8a5aa5f1029810cc1ca7f13a11e2cd41.ppt

- Количество слайдов: 16

Green Datacenters solution March 17, 2009 By: Sanjay Sharma

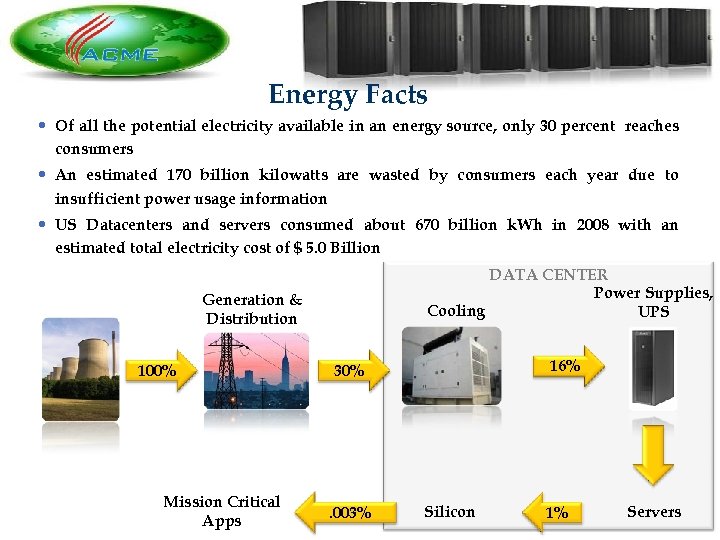

Energy Facts • Of all the potential electricity available in an energy source, only 30 percent reaches consumers • An estimated 170 billion kilowatts are wasted by consumers each year due to insufficient power usage information • US Datacenters and servers consumed about 670 billion k. Wh in 2008 with an estimated total electricity cost of $ 5. 0 Billion DATA CENTER Power Supplies, Cooling UPS Generation & Distribution 100% 22 Mission Critical Apps 16% 30% . 003% Silicon 1% Servers

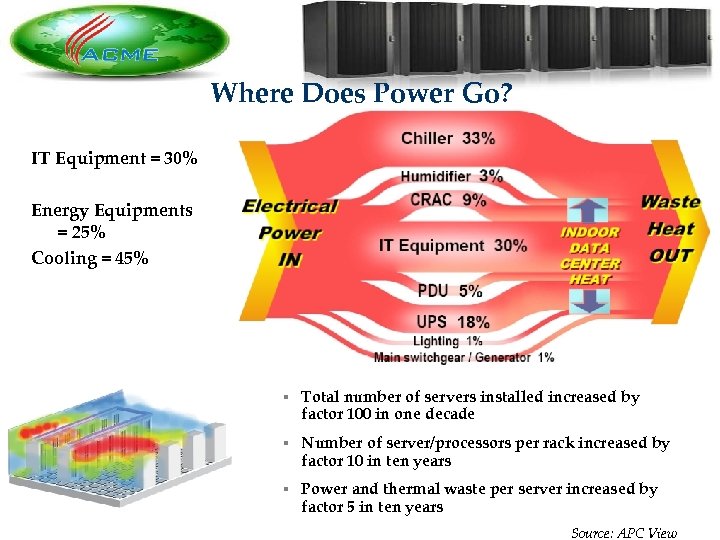

Where Does Power Go? IT Equipment = 30% Energy Equipments = 25% Cooling = 45% § § 33 Total number of servers installed increased by factor 100 in one decade Number of server/processors per rack increased by factor 10 in ten years § Power and thermal waste per server increased by factor 5 in ten years Source: APC View

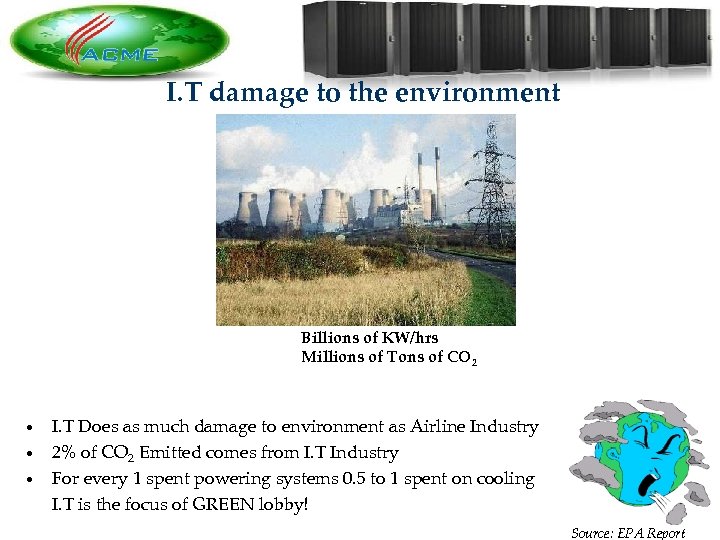

I. T damage to the environment Billions of KW/hrs Millions of Tons of CO 2 I. T Does as much damage to environment as Airline Industry • 2% of CO 2 Emitted comes from I. T Industry • For every 1 spent powering systems 0. 5 to 1 spent on cooling 4 4 I. T is the focus of GREEN lobby! • Source: EPA Report

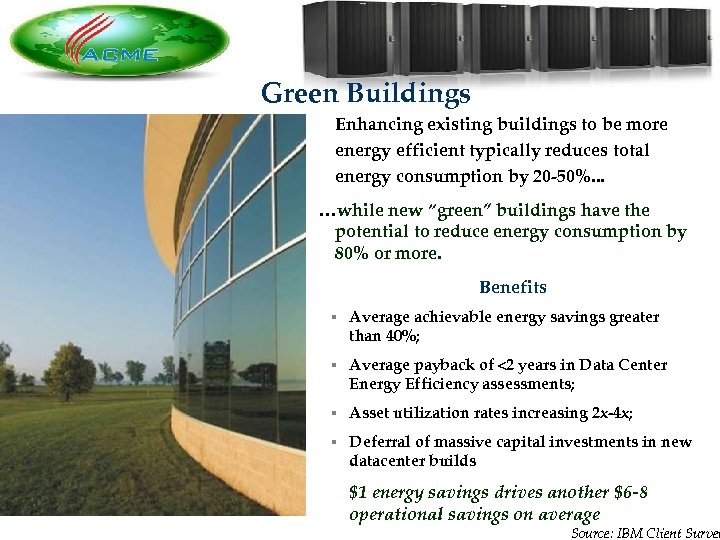

Green Buildings Enhancing existing buildings to be more energy efficient typically reduces total energy consumption by 20 -50%. . . …while new “green” buildings have the potential to reduce energy consumption by 80% or more. Benefits § Average achievable energy savings greater IBM Example than 40%; § § Asset utilization rates increasing 2 x-4 x; § 55 Average payback of <2 years in Data Center Energy Efficiency assessments; Deferral of massive capital investments in new datacenter builds $1 energy savings drives another $6 -8 operational savings on average Source: IBM Client Survey

Case Study Energy Management Solutions for Bharti’s Telecom Towers 66

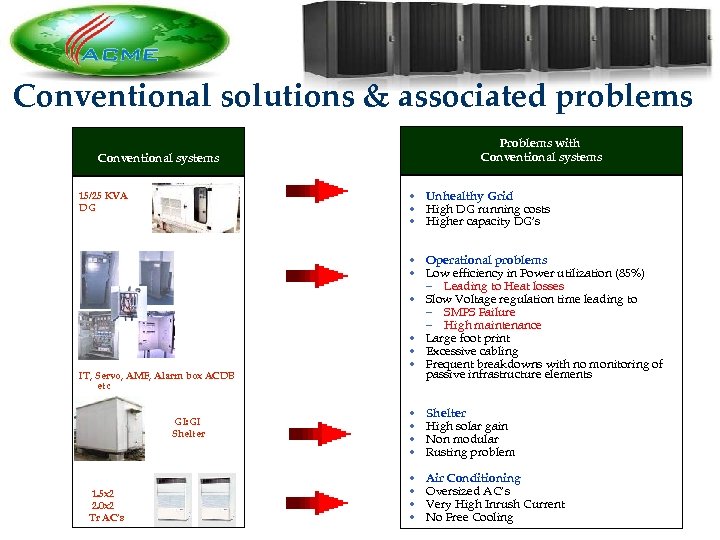

Conventional solutions & associated problems Problems with Conventional systems • Unhealthy Grid • High DG running costs • Higher capacity DG’s 15/25 KVA DG IT, Servo, AMF, Alarm box ACDB etc GI: GI Shelter 77 1. 5 x 2 2. 0 x 2 Tr AC’s • Operational problems • Low efficiency in Power utilization (85%) – Leading to Heat losses • Slow Voltage regulation time leading to – SMPS Failure – High maintenance • Large foot print • Excessive cabling • Frequent breakdowns with no monitoring of passive infrastructure elements • • Shelter High solar gain Non modular Rusting problem • • Air Conditioning Oversized AC’s Very High Inrush Current No Free Cooling

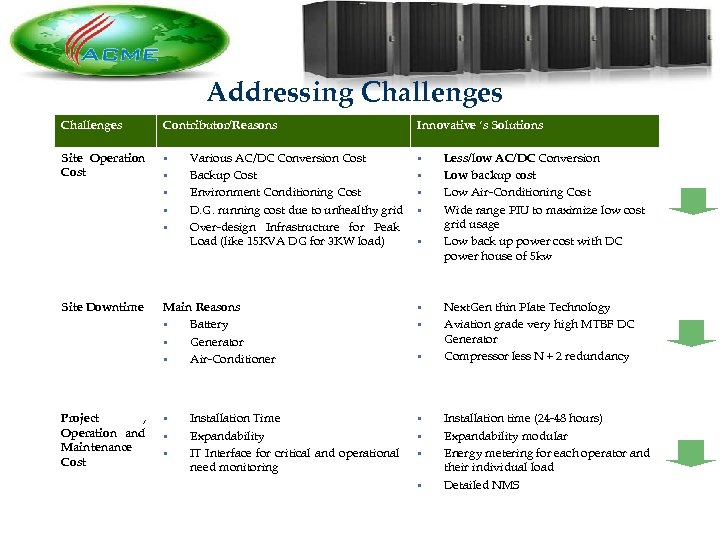

Addressing Challenges Contributor/Reasons Site Operation Cost • • • Site Downtime Project , Operation and Maintenance Cost Various AC/DC Conversion Cost Backup Cost Environment Conditioning Cost D. G. running cost due to unhealthy grid Over-design Infrastructure for Peak Load (like 15 KVA DG for 3 KW load) Main Reasons • Battery • Generator • Air-Conditioner • • • Installation Time Expandability IT Interface for critical and operational need monitoring Innovative ‘s Solutions • • • 88 Less/low AC/DC Conversion Low backup cost Low Air-Conditioning Cost Wide range PIU to maximize low cost grid usage Low back up power cost with DC power house of 5 kw Next. Gen thin Plate Technology Aviation grade very high MTBF DC Generator Compressor less N + 2 redundancy Installation time (24 -48 hours) Expandability modular Energy metering for each operator and their individual load Detailed NMS

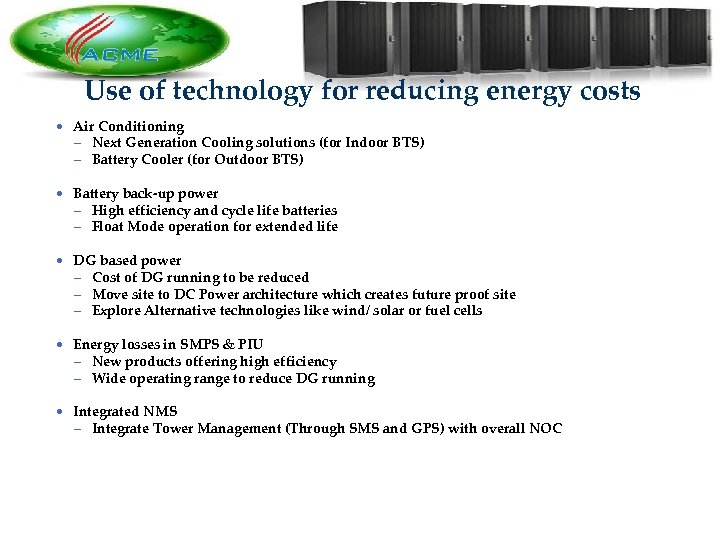

Use of technology for reducing energy costs • Air Conditioning – Next Generation Cooling solutions (for Indoor BTS) – Battery Cooler (for Outdoor BTS) • Battery back-up power – High efficiency and cycle life batteries – Float Mode operation for extended life • DG based power – Cost of DG running to be reduced – Move site to DC Power architecture which creates future proof site – Explore Alternative technologies like wind/ solar or fuel cells • Energy losses in SMPS & PIU – New products offering high efficiency – Wide operating range to reduce DG running • Integrated NMS – Integrate Tower Management (Through SMS and GPS) with overall NOC 99

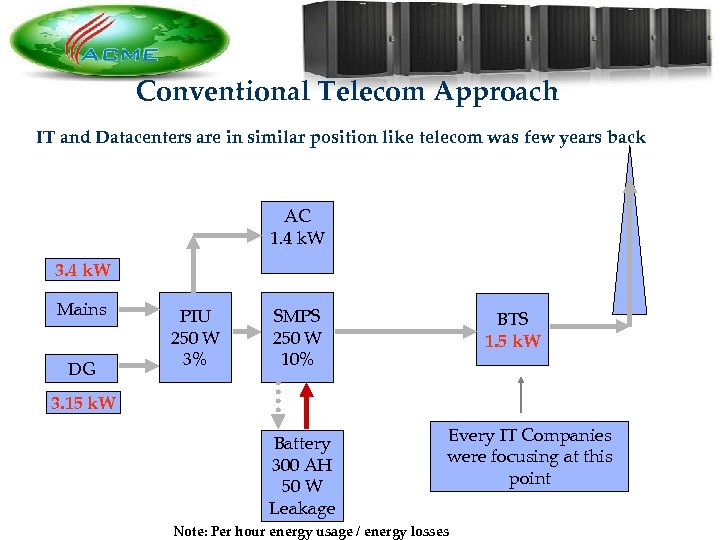

Conventional Telecom Approach IT and Datacenters are in similar position like telecom was few years back AC 1. 4 k. W 3. 4 k. W Mains DG PIU 250 W 3% SMPS 250 W 10% BTS 1. 5 k. W 3. 15 k. W 100 1 Battery 300 AH 50 W Leakage Every IT Companies were focusing at this point Note: Per hour energy usage / energy losses

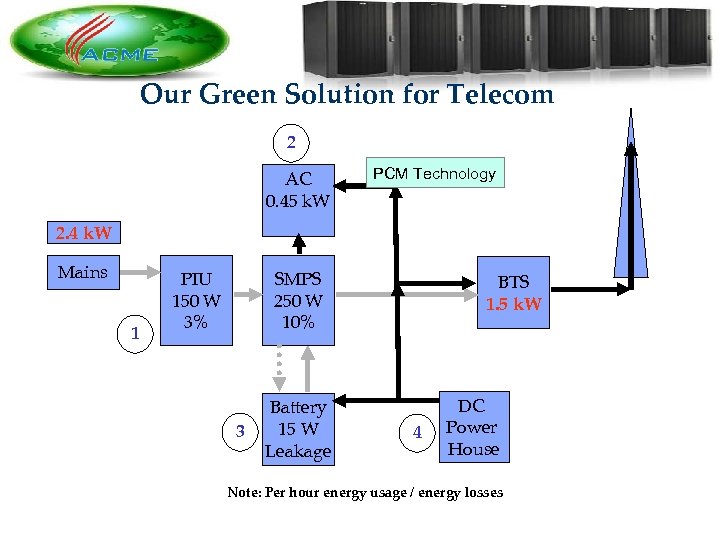

Our Green Solution for Telecom 2 AC 0. 45 k. W PCM Technology 2. 4 k. W Mains 1 PIU 150 W 3% SMPS 250 W 10% 3 111 1 Battery 15 W Leakage BTS 1. 5 k. W 4 DC Power House Note: Per hour energy usage / energy losses

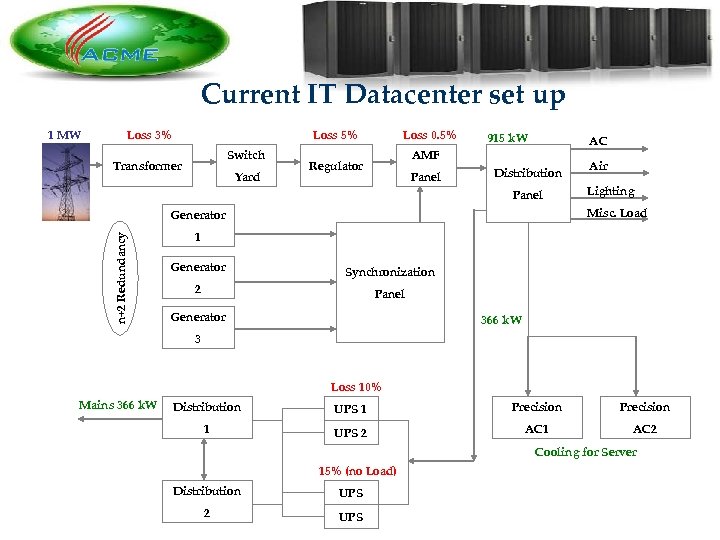

Current IT Datacenter set up 1 MW Loss 5% Loss 3% Switch Transformer Yard Loss 0. 5% 915 k. W AC AMF Regulator Panel Distribution Panel Lighting Misc. Load Generator n+2 Redundancy Air 1 Generator Synchronization 2 Panel Generator 366 k. W 3 Loss 10% Mains 366 k. W Distribution UPS 1 Precision 1 UPS 2 AC 1 AC 2 Cooling for Server 15% (no Load) 122 1 Distribution UPS 2 UPS

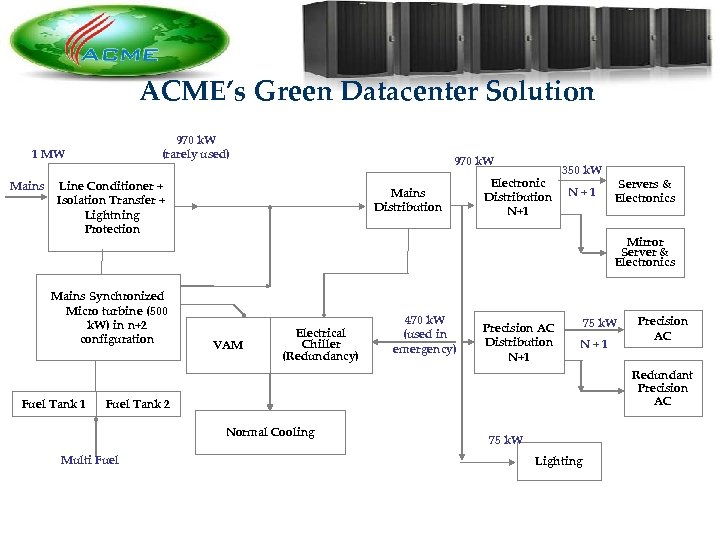

ACME’s Green Datacenter Solution 970 k. W (rarely used) 1 MW Mains 970 k. W Line Conditioner + Isolation Transfer + Lightning Protection Mains Synchronized Micro turbine (500 k. W) in n+2 configuration Fuel Tank 1 Mains Distribution 350 k. W N+1 Hot air VAM Electrical Chiller (Redundancy) 470 k. W (used in emergency) Precision AC Distribution N+1 75 k. W N+1 Precision AC Redundant Precision AC Fuel Tank 2 Multi Fuel Servers & Electronics Mirror Server & Electronics Normal Cooling 133 1 Electronic Distribution N+1 75 k. W Lighting

Macro level Savings • On site power generation 24 x 7 • No separate expenditure on Air Conditioners • Elimination of various AC-DC conversion losses • Energy generation at low cost in cogeneration mode • Carbon credit benefit • No operation and maintenance expenditure of DG 144 1

Making green solution profitable • ACME can built clean energy infrastructure for new IT Datacenter set up and reduce – 20% Capex (approx. ) – 15% Opex – 30% Carbon Emission • ACME can take up existing infrastructure and reduce – 10% Opex – 20% Carbon emission 155 1

Thank You !! Partnership Contact: Email: snajy. sharma@acme. in Mobile: +919810159777 166 1

8a5aa5f1029810cc1ca7f13a11e2cd41.ppt