d9b02a50418baafb9429c5b4977091ae.ppt

- Количество слайдов: 54

Getting Smarter About Quality John Urquhart Tony Woods Stephen Boyd Megan Mc. Niven Greg Hoy Office of Technical Services Griffith University Brisbane/Gold Coast

I) The Quality Environment John Urquhart II) OTS Quality Management System Tony Woods III) Benchmarking…. Implementation and Action Plans Stephen Boyd IV) Process Improvements (Laboratory Inspections for the Gene Technology Regulator – OGTR) Megan Mc. Niven V) Digital Imaging Systems Greg Hoy VI) Questions and Sharing Best Practice

Office of Technical Services Director Campus Managers Deputy Director – Planning & Quality Workshop Managers Health & Safety Manager

Office of Technical Services

Quality to date in OTS § Focus on quality in OTS Mission, Vision & Goals § Staff commitment to quality service § Formation of Quality Reference Group (QRG) § Quality Awareness Courses § Quality Grants - eg benchmarking, web-based systems § Development of QMS

Why Implement a QMS? § Recommended in Tech Services Review 1997 § Increased emphasis by Industry, Govt & Unis - AUQA § Quality - goal of any self-respecting service provider § OTS staff committed to service quality § Need to check that we’re doing the best job possible & not becoming complacent § QMS provides structured mechanism

I) The Quality Environment John Urquhart II) OTS Quality Management System Tony Woods III) Benchmarking…. Implementation and Action Plans Stephen Boyd IV) Process Improvements (Laboratory Inspections for the Gene Technology Regulator – OGTR) Megan Mc. Niven V) Digital Imaging Systems Greg Hoy VI) Questions and Sharing Best Practice

OTS Quality Management System Tony Woods

Approach to Developing the QMS § Based around ISO 9001 & ISO 9004 international quality standards - credibility § Unobtrusive & customised for OTS § External accreditation not sought – paperwork § Not a separate system or unit – integrated into all that we do § Essentially a comprehensive summary of how we conduct our business/operations

Status § Draft QMS Completed Oct 2003 § Reviewed at Workshop & by QRG Nov 2003 § Revised QMS published as Quality Handbook March 2004 § On OTS website – easy access and version control

Quality Handbook Contents 1. 0 Overview of the Quality Management System 2. 0 Our Quality Policy 3. 0 OTS’ Role and Structure 4. 0 Staff Roles in the QMS 5. 0 Internal Planning & Management Processes 6. 0 Working With Our Clients & Stakeholders* 7. 0 Introducing or Changing a Service* 8. 0 Process Improvements – Sharing Best Practice* 9. 0 Preventing & Correcting Operational Problems*

Quality Handbook Contents cont. 10. 0 Handling Complaints* 11. 0 Keeping Track of Documents 12. 0 Guidelines for Developing Policies & Procedures 13. 0 Benchmarking & Self-Assessment 14. 0 Training & Development 15. 0 Managing Risks 16. 0 Internal Audits – Checking Our QMS 17. 0 Annual Review Appendix 1: Policies, Procedures & Related Documents Library

Quality Handbook Contents cont. Policies, Procedures & Related Documents Library – Undergraduate teaching support – Stores – Workshops – Health and Safety – Administration – Staffing – Administration – Budget/Finances – Research Support – Partnership Agreements – Client Interactions

Examples of QMS Sections § Section 6 – Working With Our Clients And Stakeholders § Section 11 – Keeping Track Of Documents

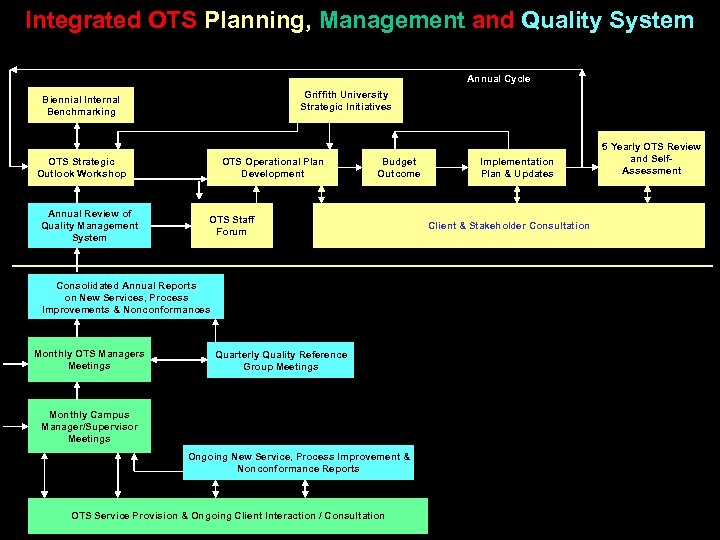

Integrated Nature of QMS Approach to Developing the QMS: § Not a separate system or unit – integrated into all that we do § Essentially a comprehensive summary of how we conduct our business/operations Reflected in: § Section 5. 0 - Internal Planning & Management Processes flowchart

Integrated OTS Planning, Management and Quality System Annual Cycle Griffith University Strategic Initiatives Biennial Internal Benchmarking OTS Strategic Outlook Workshop Annual Review of Quality Management System OTS Operational Plan Development Budget Outcome OTS Staff Forum Consolidated Annual Reports on New Services, Process Improvements & Nonconformances Monthly OTS Managers Meetings Quarterly Quality Reference Group Meetings Monthly Campus Manager/Supervisor Meetings Ongoing New Service, Process Improvement & Nonconformance Reports OTS Service Provision & Ongoing Client Interaction / Consultation Implementation Plan & Updates Client & Stakeholder Consultation 5 Yearly OTS Review and Self. Assessment

Implementing the QMS Objective : § Unobtrusive/seamless/transparent implementation Process: § Overview briefings to campus staff meetings § Detailed briefings to managers & supervisors § Forms & procedures introduced at work team level § Quality-related objectives in individual performance objectives

Some Examples § Developing a new Lab Resource Statement or other procedure? – Check the Policy/Procedures Library before you start. – Read the Section on “Developing New Policies or Procedures” for hints on what to include & how to structure it. § Exchanging versions of draft electronic documents? –Check the section on Keeping Track of about version numbering. Documents

Some Examples § Do you support labs? – use the end of semester feedback form with the course convenor or demonstrator. § Got an idea for improving the way you/we do something? –share it with others, using the Best Practice Feedback form.

I) The Quality Environment John Urquhart II) OTS Quality Management System Tony Woods III) Benchmarking…. Implementation and Action Plans Stephen Boyd IV) Process Improvements (Laboratory Inspections for the Gene Technology Regulator – OGTR) Megan Mc. Niven V) Digital Imaging Systems Greg Hoy VI) Questions and Sharing Best Practice

Benchmarking …Implementation and Action Plans Stephen Boyd

What are…? § Benchmark Guidelines (Manual) § Indicators of Good Practice § Representative of Technical support activities in Universities § Organisation’s rating against reference criteria

Anatomy of a Benchmark § Area and Element § Type (lagging, leading or learning) § Benchmark rationale § Sources of data § Good Practice Statement § Levels

The Phases § Phase 1 – Benchmark Implementation § Phase 2 – Results Assessment & Development of Improvement Strategies § Phase 3 – Implementation § Phase 4 – Monitor & Review

PHASE 1 Benchmark Implementation § Involvement all staff all disciplines concurrent group assessment § Data (lots!) → Meaningful Information

PHASE 2 Results Assessment & Development of Improvement Strategies § Assessment & Selection Use of both Quantitative (low scores) and Qualitative responses ‘Swamped’ issues § Confirm selection with originators

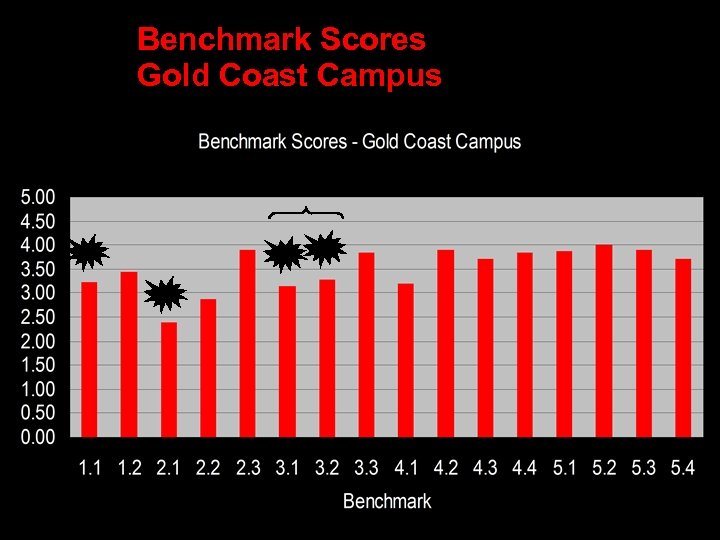

Benchmark Scores Gold Coast Campus

Strategies § Benchmark Statement Score (Quant/Qual. ) § Objective/Action § Stakeholders § Accountabilities § Resources Required § Constraints § Outcome Measurement § Comments § Review Date

PHASE 3 Implementation § Comprehensive involvement All staff § Integration into operations Performance Management § Limitations Budget

PHASE 4 Monitor and Review § Review and modify if necessary § Improvement Strategy Outcomes

I) The Quality Environment John Urquhart II) OTS Quality Management System Tony Woods III) Benchmarking…. Implementation and Action Plans Stephen Boyd IV) Process Improvements (Laboratory Inspections for the Gene Technology Regulator – OGTR) Megan Mc. Niven V) Digital Imaging Systems Greg Hoy VI) Questions and Sharing Best Practice

Process Improvements (Laboratory Inspections for the Gene Technology Regulator – OGTR) Megan Mc. Niven

What should the QMS mean to technical staff? • Best practice • Continuous improvement • Monitoring and improving performance • Impose minimal additional bureaucracy on staff

Context • How can I use the QMS to improve the process of laboratory inspections for the Gene Technology Regulator (OGTR)?

The Quality Handbook • Section 6: Working with our clients and stakeholders • Section 7: Introducing or changing a service • Section 8: Process Improvements • Section 11: Keeping Track of Documents

Inspection Process Present checklist to laboratory contact via email Nominate Inspection time Using the principles of the QMS Provide information to the laboratory contact Keep the lab contact informed Make them feel at ease No reply Some replies Phone laboratory contact Make an inspection time Provide Action Plan to Facilities for repairs Phone contact to make reinspection time Reinspect lab Lab inspection may fail Request that lab contact fill out checklist Inspector has knowledge of deficiencies and assists where possible Inspect lab Provide Action Plan to Lab contact Offer assistance Request details of progress Inspector provides assistance where possible Increased chance of Lab passing

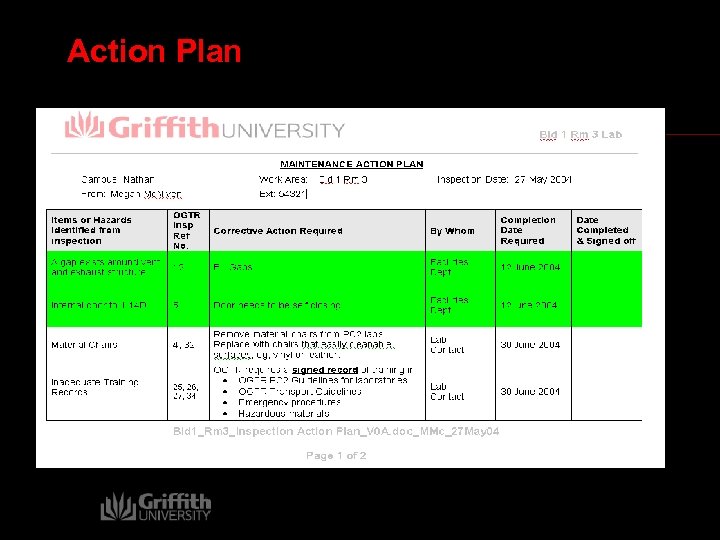

Example 2: Action Plan • Ineffective • Seek feedback • Alter format • Monitor effectiveness Example 3: Version control

Action Plan

Conclusion The benefits of using the principles of the QMS • Faults in the process have been identified, corrected and monitored • Clients are prompted, kept informed and guided through the process • The laboratory inspection process is more efficient and less onerous • Compliance and satisfaction of clients has is improved

I) The Quality Environment John Urquhart II) OTS Quality Management System Tony Woods III) Benchmarking…. Implementation and Action Plans Stephen Boyd IV) Process Improvements (Laboratory Inspections for the Gene Technology Regulator – OGTR) Megan Mc. Niven V) Digital Imaging Systems Greg Hoy VI) Questions and Sharing Best Practice

Digital Imaging System Greg Hoy

Introduction • Technical officer supporting the photography school within the Queensland College of Arts • Griffith University • South Bank campus

Old and the New • Silver Halide films and papers • CCD CMOS and micro pore layered papers • Digital consumer market Low resolution cameras 1 - 4 megapixel • Low resolution scanners and printer • Professional high Resolution cameras 16 -22 megapixel • High resolution scanners and printer (2880 dpi) • True photographic quality • Longevity greater than traditional photographic papers

Colour Managed Digital Workflow • Using the Mac. Beth IOne Spectrophotometer • Calibrated and Profiled Monitors in photography computer lab • Calibrated Profiled Monitor for the printing computer • Profiled printer • To ICC (International Colour Consortium) standards • Calibrated and profiled monitors in addition to profiled printer will give you a colour managed workflow. • An image printed will look exactly the same as the image on the monitor (colour and contrast)

Components of the Quality Management System Used 6. 0 Working with our clients and stakeholders 8. 0 Process improvement – sharing best practice 9. 0 Preventing and correcting operational problems 13. 0 Benchmarking and self-assessment

6. 0 Working with our clients and stakeholders • First assisted in establishing what was required from the new process • Lastly helped to develop a feedback mechanism • Formal and Informal

8. 0 Process improvement – sharing best practice • Used to gather information from stakeholders • Used to gather information from informed sources • Working document used in the planing, implementation and review stages

9. 0 Preventing and correcting operational problems • This form was used to formulate improvements with procedures already implemented

13. 0 Benchmarking and self– assessment • This is yet to be undertaken but will be in the near future

Epson 3000 Epson 7600 pro

Printing Computer Photography Computer Lab

Formalised planning of the QMS assisted in the selection of the appropriate • Printer • Software • Monitors • Paper Stock • Inks • Network Instils an ethos of quality, best practice and continuous improvement

I) The Quality Environment John Urquhart II) OTS Quality Management System Tony Woods III) Benchmarking…. Implementation and Action Plans Stephen Boyd IV) Process Improvements (Laboratory Inspections for the Gene Technology Regulator – OGTR) Megan Mc. Niven V) Digital Imaging Systems Greg Hoy VI) Questions and Sharing Best Practice

d9b02a50418baafb9429c5b4977091ae.ppt