dab20f4e9838c450513c7c97402f471c.ppt

- Количество слайдов: 38

Get the Most from Your Maintenance Systems by Integrating Them with Open Standards Cliff Pedersen Manager, Production Processes Suncor Energy Services Inc. Scott Hokeness Business Development Manager Emerson Process Management

Presenters • Cliff Pedersen • Scott Hokeness

Agenda • Open standards for communicating with business systems • Using open standards to connect Emerson’s asset management applications to business systems • P 2 B Integration at Suncor

Open standards for communicating with business systems • • • MIMOSA ISA-95 B 2 MML OAGi OPC

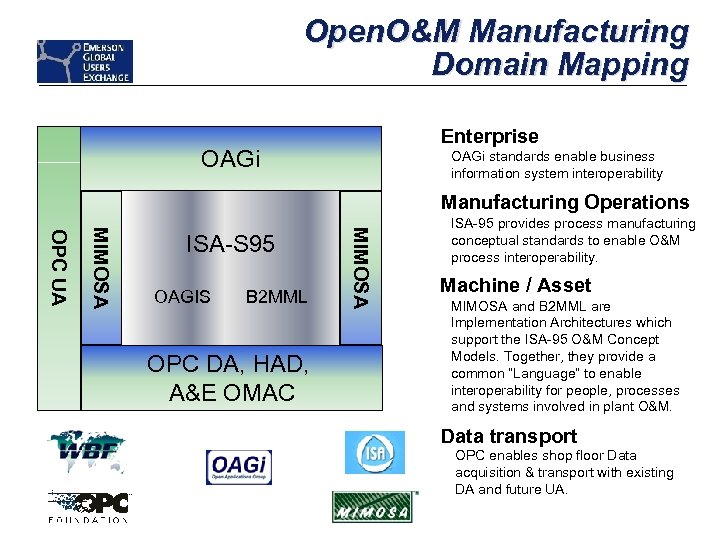

Open. O&M Manufacturing Domain Mapping Enterprise OAGi standards enable business information system interoperability Manufacturing Operations OAGIS B 2 MML OPC DA, HAD, A&E OMAC MIMOSA OPC UA ISA-S 95 ISA-95 provides process manufacturing conceptual standards to enable O&M process interoperability. Machine / Asset MIMOSA and B 2 MML are Implementation Architectures which support the ISA-95 O&M Concept Models. Together, they provide a common “Language” to enable interoperability for people, processes and systems involved in plant O&M. Data transport OPC enables shop floor Data acquisition & transport with existing DA and future UA.

Open. O&M™ Initiative • The Open. O&M Initiative is an effort by multiple industry standards organizations to provide a set of standards for the exchange of O&M data. • The Open. O&M Initiative is an open, collaborative, effort composed of diverse groups of subject matter experts organized in industry specific Joint Working Groups. • Open. O&M is a virtual organization, maintained by MIMOSA, which serves as an umbrella for collaboration.

What Is Open. O&M™ ? • MIMOSA, OPC Foundation, WBF, and ISA SP 95 have collaborated to develop a comprehensive, open information architecture for Operations & Maintenance (O&M) information flow. • Open. O&M™ leverages a combination of existing standards • The standards are vendor, platform and application neutral • The standards are applicable to manufacturing, fleet and facilities O&M applications integration

Key Standards • Key members/standards of the Open. O&M Manufacturing Joint Working Group include: – MIMOSA – What (asset management-related information standards) – OPC Foundation – How (data transport standards) – ISA SP 95 – Why (Manufacturing Process Flow Models) • Enterprise-Control System Integration Standards Committee – WBF – B 2 MML (Business To Manufacturing Markup Language)

What Are The Key Problems Open O&M Addresses? O&M Interoperability Key Business Drivers – Enterprise Interoperability Business Drivers • P 2 B-Ability to have properly coordinated, bi-directional information flow between plant and business systems • Intra-Enterprise-Ability to synthesize O&M information across multiple plant sites (like BP e. RTIS ~ Enterprise Portal Project) – Multi-Site, Multi-Enterprise Traceability / Root Cause Analysis / Reliability. Driven Organization • Life-cycle Management • Design/Engineer/Construct Information Synchronization with O&M • Comprehensive Asset Tracing & Tracking • 3 rd Party Maintainers – Remove/Replace Operations – Capability to Promise [CTP] (Sales & Marketing Organization) – Promise to Delivery [PTD] (Plant Operational Planning & Scheduling) – Safety & Security of Plants – Human Performance Improvement

Agenda • Open standards for communicating with business systems • Using open standards to connect Emerson’s asset management applications to business systems • P 2 B Integration at Suncor

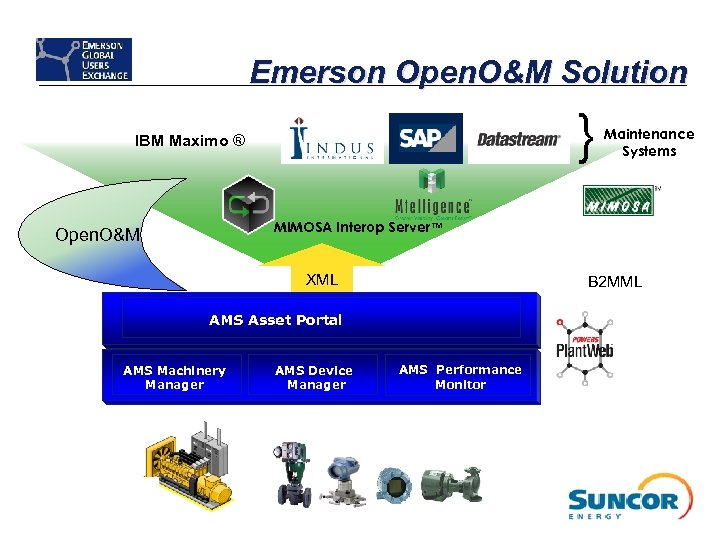

Emerson Open. O&M Solution } IBM Maximo ® Maintenance Systems MIMOSA Interop Server™ Open. O&M XML B 2 MML AMS Asset Portal AMS Machinery Manager AMS Device Manager AMS Performance Monitor

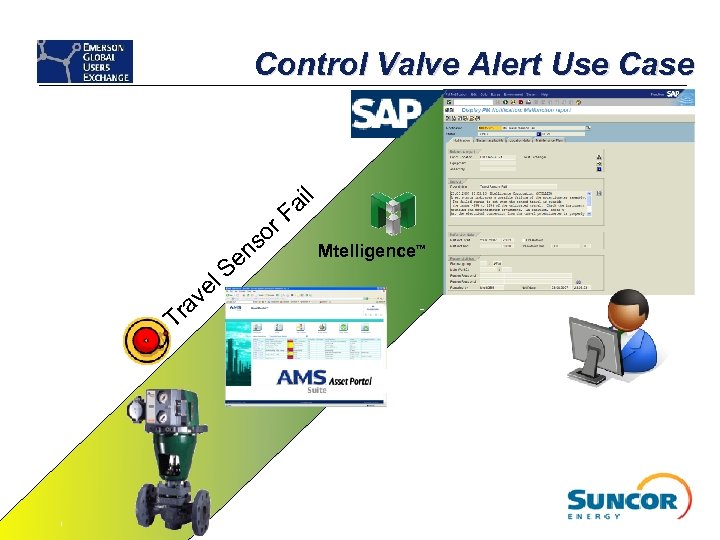

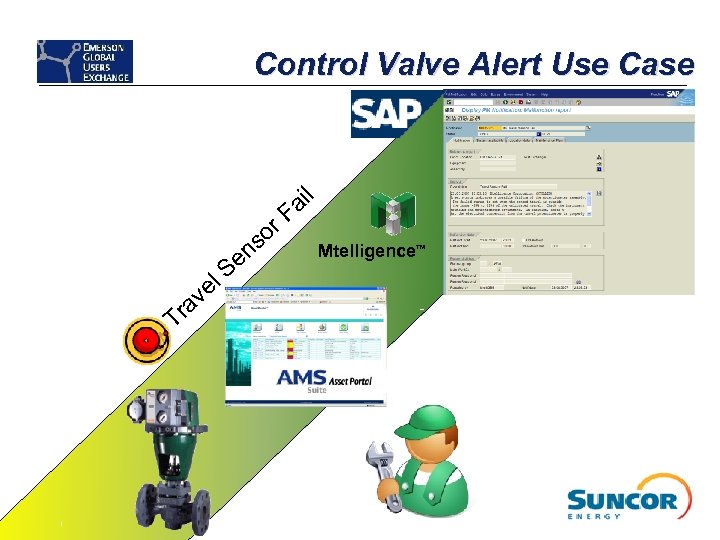

Control Valve Alert Use Case or s en ra T v l. S e l ai F Mtelligence TM

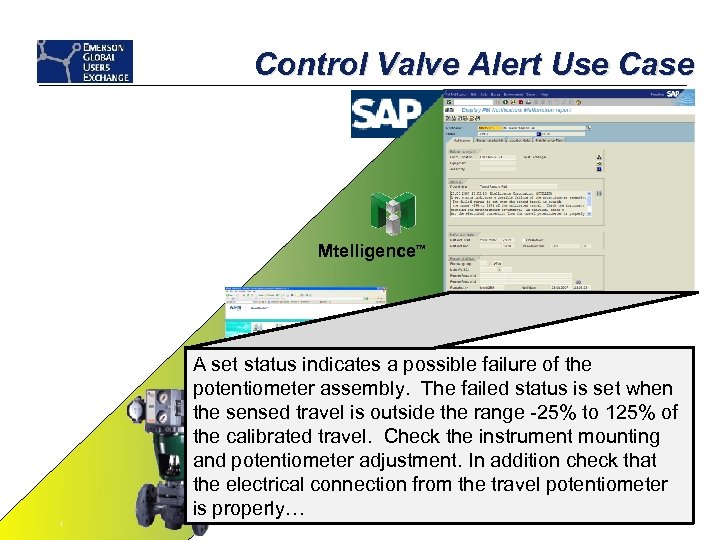

Control Valve Alert Use Case Mtelligence TM A set status indicates a possible failure of the potentiometer assembly. The failed status is set when the sensed travel is outside the range -25% to 125% of the calibrated travel. Check the instrument mounting and potentiometer adjustment. In addition check that the electrical connection from the travel potentiometer is properly…

Control Valve Alert Use Case or s en ra T v l. S e l ai F Mtelligence TM

Integrated Maintenance Management Systems Historically… • There has been a huge gap between the original vision of EAM and most currently implemented maintenance and reliability systems. • Many organizations are still not fully utilizing CMMS capabilities delivered in the 1980 s • Executives are mostly focused on improving overall operations performance, not maintenance & reliability

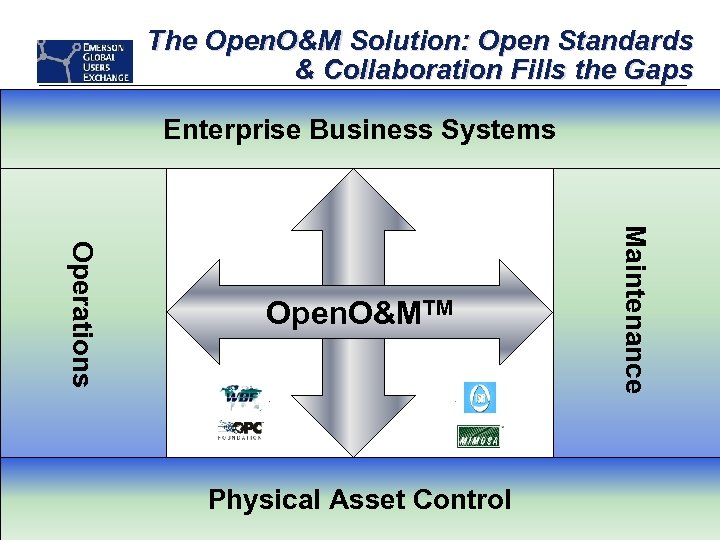

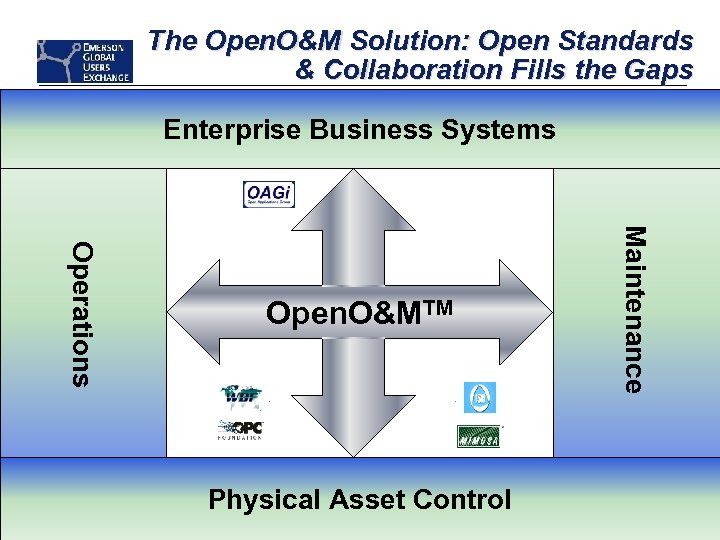

The Open. O&M Solution: Open Standards & Collaboration Fills the Gaps Enterprise Business Systems Physical Asset Control Maintenance Operations Open. O&MTM

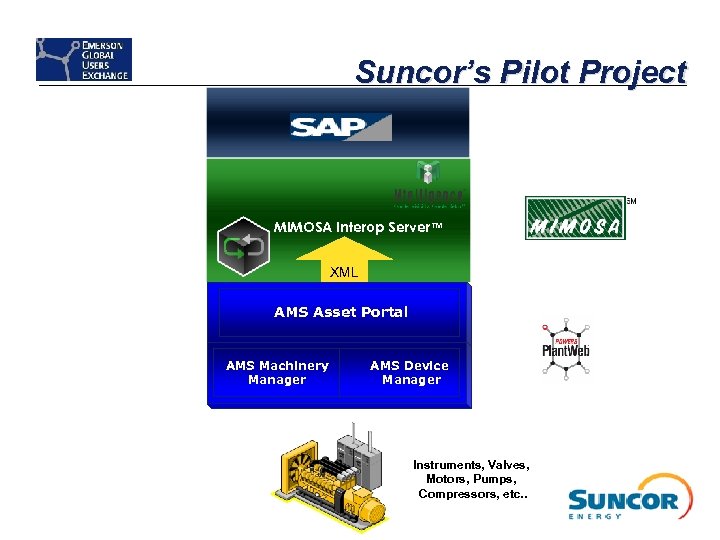

Suncor’s Pilot Project MIMOSA Interop Server™ XML AMS Asset Portal AMS Machinery Manager AMS Device Manager Instruments, Valves, Motors, Pumps, Compressors, etc. . Plant Integration to Existing Plant System

Agenda • Open standards for communicating with business systems • Using open standards to connect Emerson’s asset management applications to business systems • P 2 B Integration at Suncor

P 2 B Integration at Suncor Open. O&M, Please! Suncor Energy Inc. Presented by: Cliff Pedersen Manager, Production Processes Suncor Energy Services Inc. ISA Expo 2007 Houston, TX October 2, 2007

Legal Notice • This presentation contains certain forward-looking statements, including statements about Suncor's growth strategy and expected future production, operating and financial results that are based on Suncor's current expectations and assumptions. The forward-looking statements, identified by words such as “targets”, “strategy”, “estimates”, “pending”, “plans” and “objectives”, are not guarantees of future performance. Actual results may differ materially as a result of risks, uncertainties and other factors, such as changes in general economic, market, regulatory and business conditions; fluctuations in commodity prices and currency exchange rates; the successful and timely implementation of capital projects; the accuracy of cost estimates; labour and material supply issues; and uncertainties resulting from potential delays or changes in plans, among others. See Suncor's current Annual Report and other documents Suncor files with securities regulatory authorities for further details, copies of which are available from the company. The forwardlooking statements speak only as of the date hereof and Suncor undertakes no duty to update these statements to reflect subsequent changes in assumptions (or the trends or factors underlying them) or actual events or experience. • Unless noted otherwise, financial information is for the most recent quarter or year end. • A boe conversion ratio of six thousand cubic feet of natural gas: one barrel of crude oil is based on an energy equivalency conversion method primarily applicable at the burner tip and does not represent a value equivalency at the wellhead. Accordingly, boe’s may be misleading if used in isolation.

Suncor Energy at a Glance • Integrated energy company - upstream, refining, & marketing, pipelines and wind power • Market capitalization $40 billion (US$34 billion) • Original and single largest investor in the Athabasca oil sands • Production capacity of nearly 300, 000 BOE/day • More than 5, 500 employees • Sustainability: benefiting all stakeholders

Suncor Operating Areas

Market access

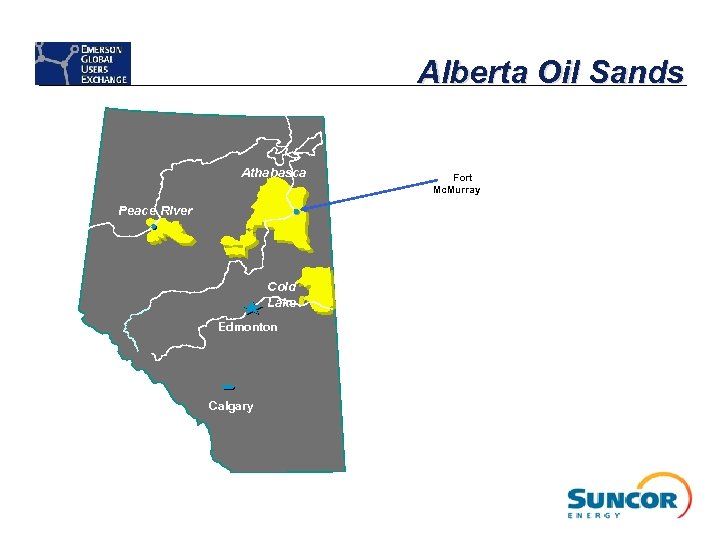

Alberta Oil Sands Athabasca Peace River Cold Lake Edmonton Calgary Fort Mc. Murray

Alberta Oil Sands & Heavy Oil • Alberta area oil sands & heavy oil deposits contain 2. 5 trillion barrels - 41% of world’s known petroleum reserves (greater than combined Middle East, United States, Soviet Bloc, Western Europe, Australia, Asia, & Africa) • Alberta deposits cover 77, 000 sq km (~30, 000 sq mi) • Athabasca deposits = 950 B barrels • 20% within 250 ft. of surface

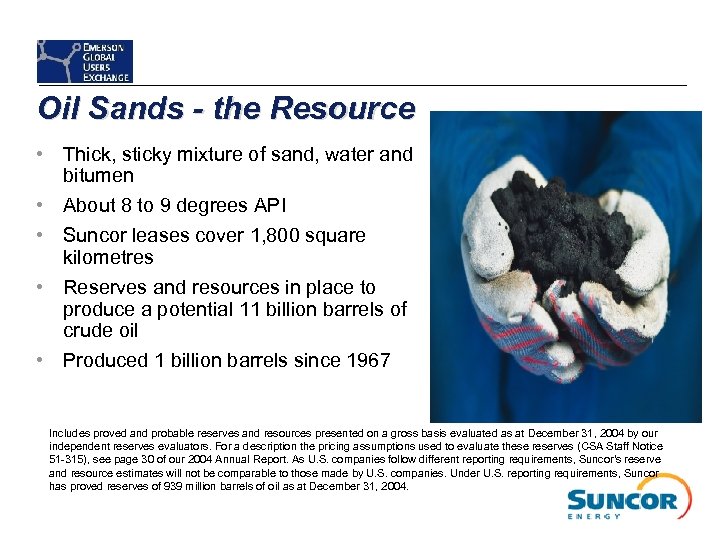

Oil Sands - the Resource • Thick, sticky mixture of sand, water and bitumen • About 8 to 9 degrees API • Suncor leases cover 1, 800 square kilometres • Reserves and resources in place to produce a potential 11 billion barrels of crude oil • Produced 1 billion barrels since 1967 Includes proved and probable reserves and resources presented on a gross basis evaluated as at December 31, 2004 by our independent reserves evaluators. For a description the pricing assumptions used to evaluate these reserves (CSA Staff Notice 51 -315), see page 30 of our 2004 Annual Report. As U. S. companies follow different reporting requirements, Suncor's reserve and resource estimates will not be comparable to those made by U. S. companies. Under U. S. reporting requirements, Suncor has proved reserves of 939 million barrels of oil as at December 31, 2004.

Oil Sands - Mining

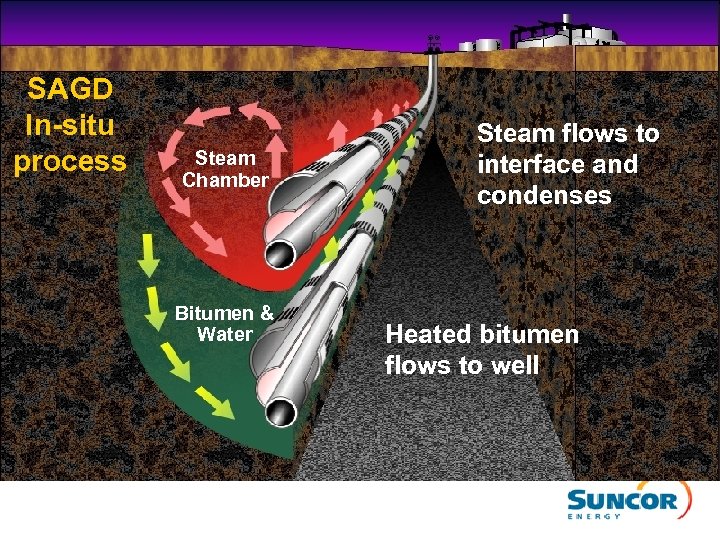

SAGD In-situ process Steam Chamber Bitumen & Water Steam flows to interface and condenses Heated bitumen flows to well

Oil Sands - Extraction and Upgrading

Suncor Products

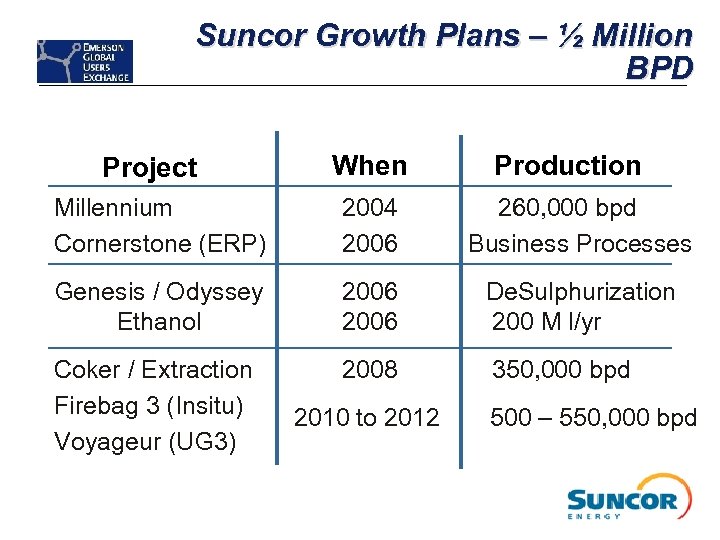

Suncor Growth Plans – ½ Million BPD Project When Production Millennium Cornerstone (ERP) 2004 2006 260, 000 bpd Business Processes Genesis / Odyssey Ethanol 2006 De. Sulphurization 200 M l/yr Coker / Extraction Firebag 3 (Insitu) Voyageur (UG 3) 2008 350, 000 bpd 2010 to 2012 500 – 550, 000 bpd

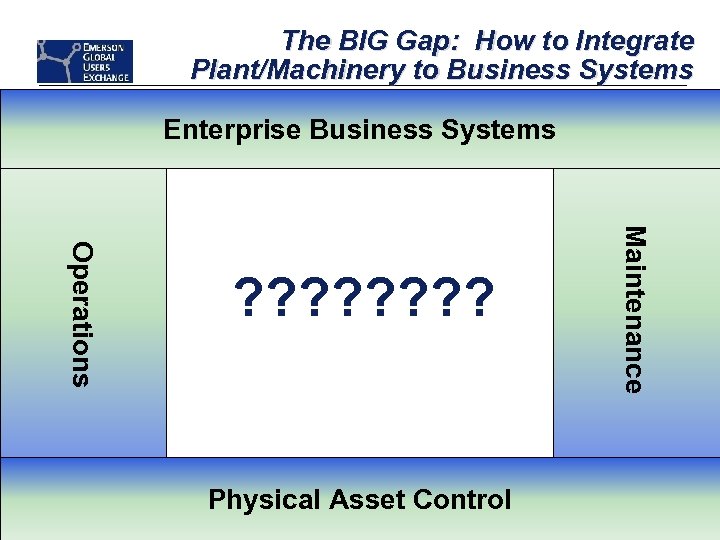

The BIG Gap: How to Integrate Plant/Machinery to Business Systems Enterprise Business Systems Physical Asset Control Maintenance Operations ? ? ? ?

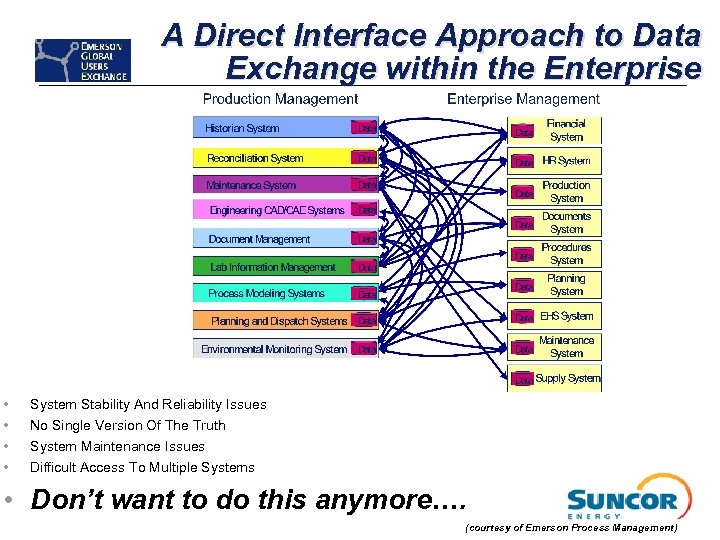

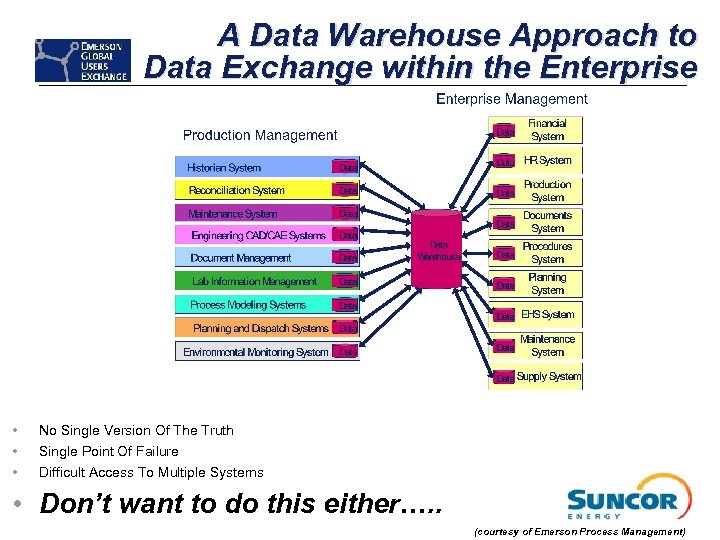

A Direct Interface Approach to Data Exchange within the Enterprise • • System Stability And Reliability Issues No Single Version Of The Truth System Maintenance Issues Difficult Access To Multiple Systems • Don’t want to do this anymore…. (courtesy of Emerson Process Management)

A Data Warehouse Approach to Data Exchange within the Enterprise • • • No Single Version Of The Truth Single Point Of Failure Difficult Access To Multiple Systems • Don’t want to do this either…. . (courtesy of Emerson Process Management)

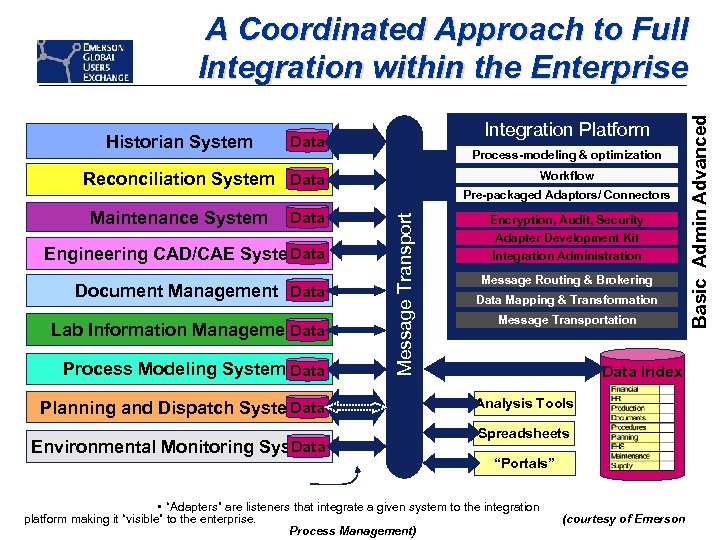

Historian System Integration Platform Data Process-modeling & optimization Reconciliation System Data Engineering CAD/CAE Systems Document Management Data Lab Information Management Process Modeling Systems Data Planning and Dispatch Systems Data Environmental Monitoring System Pre-packaged Adaptors/ Connectors Message Transport Maintenance System Workflow Encryption, Audit, Security Adapter Development Kit Integration Administration Message Routing & Brokering Data Mapping & Transformation Message Transportation Data Index Analysis Tools Spreadsheets “Portals” • “Adapters” are listeners that integrate a given system to the integration platform making it “visible” to the enterprise. Process Management) (courtesy of Emerson Basic Admin Advanced A Coordinated Approach to Full Integration within the Enterprise

The Open. O&M Solution: Open Standards & Collaboration Fills the Gaps Enterprise Business Systems Physical Asset Control Maintenance Operations Open. O&MTM

What’s Needed Now? • Open Architecture Solution to integrate process/operational, maintenance & business processes/systems • By 2007 • NOT more research • Field Proven Solution (i. e. BP’s e. RTIS) – IT WORKS!! • All software vendors to write Adapters to talk Open. O&M • Manufacturing Industry to demand compliance to Open. O&M standards • Get Involved – Lead, Follow, Support!

Where To Get More Information Websites • www. openoandm. org • www. mimosa. org ISA Expo 2007 – Oct. 2 -5, 2007 / Houston TX (Demo in the exhibit area) IMC (International Maintenance Conference) Dec. 3 -7, 2007 / Daytona Beach, FL (Demo in the exhibit area)

dab20f4e9838c450513c7c97402f471c.ppt