4481a190ea48ee81e2977c7c83bd7074.ppt

- Количество слайдов: 131

GLAST LAT Project Gamma-ray Large Area Space Telescope CDR/CD 3 Review May 12 -16, 2003 GLAST Large Area Telescope: Mechanical Systems WBS: 4. 1. 8 Section 13 Marc Campell SLAC Mechanical Systems Manager marcc@slac. stanford. edu Document: LAT-PR-01967 Section 13 Mechanical Subsystem 1

GLAST LAT Project Gamma-ray Large Area Space Telescope CDR/CD 3 Review May 12 -16, 2003 GLAST Large Area Telescope: Mechanical Systems WBS: 4. 1. 8 Section 13 Marc Campell SLAC Mechanical Systems Manager marcc@slac. stanford. edu Document: LAT-PR-01967 Section 13 Mechanical Subsystem 1

GLAST LAT Project Gamma-ray Large Area Space Telescope Document: LAT-PR-01967 CDR/CD 3 Review May 12 -16, 2003 Overview Section 13. 1 Section 13 Mechanical Subsystem 2

GLAST LAT Project Gamma-ray Large Area Space Telescope Document: LAT-PR-01967 CDR/CD 3 Review May 12 -16, 2003 Overview Section 13. 1 Section 13 Mechanical Subsystem 2

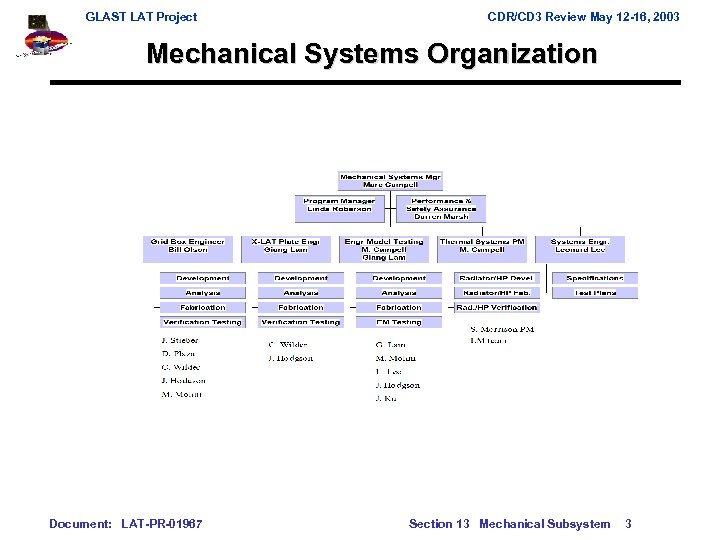

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Mechanical Systems Organization Document: LAT-PR-01967 Section 13 Mechanical Subsystem 3

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Mechanical Systems Organization Document: LAT-PR-01967 Section 13 Mechanical Subsystem 3

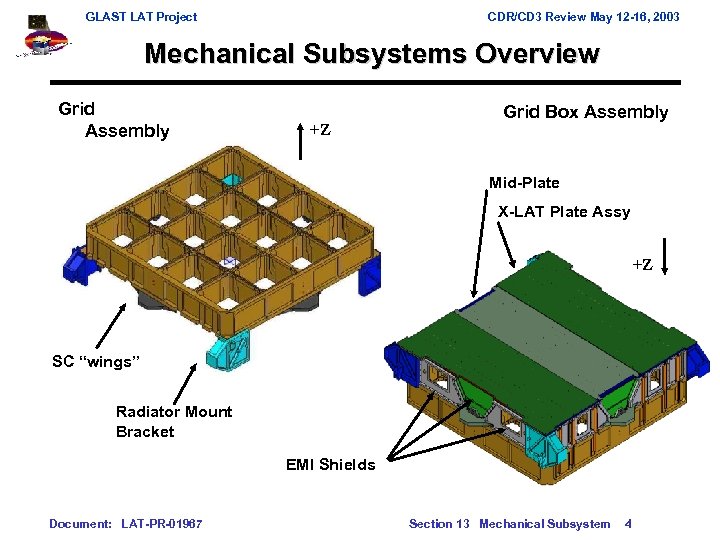

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Mechanical Subsystems Overview Grid Assembly +Z Grid Box Assembly Mid-Plate X-LAT Plate Assy +Z SC “wings” Radiator Mount Bracket EMI Shields Document: LAT-PR-01967 Section 13 Mechanical Subsystem 4

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Mechanical Subsystems Overview Grid Assembly +Z Grid Box Assembly Mid-Plate X-LAT Plate Assy +Z SC “wings” Radiator Mount Bracket EMI Shields Document: LAT-PR-01967 Section 13 Mechanical Subsystem 4

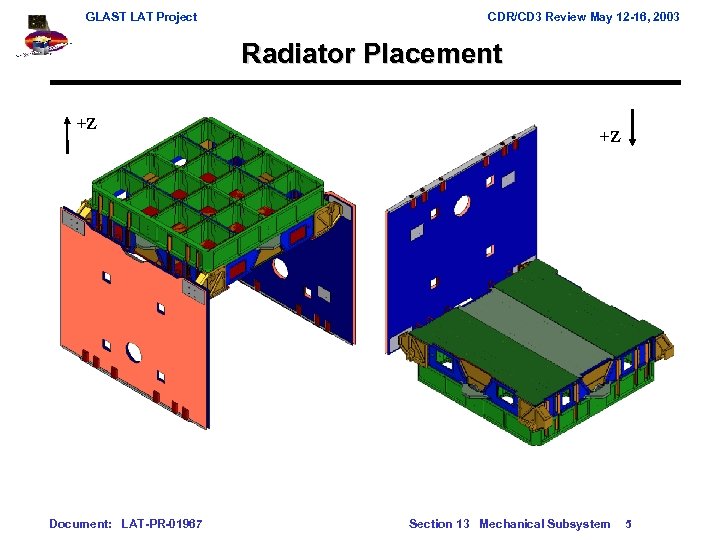

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Radiator Placement +Z Document: LAT-PR-01967 +Z Section 13 Mechanical Subsystem 5

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Radiator Placement +Z Document: LAT-PR-01967 +Z Section 13 Mechanical Subsystem 5

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Major Subassemblies • Grid Box Assembly – Mechanical Systems Top Assembly test configuration – Static Load and Thermal Cycle tests • Grid Box Base Assembly – Configuration delivered to I & T for LAT integration – Defines base configuration for LAT assembly drawings • Grid Assembly – Mechanical backbone • Radiators – Fabricated and tested by LM • X-LAT and Mid-plates – Fabricated and tested by LM Document: LAT-PR-01967 Section 13 Mechanical Subsystem 6

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Major Subassemblies • Grid Box Assembly – Mechanical Systems Top Assembly test configuration – Static Load and Thermal Cycle tests • Grid Box Base Assembly – Configuration delivered to I & T for LAT integration – Defines base configuration for LAT assembly drawings • Grid Assembly – Mechanical backbone • Radiators – Fabricated and tested by LM • X-LAT and Mid-plates – Fabricated and tested by LM Document: LAT-PR-01967 Section 13 Mechanical Subsystem 6

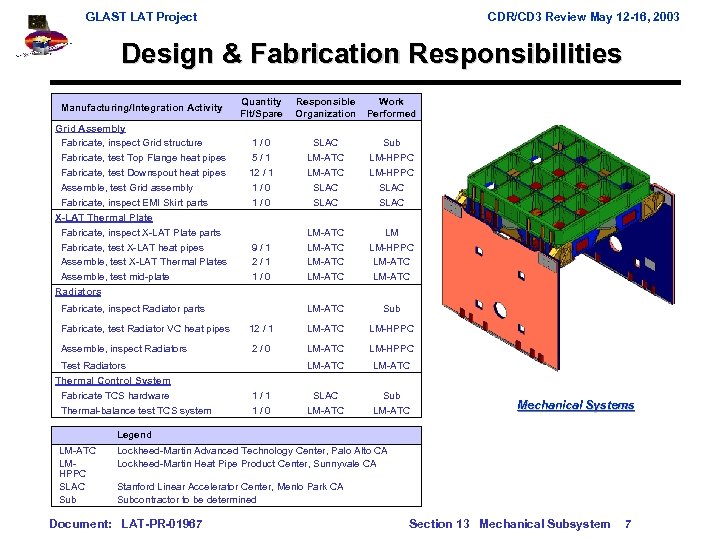

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Design & Fabrication Responsibilities Manufacturing/Integration Activity Grid Assembly Fabricate, inspect Grid structure Fabricate, test Top Flange heat pipes Fabricate, test Downspout heat pipes Assemble, test Grid assembly Fabricate, inspect EMI Skirt parts X-LAT Thermal Plate Fabricate, inspect X-LAT Plate parts Fabricate, test X-LAT heat pipes Assemble, test X-LAT Thermal Plates Assemble, test mid-plate Radiators Quantity Flt/Spare Responsible Work Organization Performed 1/0 5/1 12 / 1 1/0 SLAC LM-ATC SLAC Sub LM-HPPC SLAC 9/1 2/1 1/0 LM-ATC LM LM-HPPC LM-ATC Sub Fabricate, inspect Radiator parts Fabricate, test Radiator VC heat pipes 12 / 1 LM-ATC LM-HPPC Assemble, inspect Radiators 2/0 LM-ATC LM-HPPC LM-ATC SLAC LM-ATC Sub LM-ATC Test Radiators Thermal Control System Fabricate TCS hardware Thermal-balance test TCS system 1/1 1/0 Mechanical Systems Legend LM-ATC LMHPPC SLAC Sub Lockheed-Martin Advanced Technology Center, Palo Alto CA Lockheed-Martin Heat Pipe Product Center, Sunnyvale CA Stanford Linear Accelerator Center, Menlo Park CA Subcontractor to be determined Document: LAT-PR-01967 Section 13 Mechanical Subsystem 7

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Design & Fabrication Responsibilities Manufacturing/Integration Activity Grid Assembly Fabricate, inspect Grid structure Fabricate, test Top Flange heat pipes Fabricate, test Downspout heat pipes Assemble, test Grid assembly Fabricate, inspect EMI Skirt parts X-LAT Thermal Plate Fabricate, inspect X-LAT Plate parts Fabricate, test X-LAT heat pipes Assemble, test X-LAT Thermal Plates Assemble, test mid-plate Radiators Quantity Flt/Spare Responsible Work Organization Performed 1/0 5/1 12 / 1 1/0 SLAC LM-ATC SLAC Sub LM-HPPC SLAC 9/1 2/1 1/0 LM-ATC LM LM-HPPC LM-ATC Sub Fabricate, inspect Radiator parts Fabricate, test Radiator VC heat pipes 12 / 1 LM-ATC LM-HPPC Assemble, inspect Radiators 2/0 LM-ATC LM-HPPC LM-ATC SLAC LM-ATC Sub LM-ATC Test Radiators Thermal Control System Fabricate TCS hardware Thermal-balance test TCS system 1/1 1/0 Mechanical Systems Legend LM-ATC LMHPPC SLAC Sub Lockheed-Martin Advanced Technology Center, Palo Alto CA Lockheed-Martin Heat Pipe Product Center, Sunnyvale CA Stanford Linear Accelerator Center, Menlo Park CA Subcontractor to be determined Document: LAT-PR-01967 Section 13 Mechanical Subsystem 7

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Design Problem Areas • CAL-GRID Interface • Electronics-Box to X-LAT Interface Document: LAT-PR-01967 Section 13 Mechanical Subsystem 8

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Design Problem Areas • CAL-GRID Interface • Electronics-Box to X-LAT Interface Document: LAT-PR-01967 Section 13 Mechanical Subsystem 8

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 CAL-GRID Interface Design Problem Status • At PDR & d. PDR the baseline design was a bolted interface that relied on friction between the CAL plates and the Grid to react shear forces. • By Peer Review, we had not demonstrated (EM test) that we could develop the coefficient of friction required at the most highly loaded (<10% of) locations with ample margin. • A pinned approach was implemented analyzed. Document: LAT-PR-01967 Section 13 Mechanical Subsystem 9

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 CAL-GRID Interface Design Problem Status • At PDR & d. PDR the baseline design was a bolted interface that relied on friction between the CAL plates and the Grid to react shear forces. • By Peer Review, we had not demonstrated (EM test) that we could develop the coefficient of friction required at the most highly loaded (<10% of) locations with ample margin. • A pinned approach was implemented analyzed. Document: LAT-PR-01967 Section 13 Mechanical Subsystem 9

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 CAL-GRID Interface Design Problem Resolution • The pins cannot carry the loads at the highly loaded locations. • Request to GSFC to re-evaluate loads that were specified to LAT which we believe may overstate the shear loads by a factor of 2 or 3 (but correctly state the SC – LAT interface loads) • Acceptable options that impact only Mech have been exhausted or rejected on principal • Other options under evaluation which impact at least the CAL subsystem as well Document: LAT-PR-01967 Section 13 Mechanical Subsystem 10

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 CAL-GRID Interface Design Problem Resolution • The pins cannot carry the loads at the highly loaded locations. • Request to GSFC to re-evaluate loads that were specified to LAT which we believe may overstate the shear loads by a factor of 2 or 3 (but correctly state the SC – LAT interface loads) • Acceptable options that impact only Mech have been exhausted or rejected on principal • Other options under evaluation which impact at least the CAL subsystem as well Document: LAT-PR-01967 Section 13 Mechanical Subsystem 10

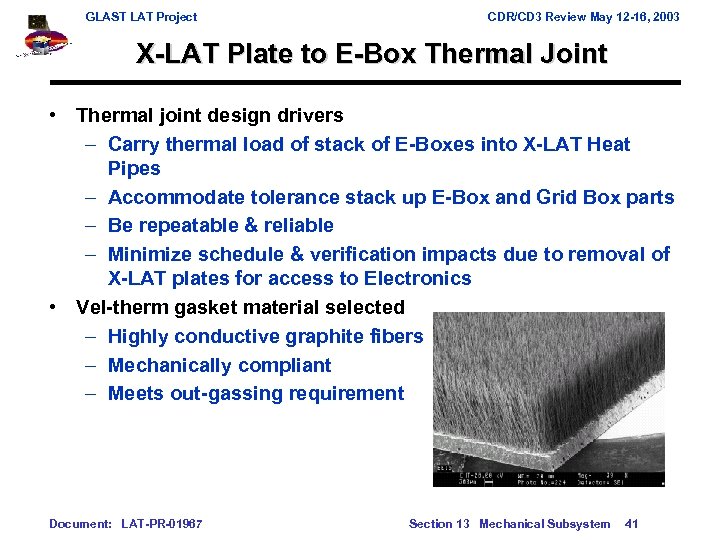

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 X-LAT to Electronics-Box Thermal Joint Design Problem Status • At PDR & d. PDR the baseline design was a bolted and thermally bonded joint between bottom of each E-Box and the X-LAT plate. There were flexures between the top of the E-box stack and the CAL plates. – Concern raised that E-boxes were not serviceable • Large bonded area to de-mate. • Re-verification issues after re-integrating. • For Peer Review, trade study presented for design that – Carried thermal load of E-Boxes into X-LAT heat pipes – Accommodate tolerance buildup from E-Box and Grid Box components – Repeatable interface (make & break) – Minimize schedule & verification impacts resulting from XLAT plate removal for Electronics box access Document: LAT-PR-01967 Section 13 Mechanical Subsystem 11

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 X-LAT to Electronics-Box Thermal Joint Design Problem Status • At PDR & d. PDR the baseline design was a bolted and thermally bonded joint between bottom of each E-Box and the X-LAT plate. There were flexures between the top of the E-box stack and the CAL plates. – Concern raised that E-boxes were not serviceable • Large bonded area to de-mate. • Re-verification issues after re-integrating. • For Peer Review, trade study presented for design that – Carried thermal load of E-Boxes into X-LAT heat pipes – Accommodate tolerance buildup from E-Box and Grid Box components – Repeatable interface (make & break) – Minimize schedule & verification impacts resulting from XLAT plate removal for Electronics box access Document: LAT-PR-01967 Section 13 Mechanical Subsystem 11

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 X-LAT to Electronics-Box Thermal Joint Design Problem Resolution • Design changed to rigidly mount E-Box stack to CAL plate and create a thermally compliant thermal joint between the E-box & X-LAT plate • Trade study results indicate that Vel-therm gasket material optimally meets requirements and has the following characteristics: – Highly conductive graphite fibers – Mechanically compliant – Meets out-gassing requirements – Allows TEM/TPS to be mated to CAL through out its Acceptance testing • However, this approach has little Flight heritage and must be qualified for our application Document: LAT-PR-01967 Section 13 Mechanical Subsystem 12

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 X-LAT to Electronics-Box Thermal Joint Design Problem Resolution • Design changed to rigidly mount E-Box stack to CAL plate and create a thermally compliant thermal joint between the E-box & X-LAT plate • Trade study results indicate that Vel-therm gasket material optimally meets requirements and has the following characteristics: – Highly conductive graphite fibers – Mechanically compliant – Meets out-gassing requirements – Allows TEM/TPS to be mated to CAL through out its Acceptance testing • However, this approach has little Flight heritage and must be qualified for our application Document: LAT-PR-01967 Section 13 Mechanical Subsystem 12

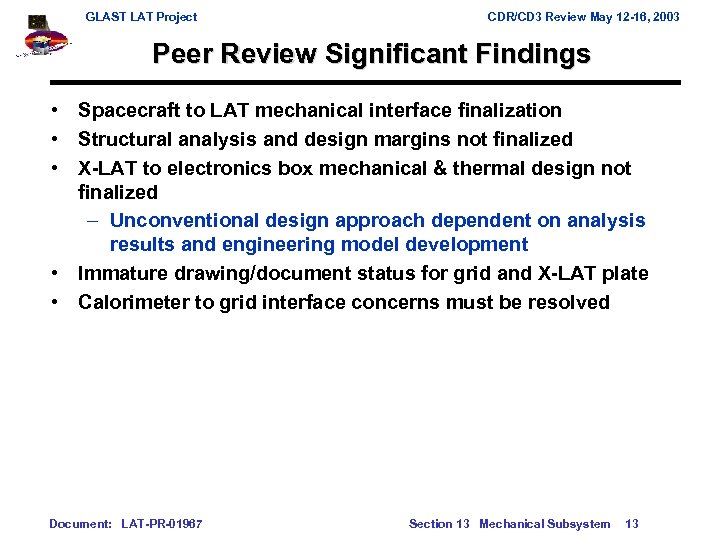

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Peer Review Significant Findings • Spacecraft to LAT mechanical interface finalization • Structural analysis and design margins not finalized • X-LAT to electronics box mechanical & thermal design not finalized – Unconventional design approach dependent on analysis results and engineering model development • Immature drawing/document status for grid and X-LAT plate • Calorimeter to grid interface concerns must be resolved Document: LAT-PR-01967 Section 13 Mechanical Subsystem 13

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Peer Review Significant Findings • Spacecraft to LAT mechanical interface finalization • Structural analysis and design margins not finalized • X-LAT to electronics box mechanical & thermal design not finalized – Unconventional design approach dependent on analysis results and engineering model development • Immature drawing/document status for grid and X-LAT plate • Calorimeter to grid interface concerns must be resolved Document: LAT-PR-01967 Section 13 Mechanical Subsystem 13

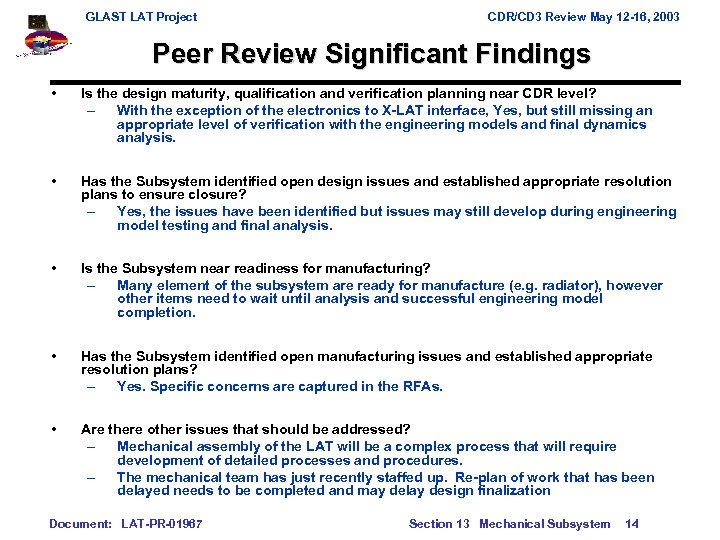

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Peer Review Significant Findings • Is the design maturity, qualification and verification planning near CDR level? – With the exception of the electronics to X-LAT interface, Yes, but still missing an appropriate level of verification with the engineering models and final dynamics analysis. • Has the Subsystem identified open design issues and established appropriate resolution plans to ensure closure? – Yes, the issues have been identified but issues may still develop during engineering model testing and final analysis. • Is the Subsystem near readiness for manufacturing? – Many element of the subsystem are ready for manufacture (e. g. radiator), however other items need to wait until analysis and successful engineering model completion. • Has the Subsystem identified open manufacturing issues and established appropriate resolution plans? – Yes. Specific concerns are captured in the RFAs. • Are there other issues that should be addressed? – Mechanical assembly of the LAT will be a complex process that will require development of detailed processes and procedures. – The mechanical team has just recently staffed up. Re-plan of work that has been delayed needs to be completed and may delay design finalization Document: LAT-PR-01967 Section 13 Mechanical Subsystem 14

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Peer Review Significant Findings • Is the design maturity, qualification and verification planning near CDR level? – With the exception of the electronics to X-LAT interface, Yes, but still missing an appropriate level of verification with the engineering models and final dynamics analysis. • Has the Subsystem identified open design issues and established appropriate resolution plans to ensure closure? – Yes, the issues have been identified but issues may still develop during engineering model testing and final analysis. • Is the Subsystem near readiness for manufacturing? – Many element of the subsystem are ready for manufacture (e. g. radiator), however other items need to wait until analysis and successful engineering model completion. • Has the Subsystem identified open manufacturing issues and established appropriate resolution plans? – Yes. Specific concerns are captured in the RFAs. • Are there other issues that should be addressed? – Mechanical assembly of the LAT will be a complex process that will require development of detailed processes and procedures. – The mechanical team has just recently staffed up. Re-plan of work that has been delayed needs to be completed and may delay design finalization Document: LAT-PR-01967 Section 13 Mechanical Subsystem 14

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Major RFA’s and Overall Status • 19 of 46 RFA’s owned by Mechanical Systems – 0 closed – X submitted – Y open, ECD June 1 st – Z open, ECD July 1 st Document: LAT-PR-01967 Section 13 Mechanical Subsystem 15

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Major RFA’s and Overall Status • 19 of 46 RFA’s owned by Mechanical Systems – 0 closed – X submitted – Y open, ECD June 1 st – Z open, ECD July 1 st Document: LAT-PR-01967 Section 13 Mechanical Subsystem 15

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 RFA Response ID # Status 1 RFA Description RFA Response/Closure Plan Open/Closed 10 12 27 28 Document: LAT-PR-01967 Section 13 Mechanical Subsystem 16

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 RFA Response ID # Status 1 RFA Description RFA Response/Closure Plan Open/Closed 10 12 27 28 Document: LAT-PR-01967 Section 13 Mechanical Subsystem 16

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 RFA Response ID # Status 29 RFA Description RFA Response/Closure Plan Open/Closed 32 33 34 36 Document: LAT-PR-01967 Section 13 Mechanical Subsystem 17

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 RFA Response ID # Status 29 RFA Description RFA Response/Closure Plan Open/Closed 32 33 34 36 Document: LAT-PR-01967 Section 13 Mechanical Subsystem 17

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 RFA Response ID # Status 37 RFA Description RFA Response/Closure Plan Open/Closed 38 39 40 41 Document: LAT-PR-01967 Section 13 Mechanical Subsystem 18

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 RFA Response ID # Status 37 RFA Description RFA Response/Closure Plan Open/Closed 38 39 40 41 Document: LAT-PR-01967 Section 13 Mechanical Subsystem 18

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 RFA Response ID # Status 42 RFA Description RFA Response/Closure Plan Open/Closed 43 45 46 Document: LAT-PR-01967 Section 13 Mechanical Subsystem 19

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 RFA Response ID # Status 42 RFA Description RFA Response/Closure Plan Open/Closed 43 45 46 Document: LAT-PR-01967 Section 13 Mechanical Subsystem 19

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Mechanical Systems’ Status Summary • • Final Design Established With Known Closure Plans For Design Trades – X- LAT Plate To Electronics ICD - ECD: 7/15/03 – Xx/yy Drawings Complete, zz/yy Drawings Draft – ECD 8/15/03 – EM Model Tests Complete - ECD: 7/28/03 Internal & External Interfaces Established – Yy TBX’s with closure planned – ECD: 7/12/03 • Performance Analyses Show Compliance Including Sufficient Design Margin – Any Exceptions noted with recovery plans • • • Qualification & Verification Plans In Place Subsystem Risk Areas Identified And Mitigation Plans Established Cost & Schedule Manageable – $$ Variance with recovery plans established – XX Week Schedule Float to Flight Delivery Need Dates Document: LAT-PR-01967 Section 13 Mechanical Subsystem 20

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Mechanical Systems’ Status Summary • • Final Design Established With Known Closure Plans For Design Trades – X- LAT Plate To Electronics ICD - ECD: 7/15/03 – Xx/yy Drawings Complete, zz/yy Drawings Draft – ECD 8/15/03 – EM Model Tests Complete - ECD: 7/28/03 Internal & External Interfaces Established – Yy TBX’s with closure planned – ECD: 7/12/03 • Performance Analyses Show Compliance Including Sufficient Design Margin – Any Exceptions noted with recovery plans • • • Qualification & Verification Plans In Place Subsystem Risk Areas Identified And Mitigation Plans Established Cost & Schedule Manageable – $$ Variance with recovery plans established – XX Week Schedule Float to Flight Delivery Need Dates Document: LAT-PR-01967 Section 13 Mechanical Subsystem 20

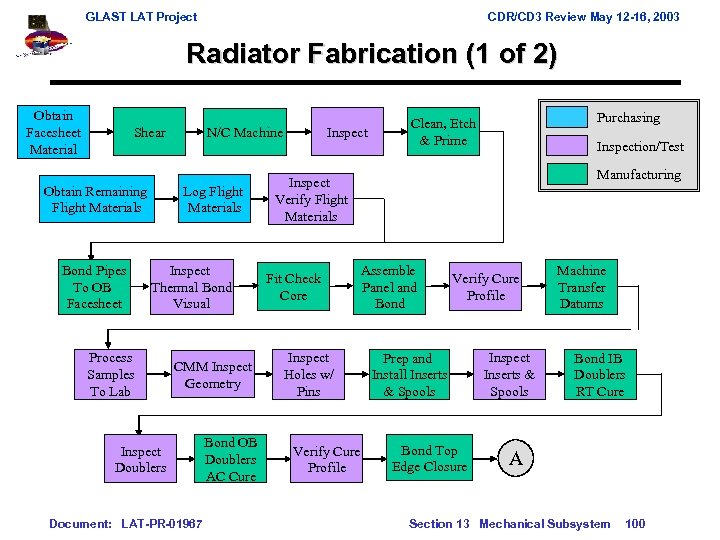

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Summary • Mechanical Systems detailed design and analysis indicates that all requirements will be met. • Mechanical Systems has accommodated changes since d. PDR. • Overall design is in good shape – Grid Box Assembly design is nearly complete. – Radiator and Heat Pipe designs are nearly complete. – Cal-Grid interface is still in development. – Risk list items are understood & mitigation plans are in place. • Radiator design has matured and fabrication will begin after ICDR. • Aluminum billets for Grid are on order. • LM’s X-LAT team has come up to speed quickly and made several design improvements. • LM has team in place to execute to their plan. Document: LAT-PR-01967 Section 13 Mechanical Subsystem 21

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Summary • Mechanical Systems detailed design and analysis indicates that all requirements will be met. • Mechanical Systems has accommodated changes since d. PDR. • Overall design is in good shape – Grid Box Assembly design is nearly complete. – Radiator and Heat Pipe designs are nearly complete. – Cal-Grid interface is still in development. – Risk list items are understood & mitigation plans are in place. • Radiator design has matured and fabrication will begin after ICDR. • Aluminum billets for Grid are on order. • LM’s X-LAT team has come up to speed quickly and made several design improvements. • LM has team in place to execute to their plan. Document: LAT-PR-01967 Section 13 Mechanical Subsystem 21

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Summary (con’t) Plans for Further Work • Engineering Modeling – Complete the remaining testing • Analysis – Complete detailed part stress analysis – Define Grid Box Assembly SLT cases • Design – Release Radiator and X-LAT specifications & Interface Def. Dwg. – Finalize CAL-Grid interface & incorporate into design – Finalize wing, EMI skirt & Radiator mount Bracket designs – Finalize X-LAT to Electronics design • Lockheed Martin – Complete detailed design and analysis – Finalize test plans • Program Management – Negotiate & award LM Phase II (fabrication) contract – Award Grid Assembly contract Document: LAT-PR-01967 Section 13 Mechanical Subsystem 22

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Summary (con’t) Plans for Further Work • Engineering Modeling – Complete the remaining testing • Analysis – Complete detailed part stress analysis – Define Grid Box Assembly SLT cases • Design – Release Radiator and X-LAT specifications & Interface Def. Dwg. – Finalize CAL-Grid interface & incorporate into design – Finalize wing, EMI skirt & Radiator mount Bracket designs – Finalize X-LAT to Electronics design • Lockheed Martin – Complete detailed design and analysis – Finalize test plans • Program Management – Negotiate & award LM Phase II (fabrication) contract – Award Grid Assembly contract Document: LAT-PR-01967 Section 13 Mechanical Subsystem 22

GLAST LAT Project Gamma-ray Large Area Space Telescope Document: LAT-PR-01967 CDR/CD 3 Review May 12 -16, 2003 Requirements Section 13. 2 Section 13 Mechanical Subsystem 23

GLAST LAT Project Gamma-ray Large Area Space Telescope Document: LAT-PR-01967 CDR/CD 3 Review May 12 -16, 2003 Requirements Section 13. 2 Section 13 Mechanical Subsystem 23

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Topics Agenda • Mechanical Systems Mass Budget • Mechanical Systems Power Budget • Requirements Flow down And Document Status • Key Mechanical Systems Requirements (Level 3) • Heat Pipe Performance Requirements • Radiator Design Requirements • Main X-LAT Design Requirements • Driving X-LAT Thermal Requirements Document: LAT-PR-01967 Section 13 Mechanical Subsystem 24

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Topics Agenda • Mechanical Systems Mass Budget • Mechanical Systems Power Budget • Requirements Flow down And Document Status • Key Mechanical Systems Requirements (Level 3) • Heat Pipe Performance Requirements • Radiator Design Requirements • Main X-LAT Design Requirements • Driving X-LAT Thermal Requirements Document: LAT-PR-01967 Section 13 Mechanical Subsystem 24

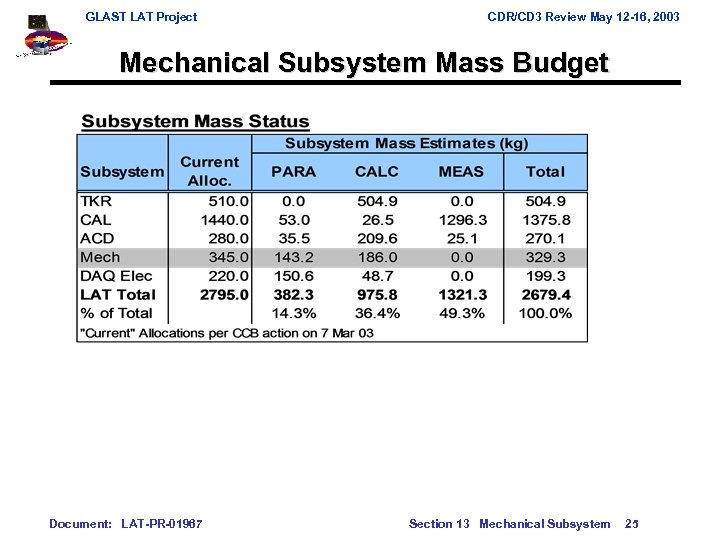

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Mechanical Subsystem Mass Budget Document: LAT-PR-01967 Section 13 Mechanical Subsystem 25

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Mechanical Subsystem Mass Budget Document: LAT-PR-01967 Section 13 Mechanical Subsystem 25

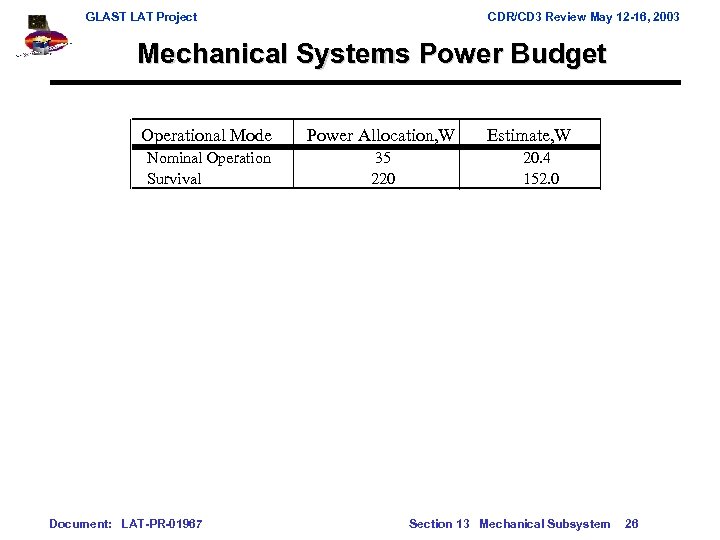

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Mechanical Systems Power Budget Operational Mode Power Allocation, W Nominal Operation Survival 35 220 Document: LAT-PR-01967 Estimate, W 20. 4 152. 0 Section 13 Mechanical Subsystem 26

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Mechanical Systems Power Budget Operational Mode Power Allocation, W Nominal Operation Survival 35 220 Document: LAT-PR-01967 Estimate, W 20. 4 152. 0 Section 13 Mechanical Subsystem 26

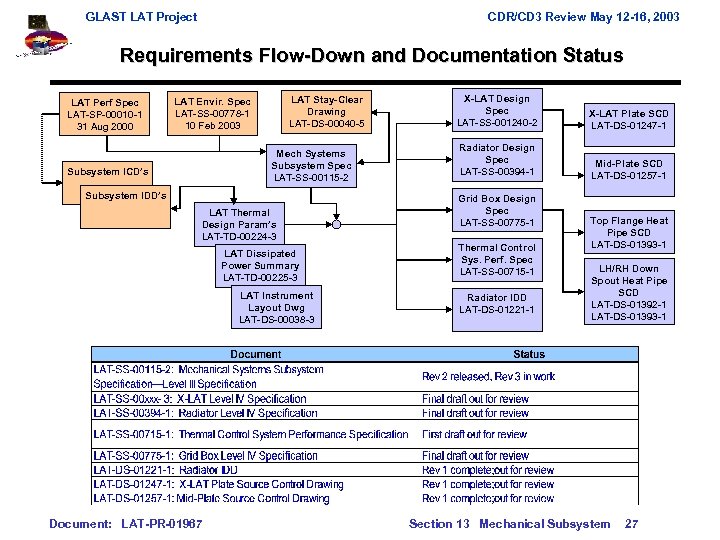

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Requirements Flow-Down and Documentation Status LAT Perf Spec LAT-SP-00010 -1 31 Aug 2000 LAT Stay-Clear Drawing LAT-DS-00040 -5 LAT Envir. Spec LAT-SS-00778 -1 10 Feb 2003 Mech Systems Subsystem Spec LAT-SS-00115 -2 Subsystem ICD’s Subsystem IDD’s LAT Thermal Design Param’s LAT-TD-00224 -3 LAT Dissipated Power Summary LAT-TD-00225 -3 LAT Instrument Layout Dwg LAT-DS-00038 -3 Document: LAT-PR-01967 X-LAT Design Spec LAT-SS-001240 -2 X-LAT Plate SCD LAT-DS-01247 -1 Radiator Design Spec LAT-SS-00394 -1 Mid-Plate SCD LAT-DS-01257 -1 Grid Box Design Spec LAT-SS-00775 -1 Thermal Control Sys. Perf. Spec LAT-SS-00715 -1 Radiator IDD LAT-DS-01221 -1 Top Flange Heat Pipe SCD LAT-DS-01393 -1 LH/RH Down Spout Heat Pipe SCD LAT-DS-01392 -1 LAT-DS-01393 -1 Section 13 Mechanical Subsystem 27

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Requirements Flow-Down and Documentation Status LAT Perf Spec LAT-SP-00010 -1 31 Aug 2000 LAT Stay-Clear Drawing LAT-DS-00040 -5 LAT Envir. Spec LAT-SS-00778 -1 10 Feb 2003 Mech Systems Subsystem Spec LAT-SS-00115 -2 Subsystem ICD’s Subsystem IDD’s LAT Thermal Design Param’s LAT-TD-00224 -3 LAT Dissipated Power Summary LAT-TD-00225 -3 LAT Instrument Layout Dwg LAT-DS-00038 -3 Document: LAT-PR-01967 X-LAT Design Spec LAT-SS-001240 -2 X-LAT Plate SCD LAT-DS-01247 -1 Radiator Design Spec LAT-SS-00394 -1 Mid-Plate SCD LAT-DS-01257 -1 Grid Box Design Spec LAT-SS-00775 -1 Thermal Control Sys. Perf. Spec LAT-SS-00715 -1 Radiator IDD LAT-DS-01221 -1 Top Flange Heat Pipe SCD LAT-DS-01393 -1 LH/RH Down Spout Heat Pipe SCD LAT-DS-01392 -1 LAT-DS-01393 -1 Section 13 Mechanical Subsystem 27

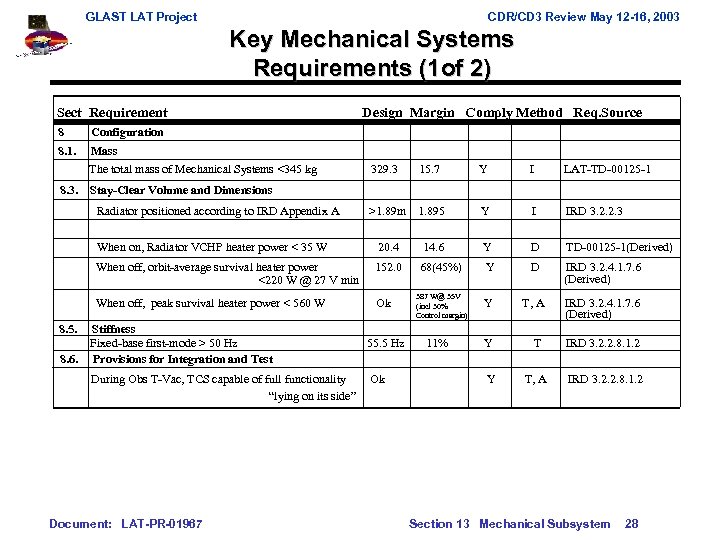

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Key Mechanical Systems Requirements (1 of 2) Sect Requirement 8 Configuration 8. 1. Mass The total mass of Mechanical Systems <345 kg Design Margin Comply Method Req. Source 15. 7 Y I LAT-TD-00125 -1 >1. 89 m 1. 895 Y I IRD 3. 2. 2. 3 When on, Radiator VCHP heater power < 35 W 20. 4 14. 6 Y D TD-00125 -1(Derived) When off, orbit-average survival heater power <220 W @ 27 V min 152. 0 68(45%) Y D IRD 3. 2. 4. 1. 7. 6 (Derived) When off, peak survival heater power < 560 W 8. 3. 329. 3 Ok 387 W@ 35 V (incl 30% Control margin) Y T, A IRD 3. 2. 4. 1. 7. 6 (Derived) Y T IRD 3. 2. 2. 8. 1. 2 Y T, A IRD 3. 2. 2. 8. 1. 2 Stay-Clear Volume and Dimensions Radiator positioned according to IRD Appendix A 8. 5. 8. 6. Stiffness Fixed-base first-mode > 50 Hz Provisions for Integration and Test During Obs T-Vac, TCS capable of full functionality “lying on its side” Document: LAT-PR-01967 55. 5 Hz Ok 11% Section 13 Mechanical Subsystem 28

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Key Mechanical Systems Requirements (1 of 2) Sect Requirement 8 Configuration 8. 1. Mass The total mass of Mechanical Systems <345 kg Design Margin Comply Method Req. Source 15. 7 Y I LAT-TD-00125 -1 >1. 89 m 1. 895 Y I IRD 3. 2. 2. 3 When on, Radiator VCHP heater power < 35 W 20. 4 14. 6 Y D TD-00125 -1(Derived) When off, orbit-average survival heater power <220 W @ 27 V min 152. 0 68(45%) Y D IRD 3. 2. 4. 1. 7. 6 (Derived) When off, peak survival heater power < 560 W 8. 3. 329. 3 Ok 387 W@ 35 V (incl 30% Control margin) Y T, A IRD 3. 2. 4. 1. 7. 6 (Derived) Y T IRD 3. 2. 2. 8. 1. 2 Y T, A IRD 3. 2. 2. 8. 1. 2 Stay-Clear Volume and Dimensions Radiator positioned according to IRD Appendix A 8. 5. 8. 6. Stiffness Fixed-base first-mode > 50 Hz Provisions for Integration and Test During Obs T-Vac, TCS capable of full functionality “lying on its side” Document: LAT-PR-01967 55. 5 Hz Ok 11% Section 13 Mechanical Subsystem 28

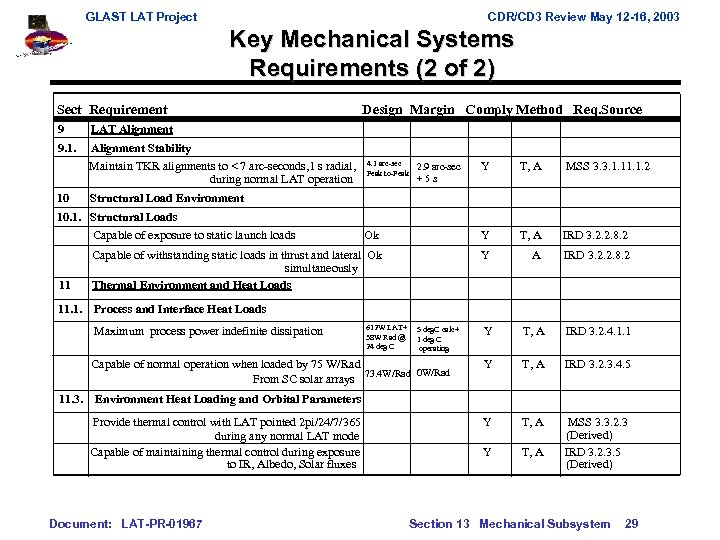

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Key Mechanical Systems Requirements (2 of 2) Sect Requirement 9 LAT Alignment 9. 1. Alignment Stability Maintain TKR alignments to < 7 arc-seconds, 1 s radial, during normal LAT operation Design Margin Comply Method Req. Source 4. 1 arc-sec Peak to-Peak Y T, A MSS 3. 3. 1. 1. 2 Ok Y T, A IRD 3. 2. 2. 8. 2 Y A IRD 3. 2. 2. 8. 2 11 Capable of withstanding static loads in thrust and lateral Ok simultaneously Thermal Environment and Heat Loads 11. 1. Process and Interface Heat Loads Y T, A IRD 3. 2. 4. 1. 1 Y T, A IRD 3. 2. 3. 4. 5 Y T, A MSS 3. 3. 2. 3 (Derived) IRD 3. 2. 3. 5 (Derived) 10 2. 9 arc-sec +5 s Structural Load Environment 10. 1. Structural Loads Capable of exposure to static launch loads Maximum process power indefinite dissipation 612 W LAT+ 38 W Rad @ 24 deg C 5 deg. C calc+ 1 deg C operating Capable of normal operation when loaded by 75 W/Rad 73. 4 W/Rad 0 W/Rad From SC solar arrays 11. 3. Environment Heat Loading and Orbital Parameters Provide thermal control with LAT pointed 2 pi/24/7/365 during any normal LAT mode Capable of maintaining thermal control during exposure to IR, Albedo, Solar fluxes Document: LAT-PR-01967 Section 13 Mechanical Subsystem 29

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Key Mechanical Systems Requirements (2 of 2) Sect Requirement 9 LAT Alignment 9. 1. Alignment Stability Maintain TKR alignments to < 7 arc-seconds, 1 s radial, during normal LAT operation Design Margin Comply Method Req. Source 4. 1 arc-sec Peak to-Peak Y T, A MSS 3. 3. 1. 1. 2 Ok Y T, A IRD 3. 2. 2. 8. 2 Y A IRD 3. 2. 2. 8. 2 11 Capable of withstanding static loads in thrust and lateral Ok simultaneously Thermal Environment and Heat Loads 11. 1. Process and Interface Heat Loads Y T, A IRD 3. 2. 4. 1. 1 Y T, A IRD 3. 2. 3. 4. 5 Y T, A MSS 3. 3. 2. 3 (Derived) IRD 3. 2. 3. 5 (Derived) 10 2. 9 arc-sec +5 s Structural Load Environment 10. 1. Structural Loads Capable of exposure to static launch loads Maximum process power indefinite dissipation 612 W LAT+ 38 W Rad @ 24 deg C 5 deg. C calc+ 1 deg C operating Capable of normal operation when loaded by 75 W/Rad 73. 4 W/Rad 0 W/Rad From SC solar arrays 11. 3. Environment Heat Loading and Orbital Parameters Provide thermal control with LAT pointed 2 pi/24/7/365 during any normal LAT mode Capable of maintaining thermal control during exposure to IR, Albedo, Solar fluxes Document: LAT-PR-01967 Section 13 Mechanical Subsystem 29

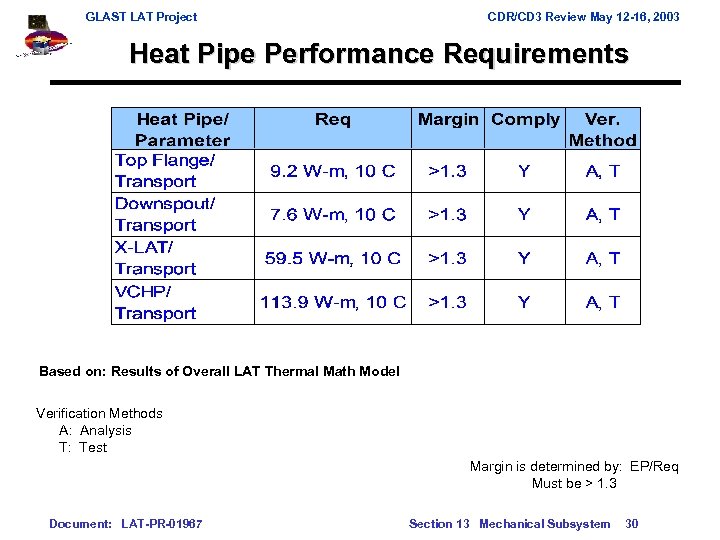

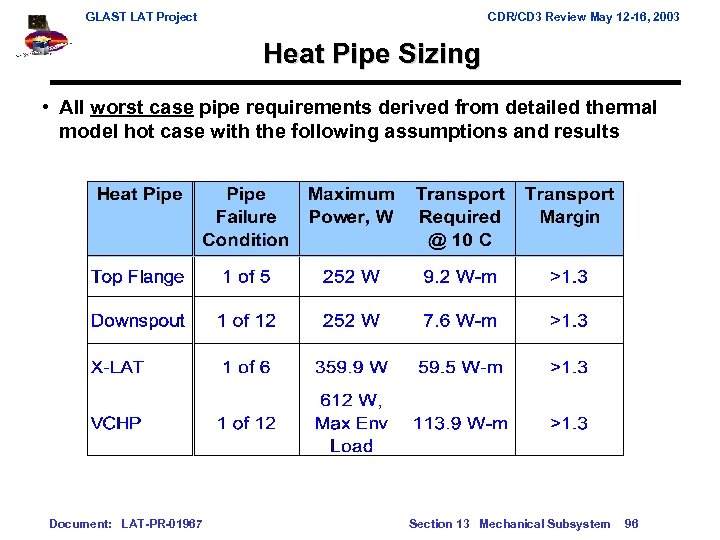

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Heat Pipe Performance Requirements Based on: Results of Overall LAT Thermal Math Model Verification Methods A: Analysis T: Test Margin is determined by: EP/Req Must be > 1. 3 Document: LAT-PR-01967 Section 13 Mechanical Subsystem 30

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Heat Pipe Performance Requirements Based on: Results of Overall LAT Thermal Math Model Verification Methods A: Analysis T: Test Margin is determined by: EP/Req Must be > 1. 3 Document: LAT-PR-01967 Section 13 Mechanical Subsystem 30

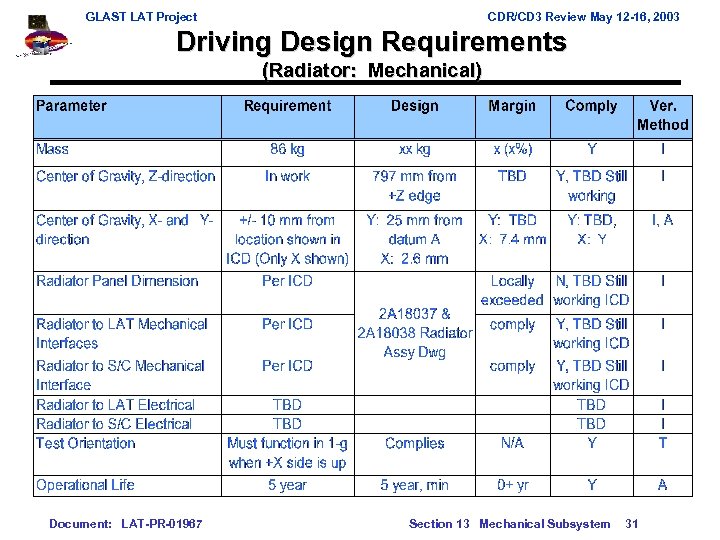

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Driving Design Requirements (Radiator: Mechanical) Document: LAT-PR-01967 Section 13 Mechanical Subsystem 31

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Driving Design Requirements (Radiator: Mechanical) Document: LAT-PR-01967 Section 13 Mechanical Subsystem 31

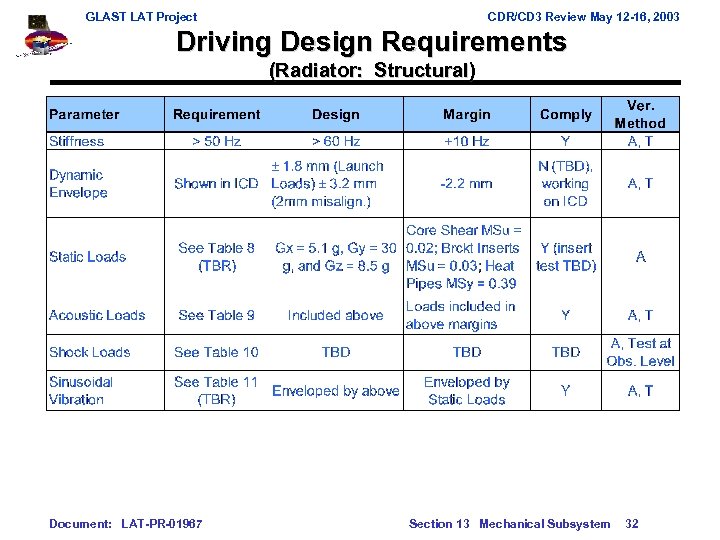

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Driving Design Requirements (Radiator: Structural) Document: LAT-PR-01967 Section 13 Mechanical Subsystem 32

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Driving Design Requirements (Radiator: Structural) Document: LAT-PR-01967 Section 13 Mechanical Subsystem 32

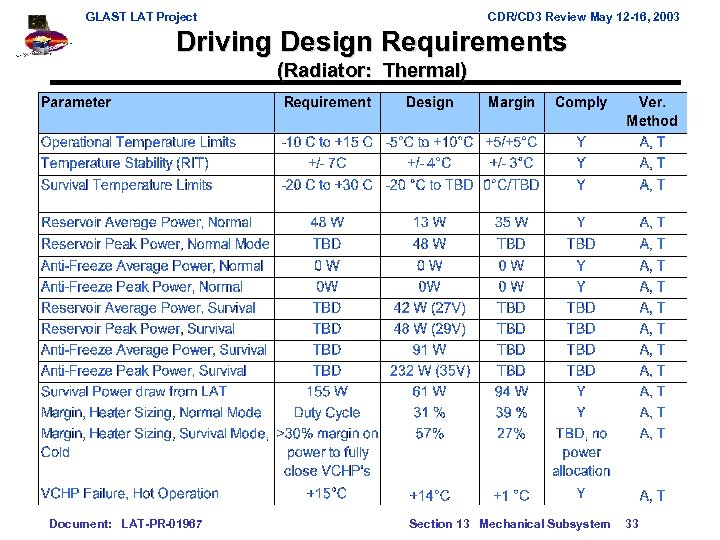

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Driving Design Requirements (Radiator: Thermal) Document: LAT-PR-01967 Section 13 Mechanical Subsystem 33

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Driving Design Requirements (Radiator: Thermal) Document: LAT-PR-01967 Section 13 Mechanical Subsystem 33

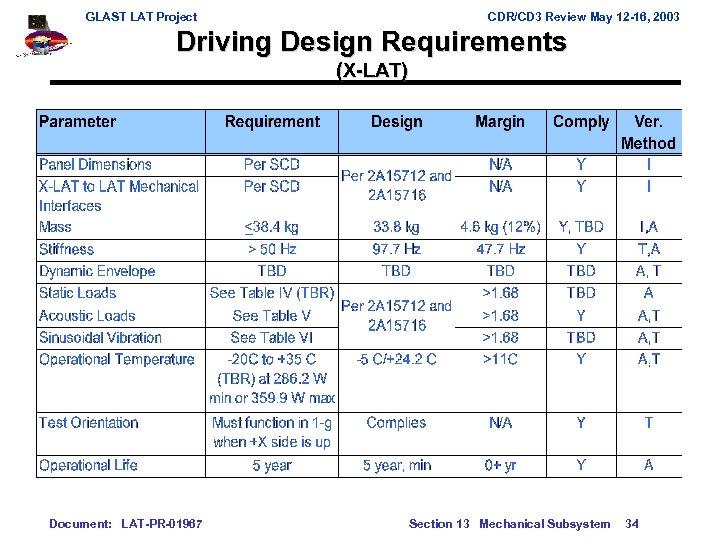

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Driving Design Requirements (X-LAT) Document: LAT-PR-01967 Section 13 Mechanical Subsystem 34

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Driving Design Requirements (X-LAT) Document: LAT-PR-01967 Section 13 Mechanical Subsystem 34

GLAST LAT Project Gamma-ray Large Area Space Telescope CDR/CD 3 Review May 12 -16, 2003 Design Grid Box Assembly Section 13. 3 Document: LAT-PR-01967 Section 13 Mechanical Subsystem 35

GLAST LAT Project Gamma-ray Large Area Space Telescope CDR/CD 3 Review May 12 -16, 2003 Design Grid Box Assembly Section 13. 3 Document: LAT-PR-01967 Section 13 Mechanical Subsystem 35

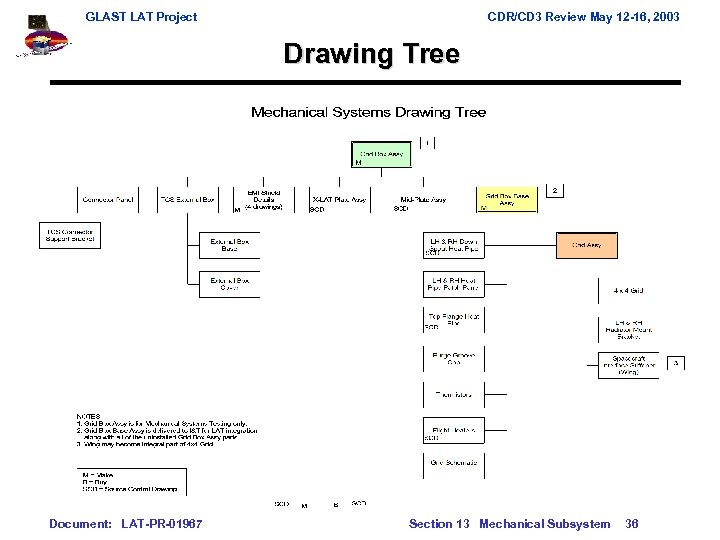

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Drawing Tree Document: LAT-PR-01967 Section 13 Mechanical Subsystem 36

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Drawing Tree Document: LAT-PR-01967 Section 13 Mechanical Subsystem 36

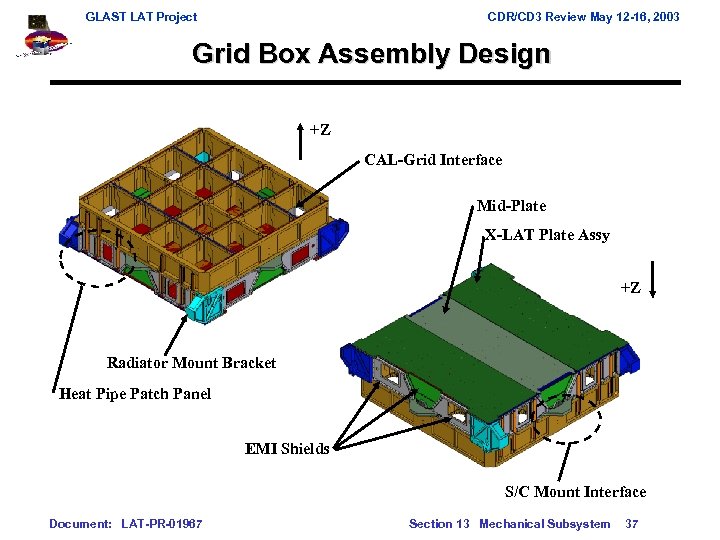

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Grid Box Assembly Design +Z CAL-Grid Interface Mid-Plate X-LAT Plate Assy +Z Radiator Mount Bracket Heat Pipe Patch Panel EMI Shields S/C Mount Interface Document: LAT-PR-01967 Section 13 Mechanical Subsystem 37

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Grid Box Assembly Design +Z CAL-Grid Interface Mid-Plate X-LAT Plate Assy +Z Radiator Mount Bracket Heat Pipe Patch Panel EMI Shields S/C Mount Interface Document: LAT-PR-01967 Section 13 Mechanical Subsystem 37

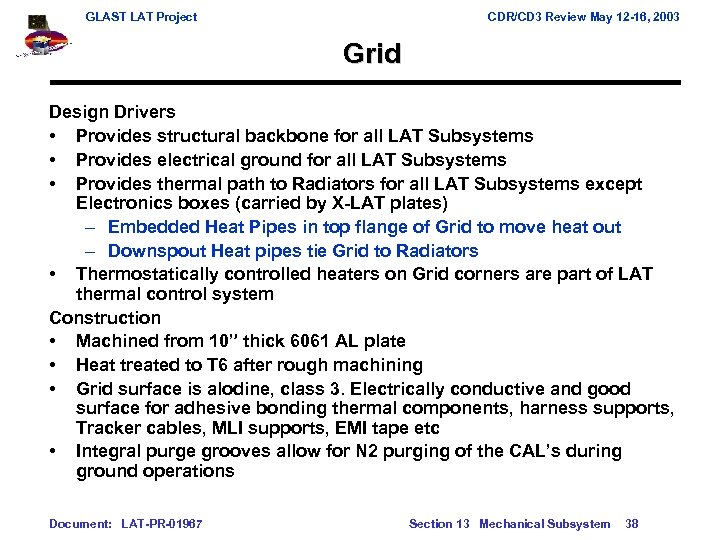

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Grid Design Drivers • Provides structural backbone for all LAT Subsystems • Provides electrical ground for all LAT Subsystems • Provides thermal path to Radiators for all LAT Subsystems except Electronics boxes (carried by X-LAT plates) – Embedded Heat Pipes in top flange of Grid to move heat out – Downspout Heat pipes tie Grid to Radiators • Thermostatically controlled heaters on Grid corners are part of LAT thermal control system Construction • Machined from 10” thick 6061 AL plate • Heat treated to T 6 after rough machining • Grid surface is alodine, class 3. Electrically conductive and good surface for adhesive bonding thermal components, harness supports, Tracker cables, MLI supports, EMI tape etc • Integral purge grooves allow for N 2 purging of the CAL’s during ground operations Document: LAT-PR-01967 Section 13 Mechanical Subsystem 38

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Grid Design Drivers • Provides structural backbone for all LAT Subsystems • Provides electrical ground for all LAT Subsystems • Provides thermal path to Radiators for all LAT Subsystems except Electronics boxes (carried by X-LAT plates) – Embedded Heat Pipes in top flange of Grid to move heat out – Downspout Heat pipes tie Grid to Radiators • Thermostatically controlled heaters on Grid corners are part of LAT thermal control system Construction • Machined from 10” thick 6061 AL plate • Heat treated to T 6 after rough machining • Grid surface is alodine, class 3. Electrically conductive and good surface for adhesive bonding thermal components, harness supports, Tracker cables, MLI supports, EMI tape etc • Integral purge grooves allow for N 2 purging of the CAL’s during ground operations Document: LAT-PR-01967 Section 13 Mechanical Subsystem 38

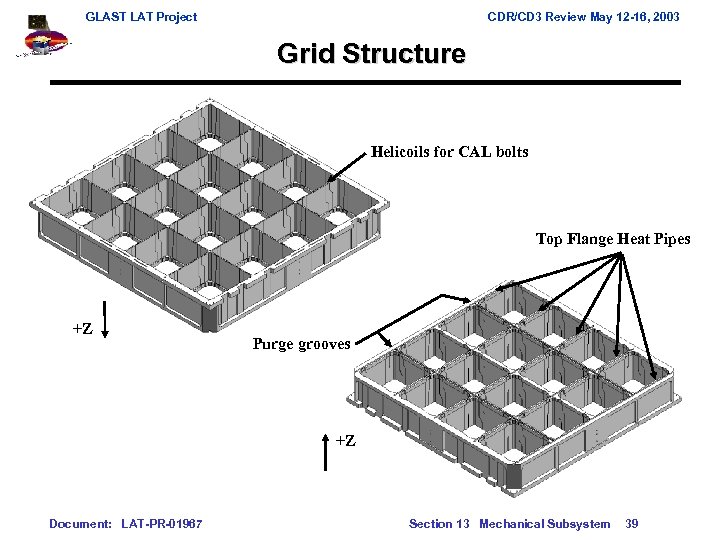

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Grid Structure Helicoils for CAL bolts Top Flange Heat Pipes +Z Purge grooves +Z Document: LAT-PR-01967 Section 13 Mechanical Subsystem 39

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Grid Structure Helicoils for CAL bolts Top Flange Heat Pipes +Z Purge grooves +Z Document: LAT-PR-01967 Section 13 Mechanical Subsystem 39

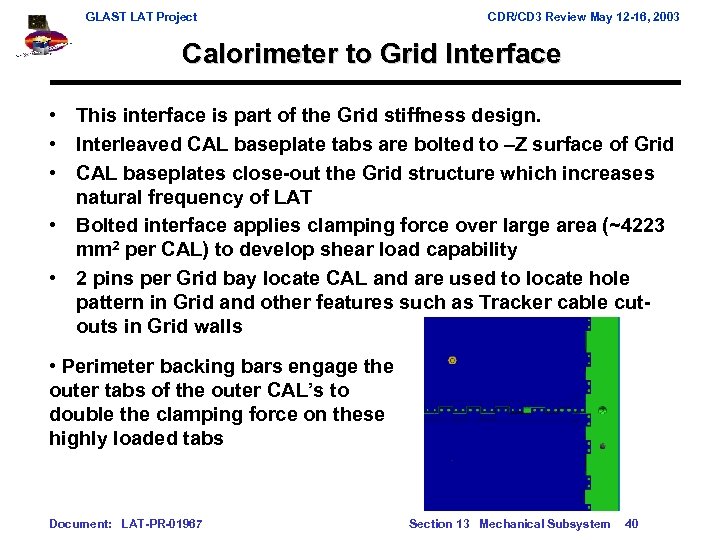

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Calorimeter to Grid Interface • This interface is part of the Grid stiffness design. • Interleaved CAL baseplate tabs are bolted to –Z surface of Grid • CAL baseplates close-out the Grid structure which increases natural frequency of LAT • Bolted interface applies clamping force over large area (~4223 mm 2 per CAL) to develop shear load capability • 2 pins per Grid bay locate CAL and are used to locate hole pattern in Grid and other features such as Tracker cable cutouts in Grid walls • Perimeter backing bars engage the outer tabs of the outer CAL’s to double the clamping force on these highly loaded tabs Document: LAT-PR-01967 Section 13 Mechanical Subsystem 40

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Calorimeter to Grid Interface • This interface is part of the Grid stiffness design. • Interleaved CAL baseplate tabs are bolted to –Z surface of Grid • CAL baseplates close-out the Grid structure which increases natural frequency of LAT • Bolted interface applies clamping force over large area (~4223 mm 2 per CAL) to develop shear load capability • 2 pins per Grid bay locate CAL and are used to locate hole pattern in Grid and other features such as Tracker cable cutouts in Grid walls • Perimeter backing bars engage the outer tabs of the outer CAL’s to double the clamping force on these highly loaded tabs Document: LAT-PR-01967 Section 13 Mechanical Subsystem 40

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 X-LAT Plate to E-Box Thermal Joint • Thermal joint design drivers – Carry thermal load of stack of E-Boxes into X-LAT Heat Pipes – Accommodate tolerance stack up E-Box and Grid Box parts – Be repeatable & reliable – Minimize schedule & verification impacts due to removal of X-LAT plates for access to Electronics • Vel-therm gasket material selected – Highly conductive graphite fibers – Mechanically compliant – Meets out-gassing requirement Document: LAT-PR-01967 Section 13 Mechanical Subsystem 41

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 X-LAT Plate to E-Box Thermal Joint • Thermal joint design drivers – Carry thermal load of stack of E-Boxes into X-LAT Heat Pipes – Accommodate tolerance stack up E-Box and Grid Box parts – Be repeatable & reliable – Minimize schedule & verification impacts due to removal of X-LAT plates for access to Electronics • Vel-therm gasket material selected – Highly conductive graphite fibers – Mechanically compliant – Meets out-gassing requirement Document: LAT-PR-01967 Section 13 Mechanical Subsystem 41

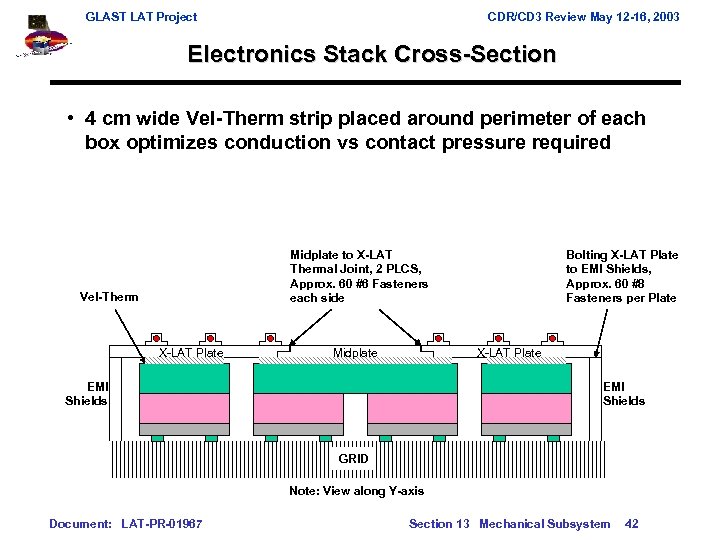

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Electronics Stack Cross-Section • 4 cm wide Vel-Therm strip placed around perimeter of each box optimizes conduction vs contact pressure required Midplate to X-LAT Thermal Joint, 2 PLCS, Approx. 60 #6 Fasteners each side Vel-Therm X-LAT Plate Midplate Bolting X-LAT Plate to EMI Shields, Approx. 60 #8 Fasteners per Plate X-LAT Plate EMI Shields GRID Note: View along Y-axis Document: LAT-PR-01967 Section 13 Mechanical Subsystem 42

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Electronics Stack Cross-Section • 4 cm wide Vel-Therm strip placed around perimeter of each box optimizes conduction vs contact pressure required Midplate to X-LAT Thermal Joint, 2 PLCS, Approx. 60 #6 Fasteners each side Vel-Therm X-LAT Plate Midplate Bolting X-LAT Plate to EMI Shields, Approx. 60 #8 Fasteners per Plate X-LAT Plate EMI Shields GRID Note: View along Y-axis Document: LAT-PR-01967 Section 13 Mechanical Subsystem 42

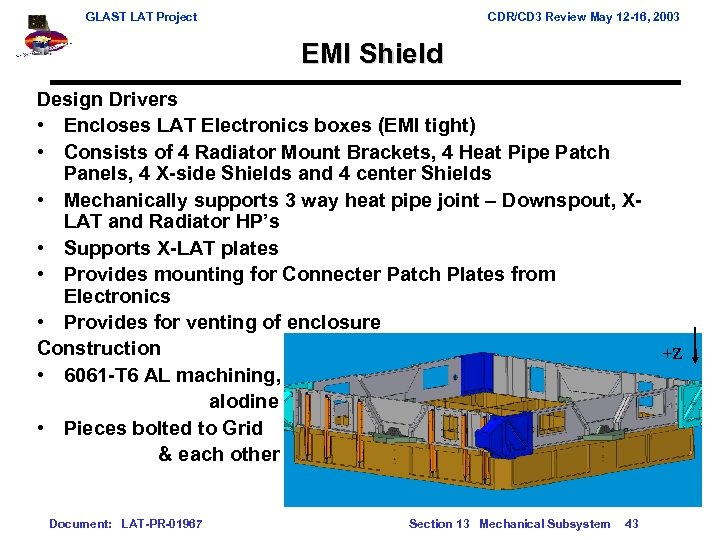

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 EMI Shield Design Drivers • Encloses LAT Electronics boxes (EMI tight) • Consists of 4 Radiator Mount Brackets, 4 Heat Pipe Patch Panels, 4 X-side Shields and 4 center Shields • Mechanically supports 3 way heat pipe joint – Downspout, XLAT and Radiator HP’s • Supports X-LAT plates • Provides mounting for Connecter Patch Plates from Electronics • Provides for venting of enclosure Construction • 6061 -T 6 AL machining, alodine • Pieces bolted to Grid & each other Document: LAT-PR-01967 Section 13 Mechanical Subsystem 43 +Z

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 EMI Shield Design Drivers • Encloses LAT Electronics boxes (EMI tight) • Consists of 4 Radiator Mount Brackets, 4 Heat Pipe Patch Panels, 4 X-side Shields and 4 center Shields • Mechanically supports 3 way heat pipe joint – Downspout, XLAT and Radiator HP’s • Supports X-LAT plates • Provides mounting for Connecter Patch Plates from Electronics • Provides for venting of enclosure Construction • 6061 -T 6 AL machining, alodine • Pieces bolted to Grid & each other Document: LAT-PR-01967 Section 13 Mechanical Subsystem 43 +Z

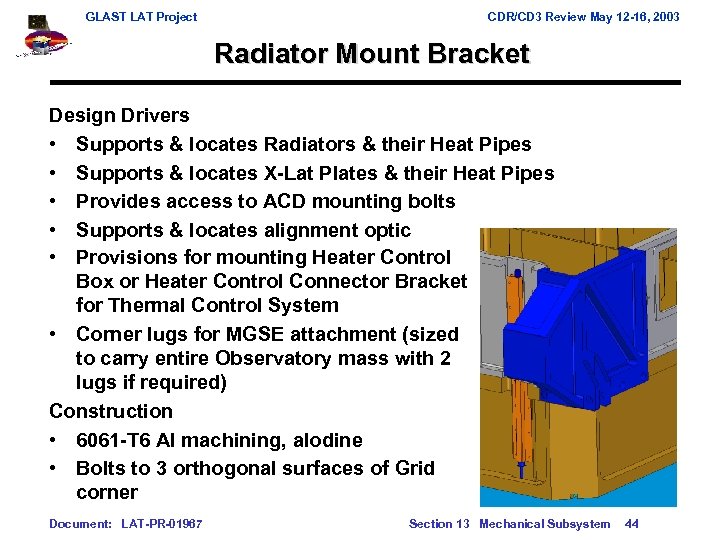

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Radiator Mount Bracket Design Drivers • Supports & locates Radiators & their Heat Pipes • Supports & locates X-Lat Plates & their Heat Pipes • Provides access to ACD mounting bolts • Supports & locates alignment optic • Provisions for mounting Heater Control Box or Heater Control Connector Bracket for Thermal Control System • Corner lugs for MGSE attachment (sized to carry entire Observatory mass with 2 lugs if required) Construction • 6061 -T 6 Al machining, alodine • Bolts to 3 orthogonal surfaces of Grid corner Document: LAT-PR-01967 Section 13 Mechanical Subsystem 44

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Radiator Mount Bracket Design Drivers • Supports & locates Radiators & their Heat Pipes • Supports & locates X-Lat Plates & their Heat Pipes • Provides access to ACD mounting bolts • Supports & locates alignment optic • Provisions for mounting Heater Control Box or Heater Control Connector Bracket for Thermal Control System • Corner lugs for MGSE attachment (sized to carry entire Observatory mass with 2 lugs if required) Construction • 6061 -T 6 Al machining, alodine • Bolts to 3 orthogonal surfaces of Grid corner Document: LAT-PR-01967 Section 13 Mechanical Subsystem 44

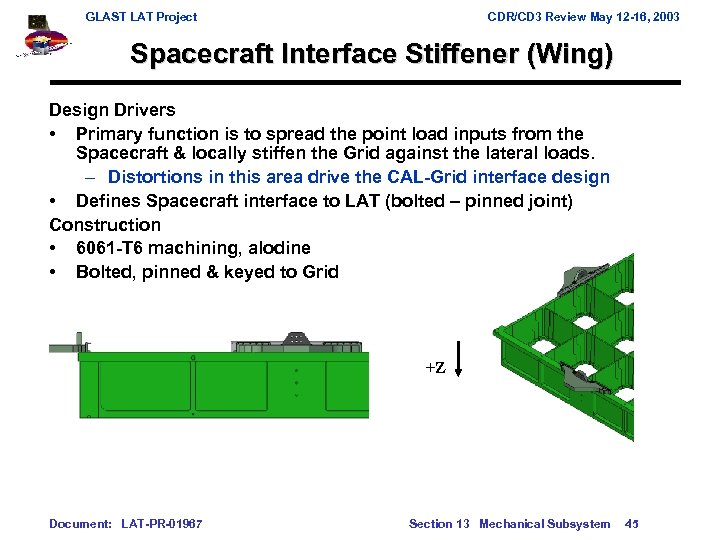

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Spacecraft Interface Stiffener (Wing) Design Drivers • Primary function is to spread the point load inputs from the Spacecraft & locally stiffen the Grid against the lateral loads. – Distortions in this area drive the CAL-Grid interface design • Defines Spacecraft interface to LAT (bolted – pinned joint) Construction • 6061 -T 6 machining, alodine • Bolted, pinned & keyed to Grid +Z Document: LAT-PR-01967 Section 13 Mechanical Subsystem 45

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Spacecraft Interface Stiffener (Wing) Design Drivers • Primary function is to spread the point load inputs from the Spacecraft & locally stiffen the Grid against the lateral loads. – Distortions in this area drive the CAL-Grid interface design • Defines Spacecraft interface to LAT (bolted – pinned joint) Construction • 6061 -T 6 machining, alodine • Bolted, pinned & keyed to Grid +Z Document: LAT-PR-01967 Section 13 Mechanical Subsystem 45

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Work to Close Out Structural Design • CAL-Grid interface under review with GSFC • Finalize design of perimeter backing plate • Investigating making the Spacecraft Interface (Wing) an integral part of the Grid • Finalizing details of Spacecraft mounting w/ Spectrum • Mass & stress optimization of EMI shields and Radiator mount brackets • Radiator mount bracket X axis compliance requirement for differential contraction of Radiators & Grid – Awaiting results of LM thermal analysis • Finalize design implementation of Vel-therm joint Document: LAT-PR-01967 Section 13 Mechanical Subsystem 46

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Work to Close Out Structural Design • CAL-Grid interface under review with GSFC • Finalize design of perimeter backing plate • Investigating making the Spacecraft Interface (Wing) an integral part of the Grid • Finalizing details of Spacecraft mounting w/ Spectrum • Mass & stress optimization of EMI shields and Radiator mount brackets • Radiator mount bracket X axis compliance requirement for differential contraction of Radiators & Grid – Awaiting results of LM thermal analysis • Finalize design implementation of Vel-therm joint Document: LAT-PR-01967 Section 13 Mechanical Subsystem 46

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Stress Analysis Topics • Cal-Grid interface load recovery • Grid Stress analysis • Radiator Mount Bracket analysis • Summary and Closure Plan Document: LAT-PR-01967 Section 13 Mechanical Subsystem 47

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Stress Analysis Topics • Cal-Grid interface load recovery • Grid Stress analysis • Radiator Mount Bracket analysis • Summary and Closure Plan Document: LAT-PR-01967 Section 13 Mechanical Subsystem 47

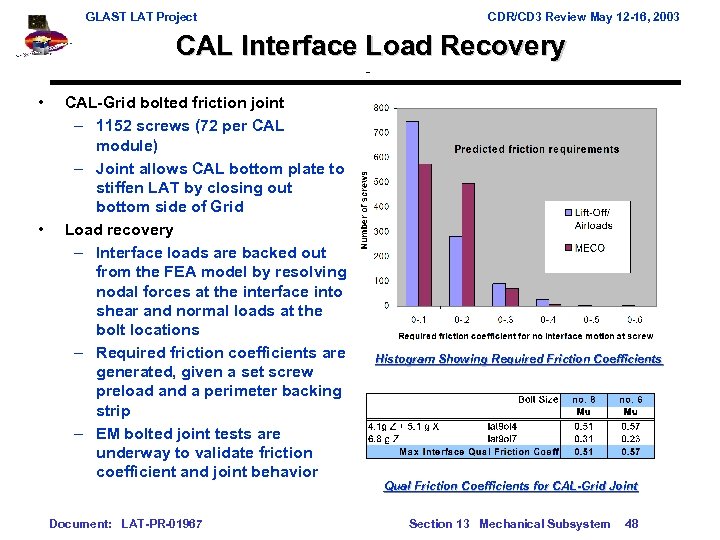

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 CAL Interface Load Recovery • • CAL-Grid bolted friction joint – 1152 screws (72 per CAL module) – Joint allows CAL bottom plate to stiffen LAT by closing out bottom side of Grid Load recovery – Interface loads are backed out from the FEA model by resolving nodal forces at the interface into shear and normal loads at the bolt locations – Required friction coefficients are generated, given a set screw preload and a perimeter backing strip – EM bolted joint tests are underway to validate friction coefficient and joint behavior Document: LAT-PR-01967 Histogram Showing Required Friction Coefficients Qual Friction Coefficients for CAL-Grid Joint Section 13 Mechanical Subsystem 48

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 CAL Interface Load Recovery • • CAL-Grid bolted friction joint – 1152 screws (72 per CAL module) – Joint allows CAL bottom plate to stiffen LAT by closing out bottom side of Grid Load recovery – Interface loads are backed out from the FEA model by resolving nodal forces at the interface into shear and normal loads at the bolt locations – Required friction coefficients are generated, given a set screw preload and a perimeter backing strip – EM bolted joint tests are underway to validate friction coefficient and joint behavior Document: LAT-PR-01967 Histogram Showing Required Friction Coefficients Qual Friction Coefficients for CAL-Grid Joint Section 13 Mechanical Subsystem 48

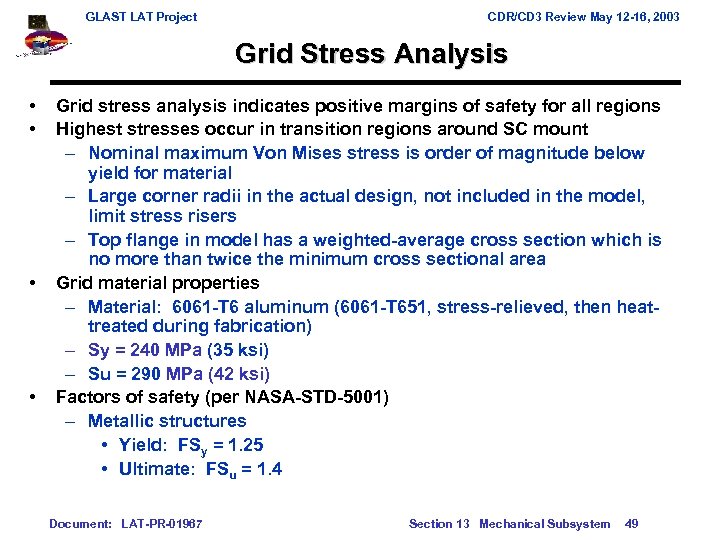

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Grid Stress Analysis • • Grid stress analysis indicates positive margins of safety for all regions Highest stresses occur in transition regions around SC mount – Nominal maximum Von Mises stress is order of magnitude below yield for material – Large corner radii in the actual design, not included in the model, limit stress risers – Top flange in model has a weighted-average cross section which is no more than twice the minimum cross sectional area Grid material properties – Material: 6061 -T 6 aluminum (6061 -T 651, stress-relieved, then heattreated during fabrication) – Sy = 240 MPa (35 ksi) – Su = 290 MPa (42 ksi) Factors of safety (per NASA-STD-5001) – Metallic structures • Yield: FSy = 1. 25 • Ultimate: FSu = 1. 4 Document: LAT-PR-01967 Section 13 Mechanical Subsystem 49

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Grid Stress Analysis • • Grid stress analysis indicates positive margins of safety for all regions Highest stresses occur in transition regions around SC mount – Nominal maximum Von Mises stress is order of magnitude below yield for material – Large corner radii in the actual design, not included in the model, limit stress risers – Top flange in model has a weighted-average cross section which is no more than twice the minimum cross sectional area Grid material properties – Material: 6061 -T 6 aluminum (6061 -T 651, stress-relieved, then heattreated during fabrication) – Sy = 240 MPa (35 ksi) – Su = 290 MPa (42 ksi) Factors of safety (per NASA-STD-5001) – Metallic structures • Yield: FSy = 1. 25 • Ultimate: FSu = 1. 4 Document: LAT-PR-01967 Section 13 Mechanical Subsystem 49

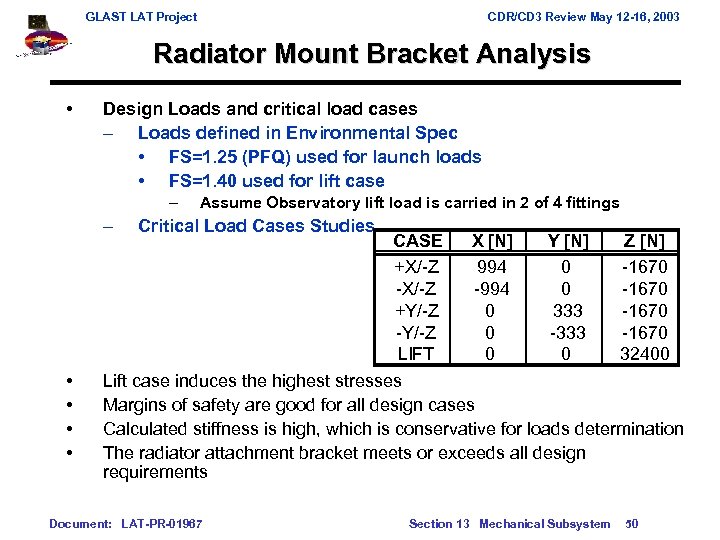

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Radiator Mount Bracket Analysis • Design Loads and critical load cases – Loads defined in Environmental Spec • FS=1. 25 (PFQ) used for launch loads • FS=1. 40 used for lift case – – • • Assume Observatory lift load is carried in 2 of 4 fittings Critical Load Cases Studies CASE +X/-Z -X/-Z +Y/-Z -Y/-Z LIFT X [N] 994 -994 0 0 0 Y [N] 0 0 333 -333 0 Z [N] -1670 32400 Lift case induces the highest stresses Margins of safety are good for all design cases Calculated stiffness is high, which is conservative for loads determination The radiator attachment bracket meets or exceeds all design requirements Document: LAT-PR-01967 Section 13 Mechanical Subsystem 50

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Radiator Mount Bracket Analysis • Design Loads and critical load cases – Loads defined in Environmental Spec • FS=1. 25 (PFQ) used for launch loads • FS=1. 40 used for lift case – – • • Assume Observatory lift load is carried in 2 of 4 fittings Critical Load Cases Studies CASE +X/-Z -X/-Z +Y/-Z -Y/-Z LIFT X [N] 994 -994 0 0 0 Y [N] 0 0 333 -333 0 Z [N] -1670 32400 Lift case induces the highest stresses Margins of safety are good for all design cases Calculated stiffness is high, which is conservative for loads determination The radiator attachment bracket meets or exceeds all design requirements Document: LAT-PR-01967 Section 13 Mechanical Subsystem 50

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Summary and Closure Plan • Summary – Integrated LAT structural analysis results of the staticequivalent load cases indicate that LAT deflections and stresses are within required limits – Grid stress analysis shows that the Grid design is not highly-stressed, but driven more by the natural frequency requirement • Tasks Remaining – Finalize design of the SC mount region with the SC contractor and complete stress analysis – Complete stress analysis on EMI skirt pieces Document: LAT-PR-01967 Section 13 Mechanical Subsystem 51

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Summary and Closure Plan • Summary – Integrated LAT structural analysis results of the staticequivalent load cases indicate that LAT deflections and stresses are within required limits – Grid stress analysis shows that the Grid design is not highly-stressed, but driven more by the natural frequency requirement • Tasks Remaining – Finalize design of the SC mount region with the SC contractor and complete stress analysis – Complete stress analysis on EMI skirt pieces Document: LAT-PR-01967 Section 13 Mechanical Subsystem 51

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Grid/Grid Box Assembly Verification Topics • 4 x 4 Grid Verification • Grid Box Assembly Verification Document: LAT-PR-01967 Section 13 Mechanical Subsystem 52

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Grid/Grid Box Assembly Verification Topics • 4 x 4 Grid Verification • Grid Box Assembly Verification Document: LAT-PR-01967 Section 13 Mechanical Subsystem 52

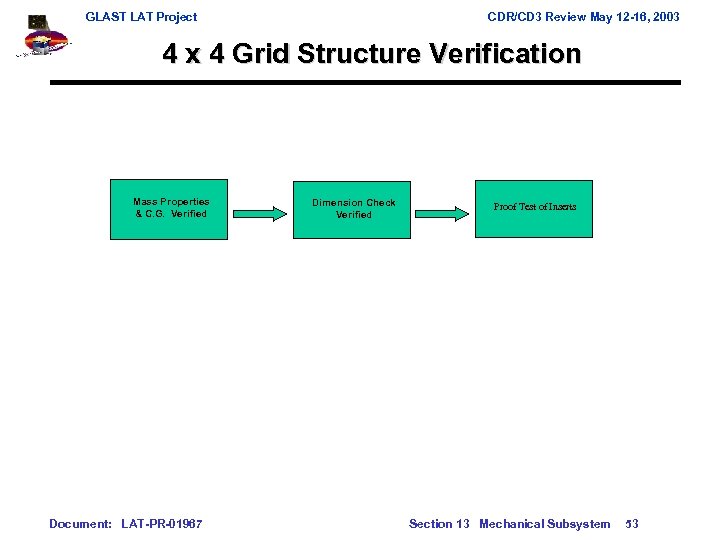

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 4 x 4 Grid Structure Verification Mass Properties & C. G. Verified Document: LAT-PR-01967 Dimension Check Verified Proof Test of Inserts Section 13 Mechanical Subsystem 53

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 4 x 4 Grid Structure Verification Mass Properties & C. G. Verified Document: LAT-PR-01967 Dimension Check Verified Proof Test of Inserts Section 13 Mechanical Subsystem 53

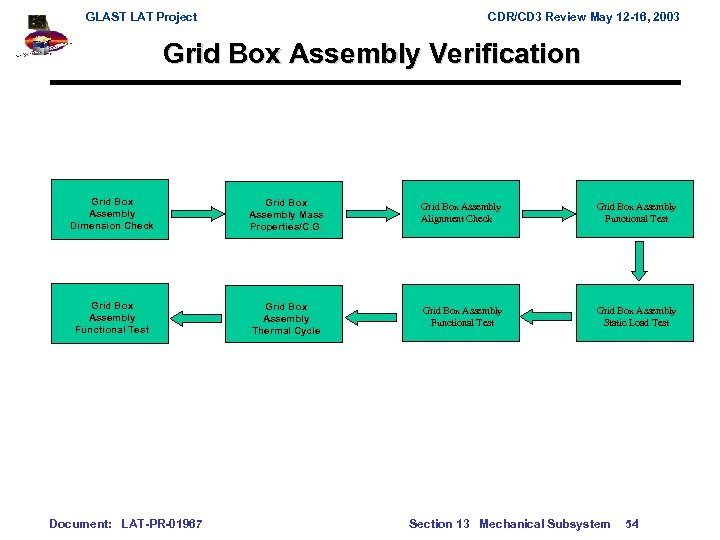

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Grid Box Assembly Verification Grid Box Assembly Dimension Check Grid Box Assembly Mass Properties/C. G. Grid Box Assembly Alignment Check Grid Box Assembly Functional Test Grid Box Assembly Thermal Cycle Grid Box Assembly Functional Test Grid Box Assembly Static Load Test Document: LAT-PR-01967 Section 13 Mechanical Subsystem 54

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Grid Box Assembly Verification Grid Box Assembly Dimension Check Grid Box Assembly Mass Properties/C. G. Grid Box Assembly Alignment Check Grid Box Assembly Functional Test Grid Box Assembly Thermal Cycle Grid Box Assembly Functional Test Grid Box Assembly Static Load Test Document: LAT-PR-01967 Section 13 Mechanical Subsystem 54

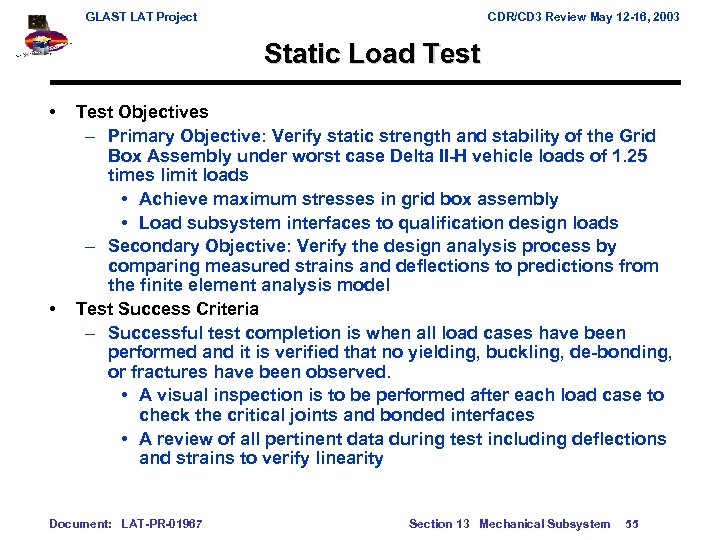

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Static Load Test • • Test Objectives – Primary Objective: Verify static strength and stability of the Grid Box Assembly under worst case Delta II-H vehicle loads of 1. 25 times limit loads • Achieve maximum stresses in grid box assembly • Load subsystem interfaces to qualification design loads – Secondary Objective: Verify the design analysis process by comparing measured strains and deflections to predictions from the finite element analysis model Test Success Criteria – Successful test completion is when all load cases have been performed and it is verified that no yielding, buckling, de-bonding, or fractures have been observed. • A visual inspection is to be performed after each load case to check the critical joints and bonded interfaces • A review of all pertinent data during test including deflections and strains to verify linearity Document: LAT-PR-01967 Section 13 Mechanical Subsystem 55

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Static Load Test • • Test Objectives – Primary Objective: Verify static strength and stability of the Grid Box Assembly under worst case Delta II-H vehicle loads of 1. 25 times limit loads • Achieve maximum stresses in grid box assembly • Load subsystem interfaces to qualification design loads – Secondary Objective: Verify the design analysis process by comparing measured strains and deflections to predictions from the finite element analysis model Test Success Criteria – Successful test completion is when all load cases have been performed and it is verified that no yielding, buckling, de-bonding, or fractures have been observed. • A visual inspection is to be performed after each load case to check the critical joints and bonded interfaces • A review of all pertinent data during test including deflections and strains to verify linearity Document: LAT-PR-01967 Section 13 Mechanical Subsystem 55

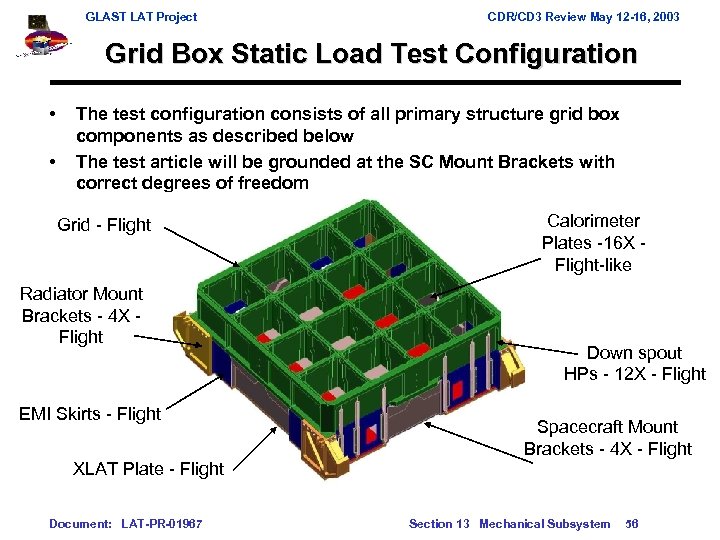

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Grid Box Static Load Test Configuration • • The test configuration consists of all primary structure grid box components as described below The test article will be grounded at the SC Mount Brackets with correct degrees of freedom Grid - Flight Radiator Mount Brackets - 4 X Flight EMI Skirts - Flight Calorimeter Plates -16 X Flight-like Down spout HPs - 12 X - Flight Spacecraft Mount Brackets - 4 X - Flight XLAT Plate - Flight Document: LAT-PR-01967 Section 13 Mechanical Subsystem 56

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Grid Box Static Load Test Configuration • • The test configuration consists of all primary structure grid box components as described below The test article will be grounded at the SC Mount Brackets with correct degrees of freedom Grid - Flight Radiator Mount Brackets - 4 X Flight EMI Skirts - Flight Calorimeter Plates -16 X Flight-like Down spout HPs - 12 X - Flight Spacecraft Mount Brackets - 4 X - Flight XLAT Plate - Flight Document: LAT-PR-01967 Section 13 Mechanical Subsystem 56

GLAST LAT Project Gamma-ray Large Area Space Telescope CDR/CD 3 Review May 12 -16, 2003 Verification Program Grid Box Assembly Section 13. 4 Document: LAT-PR-01967 Section 13 Mechanical Subsystem 57

GLAST LAT Project Gamma-ray Large Area Space Telescope CDR/CD 3 Review May 12 -16, 2003 Verification Program Grid Box Assembly Section 13. 4 Document: LAT-PR-01967 Section 13 Mechanical Subsystem 57

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Verification Topics • EM Test Plan Overview • EM Closure Plan Summary • Qualification & Flight Test Overview • Mechanical Systems Verification Test Flow • Mechanical Systems Verification Matrix • Heat Pipe Qualification/Acceptance Document: LAT-PR-01967 Section 13 Mechanical Subsystem 58

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Verification Topics • EM Test Plan Overview • EM Closure Plan Summary • Qualification & Flight Test Overview • Mechanical Systems Verification Test Flow • Mechanical Systems Verification Matrix • Heat Pipe Qualification/Acceptance Document: LAT-PR-01967 Section 13 Mechanical Subsystem 58

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 EM Test Plans Overview • EM test plans developed for: – CAL-Grid Joint Testing • Friction characterization • Bolt-Helicoil pair characterization • Pull tab coupons – 1 x 4 Grid – Grid heat pipe bonding process qualification – Joint candidates • “Wet” adhesive or gasket • Low contact pressure • No contact pressure – X-LAT heat pipe characterization Document: LAT-PR-01967 Section 13 Mechanical Subsystem 59

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 EM Test Plans Overview • EM test plans developed for: – CAL-Grid Joint Testing • Friction characterization • Bolt-Helicoil pair characterization • Pull tab coupons – 1 x 4 Grid – Grid heat pipe bonding process qualification – Joint candidates • “Wet” adhesive or gasket • Low contact pressure • No contact pressure – X-LAT heat pipe characterization Document: LAT-PR-01967 Section 13 Mechanical Subsystem 59

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 CAL-Grid Joint Testing • CAL-Grid joint is a friction joint between the CAL baseplate tabs and the Grid walls. – 70 fasteners around the perimeter of the CAL • 54 #8 , 16 #6 fasteners and 2 -. 156” dia alignment pins – Helicoils used in Grid walls • To maximize the load carrying capability of the joint – Maximize bolt clamping force – Maximize friction at interface • Tests performed – Friction Characterization – Bolt – Helicoil pair characterization tests – Pull Tab Coupons Document: LAT-PR-01967 Section 13 Mechanical Subsystem 60

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 CAL-Grid Joint Testing • CAL-Grid joint is a friction joint between the CAL baseplate tabs and the Grid walls. – 70 fasteners around the perimeter of the CAL • 54 #8 , 16 #6 fasteners and 2 -. 156” dia alignment pins – Helicoils used in Grid walls • To maximize the load carrying capability of the joint – Maximize bolt clamping force – Maximize friction at interface • Tests performed – Friction Characterization – Bolt – Helicoil pair characterization tests – Pull Tab Coupons Document: LAT-PR-01967 Section 13 Mechanical Subsystem 60

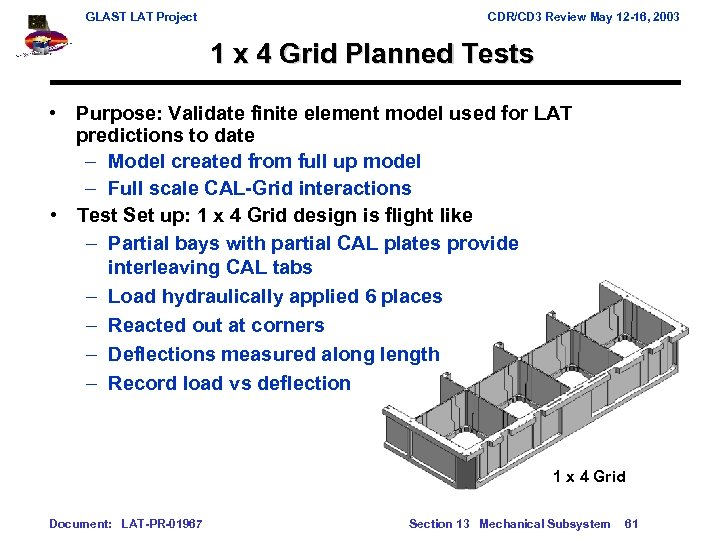

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 1 x 4 Grid Planned Tests • Purpose: Validate finite element model used for LAT predictions to date – Model created from full up model – Full scale CAL-Grid interactions • Test Set up: 1 x 4 Grid design is flight like – Partial bays with partial CAL plates provide interleaving CAL tabs – Load hydraulically applied 6 places – Reacted out at corners – Deflections measured along length – Record load vs deflection 1 x 4 Grid Document: LAT-PR-01967 Section 13 Mechanical Subsystem 61

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 1 x 4 Grid Planned Tests • Purpose: Validate finite element model used for LAT predictions to date – Model created from full up model – Full scale CAL-Grid interactions • Test Set up: 1 x 4 Grid design is flight like – Partial bays with partial CAL plates provide interleaving CAL tabs – Load hydraulically applied 6 places – Reacted out at corners – Deflections measured along length – Record load vs deflection 1 x 4 Grid Document: LAT-PR-01967 Section 13 Mechanical Subsystem 61

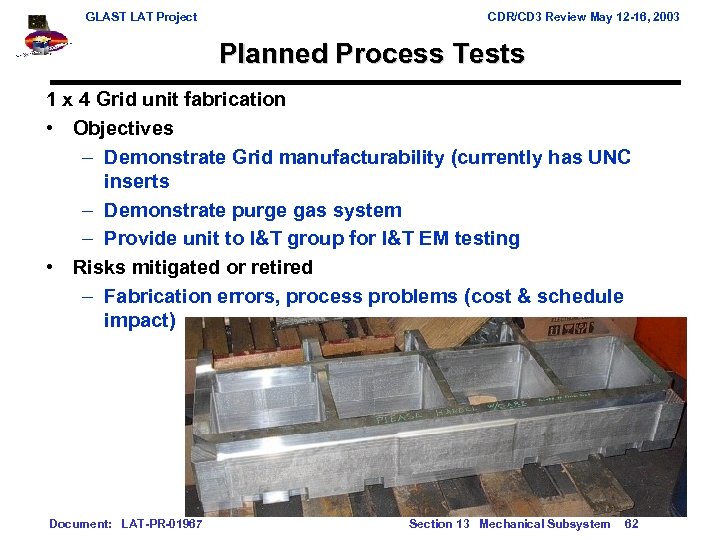

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Planned Process Tests 1 x 4 Grid unit fabrication • Objectives – Demonstrate Grid manufacturability (currently has UNC inserts – Demonstrate purge gas system – Provide unit to I&T group for I&T EM testing • Risks mitigated or retired – Fabrication errors, process problems (cost & schedule impact) Document: LAT-PR-01967 Section 13 Mechanical Subsystem 62

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Planned Process Tests 1 x 4 Grid unit fabrication • Objectives – Demonstrate Grid manufacturability (currently has UNC inserts – Demonstrate purge gas system – Provide unit to I&T group for I&T EM testing • Risks mitigated or retired – Fabrication errors, process problems (cost & schedule impact) Document: LAT-PR-01967 Section 13 Mechanical Subsystem 62

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 3 -Way Heatpipe Thermal Joint Conductance Test 3 -Way heatpipe thermal joint conductance test • Objectives – Determine thermal joint that can meet conductance and ease of assembly requirement – Develop design-specific empirical conductance values for actual bolted joint configuration • Risks mitigated – Validates thermal model based on empirical thermal conduction values Document: LAT-PR-01967 Section 13 Mechanical Subsystem 63

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 3 -Way Heatpipe Thermal Joint Conductance Test 3 -Way heatpipe thermal joint conductance test • Objectives – Determine thermal joint that can meet conductance and ease of assembly requirement – Develop design-specific empirical conductance values for actual bolted joint configuration • Risks mitigated – Validates thermal model based on empirical thermal conduction values Document: LAT-PR-01967 Section 13 Mechanical Subsystem 63

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Thermal Joint Further Work • Demonstrate Radiator installation process – 6 wet RTV joints in vertical orientation – Complete within pot life limits (bonded & torqued) – Verify bond line integrity (uniform thickness & % voids) • Demonstrate Radiator removal process – Separate 6 joints with limited access – No damage or distortions of heat pipes – Verify material can be cleaned up & surface prepared again for another bond Document: LAT-PR-01967 Section 13 Mechanical Subsystem 64

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Thermal Joint Further Work • Demonstrate Radiator installation process – 6 wet RTV joints in vertical orientation – Complete within pot life limits (bonded & torqued) – Verify bond line integrity (uniform thickness & % voids) • Demonstrate Radiator removal process – Separate 6 joints with limited access – No damage or distortions of heat pipes – Verify material can be cleaned up & surface prepared again for another bond Document: LAT-PR-01967 Section 13 Mechanical Subsystem 64

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Joint Candidates Tested • “Wet” adhesive or gasket joints – Thermally conductive silicone adhesive, Nusil CV 2946 – Sil. Pad, VO Gap Pad • Low contact pressure joints – Off-the-shelf EMI gasket products, i. e. Be. Cu spring fingers, electrically conductive elastomers – Graphite velvet pad (Vel-Therm from ESLI) • No contact pressure joints – High conductivity materials mechanically fastened at both ends – Formed Copper sheets (30 mils) – Pyrolytic Graphite Sheet (4 mils thick stock) Document: LAT-PR-01967 Section 13 Mechanical Subsystem 65

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Joint Candidates Tested • “Wet” adhesive or gasket joints – Thermally conductive silicone adhesive, Nusil CV 2946 – Sil. Pad, VO Gap Pad • Low contact pressure joints – Off-the-shelf EMI gasket products, i. e. Be. Cu spring fingers, electrically conductive elastomers – Graphite velvet pad (Vel-Therm from ESLI) • No contact pressure joints – High conductivity materials mechanically fastened at both ends – Formed Copper sheets (30 mils) – Pyrolytic Graphite Sheet (4 mils thick stock) Document: LAT-PR-01967 Section 13 Mechanical Subsystem 65

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Thermal Joints EM Evaluation Summary • Vel-Therm material is best candidate among those evaluated to meet all design drivers – Thermal data indicate material can meet required conductance – Material is bonded to one surface prior to installing X-LAT plate, minimal fasteners required – Allow sliding contact for lateral flexibility – Can bridge varying gaps from stack to stack with different stock thicknesses up to. 125 inch thick max for single layer – Two Vel-Therms can be meshed together face-to-face for larger gaps up to. 24 inch max Document: LAT-PR-01967 Section 13 Mechanical Subsystem 66

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Thermal Joints EM Evaluation Summary • Vel-Therm material is best candidate among those evaluated to meet all design drivers – Thermal data indicate material can meet required conductance – Material is bonded to one surface prior to installing X-LAT plate, minimal fasteners required – Allow sliding contact for lateral flexibility – Can bridge varying gaps from stack to stack with different stock thicknesses up to. 125 inch thick max for single layer – Two Vel-Therms can be meshed together face-to-face for larger gaps up to. 24 inch max Document: LAT-PR-01967 Section 13 Mechanical Subsystem 66

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Further Work • Integrated thermal analysis (including boxes stackup, heat paths and X-LAT thermal joint) to identify and alleviate “hot” spots (Electronics) • Final detail design of EMI Shields, X-LAT Plate, Special Electronics box bottoms to accommodate Vel-Therm joint design – stack height • Additional EM testing needed to retire risks – Conductance in high vacuum for dry tip contact – Sliding verification without generating loose fibers – Quantify contact pressure versus brush compression Document: LAT-PR-01967 Section 13 Mechanical Subsystem 67

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Further Work • Integrated thermal analysis (including boxes stackup, heat paths and X-LAT thermal joint) to identify and alleviate “hot” spots (Electronics) • Final detail design of EMI Shields, X-LAT Plate, Special Electronics box bottoms to accommodate Vel-Therm joint design – stack height • Additional EM testing needed to retire risks – Conductance in high vacuum for dry tip contact – Sliding verification without generating loose fibers – Quantify contact pressure versus brush compression Document: LAT-PR-01967 Section 13 Mechanical Subsystem 67

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Further Work (cont. ) • Proposed additional EM thermal joint test configuration for Vel -Therm material – Mock up box stackup configuration with heaters on sidewalls to simulate electronics heat source – Install cold plate and Vel-Therm sheet to simulate X-LAT and thermal joint – Flight like installation procedure for Vel-Therm to identify process problems and errors – Perform Random Vibe and Thermal Vacuum tests to retire risks associated with contamination, thermal conductance at min & max fiber compression levels Document: LAT-PR-01967 Section 13 Mechanical Subsystem 68

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Further Work (cont. ) • Proposed additional EM thermal joint test configuration for Vel -Therm material – Mock up box stackup configuration with heaters on sidewalls to simulate electronics heat source – Install cold plate and Vel-Therm sheet to simulate X-LAT and thermal joint – Flight like installation procedure for Vel-Therm to identify process problems and errors – Perform Random Vibe and Thermal Vacuum tests to retire risks associated with contamination, thermal conductance at min & max fiber compression levels Document: LAT-PR-01967 Section 13 Mechanical Subsystem 68

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 X-LAT EM Heat Pipe Characterization Tests • Objectives – Verify thermal performance of EM X-LAT heat pipe in simulated on-orbit thermal cases • Risks mitigated – Demonstrate adequate design margins – Assure that heat pipe performs as predicted Document: LAT-PR-01967 Section 13 Mechanical Subsystem 69

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 X-LAT EM Heat Pipe Characterization Tests • Objectives – Verify thermal performance of EM X-LAT heat pipe in simulated on-orbit thermal cases • Risks mitigated – Demonstrate adequate design margins – Assure that heat pipe performs as predicted Document: LAT-PR-01967 Section 13 Mechanical Subsystem 69

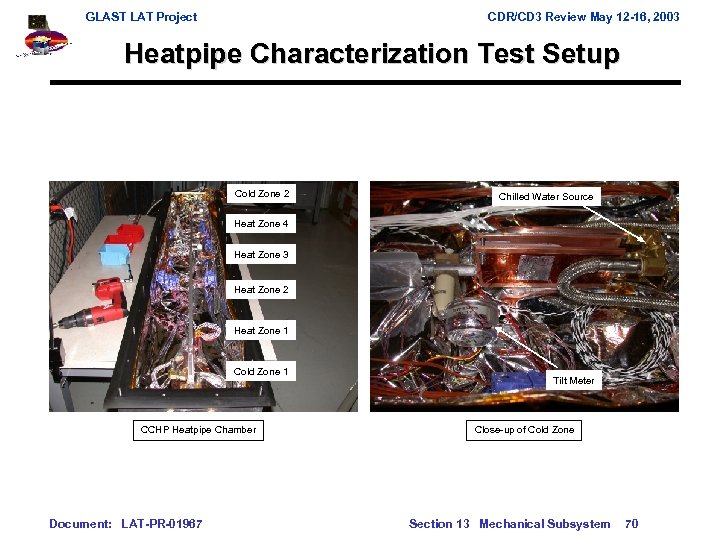

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Heatpipe Characterization Test Setup Cold Zone 2 Chilled Water Source Heat Zone 4 Heat Zone 3 Heat Zone 2 Heat Zone 1 Cold Zone 1 CCHP Heatpipe Chamber Document: LAT-PR-01967 Tilt Meter Close-up of Cold Zone Section 13 Mechanical Subsystem 70

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Heatpipe Characterization Test Setup Cold Zone 2 Chilled Water Source Heat Zone 4 Heat Zone 3 Heat Zone 2 Heat Zone 1 Cold Zone 1 CCHP Heatpipe Chamber Document: LAT-PR-01967 Tilt Meter Close-up of Cold Zone Section 13 Mechanical Subsystem 70

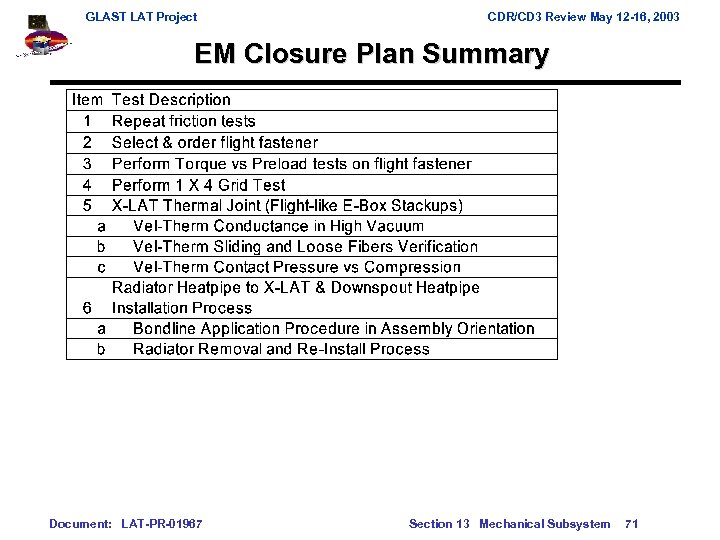

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 EM Closure Plan Summary Document: LAT-PR-01967 Section 13 Mechanical Subsystem 71

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 EM Closure Plan Summary Document: LAT-PR-01967 Section 13 Mechanical Subsystem 71

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Qualification & Flight Test Overview The intent of the Mechanical Subsystem verification plan is to ensure that the component, assembly and subsystem hardware: - Verify workmanship and performance of hardware per Level III and IV subsystem specification - Provides traceability back to requirements in the Level III and IV subsystem specifications - Satisfies LAT Performance Specification (LAT-SS-00010) - Compatible with other LAT subsystem’s interfaces Document: LAT-PR-01967 Section 13 Mechanical Subsystem 72

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Qualification & Flight Test Overview The intent of the Mechanical Subsystem verification plan is to ensure that the component, assembly and subsystem hardware: - Verify workmanship and performance of hardware per Level III and IV subsystem specification - Provides traceability back to requirements in the Level III and IV subsystem specifications - Satisfies LAT Performance Specification (LAT-SS-00010) - Compatible with other LAT subsystem’s interfaces Document: LAT-PR-01967 Section 13 Mechanical Subsystem 72

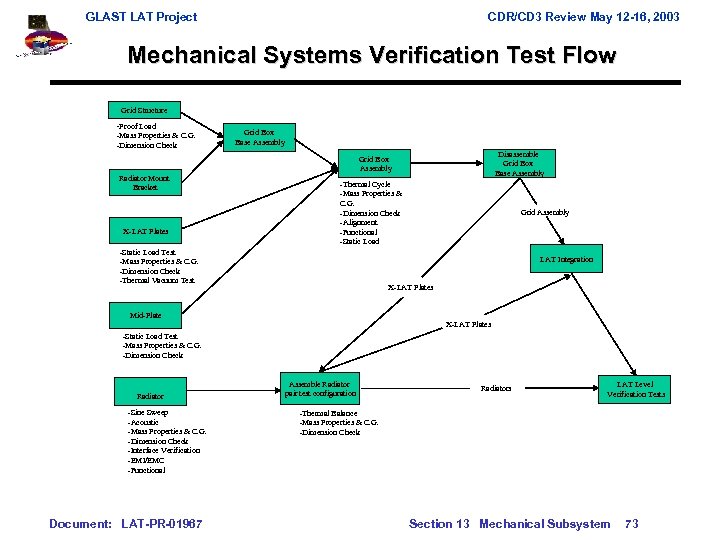

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Mechanical Systems Verification Test Flow Grid Structure -Proof Load -Mass Properties & C. G. -Dimension Check Radiator Mount Bracket X-LAT Plates Grid Box Base Assembly Disassemble Grid Box Base Assembly Grid Box Assembly -Static Load -Thermal Cycle -Mass Properties & C. G. -Dimension Check -Alignment -Functional -Static Load Test -Mass Properties & C. G. -Dimension Check -Thermal Vacuum Test Grid Assembly LAT Integration X-LAT Plates Mid-Plate X-LAT Plates -Static Load Test -Mass Properties & C. G. -Dimension Check Radiator -Sine Sweep -Acoustic -Mass Properties & C. G. -Dimension Check -Interface Verification -EMI/EMC -Functional Document: LAT-PR-01967 Assemble Radiator pair test configuration Radiators LAT Level Verification Tests -Thermal Balance -Mass Properties & C. G. -Dimension Check Section 13 Mechanical Subsystem 73

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Mechanical Systems Verification Test Flow Grid Structure -Proof Load -Mass Properties & C. G. -Dimension Check Radiator Mount Bracket X-LAT Plates Grid Box Base Assembly Disassemble Grid Box Base Assembly Grid Box Assembly -Static Load -Thermal Cycle -Mass Properties & C. G. -Dimension Check -Alignment -Functional -Static Load Test -Mass Properties & C. G. -Dimension Check -Thermal Vacuum Test Grid Assembly LAT Integration X-LAT Plates Mid-Plate X-LAT Plates -Static Load Test -Mass Properties & C. G. -Dimension Check Radiator -Sine Sweep -Acoustic -Mass Properties & C. G. -Dimension Check -Interface Verification -EMI/EMC -Functional Document: LAT-PR-01967 Assemble Radiator pair test configuration Radiators LAT Level Verification Tests -Thermal Balance -Mass Properties & C. G. -Dimension Check Section 13 Mechanical Subsystem 73

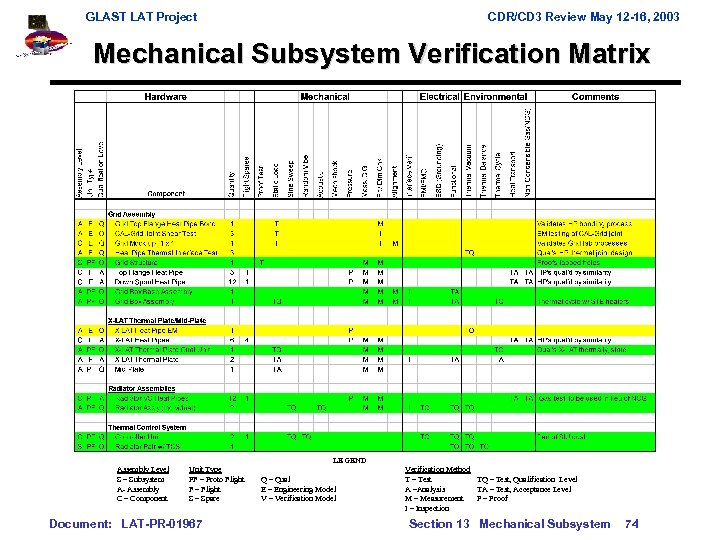

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Mechanical Subsystem Verification Matrix LEGEND Assembly Level S – Subsystem A- Assembly C – Component Unit Type PF – Proto Flight F – Flight S – Spare Document: LAT-PR-01967 Q – Qual E – Engineering Model V – Verification Model Verification Method T – Test TQ – Test, Qualification Level A –Analysis TA – Test, Acceptance Level M – Measurement P – Proof I – Inspection Section 13 Mechanical Subsystem 74

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Mechanical Subsystem Verification Matrix LEGEND Assembly Level S – Subsystem A- Assembly C – Component Unit Type PF – Proto Flight F – Flight S – Spare Document: LAT-PR-01967 Q – Qual E – Engineering Model V – Verification Model Verification Method T – Test TQ – Test, Qualification Level A –Analysis TA – Test, Acceptance Level M – Measurement P – Proof I – Inspection Section 13 Mechanical Subsystem 74

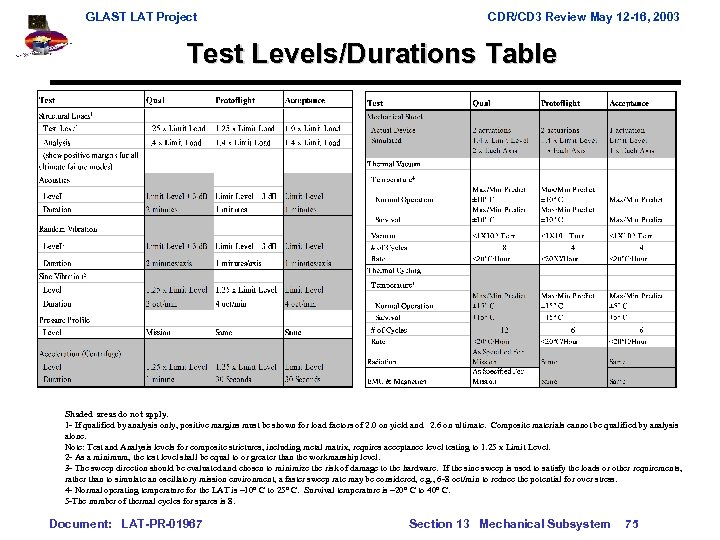

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Test Levels/Durations Table Shaded areas do not apply. 1 - If qualified by analysis only, positive margins must be shown for load factors of 2. 0 on yield and 2. 6 on ultimate. Composite materials cannot be qualified by analysis alone. Note: Test and Analysis levels for composite strictures, including metal matrix, requires acceptance level testing to 1. 25 x Limit Level. 2 - As a minimum, the test level shall be equal to or greater than the workmanship level. 3 - The sweep direction should be evaluated and chosen to minimize the risk of damage to the hardware. If the sine sweep is used to satisfy the loads or other requirements, rather than to simulate an oscillatory mission environment, a faster sweep rate may be considered, e. g. , 6 -8 oct/min to reduce the potential for over stress. 4 - Normal operating temperature for the LAT is – 10° C to 25° C. Survival temperature is – 20° C to 40° C. 5 -The number of thermal cycles for spares is 8. Document: LAT-PR-01967 Section 13 Mechanical Subsystem 75

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Test Levels/Durations Table Shaded areas do not apply. 1 - If qualified by analysis only, positive margins must be shown for load factors of 2. 0 on yield and 2. 6 on ultimate. Composite materials cannot be qualified by analysis alone. Note: Test and Analysis levels for composite strictures, including metal matrix, requires acceptance level testing to 1. 25 x Limit Level. 2 - As a minimum, the test level shall be equal to or greater than the workmanship level. 3 - The sweep direction should be evaluated and chosen to minimize the risk of damage to the hardware. If the sine sweep is used to satisfy the loads or other requirements, rather than to simulate an oscillatory mission environment, a faster sweep rate may be considered, e. g. , 6 -8 oct/min to reduce the potential for over stress. 4 - Normal operating temperature for the LAT is – 10° C to 25° C. Survival temperature is – 20° C to 40° C. 5 -The number of thermal cycles for spares is 8. Document: LAT-PR-01967 Section 13 Mechanical Subsystem 75

GLAST LAT Project Gamma-ray Large Area Space Telescope CDR/CD 3 Review May 12 -16, 2003 Fabrication Process Grid Box Assembly Section 13. 5 Document: LAT-PR-01967 Section 13 Mechanical Subsystem 76

GLAST LAT Project Gamma-ray Large Area Space Telescope CDR/CD 3 Review May 12 -16, 2003 Fabrication Process Grid Box Assembly Section 13. 5 Document: LAT-PR-01967 Section 13 Mechanical Subsystem 76

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Topics Agenda • Procurement plans – Identify critical component need dates vs. delivery dates – Summarize procurement contract status – Long lead part requirement/procurement • Fabrication plans – Mech Parts and Materials plan – Material approval status/readiness – M&P Plan, EEE Parts • Assembly plans – Grid box assembly sequence – Radiator assembly sequence – X-LAT assembly sequence • MGSE • Performance and Safety Assurance plans • Further Work Document: LAT-PR-01967 Section 13 Mechanical Subsystem 77

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Topics Agenda • Procurement plans – Identify critical component need dates vs. delivery dates – Summarize procurement contract status – Long lead part requirement/procurement • Fabrication plans – Mech Parts and Materials plan – Material approval status/readiness – M&P Plan, EEE Parts • Assembly plans – Grid box assembly sequence – Radiator assembly sequence – X-LAT assembly sequence • MGSE • Performance and Safety Assurance plans • Further Work Document: LAT-PR-01967 Section 13 Mechanical Subsystem 77

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Procurement Plans • RFP for 4 x 4 Grid & Grid Box Machining – Issue by 4/21/03 – Place contract by 5/15/03 • Long Lead Materials – PR for 2 Grid billets is in process now – Lockheed has ordered heat pipe extrusions Document: LAT-PR-01967 Section 13 Mechanical Subsystem 78

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Procurement Plans • RFP for 4 x 4 Grid & Grid Box Machining – Issue by 4/21/03 – Place contract by 5/15/03 • Long Lead Materials – PR for 2 Grid billets is in process now – Lockheed has ordered heat pipe extrusions Document: LAT-PR-01967 Section 13 Mechanical Subsystem 78

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Mechanical Parts & Materials Plan • Material requirements flow down from the Mission Assurance Requirements 433 -MAR-0001 and the Mechanical Parts Plan LAT-SS 00107 -01. • LAT Material selection of low outgassing and flight heritage • Outgassing specs: TML < 1% CVCM < 0. 1% • Important Procedures and Guidelines for Material selection • Fastener Integrity Requirements (541 -PG-8072. 1. 2) • Metallic Materials for Stress Corrosion Cracking Resistance in Sodium Chloride Environment (MSFC-STD-3029) • Standard Test Method for Total Mass Loss and Collected Volatile Condensable Materials for Outgassing (ASTM-E-595) Document: LAT-PR-01967 Section 13 Mechanical Subsystem 79

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Mechanical Parts & Materials Plan • Material requirements flow down from the Mission Assurance Requirements 433 -MAR-0001 and the Mechanical Parts Plan LAT-SS 00107 -01. • LAT Material selection of low outgassing and flight heritage • Outgassing specs: TML < 1% CVCM < 0. 1% • Important Procedures and Guidelines for Material selection • Fastener Integrity Requirements (541 -PG-8072. 1. 2) • Metallic Materials for Stress Corrosion Cracking Resistance in Sodium Chloride Environment (MSFC-STD-3029) • Standard Test Method for Total Mass Loss and Collected Volatile Condensable Materials for Outgassing (ASTM-E-595) Document: LAT-PR-01967 Section 13 Mechanical Subsystem 79

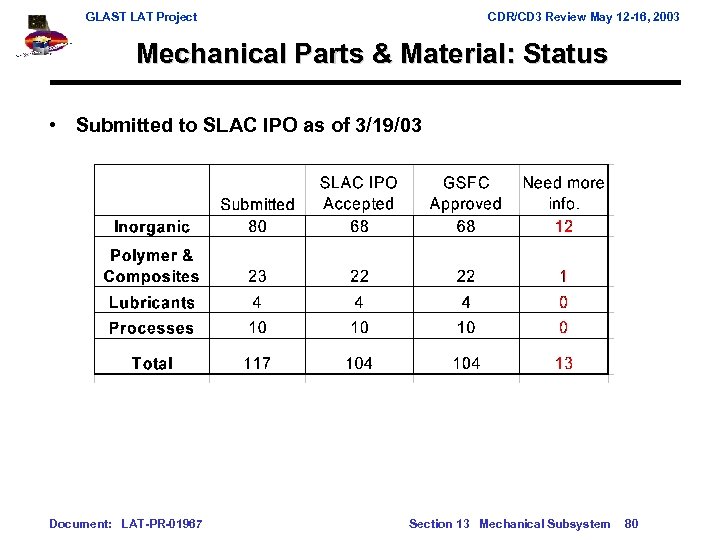

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Mechanical Parts & Material: Status • Submitted to SLAC IPO as of 3/19/03 Document: LAT-PR-01967 Section 13 Mechanical Subsystem 80

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Mechanical Parts & Material: Status • Submitted to SLAC IPO as of 3/19/03 Document: LAT-PR-01967 Section 13 Mechanical Subsystem 80

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 M & P Plan, EEE Parts • M & P Plan submitted to SLAC (GLS 00018 -2, dated 1 Feb 2003) • EEE Parts – Heaters: Minco Kapton Foil Heaters per GSFC S-311 -P-079 – Thermistors: YSI Thermistors per GSFC S-311 -P-18 – RTDs: Rosemount PRT per GSFC S-311 – Solid State Thermostats: Micropac 52372”O” • Submitted to SLAC for approval Nov 2002 Document: LAT-PR-01967 Section 13 Mechanical Subsystem 81

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 M & P Plan, EEE Parts • M & P Plan submitted to SLAC (GLS 00018 -2, dated 1 Feb 2003) • EEE Parts – Heaters: Minco Kapton Foil Heaters per GSFC S-311 -P-079 – Thermistors: YSI Thermistors per GSFC S-311 -P-18 – RTDs: Rosemount PRT per GSFC S-311 – Solid State Thermostats: Micropac 52372”O” • Submitted to SLAC for approval Nov 2002 Document: LAT-PR-01967 Section 13 Mechanical Subsystem 81

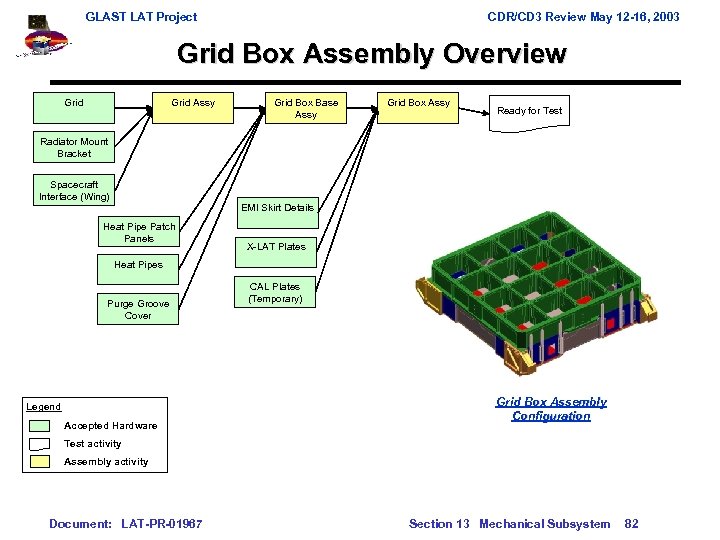

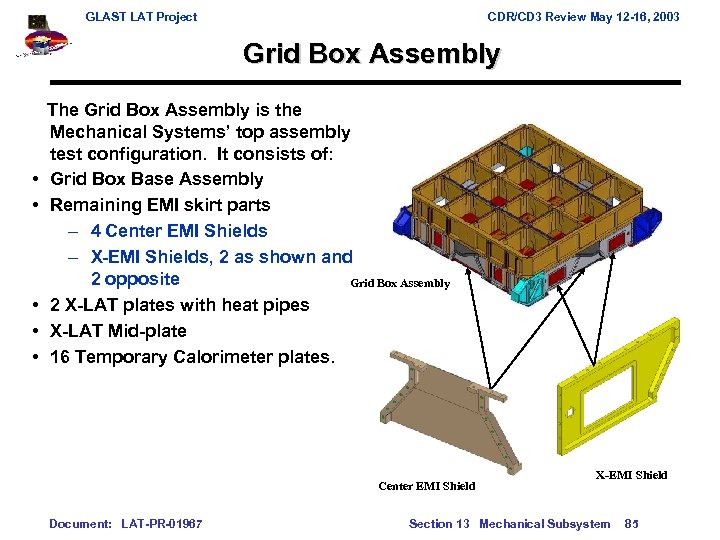

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Grid Box Assembly Overview Grid Assy Grid Box Base Assy Grid Box Assy Ready for Test Radiator Mount Bracket Spacecraft Interface (Wing) EMI Skirt Details Heat Pipe Patch Panels X-LAT Plates Heat Pipes Purge Groove Cover Legend Accepted Hardware CAL Plates (Temporary) Grid Box Assembly Configuration Test activity Assembly activity Document: LAT-PR-01967 Section 13 Mechanical Subsystem 82

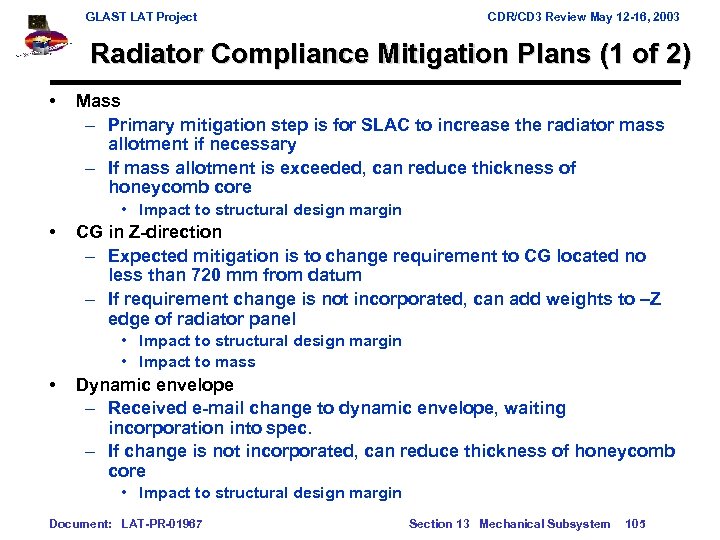

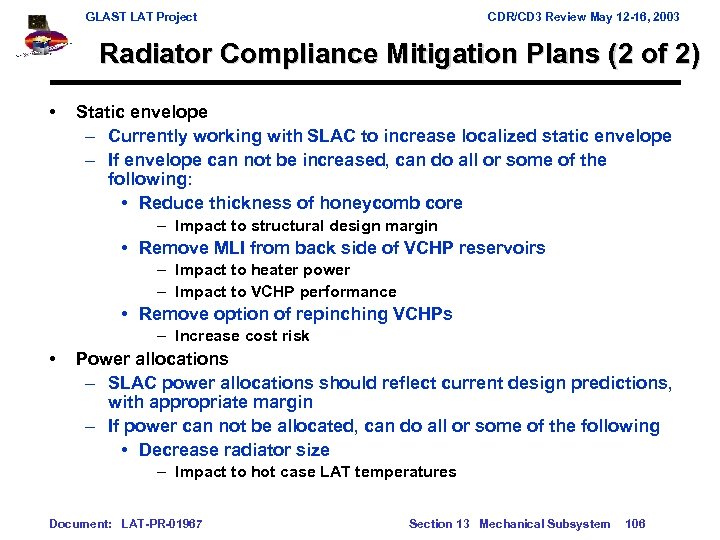

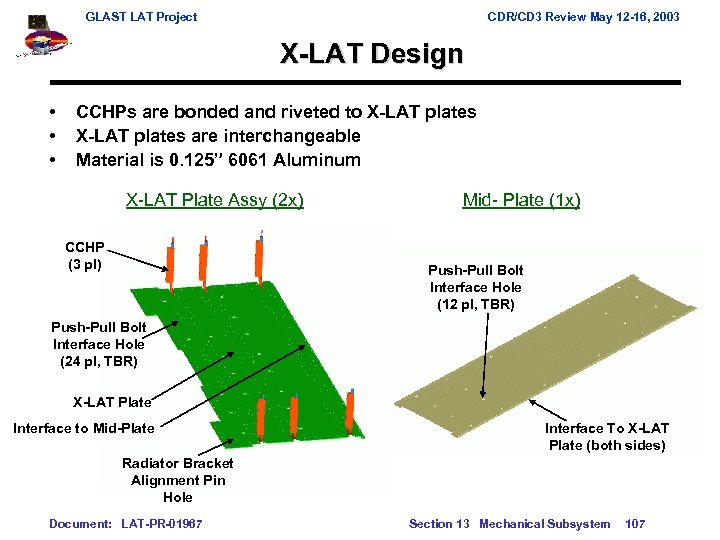

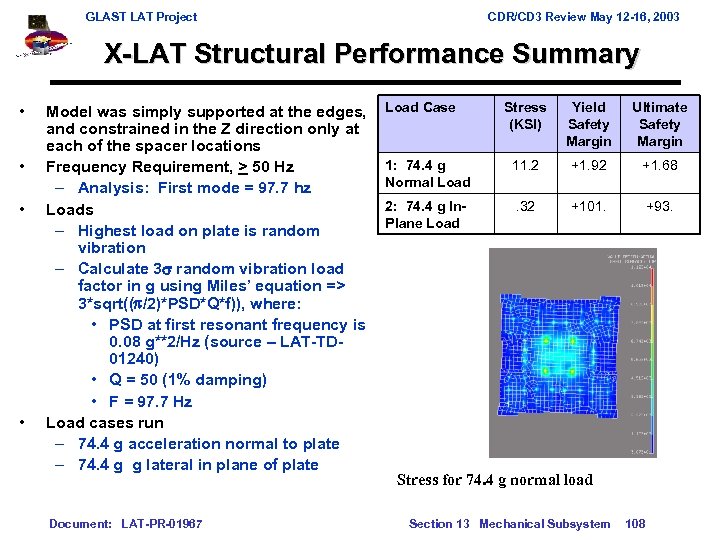

GLAST LAT Project CDR/CD 3 Review May 12 -16, 2003 Grid Box Assembly Overview Grid Assy Grid Box Base Assy Grid Box Assy Ready for Test Radiator Mount Bracket Spacecraft Interface (Wing) EMI Skirt Details Heat Pipe Patch Panels X-LAT Plates Heat Pipes Purge Groove Cover Legend Accepted Hardware CAL Plates (Temporary) Grid Box Assembly Configuration Test activity Assembly activity Document: LAT-PR-01967 Section 13 Mechanical Subsystem 82