771911546127e8b4e2df8982803183f2.ppt

- Количество слайдов: 24

General Layout n Four separate vessels: – Outer containment vessel – Inner containment vessel – Outer field cage vessel – Inner field cage vessel n Two end plates for readout ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 1

General Layout n Four separate vessels: – Outer containment vessel – Inner containment vessel – Outer field cage vessel – Inner field cage vessel n Two end plates for readout ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 1

Design Objectives n Provide high stability and uniformity for: l l n Gas gain (>104): Drift field (400 V/cm): Temperature: Drift gas purity: 0. 5% Er/Ez < 10 -4 T < 0. 1 ºC 5 ppm O 2, 10 ppm H 2 O Provide high mechanical precision for: l l Central electrode: Readout plane: ALICE-LHCC Review January 29 -30, 2001 250 µm Thomas C. Meyer/EP-AIT 2

Design Objectives n Provide high stability and uniformity for: l l n Gas gain (>104): Drift field (400 V/cm): Temperature: Drift gas purity: 0. 5% Er/Ez < 10 -4 T < 0. 1 ºC 5 ppm O 2, 10 ppm H 2 O Provide high mechanical precision for: l l Central electrode: Readout plane: ALICE-LHCC Review January 29 -30, 2001 250 µm Thomas C. Meyer/EP-AIT 2

Technical Progress n The FC prototype has undergone intensive testing during the past two years: – Individual components (electrical, mechanical, gas) – System behavior (FC + NA 35 readout chamber, cosmics & laser runs) n n Laboratory results certify the required performance of the FC in terms of field quality. High radiation test in CERES area: – Check stability under ‘realistic’ conditions – Exposed FC to proton and Pb beams ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 3

Technical Progress n The FC prototype has undergone intensive testing during the past two years: – Individual components (electrical, mechanical, gas) – System behavior (FC + NA 35 readout chamber, cosmics & laser runs) n n Laboratory results certify the required performance of the FC in terms of field quality. High radiation test in CERES area: – Check stability under ‘realistic’ conditions – Exposed FC to proton and Pb beams ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 3

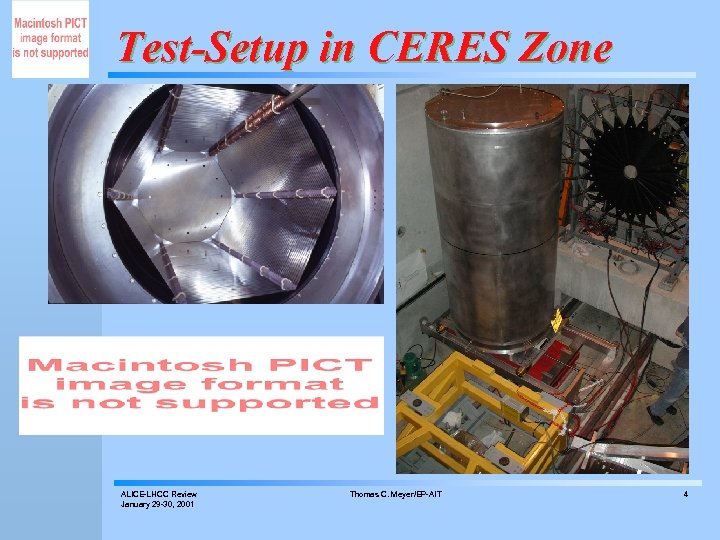

Test-Setup in CERES Zone ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 4

Test-Setup in CERES Zone ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 4

High Intensity: Proton Runs n Direct exposure to proton beam: – Locally irradiated area (1 -4 cm 2) near central electrode: CERES p-beam: 2. 5 x 105/cm 2 s (3 x 105 with Pb target) ALICE: 360/cm 2 s Stable up to 100 k. V ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 5

High Intensity: Proton Runs n Direct exposure to proton beam: – Locally irradiated area (1 -4 cm 2) near central electrode: CERES p-beam: 2. 5 x 105/cm 2 s (3 x 105 with Pb target) ALICE: 360/cm 2 s Stable up to 100 k. V ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 5

High Intensity: Pb-Ion Runs n Exposure to secondaries from Pb beam: – Global irradiation of entire cylinder CERES Pb-beam: ALICE: 6000/cm 2 s (secondaries) 360 /cm 2 s Stable to ≤ 60 k. V! ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 6

High Intensity: Pb-Ion Runs n Exposure to secondaries from Pb beam: – Global irradiation of entire cylinder CERES Pb-beam: ALICE: 6000/cm 2 s (secondaries) 360 /cm 2 s Stable to ≤ 60 k. V! ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 6

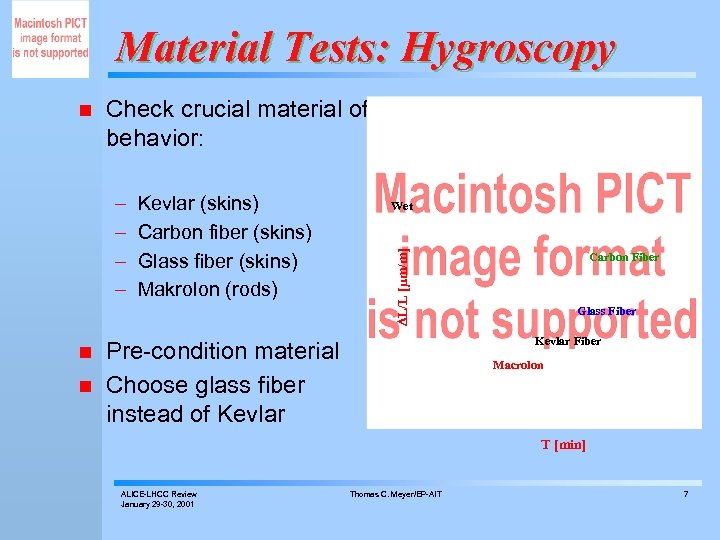

Material Tests: Hygroscopy Check crucial material of field cage for hygroscopic behavior: – – n n Kevlar (skins) Carbon fiber (skins) Glass fiber (skins) Makrolon (rods) Wet DL/L [µm/m] n Carbon Fiber Glass Fiber Kevlar Fiber Pre-condition material Choose glass fiber instead of Kevlar Macrolon Drying T [min] ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 7

Material Tests: Hygroscopy Check crucial material of field cage for hygroscopic behavior: – – n n Kevlar (skins) Carbon fiber (skins) Glass fiber (skins) Makrolon (rods) Wet DL/L [µm/m] n Carbon Fiber Glass Fiber Kevlar Fiber Pre-condition material Choose glass fiber instead of Kevlar Macrolon Drying T [min] ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 7

Material Tests: Tedlar n Does Tedlar provide an efficient moisture barrier? – Sandwich sample exposed to water-saturated air at 29 ºC on both sides: • Maximum possible water absorption by matrix is 6% of sample weight, i. e. 13. 2 g. • After 18 days of exposure, no weight increase was observed. • Reverse test is ongoing, i. e. the sandwich is placed in a 100% dry atmosphere. ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 8

Material Tests: Tedlar n Does Tedlar provide an efficient moisture barrier? – Sandwich sample exposed to water-saturated air at 29 ºC on both sides: • Maximum possible water absorption by matrix is 6% of sample weight, i. e. 13. 2 g. • After 18 days of exposure, no weight increase was observed. • Reverse test is ongoing, i. e. the sandwich is placed in a 100% dry atmosphere. ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 8

Problems & Risks: Material n Material tests basically finished. – Kevlar fallback: glass fiber (included in tender) Slightly cheaper More mass (<10% of total) – Tedlar fallback: none! Aging tests planned (≥ 1 year) – Macrolon rods replaced by ceramics? Very ALICE-LHCC Review January 29 -30, 2001 expensive (material and machining) Thomas C. Meyer/EP-AIT 9

Problems & Risks: Material n Material tests basically finished. – Kevlar fallback: glass fiber (included in tender) Slightly cheaper More mass (<10% of total) – Tedlar fallback: none! Aging tests planned (≥ 1 year) – Macrolon rods replaced by ceramics? Very ALICE-LHCC Review January 29 -30, 2001 expensive (material and machining) Thomas C. Meyer/EP-AIT 9

Cooling Tests: Resistor Chain n Four internal resistor chains supply the appropriate potentials to the strips. Their power consumption is 60 W each. n This leads to temperature gradients inside TPC of » 0. 1 °C. n n Must cool the voltage divider! ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 10

Cooling Tests: Resistor Chain n Four internal resistor chains supply the appropriate potentials to the strips. Their power consumption is 60 W each. n This leads to temperature gradients inside TPC of » 0. 1 °C. n n Must cool the voltage divider! ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 10

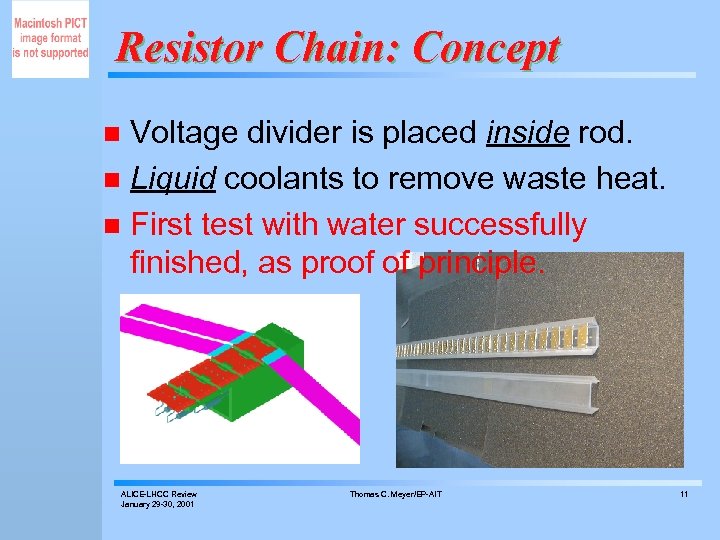

Resistor Chain: Concept Voltage divider is placed inside rod. n Liquid coolants to remove waste heat. n First test with water successfully finished, as proof of principle. n ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 11

Resistor Chain: Concept Voltage divider is placed inside rod. n Liquid coolants to remove waste heat. n First test with water successfully finished, as proof of principle. n ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 11

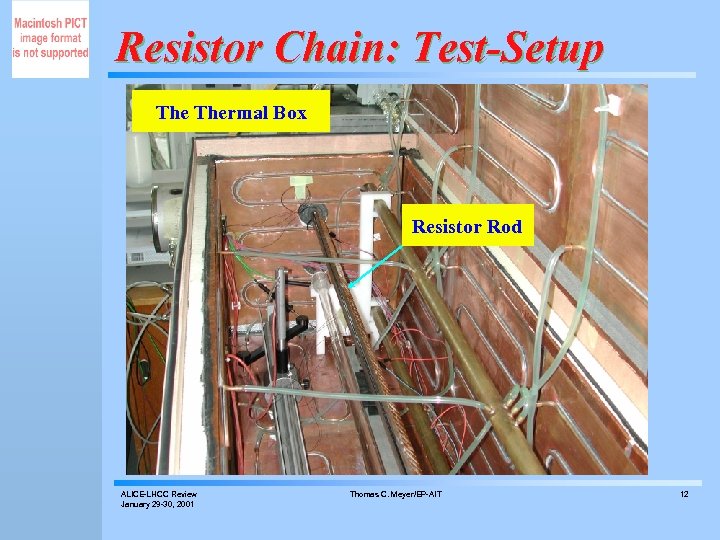

Resistor Chain: Test-Setup Thermal Box Resistor Rod ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 12

Resistor Chain: Test-Setup Thermal Box Resistor Rod ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 12

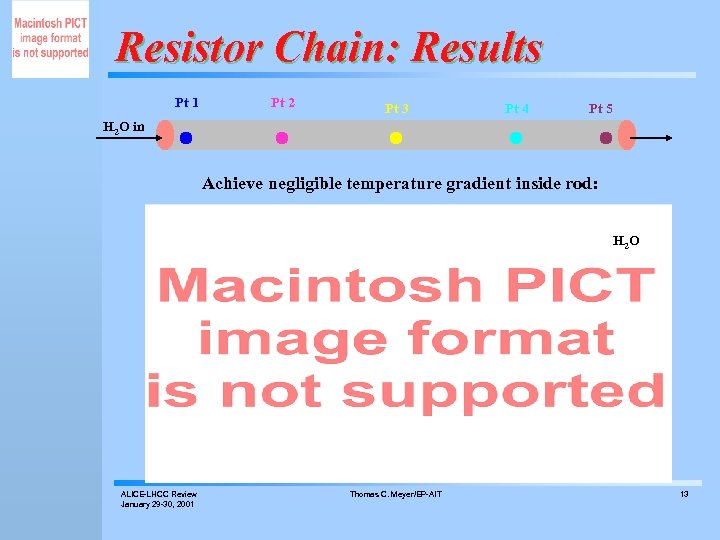

Resistor Chain: Results Pt 1 Pt 2 Pt 3 Pt 4 Pt 5 H 2 O in Achieve negligible temperature gradient inside rod: H 2 O ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 13

Resistor Chain: Results Pt 1 Pt 2 Pt 3 Pt 4 Pt 5 H 2 O in Achieve negligible temperature gradient inside rod: H 2 O ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 13

Resistor Cooling: Next Steps n We have verified that water and silicon fluid FL 200/5 remove heat equivalent to 60 W, as expected. For HV operation, only non-polar liquids can be used: n The liquid must be compatible with the rod material. n ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 14

Resistor Cooling: Next Steps n We have verified that water and silicon fluid FL 200/5 remove heat equivalent to 60 W, as expected. For HV operation, only non-polar liquids can be used: n The liquid must be compatible with the rod material. n ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 14

Problems & Risks: Charging n Understand field cage charging under high radiation load: – Examine field cage in laboratory: Bleed 300 MBe of 83 Kr into field cage gas to simulate charged particle flux. Separate tests for drift and insulation volume. – Increase number of guard rings. – Eventually repeat beam test. ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 15

Problems & Risks: Charging n Understand field cage charging under high radiation load: – Examine field cage in laboratory: Bleed 300 MBe of 83 Kr into field cage gas to simulate charged particle flux. Separate tests for drift and insulation volume. – Increase number of guard rings. – Eventually repeat beam test. ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 15

Problems & Risks: Cooling n The resistor rod is a high risk item. . . – Choose liquid that is safe for apparatus. No chemical decomposition, dissolution etc. – Run circuit below atmospheric pressure. Absolutely no leaks, cracks, capillary effects! – Tight quality control. – If all fails, use gas as coolant: Double walled cooling circuit; Needs additional, extensive testing. ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 16

Problems & Risks: Cooling n The resistor rod is a high risk item. . . – Choose liquid that is safe for apparatus. No chemical decomposition, dissolution etc. – Run circuit below atmospheric pressure. Absolutely no leaks, cracks, capillary effects! – Tight quality control. – If all fails, use gas as coolant: Double walled cooling circuit; Needs additional, extensive testing. ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 16

Stability Study: Why? ITS and beam pipe are supported by TPC moves (!) out for ITS interventions. Deformations must not harm TPC and ITS. Weights [N]: 1200 2 Rails 2000 ITS + Vac. Ch. 4000 Services ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 17

Stability Study: Why? ITS and beam pipe are supported by TPC moves (!) out for ITS interventions. Deformations must not harm TPC and ITS. Weights [N]: 1200 2 Rails 2000 ITS + Vac. Ch. 4000 Services ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 17

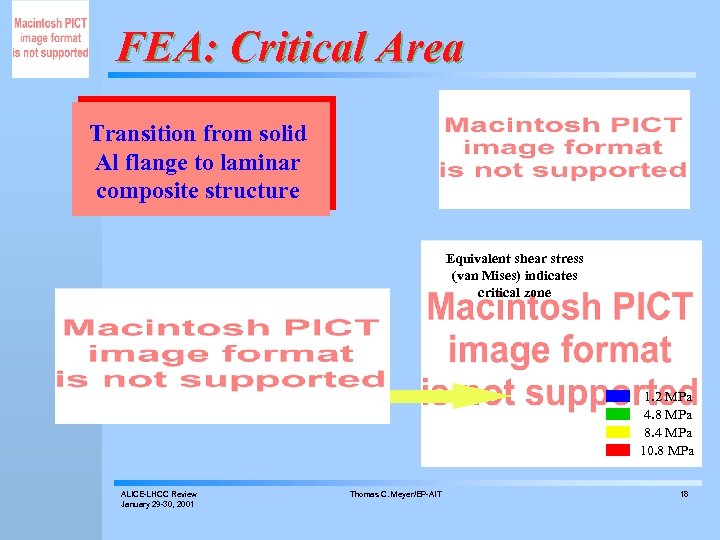

FEA: Critical Area Transition from solid Al flange to laminar composite structure Equivalent shear stress (van Mises) indicates critical zone 1. 2 MPa 4. 8 MPa 8. 4 MPa 10. 8 MPa ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 18

FEA: Critical Area Transition from solid Al flange to laminar composite structure Equivalent shear stress (van Mises) indicates critical zone 1. 2 MPa 4. 8 MPa 8. 4 MPa 10. 8 MPa ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 18

FEA: Results n Buckling: – No buckling modes induced until load is increased by a factor of ~ 60. n Stresses: – The critical zone is the transition from flange to cylinder (“ovalization” under load). – Maximum shear stress in glue joint is ≤ 3 MPa (factor of 6 from failure). – Interlaminar shear stress in composite matrix is ~ 5 k. Pa (6% risk of delamination) ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 19

FEA: Results n Buckling: – No buckling modes induced until load is increased by a factor of ~ 60. n Stresses: – The critical zone is the transition from flange to cylinder (“ovalization” under load). – Maximum shear stress in glue joint is ≤ 3 MPa (factor of 6 from failure). – Interlaminar shear stress in composite matrix is ~ 5 k. Pa (6% risk of delamination) ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 19

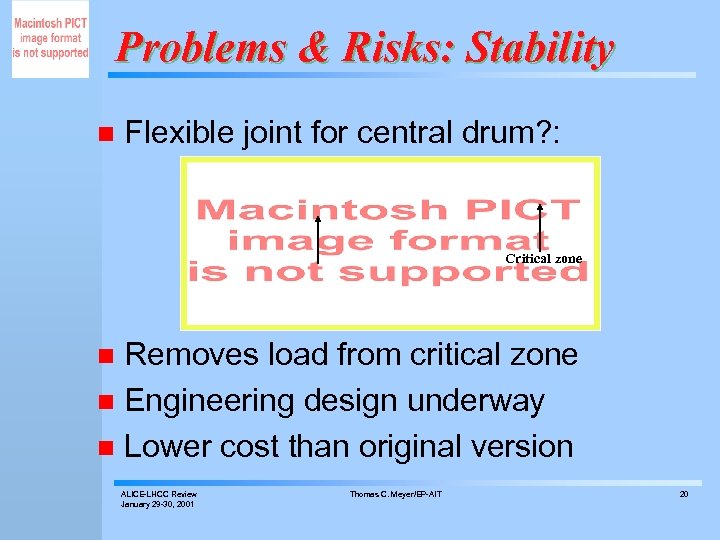

Problems & Risks: Stability n Flexible joint for central drum? : Critical zone ITS attached here Removes load from critical zone n Engineering design underway n Lower cost than original version n ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 20

Problems & Risks: Stability n Flexible joint for central drum? : Critical zone ITS attached here Removes load from critical zone n Engineering design underway n Lower cost than original version n ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 20

Problems Related to Contracting n Cylinders: – Only five offers received – Lowest offer still 3 x higher than budget n End Plates: – Lowest bid exceeds budget by factor of 5 – Splitting of production processes Separate raw material, welding and machining – Design changes n Alternative scenarios require new tenders – Could lead to delays and increased risks – Avoid market surveys (6 months delay) ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 21

Problems Related to Contracting n Cylinders: – Only five offers received – Lowest offer still 3 x higher than budget n End Plates: – Lowest bid exceeds budget by factor of 5 – Splitting of production processes Separate raw material, welding and machining – Design changes n Alternative scenarios require new tenders – Could lead to delays and increased risks – Avoid market surveys (6 months delay) ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 21

Future Activities n R&D and prototyping continues during construction in 2001: – Entire infrastructure of field cage Central electrode (3 options) Strips & Rods (4 different types) Gas distribution Alignment – Tooling and assembly techniques Prepare DELPHI support frame Test facilities (gas, survey, HV, LV, readout) ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 22

Future Activities n R&D and prototyping continues during construction in 2001: – Entire infrastructure of field cage Central electrode (3 options) Strips & Rods (4 different types) Gas distribution Alignment – Tooling and assembly techniques Prepare DELPHI support frame Test facilities (gas, survey, HV, LV, readout) ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 22

Project Schedule R&D Design & Prototyping Construction & Assembly Physics Program Chronology of the TPC Project: We are here! ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 23

Project Schedule R&D Design & Prototyping Construction & Assembly Physics Program Chronology of the TPC Project: We are here! ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 23

Field Cage: Summary n Performance – All technical issues have been studied, certifying the viability of the chosen field cage principle. n Reliability – No serious risks have been identified, except. . charging n at high particle flux (tests underway) Schedule is very tight due to increased in-house production load. ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 24

Field Cage: Summary n Performance – All technical issues have been studied, certifying the viability of the chosen field cage principle. n Reliability – No serious risks have been identified, except. . charging n at high particle flux (tests underway) Schedule is very tight due to increased in-house production load. ALICE-LHCC Review January 29 -30, 2001 Thomas C. Meyer/EP-AIT 24