df19e9abe956412e3340cd853ef2aa21.ppt

- Количество слайдов: 17

GLAST LAT Project FM 4/5 PSR, May 31, 2005 GLAST LAT Tracker Tower-4/5 Pre-Ship Review Luca. latronico@pi. infn. it INFN-Pisa Tracker Subsystem

GLAST LAT Project FM 4/5 PSR, May 31, 2005 GLAST LAT Tracker Tower-4/5 Pre-Ship Review Luca. latronico@pi. infn. it INFN-Pisa Tracker Subsystem

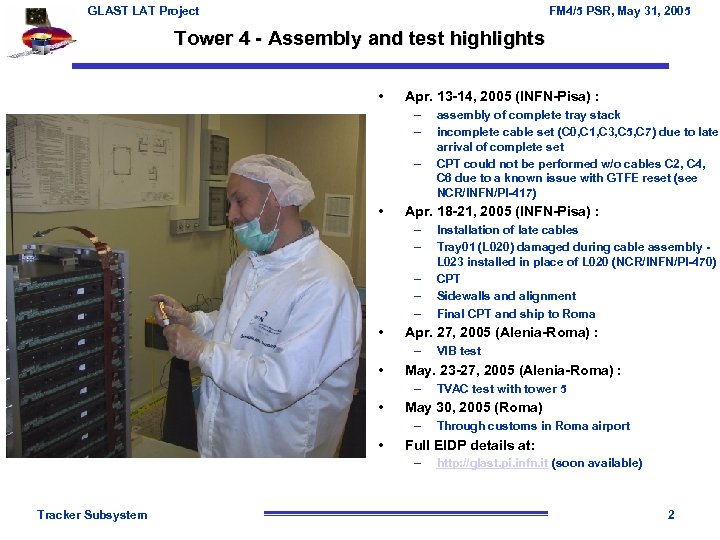

GLAST LAT Project FM 4/5 PSR, May 31, 2005 Tower 4 - Assembly and test highlights • Apr. 13 -14, 2005 (INFN-Pisa) : – – – • Apr. 18 -21, 2005 (INFN-Pisa) : – – – • Through customs in Roma airport Full EIDP details at: – Tracker Subsystem TVAC test with tower 5 May 30, 2005 (Roma) – • VIB test May. 23 -27, 2005 (Alenia-Roma) : – • Installation of late cables Tray 01 (L 020) damaged during cable assembly L 023 installed in place of L 020 (NCR/INFN/PI-470) CPT Sidewalls and alignment Final CPT and ship to Roma Apr. 27, 2005 (Alenia-Roma) : – • assembly of complete tray stack incomplete cable set (C 0, C 1, C 3, C 5, C 7) due to late arrival of complete set CPT could not be performed w/o cables C 2, C 4, C 6 due to a known issue with GTFE reset (see NCR/INFN/PI-417) http: //glast. pi. infn. it (soon available) 2

GLAST LAT Project FM 4/5 PSR, May 31, 2005 Tower 4 - Assembly and test highlights • Apr. 13 -14, 2005 (INFN-Pisa) : – – – • Apr. 18 -21, 2005 (INFN-Pisa) : – – – • Through customs in Roma airport Full EIDP details at: – Tracker Subsystem TVAC test with tower 5 May 30, 2005 (Roma) – • VIB test May. 23 -27, 2005 (Alenia-Roma) : – • Installation of late cables Tray 01 (L 020) damaged during cable assembly L 023 installed in place of L 020 (NCR/INFN/PI-470) CPT Sidewalls and alignment Final CPT and ship to Roma Apr. 27, 2005 (Alenia-Roma) : – • assembly of complete tray stack incomplete cable set (C 0, C 1, C 3, C 5, C 7) due to late arrival of complete set CPT could not be performed w/o cables C 2, C 4, C 6 due to a known issue with GTFE reset (see NCR/INFN/PI-417) http: //glast. pi. infn. it (soon available) 2

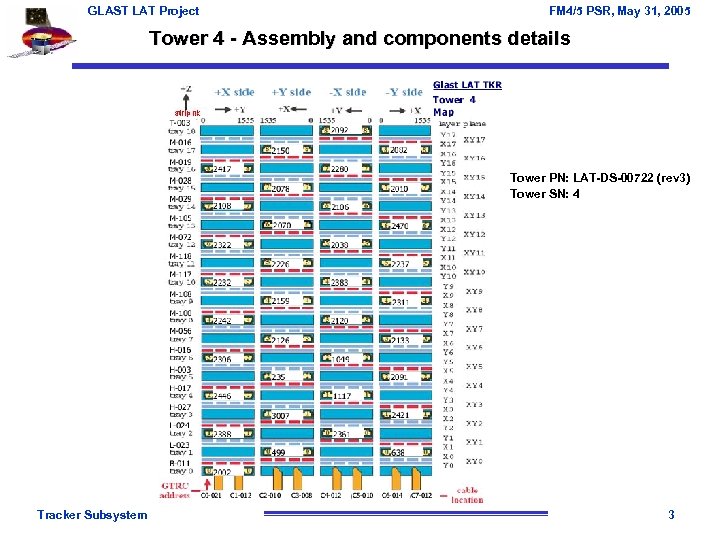

GLAST LAT Project FM 4/5 PSR, May 31, 2005 Tower 4 - Assembly and components details Tower PN: LAT-DS-00722 (rev 3) Tower SN: 4 Tracker Subsystem 3

GLAST LAT Project FM 4/5 PSR, May 31, 2005 Tower 4 - Assembly and components details Tower PN: LAT-DS-00722 (rev 3) Tower SN: 4 Tracker Subsystem 3

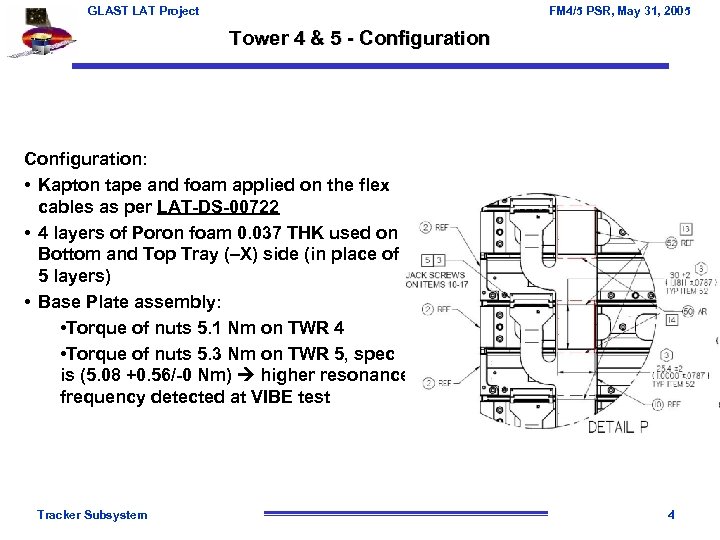

GLAST LAT Project FM 4/5 PSR, May 31, 2005 Tower 4 & 5 - Configuration: • Kapton tape and foam applied on the flex cables as per LAT-DS-00722 • 4 layers of Poron foam 0. 037 THK used on Bottom and Top Tray (–X) side (in place of 5 layers) • Base Plate assembly: • Torque of nuts 5. 1 Nm on TWR 4 • Torque of nuts 5. 3 Nm on TWR 5, spec is (5. 08 +0. 56/-0 Nm) higher resonance frequency detected at VIBE test Tracker Subsystem 4

GLAST LAT Project FM 4/5 PSR, May 31, 2005 Tower 4 & 5 - Configuration: • Kapton tape and foam applied on the flex cables as per LAT-DS-00722 • 4 layers of Poron foam 0. 037 THK used on Bottom and Top Tray (–X) side (in place of 5 layers) • Base Plate assembly: • Torque of nuts 5. 1 Nm on TWR 4 • Torque of nuts 5. 3 Nm on TWR 5, spec is (5. 08 +0. 56/-0 Nm) higher resonance frequency detected at VIBE test Tracker Subsystem 4

GLAST LAT Project FM 4/5 PSR, May 31, 2005 Tower 4 & 5 – Alignment, CG & MASS ü Tower 4 and 5 well aligned and inside stayclear ü Mass and CG near estimated values (when used real masses) ü Data available on INFN-PISA web site Tracker Subsystem 5

GLAST LAT Project FM 4/5 PSR, May 31, 2005 Tower 4 & 5 – Alignment, CG & MASS ü Tower 4 and 5 well aligned and inside stayclear ü Mass and CG near estimated values (when used real masses) ü Data available on INFN-PISA web site Tracker Subsystem 5

GLAST LAT Project FM 4/5 PSR, May 31, 2005 Tower 4 – Open NCRs • INFN/PI-494: Bad channels out of spec – with reference to tray NCRs 460, 465, 464, 463 (all closed as per MRB) layers X 6, Y 5, Y 3, Y 13 fail test TE 301 as expected and due to known problems – Status of channels was monitored through TVAC test and show no significant loss of channels (see next slide), the NCR can be closed and converted into a SLAC one for reference • INFN/PI-496: Vacuum level out of specification. – Common to Tower 5, see following slides. • INFN/PI-503: CPT reduction after TVAC – Common to Tower 5, see following slides Tracker Subsystem 6

GLAST LAT Project FM 4/5 PSR, May 31, 2005 Tower 4 – Open NCRs • INFN/PI-494: Bad channels out of spec – with reference to tray NCRs 460, 465, 464, 463 (all closed as per MRB) layers X 6, Y 5, Y 3, Y 13 fail test TE 301 as expected and due to known problems – Status of channels was monitored through TVAC test and show no significant loss of channels (see next slide), the NCR can be closed and converted into a SLAC one for reference • INFN/PI-496: Vacuum level out of specification. – Common to Tower 5, see following slides. • INFN/PI-503: CPT reduction after TVAC – Common to Tower 5, see following slides Tracker Subsystem 6

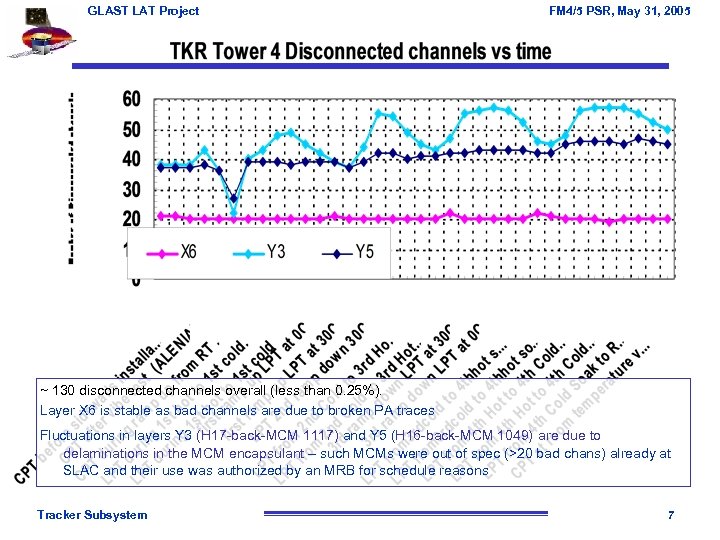

GLAST LAT Project FM 4/5 PSR, May 31, 2005 ~ 130 disconnected channels overall (less than 0. 25%). Layer X 6 is stable as bad channels are due to broken PA traces Fluctuations in layers Y 3 (H 17 -back-MCM 1117) and Y 5 (H 16 -back-MCM 1049) are due to delaminations in the MCM encapsulant – such MCMs were out of spec (>20 bad chans) already at SLAC and their use was authorized by an MRB for schedule reasons Tracker Subsystem 7

GLAST LAT Project FM 4/5 PSR, May 31, 2005 ~ 130 disconnected channels overall (less than 0. 25%). Layer X 6 is stable as bad channels are due to broken PA traces Fluctuations in layers Y 3 (H 17 -back-MCM 1117) and Y 5 (H 16 -back-MCM 1049) are due to delaminations in the MCM encapsulant – such MCMs were out of spec (>20 bad chans) already at SLAC and their use was authorized by an MRB for schedule reasons Tracker Subsystem 7

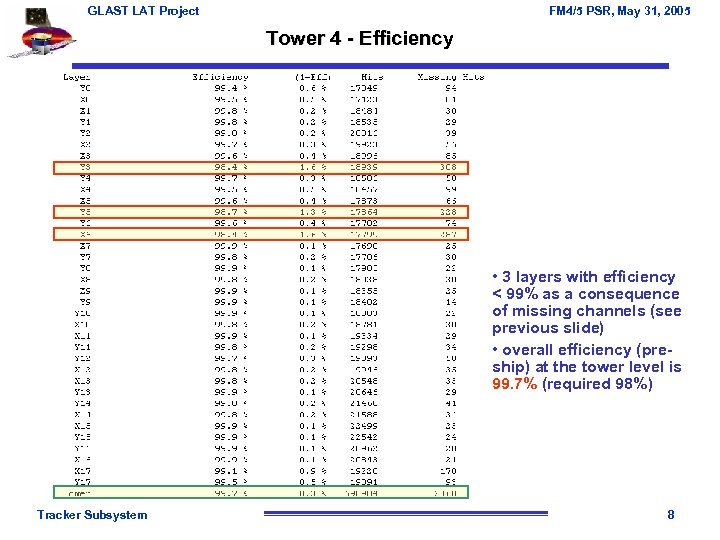

GLAST LAT Project FM 4/5 PSR, May 31, 2005 Tower 4 - Efficiency • 3 layers with efficiency < 99% as a consequence of missing channels (see previous slide) • overall efficiency (preship) at the tower level is 99. 7% (required 98%) Tracker Subsystem 8

GLAST LAT Project FM 4/5 PSR, May 31, 2005 Tower 4 - Efficiency • 3 layers with efficiency < 99% as a consequence of missing channels (see previous slide) • overall efficiency (preship) at the tower level is 99. 7% (required 98%) Tracker Subsystem 8

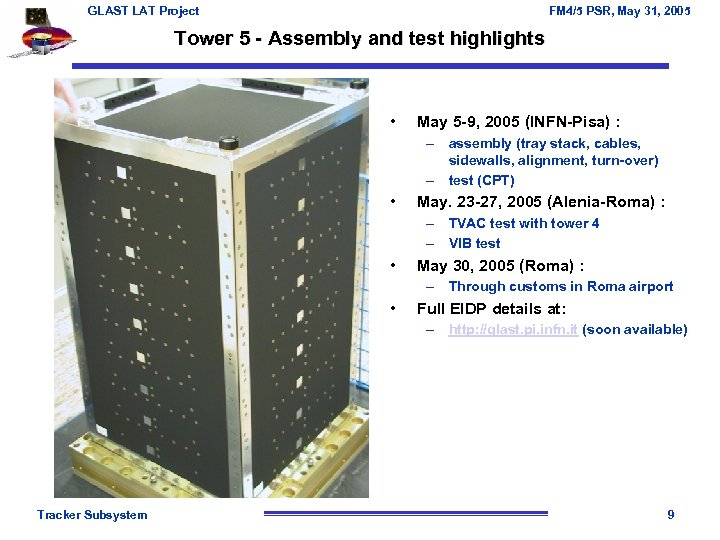

GLAST LAT Project FM 4/5 PSR, May 31, 2005 Tower 5 - Assembly and test highlights • May 5 -9, 2005 (INFN-Pisa) : – assembly (tray stack, cables, sidewalls, alignment, turn-over) – test (CPT) • May. 23 -27, 2005 (Alenia-Roma) : – TVAC test with tower 4 – VIB test • May 30, 2005 (Roma) : – Through customs in Roma airport • Full EIDP details at: – http: //glast. pi. infn. it (soon available) Tracker Subsystem 9

GLAST LAT Project FM 4/5 PSR, May 31, 2005 Tower 5 - Assembly and test highlights • May 5 -9, 2005 (INFN-Pisa) : – assembly (tray stack, cables, sidewalls, alignment, turn-over) – test (CPT) • May. 23 -27, 2005 (Alenia-Roma) : – TVAC test with tower 4 – VIB test • May 30, 2005 (Roma) : – Through customs in Roma airport • Full EIDP details at: – http: //glast. pi. infn. it (soon available) Tracker Subsystem 9

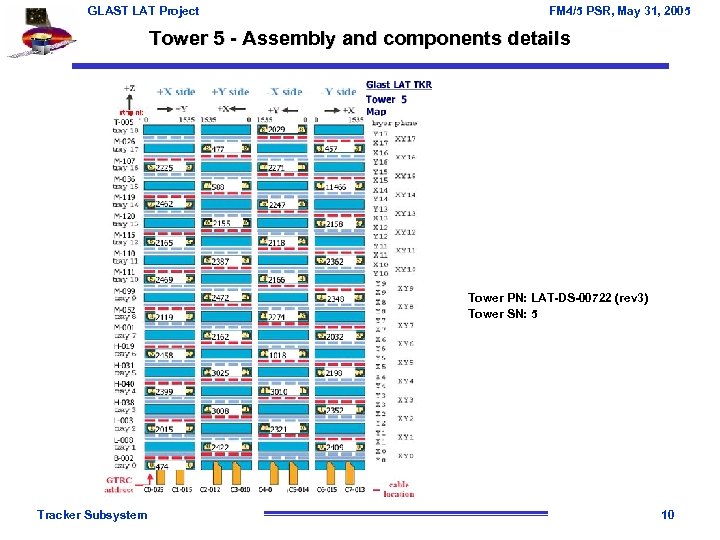

GLAST LAT Project FM 4/5 PSR, May 31, 2005 Tower 5 - Assembly and components details Tower PN: LAT-DS-00722 (rev 3) Tower SN: 5 Tracker Subsystem 10

GLAST LAT Project FM 4/5 PSR, May 31, 2005 Tower 5 - Assembly and components details Tower PN: LAT-DS-00722 (rev 3) Tower SN: 5 Tracker Subsystem 10

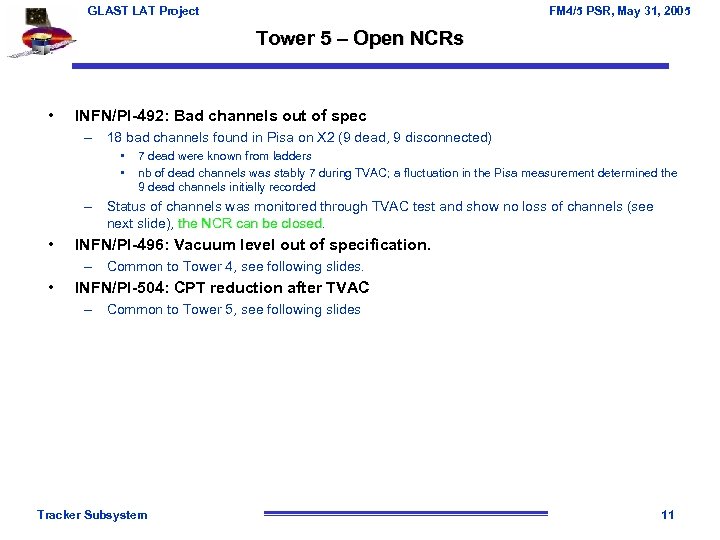

GLAST LAT Project FM 4/5 PSR, May 31, 2005 Tower 5 – Open NCRs • INFN/PI-492: Bad channels out of spec – 18 bad channels found in Pisa on X 2 (9 dead, 9 disconnected) • • 7 dead were known from ladders nb of dead channels was stably 7 during TVAC; a fluctuation in the Pisa measurement determined the 9 dead channels initially recorded – Status of channels was monitored through TVAC test and show no loss of channels (see next slide), the NCR can be closed • INFN/PI-496: Vacuum level out of specification. – Common to Tower 4, see following slides. • INFN/PI-504: CPT reduction after TVAC – Common to Tower 5, see following slides Tracker Subsystem 11

GLAST LAT Project FM 4/5 PSR, May 31, 2005 Tower 5 – Open NCRs • INFN/PI-492: Bad channels out of spec – 18 bad channels found in Pisa on X 2 (9 dead, 9 disconnected) • • 7 dead were known from ladders nb of dead channels was stably 7 during TVAC; a fluctuation in the Pisa measurement determined the 9 dead channels initially recorded – Status of channels was monitored through TVAC test and show no loss of channels (see next slide), the NCR can be closed • INFN/PI-496: Vacuum level out of specification. – Common to Tower 4, see following slides. • INFN/PI-504: CPT reduction after TVAC – Common to Tower 5, see following slides Tracker Subsystem 11

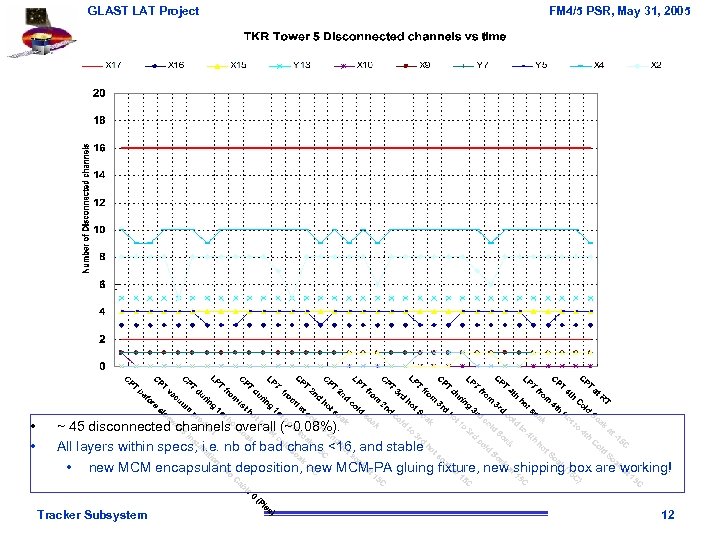

GLAST LAT Project • • FM 4/5 PSR, May 31, 2005 ~ 45 disconnected channels overall (~0. 08%). All layers within specs, i. e. nb of bad chans <16, and stable • new MCM encapsulant deposition, new MCM-PA gluing fixture, new shipping box are working! Tracker Subsystem 12

GLAST LAT Project • • FM 4/5 PSR, May 31, 2005 ~ 45 disconnected channels overall (~0. 08%). All layers within specs, i. e. nb of bad chans <16, and stable • new MCM encapsulant deposition, new MCM-PA gluing fixture, new shipping box are working! Tracker Subsystem 12

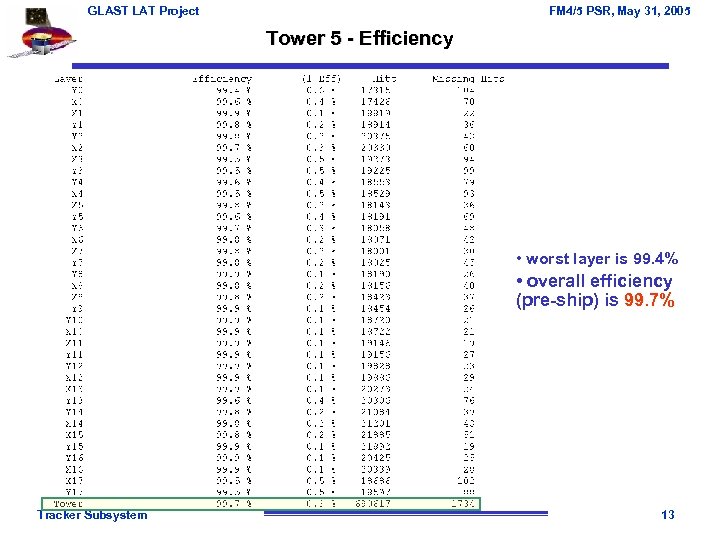

GLAST LAT Project FM 4/5 PSR, May 31, 2005 Tower 5 - Efficiency • worst layer is 99. 4% • overall efficiency (pre-ship) is 99. 7% Tracker Subsystem 13

GLAST LAT Project FM 4/5 PSR, May 31, 2005 Tower 5 - Efficiency • worst layer is 99. 4% • overall efficiency (pre-ship) is 99. 7% Tracker Subsystem 13

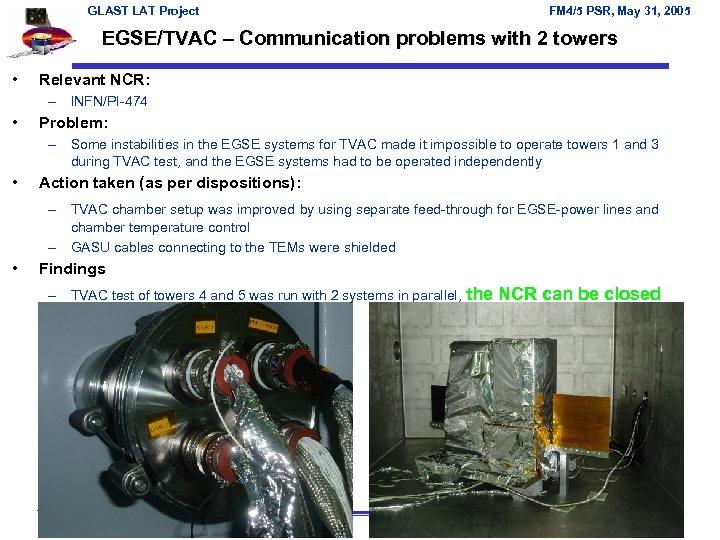

GLAST LAT Project FM 4/5 PSR, May 31, 2005 EGSE/TVAC – Communication problems with 2 towers • Relevant NCR: – INFN/PI-474 • Problem: – Some instabilities in the EGSE systems for TVAC made it impossible to operate towers 1 and 3 during TVAC test, and the EGSE systems had to be operated independently • Action taken (as per dispositions): – TVAC chamber setup was improved by using separate feed-through for EGSE-power lines and chamber temperature control – GASU cables connecting to the TEMs were shielded • Findings – TVAC test of towers 4 and 5 was run with 2 systems in parallel, the NCR can be closed Tracker Subsystem 14

GLAST LAT Project FM 4/5 PSR, May 31, 2005 EGSE/TVAC – Communication problems with 2 towers • Relevant NCR: – INFN/PI-474 • Problem: – Some instabilities in the EGSE systems for TVAC made it impossible to operate towers 1 and 3 during TVAC test, and the EGSE systems had to be operated independently • Action taken (as per dispositions): – TVAC chamber setup was improved by using separate feed-through for EGSE-power lines and chamber temperature control – GASU cables connecting to the TEMs were shielded • Findings – TVAC test of towers 4 and 5 was run with 2 systems in parallel, the NCR can be closed Tracker Subsystem 14

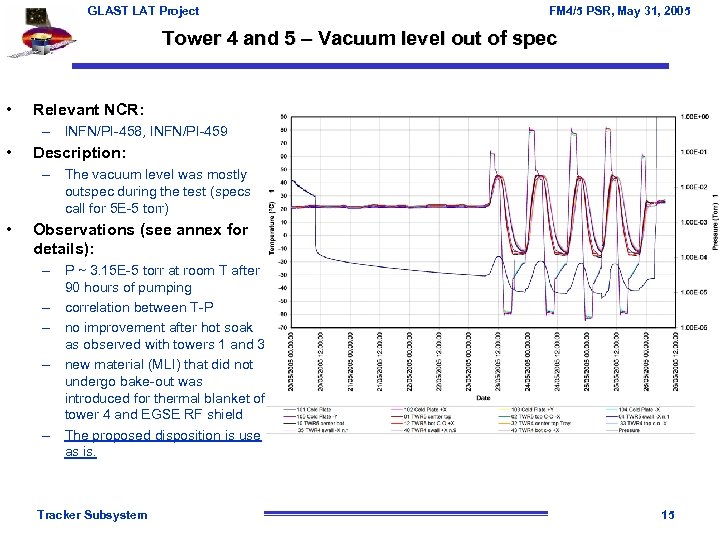

GLAST LAT Project FM 4/5 PSR, May 31, 2005 Tower 4 and 5 – Vacuum level out of spec • Relevant NCR: – INFN/PI-458, INFN/PI-459 • Description: – The vacuum level was mostly outspec during the test (specs call for 5 E-5 torr) • Observations (see annex for details): – P ~ 3. 15 E-5 torr at room T after 90 hours of pumping – correlation between T-P – no improvement after hot soak as observed with towers 1 and 3 – new material (MLI) that did not undergo bake-out was introduced for thermal blanket of tower 4 and EGSE RF shield – The proposed disposition is use as is. Tracker Subsystem 15

GLAST LAT Project FM 4/5 PSR, May 31, 2005 Tower 4 and 5 – Vacuum level out of spec • Relevant NCR: – INFN/PI-458, INFN/PI-459 • Description: – The vacuum level was mostly outspec during the test (specs call for 5 E-5 torr) • Observations (see annex for details): – P ~ 3. 15 E-5 torr at room T after 90 hours of pumping – correlation between T-P – no improvement after hot soak as observed with towers 1 and 3 – new material (MLI) that did not undergo bake-out was introduced for thermal blanket of tower 4 and EGSE RF shield – The proposed disposition is use as is. Tracker Subsystem 15

GLAST LAT Project FM 4/5 PSR, May 31, 2005 CPT reduction for TVAC • Reference NCR – 503 and 504 • Description – TE 101 (leakage current and power consumption test) not performed after towers 4 and 5 TVAC test • Proposed dispositions – only perform test TE 101 after TVAC is anomalies are detected in the tower CPT suite • Rationale: correct behaviour of tower during and after TVAC is assessed by observations of layers noise, channels status, CR detection efficiency – reduce CR data taking time to 100 k events for CPT and 50 K for LPT • Rationale: such statistics are enough for efficiency measurements and the test time reduction allow compressing TVAC in 3 days – Submit a document change request with the above changes Tracker Subsystem 16

GLAST LAT Project FM 4/5 PSR, May 31, 2005 CPT reduction for TVAC • Reference NCR – 503 and 504 • Description – TE 101 (leakage current and power consumption test) not performed after towers 4 and 5 TVAC test • Proposed dispositions – only perform test TE 101 after TVAC is anomalies are detected in the tower CPT suite • Rationale: correct behaviour of tower during and after TVAC is assessed by observations of layers noise, channels status, CR detection efficiency – reduce CR data taking time to 100 k events for CPT and 50 K for LPT • Rationale: such statistics are enough for efficiency measurements and the test time reduction allow compressing TVAC in 3 days – Submit a document change request with the above changes Tracker Subsystem 16

GLAST LAT Project FM 4/5 PSR, May 31, 2005 Tower 4 and 5 - Conclusions – Both towers well aligned and within stayclear – The overall number of disconnected channels is very low – All the silicon layers (but the bottom tray of tower 3) close to 100% efficiency – Communication issue during TVAC solved – Vacuum level still outspec during TVAC Tracker Subsystem 17

GLAST LAT Project FM 4/5 PSR, May 31, 2005 Tower 4 and 5 - Conclusions – Both towers well aligned and within stayclear – The overall number of disconnected channels is very low – All the silicon layers (but the bottom tray of tower 3) close to 100% efficiency – Communication issue during TVAC solved – Vacuum level still outspec during TVAC Tracker Subsystem 17