7cab86be6900155b84d4ef74582dc774.ppt

- Количество слайдов: 45

Getting it Right with Nutrient and Pesticide Applications Misapplication of pesticides and nutrients pose a potential threat to the environment and human health. Misapplication of pesticides and nutrients cause a financial loss in the form of: • poor pest control • lost nutrients and pesticides • crops/plant damage

Getting it Right with Nutrient and Pesticide Applications Misapplication of pesticides and nutrients pose a potential threat to the environment and human health. Misapplication of pesticides and nutrients cause a financial loss in the form of: • poor pest control • lost nutrients and pesticides • crops/plant damage

Pesticide Applicator Core Training Manual Part B, Chapter 5 Sprayer Calibration: A Groundwater Protection Practice

Pesticide Applicator Core Training Manual Part B, Chapter 5 Sprayer Calibration: A Groundwater Protection Practice

Sprayer Calibration Program developed by Michigan State University Extension Groundwater Team: R. L. Dow, M. C. Gould, H. D. Rouget, S. A. Stuby Updates By Lyndon Kelley, February-2004 To compliment the Pesticide Applicator Core Training Manual, E-2195 written by the: Pesticide Education Program

Sprayer Calibration Program developed by Michigan State University Extension Groundwater Team: R. L. Dow, M. C. Gould, H. D. Rouget, S. A. Stuby Updates By Lyndon Kelley, February-2004 To compliment the Pesticide Applicator Core Training Manual, E-2195 written by the: Pesticide Education Program

Impacts of Nitrogen • Nitrogen in the form of nitrate move easily with water • Nitrates in groundwater have been linked with methemoglobinaemia (Blue Baby Syndrome) • In most aquatic environments nitrogen is not a limiting factor for plant growth. • Most of the nitrogen entering aquatic environment will volatilize or be used by microorganisms (MSUE Bulletin WQ-12, Vitosh 1990) Nitrogen is a major threat to groundwater quality, but not to surface water quality

Impacts of Nitrogen • Nitrogen in the form of nitrate move easily with water • Nitrates in groundwater have been linked with methemoglobinaemia (Blue Baby Syndrome) • In most aquatic environments nitrogen is not a limiting factor for plant growth. • Most of the nitrogen entering aquatic environment will volatilize or be used by microorganisms (MSUE Bulletin WQ-12, Vitosh 1990) Nitrogen is a major threat to groundwater quality, but not to surface water quality

Impacts of Phosphorus • Phosphorus is the limiting nutrient for plant growth in most aquatic environments • Oxygen depletion often results from the seasonal decay of excess aquatic plant material • Most forms of livestock manure have less nitrogen concentration than phosphorus • Most crops remove three times more nitrogen than phosphorus • Phosphorus binds tightly to soil and does not move toward groundwater except for extreme situations • No known negative impacts of phosphorus in groundwater (MSUE Bulletin WQ-12, Vitosh 1990) Phosphorus is a major threat to surface water quality, but not to groundwater quality

Impacts of Phosphorus • Phosphorus is the limiting nutrient for plant growth in most aquatic environments • Oxygen depletion often results from the seasonal decay of excess aquatic plant material • Most forms of livestock manure have less nitrogen concentration than phosphorus • Most crops remove three times more nitrogen than phosphorus • Phosphorus binds tightly to soil and does not move toward groundwater except for extreme situations • No known negative impacts of phosphorus in groundwater (MSUE Bulletin WQ-12, Vitosh 1990) Phosphorus is a major threat to surface water quality, but not to groundwater quality

Impacts of Misapplied Pesticides Several pesticides have been identified as groundwater contaminates in Michigan: • alachor - Lasso • Atrazine • Cyanazine • Dicamba - Banvil • Dichloropropane • Dinoseb • Diphenamid • Hexazinone • Metolachor • Metribuxin • Prometom • Propazine • simazine Misapplied pesticides may contaminate groundwater.

Impacts of Misapplied Pesticides Several pesticides have been identified as groundwater contaminates in Michigan: • alachor - Lasso • Atrazine • Cyanazine • Dicamba - Banvil • Dichloropropane • Dinoseb • Diphenamid • Hexazinone • Metolachor • Metribuxin • Prometom • Propazine • simazine Misapplied pesticides may contaminate groundwater.

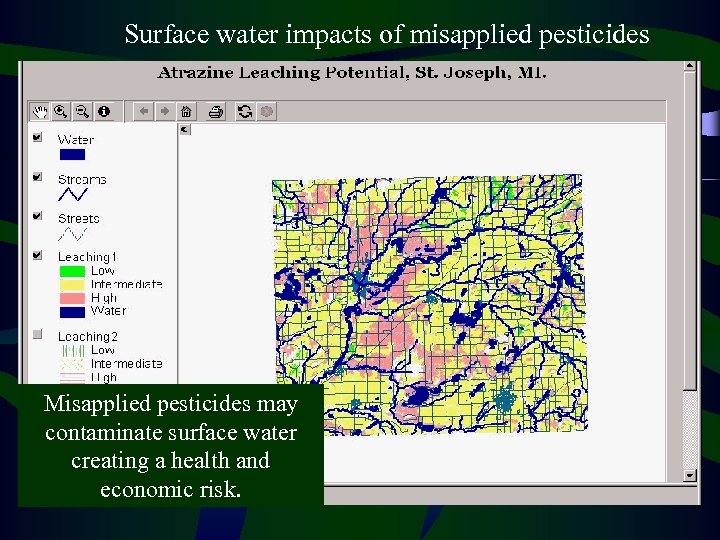

Surface water impacts of misapplied pesticides Misapplied pesticides may contaminate surface water creating a health and economic risk.

Surface water impacts of misapplied pesticides Misapplied pesticides may contaminate surface water creating a health and economic risk.

Today we’re covering: Calibration of equipment - How much is the system applying? Uniformity check of equipment - Is the amount applied, even? Avoiding mistakes - techniques for reducing the potential of mistakes

Today we’re covering: Calibration of equipment - How much is the system applying? Uniformity check of equipment - Is the amount applied, even? Avoiding mistakes - techniques for reducing the potential of mistakes

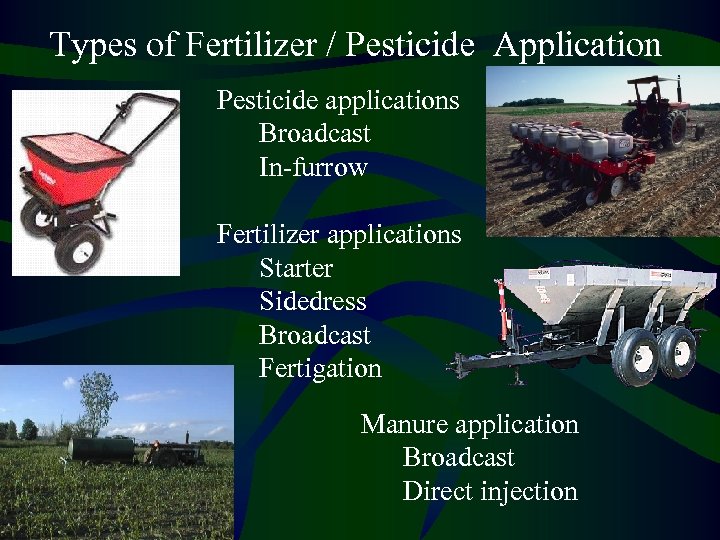

Types of Fertilizer / Pesticide Application Pesticide applications Broadcast In-furrow Fertilizer applications Starter Sidedress Broadcast Fertigation Manure application Broadcast Direct injection

Types of Fertilizer / Pesticide Application Pesticide applications Broadcast In-furrow Fertilizer applications Starter Sidedress Broadcast Fertigation Manure application Broadcast Direct injection

Fertilizer / Pesticide applications goals Apply desired rate • volume applied is what is desired • nutrient or pesticide active ingredient level is what is desired Uniform application • uniform across the width of the applicator • uniform from one end of the field/ yard to the other (start to finish)

Fertilizer / Pesticide applications goals Apply desired rate • volume applied is what is desired • nutrient or pesticide active ingredient level is what is desired Uniform application • uniform across the width of the applicator • uniform from one end of the field/ yard to the other (start to finish)

Calibration: As Easy As 1 -2 -3 #1 Nozzle - Flow Rate #2 Ground Speed #3 Nozzle or Band Width

Calibration: As Easy As 1 -2 -3 #1 Nozzle - Flow Rate #2 Ground Speed #3 Nozzle or Band Width

Why calibrate? • • Maximizes value of pesticide/fertilizer Insures legal/label rates Minimizes crop/plant injury Minimizes pest control failure

Why calibrate? • • Maximizes value of pesticide/fertilizer Insures legal/label rates Minimizes crop/plant injury Minimizes pest control failure

When to calibrate? • Each time major sprayer or applicator adjustments are made (nozzle, pressure or speed) • Change product applied • Change tractors or applicator • A minimum of once a year

When to calibrate? • Each time major sprayer or applicator adjustments are made (nozzle, pressure or speed) • Change product applied • Change tractors or applicator • A minimum of once a year

Calibration Equipment • Collection containers with graduated measurements • Calculator • Notepad and writing instrument • Stopwatch or wristwatch with second hand • Calibration formulas and a current nozzle manufacturer’s spray guide matching your nozzles

Calibration Equipment • Collection containers with graduated measurements • Calculator • Notepad and writing instrument • Stopwatch or wristwatch with second hand • Calibration formulas and a current nozzle manufacturer’s spray guide matching your nozzles

Calibration Equipment • Nozzle tip cleaning brush • One new tip matched to other nozzles on sprayer • Catch pans for granular materials. • Colored marker flags or rags • Unlined, chemical-resistant gloves

Calibration Equipment • Nozzle tip cleaning brush • One new tip matched to other nozzles on sprayer • Catch pans for granular materials. • Colored marker flags or rags • Unlined, chemical-resistant gloves

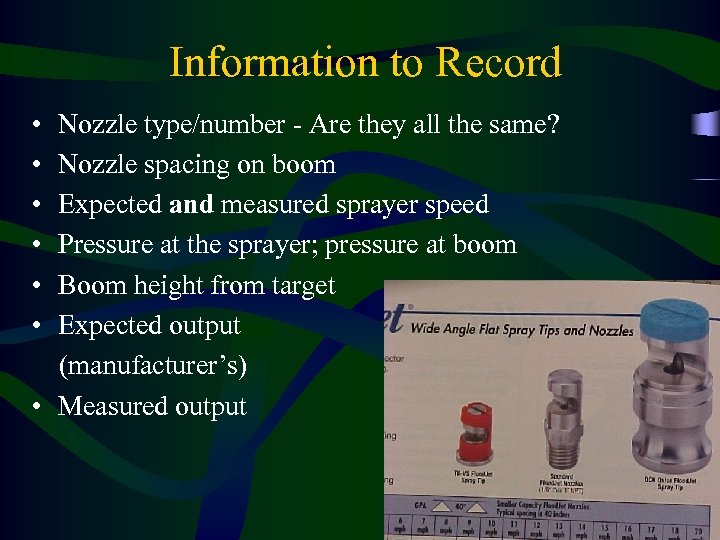

Information to Record • • • Nozzle type/number - Are they all the same? Nozzle spacing on boom Expected and measured sprayer speed Pressure at the sprayer; pressure at boom Boom height from target Expected output (manufacturer’s) • Measured output

Information to Record • • • Nozzle type/number - Are they all the same? Nozzle spacing on boom Expected and measured sprayer speed Pressure at the sprayer; pressure at boom Boom height from target Expected output (manufacturer’s) • Measured output

Methods for Calibration s Ti m M edeth flo od w n lo al G s= od ce th un Me O Tank Volume Method

Methods for Calibration s Ti m M edeth flo od w n lo al G s= od ce th un Me O Tank Volume Method

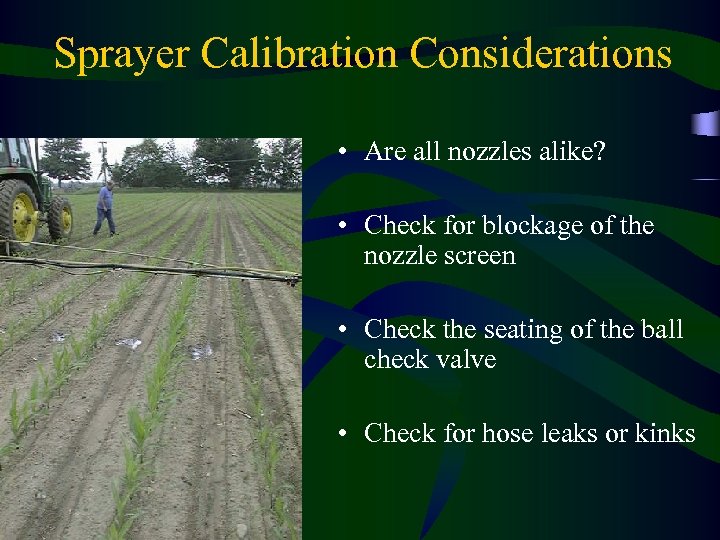

Sprayer Calibration Considerations • Are all nozzles alike? • Check for blockage of the nozzle screen • Check the seating of the ball check valve • Check for hose leaks or kinks

Sprayer Calibration Considerations • Are all nozzles alike? • Check for blockage of the nozzle screen • Check the seating of the ball check valve • Check for hose leaks or kinks

Timed Flow Method #1 Select nozzle type based on – Method of application – Field conditions – Pesticide product – Sprayer pressure – Risk of potential drift #2 Select nozzle tip (size) – Nozzle tip based on gallons per minute – GPM based on: gpa, mph, width

Timed Flow Method #1 Select nozzle type based on – Method of application – Field conditions – Pesticide product – Sprayer pressure – Risk of potential drift #2 Select nozzle tip (size) – Nozzle tip based on gallons per minute – GPM based on: gpa, mph, width

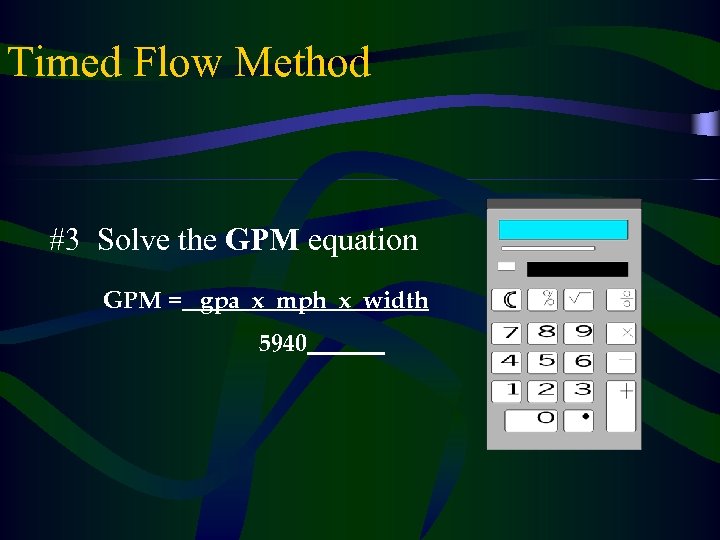

Timed Flow Method #3 Solve the GPM equation GPM = gpa x mph x width 5940

Timed Flow Method #3 Solve the GPM equation GPM = gpa x mph x width 5940

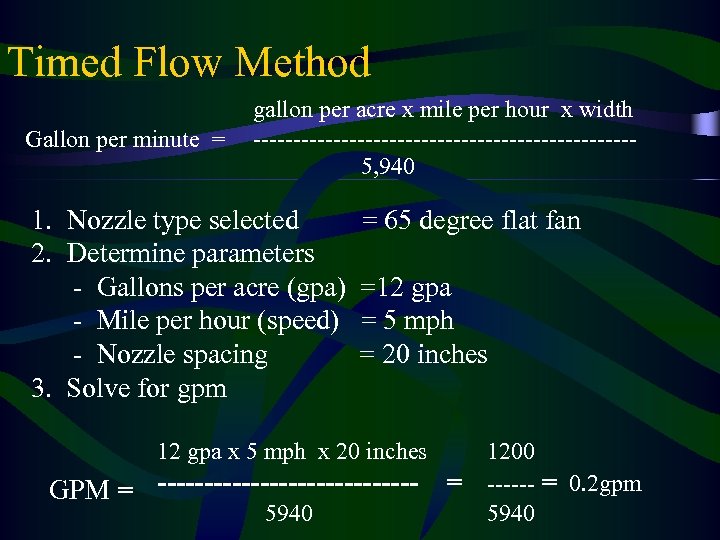

Timed Flow Method Gallon per minute = gallon per acre x mile per hour x width ------------------------5, 940 1. Nozzle type selected 2. Determine parameters - Gallons per acre (gpa) - Mile per hour (speed) - Nozzle spacing 3. Solve for gpm = 65 degree flat fan =12 gpa = 5 mph = 20 inches 12 gpa x 5 mph x 20 inches GPM = --------------5940 = 1200 ------ = 0. 2 gpm 5940

Timed Flow Method Gallon per minute = gallon per acre x mile per hour x width ------------------------5, 940 1. Nozzle type selected 2. Determine parameters - Gallons per acre (gpa) - Mile per hour (speed) - Nozzle spacing 3. Solve for gpm = 65 degree flat fan =12 gpa = 5 mph = 20 inches 12 gpa x 5 mph x 20 inches GPM = --------------5940 = 1200 ------ = 0. 2 gpm 5940

Timed Flow Method #4 Refer to manufacturer’s chart for nozzle type which delivers GPM calculated in step #3 #5 Test for uniform flow rate from each nozzle – Use water; collect from nozzle for one minute; check within ± 5% – Any nozzle discharge >10 percent of catalog specifications at a given pressure is worn out

Timed Flow Method #4 Refer to manufacturer’s chart for nozzle type which delivers GPM calculated in step #3 #5 Test for uniform flow rate from each nozzle – Use water; collect from nozzle for one minute; check within ± 5% – Any nozzle discharge >10 percent of catalog specifications at a given pressure is worn out

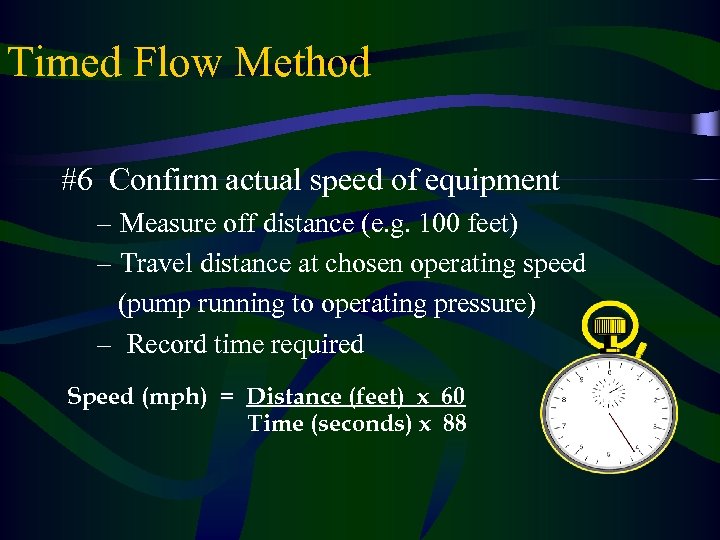

Timed Flow Method #6 Confirm actual speed of equipment – Measure off distance (e. g. 100 feet) – Travel distance at chosen operating speed (pump running to operating pressure) – Record time required Speed (mph) = Distance (feet) x 60 Time (seconds) x 88

Timed Flow Method #6 Confirm actual speed of equipment – Measure off distance (e. g. 100 feet) – Travel distance at chosen operating speed (pump running to operating pressure) – Record time required Speed (mph) = Distance (feet) x 60 Time (seconds) x 88

Ounces = Gallons Method • Before you begin: – Check nozzles for uniformity ± 5 percent – Check pressure gauges at tractor – Check that pressure is consistent with nozzle recommendations

Ounces = Gallons Method • Before you begin: – Check nozzles for uniformity ± 5 percent – Check pressure gauges at tractor – Check that pressure is consistent with nozzle recommendations

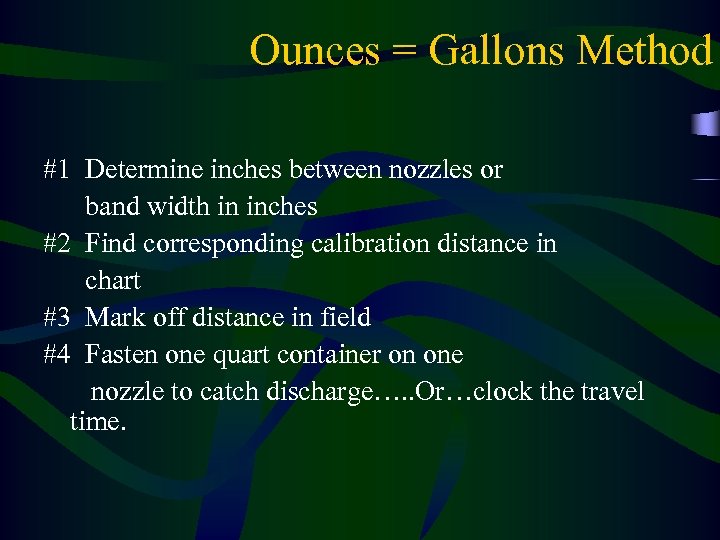

Ounces = Gallons Method #1 Determine inches between nozzles or band width in inches #2 Find corresponding calibration distance in chart #3 Mark off distance in field #4 Fasten one quart container on one nozzle to catch discharge…. . Or…clock the travel time.

Ounces = Gallons Method #1 Determine inches between nozzles or band width in inches #2 Find corresponding calibration distance in chart #3 Mark off distance in field #4 Fasten one quart container on one nozzle to catch discharge…. . Or…clock the travel time.

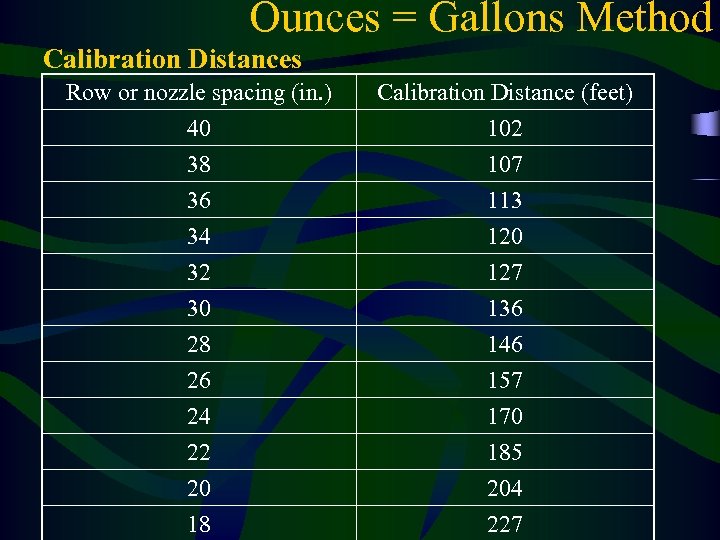

Ounces = Gallons Method Calibration Distances Row or nozzle spacing (in. ) 40 38 36 Calibration Distance (feet) 102 107 113 34 32 30 28 26 24 22 20 127 136 146 157 170 185 204 18 227

Ounces = Gallons Method Calibration Distances Row or nozzle spacing (in. ) 40 38 36 Calibration Distance (feet) 102 107 113 34 32 30 28 26 24 22 20 127 136 146 157 170 185 204 18 227

Ounces = Gallons Method #5 Run the course at operating speed, turning sprayer ON at beginning and OFF at end of course #6 Measure liquid collected (repeat and average output) #7 Ounces collected = gallons per acre

Ounces = Gallons Method #5 Run the course at operating speed, turning sprayer ON at beginning and OFF at end of course #6 Measure liquid collected (repeat and average output) #7 Ounces collected = gallons per acre

Tank - Volume Method Before you begin calibration: Check nozzles for uniformity ± 5% #1 Measure course 660 feet long in field #2 Fill spray tank to known depth (or switch to a calibration tube) #. Run the course at operating speed, turning sprayer ON at beginning and OFF at end of course

Tank - Volume Method Before you begin calibration: Check nozzles for uniformity ± 5% #1 Measure course 660 feet long in field #2 Fill spray tank to known depth (or switch to a calibration tube) #. Run the course at operating speed, turning sprayer ON at beginning and OFF at end of course

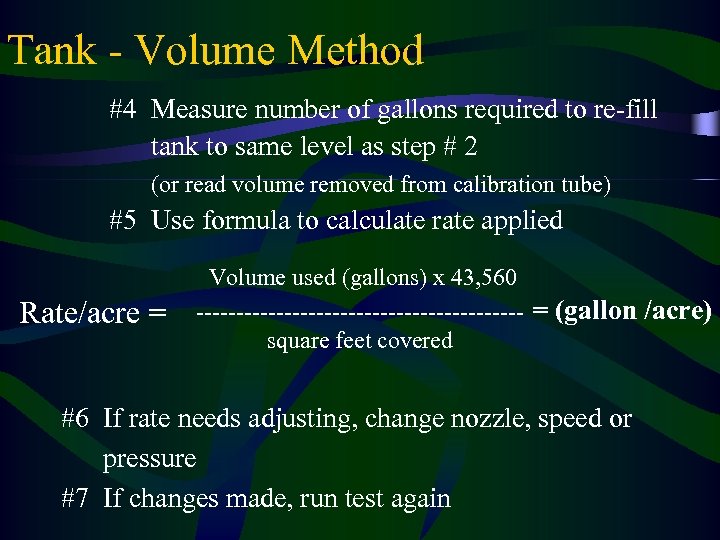

Tank - Volume Method #4 Measure number of gallons required to re-fill tank to same level as step # 2 (or read volume removed from calibration tube) #5 Use formula to calculate rate applied Rate/acre = Volume used (gallons) x 43, 560 --------------------- = (gallon /acre) square feet covered #6 If rate needs adjusting, change nozzle, speed or pressure #7 If changes made, run test again

Tank - Volume Method #4 Measure number of gallons required to re-fill tank to same level as step # 2 (or read volume removed from calibration tube) #5 Use formula to calculate rate applied Rate/acre = Volume used (gallons) x 43, 560 --------------------- = (gallon /acre) square feet covered #6 If rate needs adjusting, change nozzle, speed or pressure #7 If changes made, run test again

Sprayer Calibration Making Adjustments Increase volume/acre • Decrease ground speed • Increase operating pressure • Increase nozzle size Decrease volume / acre • Increase ground speed • Decrease operating pressure • Decrease nozzle size

Sprayer Calibration Making Adjustments Increase volume/acre • Decrease ground speed • Increase operating pressure • Increase nozzle size Decrease volume / acre • Increase ground speed • Decrease operating pressure • Decrease nozzle size

Field Information Considerations • Are the number of acres in a field accurate? • Is the applicator / sprayer spacing correct? • Do you keep accurate pesticide application records?

Field Information Considerations • Are the number of acres in a field accurate? • Is the applicator / sprayer spacing correct? • Do you keep accurate pesticide application records?

Dry Applicator/ Spreader Considerations • Check for application width varying with speed (choose speed that can be maintained) • Check for required overlap (designed over lap maybe from 0 -50%) • Check for suggested spreading width (40 ft. … 16 rows 30”… 10 ft … 20” lawn spreader) • Check for leaks and holes in tank

Dry Applicator/ Spreader Considerations • Check for application width varying with speed (choose speed that can be maintained) • Check for required overlap (designed over lap maybe from 0 -50%) • Check for suggested spreading width (40 ft. … 16 rows 30”… 10 ft … 20” lawn spreader) • Check for leaks and holes in tank

Dry Applicator/Spreader Calibration • Carefully read and follow directions for adjusting opening/flow. • Double check the products density and the use of the applicable chart. Lawn and Garden • Small, one time applications • calculate volume needed • Adjust machine for ½ of the rate desired • Cover are once • Make appropriate changes in flow and application pattern • Cover the area again with the remaining product.

Dry Applicator/Spreader Calibration • Carefully read and follow directions for adjusting opening/flow. • Double check the products density and the use of the applicable chart. Lawn and Garden • Small, one time applications • calculate volume needed • Adjust machine for ½ of the rate desired • Cover are once • Make appropriate changes in flow and application pattern • Cover the area again with the remaining product.

Dry Applicator/Spreader Calibration • Carefully read and follow directions for adjusting opening/flow. • Double check the products density and the use of the applicable chart. Ag spreaders • Adjust machine for rate desired area • With the pto off collect 1/1000 acre of flow • Calculate to find rate applied. • Make appropriate changes in flow • Check uniform application using cookie sheets • Adjust pass width to increase uniformity

Dry Applicator/Spreader Calibration • Carefully read and follow directions for adjusting opening/flow. • Double check the products density and the use of the applicable chart. Ag spreaders • Adjust machine for rate desired area • With the pto off collect 1/1000 acre of flow • Calculate to find rate applied. • Make appropriate changes in flow • Check uniform application using cookie sheets • Adjust pass width to increase uniformity

Avoiding Mistakes - techniques for reducing the potential of mistakes Proof your work when beginning. Monitor acres covered to detect changes. John’s sprayer holds 500 gallons John wants to apply at a rate of 20 gal. /acre How many acres should John cover per tank full?

Avoiding Mistakes - techniques for reducing the potential of mistakes Proof your work when beginning. Monitor acres covered to detect changes. John’s sprayer holds 500 gallons John wants to apply at a rate of 20 gal. /acre How many acres should John cover per tank full?

- Check your answers/proof your work Did the proportion of the volume used correlate with acre the should have been covered? John’s sprayer holds 500 gallons John calibrated to apply at a rate of 20 gal. /acre John sprayed 10 acres since he last filled John has 200 gallons left in the sprayer Is John’s application under , over or right on the mark?

- Check your answers/proof your work Did the proportion of the volume used correlate with acre the should have been covered? John’s sprayer holds 500 gallons John calibrated to apply at a rate of 20 gal. /acre John sprayed 10 acres since he last filled John has 200 gallons left in the sprayer Is John’s application under , over or right on the mark?

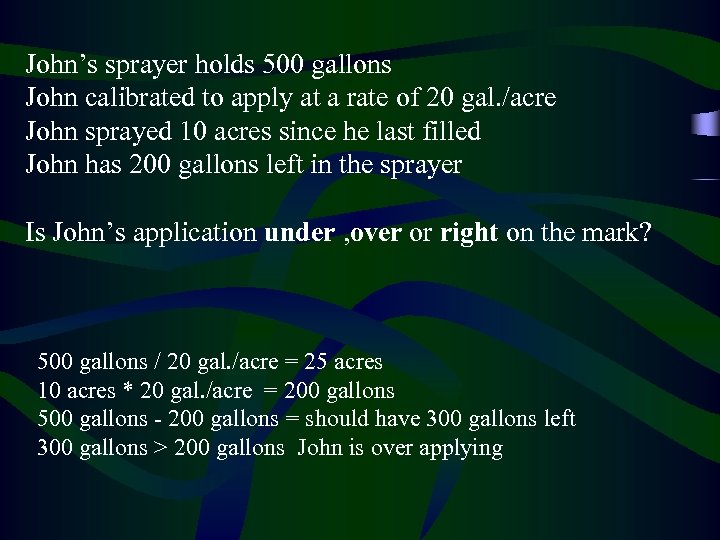

John’s sprayer holds 500 gallons John calibrated to apply at a rate of 20 gal. /acre John sprayed 10 acres since he last filled John has 200 gallons left in the sprayer Is John’s application under , over or right on the mark? 500 gallons / 20 gal. /acre = 25 acres 10 acres * 20 gal. /acre = 200 gallons 500 gallons - 200 gallons = should have 300 gallons left 300 gallons > 200 gallons John is over applying

John’s sprayer holds 500 gallons John calibrated to apply at a rate of 20 gal. /acre John sprayed 10 acres since he last filled John has 200 gallons left in the sprayer Is John’s application under , over or right on the mark? 500 gallons / 20 gal. /acre = 25 acres 10 acres * 20 gal. /acre = 200 gallons 500 gallons - 200 gallons = should have 300 gallons left 300 gallons > 200 gallons John is over applying

Avoiding Mistakes - techniques for reducing the potential of mistakes Layout a plan for each field/yard application. • Total area to be applied to • Total volume of product needed • Total amount of water needed • Calculate portion tank or number of tanks

Avoiding Mistakes - techniques for reducing the potential of mistakes Layout a plan for each field/yard application. • Total area to be applied to • Total volume of product needed • Total amount of water needed • Calculate portion tank or number of tanks

Avoiding Mistakes Make a plan …… compare your work to the plan Smith farm east field – 80 acres Tank holds 400 gallons Application rate 20 gal/acre 4 tank full (1, 600 gal) to cover the field Spray. Max (product) applied at 1. 5 qt/acre Ammonium sulfate applied at 17. 5 lb/100 gallons Spray. Max total need - 30 gallons Ammonium sulfate total need – 280 lbs Each tank Spray. Max - 7. 5 gallons Ammonium sulfate - 70 lbs

Avoiding Mistakes Make a plan …… compare your work to the plan Smith farm east field – 80 acres Tank holds 400 gallons Application rate 20 gal/acre 4 tank full (1, 600 gal) to cover the field Spray. Max (product) applied at 1. 5 qt/acre Ammonium sulfate applied at 17. 5 lb/100 gallons Spray. Max total need - 30 gallons Ammonium sulfate total need – 280 lbs Each tank Spray. Max - 7. 5 gallons Ammonium sulfate - 70 lbs

Avoiding Mistakes Make a plan …… compare your work to the plan Front Lawn – 330 Ft. x 330 = 108, 900 sq. ft. Spreader holds 40 lbs. Application rate 1 lbs. / 1000 sq. ft. * 108, 900 sq. ft. = 109 lbs. How many time will he need to fill 109 / 40 = 2. 73 hoppers full Each hopper will cover 40, 000 sq. ft.

Avoiding Mistakes Make a plan …… compare your work to the plan Front Lawn – 330 Ft. x 330 = 108, 900 sq. ft. Spreader holds 40 lbs. Application rate 1 lbs. / 1000 sq. ft. * 108, 900 sq. ft. = 109 lbs. How many time will he need to fill 109 / 40 = 2. 73 hoppers full Each hopper will cover 40, 000 sq. ft.

Avoiding Mistakes - techniques for reducing the potential of mistakes How many field passes per tank full ? 24 row applicator x 2. 5 ft/row = 60 ft. Field length 2600 ft. 20 acre /tank

Avoiding Mistakes - techniques for reducing the potential of mistakes How many field passes per tank full ? 24 row applicator x 2. 5 ft/row = 60 ft. Field length 2600 ft. 20 acre /tank

Avoiding Mistakes - techniques for reducing the potential of mistakes 24 row applicator x 2. 5 ft/row = 60 ft. Field length 2600 ft. 60 ft. X 2600 ft. = 156, 000 ft sq. /43, 560 ft sq. = 3. 6 acre/ pass 400 gallon/20 acre =20 acre /tank 20 acre / 3. 6 acre = 5. 6 passes /tank full

Avoiding Mistakes - techniques for reducing the potential of mistakes 24 row applicator x 2. 5 ft/row = 60 ft. Field length 2600 ft. 60 ft. X 2600 ft. = 156, 000 ft sq. /43, 560 ft sq. = 3. 6 acre/ pass 400 gallon/20 acre =20 acre /tank 20 acre / 3. 6 acre = 5. 6 passes /tank full

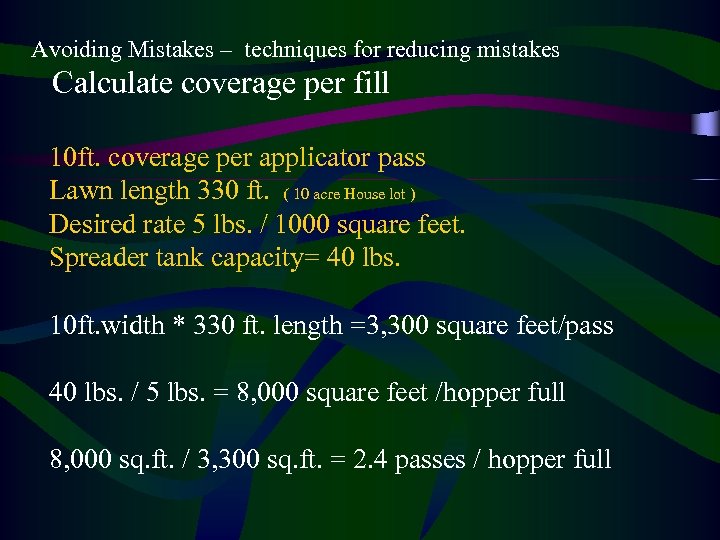

Avoiding Mistakes – techniques for reducing mistakes Calculate coverage per fill 10 ft. coverage per applicator pass Lawn length 330 ft. Desired rate 5 lbs. / 1000 square feet. Spreader tank capacity= 40 lbs.

Avoiding Mistakes – techniques for reducing mistakes Calculate coverage per fill 10 ft. coverage per applicator pass Lawn length 330 ft. Desired rate 5 lbs. / 1000 square feet. Spreader tank capacity= 40 lbs.

Avoiding Mistakes – techniques for reducing mistakes Calculate coverage per fill 10 ft. coverage per applicator pass Lawn length 330 ft. ( 10 acre House lot ) Desired rate 5 lbs. / 1000 square feet. Spreader tank capacity= 40 lbs. 10 ft. width * 330 ft. length =3, 300 square feet/pass 40 lbs. / 5 lbs. = 8, 000 square feet /hopper full 8, 000 sq. ft. / 3, 300 sq. ft. = 2. 4 passes / hopper full

Avoiding Mistakes – techniques for reducing mistakes Calculate coverage per fill 10 ft. coverage per applicator pass Lawn length 330 ft. ( 10 acre House lot ) Desired rate 5 lbs. / 1000 square feet. Spreader tank capacity= 40 lbs. 10 ft. width * 330 ft. length =3, 300 square feet/pass 40 lbs. / 5 lbs. = 8, 000 square feet /hopper full 8, 000 sq. ft. / 3, 300 sq. ft. = 2. 4 passes / hopper full

In conclusion. . . • Application calibration – protects groundwater – results in increased income / better performance – should be done at least once a year • • • Be sure application is uniform Gather calibration equipment and use it !!! Create a plan before you start Check your status with the plan as you go. If the Applicator / sprayer output is not what it is supposed to be, check for problems • Make corrections !!!

In conclusion. . . • Application calibration – protects groundwater – results in increased income / better performance – should be done at least once a year • • • Be sure application is uniform Gather calibration equipment and use it !!! Create a plan before you start Check your status with the plan as you go. If the Applicator / sprayer output is not what it is supposed to be, check for problems • Make corrections !!!