ba67ebd41742687f965722d6c5869cd2.ppt

- Количество слайдов: 28

Greening the greenhouse: general considerations Gerard Bot Wageningen UR Greenhouse Horticulture Greeningthe Greenhouse; April 2, 2008

Introduction Trends in European Horticulture Increase of scale partner in the market chain Improved control crop growth factors production : quality + quantity Year round crop production: labour + market Licence to deliver Sustainability: CPC, water, materials, energy bottleneck: energy consumption Licence to produce Greeningthe Greenhouse; April 2, 2008

Energy consumption in European greenhouses 1900 MJm-2 (45 l oil m-2) 1500 MJm-2 Amsterdam (35 l oil m-2) 500 MJm-2 (12 l oil m-2) Greeningthe Greenhouse; April 2, 2008

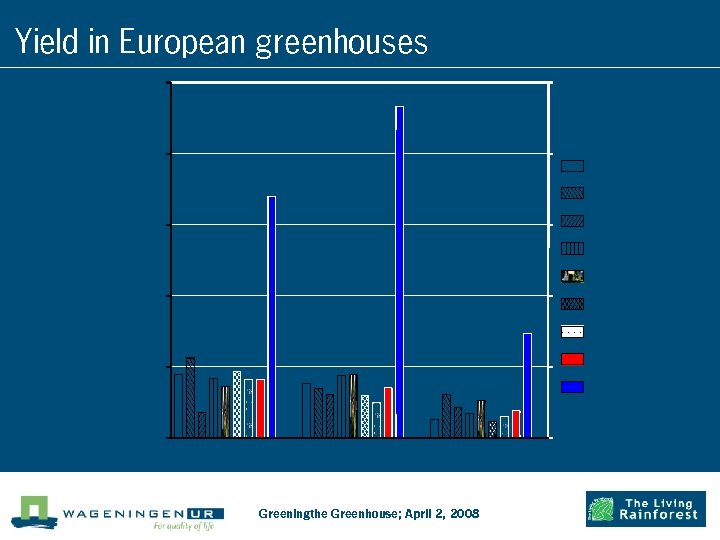

Yield in European greenhouses 750 yield (ton/ha) 600 Cyprus Spain Egypt 450 Greece Israel 300 Italy Palestina Average. Mediteranean 150 Netherlands 0 Tomato Cucumber Sweet pepper Greeningthe Greenhouse; April 2, 2008

Introduction objectives for Northern and Southern regions Year round: - maximize solar radiation (crop production!) - minimize energy consumption Hot periods: - energy efficient cooling to reduce high temperatures Of course grower needs: - profitable crop production Greeningthe Greenhouse; April 2, 2008

Greening the greenhouse: energy saving From a systems point of view: n properties: low heat loss: greenhouse cover insulation combined with high light transmission: crop production + solar energy in n control: climate settings and control strategy: temperature + humidity + CO 2 winter: heating and ventilation; summer: efficient cooling n conversion of primary energy to heat: the “engine” of the greenhouse: boiler, cogeneration, heat pump, fuel cell, …

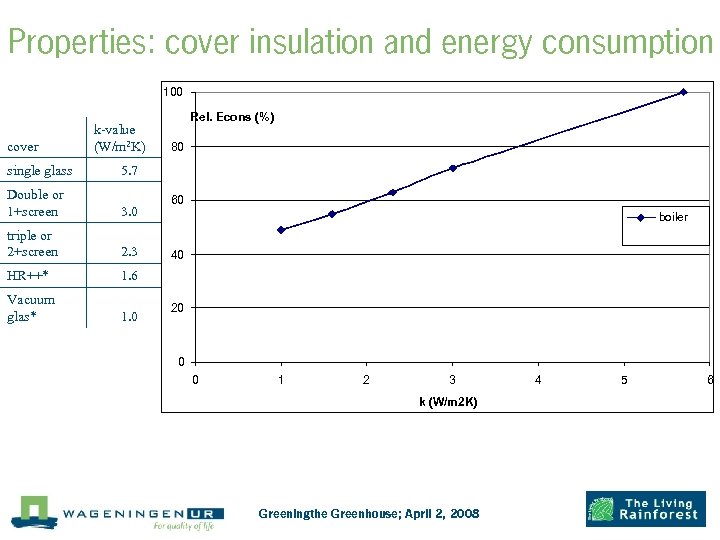

Properties: cover insulation and energy consumption 100 cover k-value (W/m 2 K) single glass 3. 0 triple or 2+screen 2. 3 HR++* 1. 6 Vacuum glas* 1. 0 80 5. 7 Double or 1+screen Rel. Econs (%) 60 boiler 40 20 0 0 1 2 3 k (W/m 2 K) Greeningthe Greenhouse; April 2, 2008 4 5 6

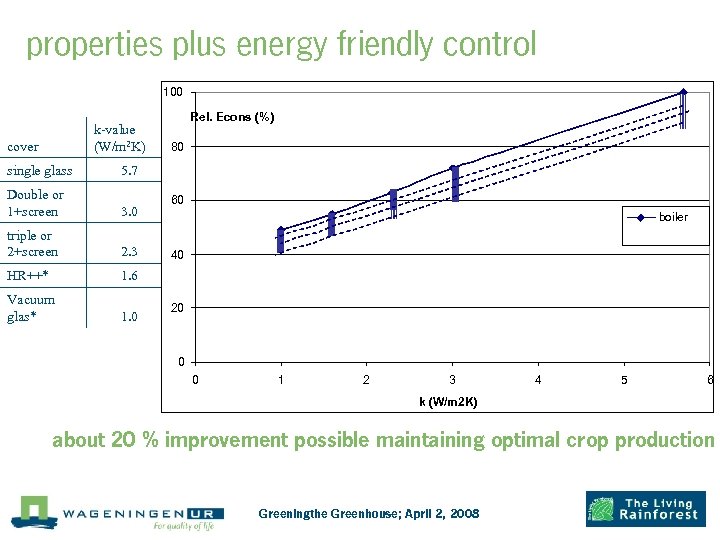

properties plus energy friendly control 100 k-value (W/m 2 K) cover single glass 3. 0 triple or 2+screen 2. 3 HR++* 1. 6 Vacuum glas* 1. 0 80 5. 7 Double or 1+screen Rel. Econs (%) 60 boiler 40 20 0 0 1 2 3 4 5 6 k (W/m 2 K) about 20 % improvement possible maintaining optimal crop production Greeningthe Greenhouse; April 2, 2008

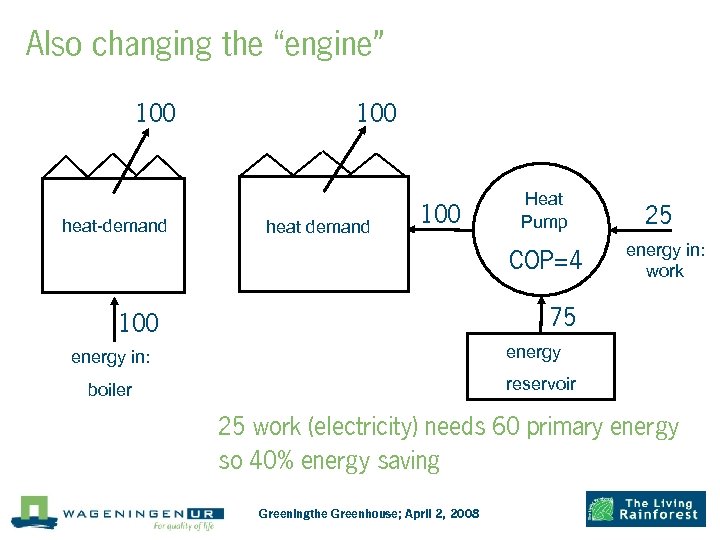

Also changing the “engine” 100 heat-demand 100 heat demand 100 Heat Pump COP=4 25 energy in: work 75 100 energy in: reservoir boiler 25 work (electricity) needs 60 primary energy so 40% energy saving Greeningthe Greenhouse; April 2, 2008

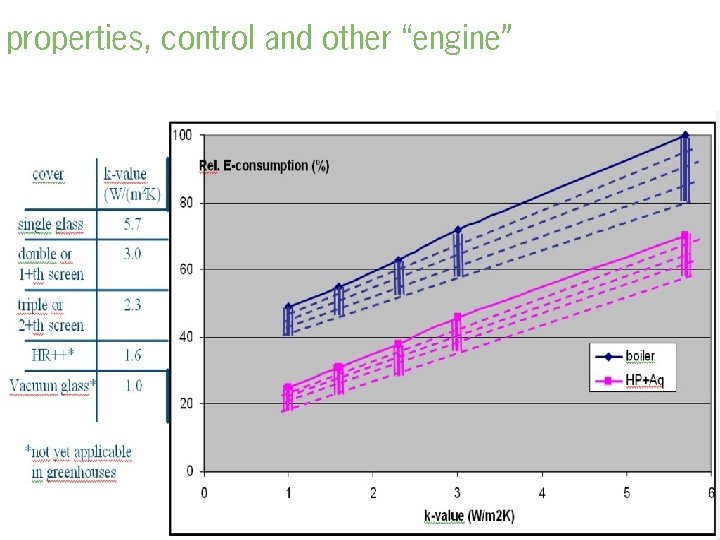

properties, control and other “engine”

Properties: Reduction of energy losses: insulation n Decreasing k-value (W/m 2 K): l Thermal screens l Double or triple cover (glass, plastic film) l Gas filled space between glass layers l Vacuum space between glass layers n Reduction of thermal radiation loss: l Low TIR emission coatings Bottleneck: Light transmission Greeningthe Greenhouse; April 2, 2008

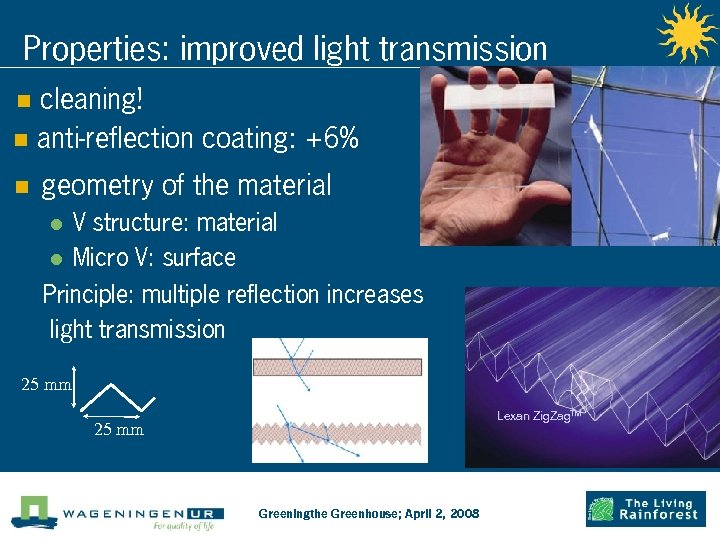

Properties: improved light transmission cleaning! n anti-reflection coating: +6% n n geometry of the material l l V structure: material Micro V: surface Principle: multiple reflection increases light transmission 25 mm Lexan Zig. Zag. TM 25 mm Greeningthe Greenhouse; April 2, 2008

Energy friendly control n aim: optimal crop production n grower holds the control-wheel n estimated risks with humidity control n crop dependent n crop oriented research Greeningthe Greenhouse; April 2, 2008

Engine: heat pump and energy reservoir n contains sufficient amount of energy in winter n to be filled in summer: exploiting excess solar energy n Large capacity, 10 l oil eq per m 2: 10 m 3 water/m 2 with ΔT = 10 K or 2000 kg PCM /m 2 n Physically only possible in the soil: Aquifer or VSHE Greeningthe Greenhouse; April 2, 2008

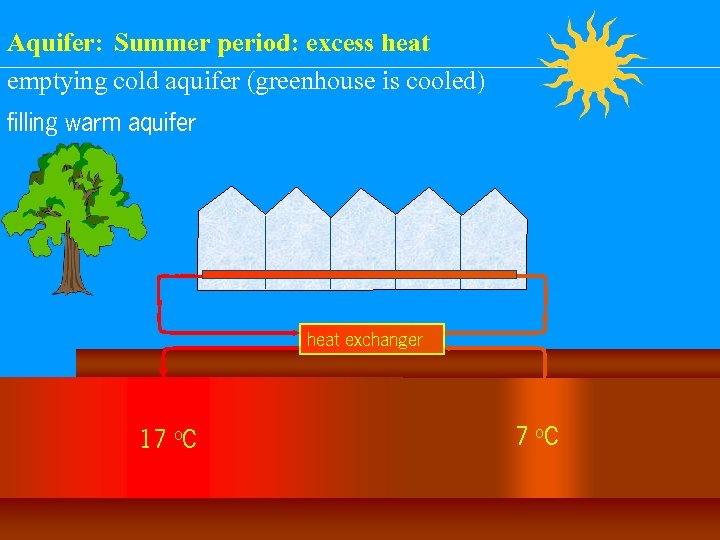

Aquifer: Summer period: excess heat emptying cold aquifer (greenhouse is cooled) filling warm aquifer heat exchanger 17 o. C

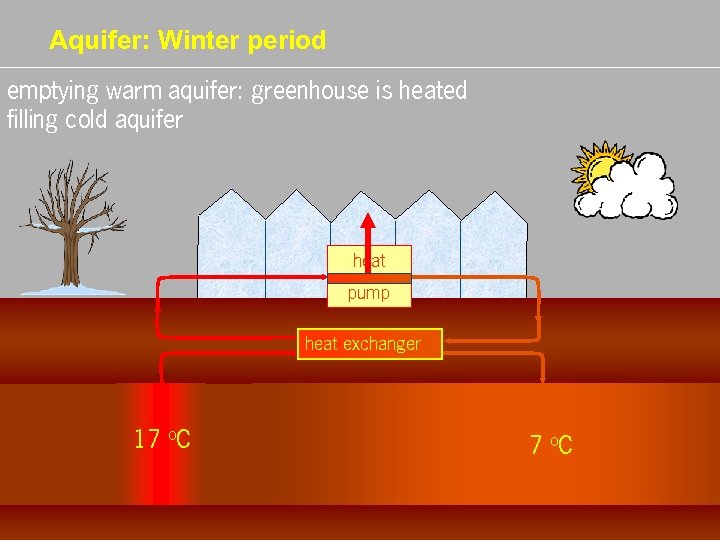

Aquifer: Winter period emptying warm aquifer: greenhouse is heated filling cold aquifer heat pump heat exchanger 17 o. C

Seasonal storage n Aquifer: 2 wells at different temperature specific geological conditions not available at TLR n Vertical Soil Heat Exchanger: passive storage via boreholes Greeningthe Greenhouse; April 2, 2008

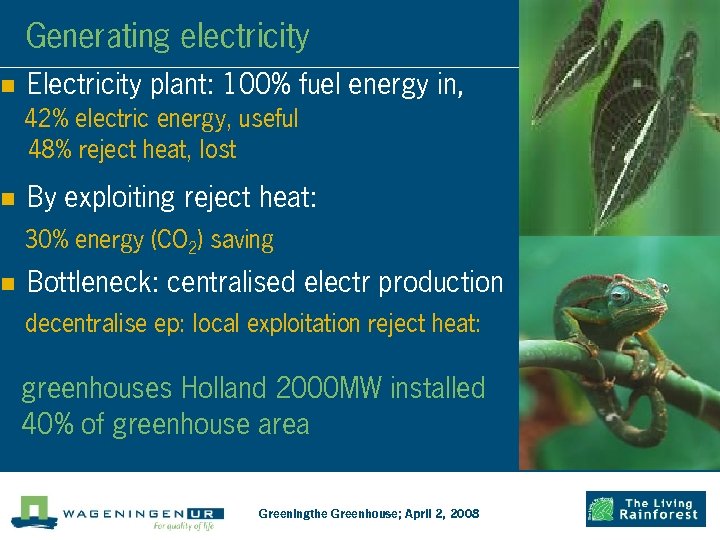

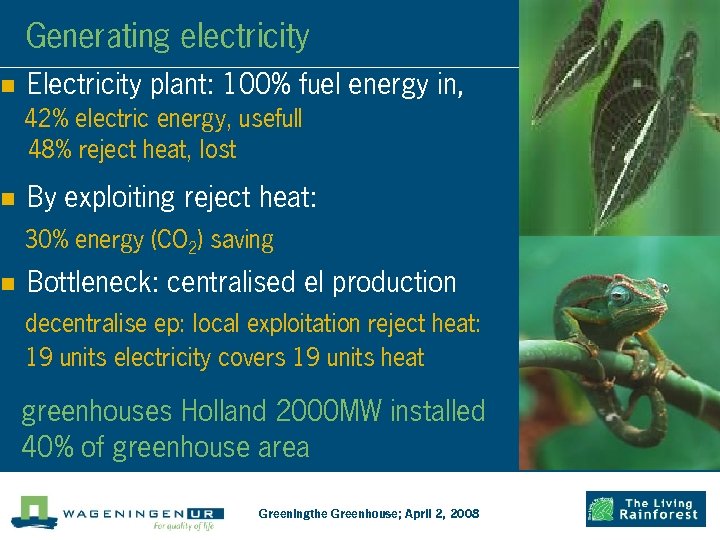

n n n Generating electricity Electricity plant: 100% fuel energy in, 42% electric energy, useful 48% reject heat, lost By exploiting reject heat: 30% energy (CO 2) saving Bottleneck: centralised electr production decentralise ep: local exploitation reject heat: greenhouses Holland 2000 MW installed 40% of greenhouse area Greeningthe Greenhouse; April 2, 2008

Conclusions n Greenhouse horticulture is vigorous in N-W Europe n Energy is bottleneck in sustainability n Energy saving via greenhouse properties, climate control and energy conversion Greeningthe Greenhouse; April 2, 2008

Conclusions n Greenhouse properties: - insulation - light transmission n Climate control: interaction T and RH control growers tool to control production crop dependent: quantity and quality growers try to avoid risks (disease control) n Energy conversion: - boiler with condensor - heat pump/seasonal storage - cogeneration Greeningthe Greenhouse; April 2, 2008

Thank you for your attention Greeningthe Greenhouse; April 2, 2008

n n n Introduction Sustainable greenhouses Seasonal energy storage To be realised conclusions Greeningthe Greenhouse; April 2, 2008

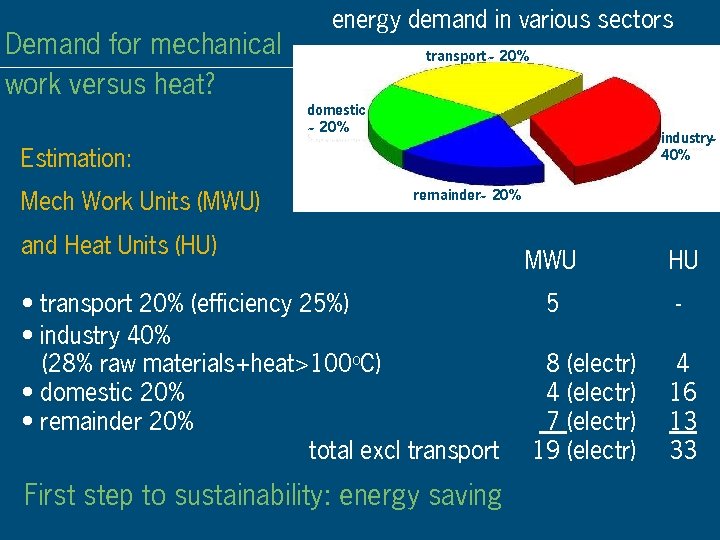

Energy demand? n n demand for energy carriers like oil, gas, coal, etc? ? in principle demand for - mechanical work, both at fixed locations and mobile - heat for processing and climate conditioning - lighting (included in mech work) - communication/info-tainment (same) Greeningthe Greenhouse; April 2, 2008

Demand for mechanical work versus heat? energy demand in various sectors transport ~ 20% domestic ~ 20% industry ~ 40% Estimation: Mech Work Units (MWU) remainder~ 20% and Heat Units (HU) • transport 20% (efficiency 25%) • industry 40% (28% raw materials+heat>100 o. C) • domestic 20% • remainder 20% total excl transport First step to sustainability: Greenhouse; Aprilsaving energy 2, 2008 Greeningthe MWU HU 5 - 8 (electr) 4 (electr) 7 (electr) 19 (electr) 4 16 13 33

n n n Generating electricity Electricity plant: 100% fuel energy in, 42% electric energy, usefull 48% reject heat, lost By exploiting reject heat: 30% energy (CO 2) saving Bottleneck: centralised el production decentralise ep: local exploitation reject heat: 19 units electricity covers 19 units heat greenhouses Holland 2000 MW installed 40% of greenhouse area Greeningthe Greenhouse; April 2, 2008

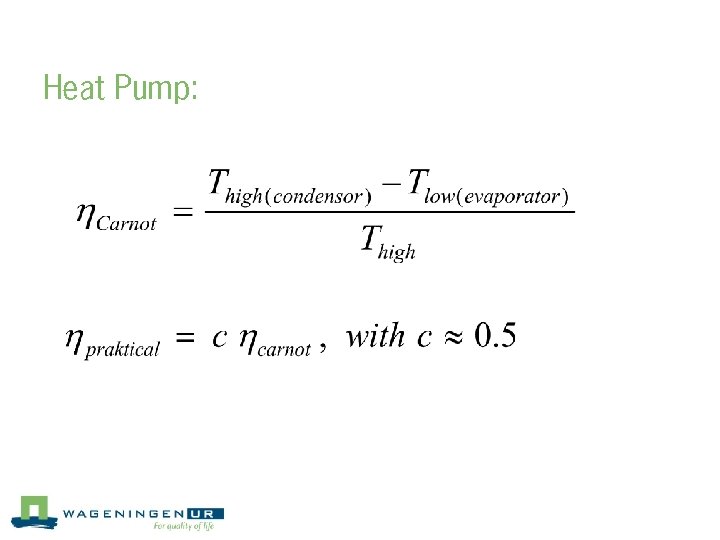

Heat Pump:

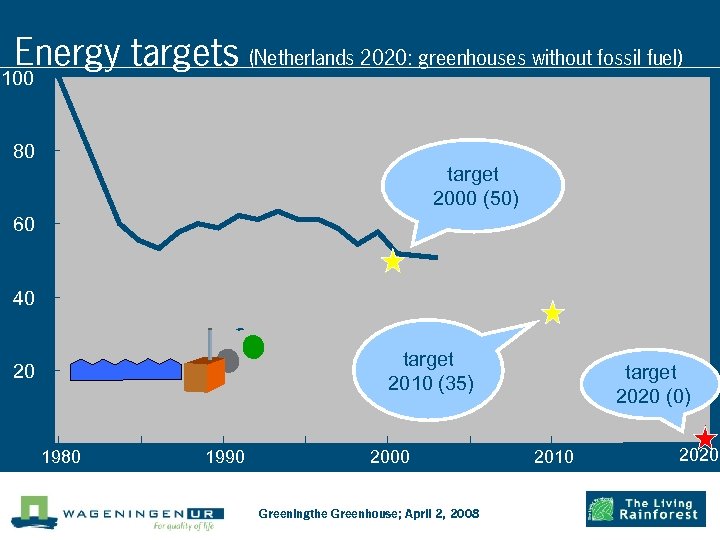

Energy targets (Netherlands 2020: greenhouses without fossil fuel) 100 80 target 2000 (50) 60 40 target 2010 (35) 20 1980 1990 2000 Greeningthe Greenhouse; April 2, 2008 target 2020 (0) 2010 2020

Greeningthe Greenhouse; April 2, 2008

ba67ebd41742687f965722d6c5869cd2.ppt