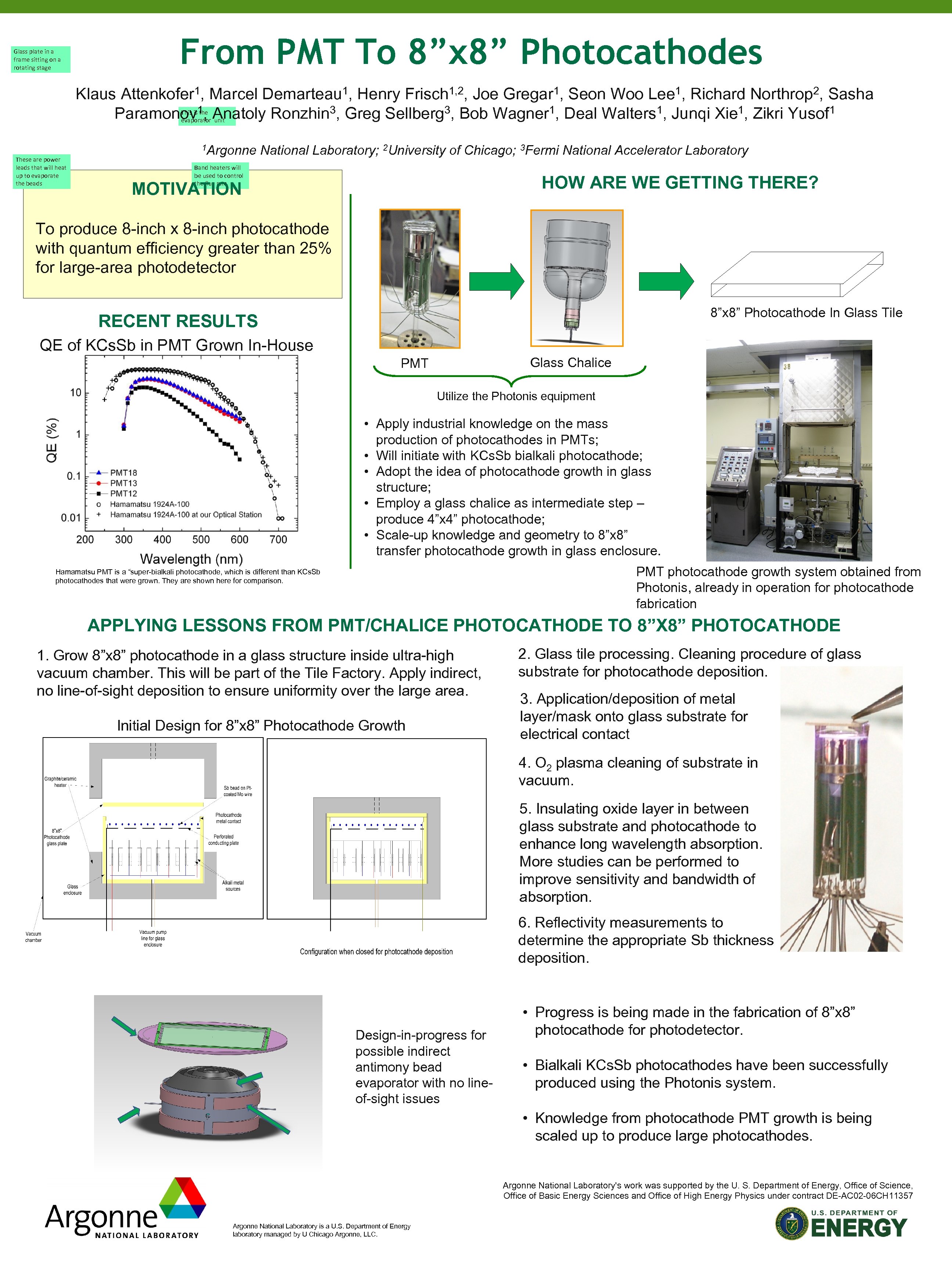

Glass plate in a frame sitting on a rotating stage From PMT To 8”x 8” Photocathodes Klaus Attenkofer 1, Marcel Demarteau 1, Henry Frisch 1, 2, Joe Gregar 1, Seon Woo Lee 1, Richard Northrop 2, Sasha This is the Paramonov 1, Anatoly Ronzhin 3, Greg Sellberg 3, Bob Wagner 1, Deal Walters 1, Junqi Xie 1, Zikri Yusof 1 evaporator unit These are power leads that will heat up to evaporate the beads 1 Argonne National Laboratory; 2 University of Chicago; 3 Fermi National Accelerator Laboratory Band heaters will be used to control the flux rate HOW ARE WE GETTING THERE? MOTIVATION To produce 8 -inch x 8 -inch photocathode with quantum efficiency greater than 25% for large-area photodetector 8”x 8” Photocathode In Glass Tile RECENT RESULTS QE of KCs. Sb in PMT Grown In-House Glass Chalice PMT Utilize the Photonis equipment • Apply industrial knowledge on the mass production of photocathodes in PMTs; • Will initiate with KCs. Sb bialkali photocathode; • Adopt the idea of photocathode growth in glass structure; • Employ a glass chalice as intermediate step – produce 4”x 4” photocathode; • Scale-up knowledge and geometry to 8”x 8” transfer photocathode growth in glass enclosure. PMT photocathode growth system obtained from Photonis, already in operation for photocathode fabrication Hamamatsu PMT is a “super-bialkali photocathode, which is different than KCs. Sb photocathodes that were grown. They are shown here for comparison. APPLYING LESSONS FROM PMT/CHALICE PHOTOCATHODE TO 8”X 8” PHOTOCATHODE 1. Grow 8”x 8” photocathode in a glass structure inside ultra-high vacuum chamber. This will be part of the Tile Factory. Apply indirect, no line-of-sight deposition to ensure uniformity over the large area. Initial Design for 8”x 8” Photocathode Growth 2. Glass tile processing. Cleaning procedure of glass substrate for photocathode deposition. 3. Application/deposition of metal layer/mask onto glass substrate for electrical contact 4. O 2 plasma cleaning of substrate in vacuum. 5. Insulating oxide layer in between glass substrate and photocathode to enhance long wavelength absorption. More studies can be performed to improve sensitivity and bandwidth of absorption. 6. Reflectivity measurements to determine the appropriate Sb thickness deposition. Design-in-progress for possible indirect antimony bead evaporator with no lineof-sight issues • Progress is being made in the fabrication of 8”x 8” photocathode for photodetector. • Bialkali KCs. Sb photocathodes have been successfully produced using the Photonis system. • Knowledge from photocathode PMT growth is being scaled up to produce large photocathodes. Argonne National Laboratory's work was supported by the U. S. Department of Energy, Office of Science, Office of Basic Energy Sciences and Office of High Energy Physics under contract DE-AC 02 -06 CH 11357 Argonne National Laboratory is a U. S. Department of Energy laboratory managed by U Chicago Argonne, LLC.

Glass plate in a frame sitting on a rotating stage From PMT To 8”x 8” Photocathodes Klaus Attenkofer 1, Marcel Demarteau 1, Henry Frisch 1, 2, Joe Gregar 1, Seon Woo Lee 1, Richard Northrop 2, Sasha This is the Paramonov 1, Anatoly Ronzhin 3, Greg Sellberg 3, Bob Wagner 1, Deal Walters 1, Junqi Xie 1, Zikri Yusof 1 evaporator unit These are power leads that will heat up to evaporate the beads 1 Argonne National Laboratory; 2 University of Chicago; 3 Fermi National Accelerator Laboratory Band heaters will be used to control the flux rate HOW ARE WE GETTING THERE? MOTIVATION To produce 8 -inch x 8 -inch photocathode with quantum efficiency greater than 25% for large-area photodetector 8”x 8” Photocathode In Glass Tile RECENT RESULTS QE of KCs. Sb in PMT Grown In-House Glass Chalice PMT Utilize the Photonis equipment • Apply industrial knowledge on the mass production of photocathodes in PMTs; • Will initiate with KCs. Sb bialkali photocathode; • Adopt the idea of photocathode growth in glass structure; • Employ a glass chalice as intermediate step – produce 4”x 4” photocathode; • Scale-up knowledge and geometry to 8”x 8” transfer photocathode growth in glass enclosure. PMT photocathode growth system obtained from Photonis, already in operation for photocathode fabrication Hamamatsu PMT is a “super-bialkali photocathode, which is different than KCs. Sb photocathodes that were grown. They are shown here for comparison. APPLYING LESSONS FROM PMT/CHALICE PHOTOCATHODE TO 8”X 8” PHOTOCATHODE 1. Grow 8”x 8” photocathode in a glass structure inside ultra-high vacuum chamber. This will be part of the Tile Factory. Apply indirect, no line-of-sight deposition to ensure uniformity over the large area. Initial Design for 8”x 8” Photocathode Growth 2. Glass tile processing. Cleaning procedure of glass substrate for photocathode deposition. 3. Application/deposition of metal layer/mask onto glass substrate for electrical contact 4. O 2 plasma cleaning of substrate in vacuum. 5. Insulating oxide layer in between glass substrate and photocathode to enhance long wavelength absorption. More studies can be performed to improve sensitivity and bandwidth of absorption. 6. Reflectivity measurements to determine the appropriate Sb thickness deposition. Design-in-progress for possible indirect antimony bead evaporator with no lineof-sight issues • Progress is being made in the fabrication of 8”x 8” photocathode for photodetector. • Bialkali KCs. Sb photocathodes have been successfully produced using the Photonis system. • Knowledge from photocathode PMT growth is being scaled up to produce large photocathodes. Argonne National Laboratory's work was supported by the U. S. Department of Energy, Office of Science, Office of Basic Energy Sciences and Office of High Energy Physics under contract DE-AC 02 -06 CH 11357 Argonne National Laboratory is a U. S. Department of Energy laboratory managed by U Chicago Argonne, LLC.

![]()