c5c6fe2f6d5ad492f50d899c9d19911b.ppt

- Количество слайдов: 17

GREEN GOWN AWARD 2008 DALHOUSIE BUILDING DEREK MITCHELL ENERGY MANAGER JUNE 2009

The Project • Take a previously untapped source of heat from our CHP Plant and use it to provide most of the heat required for our new Dalhousie building. • 3 heat exchangers were fitted in the lubricating oil circuit of the 3 Jenbacher CHP engines providing low grade heat at 47/37 deg C flow and return temperatures. • Run over 150 metres of 125 mm ID flow and return Pipe 2000 plastic pipework between the Boilerhouse and Dalhousie Building. • Plant within the Dalhousie building was oversized to accommodate the lower design temperatures.

Other Environmental Features • Air conditioning in only one Lecture theatre controlled by CO 2 detector • Natural ventilation in all other rooms • Solar shading • Enhanced U Values • Lighting control systems • Inverter drives on air handling plant • Power factor correction

Secrets of our Success • Innovation • Determination • Teamwork • Post-Evaluation

Innovation 1976 – District heating scheme 1997 – 3 MW combined heat & power plant 1998 - Free Cooling Air Blast Radiator System 2000 – Building Energy Management System 2001 – Micro CHP 2007 – Absorption Chiller (Tri-Generation)

Determination to overcome barriers • Additional space requirements for oversized plant. • Additional financial costs of approx £ 100, 000. ( Life cycle costing exercise ) • The “Risk Factor” - It may not work.

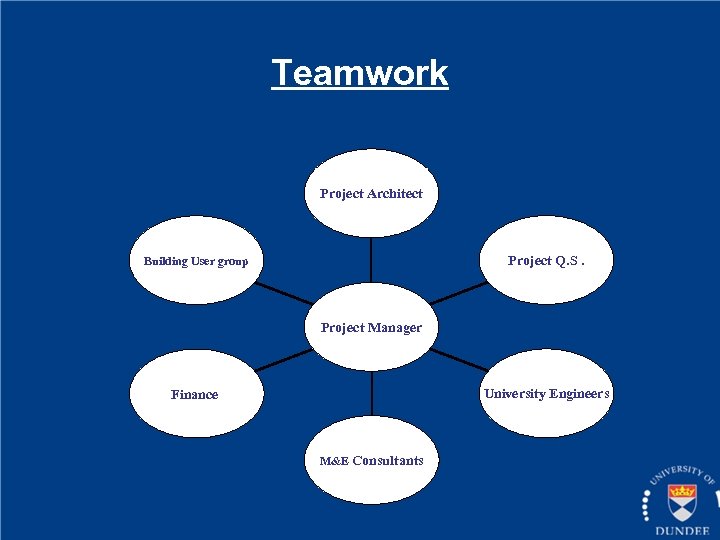

Teamwork Project Architect Project Q. S. Building User group Project Manager University Engineers Finance M&E Consultants

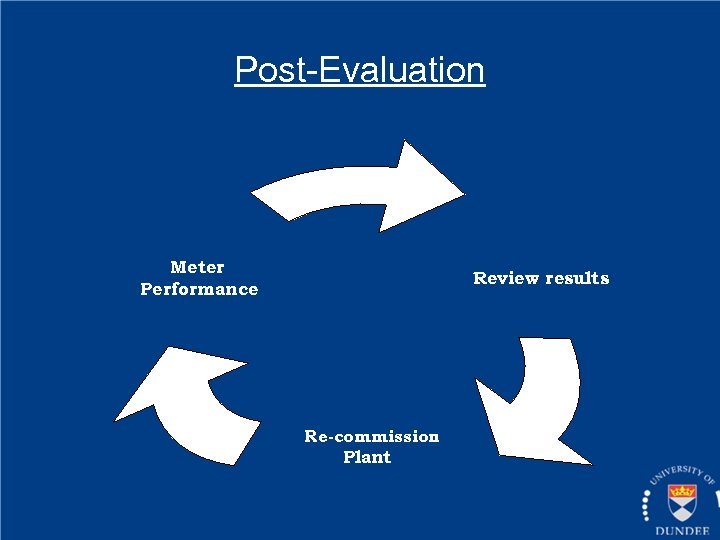

Post-Evaluation Meter Performance Review results Re-commission Plant

Headline Benefits • 60 % of teaching block heated from VLTHW Circuit. • Financial savings of £ 15, 000 p/a • Annual CO 2 savings of over 100 tonnes p/a from VLTHW Circuit alone.

Additional Future Benefits • Carbon Standard • Climate Change Declaration • Carbon Management Programme • Carbon Reduction Commitment

Not only CHP • Wind Turbine • Ground Source Heat Pump • Solar Panel Installation • Heat Recovery • Voltage Optimisation

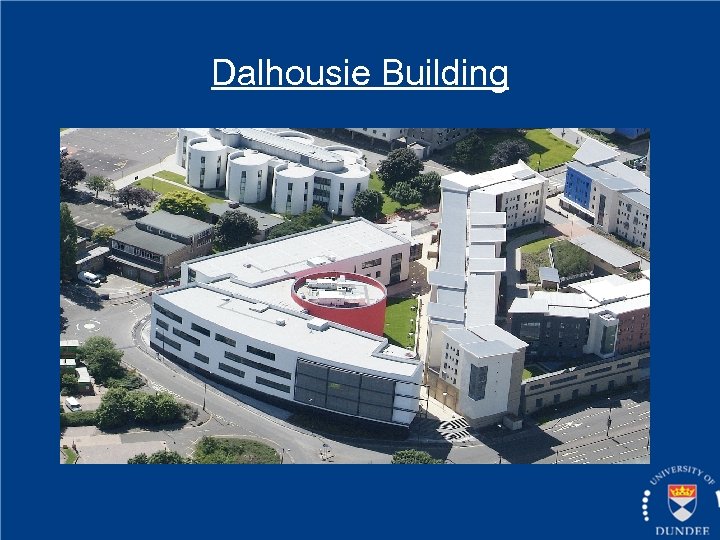

Dalhousie Building

Dalhousie Building Entrance

Entrance Foyer

Lecture Theatre – Mechanical Ventilation

Plantroom VLTHW Heat Exchanger

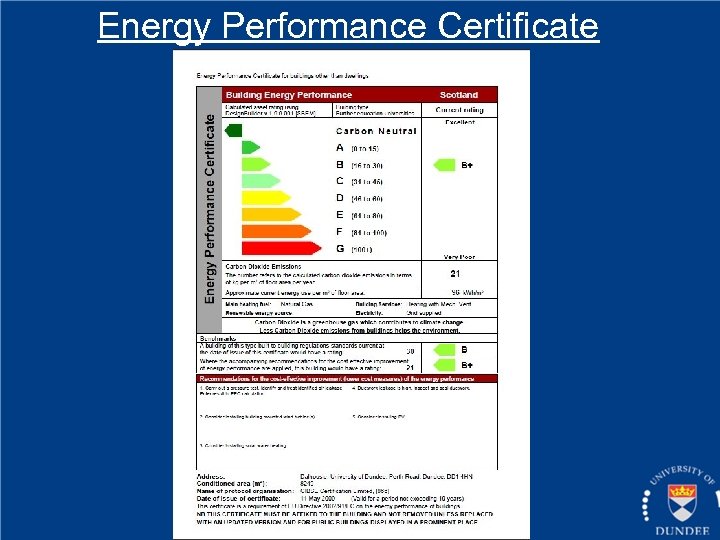

Energy Performance Certificate

c5c6fe2f6d5ad492f50d899c9d19911b.ppt