c727a9f58715ba46fdc5f4a2112ed07f.ppt

- Количество слайдов: 22

GRINDING and PARTICLE SIZE REDUCTION Keith Behnke Dept. of Grain Science and Industry Kansas State University Manhattan, Ks

WHY DO WE GRIND? ØIMPROVED ANIMAL PERFORMANCE ØINCREASED MIX UNIFORMITY ØIMPROVED PELLETING

MEASURING PARTICLE SIZE

PARTICLE SIZE TEST (ASAE STANDARD - S 319) Ø This method involves using a sieve stack to determine the geometric mean particle size (dgw) and the geometric standard deviation (sgw). Ø Results can be obtained either graphically or through calculations.

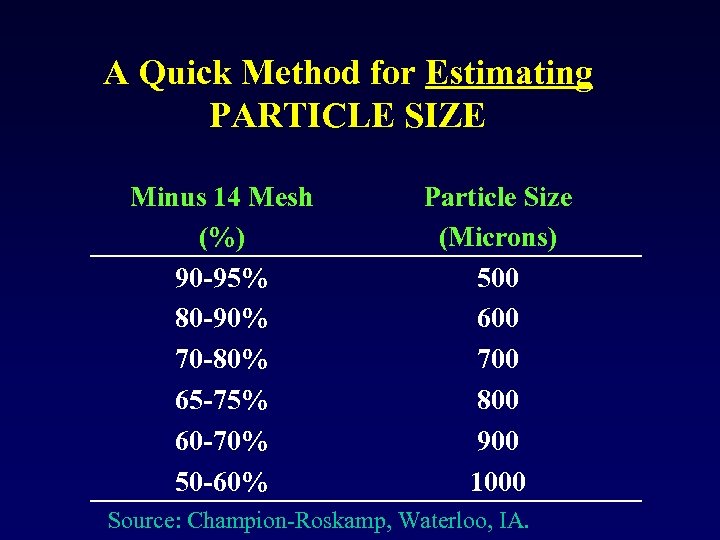

ESTIMATING PARTICLE SIZE

A Quick Method for Estimating PARTICLE SIZE Minus 14 Mesh (%) 90 -95% 80 -90% 70 -80% 65 -75% 60 -70% 50 -60% Particle Size (Microns) 500 600 700 800 900 1000 Source: Champion-Roskamp, Waterloo, IA.

METHODS OF GRINDING Ø Impact Ø Compression Ø Shear Ø Attrition

HAMMERMILLS

ADVANTAGES Ø Ability to grind a wide variety of materials Ø Ease of maintenance, less maintenance cost Ø Versatility Ø Less complicated to operate Ø Less initial cost

DISADVANTAGES Ø Energy consumption Ø Produces a greater Sgw Ø Noise and dust pollution Ø Heat generation and moisture loss

ROLLER MILLS

ADVANTAGES- Rollermills Ø Electrical efficiency Ø Particle size uniformity Ø Less maintenance Ø Less dust pollution

DISADVANTAGES Rollermills Ø Higher initial cost Ø When maintenance is needed it is expensive Ø Can not effectively grind fibrous materials Ø Reduced throughput at small particle sizes

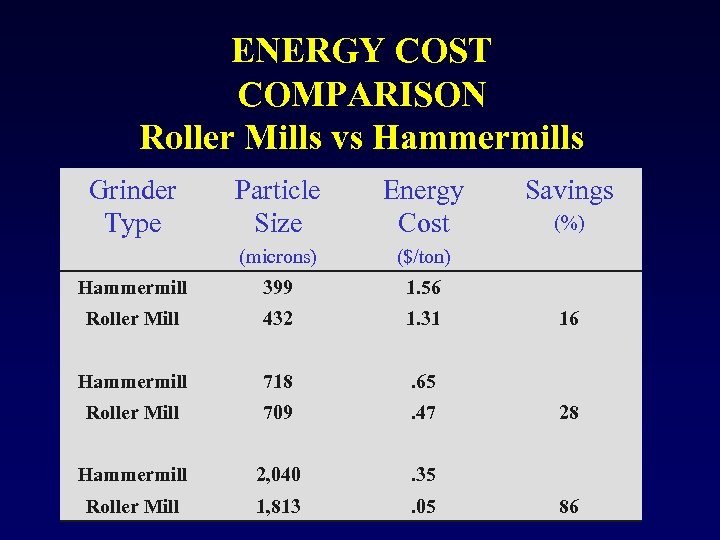

ENERGY COST COMPARISON Roller Mills vs Hammermills Grinder Type Particle Size Energy Cost (microns) ($/ton) Hammermill 399 1. 56 Roller Mill 432 1. 31 Hammermill 718 . 65 Roller Mill 709 . 47 Hammermill 2, 040 . 35 Roller Mill 1, 813 . 05 Savings (%) 16 28 86

PRE-GRINDING Vs. POST-GRINDING SYSTEMS

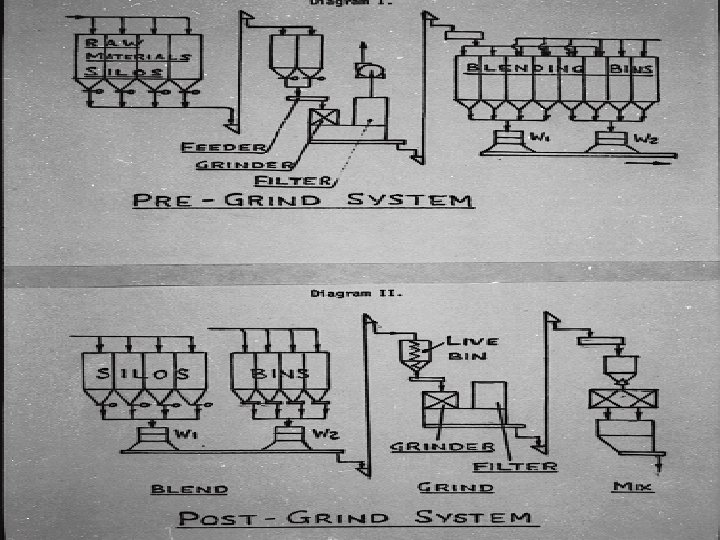

PRE-GRINDING SYSTEM Ø Advantages ØLonger grinding time a t full motor load ØGives a buffer for down time or maintenance on the grinder Ø Disadvantage ØRequires more storage bins for both ground and raw ingredients

POST GRIND SYSTEM Ø Advantages ØAccommodates material changes ØDoes not require as many storage bins Ø Disadvantages ØLess energy efficient ØDirectly affects the capacity of the facility

INNOVATIONS IN GRINDING

THE FUTURE! GRINDING OPERATIONS * Hammer Design and Metallurgy * Air Assist System Design * Noise Control * Automation and Routing * Quick-Change Screens * Quick-Change Hammer Gangs

THE FUTURE! GRINDING OPERATIONS * Vertical Shaft Hammermills? ? -European Designs now available -Air-Assist not recommended

THE FUTURE! GRINDING OPERATIONS * AUTOMATION? ? ? -The One System That Clearly Should Be Automated!! -Start-up/Shut-Down, Routing and Ingredient Changes -Lights Out Operations? ?

c727a9f58715ba46fdc5f4a2112ed07f.ppt