e3138e196a07a643fbf9572a519c8f8d.ppt

- Количество слайдов: 29

: GHG-Control from SICK Direct Measurement of the Green House Gas emissions Ralf Pakulla – Product Marketing Manager Emission Analyzer SICK AG, January 2013

: GHG-Control from SICK Direct Measurement of the Green House Gas emissions Ralf Pakulla – Product Marketing Manager Emission Analyzer SICK AG, January 2013

GHG-Control The Solution for GHG Reporting : Confidential : Ralf Pakulla 2

GHG-Control The Solution for GHG Reporting : Confidential : Ralf Pakulla 2

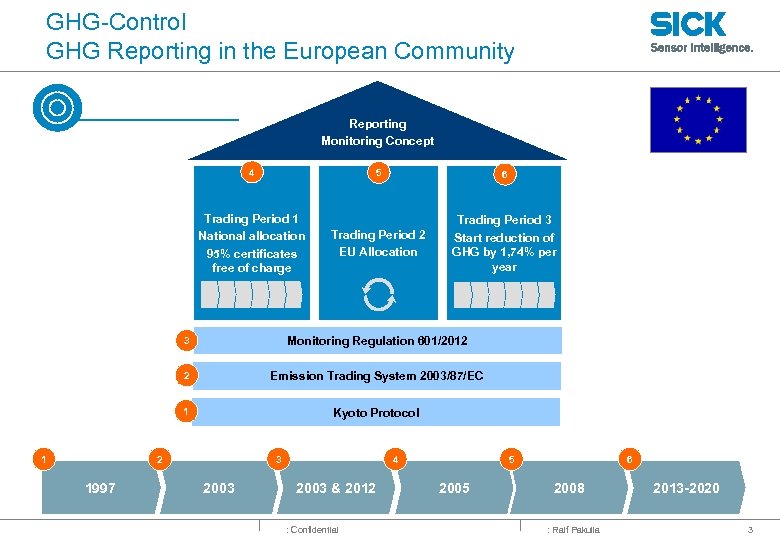

GHG-Control GHG Reporting in the European Community Reporting Monitoring Concept 4 5 6 Trading Period 1 National allocation 95% certificates free of charge Trading Period 2 EU Allocation Trading Period 3 Start reduction of GHG by 1, 74% per year 3 2 Emission Trading System 2003/87/EC 1 1 Monitoring Regulation 601/2012 Kyoto Protocol 2 1997 3 2003 4 2003 & 2012 : Confidential 5 2005 6 2008 : Ralf Pakulla 2013 -2020 3

GHG-Control GHG Reporting in the European Community Reporting Monitoring Concept 4 5 6 Trading Period 1 National allocation 95% certificates free of charge Trading Period 2 EU Allocation Trading Period 3 Start reduction of GHG by 1, 74% per year 3 2 Emission Trading System 2003/87/EC 1 1 Monitoring Regulation 601/2012 Kyoto Protocol 2 1997 3 2003 4 2003 & 2012 : Confidential 5 2005 6 2008 : Ralf Pakulla 2013 -2020 3

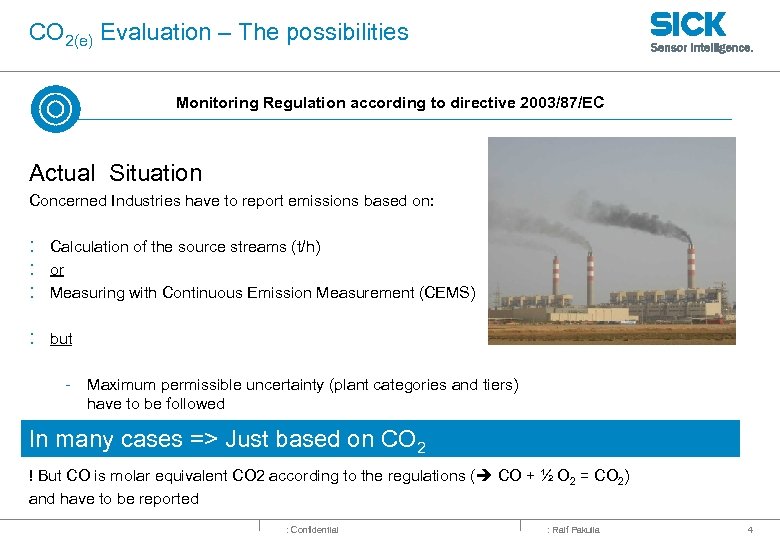

CO 2(e) Evaluation – The possibilities Monitoring Regulation according to directive 2003/87/EC Actual Situation Concerned Industries have to report emissions based on: : : : Calculation of the source streams (t/h) or Measuring with Continuous Emission Measurement (CEMS) : but - Maximum permissible uncertainty (plant categories and tiers) have to be followed In many cases => Just based on CO 2 ! But CO is molar equivalent CO 2 according to the regulations ( CO + ½ O 2 = CO 2) and have to be reported : Confidential : Ralf Pakulla 4

CO 2(e) Evaluation – The possibilities Monitoring Regulation according to directive 2003/87/EC Actual Situation Concerned Industries have to report emissions based on: : : : Calculation of the source streams (t/h) or Measuring with Continuous Emission Measurement (CEMS) : but - Maximum permissible uncertainty (plant categories and tiers) have to be followed In many cases => Just based on CO 2 ! But CO is molar equivalent CO 2 according to the regulations ( CO + ½ O 2 = CO 2) and have to be reported : Confidential : Ralf Pakulla 4

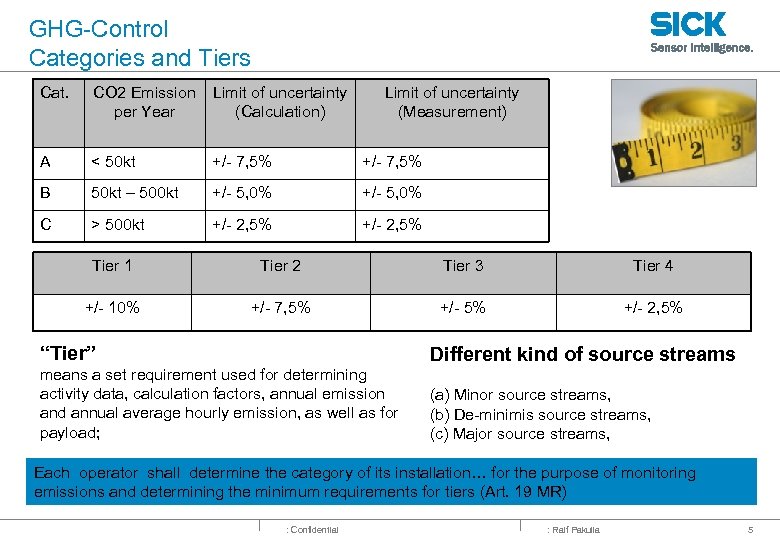

GHG-Control Categories and Tiers Cat. CO 2 Emission per Year Limit of uncertainty (Calculation) Limit of uncertainty (Measurement) A < 50 kt +/- 7, 5% B 50 kt – 500 kt +/- 5, 0% C > 500 kt +/- 2, 5% Tier 1 Tier 2 Tier 3 Tier 4 +/- 10% +/- 7, 5% +/- 2, 5% “Tier” Different kind of source streams means a set requirement used for determining activity data, calculation factors, annual emission and annual average hourly emission, as well as for payload; (a) Minor source streams, (b) De-minimis source streams, (c) Major source streams, Each operator shall determine the category of its installation… for the purpose of monitoring emissions and determining the minimum requirements for tiers (Art. 19 MR) : Confidential : Ralf Pakulla 5

GHG-Control Categories and Tiers Cat. CO 2 Emission per Year Limit of uncertainty (Calculation) Limit of uncertainty (Measurement) A < 50 kt +/- 7, 5% B 50 kt – 500 kt +/- 5, 0% C > 500 kt +/- 2, 5% Tier 1 Tier 2 Tier 3 Tier 4 +/- 10% +/- 7, 5% +/- 2, 5% “Tier” Different kind of source streams means a set requirement used for determining activity data, calculation factors, annual emission and annual average hourly emission, as well as for payload; (a) Minor source streams, (b) De-minimis source streams, (c) Major source streams, Each operator shall determine the category of its installation… for the purpose of monitoring emissions and determining the minimum requirements for tiers (Art. 19 MR) : Confidential : Ralf Pakulla 5

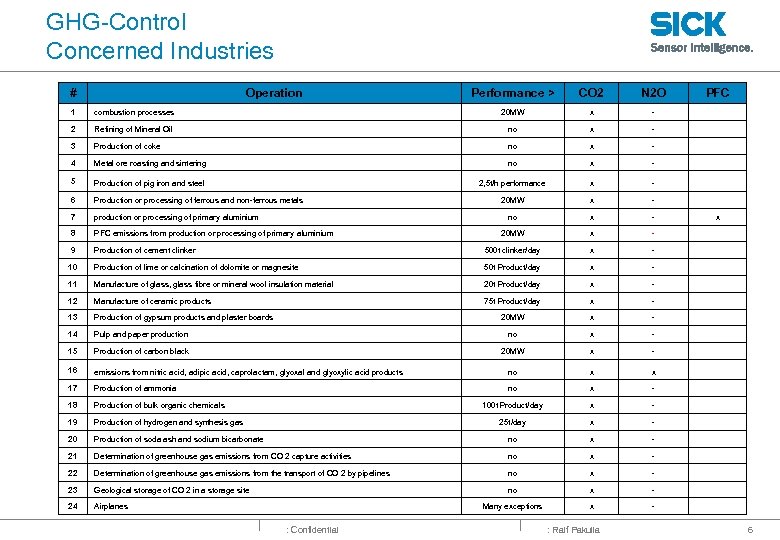

GHG-Control Concerned Industries # Operation Performance > CO 2 N 2 O PFC 1 combustion processes 20 MW x - 2 Refining of Mineral Oil no x - 3 Production of coke no x - 4 Metal ore roasting and sintering no x - 5 Production of pig iron and steel 2, 5 t/h performance x - 6 Production or processing of ferrous and non-ferrous metals 20 MW x - 7 production or processing of primary aluminium no x - x 8 PFC emissions from production or processing of primary aluminium 20 MW x - 9 Production of cement clinker 500 t clinker/day x - 10 Production of lime or calcination of dolomite or magnesite 50 t Product/day x - 11 Manufacture of glass, glass fibre or mineral wool insulation material 20 t Product/day x - 12 Manufacture of ceramic products 75 t Product/day x - 13 Production of gypsum products and plaster boards 20 MW x - 14 Pulp and paper production no x - 15 Production of carbon black 20 MW x - 16 emissions from nitric acid, adipic acid, caprolactam, glyoxal and glyoxylic acid products no x x 17 Production of ammonia no x - 18 Production of bulk organic chemicals 100 t Product/day x - 19 Production of hydrogen and synthesis gas 25 t/day x - 20 Production of soda ash and sodium bicarbonate no x - 21 Determination of greenhouse gas emissions from CO 2 capture activities no x - 22 Determination of greenhouse gas emissions from the transport of CO 2 by pipelines no x - 23 Geological storage of CO 2 in a storage site no x - 24 Airplanes Many exceptions x - : Confidential : Ralf Pakulla 6

GHG-Control Concerned Industries # Operation Performance > CO 2 N 2 O PFC 1 combustion processes 20 MW x - 2 Refining of Mineral Oil no x - 3 Production of coke no x - 4 Metal ore roasting and sintering no x - 5 Production of pig iron and steel 2, 5 t/h performance x - 6 Production or processing of ferrous and non-ferrous metals 20 MW x - 7 production or processing of primary aluminium no x - x 8 PFC emissions from production or processing of primary aluminium 20 MW x - 9 Production of cement clinker 500 t clinker/day x - 10 Production of lime or calcination of dolomite or magnesite 50 t Product/day x - 11 Manufacture of glass, glass fibre or mineral wool insulation material 20 t Product/day x - 12 Manufacture of ceramic products 75 t Product/day x - 13 Production of gypsum products and plaster boards 20 MW x - 14 Pulp and paper production no x - 15 Production of carbon black 20 MW x - 16 emissions from nitric acid, adipic acid, caprolactam, glyoxal and glyoxylic acid products no x x 17 Production of ammonia no x - 18 Production of bulk organic chemicals 100 t Product/day x - 19 Production of hydrogen and synthesis gas 25 t/day x - 20 Production of soda ash and sodium bicarbonate no x - 21 Determination of greenhouse gas emissions from CO 2 capture activities no x - 22 Determination of greenhouse gas emissions from the transport of CO 2 by pipelines no x - 23 Geological storage of CO 2 in a storage site no x - 24 Airplanes Many exceptions x - : Confidential : Ralf Pakulla 6

GHG-Control: GHG-Control The Solution: GHG-Control : Confidential : Ralf Pakulla 7

GHG-Control: GHG-Control The Solution: GHG-Control : Confidential : Ralf Pakulla 7

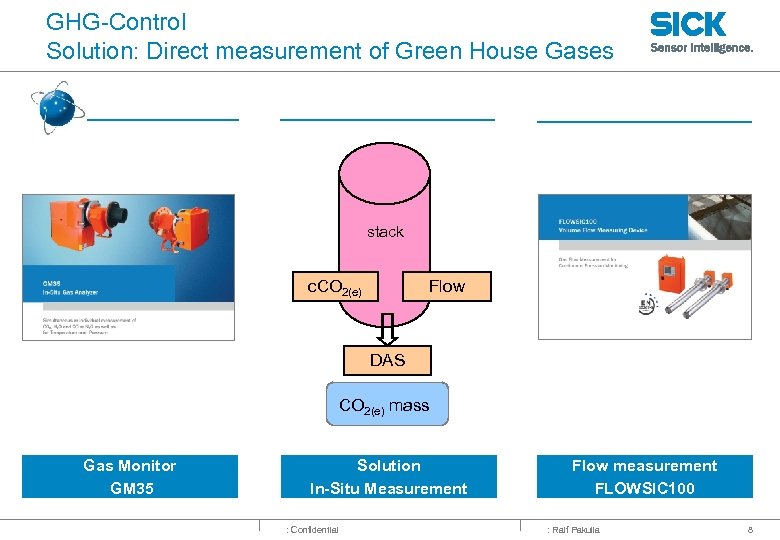

GHG-Control Solution: Direct measurement of Green House Gases stack c. CO 2(e) Flow DAS CO 2(e) mass Gas Monitor GM 35 Solution In-Situ Measurement : Confidential Flow measurement FLOWSIC 100 : Ralf Pakulla 8

GHG-Control Solution: Direct measurement of Green House Gases stack c. CO 2(e) Flow DAS CO 2(e) mass Gas Monitor GM 35 Solution In-Situ Measurement : Confidential Flow measurement FLOWSIC 100 : Ralf Pakulla 8

GHG-Control Easy Movie – “www. sick. com/ghg-control” : Confidential : Ralf Pakulla 9

GHG-Control Easy Movie – “www. sick. com/ghg-control” : Confidential : Ralf Pakulla 9

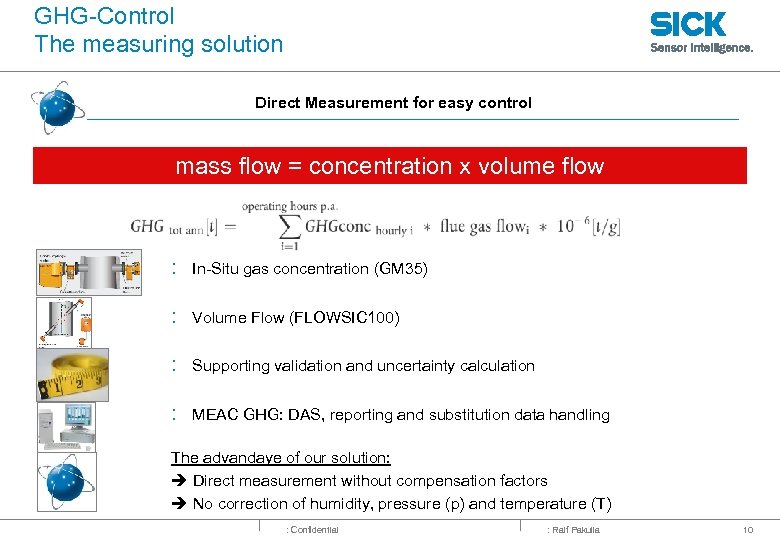

GHG-Control The measuring solution Direct Measurement for easy control mass flow = concentration x volume flow : In-Situ gas concentration (GM 35) : Volume Flow (FLOWSIC 100) : Supporting validation and uncertainty calculation : MEAC GHG: DAS, reporting and substitution data handling The advandaye of our solution: Direct measurement without compensation factors No correction of humidity, pressure (p) and temperature (T) : Confidential : Ralf Pakulla 10

GHG-Control The measuring solution Direct Measurement for easy control mass flow = concentration x volume flow : In-Situ gas concentration (GM 35) : Volume Flow (FLOWSIC 100) : Supporting validation and uncertainty calculation : MEAC GHG: DAS, reporting and substitution data handling The advandaye of our solution: Direct measurement without compensation factors No correction of humidity, pressure (p) and temperature (T) : Confidential : Ralf Pakulla 10

GHG-Control: GM 35 1 CO 2 & CO/N 2 O Monitor CO 2(e) GHG-Control : Confidential : Ralf Pakulla 11

GHG-Control: GM 35 1 CO 2 & CO/N 2 O Monitor CO 2(e) GHG-Control : Confidential : Ralf Pakulla 11

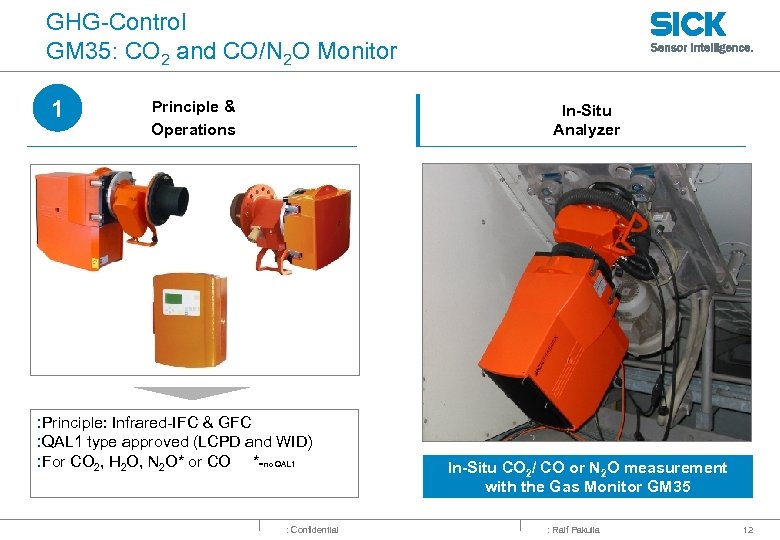

GHG-Control GM 35: CO 2 and CO/N 2 O Monitor 1 Principle & Operations In-Situ Analyzer : Principle: Infrared-IFC & GFC : QAL 1 type approved (LCPD and WID) : For CO 2, H 2 O, N 2 O* or CO *=no QAL 1 : Confidential In-Situ CO 2/ CO or N 2 O measurement with the Gas Monitor GM 35 : Ralf Pakulla 12

GHG-Control GM 35: CO 2 and CO/N 2 O Monitor 1 Principle & Operations In-Situ Analyzer : Principle: Infrared-IFC & GFC : QAL 1 type approved (LCPD and WID) : For CO 2, H 2 O, N 2 O* or CO *=no QAL 1 : Confidential In-Situ CO 2/ CO or N 2 O measurement with the Gas Monitor GM 35 : Ralf Pakulla 12

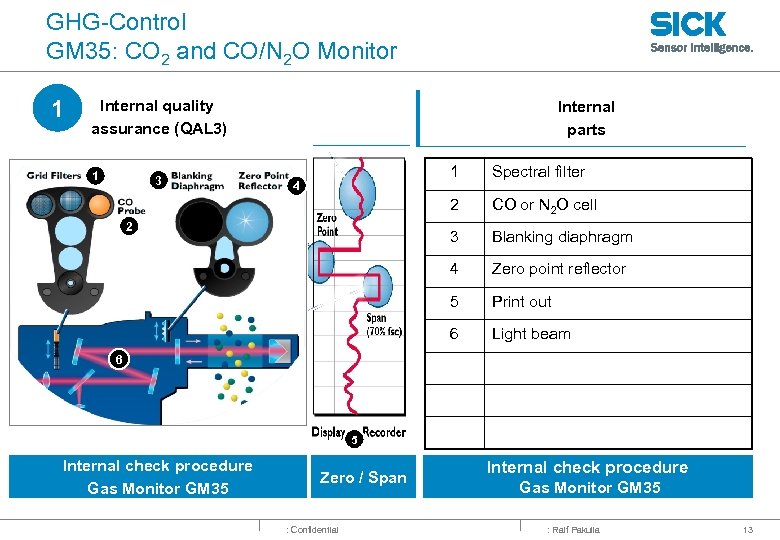

GHG-Control GM 35: CO 2 and CO/N 2 O Monitor 1 Internal quality assurance (QAL 3) Internal parts Blanking diaphragm Zero point reflector 5 Print out 6 2 CO or N 2 O cell 3 4 Spectral filter 4 3 1 2 1 Light beam 6 5 Internal check procedure Gas Monitor GM 35 Zero / Span : Confidential Internal check procedure Gas Monitor GM 35 : Ralf Pakulla 13

GHG-Control GM 35: CO 2 and CO/N 2 O Monitor 1 Internal quality assurance (QAL 3) Internal parts Blanking diaphragm Zero point reflector 5 Print out 6 2 CO or N 2 O cell 3 4 Spectral filter 4 3 1 2 1 Light beam 6 5 Internal check procedure Gas Monitor GM 35 Zero / Span : Confidential Internal check procedure Gas Monitor GM 35 : Ralf Pakulla 13

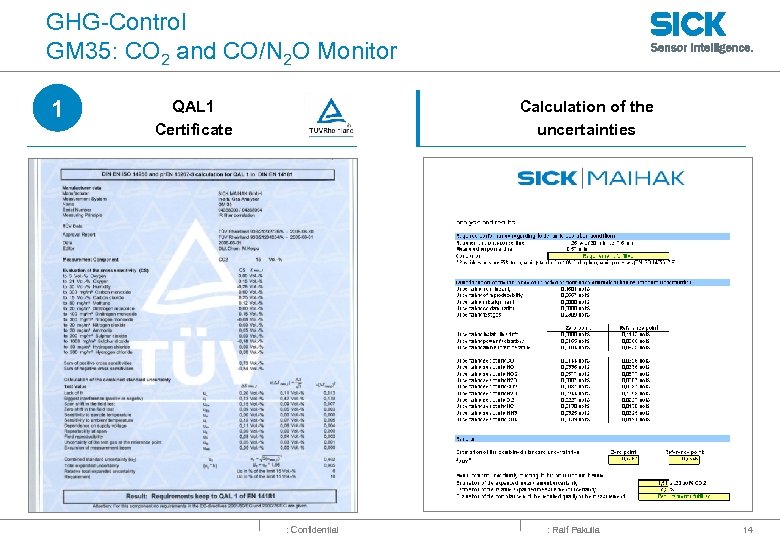

GHG-Control GM 35: CO 2 and CO/N 2 O Monitor 1 QAL 1 Certificate Calculation of the uncertainties : Confidential : Ralf Pakulla 14

GHG-Control GM 35: CO 2 and CO/N 2 O Monitor 1 QAL 1 Certificate Calculation of the uncertainties : Confidential : Ralf Pakulla 14

GHG-Control: FLOWSIC 100 2 Flow Measurement GHG-Control : Confidential : Ralf Pakulla 15

GHG-Control: FLOWSIC 100 2 Flow Measurement GHG-Control : Confidential : Ralf Pakulla 15

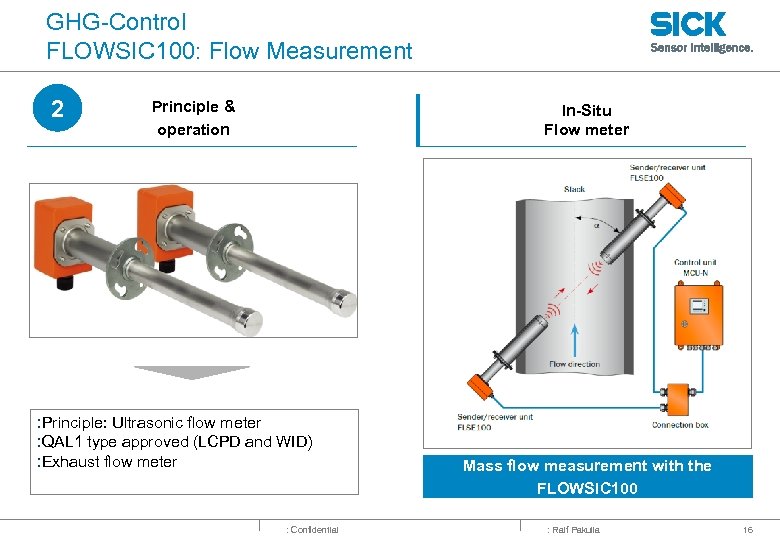

GHG-Control FLOWSIC 100: Flow Measurement 2 Principle & operation In-Situ Flow meter : Principle: Ultrasonic flow meter : QAL 1 type approved (LCPD and WID) : Exhaust flow meter : Confidential Mass flow measurement with the FLOWSIC 100 : Ralf Pakulla 16

GHG-Control FLOWSIC 100: Flow Measurement 2 Principle & operation In-Situ Flow meter : Principle: Ultrasonic flow meter : QAL 1 type approved (LCPD and WID) : Exhaust flow meter : Confidential Mass flow measurement with the FLOWSIC 100 : Ralf Pakulla 16

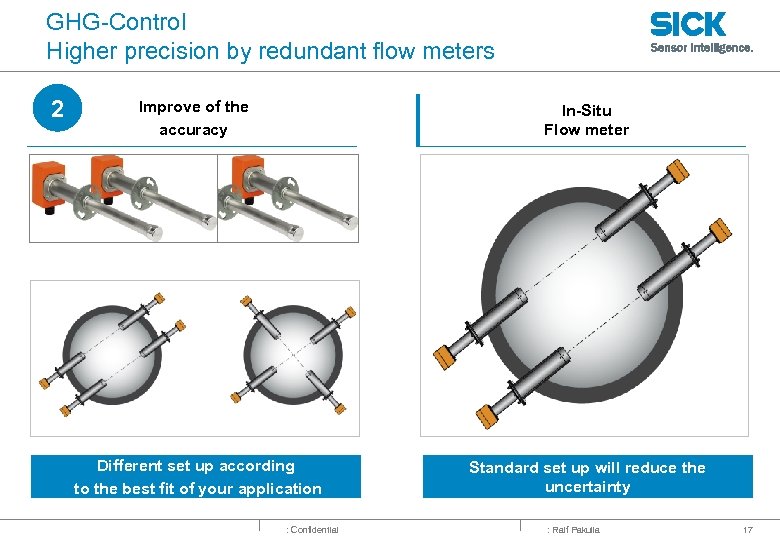

GHG-Control Higher precision by redundant flow meters 2 Improve of the accuracy In-Situ Flow meter Different set up according to the best fit of your application Standard set up will reduce the uncertainty : Confidential : Ralf Pakulla 17

GHG-Control Higher precision by redundant flow meters 2 Improve of the accuracy In-Situ Flow meter Different set up according to the best fit of your application Standard set up will reduce the uncertainty : Confidential : Ralf Pakulla 17

GHG-Control: GHG-Control 3 Services GHG-Control : Confidential : Ralf Pakulla 18

GHG-Control: GHG-Control 3 Services GHG-Control : Confidential : Ralf Pakulla 18

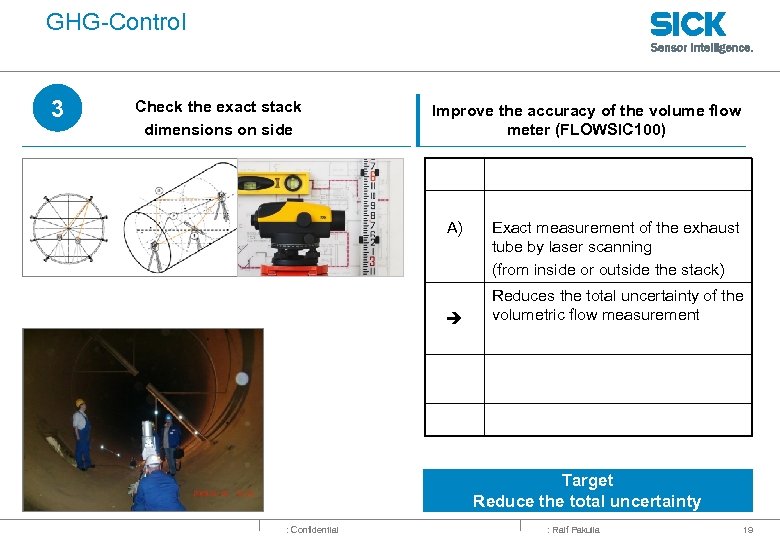

GHG-Control 3 Check the exact stack dimensions on side Improve the accuracy of the volume flow meter (FLOWSIC 100) A) Exact measurement of the exhaust tube by laser scanning (from inside or outside the stack) Reduces the total uncertainty of the volumetric flow measurement Target Reduce the total uncertainty : Confidential : Ralf Pakulla 19

GHG-Control 3 Check the exact stack dimensions on side Improve the accuracy of the volume flow meter (FLOWSIC 100) A) Exact measurement of the exhaust tube by laser scanning (from inside or outside the stack) Reduces the total uncertainty of the volumetric flow measurement Target Reduce the total uncertainty : Confidential : Ralf Pakulla 19

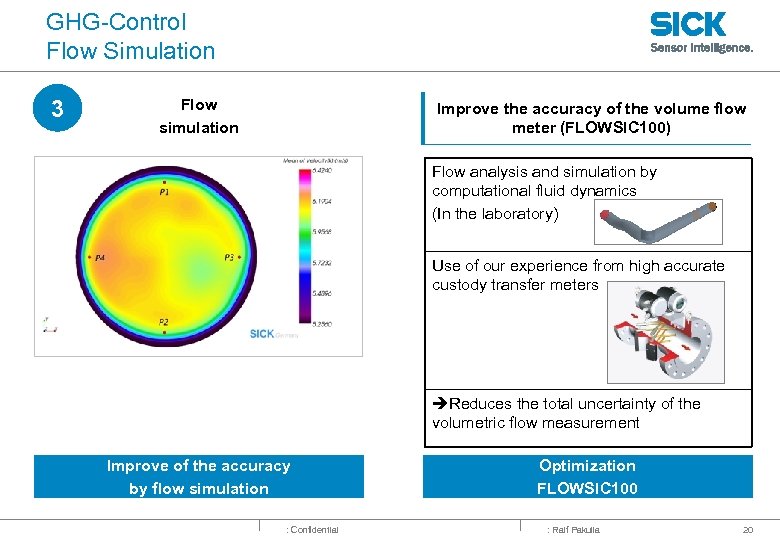

GHG-Control Flow Simulation 3 Flow simulation Improve the accuracy of the volume flow meter (FLOWSIC 100) Flow analysis and simulation by computational fluid dynamics (In the laboratory) Use of our experience from high accurate custody transfer meters Reduces the total uncertainty of the volumetric flow measurement Improve of the accuracy by flow simulation : Confidential Optimization FLOWSIC 100 : Ralf Pakulla 20

GHG-Control Flow Simulation 3 Flow simulation Improve the accuracy of the volume flow meter (FLOWSIC 100) Flow analysis and simulation by computational fluid dynamics (In the laboratory) Use of our experience from high accurate custody transfer meters Reduces the total uncertainty of the volumetric flow measurement Improve of the accuracy by flow simulation : Confidential Optimization FLOWSIC 100 : Ralf Pakulla 20

GHG-Control: GHG-Control 4 Validation GHG-Control : Confidential : Ralf Pakulla 21

GHG-Control: GHG-Control 4 Validation GHG-Control : Confidential : Ralf Pakulla 21

GHG-Control Validation Strategy 4 Use of applicable ISO and EN standards and good engineering practice Corroborating with calculation of Emissions : : The operator shall corroborate emissions determined by a measurementbased methodology…by calculating the annual emissions of each considered greenhouse gas for the same emission source and source streams The use of tier methodologies shall not be required. (Art. 46 MR) Typical methods: : Calibration and quality assurance according to EN 14181 (QAL 2) : Reference measurement of volume flow and concentration : Thermo balance measurement (EN 12952 -15) : Thermodynamic calculations using plant data management : GUM EN 13005 : Confidential : Ralf Pakulla 22

GHG-Control Validation Strategy 4 Use of applicable ISO and EN standards and good engineering practice Corroborating with calculation of Emissions : : The operator shall corroborate emissions determined by a measurementbased methodology…by calculating the annual emissions of each considered greenhouse gas for the same emission source and source streams The use of tier methodologies shall not be required. (Art. 46 MR) Typical methods: : Calibration and quality assurance according to EN 14181 (QAL 2) : Reference measurement of volume flow and concentration : Thermo balance measurement (EN 12952 -15) : Thermodynamic calculations using plant data management : GUM EN 13005 : Confidential : Ralf Pakulla 22

GHG-Control: MEAC GHG 5 Data Handling and Reporting GHG-Control : Confidential : Ralf Pakulla 23

GHG-Control: MEAC GHG 5 Data Handling and Reporting GHG-Control : Confidential : Ralf Pakulla 23

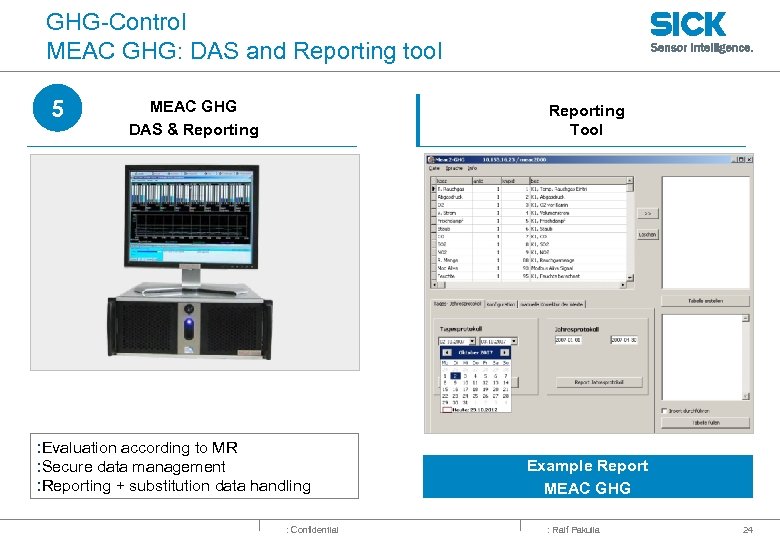

GHG-Control MEAC GHG: DAS and Reporting tool 5 MEAC GHG DAS & Reporting Tool : Evaluation according to MR : Secure data management : Reporting + substitution data handling : Confidential Example Report MEAC GHG : Ralf Pakulla 24

GHG-Control MEAC GHG: DAS and Reporting tool 5 MEAC GHG DAS & Reporting Tool : Evaluation according to MR : Secure data management : Reporting + substitution data handling : Confidential Example Report MEAC GHG : Ralf Pakulla 24

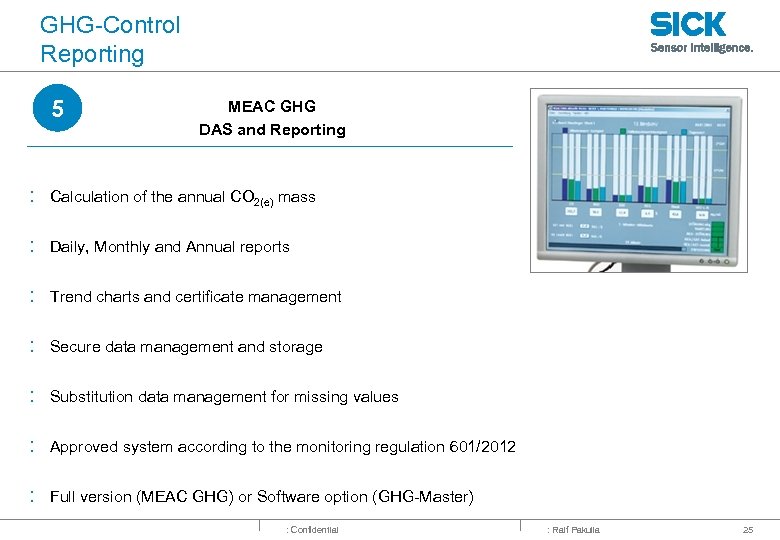

GHG-Control Reporting 5 MEAC GHG DAS and Reporting : Calculation of the annual CO 2(e) mass : Daily, Monthly and Annual reports : Trend charts and certificate management : Secure data management and storage : Substitution data management for missing values : Approved system according to the monitoring regulation 601/2012 : Full version (MEAC GHG) or Software option (GHG-Master) : Confidential : Ralf Pakulla 25

GHG-Control Reporting 5 MEAC GHG DAS and Reporting : Calculation of the annual CO 2(e) mass : Daily, Monthly and Annual reports : Trend charts and certificate management : Secure data management and storage : Substitution data management for missing values : Approved system according to the monitoring regulation 601/2012 : Full version (MEAC GHG) or Software option (GHG-Master) : Confidential : Ralf Pakulla 25

GHG-Control: GHG-Control ! Summary GHG-Control : Confidential : Ralf Pakulla 26

GHG-Control: GHG-Control ! Summary GHG-Control : Confidential : Ralf Pakulla 26

GHG-Control Summary ! GHG-Control from SICK : Matches Tier 4 and Tier 3 requirements (up to less then 2, 5% uncertainty) : Lower costs for determining substance flows and fuel qualities : No wet / dry conversion necessary : No influence from the temperature and pressure measurement : Direct measurement incorporates changing fuels and mixed fuels : No safety surcharge for using calculation method : Less emission certificates needed saving costs : Low cost of owner ship : Consulting, Project Management, Installation and Service out of one single source : Confidential : Ralf Pakulla 27

GHG-Control Summary ! GHG-Control from SICK : Matches Tier 4 and Tier 3 requirements (up to less then 2, 5% uncertainty) : Lower costs for determining substance flows and fuel qualities : No wet / dry conversion necessary : No influence from the temperature and pressure measurement : Direct measurement incorporates changing fuels and mixed fuels : No safety surcharge for using calculation method : Less emission certificates needed saving costs : Low cost of owner ship : Consulting, Project Management, Installation and Service out of one single source : Confidential : Ralf Pakulla 27

GHG-Control Summary ! GHG-Control from SICK Measure rather than calculate : Confidential : Ralf Pakulla 28

GHG-Control Summary ! GHG-Control from SICK Measure rather than calculate : Confidential : Ralf Pakulla 28

Thank you very much for your attention

Thank you very much for your attention