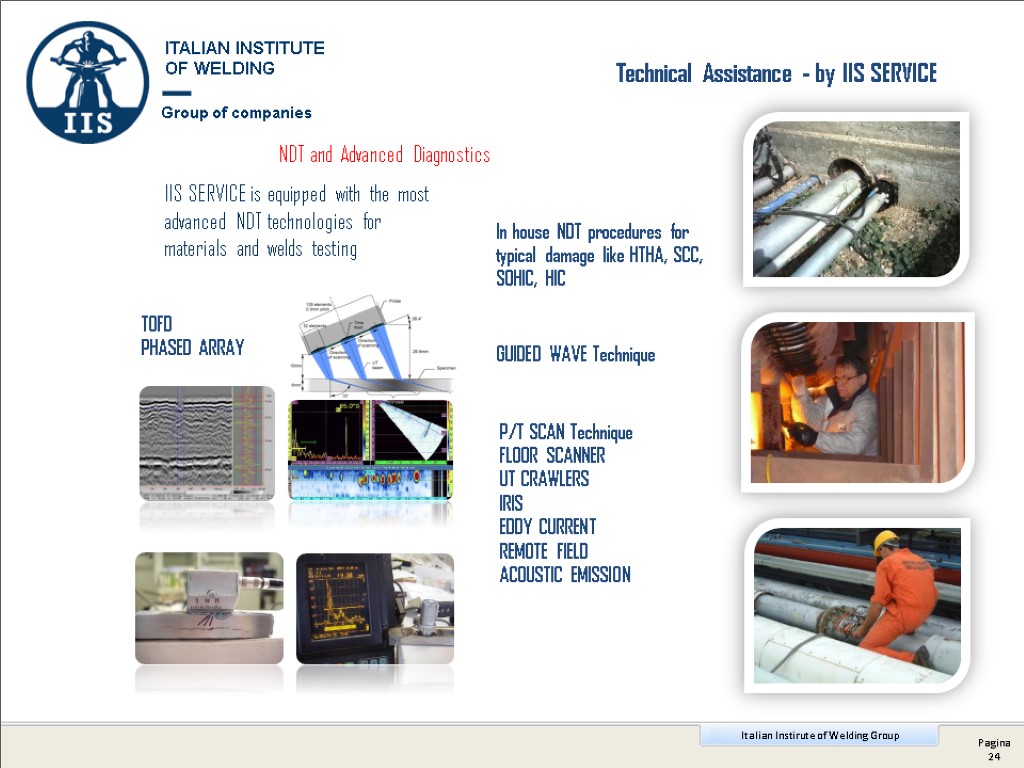

IIS SERVICE is equipped with the most advanced NDT technologies for materials and welds testing Technical Assistance - by IIS SERVICE GUIDED WAVE Technique In house NDT procedures for typical damage like HTHA, SCC, SOHIC, HIC P/T SCAN Technique FLOOR SCANNER UT CRAWLERS IRIS EDDY CURRENT REMOTE FIELD ACOUSTIC EMISSION TOFD PHASED ARRAY NDT and Advanced Diagnostics Group of companies ITALIAN INSTITUTE OF WELDING

IIS SERVICE is equipped with the most advanced NDT technologies for materials and welds testing Technical Assistance - by IIS SERVICE GUIDED WAVE Technique In house NDT procedures for typical damage like HTHA, SCC, SOHIC, HIC P/T SCAN Technique FLOOR SCANNER UT CRAWLERS IRIS EDDY CURRENT REMOTE FIELD ACOUSTIC EMISSION TOFD PHASED ARRAY NDT and Advanced Diagnostics Group of companies ITALIAN INSTITUTE OF WELDING

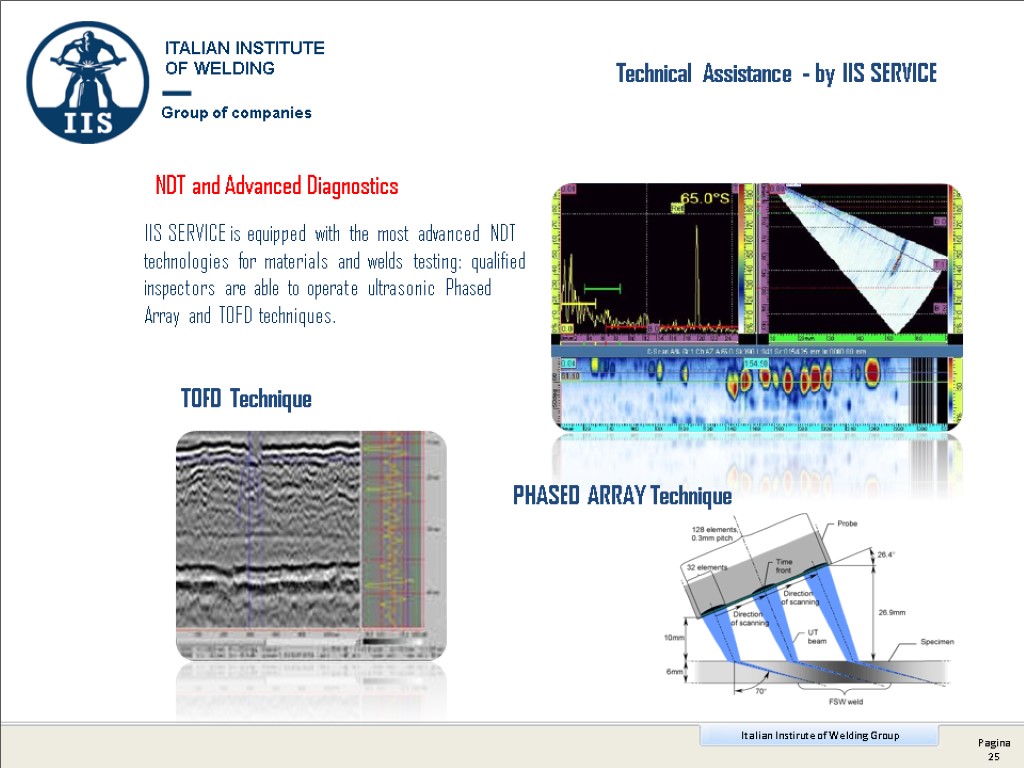

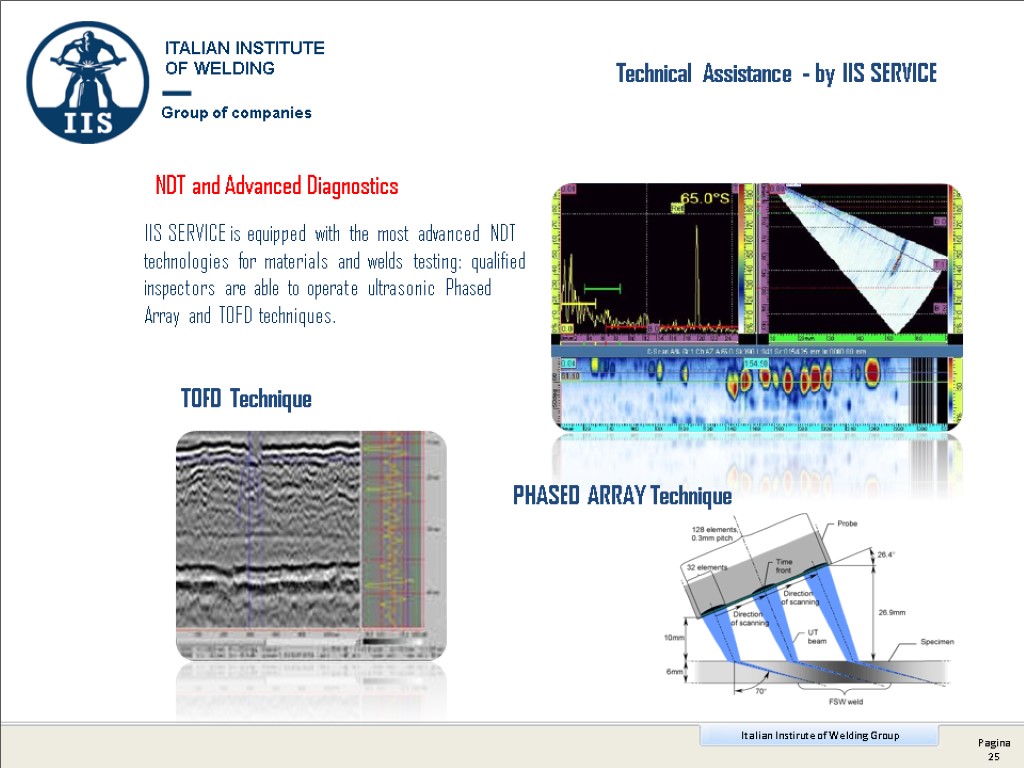

IIS SERVICE is equipped with the most advanced NDT technologies for materials and welds testing: qualified inspectors are able to operate ultrasonic Phased Array and TOFD techniques. Technical Assistance - by IIS SERVICE TOFD Technique PHASED ARRAY Technique NDT and Advanced Diagnostics Group of companies ITALIAN INSTITUTE OF WELDING

IIS SERVICE is equipped with the most advanced NDT technologies for materials and welds testing: qualified inspectors are able to operate ultrasonic Phased Array and TOFD techniques. Technical Assistance - by IIS SERVICE TOFD Technique PHASED ARRAY Technique NDT and Advanced Diagnostics Group of companies ITALIAN INSTITUTE OF WELDING

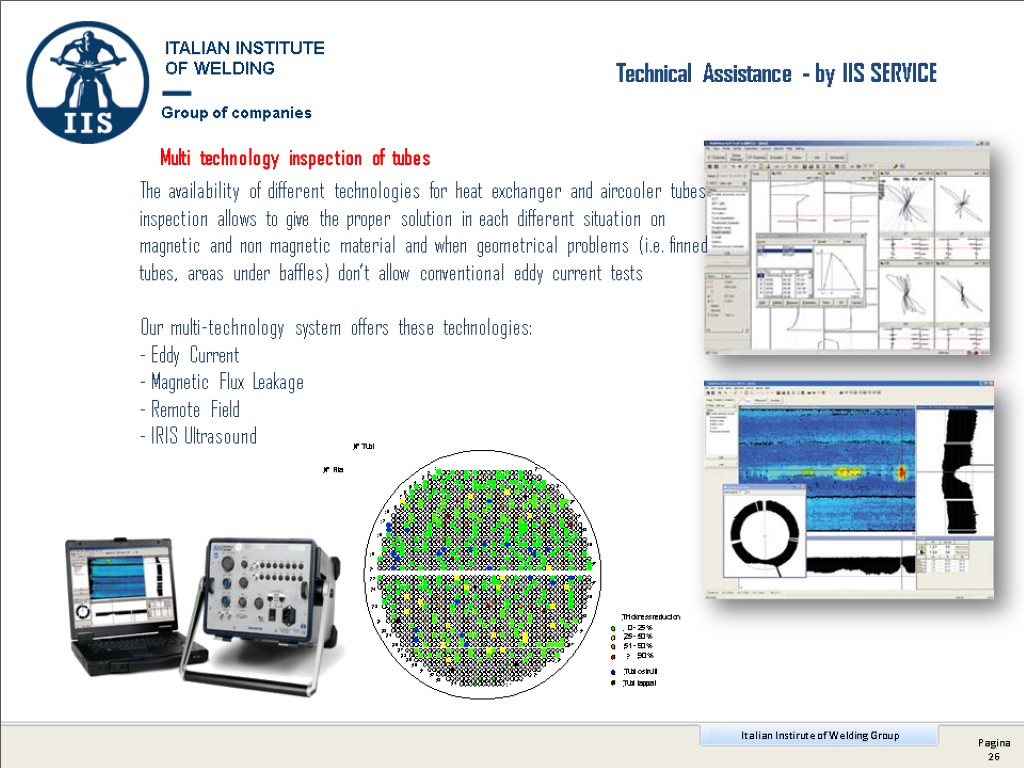

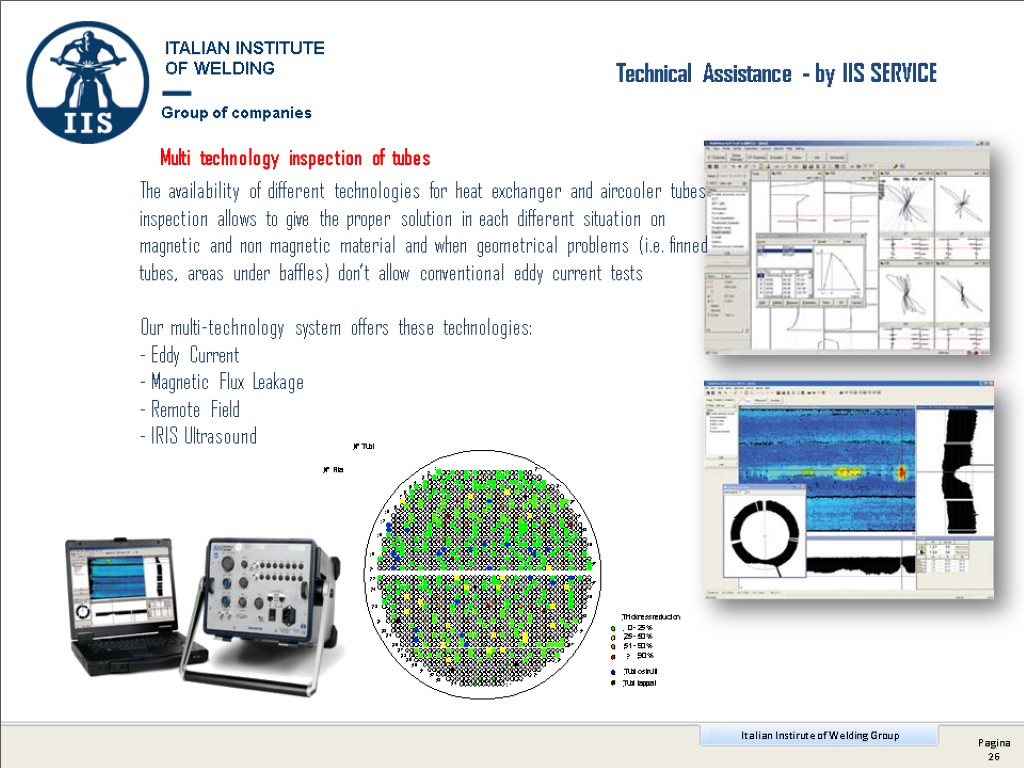

Technical Assistance - by IIS SERVICE The availability of different technologies for heat exchanger and aircooler tubes inspection allows to give the proper solution in each different situation on magnetic and non magnetic material and when geometrical problems (i.e. finned tubes, areas under baffles) don’t allow conventional eddy current tests Our multi-technology system offers these technologies: - Eddy Current - Magnetic Flux Leakage - Remote Field - IRIS Ultrasound Multi technology inspection of tubes Group of companies ITALIAN INSTITUTE OF WELDING

Technical Assistance - by IIS SERVICE The availability of different technologies for heat exchanger and aircooler tubes inspection allows to give the proper solution in each different situation on magnetic and non magnetic material and when geometrical problems (i.e. finned tubes, areas under baffles) don’t allow conventional eddy current tests Our multi-technology system offers these technologies: - Eddy Current - Magnetic Flux Leakage - Remote Field - IRIS Ultrasound Multi technology inspection of tubes Group of companies ITALIAN INSTITUTE OF WELDING

Education and Training - by IIS PROGRESS Education and Training Services for welding and NDT personnel Group of companies ITALIAN INSTITUTE OF WELDING

Education and Training - by IIS PROGRESS Education and Training Services for welding and NDT personnel Group of companies ITALIAN INSTITUTE OF WELDING

Education and Training - by IIS PROGRESS THEORETICAL TRAINING Training in Welding: International Welding Engineer (IWE) International Welding Technologist (IWT) International Welding Specialist (IWS) International Welding Practitioner (IWP) International Welding Inspector Comprehensive (IWI-C) International Welding Inspector Standard (IWI-S) International Welding Inspector Basic (IWI-B) Training in NDT (VT-PT-MT-UT-RT-ET-LT-TT) Level 1, 2, 3 according to: UNI EN ISO 9712:2012 ASNT SNT-TC-1A Training in Micro-joining Courses ESA doc. STR 258 - ESA ECSS Standards Courses IPC Trainers CIT - & Specialist CIS ITALIAN INSTITUTE OF WELDING Group of companies

Education and Training - by IIS PROGRESS THEORETICAL TRAINING Training in Welding: International Welding Engineer (IWE) International Welding Technologist (IWT) International Welding Specialist (IWS) International Welding Practitioner (IWP) International Welding Inspector Comprehensive (IWI-C) International Welding Inspector Standard (IWI-S) International Welding Inspector Basic (IWI-B) Training in NDT (VT-PT-MT-UT-RT-ET-LT-TT) Level 1, 2, 3 according to: UNI EN ISO 9712:2012 ASNT SNT-TC-1A Training in Micro-joining Courses ESA doc. STR 258 - ESA ECSS Standards Courses IPC Trainers CIT - & Specialist CIS ITALIAN INSTITUTE OF WELDING Group of companies

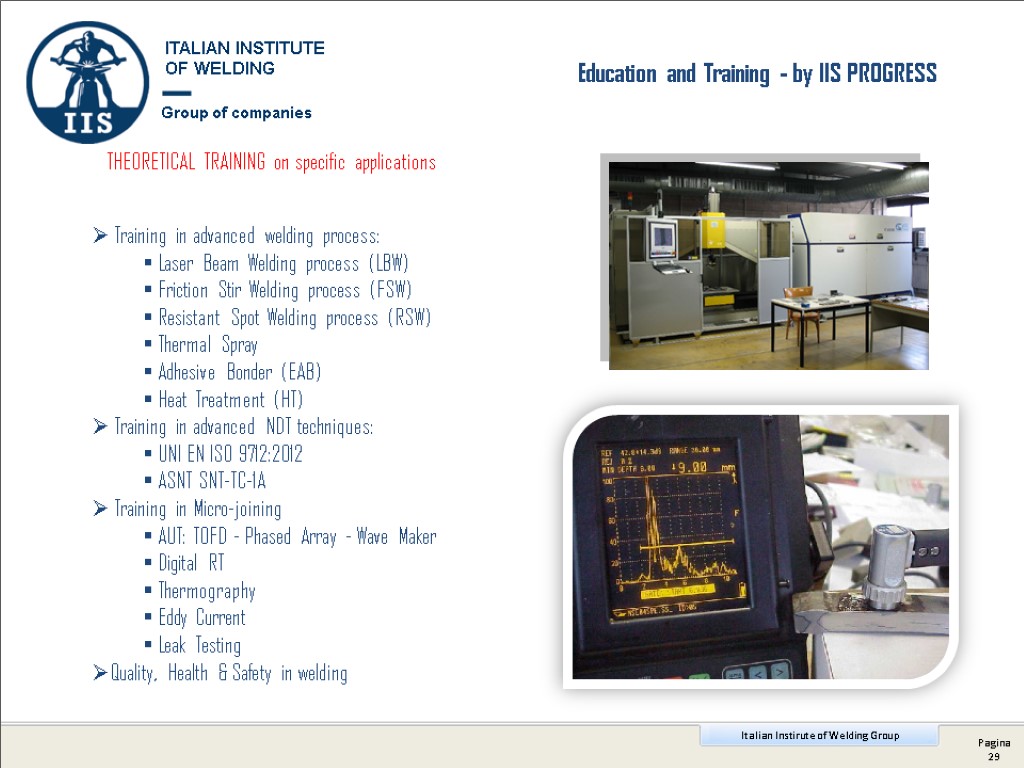

Education and Training - by IIS PROGRESS ITALIAN INSTITUTE OF WELDING Group of companies Training in advanced welding process: Laser Beam Welding process (LBW) Friction Stir Welding process (FSW) Resistant Spot Welding process (RSW) Thermal Spray Adhesive Bonder (EAB) Heat Treatment (HT) Training in advanced NDT techniques: UNI EN ISO 9712:2012 ASNT SNT-TC-1A Training in Micro-joining AUT: TOFD - Phased Array - Wave Maker Digital RT Thermography Eddy Current Leak Testing Quality, Health & Safety in welding THEORETICAL TRAINING on specific applications

Education and Training - by IIS PROGRESS ITALIAN INSTITUTE OF WELDING Group of companies Training in advanced welding process: Laser Beam Welding process (LBW) Friction Stir Welding process (FSW) Resistant Spot Welding process (RSW) Thermal Spray Adhesive Bonder (EAB) Heat Treatment (HT) Training in advanced NDT techniques: UNI EN ISO 9712:2012 ASNT SNT-TC-1A Training in Micro-joining AUT: TOFD - Phased Array - Wave Maker Digital RT Thermography Eddy Current Leak Testing Quality, Health & Safety in welding THEORETICAL TRAINING on specific applications

Education and Training - by IIS PROGRESS PRACTICAL TRAINING ITALIAN INSTITUTE OF WELDING Group of companies Training on metallic materials: Qualification courses according to ASME IX -EN 287 - ISO 9606 - EN 1418 International Welder according to the IIW scheme Underwater welder qualification Courses EN ISO 15618-1 EWG Training on thermoplastic materials: Qualification courses for thermoplastic materials (pipes, fittings, membrane in PE-PP-PVC-PVDF) European Plastic Welder according to the EWF scheme Training on Welding processes: Manual & Semiautomatic SMAW – GMAW – GTAW Automatic SAW – GTAW – PAW – FSW – Laser

Education and Training - by IIS PROGRESS PRACTICAL TRAINING ITALIAN INSTITUTE OF WELDING Group of companies Training on metallic materials: Qualification courses according to ASME IX -EN 287 - ISO 9606 - EN 1418 International Welder according to the IIW scheme Underwater welder qualification Courses EN ISO 15618-1 EWG Training on thermoplastic materials: Qualification courses for thermoplastic materials (pipes, fittings, membrane in PE-PP-PVC-PVDF) European Plastic Welder according to the EWF scheme Training on Welding processes: Manual & Semiautomatic SMAW – GMAW – GTAW Automatic SAW – GTAW – PAW – FSW – Laser

Certification Services Certification - by IIS CERT Group of companies ITALIAN INSTITUTE OF WELDING

Certification Services Certification - by IIS CERT Group of companies ITALIAN INSTITUTE OF WELDING

Certification - by IIS CERT Personnel Certification Welders and Welding Operators (ISO 9606 series, ASME Code, AWS Code, etc.) Welding Coordinators (ISO 14731 and IIW Guidelines) Welding Inspectors (IIW Guidelines) Non destructive testing personnel (ISO 9712, ASNT) Group of companies ITALIAN INSTITUTE OF WELDING

Certification - by IIS CERT Personnel Certification Welders and Welding Operators (ISO 9606 series, ASME Code, AWS Code, etc.) Welding Coordinators (ISO 14731 and IIW Guidelines) Welding Inspectors (IIW Guidelines) Non destructive testing personnel (ISO 9712, ASNT) Group of companies ITALIAN INSTITUTE OF WELDING

Certification - by IIS CERT Management Systems Certification (Welding process, Quality, Environment, Safety) Welding Manufacturers (ISO 3834) Quality (ISO 9001) Safety (BS OHSAS 18001) Environment (ISO 14001) Factory Production Control (FPC) Certification for Construction products Group of companies ITALIAN INSTITUTE OF WELDING

Certification - by IIS CERT Management Systems Certification (Welding process, Quality, Environment, Safety) Welding Manufacturers (ISO 3834) Quality (ISO 9001) Safety (BS OHSAS 18001) Environment (ISO 14001) Factory Production Control (FPC) Certification for Construction products Group of companies ITALIAN INSTITUTE OF WELDING

Management Systems Certification (Welding process, Quality, Environment, Safety) EN ISO 3834 is a guide establishing quality requirements for a proper management fabrication process, both in workshop and in site, of all types of welded construction. This standard is recalled in several product standards including: EN 15085 for the railway vehicles field EN 1090 for civil structures EN 13445 for pressure equipment … and many others Certification - by IIS CERT Group of companies ITALIAN INSTITUTE OF WELDING

Management Systems Certification (Welding process, Quality, Environment, Safety) EN ISO 3834 is a guide establishing quality requirements for a proper management fabrication process, both in workshop and in site, of all types of welded construction. This standard is recalled in several product standards including: EN 15085 for the railway vehicles field EN 1090 for civil structures EN 13445 for pressure equipment … and many others Certification - by IIS CERT Group of companies ITALIAN INSTITUTE OF WELDING

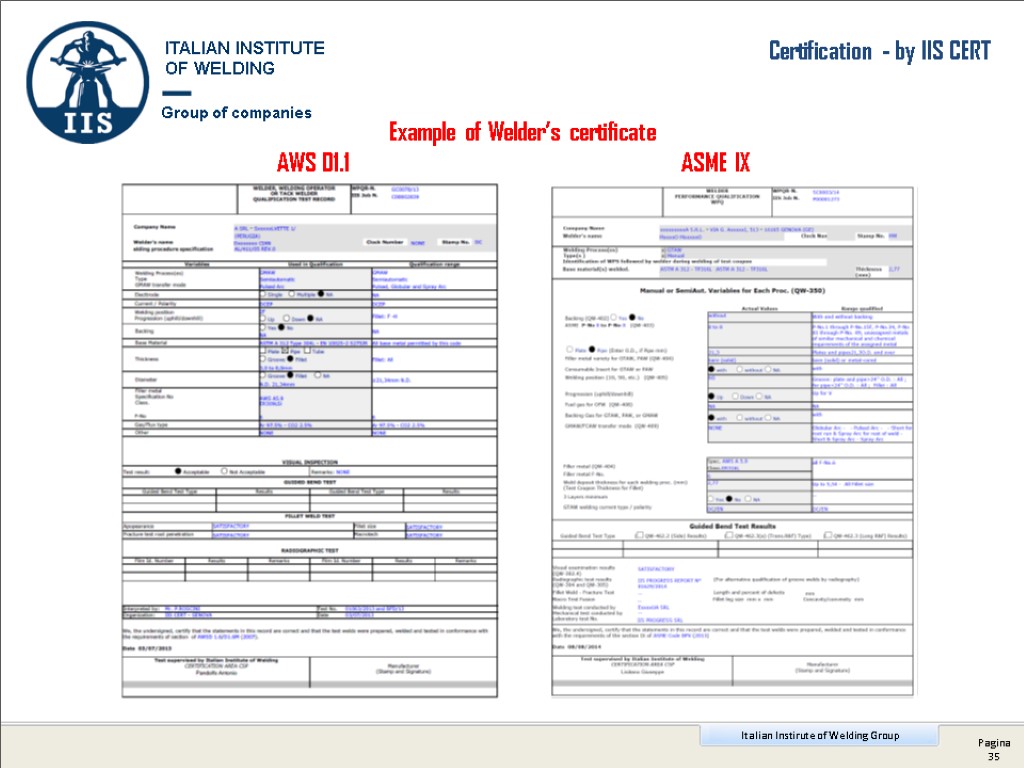

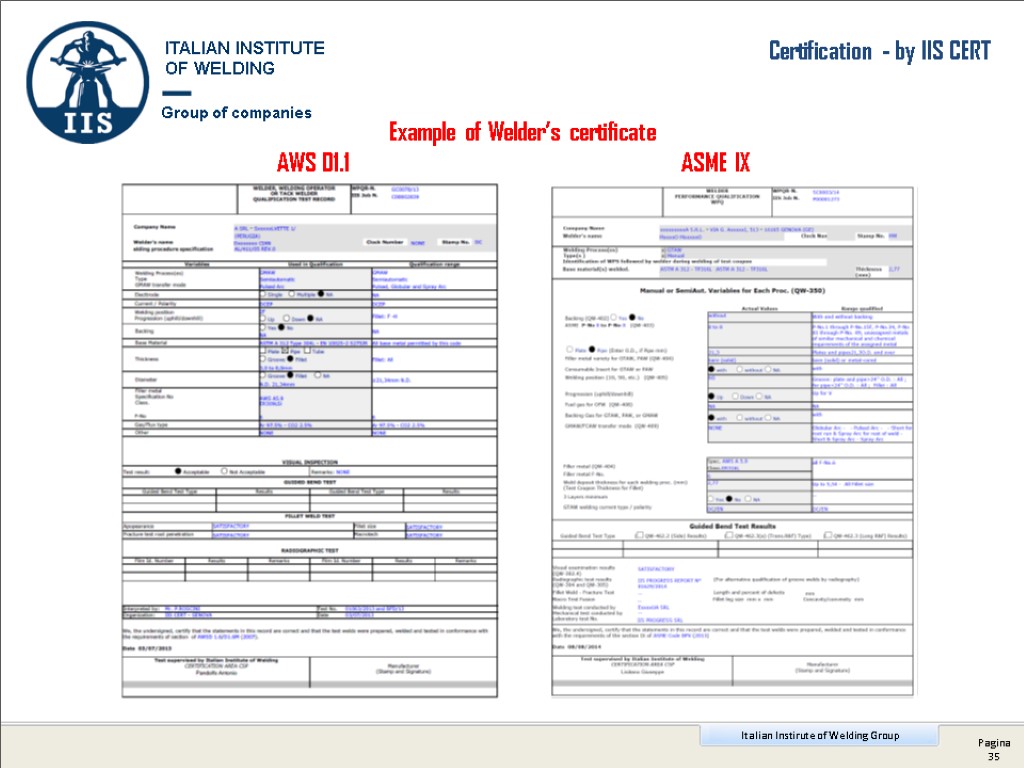

Example of Welder’s certificate AWS D1.1 ASME IX Certification - by IIS CERT Group of companies ITALIAN INSTITUTE OF WELDING

Example of Welder’s certificate AWS D1.1 ASME IX Certification - by IIS CERT Group of companies ITALIAN INSTITUTE OF WELDING

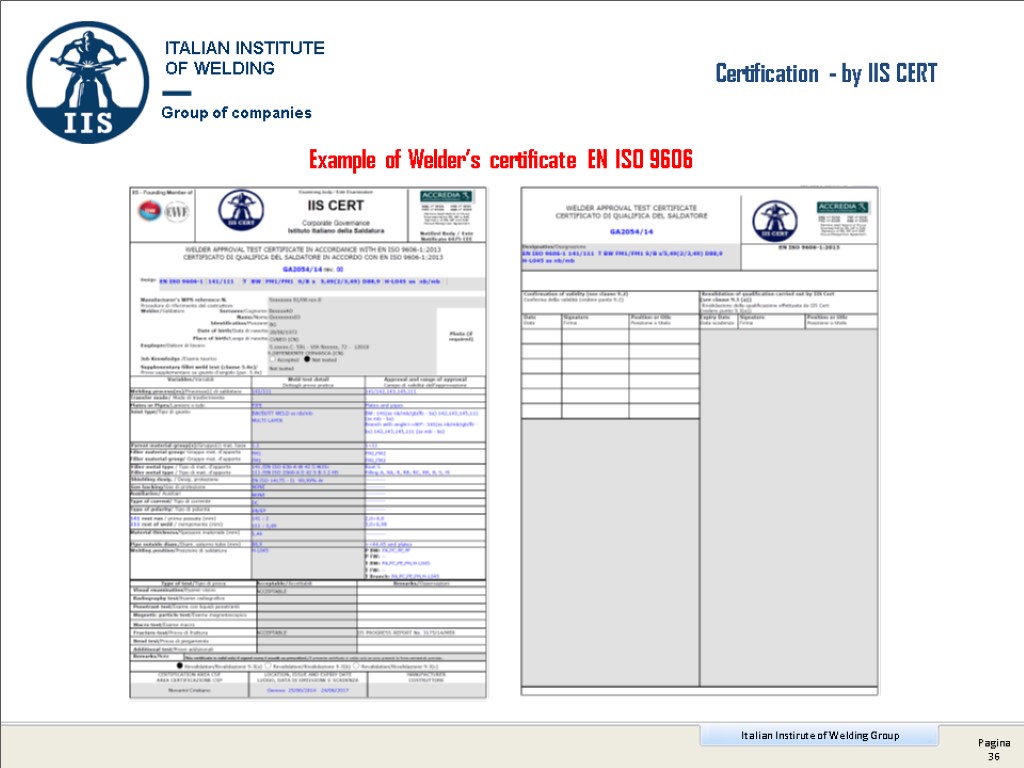

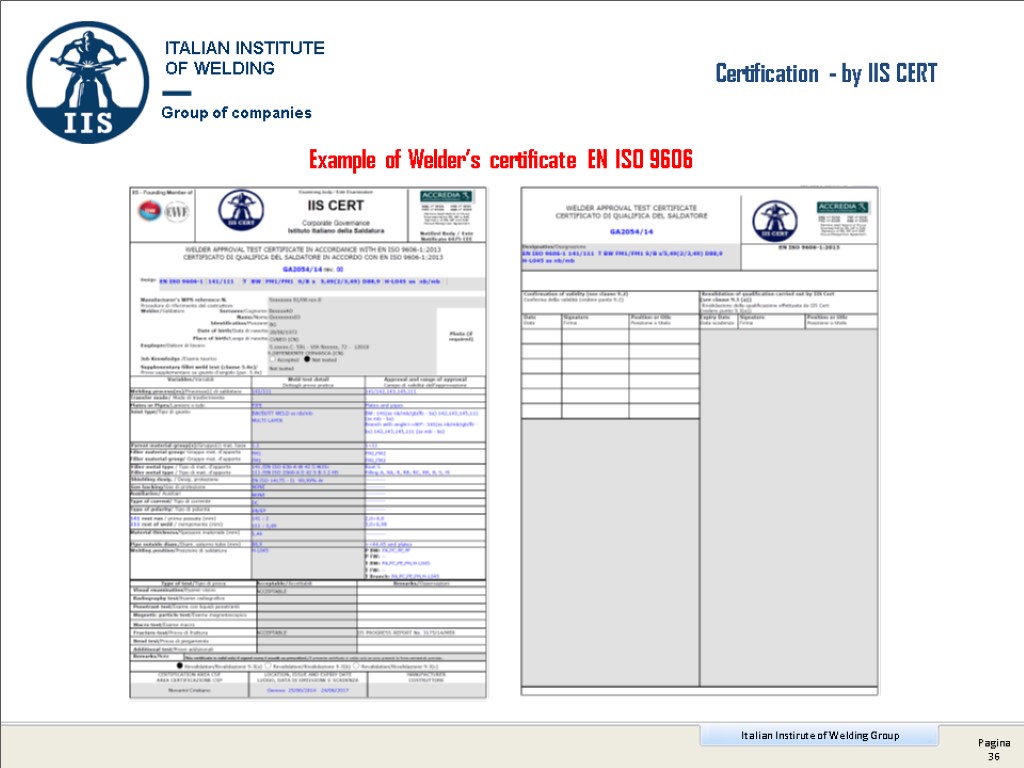

Example of Welder’s certificate EN ISO 9606 Certification - by IIS CERT Group of companies ITALIAN INSTITUTE OF WELDING

Example of Welder’s certificate EN ISO 9606 Certification - by IIS CERT Group of companies ITALIAN INSTITUTE OF WELDING

Management System Company Certification Certification - by IIS CERT In the field of railway vehicles the specific standard is EN 15085 “Railway application – Welding of railway vehicles and components”. IIS CERT is a Certification Body accredited by ACCREDIA in accordance with the scheme recognized by the National Agency for the Railway Safety. The certified companies will be recorded into the European Committee online register for Welding of Railway Vehicles (ECWRV). RAILWAY APPLICATION - UNI EN 15085 Group of companies ITALIAN INSTITUTE OF WELDING

Management System Company Certification Certification - by IIS CERT In the field of railway vehicles the specific standard is EN 15085 “Railway application – Welding of railway vehicles and components”. IIS CERT is a Certification Body accredited by ACCREDIA in accordance with the scheme recognized by the National Agency for the Railway Safety. The certified companies will be recorded into the European Committee online register for Welding of Railway Vehicles (ECWRV). RAILWAY APPLICATION - UNI EN 15085 Group of companies ITALIAN INSTITUTE OF WELDING

Organismo Notificato 0475 Certification - by IIS CERT IIS CERT is a Certification Body for the following Directives and Regulations: CPR 305/2011 for construction products Directive 2008/57/CE on the Interoperability of the Trans-European Railway System DPR 462/01 – Authorization to carry out verifications of grounding system, electrical systems in areas with danger of explosion, and systems for protection against atmospheric discharges Directive SPVD 2009/105 for simple pressure vessels Furthermore IIS CERT is a recognized Third Entity in accordance with PED 97/23/CE directive for: European approval of materials Approval of personnel involved in non-destructive testing Approval of operating procedures and personnel employed in permanent joints EUROPEAN DIRECTIVES AND MINISTERIAL AUTHORIZATION Group of companies ITALIAN INSTITUTE OF WELDING

Organismo Notificato 0475 Certification - by IIS CERT IIS CERT is a Certification Body for the following Directives and Regulations: CPR 305/2011 for construction products Directive 2008/57/CE on the Interoperability of the Trans-European Railway System DPR 462/01 – Authorization to carry out verifications of grounding system, electrical systems in areas with danger of explosion, and systems for protection against atmospheric discharges Directive SPVD 2009/105 for simple pressure vessels Furthermore IIS CERT is a recognized Third Entity in accordance with PED 97/23/CE directive for: European approval of materials Approval of personnel involved in non-destructive testing Approval of operating procedures and personnel employed in permanent joints EUROPEAN DIRECTIVES AND MINISTERIAL AUTHORIZATION Group of companies ITALIAN INSTITUTE OF WELDING

Laboratories Education and Training - by IIS PROGRESS Group of companies ITALIAN INSTITUTE OF WELDING

Laboratories Education and Training - by IIS PROGRESS Group of companies ITALIAN INSTITUTE OF WELDING

Laboratories - by IIS PROGRESS Accredited tests by ACCREDIA: Metallic materials: Tensile test @ Room Temp Bend tests Hardness test Toughness test (till to – 46°C) Macrographic examination Micrographic examination (OPT) Chemical analysis (OES) Radiographic examination (RT) Thermoplastic materials: collapse test de-cohesion test tensile test bend test Laboratory Mechanical testing ITALIAN INSTITUTE OF WELDING Group of companies

Laboratories - by IIS PROGRESS Accredited tests by ACCREDIA: Metallic materials: Tensile test @ Room Temp Bend tests Hardness test Toughness test (till to – 46°C) Macrographic examination Micrographic examination (OPT) Chemical analysis (OES) Radiographic examination (RT) Thermoplastic materials: collapse test de-cohesion test tensile test bend test Laboratory Mechanical testing ITALIAN INSTITUTE OF WELDING Group of companies

Laboratories - by IIS PROGRESS Not accredited tests: Tensile test (T = - 80°C / + 1100°C) Hardness test HB – HRC Toughness test (till to -196°C) Micrographic examination by SEM / EDS NDE by UT, MT, PT Special tests: Fracture mechanics test (down to -70°C) for the determination of toughness: CTOD – KIC – JIC also for FFS assessments according to BS 7910 and API 579/ASME Laboratory Mechanical testing ITALIAN INSTITUTE OF WELDING Group of companies

Laboratories - by IIS PROGRESS Not accredited tests: Tensile test (T = - 80°C / + 1100°C) Hardness test HB – HRC Toughness test (till to -196°C) Micrographic examination by SEM / EDS NDE by UT, MT, PT Special tests: Fracture mechanics test (down to -70°C) for the determination of toughness: CTOD – KIC – JIC also for FFS assessments according to BS 7910 and API 579/ASME Laboratory Mechanical testing ITALIAN INSTITUTE OF WELDING Group of companies

Laboratories - by IIS PROGRESS ITALIAN INSTITUTE OF WELDING Group of companies Special tests: Creep tests (up to 1100°C) Iso – temperature “Stress rupture” Interrupted tests (Omega test for remnant life assessments) Fatigue tests for: Material characterization Structural details characterization Standard samples Samples performed according to the Customer procedure specifications Laboratory Mechanical testing

Laboratories - by IIS PROGRESS ITALIAN INSTITUTE OF WELDING Group of companies Special tests: Creep tests (up to 1100°C) Iso – temperature “Stress rupture” Interrupted tests (Omega test for remnant life assessments) Fatigue tests for: Material characterization Structural details characterization Standard samples Samples performed according to the Customer procedure specifications Laboratory Mechanical testing

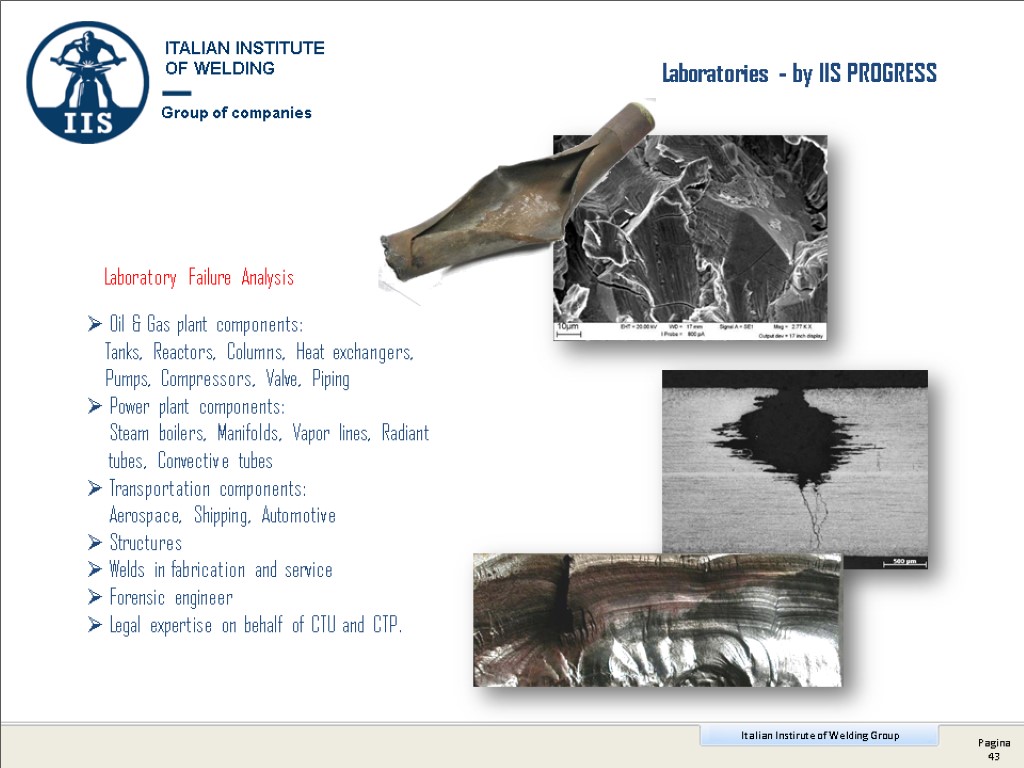

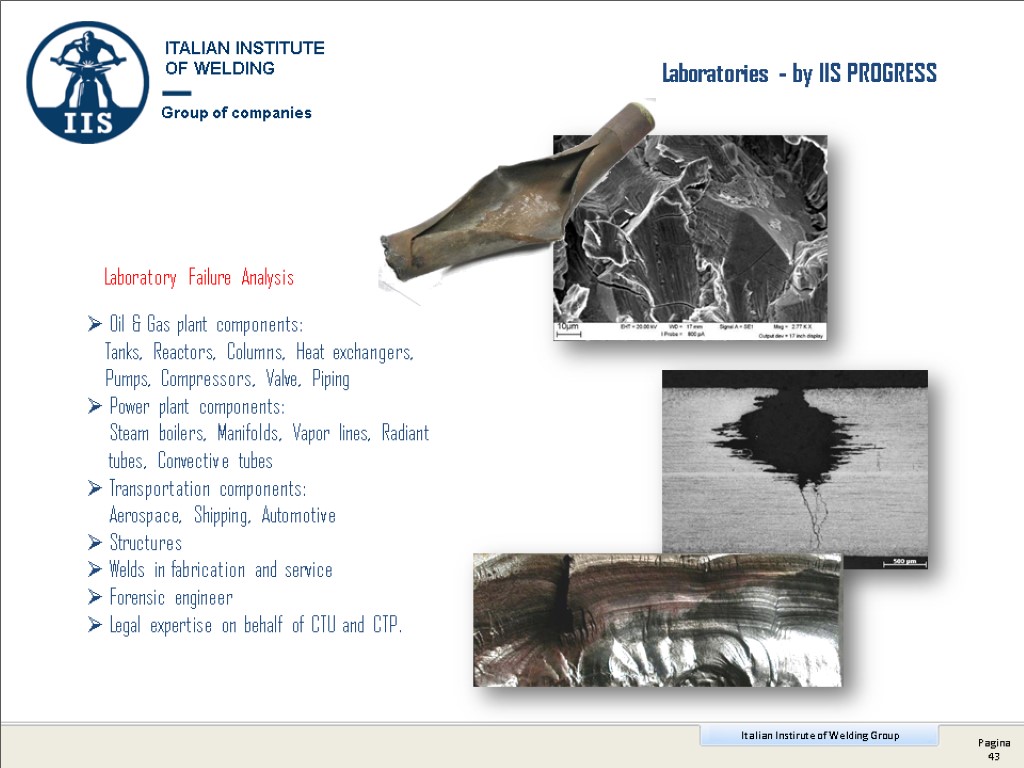

Laboratories - by IIS PROGRESS ITALIAN INSTITUTE OF WELDING Group of companies Oil & Gas plant components: Tanks, Reactors, Columns, Heat exchangers, Pumps, Compressors, Valve, Piping Power plant components: Steam boilers, Manifolds, Vapor lines, Radiant tubes, Convective tubes Transportation components: Aerospace, Shipping, Automotive Structures Welds in fabrication and service Forensic engineer Legal expertise on behalf of CTU and CTP. Laboratory Failure Analysis

Laboratories - by IIS PROGRESS ITALIAN INSTITUTE OF WELDING Group of companies Oil & Gas plant components: Tanks, Reactors, Columns, Heat exchangers, Pumps, Compressors, Valve, Piping Power plant components: Steam boilers, Manifolds, Vapor lines, Radiant tubes, Convective tubes Transportation components: Aerospace, Shipping, Automotive Structures Welds in fabrication and service Forensic engineer Legal expertise on behalf of CTU and CTP. Laboratory Failure Analysis

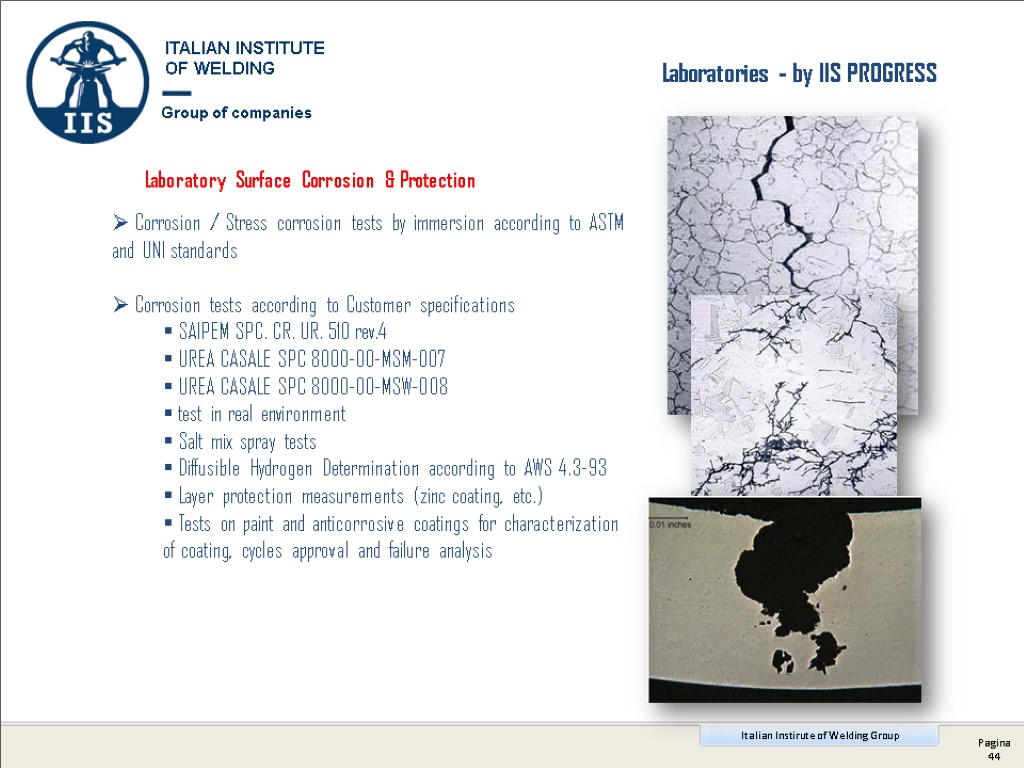

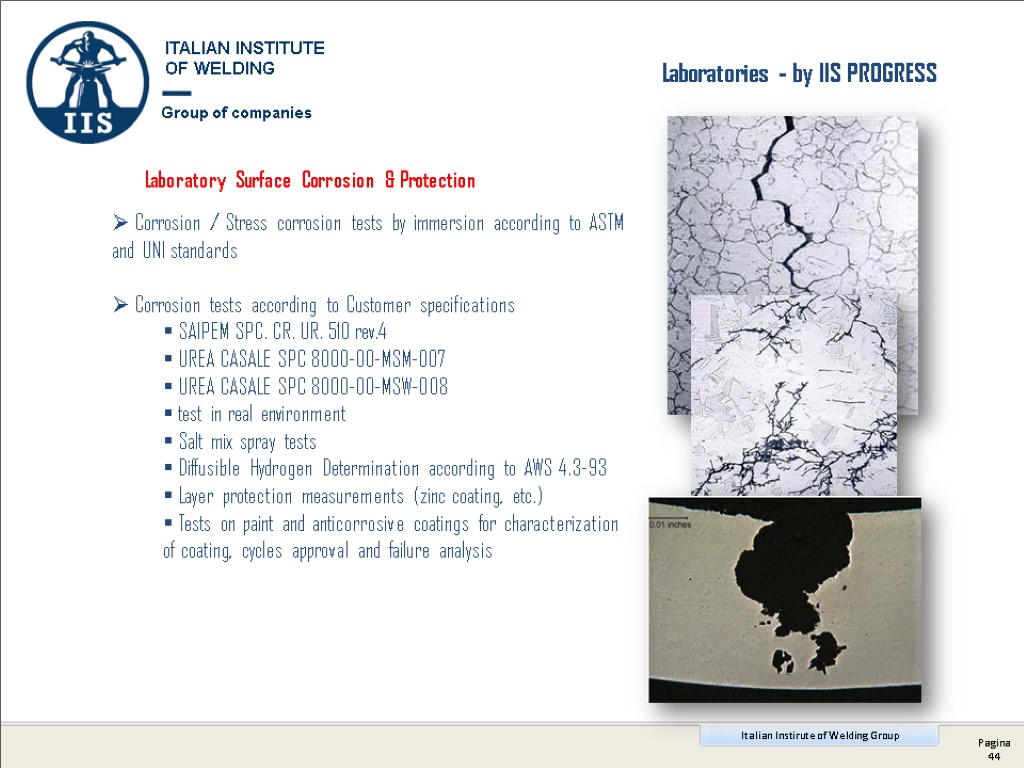

Laboratories - by IIS PROGRESS ITALIAN INSTITUTE OF WELDING Group of companies Corrosion / Stress corrosion tests by immersion according to ASTM and UNI standards Corrosion tests according to Customer specifications SAIPEM SPC. CR. UR. 510 rev.4 UREA CASALE SPC 8000-00-MSM-007 UREA CASALE SPC 8000-00-MSW-008 test in real environment Salt mix spray tests Diffusible Hydrogen Determination according to AWS 4.3-93 Layer protection measurements (zinc coating, etc.) Tests on paint and anticorrosive coatings for characterization of coating, cycles approval and failure analysis Laboratory Surface Corrosion & Protection

Laboratories - by IIS PROGRESS ITALIAN INSTITUTE OF WELDING Group of companies Corrosion / Stress corrosion tests by immersion according to ASTM and UNI standards Corrosion tests according to Customer specifications SAIPEM SPC. CR. UR. 510 rev.4 UREA CASALE SPC 8000-00-MSM-007 UREA CASALE SPC 8000-00-MSW-008 test in real environment Salt mix spray tests Diffusible Hydrogen Determination according to AWS 4.3-93 Layer protection measurements (zinc coating, etc.) Tests on paint and anticorrosive coatings for characterization of coating, cycles approval and failure analysis Laboratory Surface Corrosion & Protection

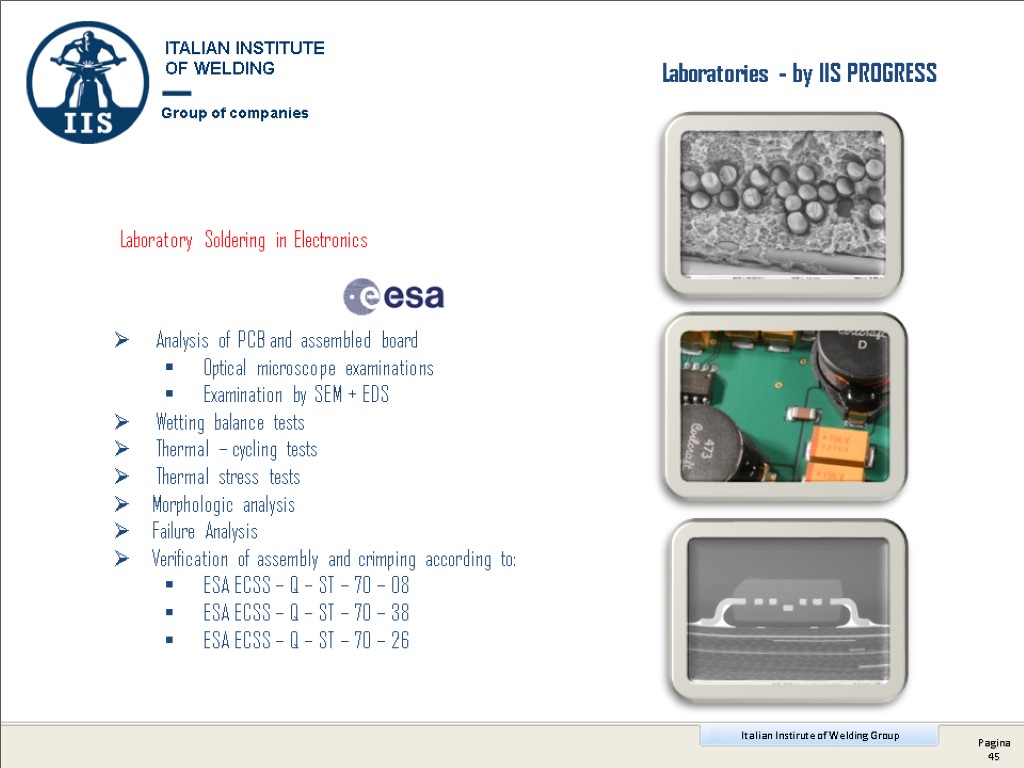

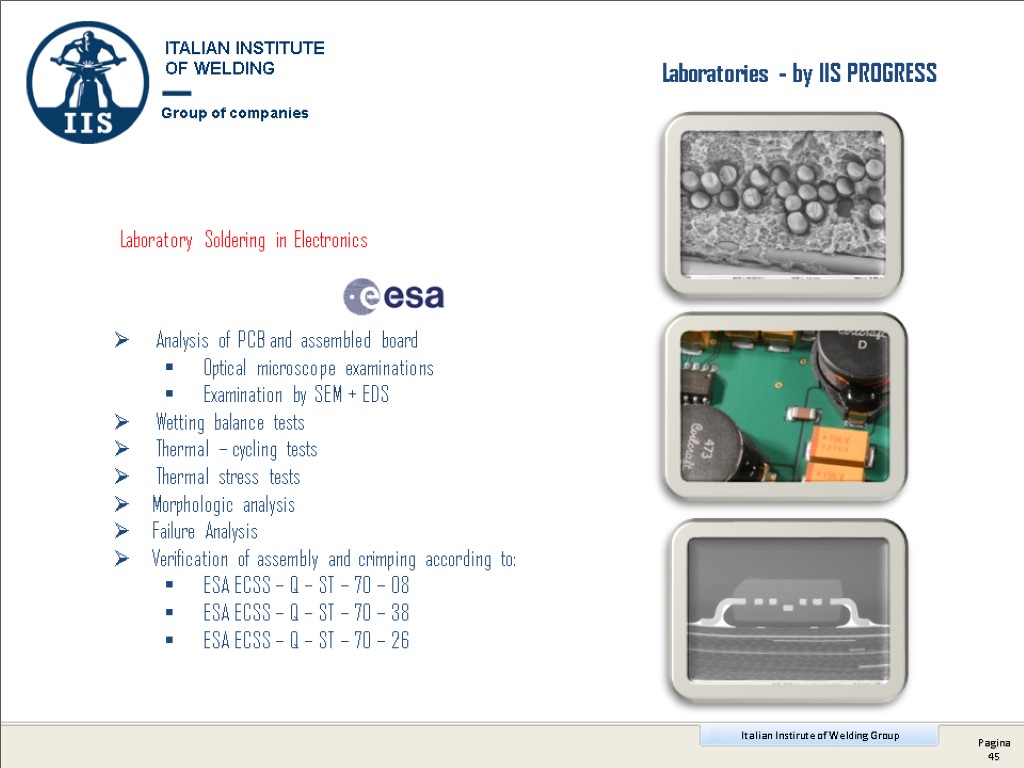

Laboratories - by IIS PROGRESS ITALIAN INSTITUTE OF WELDING Group of companies Analysis of PCB and assembled board Optical microscope examinations Examination by SEM + EDS Wetting balance tests Thermal – cycling tests Thermal stress tests Morphologic analysis Failure Analysis Verification of assembly and crimping according to: ESA ECSS – Q – ST – 70 – 08 ESA ECSS – Q – ST – 70 – 38 ESA ECSS – Q – ST – 70 – 26 Laboratory Soldering in Electronics ITALIAN INSTITUTE OF WELDING Group of companies

Laboratories - by IIS PROGRESS ITALIAN INSTITUTE OF WELDING Group of companies Analysis of PCB and assembled board Optical microscope examinations Examination by SEM + EDS Wetting balance tests Thermal – cycling tests Thermal stress tests Morphologic analysis Failure Analysis Verification of assembly and crimping according to: ESA ECSS – Q – ST – 70 – 08 ESA ECSS – Q – ST – 70 – 38 ESA ECSS – Q – ST – 70 – 26 Laboratory Soldering in Electronics ITALIAN INSTITUTE OF WELDING Group of companies

Laboratories - by IIS PROGRESS Welding Laboratory ITALIAN INSTITUTE OF WELDING Group of companies Conventional applications: SMAW GMAW GTAW SAW Advanced applications: Laser CO2 6 KW (ELEN) Micro Laser (Nd - YAG) Hybrid Solid Fiber Laser 3 KW (IPG) FSW machine (GKSS) Advanced power sources (e.g. CMT, STT) Plasma Transferred Arc (Plasma Team) Submerged Arc Welding (Lincoln Power Wave 2000) Robotic systems (COMAU) The above processes are applied on all materials: Carbon and low-alloyed steel, Stainless steels, Aluminum alloys, Copper alloys, Nickel based alloys, Titanium alloys, etc.

Laboratories - by IIS PROGRESS Welding Laboratory ITALIAN INSTITUTE OF WELDING Group of companies Conventional applications: SMAW GMAW GTAW SAW Advanced applications: Laser CO2 6 KW (ELEN) Micro Laser (Nd - YAG) Hybrid Solid Fiber Laser 3 KW (IPG) FSW machine (GKSS) Advanced power sources (e.g. CMT, STT) Plasma Transferred Arc (Plasma Team) Submerged Arc Welding (Lincoln Power Wave 2000) Robotic systems (COMAU) The above processes are applied on all materials: Carbon and low-alloyed steel, Stainless steels, Aluminum alloys, Copper alloys, Nickel based alloys, Titanium alloys, etc.

Main References Group of companies ITALIAN INSTITUTE OF WELDING

Main References Group of companies ITALIAN INSTITUTE OF WELDING

EST technology converts heavy hydrocarbons loads to high quality distillates. ITALY ENI - EST Project IIS has been chosen as qualified partner Preparation of supplying materials and component specifications Inspection at equipment suppliers’ workshop (more than 100 critical equipment) in Italy and abroad Pre-service inspections (more than 70 critical equipment) Engineering Critical Assessment In site expediting and inspection activities Laboratory tests Group of companies ITALIAN INSTITUTE OF WELDING IIS involvement

EST technology converts heavy hydrocarbons loads to high quality distillates. ITALY ENI - EST Project IIS has been chosen as qualified partner Preparation of supplying materials and component specifications Inspection at equipment suppliers’ workshop (more than 100 critical equipment) in Italy and abroad Pre-service inspections (more than 70 critical equipment) Engineering Critical Assessment In site expediting and inspection activities Laboratory tests Group of companies ITALIAN INSTITUTE OF WELDING IIS involvement

Validation of AUT procedures 3 level consultancy on Automatic Ultrasonic Techniques Welding Technical Assistance Engineering Critical Assessment on off-shore structures Assessment of suitability of bolted joints Numerical simulation of residual stress distribution on ammine reboiler tube sheet ENI Kazahstan - Kashagan Project Group of companies ITALIAN INSTITUTE OF WELDING IIS involvement

Validation of AUT procedures 3 level consultancy on Automatic Ultrasonic Techniques Welding Technical Assistance Engineering Critical Assessment on off-shore structures Assessment of suitability of bolted joints Numerical simulation of residual stress distribution on ammine reboiler tube sheet ENI Kazahstan - Kashagan Project Group of companies ITALIAN INSTITUTE OF WELDING IIS involvement

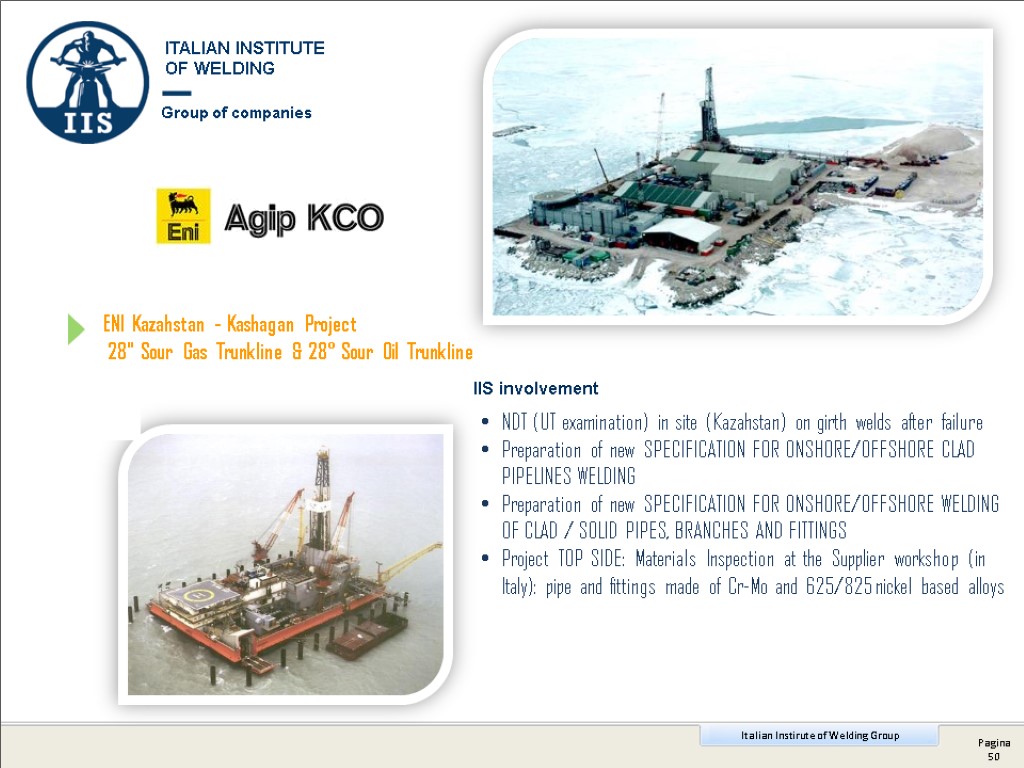

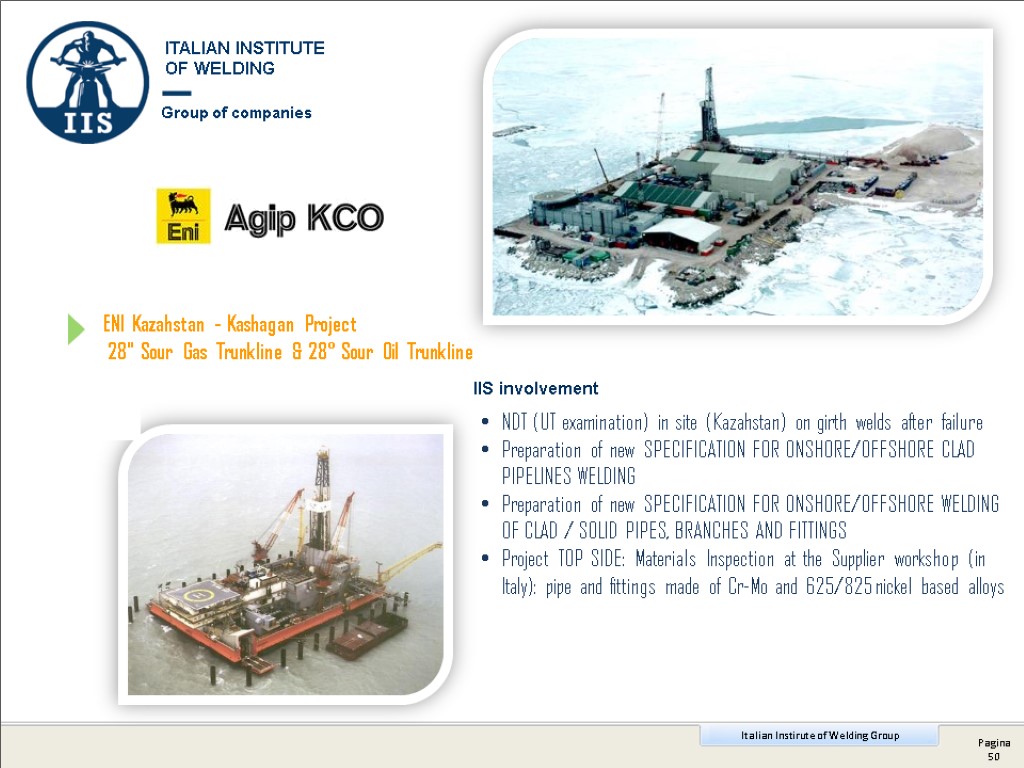

NDT (UT examination) in site (Kazahstan) on girth welds after failure Preparation of new SPECIFICATION FOR ONSHORE/OFFSHORE CLAD PIPELINES WELDING Preparation of new SPECIFICATION FOR ONSHORE/OFFSHORE WELDING OF CLAD / SOLID PIPES, BRANCHES AND FITTINGS Project TOP SIDE: Materials Inspection at the Supplier workshop (in Italy): pipe and fittings made of Cr-Mo and 625/825 nickel based alloys ENI Kazahstan - Kashagan Project 28" Sour Gas Trunkline & 28° Sour Oil Trunkline Group of companies ITALIAN INSTITUTE OF WELDING IIS involvement

NDT (UT examination) in site (Kazahstan) on girth welds after failure Preparation of new SPECIFICATION FOR ONSHORE/OFFSHORE CLAD PIPELINES WELDING Preparation of new SPECIFICATION FOR ONSHORE/OFFSHORE WELDING OF CLAD / SOLID PIPES, BRANCHES AND FITTINGS Project TOP SIDE: Materials Inspection at the Supplier workshop (in Italy): pipe and fittings made of Cr-Mo and 625/825 nickel based alloys ENI Kazahstan - Kashagan Project 28" Sour Gas Trunkline & 28° Sour Oil Trunkline Group of companies ITALIAN INSTITUTE OF WELDING IIS involvement

ITALY Venice MOSE Project Preparation of UT procedure for duplex stainless steel and performing of UT test Certification of Welding Procedures Workshop inspection at Suppliers’ facilities Group of companies ITALIAN INSTITUTE OF WELDING IIS involvement

ITALY Venice MOSE Project Preparation of UT procedure for duplex stainless steel and performing of UT test Certification of Welding Procedures Workshop inspection at Suppliers’ facilities Group of companies ITALIAN INSTITUTE OF WELDING IIS involvement

ITALY Intesa Sanpaolo Bank Tower Site supervision and surveillance during erection. NDT on welded connections in site Spot inspection at workshop Group of companies ITALIAN INSTITUTE OF WELDING IIS involvement

ITALY Intesa Sanpaolo Bank Tower Site supervision and surveillance during erection. NDT on welded connections in site Spot inspection at workshop Group of companies ITALIAN INSTITUTE OF WELDING IIS involvement

Preparation of the Welding Qualification Plan. Hundreds of weld details have been set up with the Manufacturer. More than 70 test coupon have been carried out. CTOD test provided on 15 weld coupon for welding procedure qualification have been carried out in our laboratories. Engineering advice for optimizing design solutions. Certification of Welding Procedure according to AWS D1.1 Group of companies ITALIAN INSTITUTE OF WELDING PANAMA Panama channel Project IIS involvement

Preparation of the Welding Qualification Plan. Hundreds of weld details have been set up with the Manufacturer. More than 70 test coupon have been carried out. CTOD test provided on 15 weld coupon for welding procedure qualification have been carried out in our laboratories. Engineering advice for optimizing design solutions. Certification of Welding Procedure according to AWS D1.1 Group of companies ITALIAN INSTITUTE OF WELDING PANAMA Panama channel Project IIS involvement

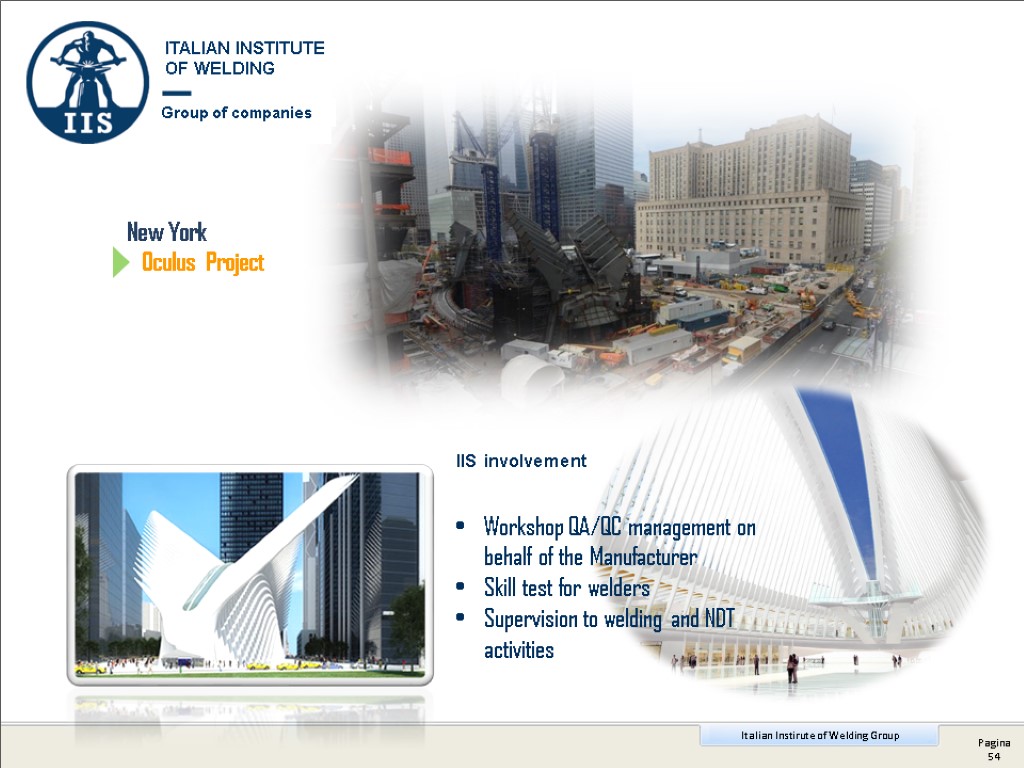

Workshop QA/QC management on behalf of the Manufacturer Skill test for welders Supervision to welding and NDT activities New York Oculus Project Group of companies ITALIAN INSTITUTE OF WELDING IIS involvement

Workshop QA/QC management on behalf of the Manufacturer Skill test for welders Supervision to welding and NDT activities New York Oculus Project Group of companies ITALIAN INSTITUTE OF WELDING IIS involvement

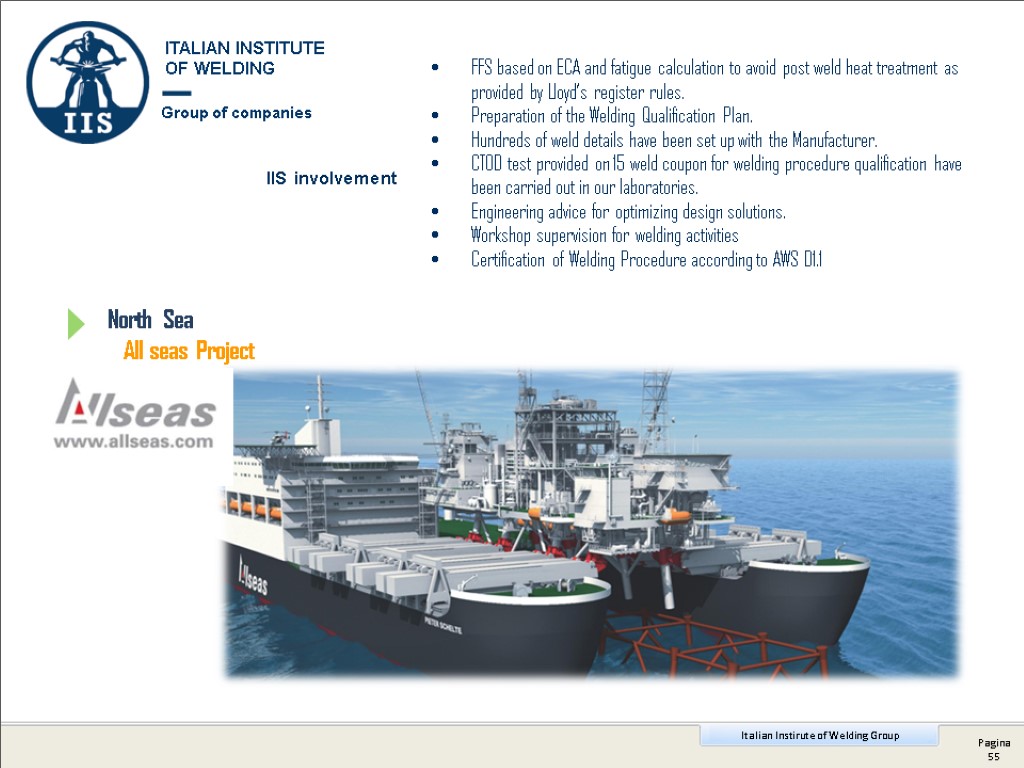

FFS based on ECA and fatigue calculation to avoid post weld heat treatment as provided by Lloyd’s register rules. Preparation of the Welding Qualification Plan. Hundreds of weld details have been set up with the Manufacturer. CTOD test provided on 15 weld coupon for welding procedure qualification have been carried out in our laboratories. Engineering advice for optimizing design solutions. Workshop supervision for welding activities Certification of Welding Procedure according to AWS D1.1 Group of companies ITALIAN INSTITUTE OF WELDING IIS involvement North Sea All seas Project

FFS based on ECA and fatigue calculation to avoid post weld heat treatment as provided by Lloyd’s register rules. Preparation of the Welding Qualification Plan. Hundreds of weld details have been set up with the Manufacturer. CTOD test provided on 15 weld coupon for welding procedure qualification have been carried out in our laboratories. Engineering advice for optimizing design solutions. Workshop supervision for welding activities Certification of Welding Procedure according to AWS D1.1 Group of companies ITALIAN INSTITUTE OF WELDING IIS involvement North Sea All seas Project

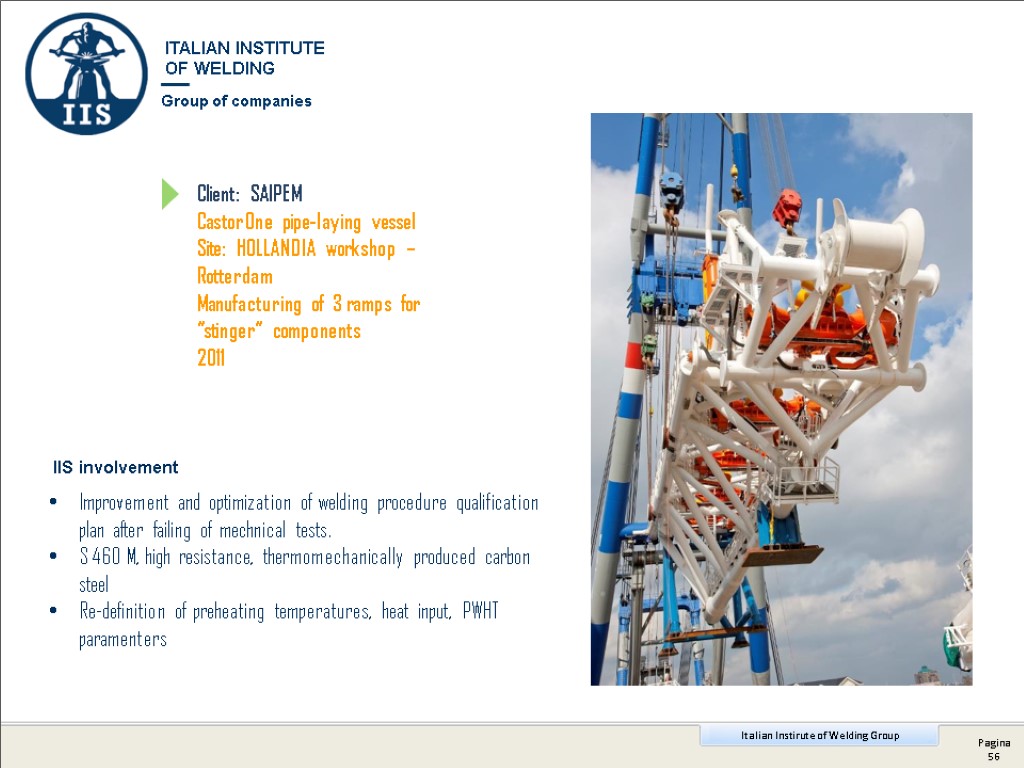

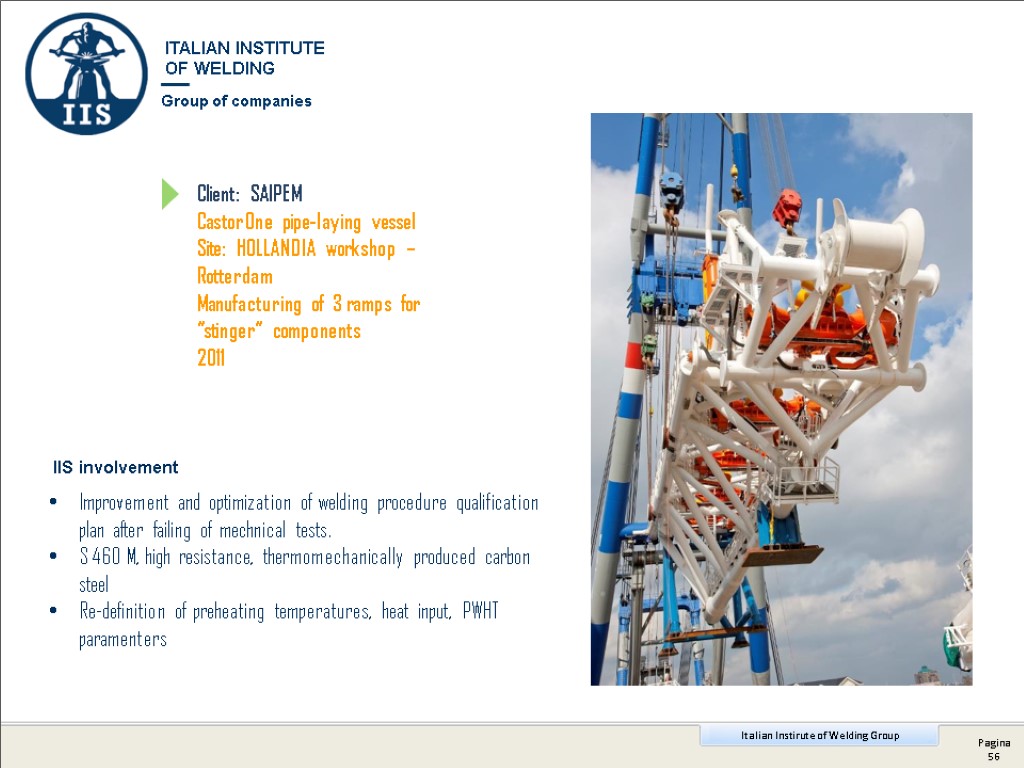

Improvement and optimization of welding procedure qualification plan after failing of mechnical tests. S 460 M, high resistance, thermomechanically produced carbon steel Re-definition of preheating temperatures, heat input, PWHT paramenters Group of companies ITALIAN INSTITUTE OF WELDING Client: SAIPEM CastorOne pipe-laying vessel Site: HOLLANDIA workshop – Rotterdam Manufacturing of 3 ramps for “stinger” components 2011 IIS involvement Group of companies ITALIAN INSTITUTE OF WELDING

Improvement and optimization of welding procedure qualification plan after failing of mechnical tests. S 460 M, high resistance, thermomechanically produced carbon steel Re-definition of preheating temperatures, heat input, PWHT paramenters Group of companies ITALIAN INSTITUTE OF WELDING Client: SAIPEM CastorOne pipe-laying vessel Site: HOLLANDIA workshop – Rotterdam Manufacturing of 3 ramps for “stinger” components 2011 IIS involvement Group of companies ITALIAN INSTITUTE OF WELDING

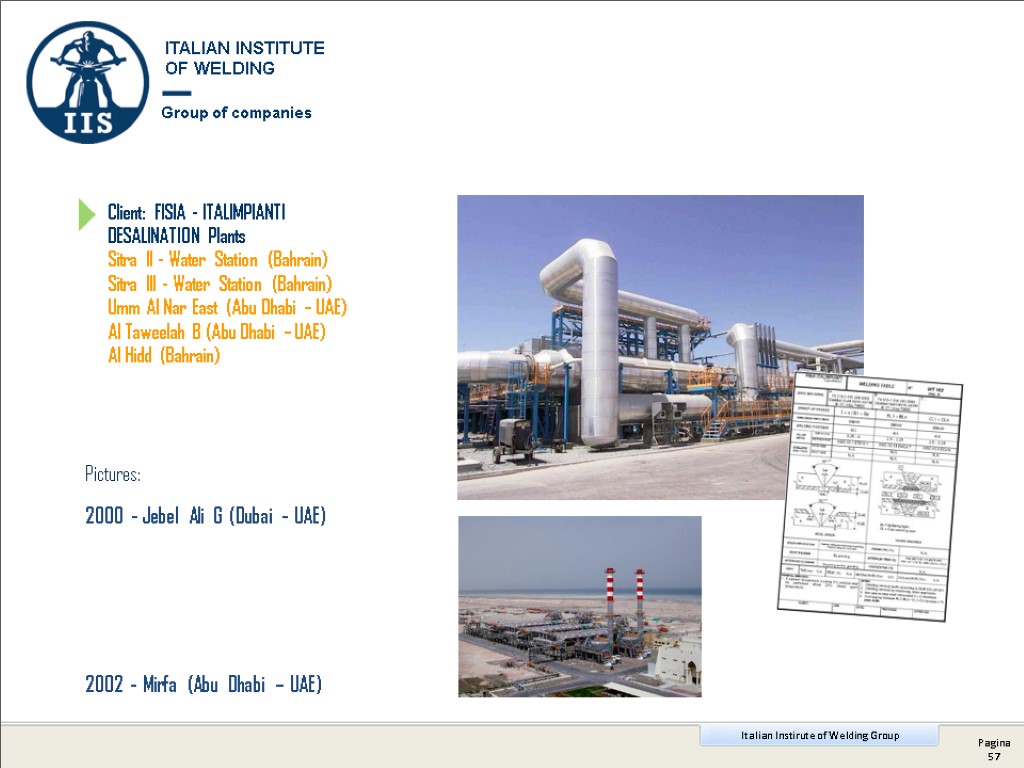

2000 - Jebel Ali G (Dubai - UAE) 2002 - Mirfa (Abu Dhabi – UAE) Pictures: Client: FISIA - ITALIMPIANTI DESALINATION Plants Sitra II - Water Station (Bahrain) Sitra III - Water Station (Bahrain) Umm Al Nar East (Abu Dhabi – UAE) Al Taweelah B (Abu Dhabi – UAE) Al Hidd (Bahrain) ITALIAN INSTITUTE OF WELDING Group of companies

2000 - Jebel Ali G (Dubai - UAE) 2002 - Mirfa (Abu Dhabi – UAE) Pictures: Client: FISIA - ITALIMPIANTI DESALINATION Plants Sitra II - Water Station (Bahrain) Sitra III - Water Station (Bahrain) Umm Al Nar East (Abu Dhabi – UAE) Al Taweelah B (Abu Dhabi – UAE) Al Hidd (Bahrain) ITALIAN INSTITUTE OF WELDING Group of companies

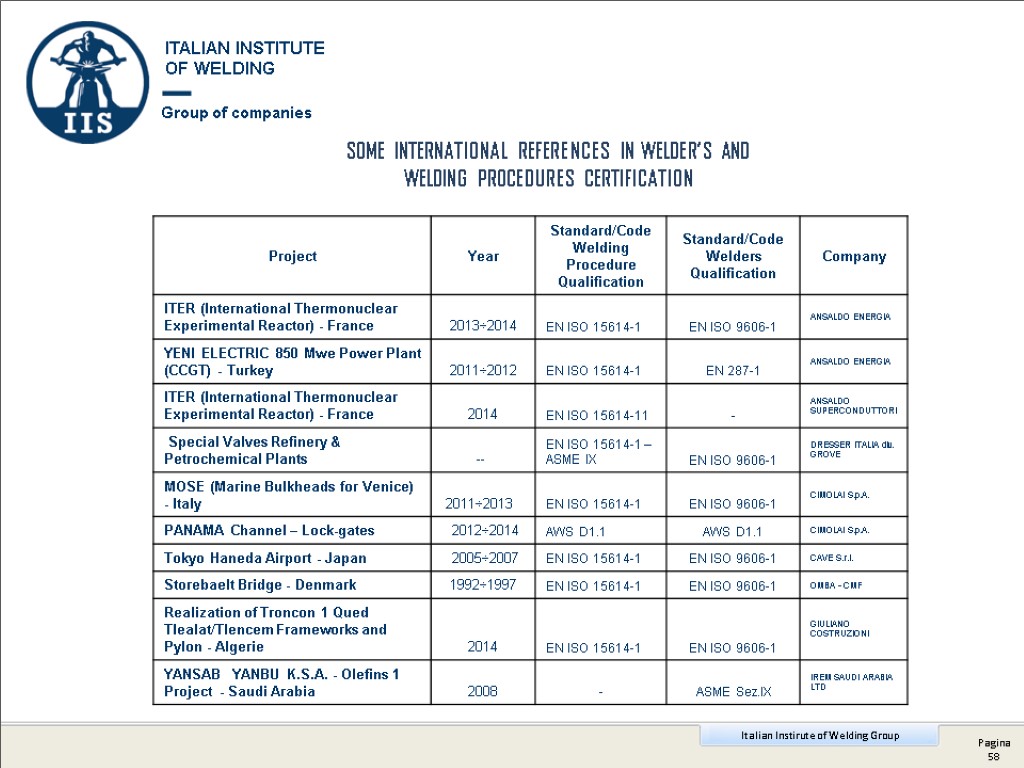

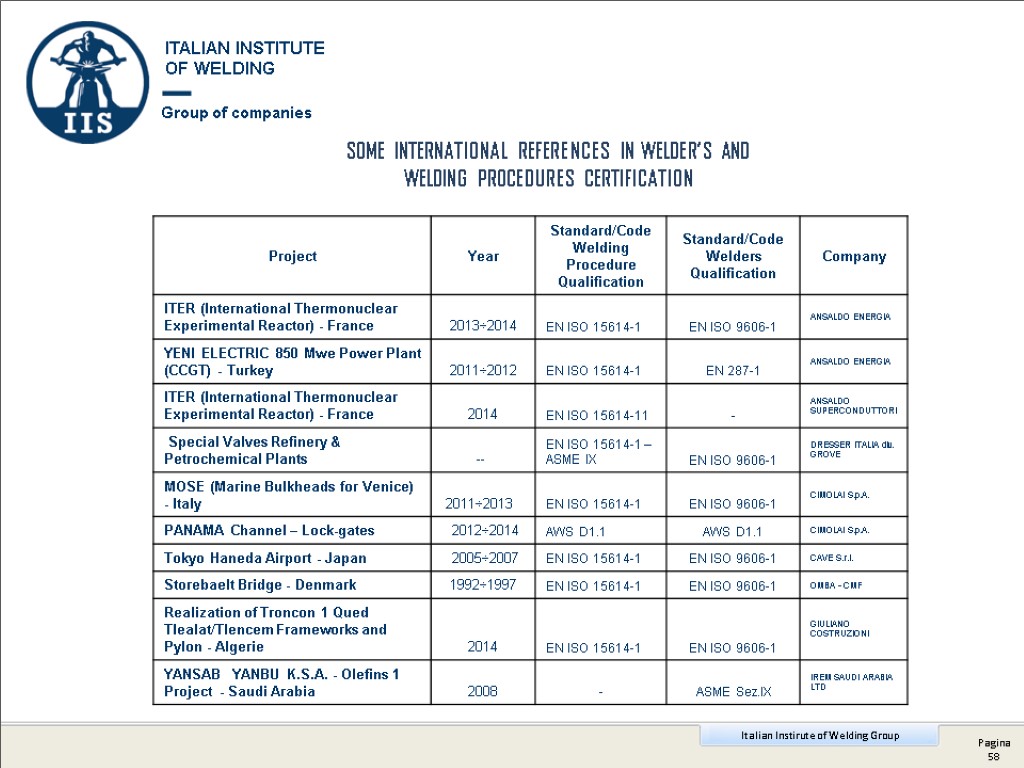

SOME INTERNATIONAL REFERENCES IN WELDER’S AND WELDING PROCEDURES CERTIFICATION Group of companies ITALIAN INSTITUTE OF WELDING

SOME INTERNATIONAL REFERENCES IN WELDER’S AND WELDING PROCEDURES CERTIFICATION Group of companies ITALIAN INSTITUTE OF WELDING

ITALIAN INSTITUTE OF WELDING GROUP Lungobisagno Istria, 15 – 16141 GENOVA – Italy Tel: +39 010 8341.1 – Fax: +39 010 836.7780, [email protected] – www.iis.it

ITALIAN INSTITUTE OF WELDING GROUP Lungobisagno Istria, 15 – 16141 GENOVA – Italy Tel: +39 010 8341.1 – Fax: +39 010 836.7780, [email protected] – www.iis.it