71fc6bc5614589198eb69c98538d3ce8.ppt

- Количество слайдов: 17

GLOBALGAP CERTIFICATION IN CROATIA Slaven Aljinović “Knowledge Power”

EUREPGAP • EUREPGAP: established 1997 by EU supermarket chains • EUREPGAP implementation started in 2001 for fruits&vegetables • Goal was to become “Global partnership for safe and sustainable agriculture” • Based on “Good Agricultural Practice”

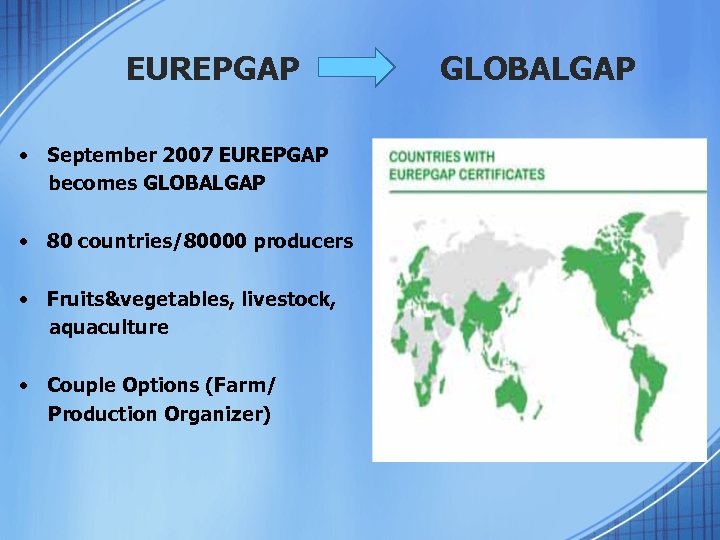

EUREPGAP • September 2007 EUREPGAP becomes GLOBALGAP • 80 countries/80000 producers • Fruits&vegetables, livestock, aquaculture • Couple Options (Farm/ Production Organizer) GLOBALGAP

FRAGARIA/KONZUM GLOBALGAP Certification Good Transportation Code Good Retailers Practice QMS/ISO/HACCP - Market Access - Increased Competitiveness End Users GAP

GLOBALGAP Certification Phases • 2006 – Austrian buyer informs DAD Neretva that EUREPGAP certification of mandarines is required • 2006 – Preparations with group with DAD Neretva & selected group of 35/200 mandarine producers • 2006/2007 – Certification of DAD Neretva & 66 farmers • 2008 – Certification of FRAGARIA & 4 strawberry farmers

Certification Options • Option 1 – Individual Farmer 199 Control Points 37 Reccomendations • Option 2 – Company/Production Organizer + Farmers Company QMS(based on ISO 9001 standard) 199 Control Points – All Farmers

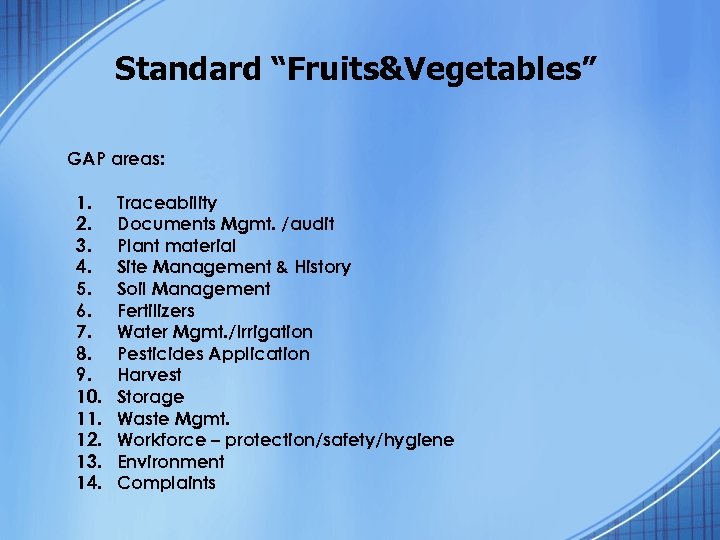

Standard “Fruits&Vegetables” GAP areas: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. Traceability Documents Mgmt. /audit Plant material Site Management & History Soil Management Fertilizers Water Mgmt. /Irrigation Pesticides Application Harvest Storage Waste Mgmt. Workforce – protection/safety/hygiene Environment Complaints

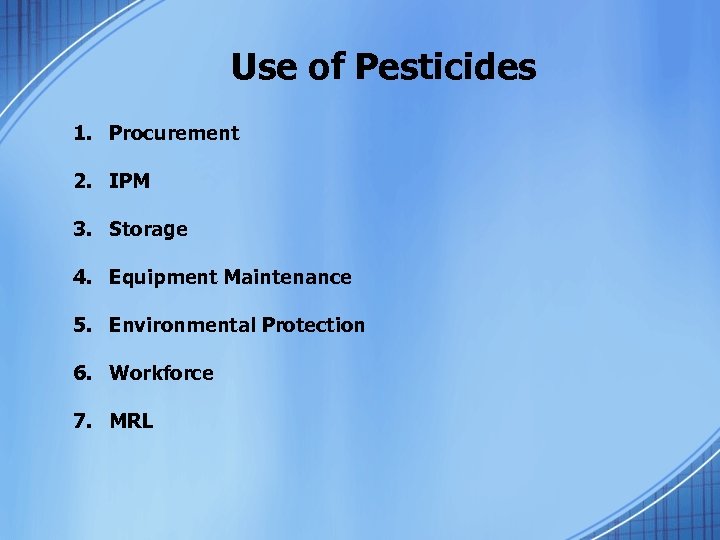

Use of Pesticides 1. Procurement 2. IPM 3. Storage 4. Equipment Maintenance 5. Environmental Protection 6. Workforce 7. MRL

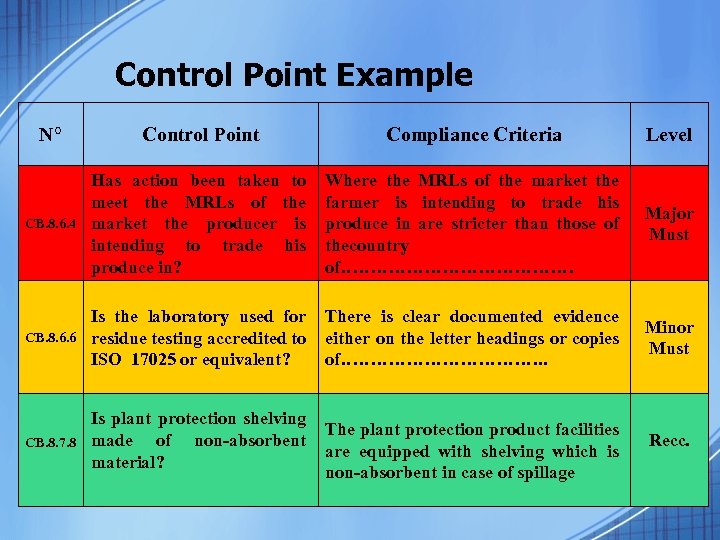

Control Point Example N° Control Point Compliance Criteria Level CB. 8. 6. 4 Has action been taken to meet the MRLs of the market the producer is intending to trade his produce in? Where the MRLs of the market the farmer is intending to trade his produce in are stricter than those of thecountry of………………… Major Must CB. 8. 6. 6 Is the laboratory used for residue testing accredited to ISO 17025 or equivalent? There is clear documented evidence either on the letter headings or copies of………………. . Minor Must CB. 8. 7. 8 Is plant protection shelving made of non-absorbent material? The plant protection product facilities are equipped with shelving which is non-absorbent in case of spillage Recc.

Challenges

Solutions Education Environmental Protection Food Safety

Solutions Records • Traceability Workers Safety Pesticide Waste

Results INCREASED COMPETITIVENESS/PROFIT OF ALL PARTNERS: • Optimising production practices • Access to EU market of more than 500 consumers • Meeting Croatian/EU legal requirements

Food Safety up the Chain HACCP - First Food Safety System: 1960/NASA/US Army/Pilsbury) 7 Principles – Proactive approach towards food safety Hazard Analysis& Critical Control Point GAP/GMP/SOP/SSOP Prerequisite Programs ISO 22000 -2005 - Interactive communication System management HACCP principles Continous improvement

Croatian Food Safety Update 1. EU Food Law – Regulation EC/178/2002 2. January 2009 - HACCP is a legal obligation in Croatia USAID Support: - Trainings for HACCP auditors - Food safety trainings - First ISO 22000 auditor trainings - Co-financed County HACCP-isation schemes

CERTIFICATION PROBLEMS 1. Administration 2. Entrepreneurs 3. Functioning Partnerships

QUESTIONS Buzin 136@gmail. com Mobile: 00385/91/661 -2164

71fc6bc5614589198eb69c98538d3ce8.ppt