2bbf92c4f6df3003e5d9b7602ccda2f5.ppt

- Количество слайдов: 54

Group 13 Heavy Lift Cargo Plane Stephen Mc. Nulty Richard-Marc Hernandez Jessica Pisano Yoosuk Kee Chi Yan Project Advisor: Siva Thangam

Group 13 Heavy Lift Cargo Plane Stephen Mc. Nulty Richard-Marc Hernandez Jessica Pisano Yoosuk Kee Chi Yan Project Advisor: Siva Thangam

Overview n n n Objectives Schedule/Progress Design Concepts and Analysis Wing n Fuselage n Tail n Landing Gear n n Goals

Overview n n n Objectives Schedule/Progress Design Concepts and Analysis Wing n Fuselage n Tail n Landing Gear n n Goals

Objectives n n n Competition Specs are finally posted for the 2004 competition The plane meets the specifications of the 2004 SAE Aero Design West competition To finish the design of the plane by December and begin construction and testing in January To compete well at competition and improve Stevens reputation For the team to improve and expand their knowledge of the design and construction of airplanes

Objectives n n n Competition Specs are finally posted for the 2004 competition The plane meets the specifications of the 2004 SAE Aero Design West competition To finish the design of the plane by December and begin construction and testing in January To compete well at competition and improve Stevens reputation For the team to improve and expand their knowledge of the design and construction of airplanes

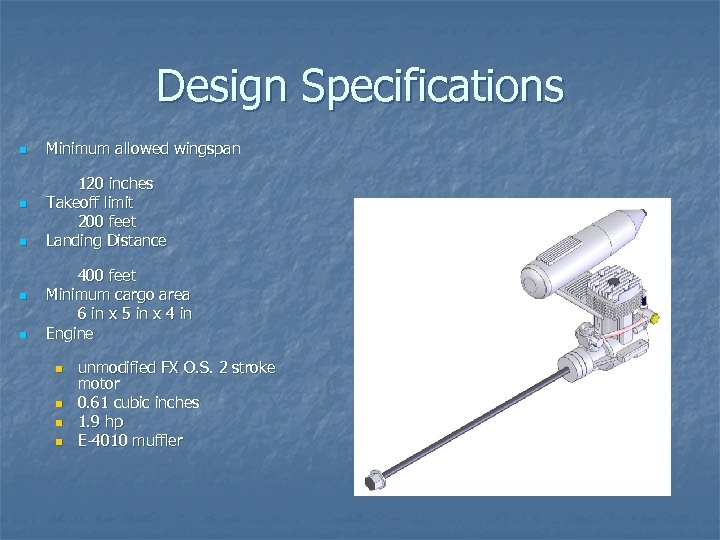

Design Specifications n n n Minimum allowed wingspan 120 inches Takeoff limit 200 feet Landing Distance 400 feet Minimum cargo area 6 in x 5 in x 4 in Engine n n unmodified FX O. S. 2 stroke motor 0. 61 cubic inches 1. 9 hp E-4010 muffler

Design Specifications n n n Minimum allowed wingspan 120 inches Takeoff limit 200 feet Landing Distance 400 feet Minimum cargo area 6 in x 5 in x 4 in Engine n n unmodified FX O. S. 2 stroke motor 0. 61 cubic inches 1. 9 hp E-4010 muffler

Design Specs Comparison Design Specifications: This Year (2004) Previous Year (2003) Wing Span Minimum 10 ft Maximum 6 ft Wing Chord No restriction Maximum 1 ft Cargo Volume Minimum 120 in 3 Minimum 300 in 3 Maximum Takeoff Distance 200 ft Maximum Landing Distance 400 ft Engine . 61 FX-OS or K&B. 61 R/C ABC Battery Minimum 500 m. Ah

Design Specs Comparison Design Specifications: This Year (2004) Previous Year (2003) Wing Span Minimum 10 ft Maximum 6 ft Wing Chord No restriction Maximum 1 ft Cargo Volume Minimum 120 in 3 Minimum 300 in 3 Maximum Takeoff Distance 200 ft Maximum Landing Distance 400 ft Engine . 61 FX-OS or K&B. 61 R/C ABC Battery Minimum 500 m. Ah

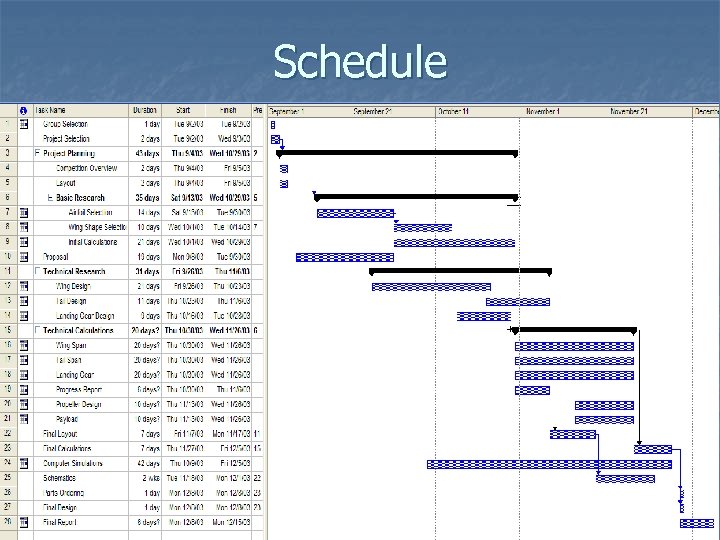

Schedule

Schedule

Journal/Progress n n Researched airfoil computer analysis software Calculations Stereo-lithography Lab Final Design Landing Gear models and analysis n Fuselage Design and Calculations n Tail Design n Wing Design n

Journal/Progress n n Researched airfoil computer analysis software Calculations Stereo-lithography Lab Final Design Landing Gear models and analysis n Fuselage Design and Calculations n Tail Design n Wing Design n

Rules for Wing n n n 16. 1 Fixed Wing Aircraft Type Requirements and Restrictions n Only fixed-wing designs are allowed to compete. Dirigibles, lighterthan-air craft, gyrocopters or helicopters are not allowed to compete, but are welcome to demonstrate their capability's hors-concurs. n © 2003 SAE International 9 2004 Aero Design East & West Rules 20. REGULAR CLASS - WINGSPAN LIMITATIONS n The minimum wing span may not be smaller than 305 cm (120 inches). The wing span is defined as the maximum overall width of the aircraft. Aircraft with a maximum overall width less than 305 cm (120 inches) shall be disqualified from the event. 20. 1 Not Meeting the Minimum wingspan n Aircraft not meeting the minimum wingspan limitation will be disqualified from the contest. If schedule permits, at the discretion of the contest director, the team may perform demonstration flights during the contest.

Rules for Wing n n n 16. 1 Fixed Wing Aircraft Type Requirements and Restrictions n Only fixed-wing designs are allowed to compete. Dirigibles, lighterthan-air craft, gyrocopters or helicopters are not allowed to compete, but are welcome to demonstrate their capability's hors-concurs. n © 2003 SAE International 9 2004 Aero Design East & West Rules 20. REGULAR CLASS - WINGSPAN LIMITATIONS n The minimum wing span may not be smaller than 305 cm (120 inches). The wing span is defined as the maximum overall width of the aircraft. Aircraft with a maximum overall width less than 305 cm (120 inches) shall be disqualified from the event. 20. 1 Not Meeting the Minimum wingspan n Aircraft not meeting the minimum wingspan limitation will be disqualified from the contest. If schedule permits, at the discretion of the contest director, the team may perform demonstration flights during the contest.

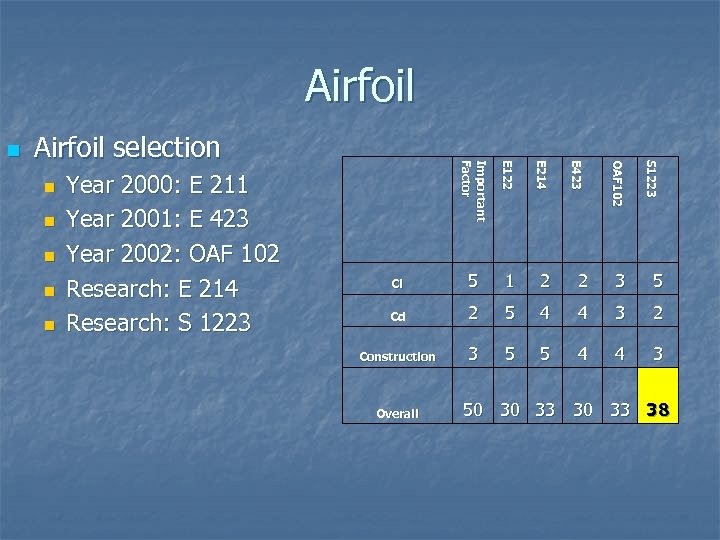

Airfoil Cl 5 1 2 2 3 5 Cd 2 5 4 4 3 2 Construction 3 5 5 4 4 3 Overall S 1223 n OAF 102 n E 423 n E 214 n Year 2000: E 211 Year 2001: E 423 Year 2002: OAF 102 Research: E 214 Research: S 1223 E 122 n Important Factor Airfoil selection n 50 30 33 38

Airfoil Cl 5 1 2 2 3 5 Cd 2 5 4 4 3 2 Construction 3 5 5 4 4 3 Overall S 1223 n OAF 102 n E 423 n E 214 n Year 2000: E 211 Year 2001: E 423 Year 2002: OAF 102 Research: E 214 Research: S 1223 E 122 n Important Factor Airfoil selection n 50 30 33 38

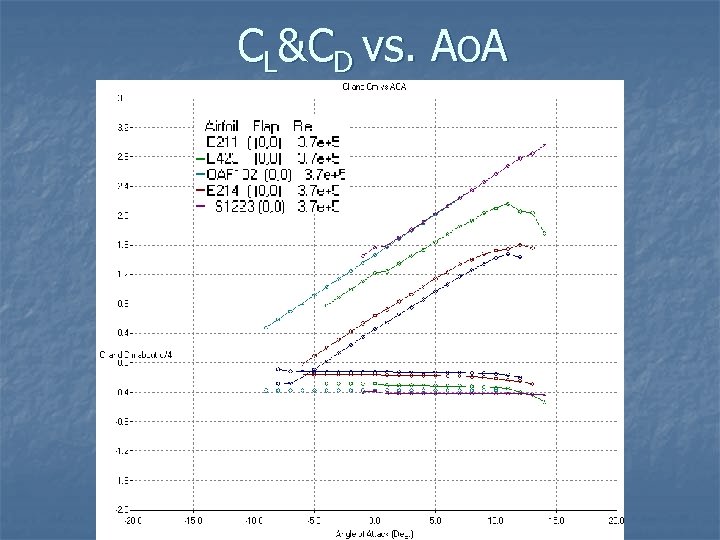

CL&CD vs. Ao. A

CL&CD vs. Ao. A

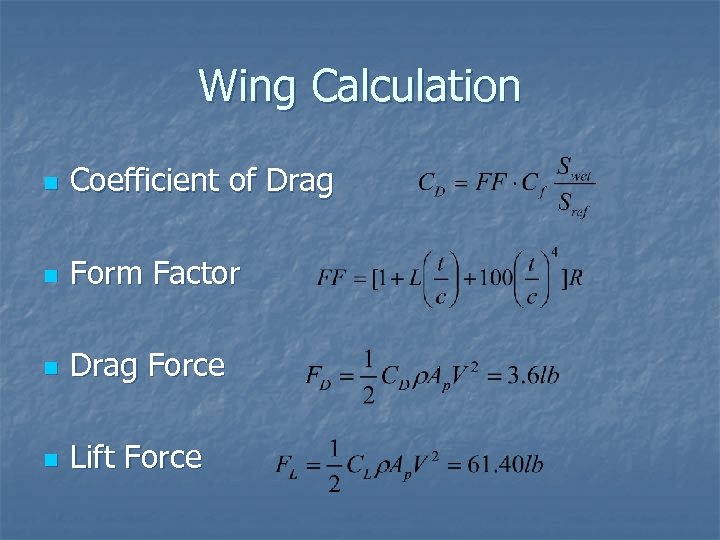

Wing Calculation n Coefficient of Drag n Form Factor n Drag Force n Lift Force

Wing Calculation n Coefficient of Drag n Form Factor n Drag Force n Lift Force

![Wing Calculations Wing: Re (S 1223) 326529 Swet [in^2] 3016. 6402 Wing Span [in] Wing Calculations Wing: Re (S 1223) 326529 Swet [in^2] 3016. 6402 Wing Span [in]](https://present5.com/presentation/2bbf92c4f6df3003e5d9b7602ccda2f5/image-12.jpg) Wing Calculations Wing: Re (S 1223) 326529 Swet [in^2] 3016. 6402 Wing Span [in] 120 Wing Chord [in] 12 Sref [in^2] 1440 Clmax 2. 3648 Cf (turbulent) 0. 005559594 Cf (laminar) 0. 002324006 t/c 0. 121 x/c 0. 2 FF 1. 384435888 Cdmin (turb) 0. 016124153 Cdmin (laminar) 0. 006740173

Wing Calculations Wing: Re (S 1223) 326529 Swet [in^2] 3016. 6402 Wing Span [in] 120 Wing Chord [in] 12 Sref [in^2] 1440 Clmax 2. 3648 Cf (turbulent) 0. 005559594 Cf (laminar) 0. 002324006 t/c 0. 121 x/c 0. 2 FF 1. 384435888 Cdmin (turb) 0. 016124153 Cdmin (laminar) 0. 006740173

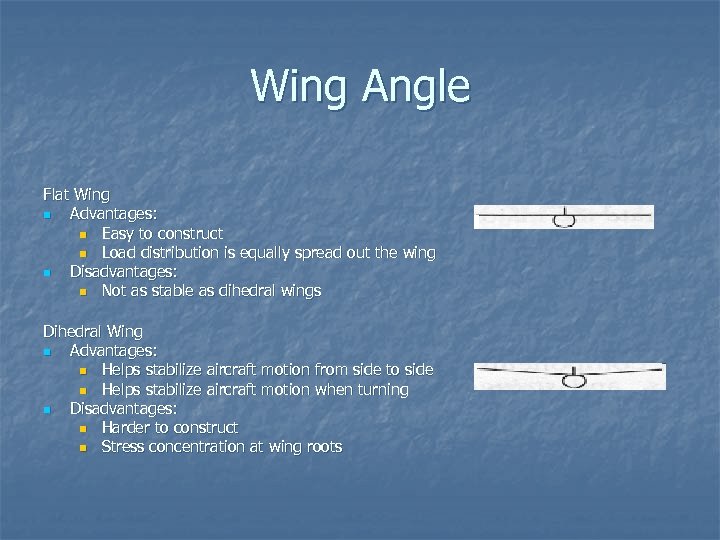

Wing Angle Flat Wing n Advantages: n Easy to construct n Load distribution is equally spread out the wing n Disadvantages: n Not as stable as dihedral wings Dihedral Wing n Advantages: n Helps stabilize aircraft motion from side to side n Helps stabilize aircraft motion when turning n Disadvantages: n Harder to construct n Stress concentration at wing roots

Wing Angle Flat Wing n Advantages: n Easy to construct n Load distribution is equally spread out the wing n Disadvantages: n Not as stable as dihedral wings Dihedral Wing n Advantages: n Helps stabilize aircraft motion from side to side n Helps stabilize aircraft motion when turning n Disadvantages: n Harder to construct n Stress concentration at wing roots

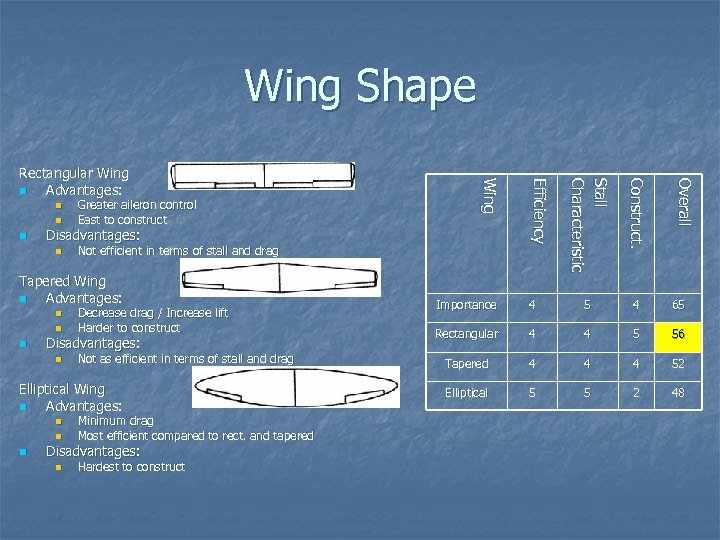

Wing Shape n n Decrease drag / Increase lift Harder to construct Disadvantages: n Not as efficient in terms of stall and drag Elliptical Wing n Advantages: n n Minimum drag Most efficient compared to rect. and tapered Disadvantages: n Hardest to construct Overallll O ve r a 4 5 4 65 Rectangular 4 4 5 56 Tapered 4 4 4 52 Elliptical 5 5 2 48 Not efficient in terms of stall and drag Tapered Wing n Advantages: n Importance Disadvantages: n n C o n st ru c t. n Greater aileron control East to construct Stallll St a C h a ra c t eri st i c n Effiiciiency Ef f c e n c y n W ing Rectangular Wing n Advantages:

Wing Shape n n Decrease drag / Increase lift Harder to construct Disadvantages: n Not as efficient in terms of stall and drag Elliptical Wing n Advantages: n n Minimum drag Most efficient compared to rect. and tapered Disadvantages: n Hardest to construct Overallll O ve r a 4 5 4 65 Rectangular 4 4 5 56 Tapered 4 4 4 52 Elliptical 5 5 2 48 Not efficient in terms of stall and drag Tapered Wing n Advantages: n Importance Disadvantages: n n C o n st ru c t. n Greater aileron control East to construct Stallll St a C h a ra c t eri st i c n Effiiciiency Ef f c e n c y n W ing Rectangular Wing n Advantages:

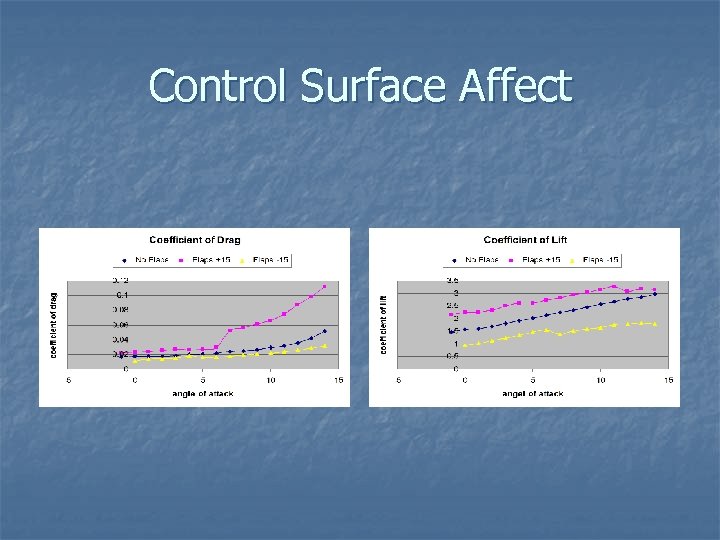

Control Surface Affect

Control Surface Affect

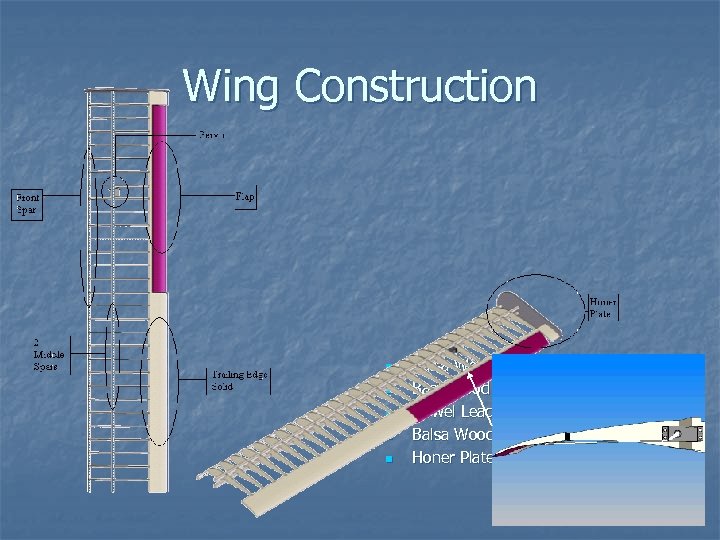

Wing Construction n n n Balsa Wood Risers Bass Wood Spars Dowel Leading Edge Balsa Wood Trailing Edge Honer Plate

Wing Construction n n n Balsa Wood Risers Bass Wood Spars Dowel Leading Edge Balsa Wood Trailing Edge Honer Plate

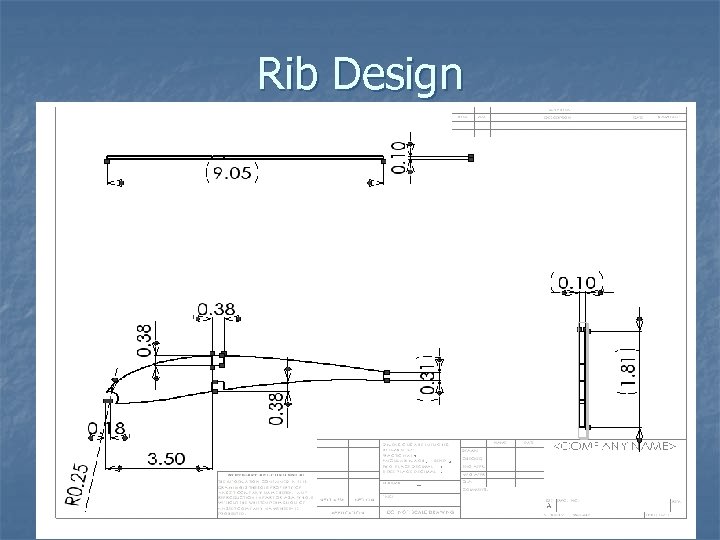

Rib Design

Rib Design

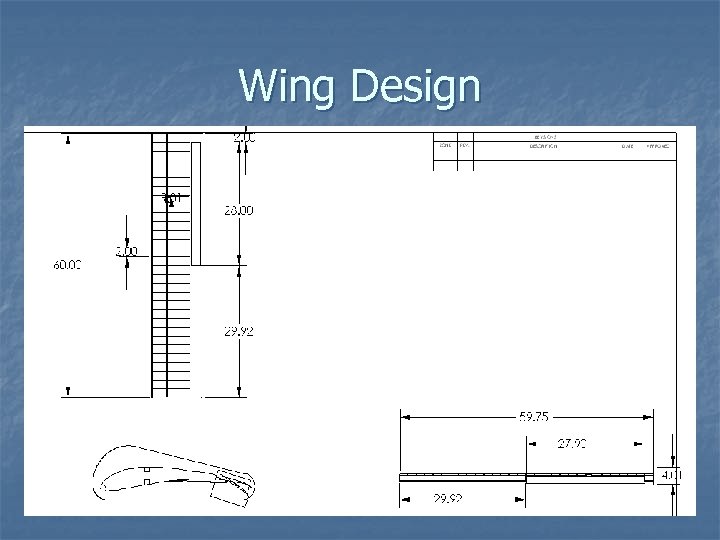

Wing Design

Wing Design

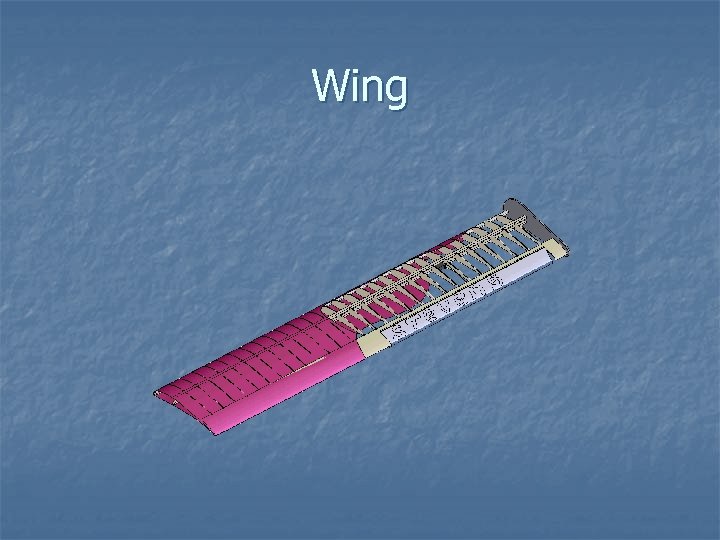

Wing

Wing

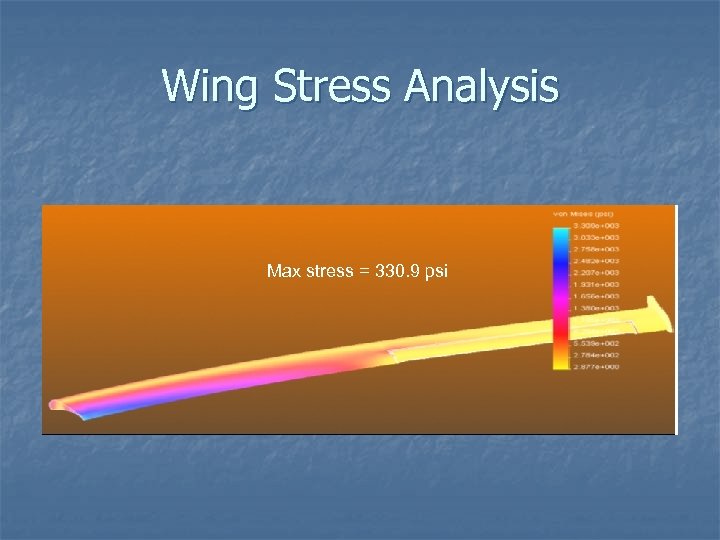

Wing Stress Analysis Max stress = 330. 9 psi

Wing Stress Analysis Max stress = 330. 9 psi

Fuselage Guidelines 16. 5 Payload 16. 5. 1 Payload and Payload Support The payload must consist of a support assembly and plates. 21. CARGO BAY/MINIMUM CARGO VOLUME Regular Class aircraft shall be capable of carrying and fully enclosing a rectangular block measuring 6 inches by 5 inches by 4 inches. During technical inspection, compliance with this rule shall be tested by inserting a block with these dimensions into the aircraft. This block must be easily inserted and removed without application of excess force during insertion or extraction, and the aircraft must be structurally airworthy with the block installed. When the aircraft is ready to fly, the bay must be fully enclosed. The cargo bay must be shown clearly in the design plans, with dimensions included. Note: The block does not guarantee enough area for your required weight. 21. 1 Undersized Cargo Bay – Penalty Planes that are unable to fit the 6 inches by 5 inches by 4 inches block into their cargo bay will not be eligible to fly. 22. REQUIRED ENGINE Regular Class aircraft must be powered by a single, unmodified O. S. . 61 FX with E-4010 Muffler. No muffler extensions or headers that fit between the engine cylinder and the muffler may be used. Muffler baffles must be installed, and must be unmodified from the factory installed configuration. No fuel pumps are allowed. While the engine may not be modified from its stock configuration, two specific components may be installed on the engine for convenience and/or safety purposes: · Remote needle valves, including needle valves that may be adjusted in flight are allowed. · Tubes that redirect the exhaust flow may be affixed to the exhaust pipe. Note: engine tear-down and inspection may be performed by the competition officials at any time during the competition.

Fuselage Guidelines 16. 5 Payload 16. 5. 1 Payload and Payload Support The payload must consist of a support assembly and plates. 21. CARGO BAY/MINIMUM CARGO VOLUME Regular Class aircraft shall be capable of carrying and fully enclosing a rectangular block measuring 6 inches by 5 inches by 4 inches. During technical inspection, compliance with this rule shall be tested by inserting a block with these dimensions into the aircraft. This block must be easily inserted and removed without application of excess force during insertion or extraction, and the aircraft must be structurally airworthy with the block installed. When the aircraft is ready to fly, the bay must be fully enclosed. The cargo bay must be shown clearly in the design plans, with dimensions included. Note: The block does not guarantee enough area for your required weight. 21. 1 Undersized Cargo Bay – Penalty Planes that are unable to fit the 6 inches by 5 inches by 4 inches block into their cargo bay will not be eligible to fly. 22. REQUIRED ENGINE Regular Class aircraft must be powered by a single, unmodified O. S. . 61 FX with E-4010 Muffler. No muffler extensions or headers that fit between the engine cylinder and the muffler may be used. Muffler baffles must be installed, and must be unmodified from the factory installed configuration. No fuel pumps are allowed. While the engine may not be modified from its stock configuration, two specific components may be installed on the engine for convenience and/or safety purposes: · Remote needle valves, including needle valves that may be adjusted in flight are allowed. · Tubes that redirect the exhaust flow may be affixed to the exhaust pipe. Note: engine tear-down and inspection may be performed by the competition officials at any time during the competition.

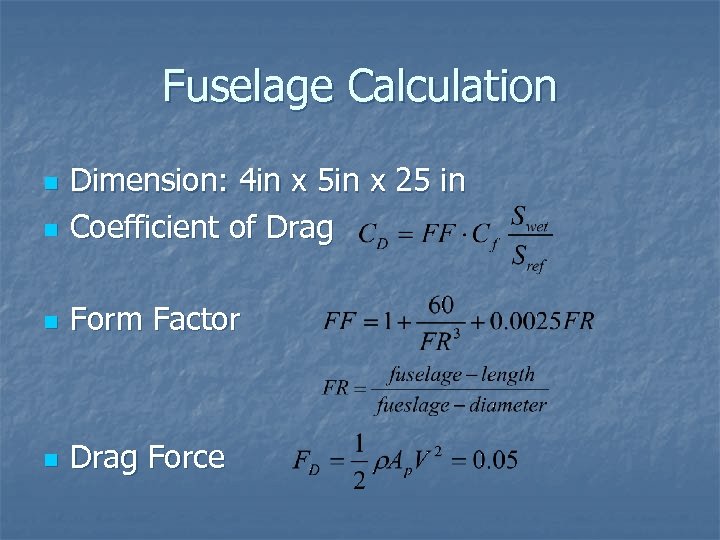

Fuselage Calculation n Dimension: 4 in x 5 in x 25 in Coefficient of Drag n Form Factor n Drag Force n

Fuselage Calculation n Dimension: 4 in x 5 in x 25 in Coefficient of Drag n Form Factor n Drag Force n

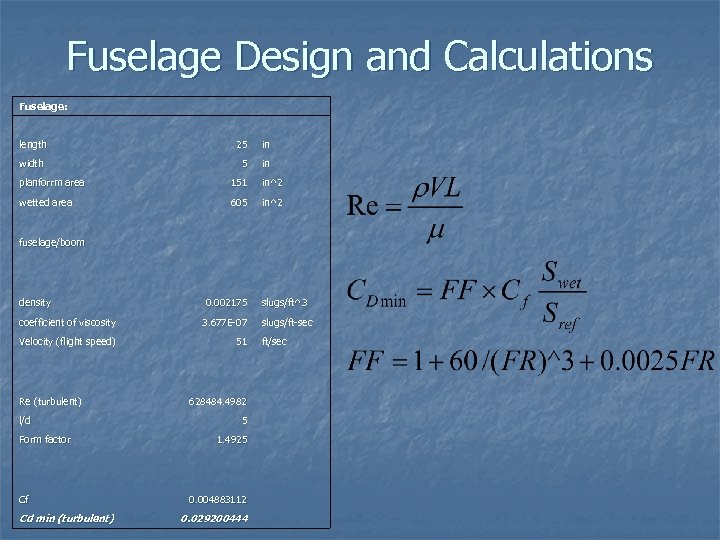

Fuselage Design and Calculations Fuselage: length 25 in width 5 in planforrm area 151 in^2 wetted area 605 in^2 fuselage/boom density 0. 002175 slugs/ft^3 coefficient of viscosity 3. 677 E-07 slugs/ft-sec Velocity (flight speed) 51 Re (turbulent) l/d Form factor 628484. 4982 5 1. 4925 Cf Cd min (turbulent) ft/sec 0. 004883112 0. 029200444

Fuselage Design and Calculations Fuselage: length 25 in width 5 in planforrm area 151 in^2 wetted area 605 in^2 fuselage/boom density 0. 002175 slugs/ft^3 coefficient of viscosity 3. 677 E-07 slugs/ft-sec Velocity (flight speed) 51 Re (turbulent) l/d Form factor 628484. 4982 5 1. 4925 Cf Cd min (turbulent) ft/sec 0. 004883112 0. 029200444

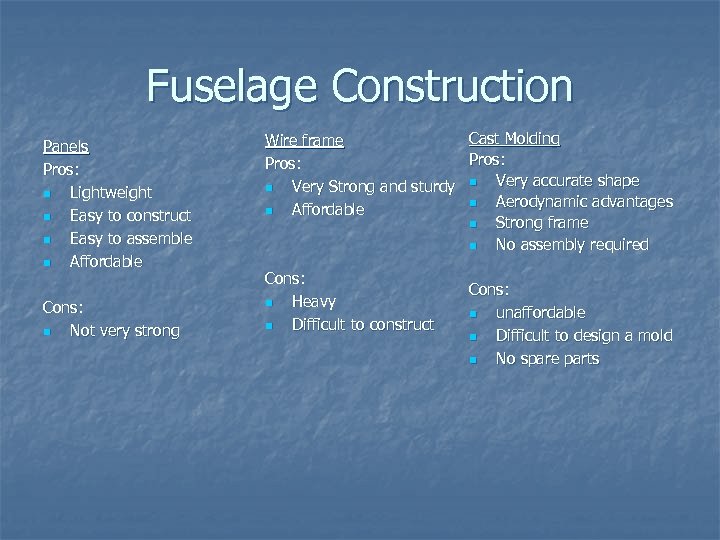

Fuselage Construction Panels Pros: n Lightweight n Easy to construct n Easy to assemble n Affordable Cons: n Not very strong Cast Molding Wire frame Pros: n Very Strong and sturdy n Very accurate shape n Aerodynamic advantages n Affordable n Strong frame n No assembly required Cons: n Heavy n Difficult to construct Cons: n unaffordable n Difficult to design a mold n No spare parts

Fuselage Construction Panels Pros: n Lightweight n Easy to construct n Easy to assemble n Affordable Cons: n Not very strong Cast Molding Wire frame Pros: n Very Strong and sturdy n Very accurate shape n Aerodynamic advantages n Affordable n Strong frame n No assembly required Cons: n Heavy n Difficult to construct Cons: n unaffordable n Difficult to design a mold n No spare parts

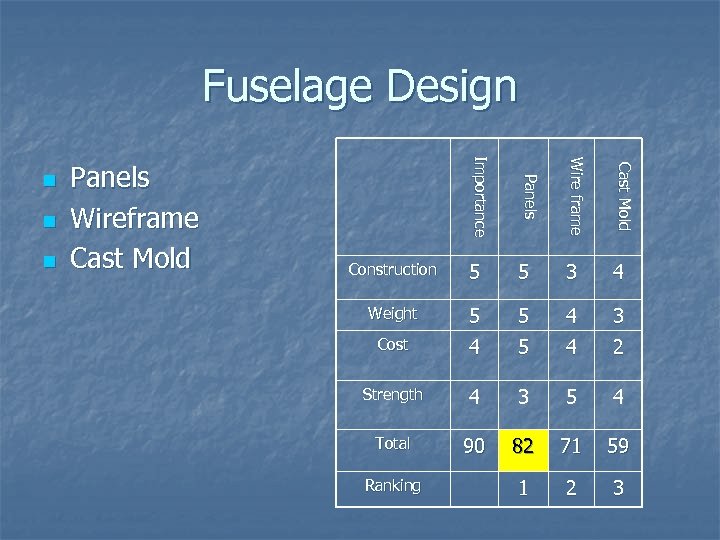

Fuselage Design Wiire frame W re fra m e Cast Molld C a st M o d n Panells Pa n e s n Panels Wireframe Cast Mold Im p o r t a n c e n Construction 5 5 3 4 Weight 5 5 4 3 Cost 4 5 4 2 Strength 4 3 5 4 Total 90 82 71 59 1 2 3 Ranking

Fuselage Design Wiire frame W re fra m e Cast Molld C a st M o d n Panells Pa n e s n Panels Wireframe Cast Mold Im p o r t a n c e n Construction 5 5 3 4 Weight 5 5 4 3 Cost 4 5 4 2 Strength 4 3 5 4 Total 90 82 71 59 1 2 3 Ranking

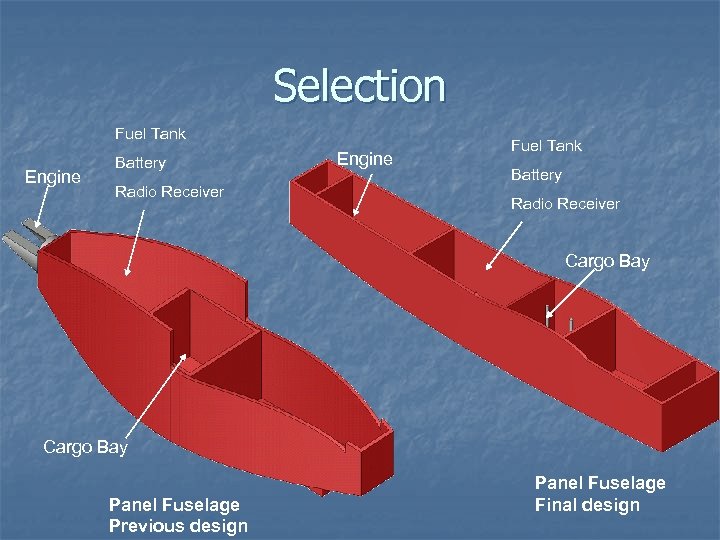

Selection Fuel Tank Engine Battery Radio Receiver Engine Fuel Tank Battery Radio Receiver Cargo Bay Panel Fuselage Previous design Panel Fuselage Final design

Selection Fuel Tank Engine Battery Radio Receiver Engine Fuel Tank Battery Radio Receiver Cargo Bay Panel Fuselage Previous design Panel Fuselage Final design

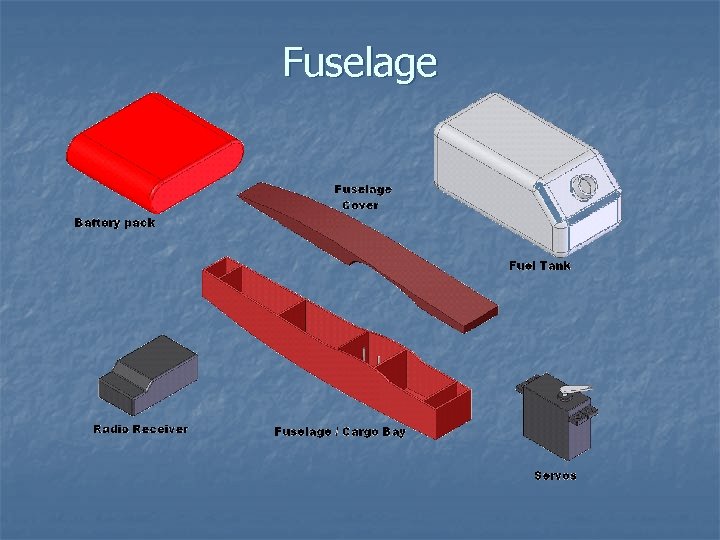

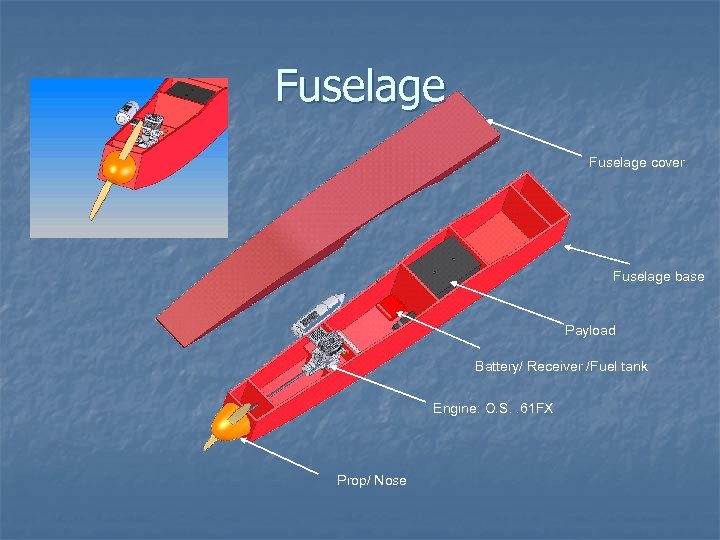

Fuselage

Fuselage

Fuselage cover Fuselage base Payload Battery/ Receiver /Fuel tank Engine: O. S. . 61 FX Prop/ Nose

Fuselage cover Fuselage base Payload Battery/ Receiver /Fuel tank Engine: O. S. . 61 FX Prop/ Nose

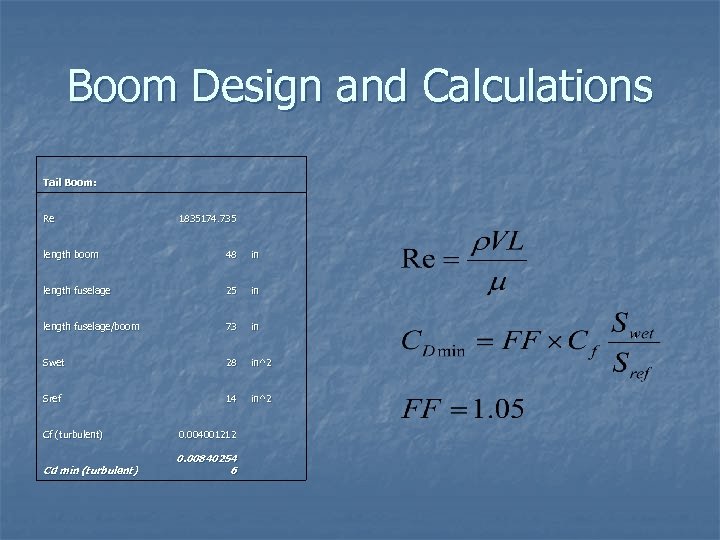

Boom Design and Calculations Tail Boom: Re 1835174. 735 length boom 48 in length fuselage 25 in length fuselage/boom 73 in Swet 28 in^2 Sref 14 in^2 Cf (turbulent) 0. 004001212 Cd min (turbulent) 0. 00840254 6

Boom Design and Calculations Tail Boom: Re 1835174. 735 length boom 48 in length fuselage 25 in length fuselage/boom 73 in Swet 28 in^2 Sref 14 in^2 Cf (turbulent) 0. 004001212 Cd min (turbulent) 0. 00840254 6

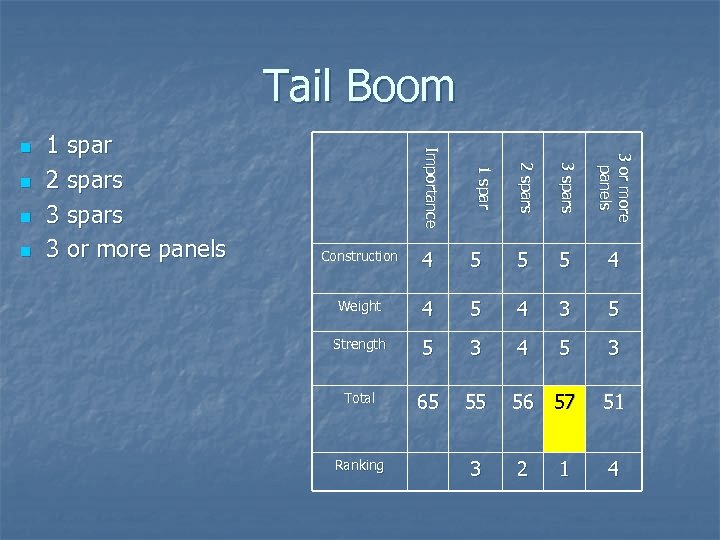

Tail Boom 2 sp a rs 3 o r m o re p a n el s 4 5 5 5 4 Weight 4 5 4 3 5 Strength 5 3 4 5 3 Total 65 55 56 57 51 3 2 4 Im p o r t a n c e n n 1 Ranking 1 sp a r Construction n 1 spar 2 spars 3 or more panels n

Tail Boom 2 sp a rs 3 o r m o re p a n el s 4 5 5 5 4 Weight 4 5 4 3 5 Strength 5 3 4 5 3 Total 65 55 56 57 51 3 2 4 Im p o r t a n c e n n 1 Ranking 1 sp a r Construction n 1 spar 2 spars 3 or more panels n

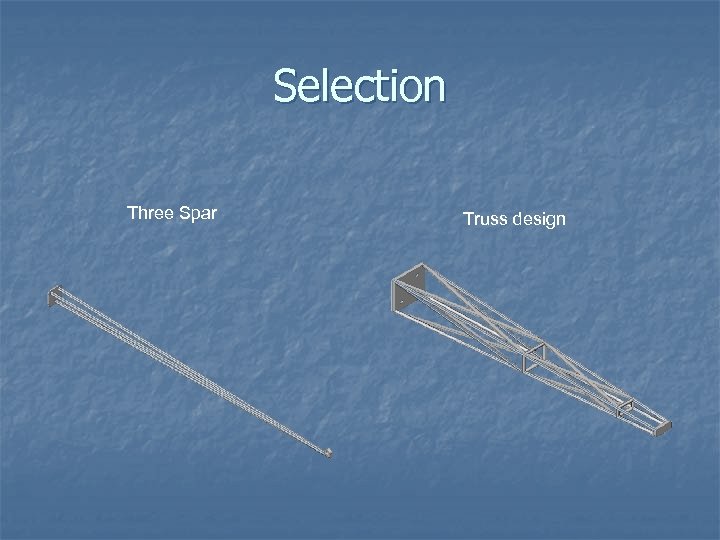

Selection Three Spar Truss design

Selection Three Spar Truss design

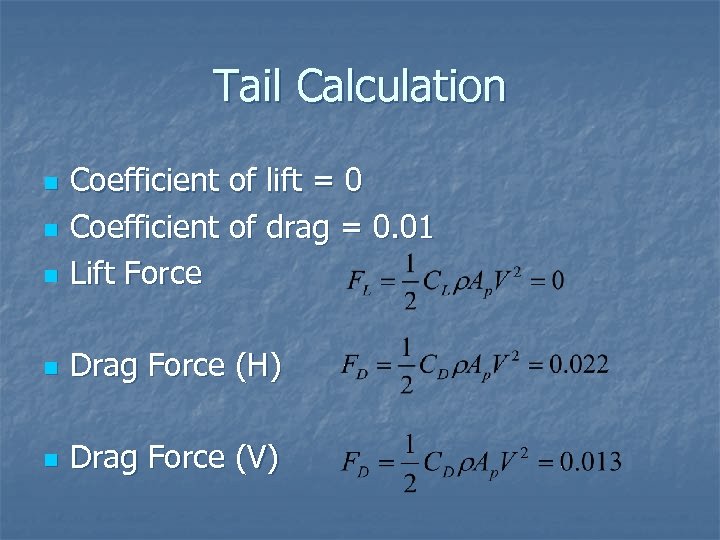

Tail Calculation n Coefficient of lift = 0 Coefficient of drag = 0. 01 Lift Force n Drag Force (H) n Drag Force (V) n n

Tail Calculation n Coefficient of lift = 0 Coefficient of drag = 0. 01 Lift Force n Drag Force (H) n Drag Force (V) n n

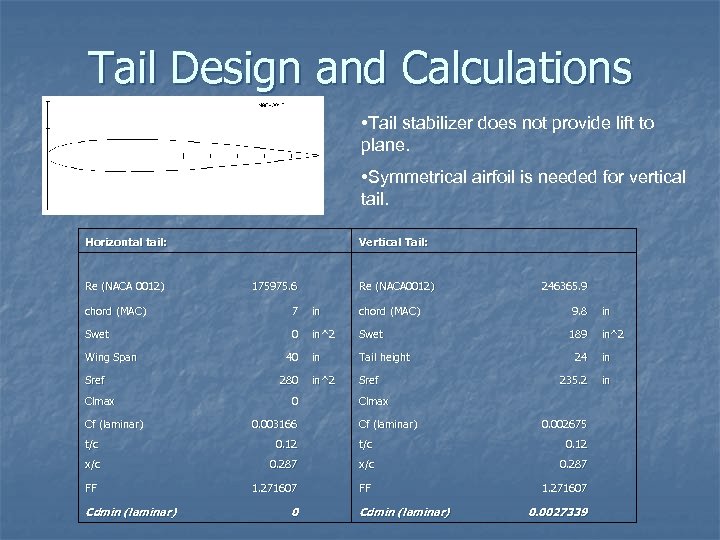

Tail Design and Calculations • Tail stabilizer does not provide lift to plane. • Symmetrical airfoil is needed for vertical tail. Horizontal tail: Re (NACA 0012) Vertical Tail: 175975. 6 Re (NACA 0012) 246365. 9 chord (MAC) 7 in chord (MAC) 9. 8 in Swet 0 in^2 Swet 189 in^2 in Tail height in^2 Sref 0 Clmax 0. 003166 Cf (laminar) t/c 0. 12 x/c 0. 287 FF Wing Span Sref Clmax Cf (laminar) Cdmin (laminar) 40 280 24 in 235. 2 in 0. 002675 t/c 0. 12 x/c 0. 287 1. 271607 FF 1. 271607 0 Cdmin (laminar) 0. 0027339

Tail Design and Calculations • Tail stabilizer does not provide lift to plane. • Symmetrical airfoil is needed for vertical tail. Horizontal tail: Re (NACA 0012) Vertical Tail: 175975. 6 Re (NACA 0012) 246365. 9 chord (MAC) 7 in chord (MAC) 9. 8 in Swet 0 in^2 Swet 189 in^2 in Tail height in^2 Sref 0 Clmax 0. 003166 Cf (laminar) t/c 0. 12 x/c 0. 287 FF Wing Span Sref Clmax Cf (laminar) Cdmin (laminar) 40 280 24 in 235. 2 in 0. 002675 t/c 0. 12 x/c 0. 287 1. 271607 FF 1. 271607 0 Cdmin (laminar) 0. 0027339

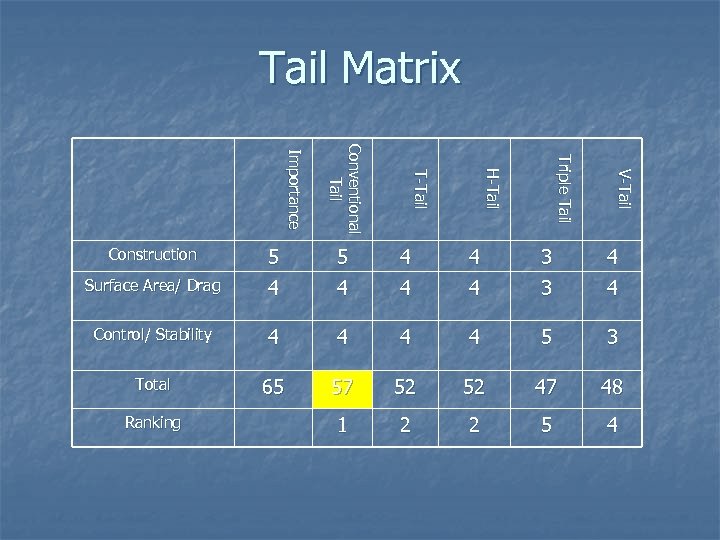

Tail Matrix V-Taiill V -T a Triiplle Taiill T r p e T a H-Taiill H-T a T-Taiill T -T a 5 5 4 4 3 4 Surface Area/ Drag 4 4 3 4 Control/ Stability 4 4 5 3 Total 65 57 52 52 47 48 1 2 2 5 4 Ranking Conventiionall C o n ve n t o n a Taiill Ta Im p o r t a n c e Construction

Tail Matrix V-Taiill V -T a Triiplle Taiill T r p e T a H-Taiill H-T a T-Taiill T -T a 5 5 4 4 3 4 Surface Area/ Drag 4 4 3 4 Control/ Stability 4 4 5 3 Total 65 57 52 52 47 48 1 2 2 5 4 Ranking Conventiionall C o n ve n t o n a Taiill Ta Im p o r t a n c e Construction

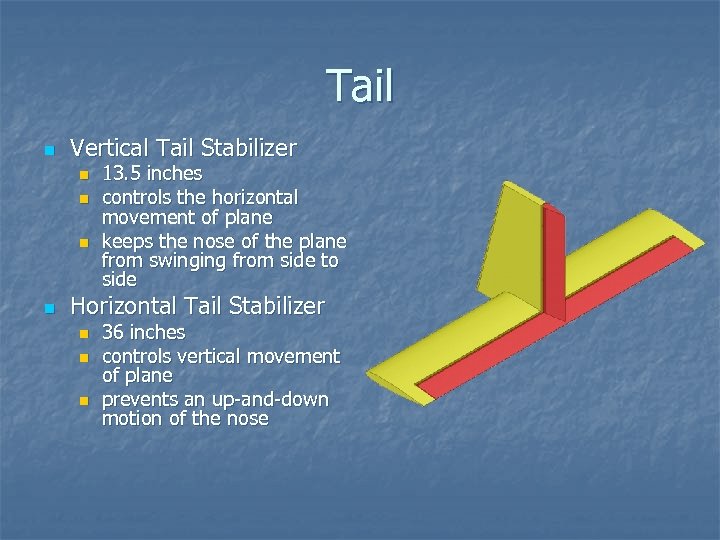

Tail n Vertical Tail Stabilizer n n 13. 5 inches controls the horizontal movement of plane keeps the nose of the plane from swinging from side to side Horizontal Tail Stabilizer n n n 36 inches controls vertical movement of plane prevents an up-and-down motion of the nose

Tail n Vertical Tail Stabilizer n n 13. 5 inches controls the horizontal movement of plane keeps the nose of the plane from swinging from side to side Horizontal Tail Stabilizer n n n 36 inches controls vertical movement of plane prevents an up-and-down motion of the nose

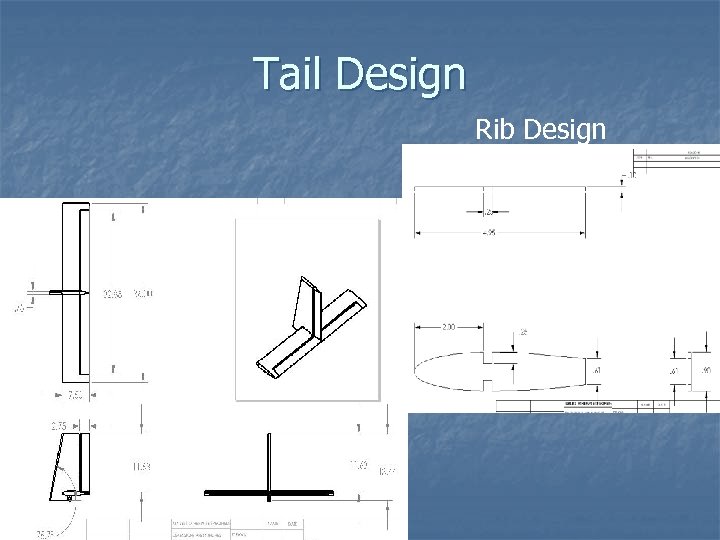

Tail Design Rib Design

Tail Design Rib Design

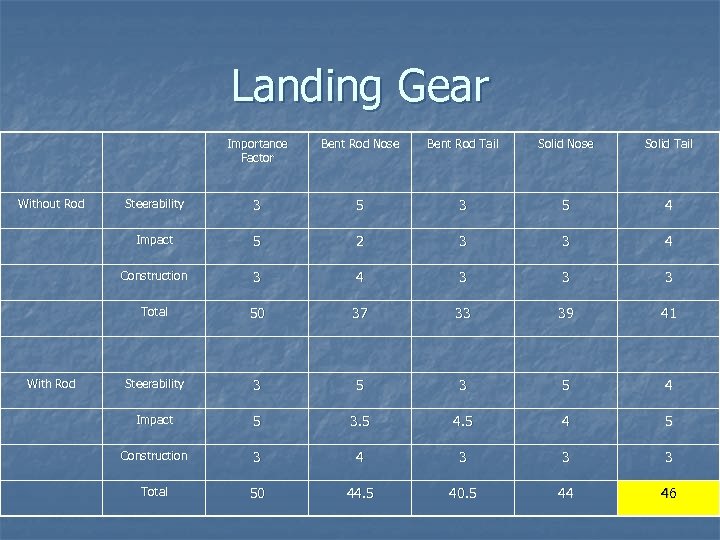

Landing Gear Importance Factor Solid Nose Solid Tail Steerability 3 5 4 5 2 3 3 4 Construction 3 4 3 3 3 Total With Rod Bent Rod Tail Impact Without Rod Bent Rod Nose 50 37 33 39 41 Steerability 3 5 4 Impact 5 3. 5 4 5 Construction 3 4 3 3 3 Total 50 44. 5 40. 5 44 46

Landing Gear Importance Factor Solid Nose Solid Tail Steerability 3 5 4 5 2 3 3 4 Construction 3 4 3 3 3 Total With Rod Bent Rod Tail Impact Without Rod Bent Rod Nose 50 37 33 39 41 Steerability 3 5 4 Impact 5 3. 5 4 5 Construction 3 4 3 3 3 Total 50 44. 5 40. 5 44 46

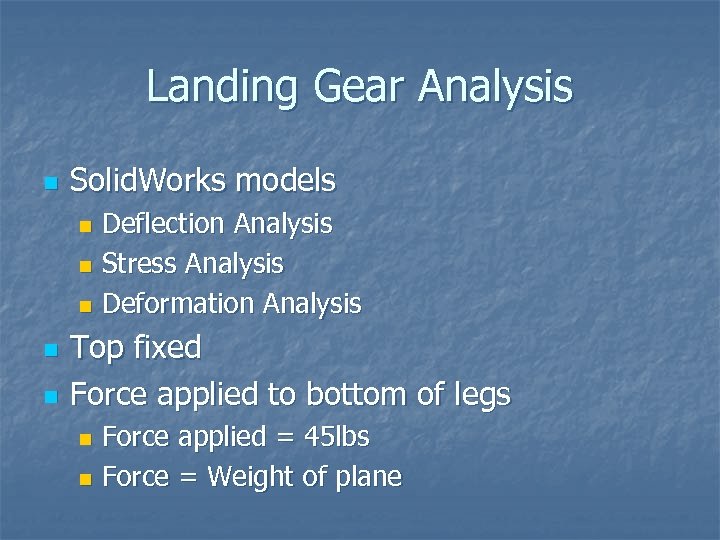

Landing Gear Analysis n Solid. Works models Deflection Analysis n Stress Analysis n Deformation Analysis n n n Top fixed Force applied to bottom of legs Force applied = 45 lbs n Force = Weight of plane n

Landing Gear Analysis n Solid. Works models Deflection Analysis n Stress Analysis n Deformation Analysis n n n Top fixed Force applied to bottom of legs Force applied = 45 lbs n Force = Weight of plane n

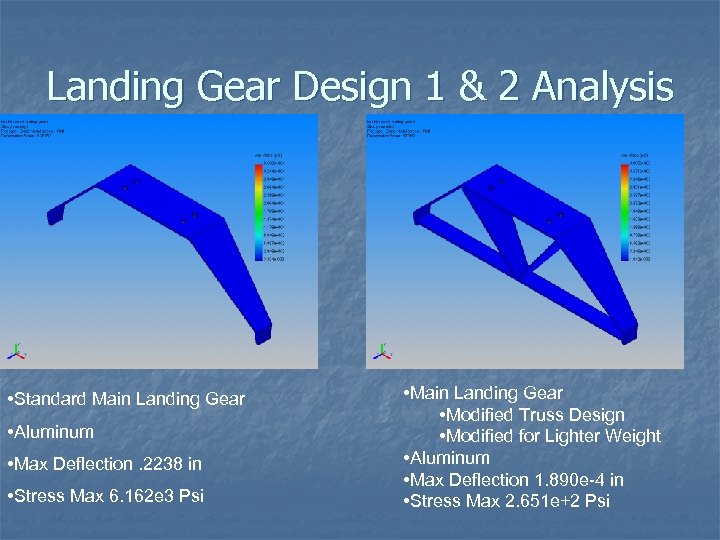

Landing Gear Design 1 & 2 Analysis • Standard Main Landing Gear • Aluminum • Max Deflection. 2238 in • Stress Max 6. 162 e 3 Psi • Main Landing Gear • Modified Truss Design • Modified for Lighter Weight • Aluminum • Max Deflection 1. 890 e-4 in • Stress Max 2. 651 e+2 Psi

Landing Gear Design 1 & 2 Analysis • Standard Main Landing Gear • Aluminum • Max Deflection. 2238 in • Stress Max 6. 162 e 3 Psi • Main Landing Gear • Modified Truss Design • Modified for Lighter Weight • Aluminum • Max Deflection 1. 890 e-4 in • Stress Max 2. 651 e+2 Psi

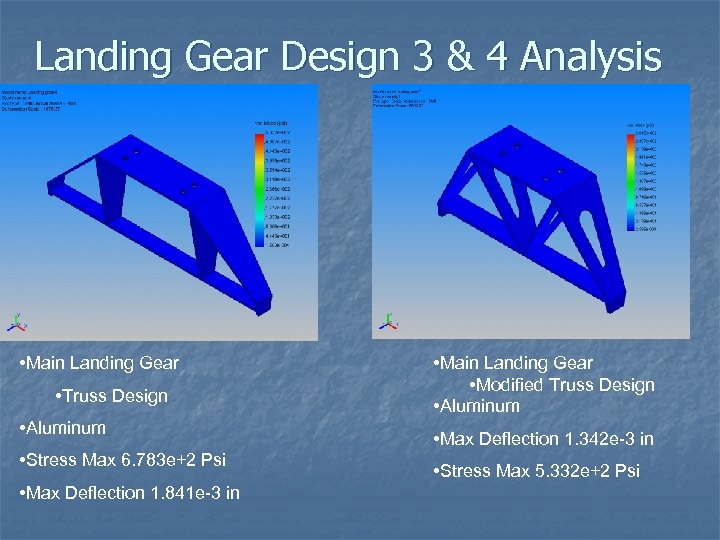

Landing Gear Design 3 & 4 Analysis • Main Landing Gear • Truss Design • Aluminum • Stress Max 6. 783 e+2 Psi • Max Deflection 1. 841 e-3 in • Main Landing Gear • Modified Truss Design • Aluminum • Max Deflection 1. 342 e-3 in • Stress Max 5. 332 e+2 Psi

Landing Gear Design 3 & 4 Analysis • Main Landing Gear • Truss Design • Aluminum • Stress Max 6. 783 e+2 Psi • Max Deflection 1. 841 e-3 in • Main Landing Gear • Modified Truss Design • Aluminum • Max Deflection 1. 342 e-3 in • Stress Max 5. 332 e+2 Psi

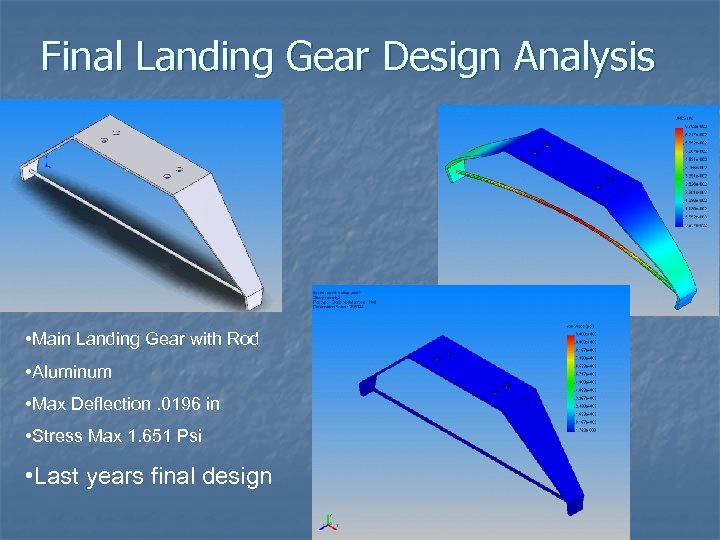

Final Landing Gear Design Analysis • Main Landing Gear with Rod • Aluminum • Max Deflection. 0196 in • Stress Max 1. 651 Psi • Last years final design

Final Landing Gear Design Analysis • Main Landing Gear with Rod • Aluminum • Max Deflection. 0196 in • Stress Max 1. 651 Psi • Last years final design

Landing Gear Configuration n Tail Dragger Tricycle Not decided until Spring n Perform testing on which is more efficient

Landing Gear Configuration n Tail Dragger Tricycle Not decided until Spring n Perform testing on which is more efficient

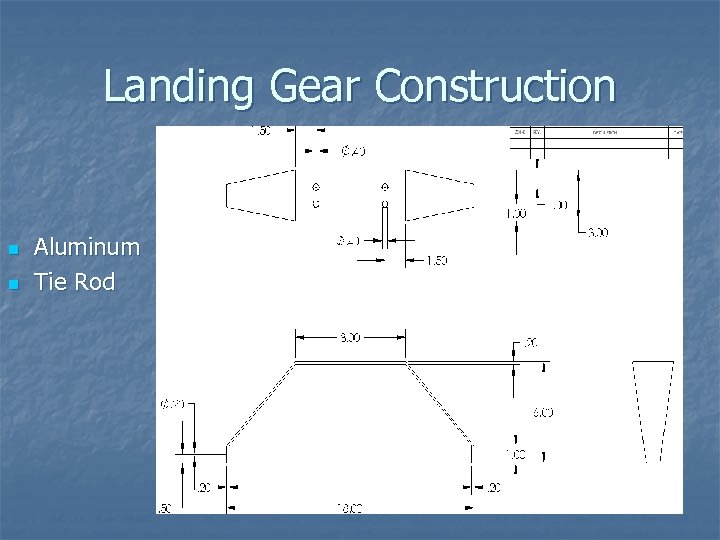

Landing Gear Construction n n Aluminum Tie Rod

Landing Gear Construction n n Aluminum Tie Rod

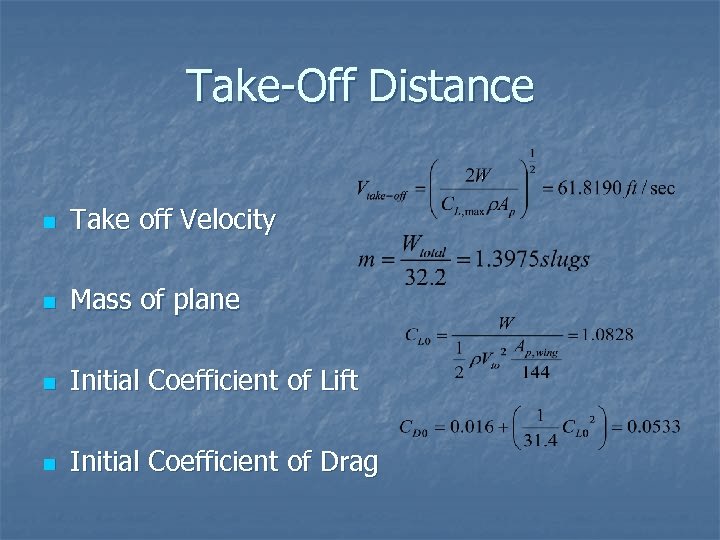

Take-Off Distance n Take off Velocity n Mass of plane n Initial Coefficient of Lift n Initial Coefficient of Drag

Take-Off Distance n Take off Velocity n Mass of plane n Initial Coefficient of Lift n Initial Coefficient of Drag

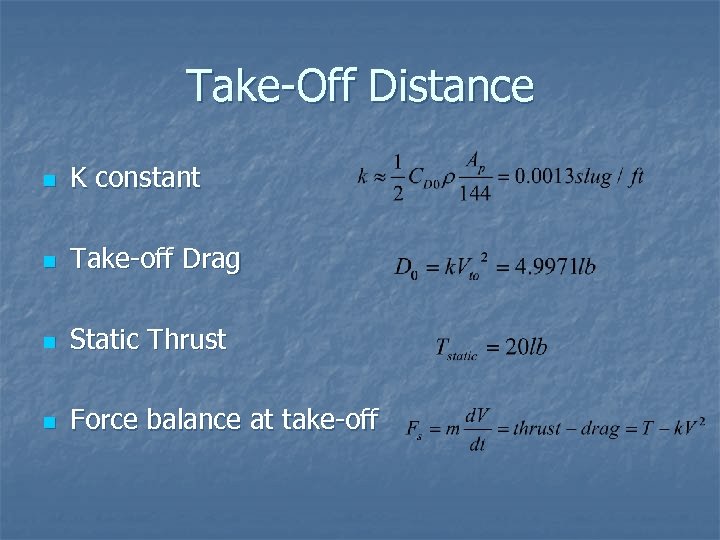

Take-Off Distance n K constant n Take-off Drag n Static Thrust n Force balance at take-off

Take-Off Distance n K constant n Take-off Drag n Static Thrust n Force balance at take-off

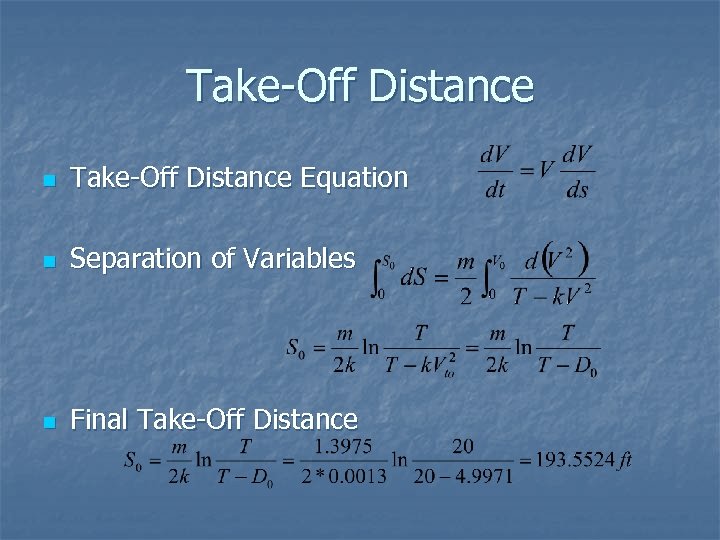

Take-Off Distance n Take-Off Distance Equation n Separation of Variables n Final Take-Off Distance

Take-Off Distance n Take-Off Distance Equation n Separation of Variables n Final Take-Off Distance

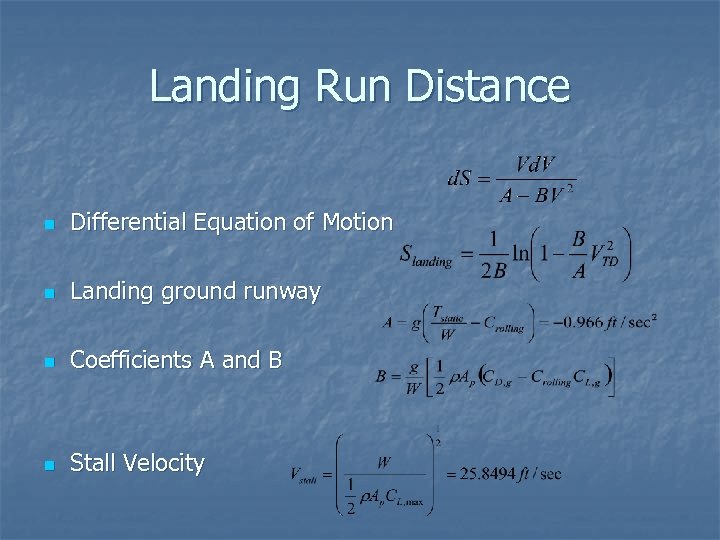

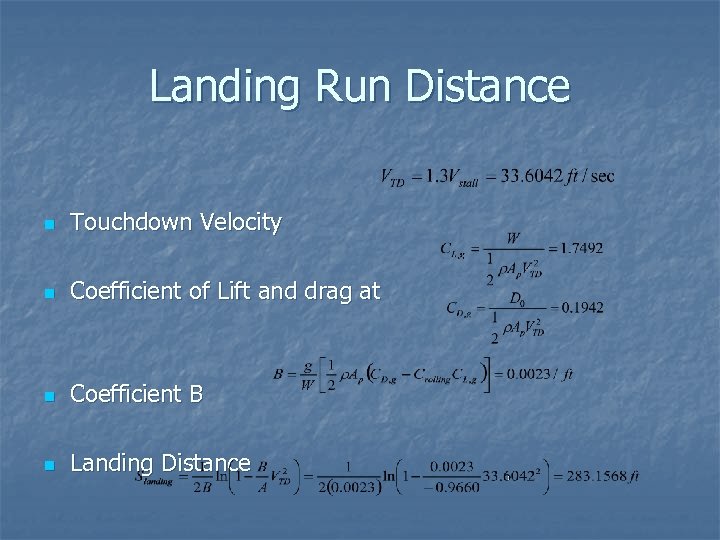

Landing Run Distance n Differential Equation of Motion n Landing ground runway n Coefficients A and B n Stall Velocity

Landing Run Distance n Differential Equation of Motion n Landing ground runway n Coefficients A and B n Stall Velocity

Landing Run Distance n Touchdown Velocity n Coefficient of Lift and drag at n Coefficient B n Landing Distance

Landing Run Distance n Touchdown Velocity n Coefficient of Lift and drag at n Coefficient B n Landing Distance

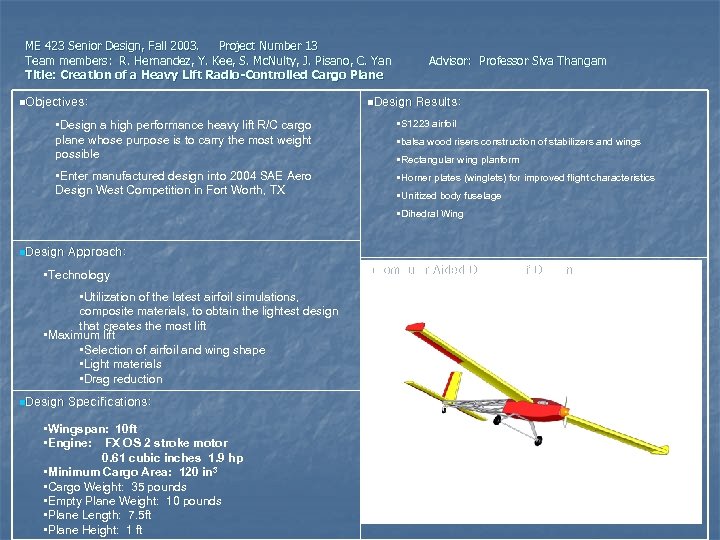

ME 423 Senior Design, Fall 2003. Project Number 13 Team members: R. Hernandez, Y. Kee, S. Mc. Nulty, J. Pisano, C. Yan Advisor: Professor Siva Thangam Title: Creation of a Heavy Lift Radio-Controlled Cargo Plane n. Objectives: n. Design Results: • Design a high performance heavy lift R/C cargo plane whose purpose is to carry the most weight possible • S 1223 airfoil • Enter manufactured design into 2004 SAE Aero Design West Competition in Fort Worth, TX • Horner plates (winglets) for improved flight characteristics • balsa wood risers construction of stabilizers and wings • Rectangular wing planform • Unitized body fuselage • Dihedral Wing n. Design Approach: • Technology • Utilization of the latest airfoil simulations, composite materials, to obtain the lightest design that creates the most lift • Maximum lift • Selection of airfoil and wing shape • Light materials • Drag reduction n. Design Specifications: • Wingspan: 10 ft • Engine: FX OS 2 stroke motor 0. 61 cubic inches 1. 9 hp • Minimum Cargo Area: 120 in 3 • Cargo Weight: 35 pounds • Empty Plane Weight: 10 pounds • Plane Length: 7. 5 ft • Plane Height: 1 ft n. Computer Aided Drawing of Design:

ME 423 Senior Design, Fall 2003. Project Number 13 Team members: R. Hernandez, Y. Kee, S. Mc. Nulty, J. Pisano, C. Yan Advisor: Professor Siva Thangam Title: Creation of a Heavy Lift Radio-Controlled Cargo Plane n. Objectives: n. Design Results: • Design a high performance heavy lift R/C cargo plane whose purpose is to carry the most weight possible • S 1223 airfoil • Enter manufactured design into 2004 SAE Aero Design West Competition in Fort Worth, TX • Horner plates (winglets) for improved flight characteristics • balsa wood risers construction of stabilizers and wings • Rectangular wing planform • Unitized body fuselage • Dihedral Wing n. Design Approach: • Technology • Utilization of the latest airfoil simulations, composite materials, to obtain the lightest design that creates the most lift • Maximum lift • Selection of airfoil and wing shape • Light materials • Drag reduction n. Design Specifications: • Wingspan: 10 ft • Engine: FX OS 2 stroke motor 0. 61 cubic inches 1. 9 hp • Minimum Cargo Area: 120 in 3 • Cargo Weight: 35 pounds • Empty Plane Weight: 10 pounds • Plane Length: 7. 5 ft • Plane Height: 1 ft n. Computer Aided Drawing of Design:

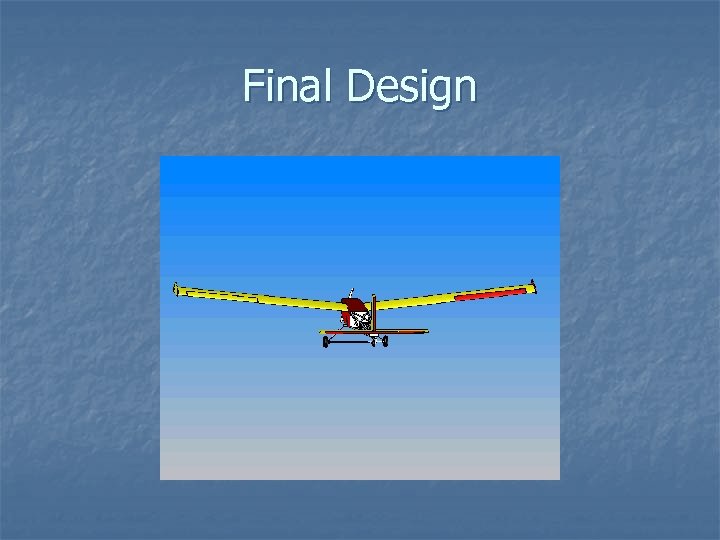

Final Design

Final Design

Final Design

Final Design

Goals n Intercession n n Make a budget Next Semester Complete construction early n Test Landing Gear Configuration n Test Plane design and modify if necessary n n Compete in June

Goals n Intercession n n Make a budget Next Semester Complete construction early n Test Landing Gear Configuration n Test Plane design and modify if necessary n n Compete in June

Summary n n n Objectives Schedule/Progress Design Concepts and Analysis Airfoil n Fuselage n Tail n Landing Gear n n Goals

Summary n n n Objectives Schedule/Progress Design Concepts and Analysis Airfoil n Fuselage n Tail n Landing Gear n n Goals

Thank You

Thank You