5b7775f6e7f860b298125270cc7a6912.ppt

- Количество слайдов: 46

GASS™-2040 Gas Analysis Sampling Systems PERMA PURE 2040 -001

GASS™-2040 Gas Analysis Sampling Systems PERMA PURE 2040 -001

GASS-2040 • New product introduction at AWMA • ™ and Combines capabilities of Probe / Mini-GASS™-II systems • Can be mounted anywhere, including directly on stack flange with optional integral sample probe • Most complete sample conditioning system on the market GASS-II discontinued, all other GASS systems still available PERMA PURE • 2040 -002

GASS-2040 • New product introduction at AWMA • ™ and Combines capabilities of Probe / Mini-GASS™-II systems • Can be mounted anywhere, including directly on stack flange with optional integral sample probe • Most complete sample conditioning system on the market GASS-II discontinued, all other GASS systems still available PERMA PURE • 2040 -002

The General Problem Gas analysis for Emissions or Process Monitoring involves three steps: 1. Sampling 2. Conditioning Samples are typically: Hot Analyzers require samples to be: Cool 3. Analysis Wet Dry Dirty Clean Sample conditioning receives little attention, but is often the most difficult step of the three. PERMA PURE 2040 -003

The General Problem Gas analysis for Emissions or Process Monitoring involves three steps: 1. Sampling 2. Conditioning Samples are typically: Hot Analyzers require samples to be: Cool 3. Analysis Wet Dry Dirty Clean Sample conditioning receives little attention, but is often the most difficult step of the three. PERMA PURE 2040 -003

Sampling Methods 1. In-situ analysis 2. Extraction a. Wet (filtered only) b. Dilution c. Drying 1) Absorption 2) Condensation 3) Selective permeation PERMA PURE 2040 -004

Sampling Methods 1. In-situ analysis 2. Extraction a. Wet (filtered only) b. Dilution c. Drying 1) Absorption 2) Condensation 3) Selective permeation PERMA PURE 2040 -004

Typical Problems in Gas Samples Gases • Rarely a problem Liquids • Water • Acid mists (sulfuric acid) Solids • Ammonia salts • Excessive particulates PERMA PURE 2040 -005

Typical Problems in Gas Samples Gases • Rarely a problem Liquids • Water • Acid mists (sulfuric acid) Solids • Ammonia salts • Excessive particulates PERMA PURE 2040 -005

Water Problems • Clogging or damage to analyzers or components • Requirement for heated lines or analyzers • Long calibration times due to adsorption/ desorption • Interference in infrared (or other) measurements • Loss of water-soluble analytes • Participation in unwanted chemical reactions PERMA PURE 2040 -006

Water Problems • Clogging or damage to analyzers or components • Requirement for heated lines or analyzers • Long calibration times due to adsorption/ desorption • Interference in infrared (or other) measurements • Loss of water-soluble analytes • Participation in unwanted chemical reactions PERMA PURE 2040 -006

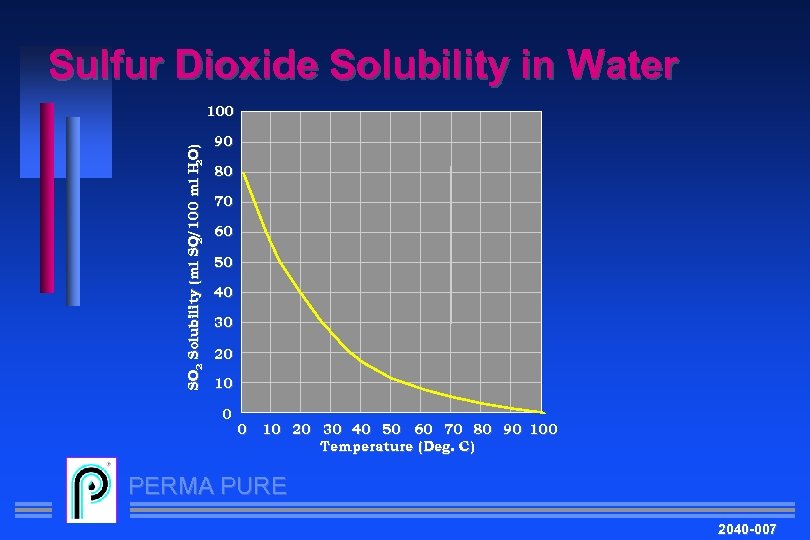

Sulfur Dioxide Solubility in Water SO 2 Solubility (ml SO/100 ml H O) 2 2 100 90 80 70 60 50 40 30 20 10 0 0 10 20 30 40 50 60 70 80 90 100 Temperature (Deg. C) PERMA PURE 2040 -007

Sulfur Dioxide Solubility in Water SO 2 Solubility (ml SO/100 ml H O) 2 2 100 90 80 70 60 50 40 30 20 10 0 0 10 20 30 40 50 60 70 80 90 100 Temperature (Deg. C) PERMA PURE 2040 -007

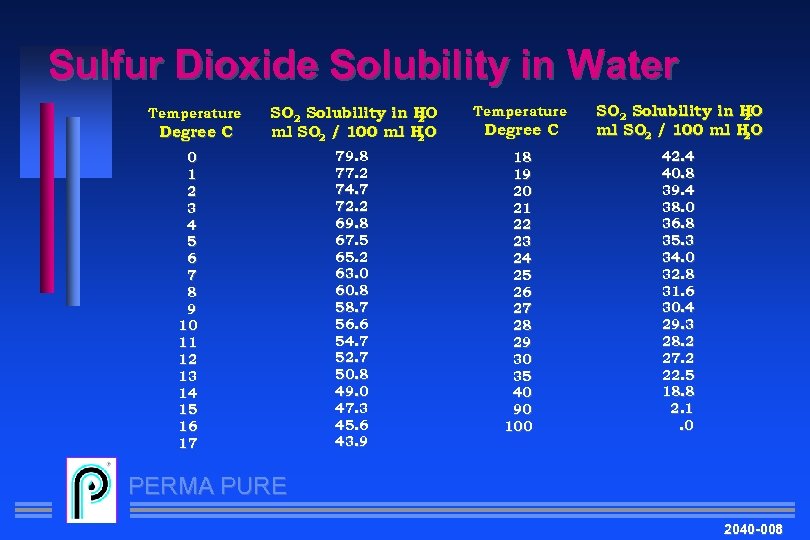

Sulfur Dioxide Solubility in Water Temperature Degree C SO 2 Solubility in HO 2 ml SO 2 / 100 ml H O 2 79. 8 77. 2 74. 7 72. 2 69. 8 67. 5 65. 2 63. 0 60. 8 58. 7 56. 6 54. 7 52. 7 50. 8 49. 0 47. 3 45. 6 43. 9 18 19 20 21 22 23 24 25 26 27 28 29 30 35 40 90 100 42. 4 40. 8 39. 4 38. 0 36. 8 35. 3 34. 0 32. 8 31. 6 30. 4 29. 3 28. 2 27. 2 22. 5 18. 8 2. 1. 0 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PERMA PURE 2040 -008

Sulfur Dioxide Solubility in Water Temperature Degree C SO 2 Solubility in HO 2 ml SO 2 / 100 ml H O 2 79. 8 77. 2 74. 7 72. 2 69. 8 67. 5 65. 2 63. 0 60. 8 58. 7 56. 6 54. 7 52. 7 50. 8 49. 0 47. 3 45. 6 43. 9 18 19 20 21 22 23 24 25 26 27 28 29 30 35 40 90 100 42. 4 40. 8 39. 4 38. 0 36. 8 35. 3 34. 0 32. 8 31. 6 30. 4 29. 3 28. 2 27. 2 22. 5 18. 8 2. 1. 0 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PERMA PURE 2040 -008

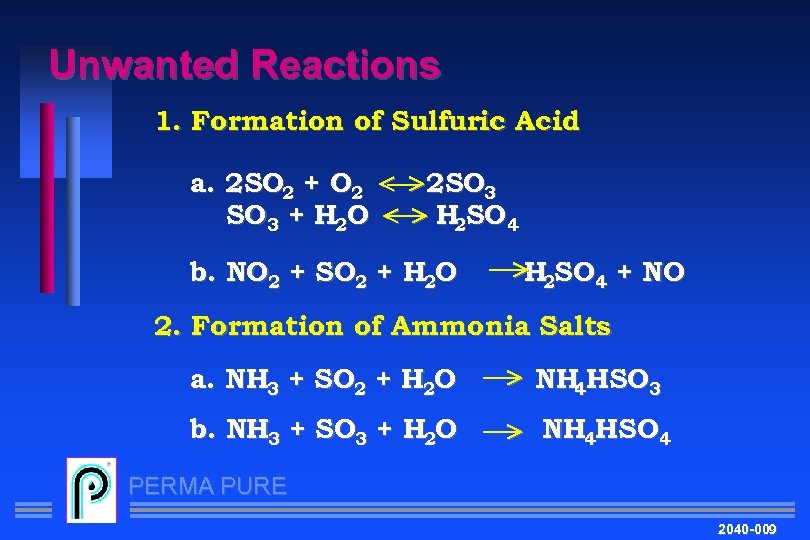

Unwanted Reactions 1. Formation of Sulfuric Acid a. 2 SO 2 + O 2 2 SO 3 + H 2 O H 2 SO 4 b. NO 2 + SO 2 + H 2 O H 2 SO 4 + NO 2. Formation of Ammonia Salts a. NH 3 + SO 2 + H 2 O NH 4 HSO 3 b. NH 3 + SO 3 + H 2 O NH 4 HSO 4 PERMA PURE 2040 -009

Unwanted Reactions 1. Formation of Sulfuric Acid a. 2 SO 2 + O 2 2 SO 3 + H 2 O H 2 SO 4 b. NO 2 + SO 2 + H 2 O H 2 SO 4 + NO 2. Formation of Ammonia Salts a. NH 3 + SO 2 + H 2 O NH 4 HSO 3 b. NH 3 + SO 3 + H 2 O NH 4 HSO 4 PERMA PURE 2040 -009

Acid Mist Problems • Mists are very corrosive, viscous, clogging • Difficult to remove; slow to coalesce into sizeable droplets when cooled • Special coalescing filters helpful PERMA PURE 2040 -010

Acid Mist Problems • Mists are very corrosive, viscous, clogging • Difficult to remove; slow to coalesce into sizeable droplets when cooled • Special coalescing filters helpful PERMA PURE 2040 -010

Ammonia Salts Problems Present special problems • Ammonia is gas, passes through probe filter • Forms clogs if allowed to cool, react with SO 2 or SO 3 and H 2 O to form ammonium salts • Requires special absorbents to remove ammonia before cooling to prevent clogs PERMA PURE 2040 -011

Ammonia Salts Problems Present special problems • Ammonia is gas, passes through probe filter • Forms clogs if allowed to cool, react with SO 2 or SO 3 and H 2 O to form ammonium salts • Requires special absorbents to remove ammonia before cooling to prevent clogs PERMA PURE 2040 -011

Excessive Particulates Easiest to solve • Probe filter with heated blowback • Secondary filter with finer porosity • Inertial bypass filters if necessary PERMA PURE 2040 -012

Excessive Particulates Easiest to solve • Probe filter with heated blowback • Secondary filter with finer porosity • Inertial bypass filters if necessary PERMA PURE 2040 -012

The Solution GASS™-2040 Gas Analysis Sampling Systems • Retain water-soluble analytes (HCl, SO 2, NOX) • Achieve low final sample dew points (down to o. C) -25 • Accept high sample flow rates (up to 25 L/minute) • Accommodate nearly any sample (customized) • Eliminate heated sample lines (stack mounting) PERMA PURE 2040 -013

The Solution GASS™-2040 Gas Analysis Sampling Systems • Retain water-soluble analytes (HCl, SO 2, NOX) • Achieve low final sample dew points (down to o. C) -25 • Accept high sample flow rates (up to 25 L/minute) • Accommodate nearly any sample (customized) • Eliminate heated sample lines (stack mounting) PERMA PURE 2040 -013

™ GASS -2040 Gas Analysis Sampling System PERMA PURE 2040 -014

™ GASS -2040 Gas Analysis Sampling System PERMA PURE 2040 -014

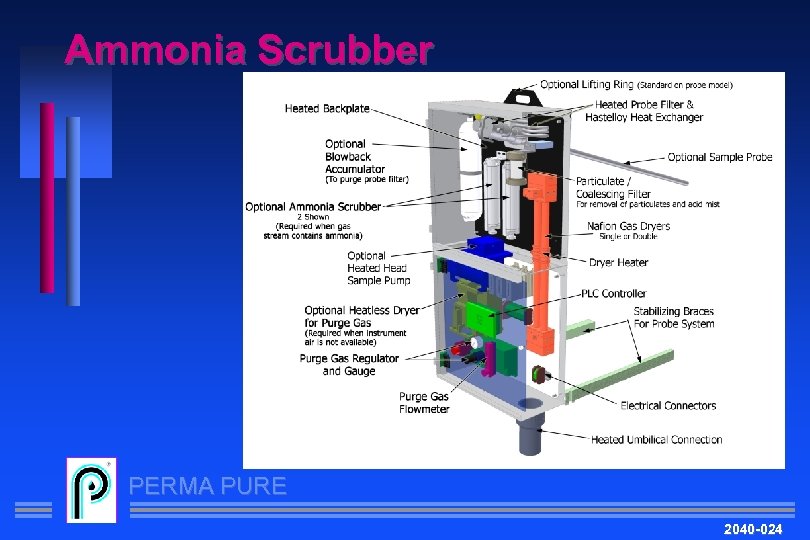

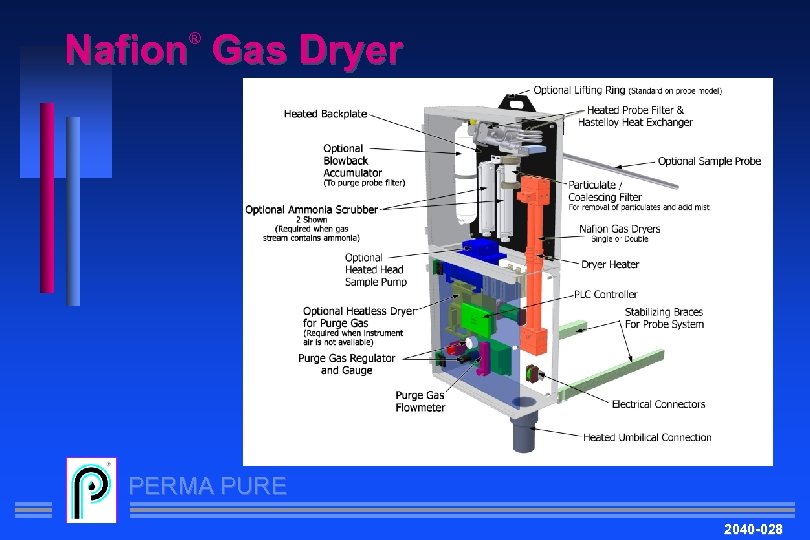

GASS -2040 Overview ™ • Stainless steel NEMA-4 X enclosure • Integral probe with heated filter and blowback • Hastelloyheat exchanger • Coalescing/particulate filter with automatic drain • Ammoniascrubber(s) • Wide range of dryers, double dryers • PLC with Ethernet for remote control • Safety interlocks and alarms • Sample pump, other options to customize system PERMA PURE 2040 -015

GASS -2040 Overview ™ • Stainless steel NEMA-4 X enclosure • Integral probe with heated filter and blowback • Hastelloyheat exchanger • Coalescing/particulate filter with automatic drain • Ammoniascrubber(s) • Wide range of dryers, double dryers • PLC with Ethernet for remote control • Safety interlocks and alarms • Sample pump, other options to customize system PERMA PURE 2040 -015

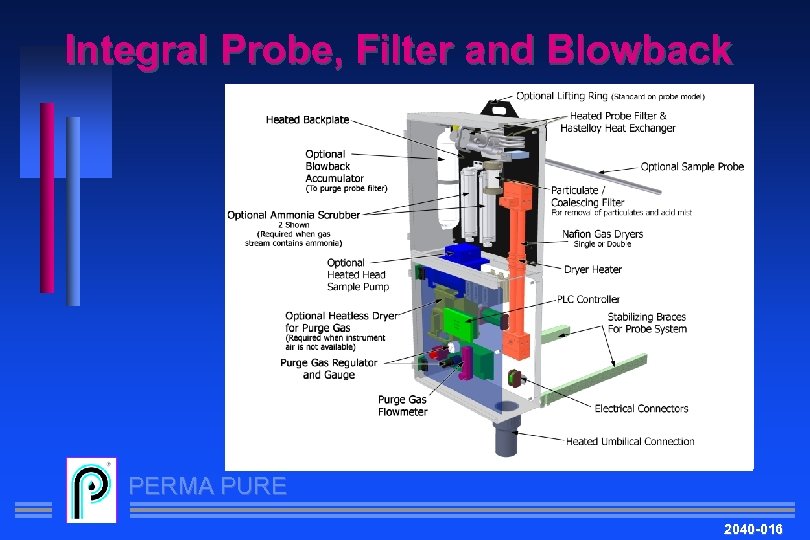

Integral Probe, Filter and Blowback PERMA PURE 2040 -016

Integral Probe, Filter and Blowback PERMA PURE 2040 -016

Integral Probe, Filter and Blowback • Range of probe lengths and materials Directly connected, no heated line • Probe filter stainless steel or glass-coated Temperature controlled by PLC Avoids losses of analytes in filter • Blowback heated, closely coupled Blowback timing controlled by PLC Avoids condensation during blowback PERMA PURE 2040 -017

Integral Probe, Filter and Blowback • Range of probe lengths and materials Directly connected, no heated line • Probe filter stainless steel or glass-coated Temperature controlled by PLC Avoids losses of analytes in filter • Blowback heated, closely coupled Blowback timing controlled by PLC Avoids condensation during blowback PERMA PURE 2040 -017

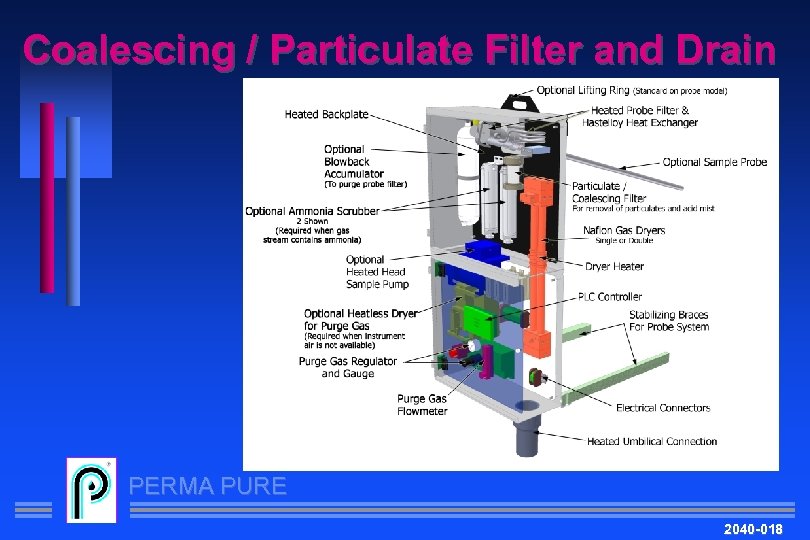

Coalescing / Particulate Filter and Drain PERMA PURE 2040 -018

Coalescing / Particulate Filter and Drain PERMA PURE 2040 -018

Coalescing / Particulate Filter PERMA PURE 2040 -019

Coalescing / Particulate Filter PERMA PURE 2040 -019

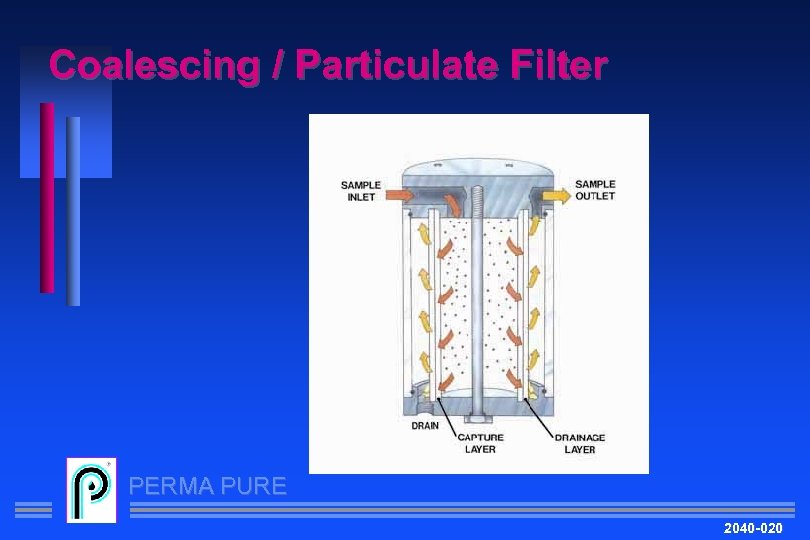

Coalescing / Particulate Filter PERMA PURE 2040 -020

Coalescing / Particulate Filter PERMA PURE 2040 -020

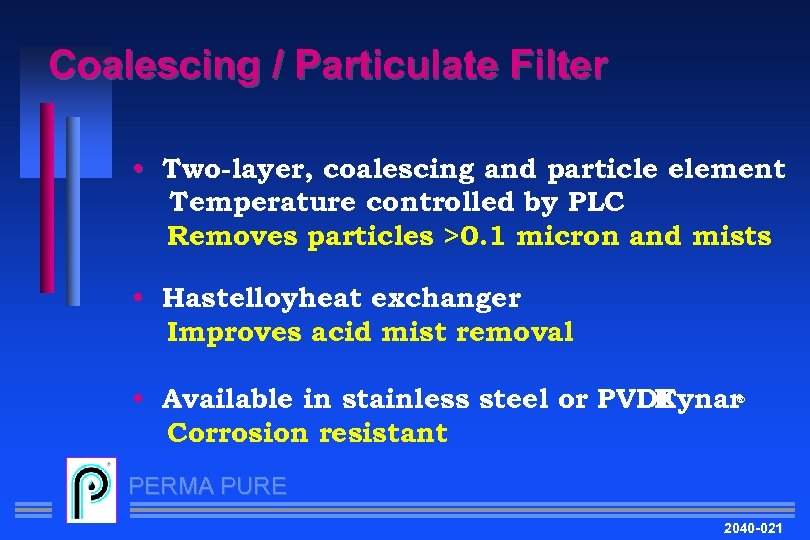

Coalescing / Particulate Filter • Two-layer, coalescing and particle element Temperature controlled by PLC Removes particles >0. 1 micron and mists • Hastelloyheat exchanger Improves acid mist removal • Available in stainless steel or PVDF Kynar Corrosion resistant ® PERMA PURE 2040 -021

Coalescing / Particulate Filter • Two-layer, coalescing and particle element Temperature controlled by PLC Removes particles >0. 1 micron and mists • Hastelloyheat exchanger Improves acid mist removal • Available in stainless steel or PVDF Kynar Corrosion resistant ® PERMA PURE 2040 -021

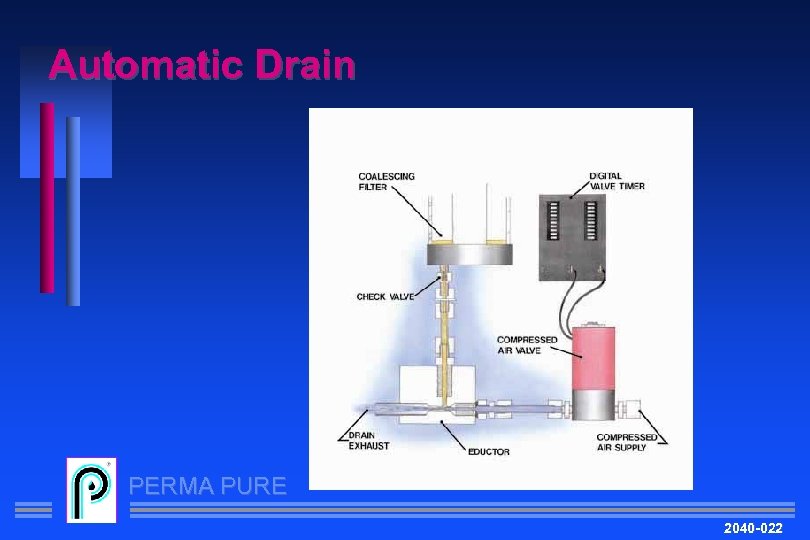

Automatic Drain PERMA PURE 2040 -022

Automatic Drain PERMA PURE 2040 -022

Automatic Drain • Coalesced liquid removed by eductor Drain timing controlled by PLC Reliable, no peristaltic pump ® • Eductor entirely PTFE Teflon Full corrosion resistance • Teflon check valve Positive seal when not operating PERMA PURE 2040 -023

Automatic Drain • Coalesced liquid removed by eductor Drain timing controlled by PLC Reliable, no peristaltic pump ® • Eductor entirely PTFE Teflon Full corrosion resistance • Teflon check valve Positive seal when not operating PERMA PURE 2040 -023

Ammonia Scrubber PERMA PURE 2040 -024

Ammonia Scrubber PERMA PURE 2040 -024

Ammonia Scrubber PERMA PURE 2040 -025

Ammonia Scrubber PERMA PURE 2040 -025

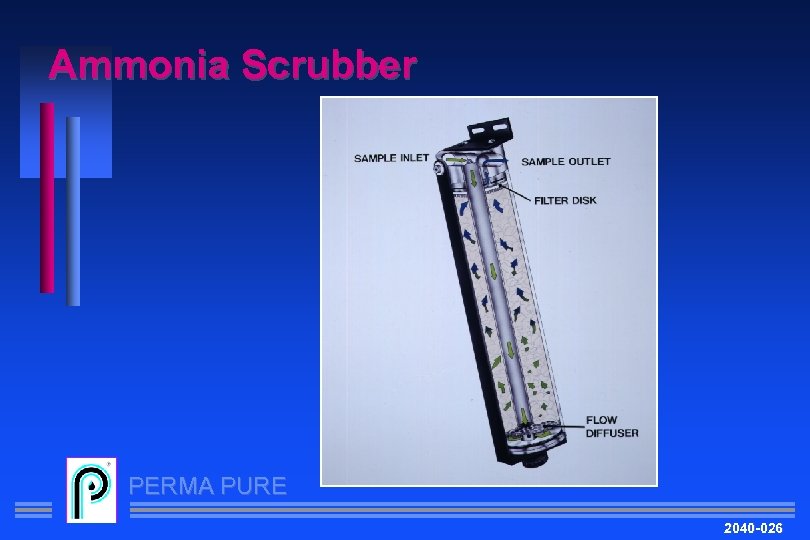

Ammonia Scrubber PERMA PURE 2040 -026

Ammonia Scrubber PERMA PURE 2040 -026

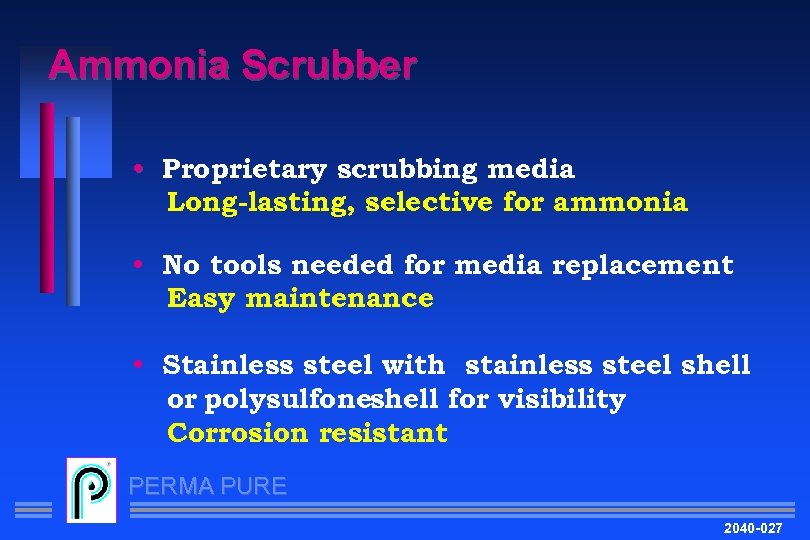

Ammonia Scrubber • Proprietary scrubbing media Long-lasting, selective for ammonia • No tools needed for media replacement Easy maintenance • Stainless steel with stainless steel shell or polysulfoneshell for visibility Corrosion resistant PERMA PURE 2040 -027

Ammonia Scrubber • Proprietary scrubbing media Long-lasting, selective for ammonia • No tools needed for media replacement Easy maintenance • Stainless steel with stainless steel shell or polysulfoneshell for visibility Corrosion resistant PERMA PURE 2040 -027

Nafion Gas Dryer ® PERMA PURE 2040 -028

Nafion Gas Dryer ® PERMA PURE 2040 -028

![NAFION Chemical Structure ® [ (CF 2 )m CF CF ] n 2 O NAFION Chemical Structure ® [ (CF 2 )m CF CF ] n 2 O](https://present5.com/presentation/5b7775f6e7f860b298125270cc7a6912/image-29.jpg) NAFION Chemical Structure ® [ (CF 2 )m CF CF ] n 2 O CF 2 CF WHEN: m = 5 to 13. 5 n = ca 1, 000 z = 1, 2, 3. . . x = 1 to 13 CF 3 Z O CF 2 SO 3 H ● [H 2 O]X PERMA PURE 2040 -029

NAFION Chemical Structure ® [ (CF 2 )m CF CF ] n 2 O CF 2 CF WHEN: m = 5 to 13. 5 n = ca 1, 000 z = 1, 2, 3. . . x = 1 to 13 CF 3 Z O CF 2 SO 3 H ● [H 2 O]X PERMA PURE 2040 -029

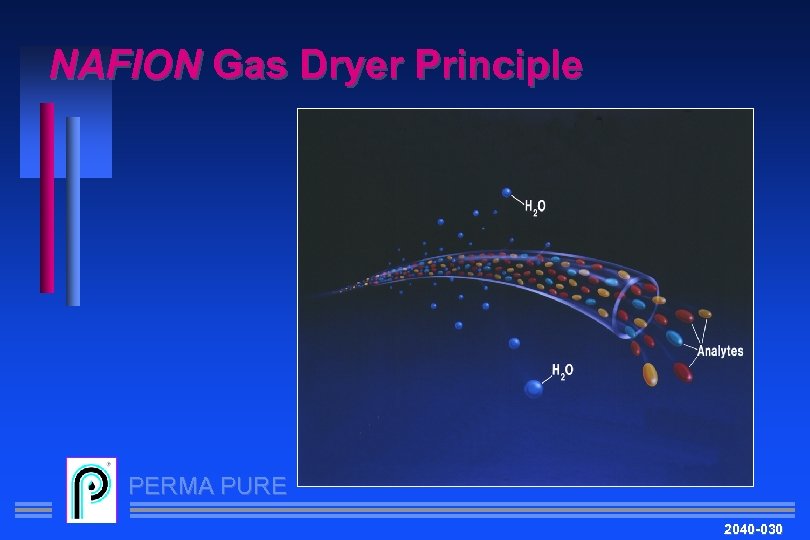

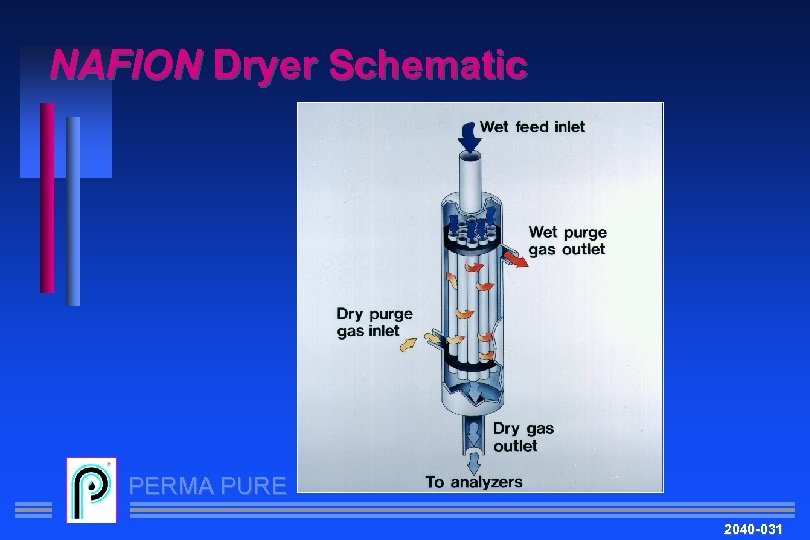

NAFION Gas Dryer Principle PERMA PURE 2040 -030

NAFION Gas Dryer Principle PERMA PURE 2040 -030

NAFION Dryer Schematic PERMA PURE 2040 -031

NAFION Dryer Schematic PERMA PURE 2040 -031

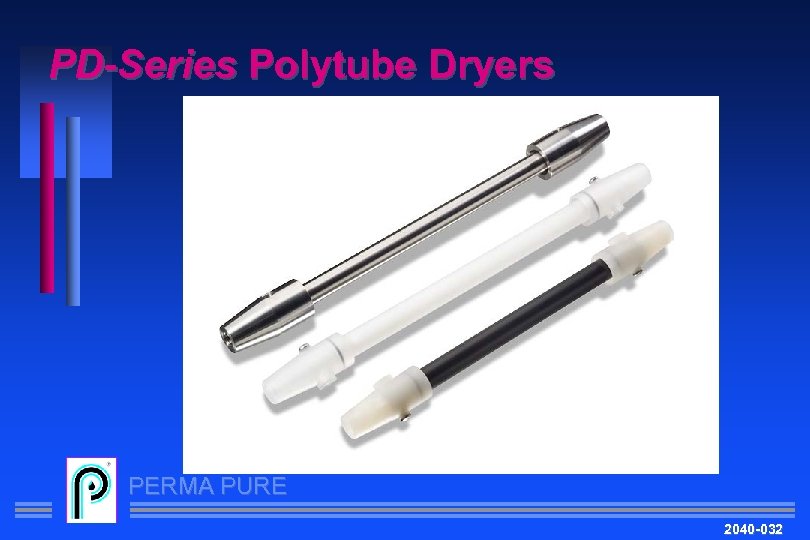

PD-Series Polytube Dryers PERMA PURE 2040 -032

PD-Series Polytube Dryers PERMA PURE 2040 -032

NAFION Selectivity • Nafion permeation selectivity is based on chemical reactivity, not size • Only compounds that chemically associate with sulfonic acid permeate through Nafion • Bases associate with sulfonic acid and permeate through Nafion • Very few bases are gases at typical operating temperatures, so very few compounds permeate PERMA PURE 2040 -033

NAFION Selectivity • Nafion permeation selectivity is based on chemical reactivity, not size • Only compounds that chemically associate with sulfonic acid permeate through Nafion • Bases associate with sulfonic acid and permeate through Nafion • Very few bases are gases at typical operating temperatures, so very few compounds permeate PERMA PURE 2040 -033

Effect on Analytes • Removes water directly as water vapor. No condensate forms to dissolve analytes. • Removes compounds with hydroxyl groups (-OH) H 2 O, some organics • Retains important compounds O 2, O 3, CO 2, NOX, SO 2, SO 3, H 2 S, Hg, HCl PERMA PURE 2040 -034

Effect on Analytes • Removes water directly as water vapor. No condensate forms to dissolve analytes. • Removes compounds with hydroxyl groups (-OH) H 2 O, some organics • Retains important compounds O 2, O 3, CO 2, NOX, SO 2, SO 3, H 2 S, Hg, HCl PERMA PURE 2040 -034

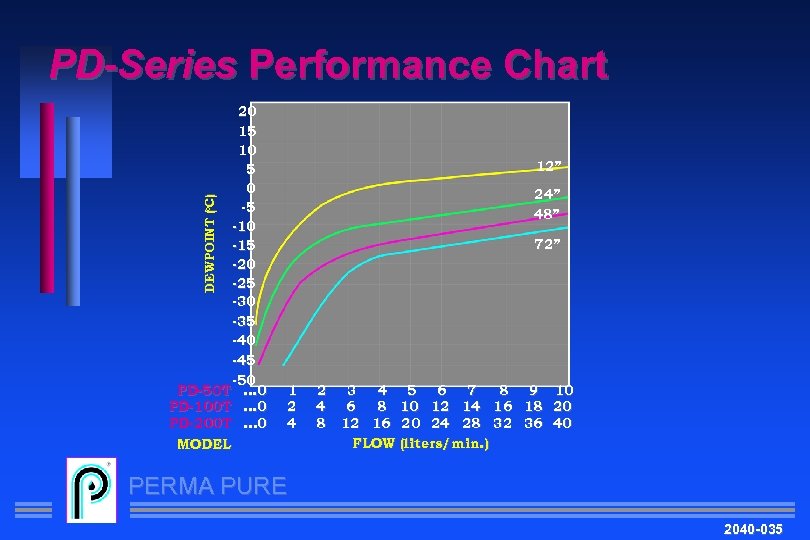

PD-Series Performance Chart 12” 24” 48” DEWPOINT (o. C) 20 15 10 5 0 -5 -10 -15 -20 -25 -30 -35 -40 -45 -50 PD-50 T. . . 0 PD-100 T. . . 0 PD-200 T. . . 0 MODEL 72” 1 2 4 8 3 4 5 6 7 8 9 10 6 8 10 12 14 16 18 20 12 16 20 24 28 32 36 40 FLOW (liters/min. ) PERMA PURE 2040 -035

PD-Series Performance Chart 12” 24” 48” DEWPOINT (o. C) 20 15 10 5 0 -5 -10 -15 -20 -25 -30 -35 -40 -45 -50 PD-50 T. . . 0 PD-100 T. . . 0 PD-200 T. . . 0 MODEL 72” 1 2 4 8 3 4 5 6 7 8 9 10 6 8 10 12 14 16 18 20 12 16 20 24 28 32 36 40 FLOW (liters/min. ) PERMA PURE 2040 -035

Low Final Dew Points o • Dew point as low as -45 C can be achieved. o o • Dew point of -10 C to -25 C is typical. • Performance is a function of dryer size and sample flow rate. • Analytical results and reliability improved by reducing water interferences. • Acid mist problems overcome. PERMA PURE 2040 -036

Low Final Dew Points o • Dew point as low as -45 C can be achieved. o o • Dew point of -10 C to -25 C is typical. • Performance is a function of dryer size and sample flow rate. • Analytical results and reliability improved by reducing water interferences. • Acid mist problems overcome. PERMA PURE 2040 -036

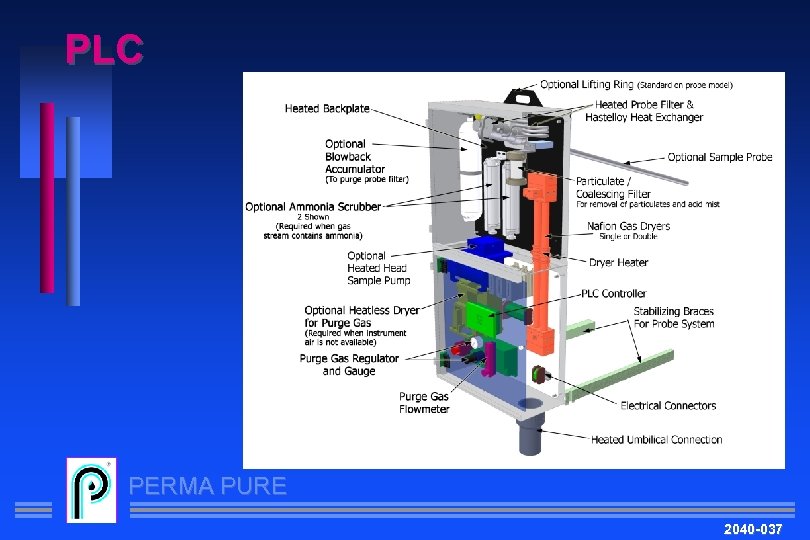

PLC PERMA PURE 2040 -037

PLC PERMA PURE 2040 -037

PLC • Digital selection of operating conditions Precise control of operating parameters • Standard unit, easy programming Easy maintenance and updating • Optional Ethernet connection Remote control and data display PERMA PURE 2040 -038

PLC • Digital selection of operating conditions Precise control of operating parameters • Standard unit, easy programming Easy maintenance and updating • Optional Ethernet connection Remote control and data display PERMA PURE 2040 -038

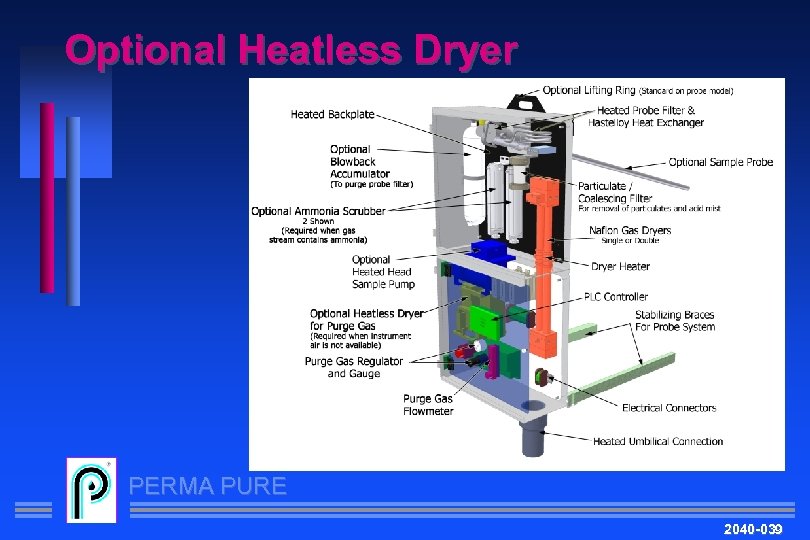

Optional Heatless Dryer PERMA PURE 2040 -039

Optional Heatless Dryer PERMA PURE 2040 -039

Optional Heatless Dryer PERMA PURE 2040 -040

Optional Heatless Dryer PERMA PURE 2040 -040

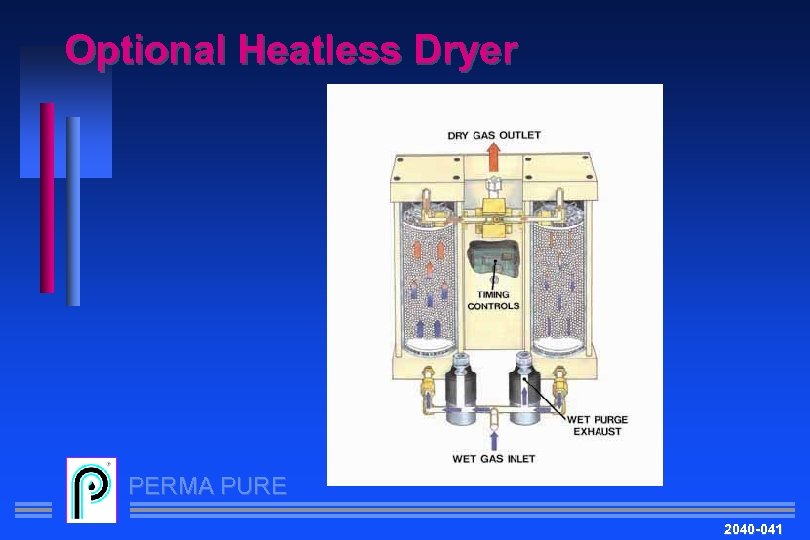

Optional Heatless Dryer PERMA PURE 2040 -041

Optional Heatless Dryer PERMA PURE 2040 -041

Optional Heatless Dryer • Steady supply of dry air for system use Continuous 60 L/min. to -45ºC dewpoint • No line pressure surges Inactive canister repressurizedbefore reuse • Very reliable with no maintenance Electronic switching, permanent springloaded molecular sieve PERMA PURE 2040 -042

Optional Heatless Dryer • Steady supply of dry air for system use Continuous 60 L/min. to -45ºC dewpoint • No line pressure surges Inactive canister repressurizedbefore reuse • Very reliable with no maintenance Electronic switching, permanent springloaded molecular sieve PERMA PURE 2040 -042

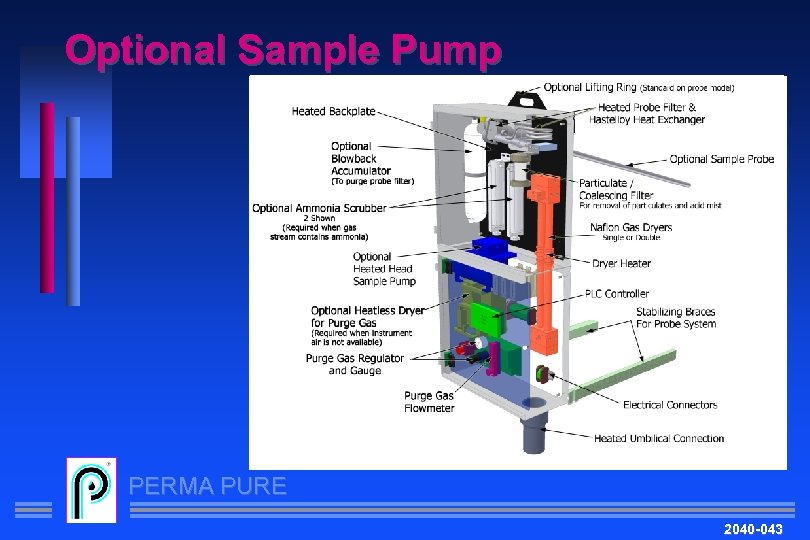

Optional Sample Pump PERMA PURE 2040 -043

Optional Sample Pump PERMA PURE 2040 -043

Optional Sample Pump • Pump head mounted in heated zone Prevents sample condensation • Pump motor mounted in unheated zone Improves pump reliability • Pump head stainless steel or Teflon Corrosion-resistant, long life • Sample transported under pressure Avoids contamination from minor leaks PERMA PURE 2040 -044

Optional Sample Pump • Pump head mounted in heated zone Prevents sample condensation • Pump motor mounted in unheated zone Improves pump reliability • Pump head stainless steel or Teflon Corrosion-resistant, long life • Sample transported under pressure Avoids contamination from minor leaks PERMA PURE 2040 -044

GASS-2040 Options • Integral Probe • Dryer Sizes • Probe Filter • Purge Heatless Dryer • Blowback • Ethernet Connection • Bypass Filter • X- or Z-Purge • Coalescing Filter • Kynar® Fittings • Automatic Drain • Sample Pump • Ammonia Scrubbers • Purge Eductor PERMA PURE 2040 -045

GASS-2040 Options • Integral Probe • Dryer Sizes • Probe Filter • Purge Heatless Dryer • Blowback • Ethernet Connection • Bypass Filter • X- or Z-Purge • Coalescing Filter • Kynar® Fittings • Automatic Drain • Sample Pump • Ammonia Scrubbers • Purge Eductor PERMA PURE 2040 -045

Summation ™ • GASS -2040 combines all necessary sampling and conditioning in one package • Proven technology, years of experience • Opportunity to eliminate heated lines • Many options; buy only what is needed • Smaller systems available for less demanding applications PERMA PURE 2040 -046

Summation ™ • GASS -2040 combines all necessary sampling and conditioning in one package • Proven technology, years of experience • Opportunity to eliminate heated lines • Many options; buy only what is needed • Smaller systems available for less demanding applications PERMA PURE 2040 -046