102813f3a363f1328e2a0af0867ff0db.ppt

- Количество слайдов: 38

General Motors Globális Gyártási Rendszer General Motors Global Manufacturing System General Motors Powertrain – Magyarország Kft. Dátum: 2008. Április 16 Előadó: Kovács János Minőségügyi Igazgató Presentation Title

Cél: Minőségügyi alapelvek alkalmazásának bemutatása a GM Globális Gyártási Rendszer ismertetésén keresztül Első előadás témái: ü A vevő fogalma, vevői elégedettség ü Termékminőségi követelmények ü Termelési folyamat jóváhagyás Második előadás témái: ü Folyamatközi ellenőrzés és folyamat igazolás ü Minőség visszajelzés - előrejelzés rendszere ü Minőségirányítási rendszer 2

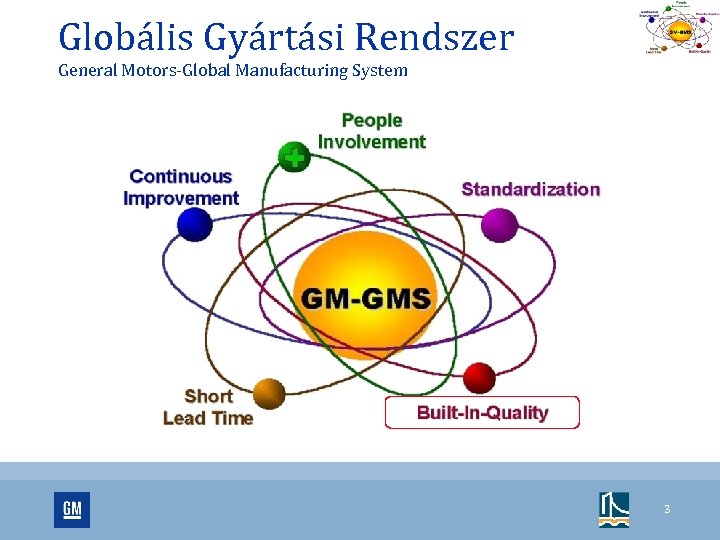

Globális Gyártási Rendszer General Motors-Global Manufacturing System 3

4

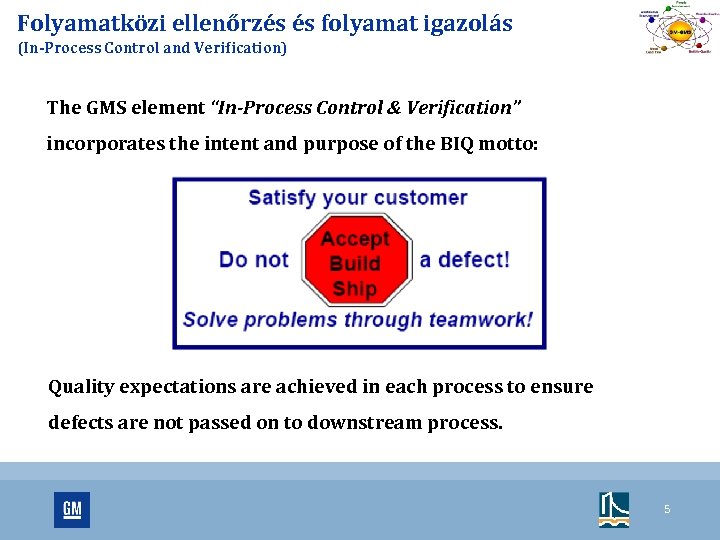

Folyamatközi ellenőrzés és folyamat igazolás (In-Process Control and Verification) The GMS element “In-Process Control & Verification” incorporates the intent and purpose of the BIQ motto: Quality expectations are achieved in each process to ensure defects are not passed on to downstream process. 5

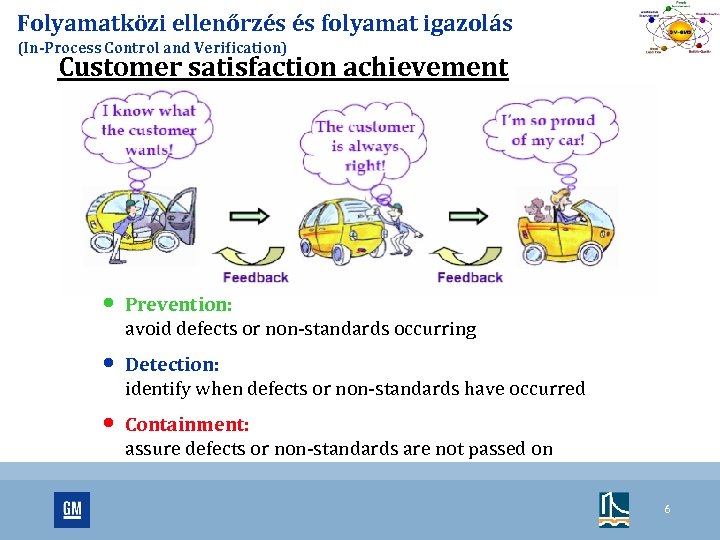

Folyamatközi ellenőrzés és folyamat igazolás (In-Process Control and Verification) Customer satisfaction achievement Customer satisfaction is achieved through three sub-elements: • Prevention: avoid defects or non-standards occurring • Detection: identify when defects or non-standards have occurred • Containment: assure defects or non-standards are not passed on 6

Folyamatközi ellenőrzés és folyamat igazolás (In-Process Control and Verification) Benefits Ø To External customers (people buying our vehicle). • Protect Customers from sub-standard vehicle quality. • Assure customer satisfaction Ø To Internal customer (downstream operation). • Prevent major repair and rework by detecting a non-conformity early in the process. • station Prevent the flow of defects from department to department and station to Ø To Internal customer (from supplier). • Protect Team Members from non-compliant parts from suppliers through advanced quality planning and prompt containment during spills. 7

Folyamatközi ellenőrzés és folyamat igazolás (In-Process Control and Verification) 8

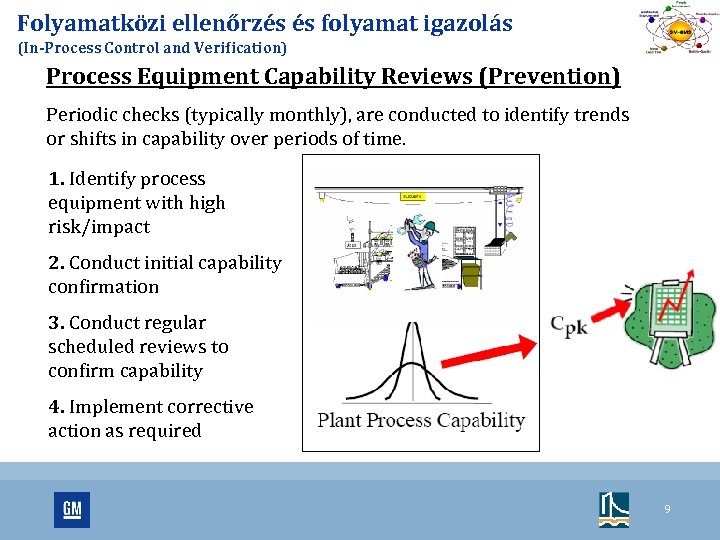

Folyamatközi ellenőrzés és folyamat igazolás (In-Process Control and Verification) Process Equipment Capability Reviews (Prevention) Periodic checks (typically monthly), are conducted to identify trends or shifts in capability over periods of time. 1. Identify process equipment with high risk/impact 2. Conduct initial capability confirmation 3. Conduct regular scheduled reviews to confirm capability 4. Implement corrective action as required 9

Folyamatközi ellenőrzés és folyamat igazolás (In-Process Control and Verification) Detection Purpose of Detection: Ø To make non-standard conditions in the manufacturing process visible - identify when defects or non-standards have occurred. ØThis supports the “Do Not Accept” element of the quality motto: § inspection process that confirms quality as soon as possible following manufacture § measures the output of the manufacturing process § alerts organization to out of standard conditions § supports containment and provides input into continuous improvement 10

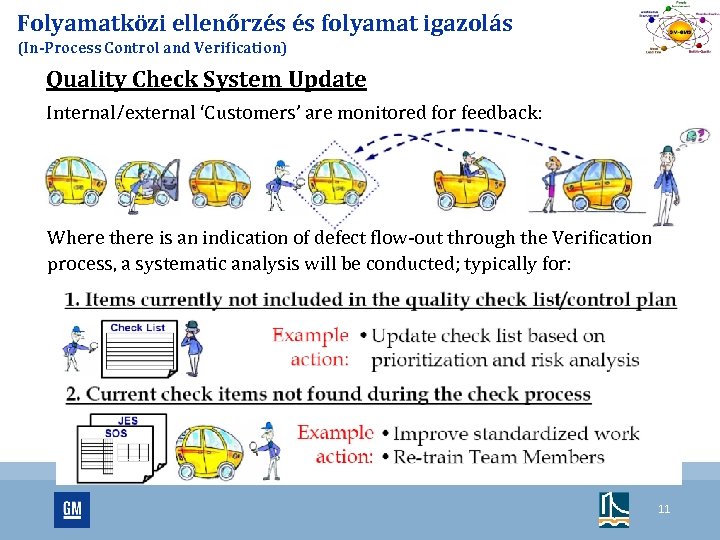

Folyamatközi ellenőrzés és folyamat igazolás (In-Process Control and Verification) Quality Check System Update Internal/external ‘Customers’ are monitored for feedback: Where there is an indication of defect flow-out through the Verification process, a systematic analysis will be conducted; typically for: 11

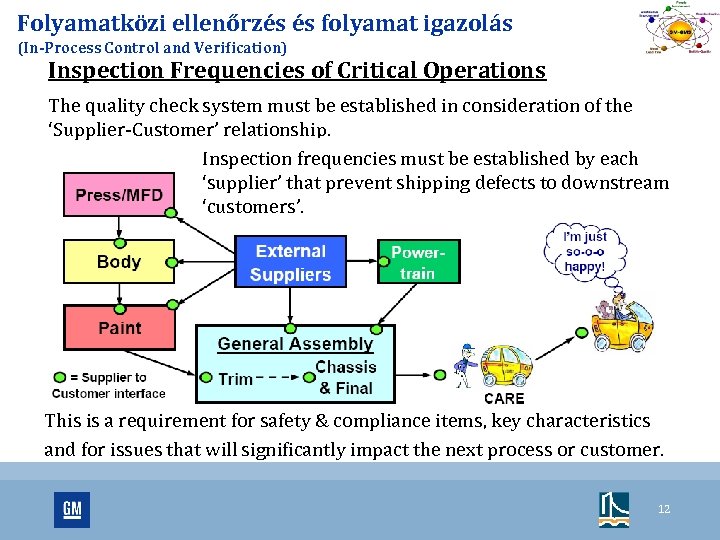

Folyamatközi ellenőrzés és folyamat igazolás (In-Process Control and Verification) Inspection Frequencies of Critical Operations The quality check system must be established in consideration of the ‘Supplier-Customer’ relationship. Inspection frequencies must be established by each ‘supplier’ that prevent shipping defects to downstream ‘customers’. This is a requirement for safety & compliance items, key characteristics and for issues that will significantly impact the next process or customer. 12

Folyamatközi ellenőrzés és folyamat igazolás (In-Process Control and Verification) Independent Repair Confirmation During a repair, the risk for a discrepancy to occur is increased - many aspects of the repair operation are non-standard: Any documented repair must be verified by Repair Confirmation (both onand off-line) Ø Repair Confirmation must be conducted independently (e. g. by Quality). Ø Standardized work (non-cyclic) should be used for the confirmation Ø process – quality standards must be available. Ø Appropriate training and knowledge of standards must be developed to Ø conduct or confirm repairs. Ø Repair confirmation should be as close to the repair process as possible. Ø Repair confirmation can be conducted by man or machine. 13

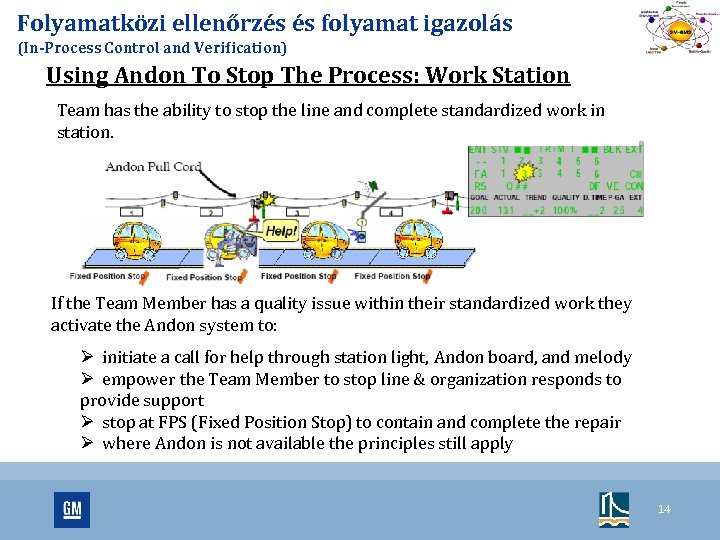

Folyamatközi ellenőrzés és folyamat igazolás (In-Process Control and Verification) Using Andon To Stop The Process: Work Station Team has the ability to stop the line and complete standardized work in station. If the Team Member has a quality issue within their standardized work they activate the Andon system to: Ø initiate a call for help through station light, Andon board, and melody Ø empower the Team Member to stop line & organization responds to provide support Ø stop at FPS (Fixed Position Stop) to contain and complete the repair Ø where Andon is not available the principles still apply 14

Folyamatközi ellenőrzés és folyamat igazolás (In-Process Control and Verification) Alarm & Escalation Processes When a defect is detected, feedback to the appropriate team or individual will be given by using a communication system. The alarm is raised by using audio/visual signals (e. g. Andon). The alarm process directs the support functions to: Ø ‘Go and See’ the problem Ø Apply containment to prevent further flow of defects Ø Initiate problem solving 15

Folyamatközi ellenőrzés és folyamat igazolás (In-Process Control and Verification) Containment Purpose of Containment: • The achievement of customer expectations relies on a method to contain defects within the manufacturing process, and implement corrections to protect the next/downstream customer. • This supports the “Do Not Ship” element of the quality motto: Ø vehicle delivery to the customer Ø Powertrain and MFD plants to vehicle assembly Ø external supplier to the manufacturing plant Ø internal departments (e. g. between body, paint and GA) Ø between work stations within a department 16

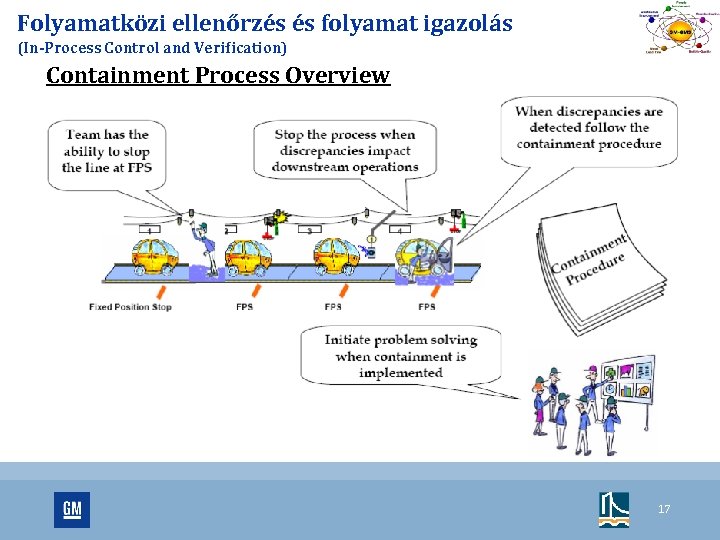

Folyamatközi ellenőrzés és folyamat igazolás (In-Process Control and Verification) Containment Process Overview 17

Folyamatközi ellenőrzés és folyamat igazolás (In-Process Control and Verification) Summary Ø Standardized work is performed in every process and includes the required quality checks. Ø Process control activities are implemented on equipment to control variation on a daily basis and maintain capability over a period of time. Ø Detection confirms the manufacturing process and ensures both internal (Production Team Members) and External Customers (people who buy our products) are receiving products that meet or exceed the quality standards. Ø A process is in place to contain defects within the manufacturing process and implement permanent corrective actions that are verified as being effective. 18

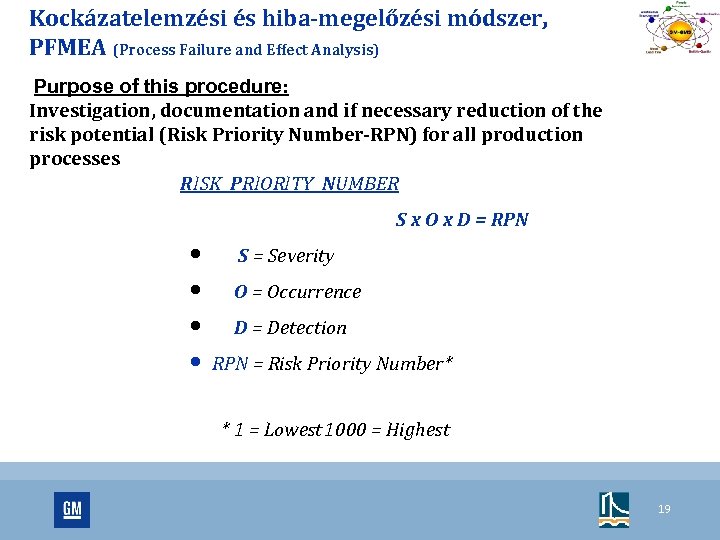

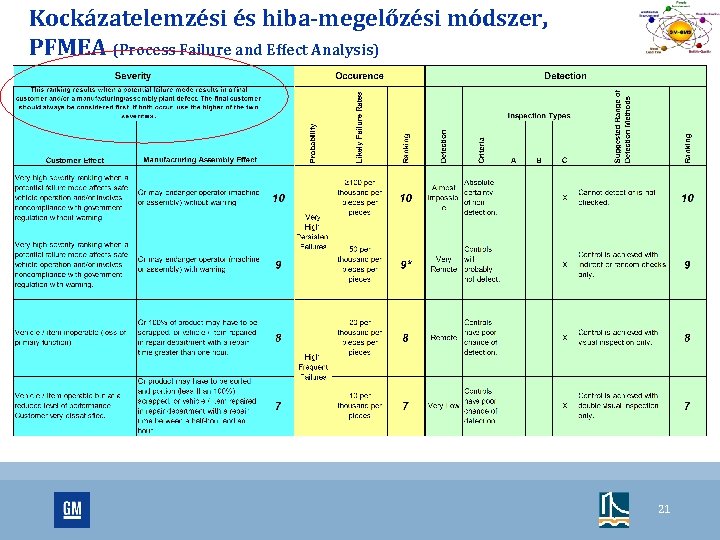

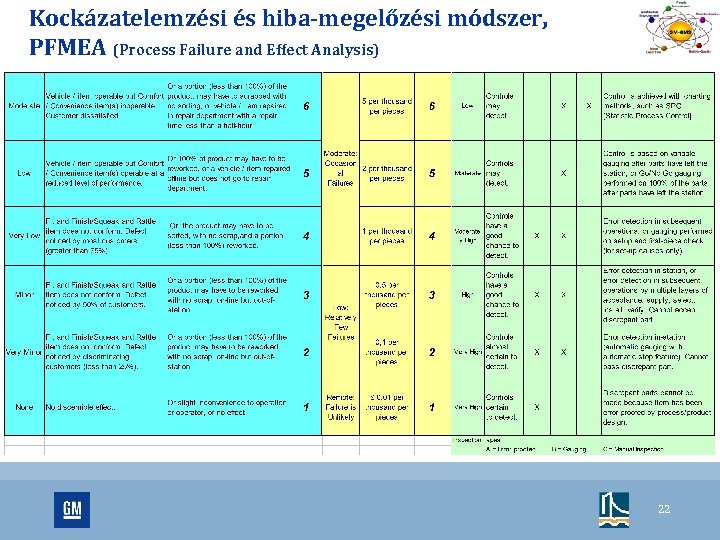

Kockázatelemzési és hiba-megelőzési módszer, PFMEA (Process Failure and Effect Analysis) Purpose of this procedure: Investigation, documentation and if necessary reduction of the risk potential (Risk Priority Number-RPN) for all production processes RISK PRIORITY NUMBER S x O x D = RPN • S = Severity • O = Occurrence • D = Detection • RPN = Risk Priority Number* * 1 = Lowest 1000 = Highest 19

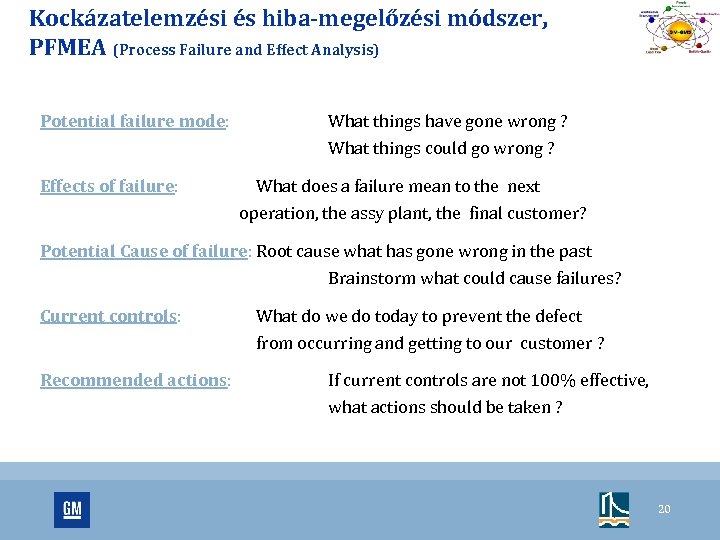

Kockázatelemzési és hiba-megelőzési módszer, PFMEA (Process Failure and Effect Analysis) Potential failure mode: What things have gone wrong ? What things could go wrong ? Effects of failure: What does a failure mean to the next operation, the assy plant, the final customer? Potential Cause of failure: Root cause what has gone wrong in the past Brainstorm what could cause failures? Current controls: Recommended actions: What do we do today to prevent the defect from occurring and getting to our customer ? If current controls are not 100% effective, what actions should be taken ? 20

Kockázatelemzési és hiba-megelőzési módszer, PFMEA (Process Failure and Effect Analysis) 21

Kockázatelemzési és hiba-megelőzési módszer, PFMEA (Process Failure and Effect Analysis) 22

Kockázatelemzési és hiba-megelőzési módszer, PFMEA (Process Failure and Effect Analysis) Requirement: Satisfy thirst Potential Cause Mechanism of Failure Current Process Controls PREVENTION 5 Still thirsty Increased irritability Daily inventory (layered audit) 6 60 Not enough available 1 Thermostatically Random 8 2 controlled environment Sampling -a. k. a. refrigerator visual inspection 160 Wrong brand Remove people who don’t like my favorite 3 brand of beer from invitation list 120 10 Automatic restocking system DETECTION RPN Temperature too high Dehydration Function: Drink cold beer Potential Effects of Failure DETECTION Potential Failure Mode OCCURANCE Process Function and Requirement s SEVERITY A practical example – „with user friendly logistic solution „ Registered complaints - Warning 4 23

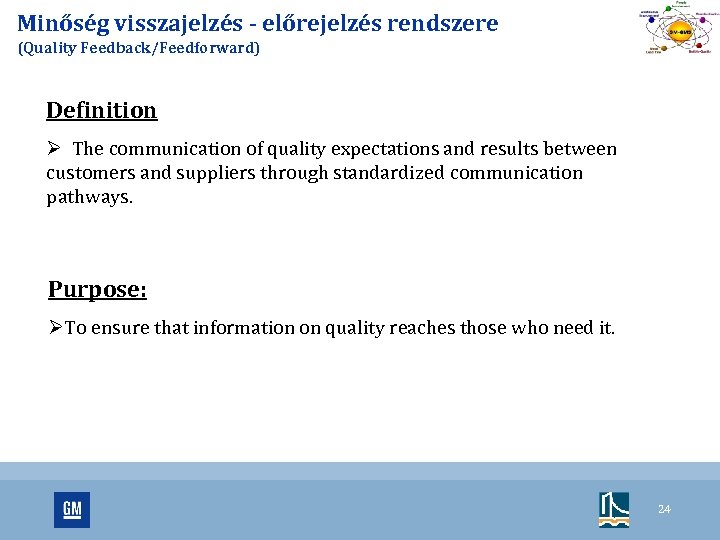

Minőség visszajelzés - előrejelzés rendszere (Quality Feedback/Feedforward) Definition Ø The communication of quality expectations and results between customers and suppliers through standardized communication pathways. Purpose: ØTo ensure that information on quality reaches those who need it. 24

Minőség visszajelzés - előrejelzés rendszere (Quality Feedback/Feedforward) Feed Information Forward Internal and external suppliers communicate known/potential problems and/or problem solving status to their customers in a timely manner. This provides the customer with sufficient lead time to react to upcoming changes and take appropriate measures. 25

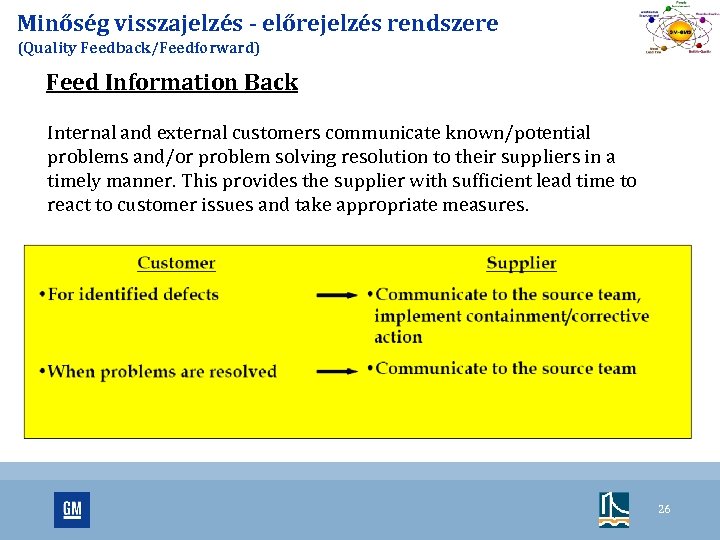

Minőség visszajelzés - előrejelzés rendszere (Quality Feedback/Feedforward) Feed Information Back Internal and external customers communicate known/potential problems and/or problem solving resolution to their suppliers in a timely manner. This provides the supplier with sufficient lead time to react to customer issues and take appropriate measures. 26

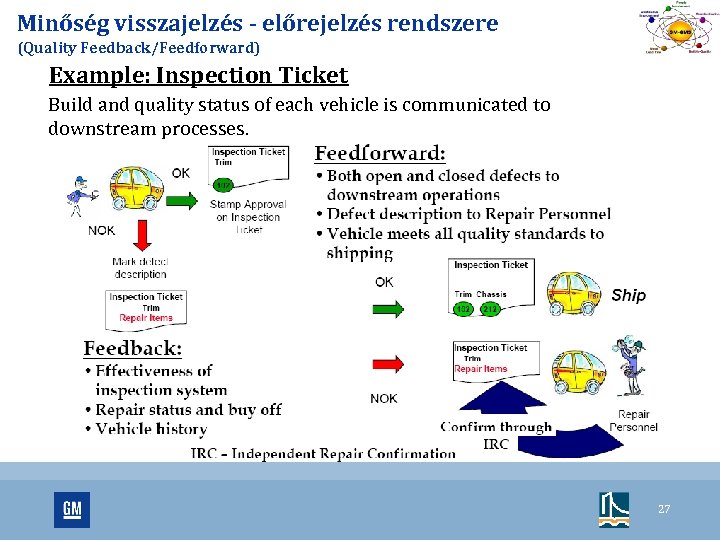

Minőség visszajelzés - előrejelzés rendszere (Quality Feedback/Feedforward) Example: Inspection Ticket Build and quality status of each vehicle is communicated to downstream processes. 27

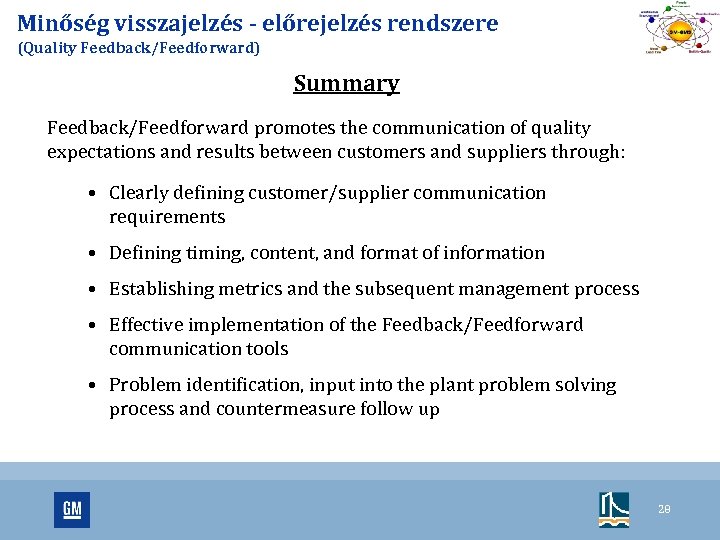

Minőség visszajelzés - előrejelzés rendszere (Quality Feedback/Feedforward) Summary Feedback/Feedforward promotes the communication of quality expectations and results between customers and suppliers through: • Clearly defining customer/supplier communication requirements • Defining timing, content, and format of information • Establishing metrics and the subsequent management process • Effective implementation of the Feedback/Feedforward communication tools • Problem identification, input into the plant problem solving process and countermeasure follow up 28

Minőségirányítási rendszer (Quality System Management) Who is responsible for Quality? • Team work is absolutely essential to deliver world-class quality. Everyone! Quality is a shared responsibility 29

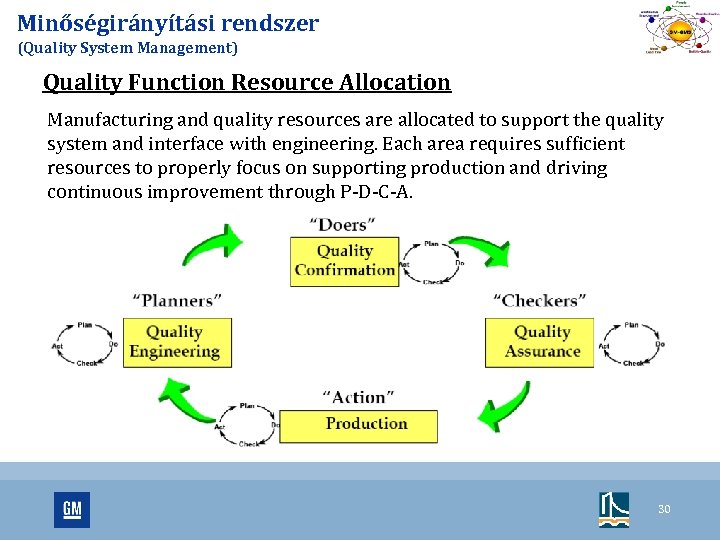

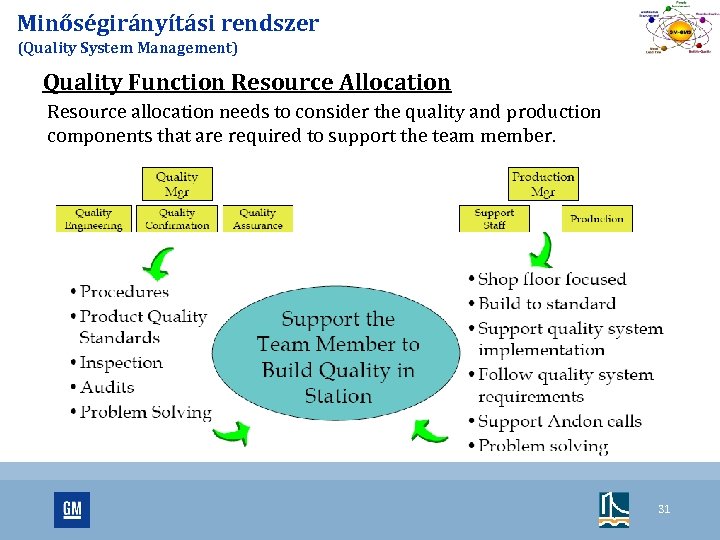

Minőségirányítási rendszer (Quality System Management) Quality Function Resource Allocation Manufacturing and quality resources are allocated to support the quality system and interface with engineering. Each area requires sufficient resources to properly focus on supporting production and driving continuous improvement through P-D-C-A. 30

Minőségirányítási rendszer (Quality System Management) Quality Function Resource Allocation Resource allocation needs to consider the quality and production components that are required to support the team member. 31

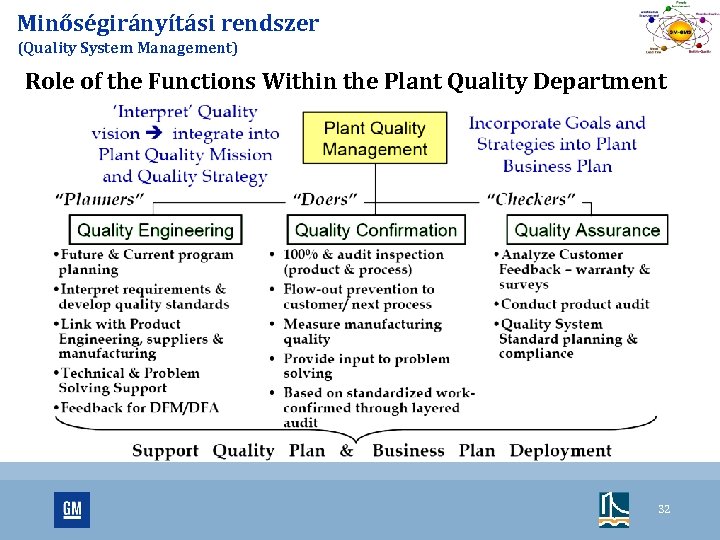

Minőségirányítási rendszer (Quality System Management) Role of the Functions Within the Plant Quality Department 32

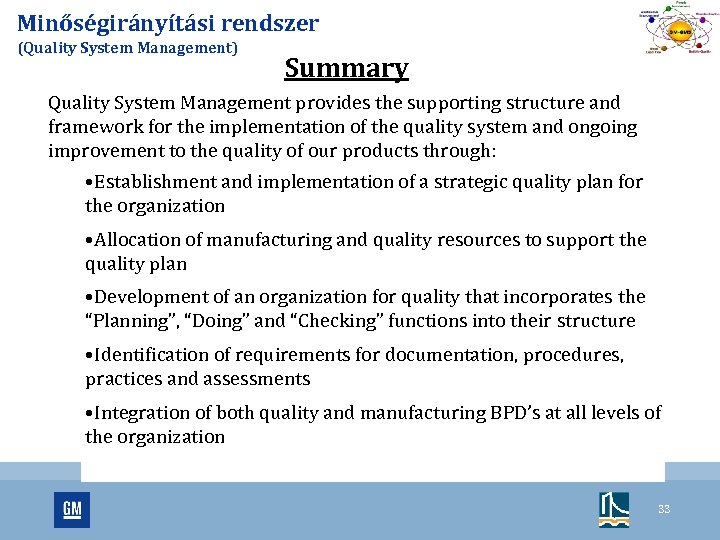

Minőségirányítási rendszer (Quality System Management) Summary Quality System Management provides the supporting structure and framework for the implementation of the quality system and ongoing improvement to the quality of our products through: • Establishment and implementation of a strategic quality plan for the organization • Allocation of manufacturing and quality resources to support the quality plan • Development of an organization for quality that incorporates the “Planning”, “Doing” and “Checking” functions into their structure • Identification of requirements for documentation, procedures, practices and assessments • Integration of both quality and manufacturing BPD’s at all levels of the organization 33

Folyamatközi ellenőrzés és folyamat igazolás (In-Process Control and Verification) Ellenőrző kérdések: 1. Mi a beépített minőségi előírások jelmondat? (What is the motto of the BIQ? ) 2. Mi az a három alapelv amivel ki lehet vívni a vevői elégedettséget? (What is the three principle wherewith you can achieve the costumer satisfaction? ) 3. Miknek a folyamatos ellenőrzésével és milyen módon lehet a hiba előfordulásának megelőzését támogatni? (What monitoring and what way can you support the prevention with? ) 4. Mire használják az Andon rendszert, és mi történik a működtetésekor? (What is the Andon system for and what happen when it is activated? ) 34

Kockázatelemzési és hiba-megelőzési módszer, PFMEA (Process Failure and Effect Analysis) Ellenőrző kérdések: 1. Mi a PFMEA és mit támogat a quality jelmondatban? (What is the PFMEA and what supports in the quality motto? ) 2. Mit jelent a súlyosság az RPN szám meghatározásánál? (What is the severity at the calculation of the RPN number? ) 35

Minőség visszajelzés - előrejelzés rendszere (Quality Feedback/Feedforward) Ellenőrző kérdések: 1. Mi a meghatározása a minőség visszajelzés-előrejelzés rendszerének? (What is the definition of the Quality Feedback/Feedforward system? ) 2. Milyen információkat kell továbbítania a szállítónak a vevő felé? (What information have to be forwarded to the costumer by supplyer? ) 3. Milyen információkat továbbít a vevő a szállító felé? (What information is forwarded back to the supplier? ) 36

Minőségirányítási rendszer (Quality System Management) Ellenőrző kérdések: 1. Milyen fő funkciók vannak a Quality osztályon belül a GMS szerint? (What functions are there in the Quality Department according to the GMS? ) 2. Mi a „Quality Engineering” feladata? (What is Quality Engineering responsible for? ) 3. Mi a „Quality Confirmation” feladata? (What is Quality Confirmation responsible for? ) 4. Mi a „Quality Assurance” feladata? (What is Quality Assurance responsible for? ) 37

Köszönöm a figyelmet! Thank you for your attention! 38

102813f3a363f1328e2a0af0867ff0db.ppt