2ee1392da08f13565d3c404d1d344eb0.ppt

- Количество слайдов: 25

German Standard (DIN) for Rainwater Harvesting: technology and products

German Standard (DIN) for Rainwater Harvesting: technology and products

Ecological and sustainable water management is a goal of the precipitation water management. The alternatives to the customary drainage of precipitation water are, among other things, rainwater harvesting and infiltration, as well as the decentralized retention of rainwater. A new system technology with new components has been developed for rainwater harvesting in households and commercial and industrial companies. The standard for rainwater harvesting was developed taking the generally-recognized rules of technology for drinking water installations into consideration according to the standard series DIN 1988 and according to DIN EN 1717 and for drainage systems according to the standard series DIN EN 12056 and DIN 1986. Requirements on system technology for the planning, installation, operation and maintenance that have proven themselves in practice are set down in this standard DIN 1989 Rainwater Harvesting Systems

Ecological and sustainable water management is a goal of the precipitation water management. The alternatives to the customary drainage of precipitation water are, among other things, rainwater harvesting and infiltration, as well as the decentralized retention of rainwater. A new system technology with new components has been developed for rainwater harvesting in households and commercial and industrial companies. The standard for rainwater harvesting was developed taking the generally-recognized rules of technology for drinking water installations into consideration according to the standard series DIN 1988 and according to DIN EN 1717 and for drainage systems according to the standard series DIN EN 12056 and DIN 1986. Requirements on system technology for the planning, installation, operation and maintenance that have proven themselves in practice are set down in this standard DIN 1989 Rainwater Harvesting Systems

The standard series DIN 1989 „Rainwater Harvesting Systems“ consists of the following parts: • Part 1: Planning, Installation, Operation and Maintenance • Part 2: Filter for Rainwater harvesting • Part 3: Rainwater Reservoirs • Part 4: Components for Control and supplemental supply DIN 1989 Rainwater Harvesting Systems

The standard series DIN 1989 „Rainwater Harvesting Systems“ consists of the following parts: • Part 1: Planning, Installation, Operation and Maintenance • Part 2: Filter for Rainwater harvesting • Part 3: Rainwater Reservoirs • Part 4: Components for Control and supplemental supply DIN 1989 Rainwater Harvesting Systems

The standard series DIN 1989 -1 „Rainwater Harvesting Systems“ Part 1: Planning, Installation, Operation and Maintenance This standard applies to systems utilizing rainwater in households and commercial and industrial companies, as well as in public organizations, in which it is used for flushing toilets, for cooling purposes, for washing and cleaning systems and for watering green areas, for instance. Following parts are treated: Collection Areas, Treatment, Rainwater Reservoirs and Add-On Parts, Process Water Pumps, Supplemental Feed Systems, System Control Unit, Supplemental Feed Modules, Central Rainwater Systems and Hybrid Systems, Pipe Systems and Labelling, Seepage of the Overflow Water, Protection against Backflow, Types of systems and set up possibilities, Design of the Reservoir Size, Operation, Inspection and Maintenance DIN 1989 Rainwater Harvesting Systems

The standard series DIN 1989 -1 „Rainwater Harvesting Systems“ Part 1: Planning, Installation, Operation and Maintenance This standard applies to systems utilizing rainwater in households and commercial and industrial companies, as well as in public organizations, in which it is used for flushing toilets, for cooling purposes, for washing and cleaning systems and for watering green areas, for instance. Following parts are treated: Collection Areas, Treatment, Rainwater Reservoirs and Add-On Parts, Process Water Pumps, Supplemental Feed Systems, System Control Unit, Supplemental Feed Modules, Central Rainwater Systems and Hybrid Systems, Pipe Systems and Labelling, Seepage of the Overflow Water, Protection against Backflow, Types of systems and set up possibilities, Design of the Reservoir Size, Operation, Inspection and Maintenance DIN 1989 Rainwater Harvesting Systems

The standard series DIN 1989 -2 „Rainwater Harvesting Systems“ • Part 2: Filter for Rainwater harvesting This part lay down the standard and tests for mechanical working filters which are installed in the supply of reservoirs for rainwater harvesting systems. There is a multitude of special filters for rainwater harvesting systems that are distinguished by design, installation position and functional principle (e. g. filter matting , filter screen). Filters are to be installed in the supply line to the reservoir as a general rule. They keep foreign material away from the rainwater reservoir that could bring about malfunctions in the system or make the water quality poorer. Rainfall pipes or central location in front of the reservoir are possible installation places. Furthermore, filters can be directly located in the rainwater supply line inside of the reservoir. DIN 1989 Rainwater Harvesting Systems

The standard series DIN 1989 -2 „Rainwater Harvesting Systems“ • Part 2: Filter for Rainwater harvesting This part lay down the standard and tests for mechanical working filters which are installed in the supply of reservoirs for rainwater harvesting systems. There is a multitude of special filters for rainwater harvesting systems that are distinguished by design, installation position and functional principle (e. g. filter matting , filter screen). Filters are to be installed in the supply line to the reservoir as a general rule. They keep foreign material away from the rainwater reservoir that could bring about malfunctions in the system or make the water quality poorer. Rainfall pipes or central location in front of the reservoir are possible installation places. Furthermore, filters can be directly located in the rainwater supply line inside of the reservoir. DIN 1989 Rainwater Harvesting Systems

The standard series DIN 1989 -3 „Rainwater Harvesting Systems“ • Part 3: Rainwater Reservoirs This part lay down the standard, tests and assessments of conformance for manufactured monolithic reservoirs, for manufactured multi-parts reservoirs and for reservoirs made on-site. Rainwater reservoirs are for both the storage and the cleaning of the rainwater. Reservoirs can be set up both above-ground and below-ground. The set up location should be chosen in such a way that the stored water is protected against strong thermal effects, frost and light. The selection of the reservoir has to be done in coordination with the installation location and the pollution to be expected. Standardized reservoirs are to be used. DIN 1989 Rainwater Harvesting Systems

The standard series DIN 1989 -3 „Rainwater Harvesting Systems“ • Part 3: Rainwater Reservoirs This part lay down the standard, tests and assessments of conformance for manufactured monolithic reservoirs, for manufactured multi-parts reservoirs and for reservoirs made on-site. Rainwater reservoirs are for both the storage and the cleaning of the rainwater. Reservoirs can be set up both above-ground and below-ground. The set up location should be chosen in such a way that the stored water is protected against strong thermal effects, frost and light. The selection of the reservoir has to be done in coordination with the installation location and the pollution to be expected. Standardized reservoirs are to be used. DIN 1989 Rainwater Harvesting Systems

The standard series DIN 1989 -4 „Rainwater Harvesting Systems“ • Part 4: Components for Control and supplemental supply This part lay down the standard and tests for manufactured or made on-site assembly units for supplemental supply units for reservoirs, for system control units of process water pump and hybrid units. Supplemental feed modules consist of a supplemental feed device and a system control unit and are usually produced in the factory as an assembly. Process water pumps, the supplemental feed system and the system control unit are combined in one assembly in the factory into central rainwater systems. Hybrid containers are used as a preference in larger rainwater harvesting systems. DIN 1989 Rainwater Harvesting Systems

The standard series DIN 1989 -4 „Rainwater Harvesting Systems“ • Part 4: Components for Control and supplemental supply This part lay down the standard and tests for manufactured or made on-site assembly units for supplemental supply units for reservoirs, for system control units of process water pump and hybrid units. Supplemental feed modules consist of a supplemental feed device and a system control unit and are usually produced in the factory as an assembly. Process water pumps, the supplemental feed system and the system control unit are combined in one assembly in the factory into central rainwater systems. Hybrid containers are used as a preference in larger rainwater harvesting systems. DIN 1989 Rainwater Harvesting Systems

System Control unit • The system control unit controls automatically the functioning of the rainwater harvesting system • The supplemental feed has to be done via a safety device Type AA (unobstructed free outlet) or Type AB (free outlet with a non circular overflow) according DIN EN 1717 when drinking water is used. • The safety device is to be installed outside of the rainwater reservoir and outside of the entry shaft (dome). • For continuous operating, the rainwater harvesting system can also be operated independently of the rainwater reservoir. DIN 1989 Rainwater Harvesting Systems

System Control unit • The system control unit controls automatically the functioning of the rainwater harvesting system • The supplemental feed has to be done via a safety device Type AA (unobstructed free outlet) or Type AB (free outlet with a non circular overflow) according DIN EN 1717 when drinking water is used. • The safety device is to be installed outside of the rainwater reservoir and outside of the entry shaft (dome). • For continuous operating, the rainwater harvesting system can also be operated independently of the rainwater reservoir. DIN 1989 Rainwater Harvesting Systems

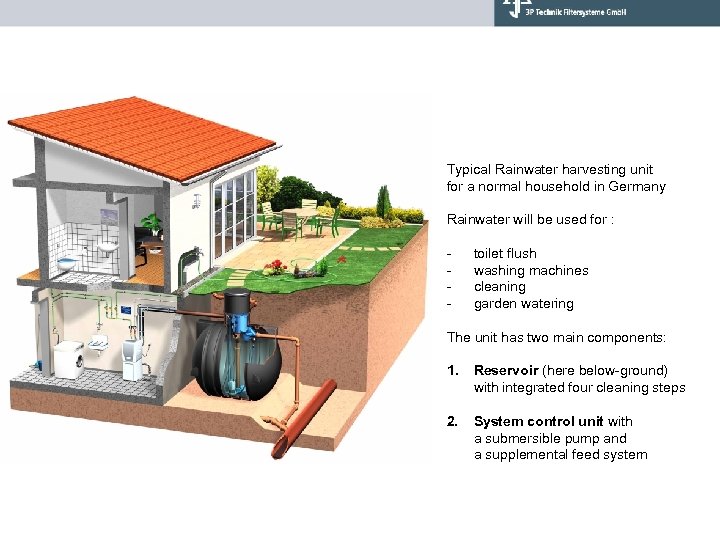

Typical Rainwater harvesting unit for a normal household in Germany Rainwater will be used for : - toilet flush washing machines cleaning garden watering The unit has two main components: 1. Reservoir (here below-ground) with integrated four cleaning steps 2. System control unit with a submersible pump and a supplemental feed system

Typical Rainwater harvesting unit for a normal household in Germany Rainwater will be used for : - toilet flush washing machines cleaning garden watering The unit has two main components: 1. Reservoir (here below-ground) with integrated four cleaning steps 2. System control unit with a submersible pump and a supplemental feed system

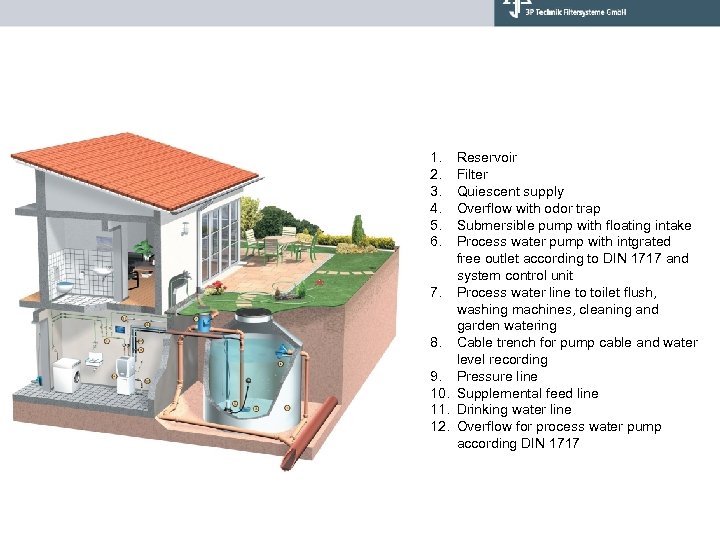

1. 2. 3. 4. 5. 6. Reservoir Filter Quiescent supply Overflow with odor trap Submersible pump with floating intake Process water pump with intgrated free outlet according to DIN 1717 and system control unit 7. Process water line to toilet flush, washing machines, cleaning and garden watering 8. Cable trench for pump cable and water level recording 9. Pressure line 10. Supplemental feed line 11. Drinking water line 12. Overflow for process water pump according DIN 1717

1. 2. 3. 4. 5. 6. Reservoir Filter Quiescent supply Overflow with odor trap Submersible pump with floating intake Process water pump with intgrated free outlet according to DIN 1717 and system control unit 7. Process water line to toilet flush, washing machines, cleaning and garden watering 8. Cable trench for pump cable and water level recording 9. Pressure line 10. Supplemental feed line 11. Drinking water line 12. Overflow for process water pump according DIN 1717

Products for rainwater harvesting special for cleaning rainwater CLEAN WATER OUR MISSION

Products for rainwater harvesting special for cleaning rainwater CLEAN WATER OUR MISSION

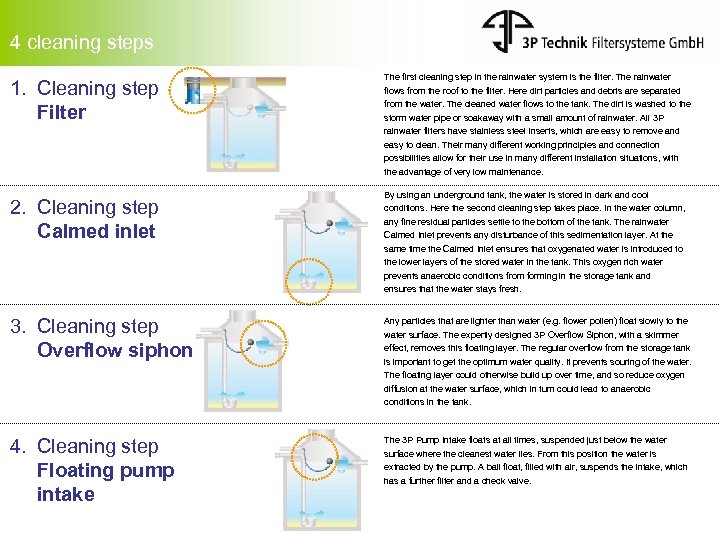

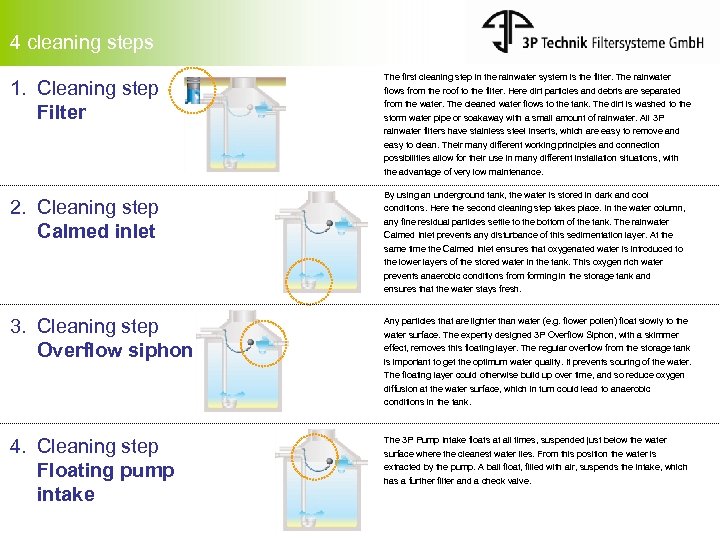

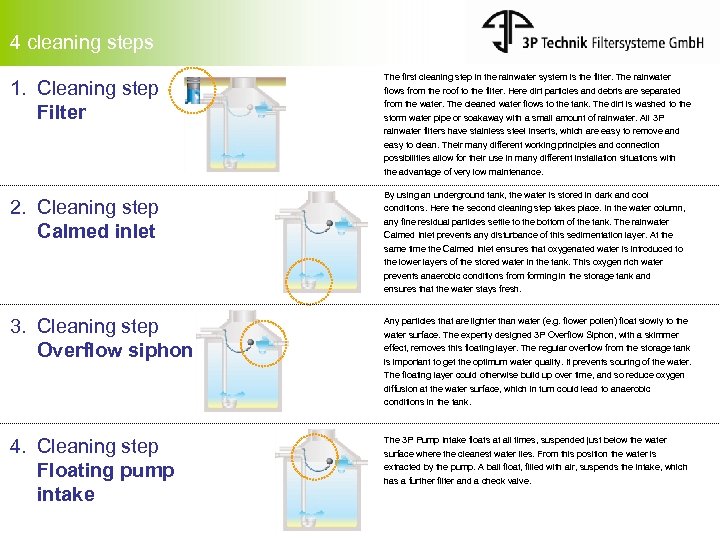

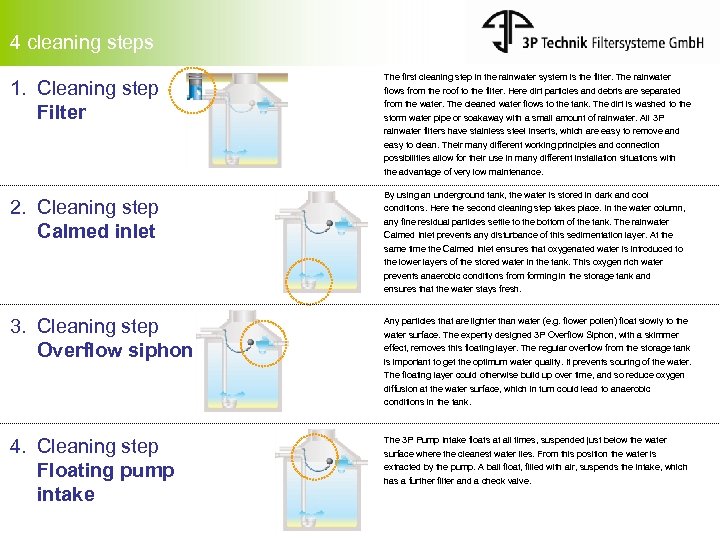

4 cleaning steps 1. Cleaning step Filter The first cleaning step in the rainwater system is the filter. The rainwater flows from the roof to the filter. Here dirt particles and debris are separated from the water. The cleaned water flows to the tank. The dirt is washed to the storm water pipe or soakaway with a small amount of rainwater. All 3 P rainwater filters have stainless steel inserts, which are easy to remove and easy to clean. Their many different working principles and connection possibilities allow for their use in many different installation situations, with the advantage of very low maintenance. 2. Cleaning step Calmed inlet 3. Cleaning step Overflow siphon By using an underground tank, the water is stored in dark and cool conditions. Here the second cleaning step takes place. In the water column, any fine residual particles settle to the bottom of the tank. The rainwater Calmed Inlet prevents any disturbance of this sedimentation layer. At the same time the Calmed Inlet ensures that oxygenated water is introduced to the lower layers of the stored water in the tank. This oxygen rich water prevents anaerobic conditions from forming in the storage tank and ensures that the water stays fresh. Any particles that are lighter than water (e. g. flower pollen) float slowly to the water surface. The expertly designed 3 P Overflow Siphon, with a skimmer effect, removes this floating layer. The regular overflow from the storage tank is important to get the optimum water quality. It prevents souring of the water. The floating layer could otherwise build up over time, and so reduce oxygen diffusion at the water surface, which in turn could lead to anaerobic conditions in the tank. 4. Cleaning step Floating pump intake The 3 P Pump Intake floats at all times, suspended just below the water surface where the cleanest water lies. From this position the water is extracted by the pump. A ball float, filled with air, suspends the intake, which has a further filter and a check valve.

4 cleaning steps 1. Cleaning step Filter The first cleaning step in the rainwater system is the filter. The rainwater flows from the roof to the filter. Here dirt particles and debris are separated from the water. The cleaned water flows to the tank. The dirt is washed to the storm water pipe or soakaway with a small amount of rainwater. All 3 P rainwater filters have stainless steel inserts, which are easy to remove and easy to clean. Their many different working principles and connection possibilities allow for their use in many different installation situations, with the advantage of very low maintenance. 2. Cleaning step Calmed inlet 3. Cleaning step Overflow siphon By using an underground tank, the water is stored in dark and cool conditions. Here the second cleaning step takes place. In the water column, any fine residual particles settle to the bottom of the tank. The rainwater Calmed Inlet prevents any disturbance of this sedimentation layer. At the same time the Calmed Inlet ensures that oxygenated water is introduced to the lower layers of the stored water in the tank. This oxygen rich water prevents anaerobic conditions from forming in the storage tank and ensures that the water stays fresh. Any particles that are lighter than water (e. g. flower pollen) float slowly to the water surface. The expertly designed 3 P Overflow Siphon, with a skimmer effect, removes this floating layer. The regular overflow from the storage tank is important to get the optimum water quality. It prevents souring of the water. The floating layer could otherwise build up over time, and so reduce oxygen diffusion at the water surface, which in turn could lead to anaerobic conditions in the tank. 4. Cleaning step Floating pump intake The 3 P Pump Intake floats at all times, suspended just below the water surface where the cleanest water lies. From this position the water is extracted by the pump. A ball float, filled with air, suspends the intake, which has a further filter and a check valve.

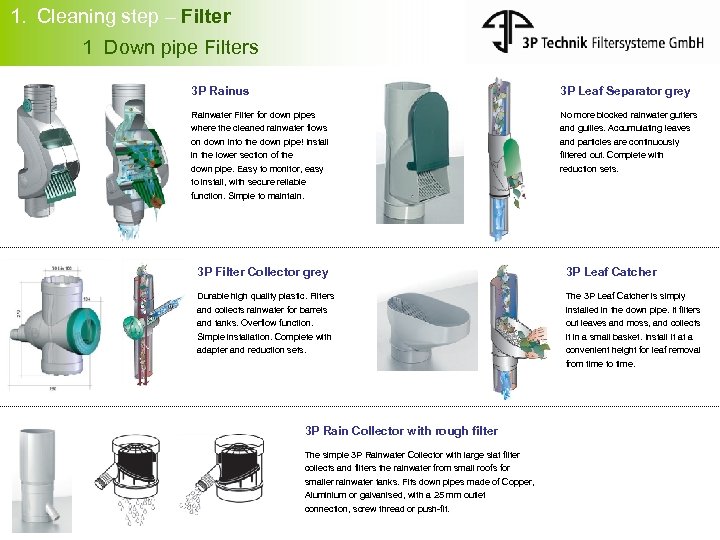

1. Cleaning step – Filter 1 Down pipe Filters 3 P Rainus 3 P Leaf Separator grey Rainwater Filter for down pipes No more blocked rainwater gutters where the cleaned rainwater flows on down into the down pipe! Install in the lower section of the down pipe. Easy to monitor, easy to install, with secure reliable function. Simple to maintain. and gullies. Accumulating leaves and particles are continuously filtered out. Complete with reduction sets. 3 P Filter Collector grey 3 P Leaf Catcher Durable high quality plastic. Filters The 3 P Leaf Catcher is simply and collects rainwater for barrels and tanks. Overflow function. installed in the down pipe. It filters out leaves and moss, and collects Simple installation. Complete with adapter and reduction sets. it in a small basket. Install it at a convenient height for leaf removal from time to time. 3 P Rain Collector with rough filter The simple 3 P Rainwater Collector with large slat filter collects and filters the rainwater from small roofs for smaller rainwater tanks. Fits down pipes made of Copper, Aluminium or galvanised, with a 25 mm outlet connection, screw thread or push-fit.

1. Cleaning step – Filter 1 Down pipe Filters 3 P Rainus 3 P Leaf Separator grey Rainwater Filter for down pipes No more blocked rainwater gutters where the cleaned rainwater flows on down into the down pipe! Install in the lower section of the down pipe. Easy to monitor, easy to install, with secure reliable function. Simple to maintain. and gullies. Accumulating leaves and particles are continuously filtered out. Complete with reduction sets. 3 P Filter Collector grey 3 P Leaf Catcher Durable high quality plastic. Filters The 3 P Leaf Catcher is simply and collects rainwater for barrels and tanks. Overflow function. installed in the down pipe. It filters out leaves and moss, and collects Simple installation. Complete with adapter and reduction sets. it in a small basket. Install it at a convenient height for leaf removal from time to time. 3 P Rain Collector with rough filter The simple 3 P Rainwater Collector with large slat filter collects and filters the rainwater from small roofs for smaller rainwater tanks. Fits down pipes made of Copper, Aluminium or galvanised, with a 25 mm outlet connection, screw thread or push-fit.

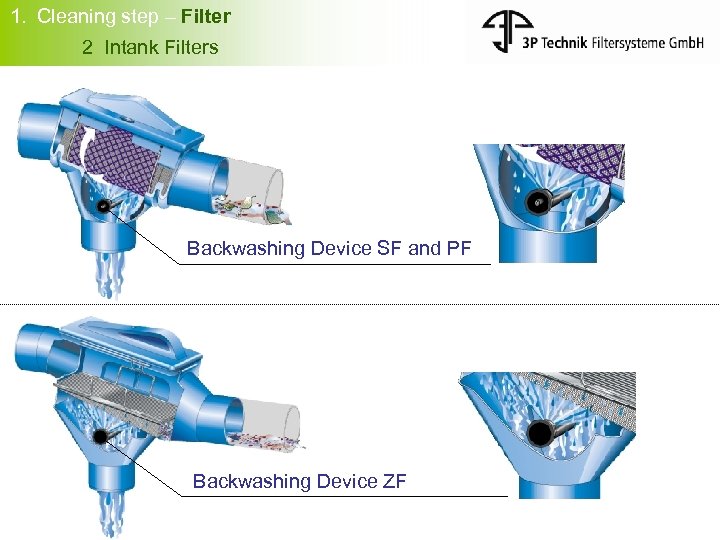

1. Cleaning step – Filter 2 Intank Filters Backwashing Device SF and PF Backwashing Device ZF

1. Cleaning step – Filter 2 Intank Filters Backwashing Device SF and PF Backwashing Device ZF

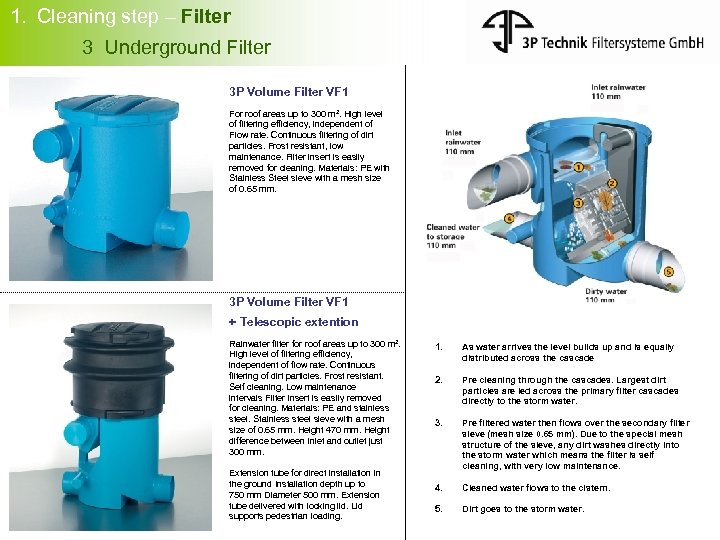

1. Cleaning step – Filter 3 Underground Filter 3 P Volume Filter VF 1 For roof areas up to 300 m². High level of filtering efficiency, independent of Flow rate. Continuous filtering of dirt particles. Frost resistant, low maintenance. Filter insert is easily removed for cleaning. Materials: PE with Stainless Steel sieve with a mesh size of 0. 65 mm. 3 P Volume Filter VF 1 + Telescopic extention Rainwater filter for roof areas up to 300 m². High level of filtering efficiency, independent of flow rate. Continuous filtering of dirt particles. Frost resistant. Self cleaning. Low maintenance intervals Filter insert is easily removed for cleaning. Materials: PE and stainless steel. Stainless steel sieve with a mesh size of 0. 65 mm. Height 470 mm. Height difference between inlet and outlet just 300 mm. Extension tube for direct installation in the ground Installation depth up to 750 mm Diameter 500 mm. Extension tube delivered with locking lid. Lid supports pedestrian loading. 1. As water arrives the level builds up and is equally distributed across the cascade 2. Pre cleaning through the cascades. Largest dirt particles are led across the primary filter cascades directly to the storm water. 3. Pre filtered water then flows over the secondary filter sieve (mesh size 0. 65 mm). Due to the special mesh structure of the sieve, any dirt washes directly into the storm water which means the filter is self cleaning, with very low maintenance. 4. Cleaned water flows to the cistern. 5. Dirt goes to the storm water.

1. Cleaning step – Filter 3 Underground Filter 3 P Volume Filter VF 1 For roof areas up to 300 m². High level of filtering efficiency, independent of Flow rate. Continuous filtering of dirt particles. Frost resistant, low maintenance. Filter insert is easily removed for cleaning. Materials: PE with Stainless Steel sieve with a mesh size of 0. 65 mm. 3 P Volume Filter VF 1 + Telescopic extention Rainwater filter for roof areas up to 300 m². High level of filtering efficiency, independent of flow rate. Continuous filtering of dirt particles. Frost resistant. Self cleaning. Low maintenance intervals Filter insert is easily removed for cleaning. Materials: PE and stainless steel. Stainless steel sieve with a mesh size of 0. 65 mm. Height 470 mm. Height difference between inlet and outlet just 300 mm. Extension tube for direct installation in the ground Installation depth up to 750 mm Diameter 500 mm. Extension tube delivered with locking lid. Lid supports pedestrian loading. 1. As water arrives the level builds up and is equally distributed across the cascade 2. Pre cleaning through the cascades. Largest dirt particles are led across the primary filter cascades directly to the storm water. 3. Pre filtered water then flows over the secondary filter sieve (mesh size 0. 65 mm). Due to the special mesh structure of the sieve, any dirt washes directly into the storm water which means the filter is self cleaning, with very low maintenance. 4. Cleaned water flows to the cistern. 5. Dirt goes to the storm water.

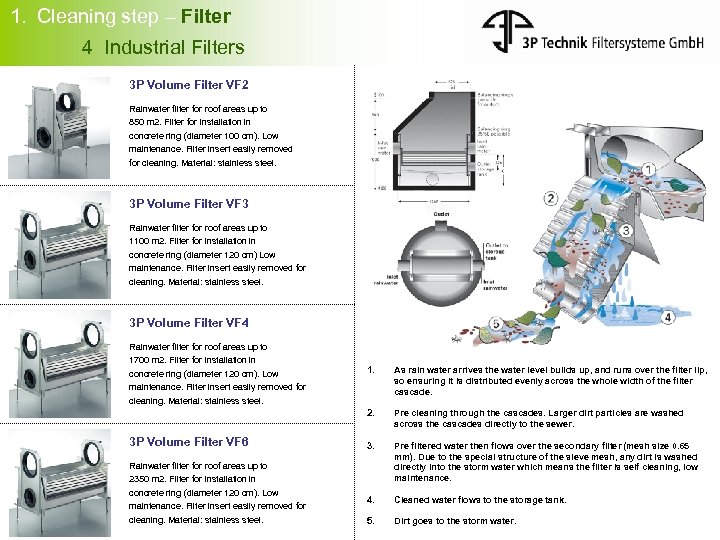

1. Cleaning step – Filter 4 Industrial Filters 3 P Volume Filter VF 2 Rainwater filter for roof areas up to 850 m 2. Filter for installation in concrete ring (diameter 100 cm). Low maintenance. Filter insert easily removed for cleaning. Material: stainless steel. 3 P Volume Filter VF 3 Rainwater filter for roof areas up to 1100 m 2. Filter for installation in concrete ring (diameter 120 cm) Low maintenance. Filter insert easily removed for cleaning. Material: stainless steel. 3 P Volume Filter VF 4 Rainwater filter for roof areas up to 1700 m 2. Filter for installation in concrete ring (diameter 120 cm). Low maintenance. Filter insert easily removed for cleaning. Material: stainless steel. As rain water arrives the water level builds up, and runs over the filter lip, so ensuring it is distributed evenly across the whole width of the filter cascade. 2. 3 P Volume Filter VF 6 1. Pre cleaning through the cascades. Larger dirt particles are washed across the cascades directly to the sewer. 3. Pre filtered water then flows over the secondary filter (mesh size 0. 65 mm). Due to the special structure of the sieve mesh, any dirt is washed directly into the storm water which means the filter is self cleaning, low maintenance. 4. Cleaned water flows to the storage tank. 5. Dirt goes to the storm water. Rainwater filter for roof areas up to 2350 m 2. Filter for installation in concrete ring (diameter 120 cm). Low maintenance. Filter insert easily removed for cleaning. Material: stainless steel.

1. Cleaning step – Filter 4 Industrial Filters 3 P Volume Filter VF 2 Rainwater filter for roof areas up to 850 m 2. Filter for installation in concrete ring (diameter 100 cm). Low maintenance. Filter insert easily removed for cleaning. Material: stainless steel. 3 P Volume Filter VF 3 Rainwater filter for roof areas up to 1100 m 2. Filter for installation in concrete ring (diameter 120 cm) Low maintenance. Filter insert easily removed for cleaning. Material: stainless steel. 3 P Volume Filter VF 4 Rainwater filter for roof areas up to 1700 m 2. Filter for installation in concrete ring (diameter 120 cm). Low maintenance. Filter insert easily removed for cleaning. Material: stainless steel. As rain water arrives the water level builds up, and runs over the filter lip, so ensuring it is distributed evenly across the whole width of the filter cascade. 2. 3 P Volume Filter VF 6 1. Pre cleaning through the cascades. Larger dirt particles are washed across the cascades directly to the sewer. 3. Pre filtered water then flows over the secondary filter (mesh size 0. 65 mm). Due to the special structure of the sieve mesh, any dirt is washed directly into the storm water which means the filter is self cleaning, low maintenance. 4. Cleaned water flows to the storage tank. 5. Dirt goes to the storm water. Rainwater filter for roof areas up to 2350 m 2. Filter for installation in concrete ring (diameter 120 cm). Low maintenance. Filter insert easily removed for cleaning. Material: stainless steel.

4 cleaning steps 1. Cleaning step Filter The first cleaning step in the rainwater system is the filter. The rainwater flows from the roof to the filter. Here dirt particles and debris are separated from the water. The cleaned water flows to the tank. The dirt is washed to the storm water pipe or soakaway with a small amount of rainwater. All 3 P rainwater filters have stainless steel inserts, which are easy to remove and easy to clean. Their many different working principles and connection possibilities allow for their use in many different installation situations, with the advantage of very low maintenance. 2. Cleaning step Calmed inlet 3. Cleaning step Overflow siphon By using an underground tank, the water is stored in dark and cool conditions. Here the second cleaning step takes place. In the water column, any fine residual particles settle to the bottom of the tank. The rainwater Calmed Inlet prevents any disturbance of this sedimentation layer. At the same time the Calmed Inlet ensures that oxygenated water is introduced to the lower layers of the stored water in the tank. This oxygen rich water prevents anaerobic conditions from forming in the storage tank and ensures that the water stays fresh. Any particles that are lighter than water (e. g. flower pollen) float slowly to the water surface. The expertly designed 3 P Overflow Siphon, with a skimmer effect, removes this floating layer. The regular overflow from the storage tank is important to get the optimum water quality. It prevents souring of the water. The floating layer could otherwise build up over time, and so reduce oxygen diffusion at the water surface, which in turn could lead to anaerobic conditions in the tank. 4. Cleaning step Floating pump intake The 3 P Pump Intake floats at all times, suspended just below the water surface where the cleanest water lies. From this position the water is extracted by the pump. A ball float, filled with air, suspends the intake, which has a further filter and a check valve.

4 cleaning steps 1. Cleaning step Filter The first cleaning step in the rainwater system is the filter. The rainwater flows from the roof to the filter. Here dirt particles and debris are separated from the water. The cleaned water flows to the tank. The dirt is washed to the storm water pipe or soakaway with a small amount of rainwater. All 3 P rainwater filters have stainless steel inserts, which are easy to remove and easy to clean. Their many different working principles and connection possibilities allow for their use in many different installation situations, with the advantage of very low maintenance. 2. Cleaning step Calmed inlet 3. Cleaning step Overflow siphon By using an underground tank, the water is stored in dark and cool conditions. Here the second cleaning step takes place. In the water column, any fine residual particles settle to the bottom of the tank. The rainwater Calmed Inlet prevents any disturbance of this sedimentation layer. At the same time the Calmed Inlet ensures that oxygenated water is introduced to the lower layers of the stored water in the tank. This oxygen rich water prevents anaerobic conditions from forming in the storage tank and ensures that the water stays fresh. Any particles that are lighter than water (e. g. flower pollen) float slowly to the water surface. The expertly designed 3 P Overflow Siphon, with a skimmer effect, removes this floating layer. The regular overflow from the storage tank is important to get the optimum water quality. It prevents souring of the water. The floating layer could otherwise build up over time, and so reduce oxygen diffusion at the water surface, which in turn could lead to anaerobic conditions in the tank. 4. Cleaning step Floating pump intake The 3 P Pump Intake floats at all times, suspended just below the water surface where the cleanest water lies. From this position the water is extracted by the pump. A ball float, filled with air, suspends the intake, which has a further filter and a check valve.

2. Cleaning step Calmed Inlet 3 P Calmed Inlet 125 mm/110 mm Provides a calmed inlet for rainwater in the storage tank. Prevents disturbance of settled sedimentation layer and oxygenises lower layer of water

2. Cleaning step Calmed Inlet 3 P Calmed Inlet 125 mm/110 mm Provides a calmed inlet for rainwater in the storage tank. Prevents disturbance of settled sedimentation layer and oxygenises lower layer of water

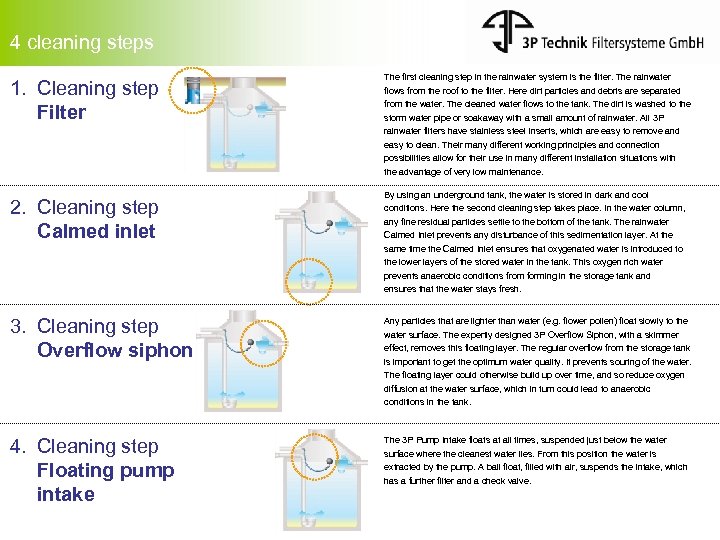

4 cleaning steps 1. Cleaning step Filter The first cleaning step in the rainwater system is the filter. The rainwater flows from the roof to the filter. Here dirt particles and debris are separated from the water. The cleaned water flows to the tank. The dirt is washed to the storm water pipe or soakaway with a small amount of rainwater. All 3 P rainwater filters have stainless steel inserts, which are easy to remove and easy to clean. Their many different working principles and connection possibilities allow for their use in many different installation situations with the advantage of very low maintenance. 2. Cleaning step Calmed inlet 3. Cleaning step Overflow siphon By using an underground tank, the water is stored in dark and cool conditions. Here the second cleaning step takes place. In the water column, any fine residual particles settle to the bottom of the tank. The rainwater Calmed Inlet prevents any disturbance of this sedimentation layer. At the same time the Calmed Inlet ensures that oxygenated water is introduced to the lower layers of the stored water in the tank. This oxygen rich water prevents anaerobic conditions from forming in the storage tank and ensures that the water stays fresh. Any particles that are lighter than water (e. g. flower pollen) float slowly to the water surface. The expertly designed 3 P Overflow Siphon, with a skimmer effect, removes this floating layer. The regular overflow from the storage tank is important to get the optimum water quality. It prevents souring of the water. The floating layer could otherwise build up over time, and so reduce oxygen diffusion at the water surface, which in turn could lead to anaerobic conditions in the tank. 4. Cleaning step Floating pump intake The 3 P Pump Intake floats at all times, suspended just below the water surface where the cleanest water lies. From this position the water is extracted by the pump. A ball float, filled with air, suspends the intake, which has a further filter and a check valve.

4 cleaning steps 1. Cleaning step Filter The first cleaning step in the rainwater system is the filter. The rainwater flows from the roof to the filter. Here dirt particles and debris are separated from the water. The cleaned water flows to the tank. The dirt is washed to the storm water pipe or soakaway with a small amount of rainwater. All 3 P rainwater filters have stainless steel inserts, which are easy to remove and easy to clean. Their many different working principles and connection possibilities allow for their use in many different installation situations with the advantage of very low maintenance. 2. Cleaning step Calmed inlet 3. Cleaning step Overflow siphon By using an underground tank, the water is stored in dark and cool conditions. Here the second cleaning step takes place. In the water column, any fine residual particles settle to the bottom of the tank. The rainwater Calmed Inlet prevents any disturbance of this sedimentation layer. At the same time the Calmed Inlet ensures that oxygenated water is introduced to the lower layers of the stored water in the tank. This oxygen rich water prevents anaerobic conditions from forming in the storage tank and ensures that the water stays fresh. Any particles that are lighter than water (e. g. flower pollen) float slowly to the water surface. The expertly designed 3 P Overflow Siphon, with a skimmer effect, removes this floating layer. The regular overflow from the storage tank is important to get the optimum water quality. It prevents souring of the water. The floating layer could otherwise build up over time, and so reduce oxygen diffusion at the water surface, which in turn could lead to anaerobic conditions in the tank. 4. Cleaning step Floating pump intake The 3 P Pump Intake floats at all times, suspended just below the water surface where the cleanest water lies. From this position the water is extracted by the pump. A ball float, filled with air, suspends the intake, which has a further filter and a check valve.

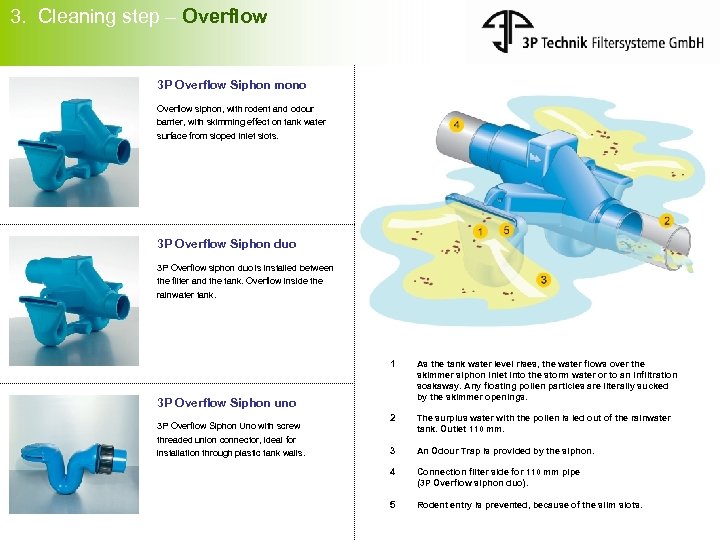

3. Cleaning step – Overflow 3 P Overflow Siphon mono Overflow siphon, with rodent and odour barrier, with skimming effect on tank water surface from sloped inlet slots. 3 P Overflow Siphon duo 3 P Overflow siphon duo is installed between the filter and the tank. Overflow inside the rainwater tank. 1 As the tank water level rises, the water flows over the skimmer siphon inlet into the storm water or to an infiltration soakaway. Any floating pollen particles are literally sucked by the skimmer openings. 2 The surplus water with the pollen is led out of the rainwater tank. Outlet 110 mm. 3 An Odour Trap is provided by the siphon. 4 Connection filter side for 110 mm pipe (3 P Overflow siphon duo). 5 Rodent entry is prevented, because of the slim slots. 3 P Overflow Siphon uno 3 P Overflow Siphon Uno with screw threaded union connector, ideal for installation through plastic tank walls.

3. Cleaning step – Overflow 3 P Overflow Siphon mono Overflow siphon, with rodent and odour barrier, with skimming effect on tank water surface from sloped inlet slots. 3 P Overflow Siphon duo 3 P Overflow siphon duo is installed between the filter and the tank. Overflow inside the rainwater tank. 1 As the tank water level rises, the water flows over the skimmer siphon inlet into the storm water or to an infiltration soakaway. Any floating pollen particles are literally sucked by the skimmer openings. 2 The surplus water with the pollen is led out of the rainwater tank. Outlet 110 mm. 3 An Odour Trap is provided by the siphon. 4 Connection filter side for 110 mm pipe (3 P Overflow siphon duo). 5 Rodent entry is prevented, because of the slim slots. 3 P Overflow Siphon uno 3 P Overflow Siphon Uno with screw threaded union connector, ideal for installation through plastic tank walls.

4 cleaning steps 1. Cleaning step Filter The first cleaning step in the rainwater system is the filter. The rainwater flows from the roof to the filter. Here dirt particles and debris are separated from the water. The cleaned water flows to the tank. The dirt is washed to the storm water pipe or soakaway with a small amount of rainwater. All 3 P rainwater filters have stainless steel inserts, which are easy to remove and easy to clean. Their many different working principles and connection possibilities allow for their use in many different installation situations with the advantage of very low maintenance. 2. Cleaning step Calmed inlet 3. Cleaning step Overflow siphon By using an underground tank, the water is stored in dark and cool conditions. Here the second cleaning step takes place. In the water column, any fine residual particles settle to the bottom of the tank. The rainwater Calmed Inlet prevents any disturbance of this sedimentation layer. At the same time the Calmed Inlet ensures that oxygenated water is introduced to the lower layers of the stored water in the tank. This oxygen rich water prevents anaerobic conditions from forming in the storage tank and ensures that the water stays fresh. Any particles that are lighter than water (e. g. flower pollen) float slowly to the water surface. The expertly designed 3 P Overflow Siphon, with a skimmer effect, removes this floating layer. The regular overflow from the storage tank is important to get the optimum water quality. It prevents souring of the water. The floating layer could otherwise build up over time, and so reduce oxygen diffusion at the water surface, which in turn could lead to anaerobic conditions in the tank. 4. Cleaning step Floating pump intake The 3 P Pump Intake floats at all times, suspended just below the water surface where the cleanest water lies. From this position the water is extracted by the pump. A ball float, filled with air, suspends the intake, which has a further filter and a check valve.

4 cleaning steps 1. Cleaning step Filter The first cleaning step in the rainwater system is the filter. The rainwater flows from the roof to the filter. Here dirt particles and debris are separated from the water. The cleaned water flows to the tank. The dirt is washed to the storm water pipe or soakaway with a small amount of rainwater. All 3 P rainwater filters have stainless steel inserts, which are easy to remove and easy to clean. Their many different working principles and connection possibilities allow for their use in many different installation situations with the advantage of very low maintenance. 2. Cleaning step Calmed inlet 3. Cleaning step Overflow siphon By using an underground tank, the water is stored in dark and cool conditions. Here the second cleaning step takes place. In the water column, any fine residual particles settle to the bottom of the tank. The rainwater Calmed Inlet prevents any disturbance of this sedimentation layer. At the same time the Calmed Inlet ensures that oxygenated water is introduced to the lower layers of the stored water in the tank. This oxygen rich water prevents anaerobic conditions from forming in the storage tank and ensures that the water stays fresh. Any particles that are lighter than water (e. g. flower pollen) float slowly to the water surface. The expertly designed 3 P Overflow Siphon, with a skimmer effect, removes this floating layer. The regular overflow from the storage tank is important to get the optimum water quality. It prevents souring of the water. The floating layer could otherwise build up over time, and so reduce oxygen diffusion at the water surface, which in turn could lead to anaerobic conditions in the tank. 4. Cleaning step Floating pump intake The 3 P Pump Intake floats at all times, suspended just below the water surface where the cleanest water lies. From this position the water is extracted by the pump. A ball float, filled with air, suspends the intake, which has a further filter and a check valve.

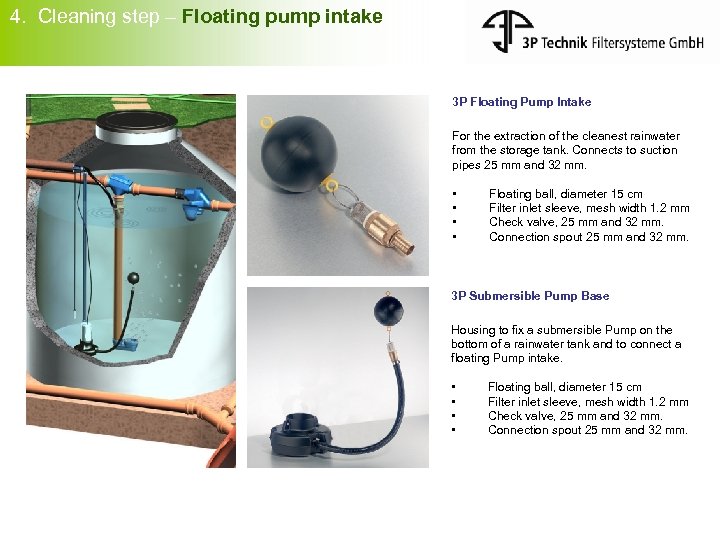

4. Cleaning step – Floating pump intake 3 P Floating Pump Intake For the extraction of the cleanest rainwater from the storage tank. Connects to suction pipes 25 mm and 32 mm. • • Floating ball, diameter 15 cm Filter inlet sleeve, mesh width 1. 2 mm Check valve, 25 mm and 32 mm. Connection spout 25 mm and 32 mm. 3 P Submersible Pump Base Housing to fix a submersible Pump on the bottom of a rainwater tank and to connect a floating Pump intake. • • Floating ball, diameter 15 cm Filter inlet sleeve, mesh width 1. 2 mm Check valve, 25 mm and 32 mm. Connection spout 25 mm and 32 mm.

4. Cleaning step – Floating pump intake 3 P Floating Pump Intake For the extraction of the cleanest rainwater from the storage tank. Connects to suction pipes 25 mm and 32 mm. • • Floating ball, diameter 15 cm Filter inlet sleeve, mesh width 1. 2 mm Check valve, 25 mm and 32 mm. Connection spout 25 mm and 32 mm. 3 P Submersible Pump Base Housing to fix a submersible Pump on the bottom of a rainwater tank and to connect a floating Pump intake. • • Floating ball, diameter 15 cm Filter inlet sleeve, mesh width 1. 2 mm Check valve, 25 mm and 32 mm. Connection spout 25 mm and 32 mm.

4 cleaning steps 1. Cleaning step Filter The first cleaning step in the rainwater system is the filter. The rainwater flows from the roof to the filter. Here dirt particles and debris are separated from the water. The cleaned water flows to the tank. The dirt is washed to the storm water pipe or soakaway with a small amount of rainwater. All 3 P rainwater filters have stainless steel inserts, which are easy to remove and easy to clean. Their many different working principles and connection possibilities allow for their use in many different installation situations with the advantage of very low maintenance. 2. Cleaning step Calmed inlet 3. Cleaning step Overflow siphon By using an underground tank, the water is stored in dark and cool conditions. Here the second cleaning step takes place. In the water column, any fine residual particles settle to the bottom of the tank. The rainwater Calmed Inlet prevents any disturbance of this sedimentation layer. At the same time the Calmed Inlet ensures that oxygenated water is introduced to the lower layers of the stored water in the tank. This oxygen rich water prevents anaerobic conditions from forming in the storage tank and ensures that the water stays fresh. Any particles that are lighter than water (e. g. flower pollen) float slowly to the water surface. The expertly designed 3 P Overflow Siphon, with a skimmer effect, removes this floating layer. The regular overflow from the storage tank is important to get the optimum water quality. It prevents souring of the water. The floating layer could otherwise build up over time, and so reduce oxygen diffusion at the water surface, which in turn could lead to anaerobic conditions in the tank. 4. Cleaning step Floating pump intake The 3 P Pump Intake floats at all times, suspended just below the water surface where the cleanest water lies. From this position the water is extracted by the pump. A ball float, filled with air, suspends the intake, which has a further filter and a check valve.

4 cleaning steps 1. Cleaning step Filter The first cleaning step in the rainwater system is the filter. The rainwater flows from the roof to the filter. Here dirt particles and debris are separated from the water. The cleaned water flows to the tank. The dirt is washed to the storm water pipe or soakaway with a small amount of rainwater. All 3 P rainwater filters have stainless steel inserts, which are easy to remove and easy to clean. Their many different working principles and connection possibilities allow for their use in many different installation situations with the advantage of very low maintenance. 2. Cleaning step Calmed inlet 3. Cleaning step Overflow siphon By using an underground tank, the water is stored in dark and cool conditions. Here the second cleaning step takes place. In the water column, any fine residual particles settle to the bottom of the tank. The rainwater Calmed Inlet prevents any disturbance of this sedimentation layer. At the same time the Calmed Inlet ensures that oxygenated water is introduced to the lower layers of the stored water in the tank. This oxygen rich water prevents anaerobic conditions from forming in the storage tank and ensures that the water stays fresh. Any particles that are lighter than water (e. g. flower pollen) float slowly to the water surface. The expertly designed 3 P Overflow Siphon, with a skimmer effect, removes this floating layer. The regular overflow from the storage tank is important to get the optimum water quality. It prevents souring of the water. The floating layer could otherwise build up over time, and so reduce oxygen diffusion at the water surface, which in turn could lead to anaerobic conditions in the tank. 4. Cleaning step Floating pump intake The 3 P Pump Intake floats at all times, suspended just below the water surface where the cleanest water lies. From this position the water is extracted by the pump. A ball float, filled with air, suspends the intake, which has a further filter and a check valve.

CLEAN WATER OUR MISSION

CLEAN WATER OUR MISSION