Grain. Pro® Cocoon™ Flood Protected Self-Verifying Cocoon™ Doc. Code: TSD-PP 005 -1

Grain. Pro® Cocoon™ Flood Protected Self-Verifying Cocoon™ Doc. Code: TSD-PP 005 -1

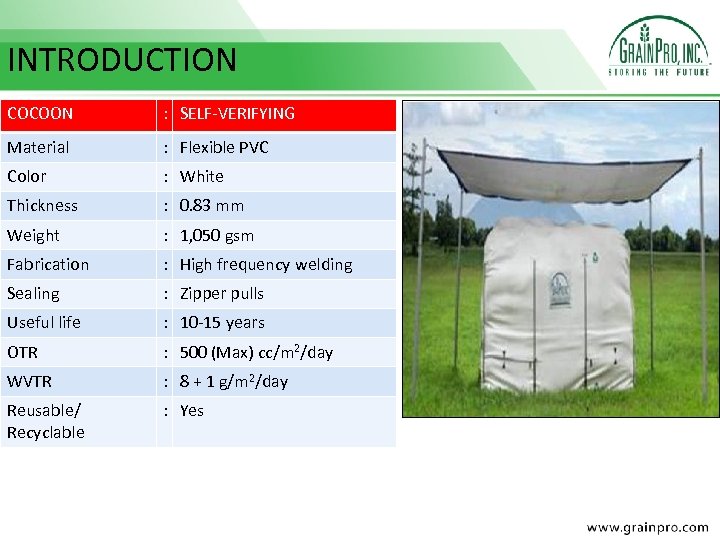

INTRODUCTION COCOON : SELF-VERIFYING Material : Flexible PVC Color : White Thickness : 0. 83 mm Weight : 1, 050 gsm Fabrication : High frequency welding Sealing : Zipper pulls Useful life : 10 -15 years OTR : 500 (Max) cc/m 2/day WVTR : 8 + 1 g/m 2/day Reusable/ Recyclable : Yes

INTRODUCTION COCOON : SELF-VERIFYING Material : Flexible PVC Color : White Thickness : 0. 83 mm Weight : 1, 050 gsm Fabrication : High frequency welding Sealing : Zipper pulls Useful life : 10 -15 years OTR : 500 (Max) cc/m 2/day WVTR : 8 + 1 g/m 2/day Reusable/ Recyclable : Yes

DESCRIPTION § The Grain. Pro® Self Verifying Cocoon (S-VC) is a sealed flexible structure that is specifically designed to provide protection to dry agricultural commodities without the use of fumigants; § It is made from a specially designed flexible polyvinyl chloride (PVC) with an airtight zipper system; § It utilizes the principle of hermetic storage to prevent insect infestation during storage; § The S-VC has sealed structures that enable insects and other aerobic organisms in the commodity, or the commodity itself, to create a modified atmosphere by reducing the O 2 and increasing the CO 2 concentrations; and § The modification process often tries to lower the amount of O 2, moving it from 20. 9% to 0. 1%, in order to slow down the growth of aerobic organisms and the speed of oxidation reactions.

DESCRIPTION § The Grain. Pro® Self Verifying Cocoon (S-VC) is a sealed flexible structure that is specifically designed to provide protection to dry agricultural commodities without the use of fumigants; § It is made from a specially designed flexible polyvinyl chloride (PVC) with an airtight zipper system; § It utilizes the principle of hermetic storage to prevent insect infestation during storage; § The S-VC has sealed structures that enable insects and other aerobic organisms in the commodity, or the commodity itself, to create a modified atmosphere by reducing the O 2 and increasing the CO 2 concentrations; and § The modification process often tries to lower the amount of O 2, moving it from 20. 9% to 0. 1%, in order to slow down the growth of aerobic organisms and the speed of oxidation reactions.

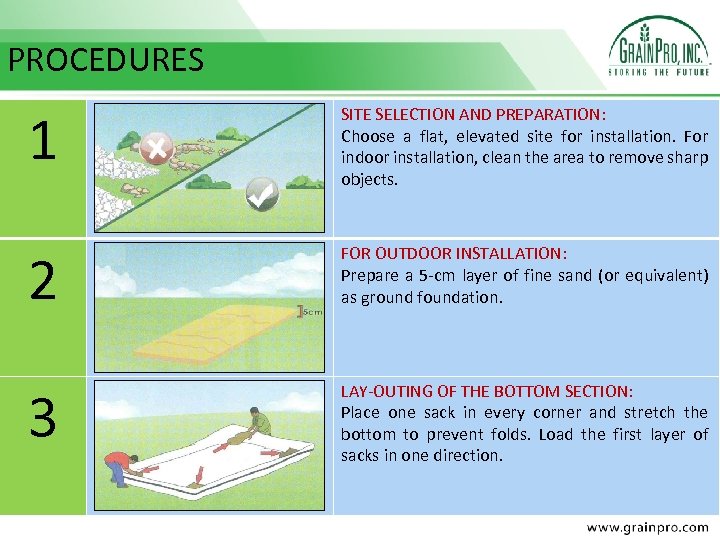

PROCEDURES 1 SITE SELECTION AND PREPARATION: Choose a flat, elevated site for installation. For indoor installation, clean the area to remove sharp objects. 2 FOR OUTDOOR INSTALLATION: Prepare a 5 -cm layer of fine sand (or equivalent) as ground foundation. 3 LAY-OUTING OF THE BOTTOM SECTION: Place one sack in every corner and stretch the bottom to prevent folds. Load the first layer of sacks in one direction.

PROCEDURES 1 SITE SELECTION AND PREPARATION: Choose a flat, elevated site for installation. For indoor installation, clean the area to remove sharp objects. 2 FOR OUTDOOR INSTALLATION: Prepare a 5 -cm layer of fine sand (or equivalent) as ground foundation. 3 LAY-OUTING OF THE BOTTOM SECTION: Place one sack in every corner and stretch the bottom to prevent folds. Load the first layer of sacks in one direction.

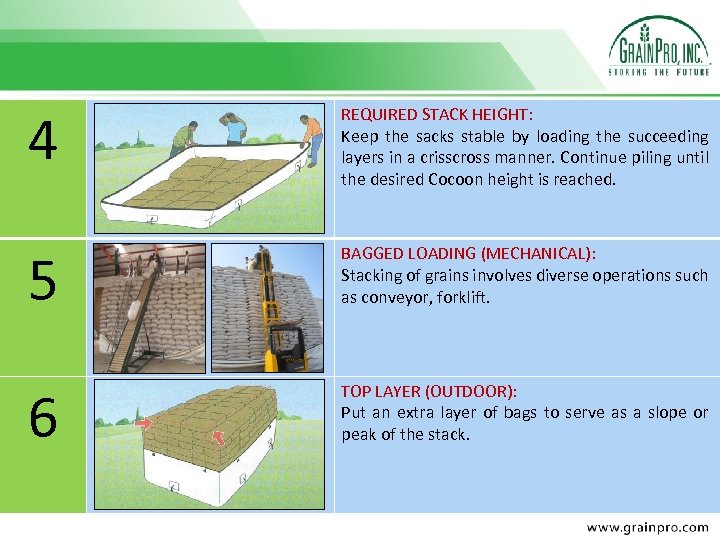

4 REQUIRED STACK HEIGHT: Keep the sacks stable by loading the succeeding layers in a crisscross manner. Continue piling until the desired Cocoon height is reached. 5 BAGGED LOADING (MECHANICAL): Stacking of grains involves diverse operations such as conveyor, forklift. 6 TOP LAYER (OUTDOOR): Put an extra layer of bags to serve as a slope or peak of the stack.

4 REQUIRED STACK HEIGHT: Keep the sacks stable by loading the succeeding layers in a crisscross manner. Continue piling until the desired Cocoon height is reached. 5 BAGGED LOADING (MECHANICAL): Stacking of grains involves diverse operations such as conveyor, forklift. 6 TOP LAYER (OUTDOOR): Put an extra layer of bags to serve as a slope or peak of the stack.

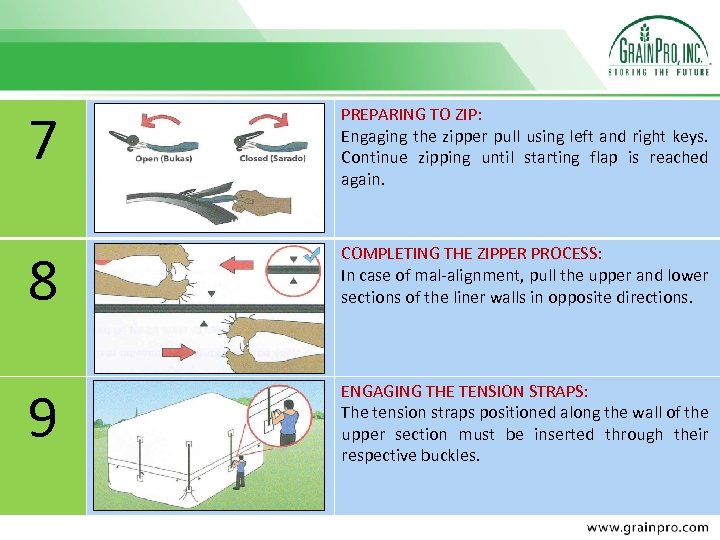

7 PREPARING TO ZIP: Engaging the zipper pull using left and right keys. Continue zipping until starting flap is reached again. 8 COMPLETING THE ZIPPER PROCESS: In case of mal-alignment, pull the upper and lower sections of the liner walls in opposite directions. 9 ENGAGING THE TENSION STRAPS: The tension straps positioned along the wall of the upper section must be inserted through their respective buckles.

7 PREPARING TO ZIP: Engaging the zipper pull using left and right keys. Continue zipping until starting flap is reached again. 8 COMPLETING THE ZIPPER PROCESS: In case of mal-alignment, pull the upper and lower sections of the liner walls in opposite directions. 9 ENGAGING THE TENSION STRAPS: The tension straps positioned along the wall of the upper section must be inserted through their respective buckles.

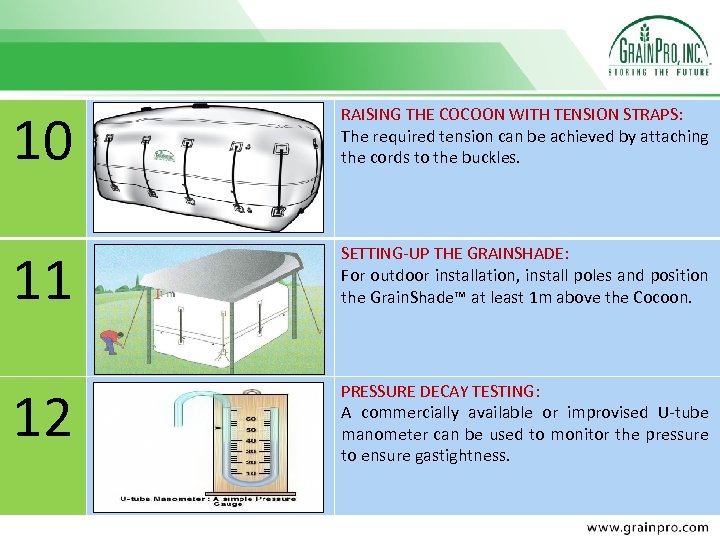

10 RAISING THE COCOON WITH TENSION STRAPS: The required tension can be achieved by attaching the cords to the buckles. 11 SETTING-UP THE GRAINSHADE: For outdoor installation, install poles and position the Grain. Shade™ at least 1 m above the Cocoon. 12 PRESSURE DECAY TESTING: A commercially available or improvised U-tube manometer can be used to monitor the pressure to ensure gastightness.

10 RAISING THE COCOON WITH TENSION STRAPS: The required tension can be achieved by attaching the cords to the buckles. 11 SETTING-UP THE GRAINSHADE: For outdoor installation, install poles and position the Grain. Shade™ at least 1 m above the Cocoon. 12 PRESSURE DECAY TESTING: A commercially available or improvised U-tube manometer can be used to monitor the pressure to ensure gastightness.

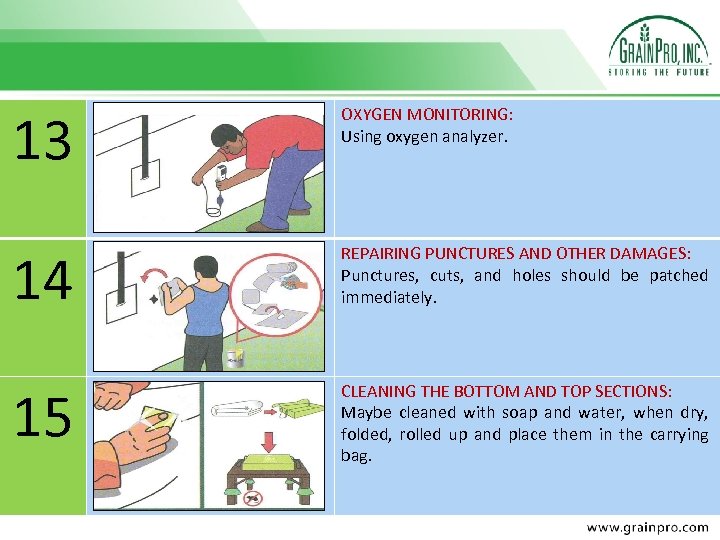

13 OXYGEN MONITORING: Using oxygen analyzer. 14 REPAIRING PUNCTURES AND OTHER DAMAGES: Punctures, cuts, and holes should be patched immediately. 15 CLEANING THE BOTTOM AND TOP SECTIONS: Maybe cleaned with soap and water, when dry, folded, rolled up and place them in the carrying bag.

13 OXYGEN MONITORING: Using oxygen analyzer. 14 REPAIRING PUNCTURES AND OTHER DAMAGES: Punctures, cuts, and holes should be patched immediately. 15 CLEANING THE BOTTOM AND TOP SECTIONS: Maybe cleaned with soap and water, when dry, folded, rolled up and place them in the carrying bag.

Visit Us THANK YOU www. grainpro. com

Visit Us THANK YOU www. grainpro. com