4178a43a0dc99b6cf75ac646d8e8aeda.ppt

- Количество слайдов: 32

Gas-insulated lines (GIL) - next generation of power transmission technologies Electrical Networks of Russia ENR 2010 Moscow 2 December 2010 AG 2010 Siemens GIL: Update in High Power Transmission Technology Energy Sector Dr. Petr Rudenko © 1

Gas-insulated lines (GIL) - next generation of power transmission technologies Electrical Networks of Russia ENR 2010 Moscow 2 December 2010 AG 2010 Siemens GIL: Update in High Power Transmission Technology Energy Sector Dr. Petr Rudenko © 1

Content Challenges in Mega Cities Data, Site Works & Laying Methods of GIL Technical Advantages of GIL EMV Radiation Transmission Losses Auto Reclosure Functionality Innovative Arc Location References Summary © Siemens 2 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

Content Challenges in Mega Cities Data, Site Works & Laying Methods of GIL Technical Advantages of GIL EMV Radiation Transmission Losses Auto Reclosure Functionality Innovative Arc Location References Summary © Siemens 2 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

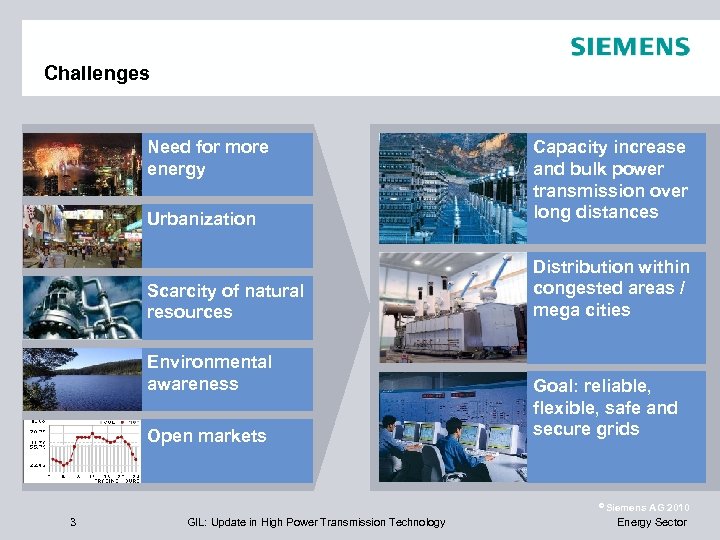

Challenges Need for more energy Urbanization Capacity increase and bulk power transmission over long distances Scarcity of natural resources Distribution within congested areas / mega cities Environmental awareness Open markets Goal: reliable, flexible, safe and secure grids © Siemens 3 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

Challenges Need for more energy Urbanization Capacity increase and bulk power transmission over long distances Scarcity of natural resources Distribution within congested areas / mega cities Environmental awareness Open markets Goal: reliable, flexible, safe and secure grids © Siemens 3 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

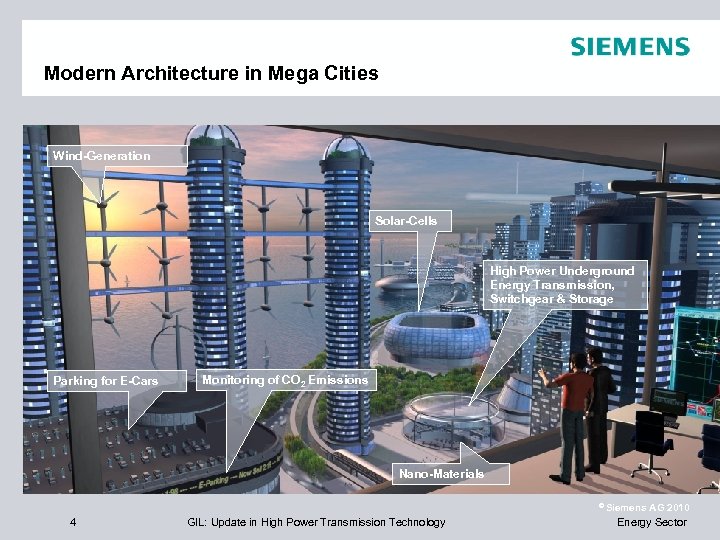

Modern Architecture in Mega Cities Wind-Generation Solar-Cells High Power Underground Energy Transmission, Switchgear & Storage Parking for E-Cars Monitoring of CO 2 Emissions Nano-Materials © Siemens 4 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

Modern Architecture in Mega Cities Wind-Generation Solar-Cells High Power Underground Energy Transmission, Switchgear & Storage Parking for E-Cars Monitoring of CO 2 Emissions Nano-Materials © Siemens 4 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

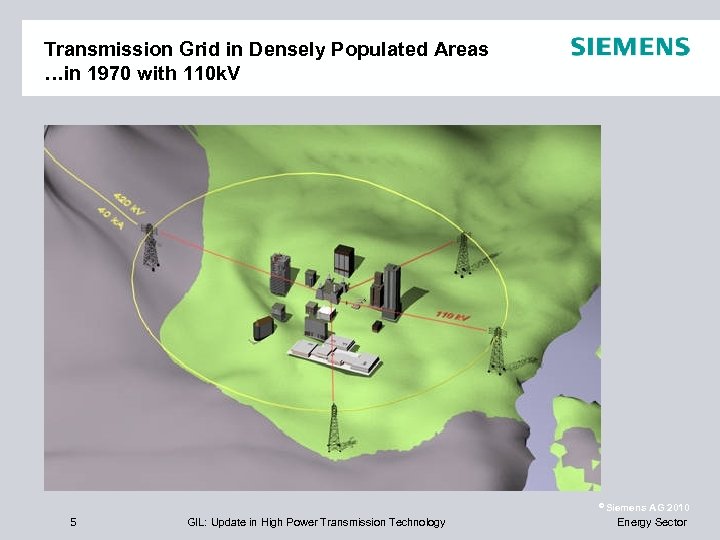

Transmission Grid in Densely Populated Areas …in 1970 with 110 k. V © Siemens 5 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

Transmission Grid in Densely Populated Areas …in 1970 with 110 k. V © Siemens 5 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

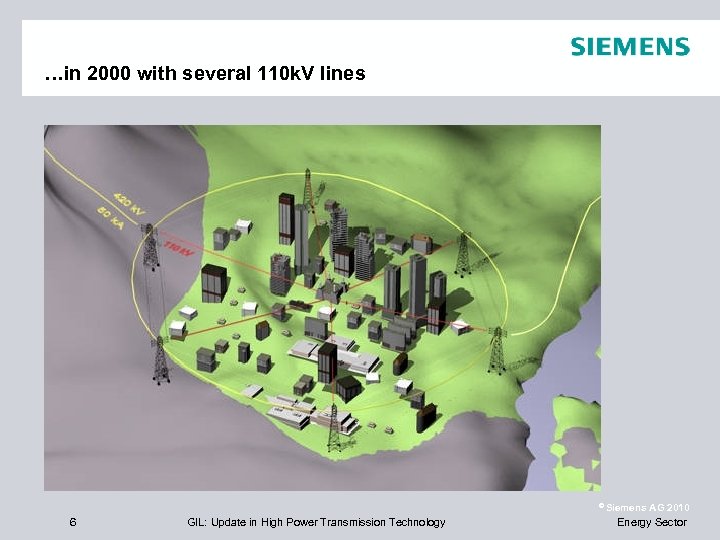

…in 2000 with several 110 k. V lines © Siemens 6 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

…in 2000 with several 110 k. V lines © Siemens 6 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

…in Future with 400(500)k. V © Siemens 7 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

…in Future with 400(500)k. V © Siemens 7 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

Our High Voltage System Solutions for Megacities Gas-Insulated Switchgear (GIS) Gas-Insulated Lines (GIL) © Siemens 8 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

Our High Voltage System Solutions for Megacities Gas-Insulated Switchgear (GIS) Gas-Insulated Lines (GIL) © Siemens 8 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

Content Challenges in Mega Cities Data, Site Works & Laying Methods of GIL Technical Advantages of GIL EMV Radiation Transmission Losses Auto Reclosure Functionality Innovative Arc Location References Summary © Siemens 9 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

Content Challenges in Mega Cities Data, Site Works & Laying Methods of GIL Technical Advantages of GIL EMV Radiation Transmission Losses Auto Reclosure Functionality Innovative Arc Location References Summary © Siemens 9 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

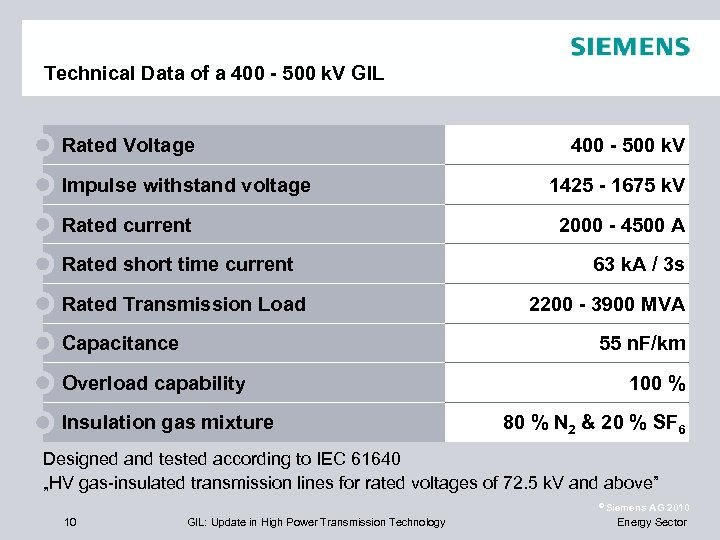

Technical Data of a 400 - 500 k. V GIL Rated Voltage Impulse withstand voltage Rated current Rated short time current Rated Transmission Load Capacitance 400 - 500 k. V 1425 - 1675 k. V 2000 - 4500 A 63 k. A / 3 s 2200 - 3900 MVA 55 n. F/km Overload capability Insulation gas mixture 100 % 80 % N 2 & 20 % SF 6 Designed and tested according to IEC 61640 „HV gas-insulated transmission lines for rated voltages of 72. 5 k. V and above” © Siemens 10 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

Technical Data of a 400 - 500 k. V GIL Rated Voltage Impulse withstand voltage Rated current Rated short time current Rated Transmission Load Capacitance 400 - 500 k. V 1425 - 1675 k. V 2000 - 4500 A 63 k. A / 3 s 2200 - 3900 MVA 55 n. F/km Overload capability Insulation gas mixture 100 % 80 % N 2 & 20 % SF 6 Designed and tested according to IEC 61640 „HV gas-insulated transmission lines for rated voltages of 72. 5 k. V and above” © Siemens 10 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

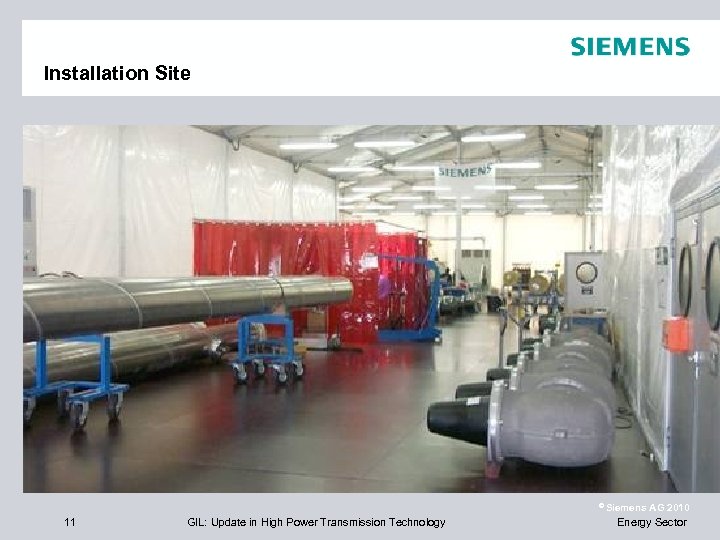

Installation Site © Siemens 11 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

Installation Site © Siemens 11 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

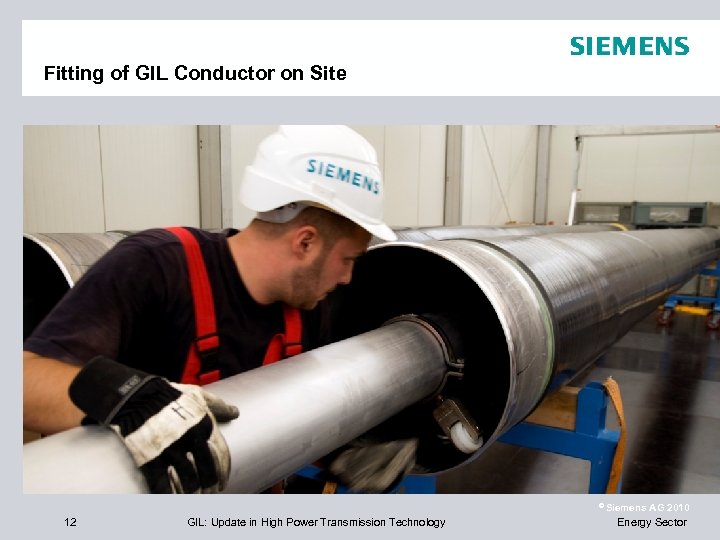

Fitting of GIL Conductor on Site © Siemens 12 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

Fitting of GIL Conductor on Site © Siemens 12 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

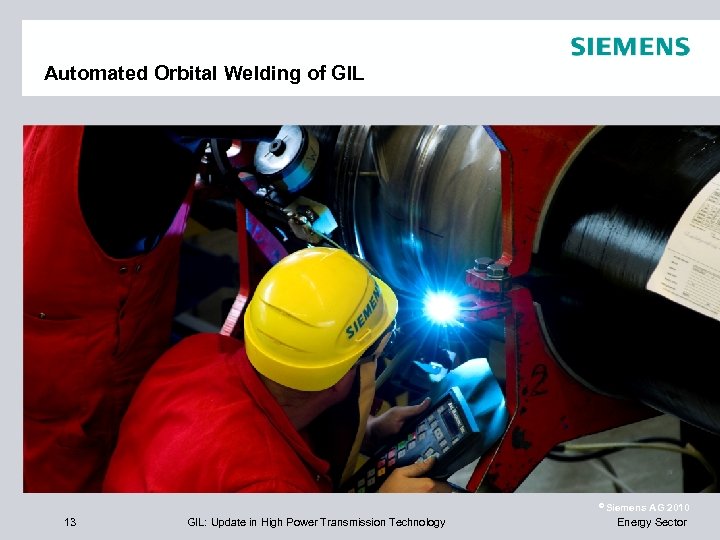

Automated Orbital Welding of GIL © Siemens 13 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

Automated Orbital Welding of GIL © Siemens 13 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

GIL above Ground © Siemens GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

GIL above Ground © Siemens GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

GIL High Power Transmission in the Underground © Siemens 15 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

GIL High Power Transmission in the Underground © Siemens 15 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

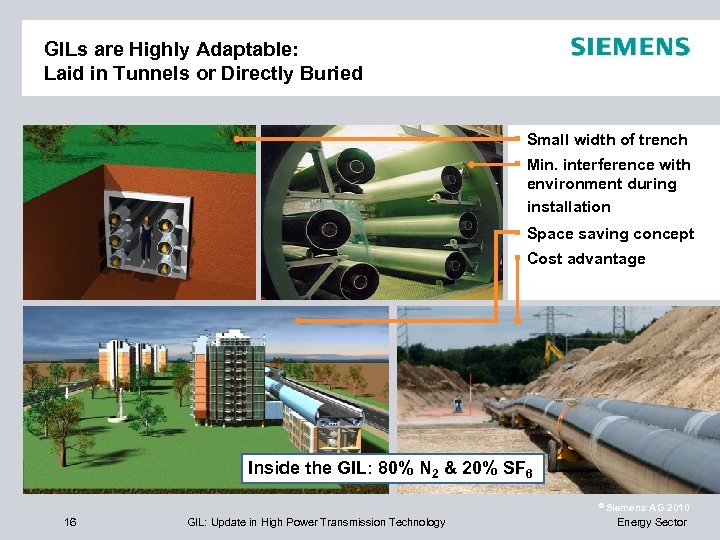

GILs are Highly Adaptable: Laid in Tunnels or Directly Buried Small width of trench Min. interference with environment during installation Space saving concept Cost advantage Inside the GIL: 80% N 2 & 20% SF 6 © Siemens 16 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

GILs are Highly Adaptable: Laid in Tunnels or Directly Buried Small width of trench Min. interference with environment during installation Space saving concept Cost advantage Inside the GIL: 80% N 2 & 20% SF 6 © Siemens 16 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

Content Challenges in Mega Cities Data, Site Works & Laying Methods of GIL Technical Advantages of GIL EMV Radiation Transmission Losses Auto Reclosure Functionality Innovative Arc Location References Summary © Siemens 17 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

Content Challenges in Mega Cities Data, Site Works & Laying Methods of GIL Technical Advantages of GIL EMV Radiation Transmission Losses Auto Reclosure Functionality Innovative Arc Location References Summary © Siemens 17 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

GIL Comprise Low Electromagnetic Field: Calculated Enclosure Currents of GIL © Siemens 18 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

GIL Comprise Low Electromagnetic Field: Calculated Enclosure Currents of GIL © Siemens 18 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

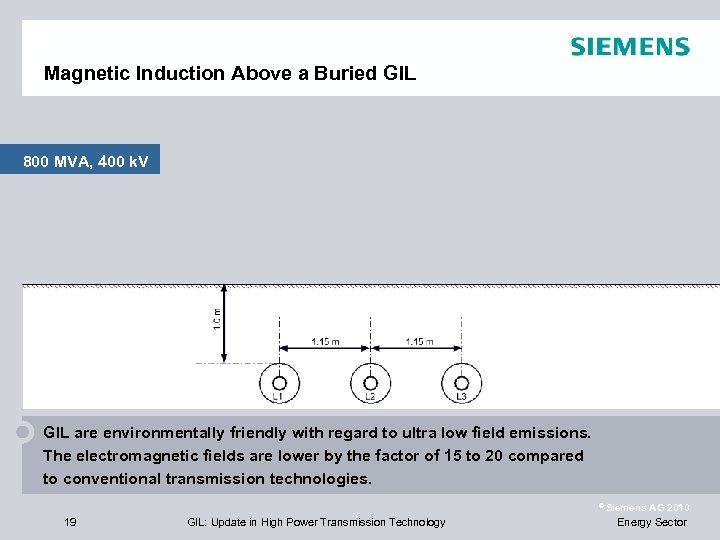

Magnetic Induction Above a Buried GIL 800 MVA, 400 k. V GIL are environmentally friendly with regard to ultra low field emissions. The electromagnetic fields are lower by the factor of 15 to 20 compared to conventional transmission technologies. © Siemens 19 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

Magnetic Induction Above a Buried GIL 800 MVA, 400 k. V GIL are environmentally friendly with regard to ultra low field emissions. The electromagnetic fields are lower by the factor of 15 to 20 compared to conventional transmission technologies. © Siemens 19 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

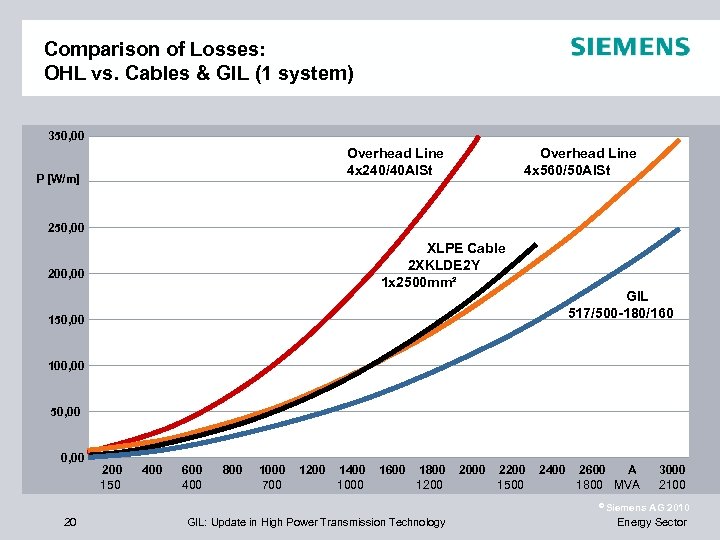

Comparison of Losses: OHL vs. Cables & GIL (1 system) 350, 00 Overhead Line 4 x 240/40 Al. St P [W/m] Overhead Line 4 x 560/50 Al. St 250, 00 XLPE Cable 2 XKLDE 2 Y 1 x 2500 mm² 200, 00 GIL 517/500 -180/160 150, 00 100, 00 50, 00 200 150 400 600 400 800 1000 700 1200 1400 1000 1600 1800 1200 2000 2200 1500 2400 2600 A 1800 MVA © Siemens 20 GIL: Update in High Power Transmission Technology 3000 2100 AG 2010 Energy Sector

Comparison of Losses: OHL vs. Cables & GIL (1 system) 350, 00 Overhead Line 4 x 240/40 Al. St P [W/m] Overhead Line 4 x 560/50 Al. St 250, 00 XLPE Cable 2 XKLDE 2 Y 1 x 2500 mm² 200, 00 GIL 517/500 -180/160 150, 00 100, 00 50, 00 200 150 400 600 400 800 1000 700 1200 1400 1000 1600 1800 1200 2000 2200 1500 2400 2600 A 1800 MVA © Siemens 20 GIL: Update in High Power Transmission Technology 3000 2100 AG 2010 Energy Sector

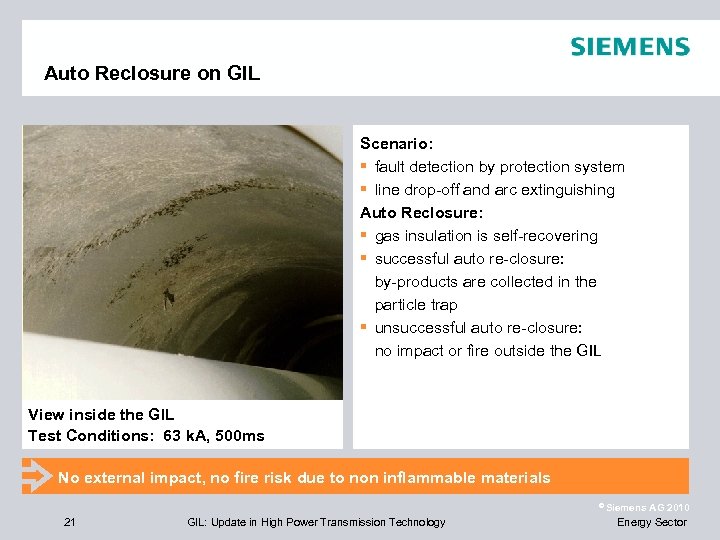

Auto Reclosure on GIL Scenario: fault detection by protection system line drop-off and arc extinguishing Auto Reclosure: gas insulation is self-recovering successful auto re-closure: by-products are collected in the particle trap unsuccessful auto re-closure: no impact or fire outside the GIL View inside the GIL Test Conditions: 63 k. A, 500 ms No external impact, no fire risk due to non inflammable materials © Siemens 21 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

Auto Reclosure on GIL Scenario: fault detection by protection system line drop-off and arc extinguishing Auto Reclosure: gas insulation is self-recovering successful auto re-closure: by-products are collected in the particle trap unsuccessful auto re-closure: no impact or fire outside the GIL View inside the GIL Test Conditions: 63 k. A, 500 ms No external impact, no fire risk due to non inflammable materials © Siemens 21 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

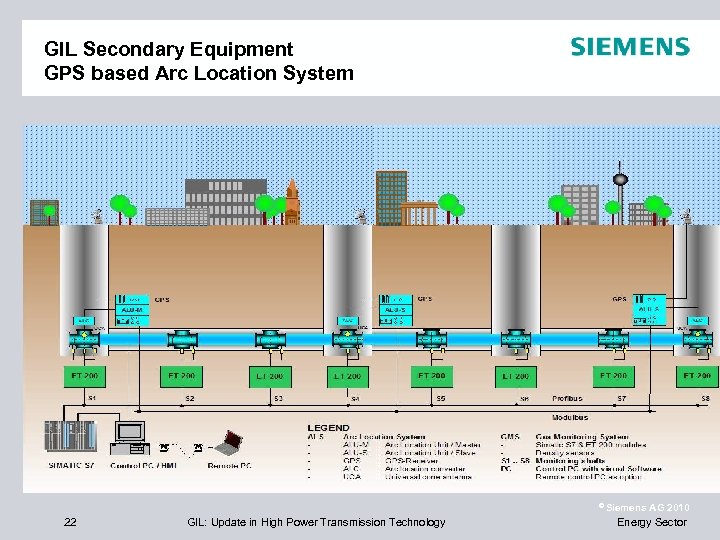

GIL Secondary Equipment GPS based Arc Location System © Siemens 22 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

GIL Secondary Equipment GPS based Arc Location System © Siemens 22 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

Content Challenges in Mega Cities Data, Site Works & Laying Methods of GIL Technical Advantages of GIL EMV Radiation Transmission Losses Auto Reclosure Functionality Innovative Arc Location References Summary © Siemens 23 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

Content Challenges in Mega Cities Data, Site Works & Laying Methods of GIL Technical Advantages of GIL EMV Radiation Transmission Losses Auto Reclosure Functionality Innovative Arc Location References Summary © Siemens 23 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

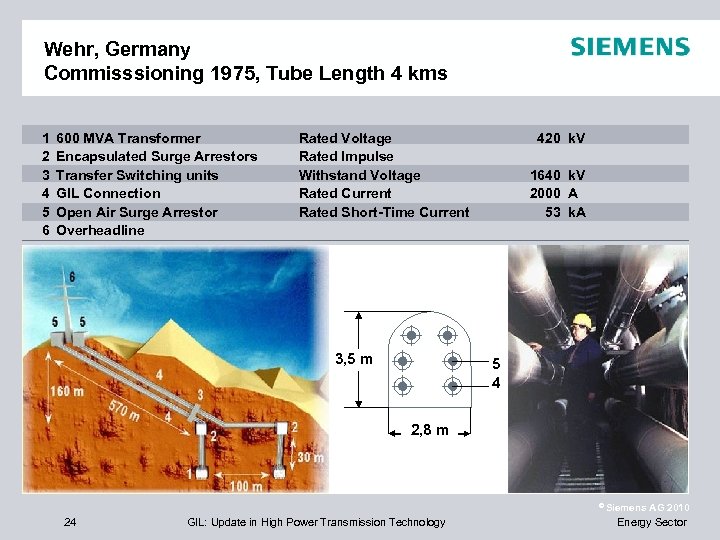

Wehr, Germany Commisssioning 1975, Tube Length 4 kms 1 2 3 4 5 6 600 MVA Transformer Encapsulated Surge Arrestors Transfer Switching units GIL Connection Open Air Surge Arrestor Overheadline Rated Voltage Rated Impulse Withstand Voltage Rated Current Rated Short-Time Current 3, 5 m 420 k. V 1640 k. V 2000 A 53 k. A 5 4 2, 8 m © Siemens 24 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

Wehr, Germany Commisssioning 1975, Tube Length 4 kms 1 2 3 4 5 6 600 MVA Transformer Encapsulated Surge Arrestors Transfer Switching units GIL Connection Open Air Surge Arrestor Overheadline Rated Voltage Rated Impulse Withstand Voltage Rated Current Rated Short-Time Current 3, 5 m 420 k. V 1640 k. V 2000 A 53 k. A 5 4 2, 8 m © Siemens 24 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

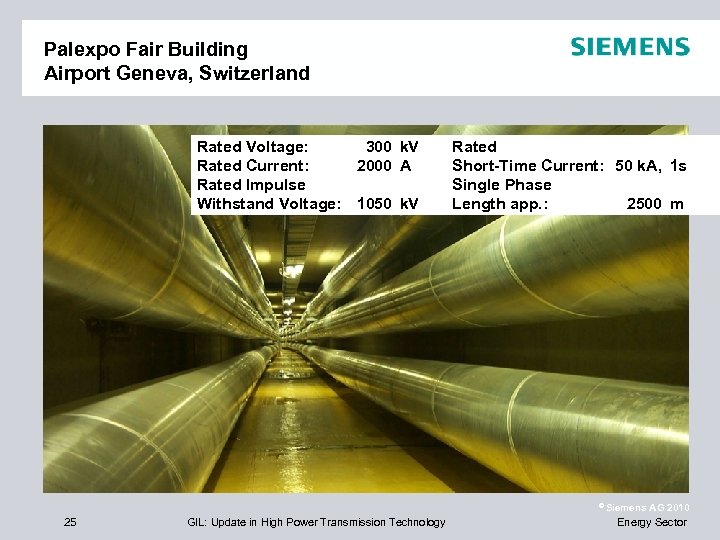

Palexpo Fair Building Airport Geneva, Switzerland Rated Voltage: 300 k. V Tower 176 Rated Current: 2000 A Rated Impulse Withstand Voltage: 1050 k. V Rated Short-Time Current: 50 k. A, 1 s Single Phase Length app. : 2500 m Tower 175 PALEXPO Hall 6 © Siemens 25 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

Palexpo Fair Building Airport Geneva, Switzerland Rated Voltage: 300 k. V Tower 176 Rated Current: 2000 A Rated Impulse Withstand Voltage: 1050 k. V Rated Short-Time Current: 50 k. A, 1 s Single Phase Length app. : 2500 m Tower 175 PALEXPO Hall 6 © Siemens 25 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

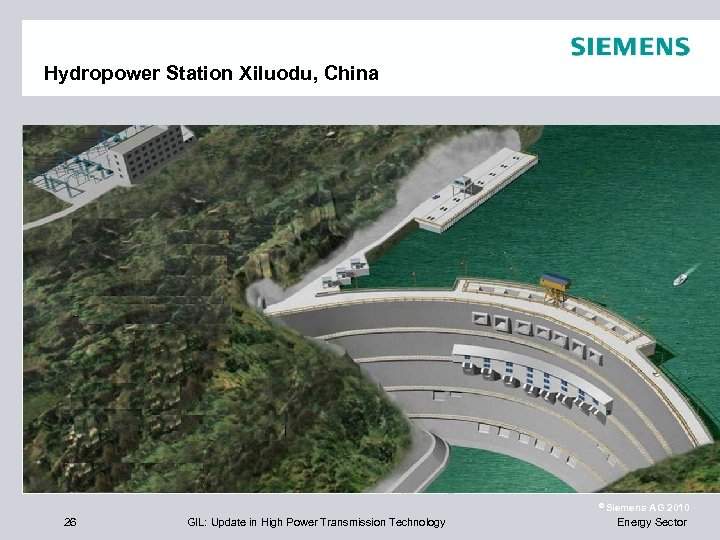

Hydropower Station Xiluodu, China Left Bank Right Bank 620 m End User China Three Gorges Project Corp. Project Highlights Biggest Siemens GIL installation applying welding technology worldwide 7 vertical GIL Systems (option: 1 system) ~12 kms of GIL tubes Technical Data Rated Power: up to 3900 Rated Voltage: 550 Rated Current: up to 4, 500 Insulation Gas: 100% Contract Award: 19. 05. 09 Commercial Operation (planned): 2013 © Siemens 26 GIL: Update in High Power Transmission Technology MVA k. V A SF 6 AG 2010 Energy Sector

Hydropower Station Xiluodu, China Left Bank Right Bank 620 m End User China Three Gorges Project Corp. Project Highlights Biggest Siemens GIL installation applying welding technology worldwide 7 vertical GIL Systems (option: 1 system) ~12 kms of GIL tubes Technical Data Rated Power: up to 3900 Rated Voltage: 550 Rated Current: up to 4, 500 Insulation Gas: 100% Contract Award: 19. 05. 09 Commercial Operation (planned): 2013 © Siemens 26 GIL: Update in High Power Transmission Technology MVA k. V A SF 6 AG 2010 Energy Sector

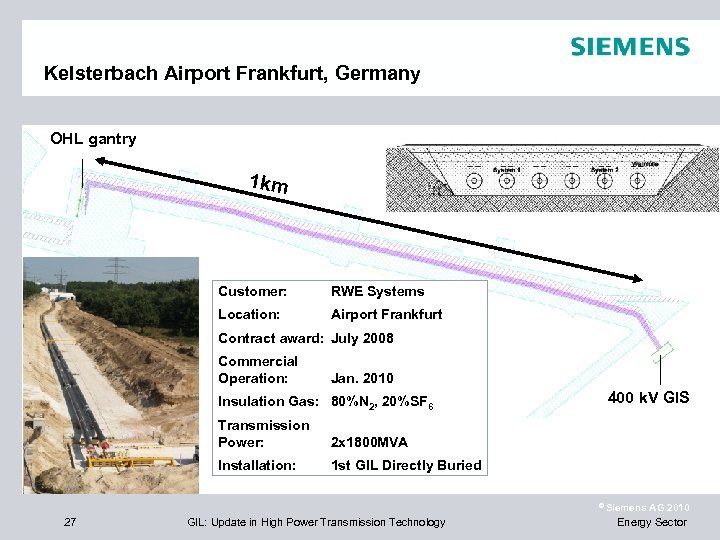

Kelsterbach Airport Frankfurt, Germany OHL gantry 1 km Customer: RWE Systems Location: Airport Frankfurt Contract award: July 2008 Commercial Operation: Jan. 2010 Insulation Gas: 80%N 2, 20%SF 6 Transmission Power: 2 x 1800 MVA Installation: 400 k. V GIS 1 st GIL Directly Buried © Siemens 27 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

Kelsterbach Airport Frankfurt, Germany OHL gantry 1 km Customer: RWE Systems Location: Airport Frankfurt Contract award: July 2008 Commercial Operation: Jan. 2010 Insulation Gas: 80%N 2, 20%SF 6 Transmission Power: 2 x 1800 MVA Installation: 400 k. V GIS 1 st GIL Directly Buried © Siemens 27 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

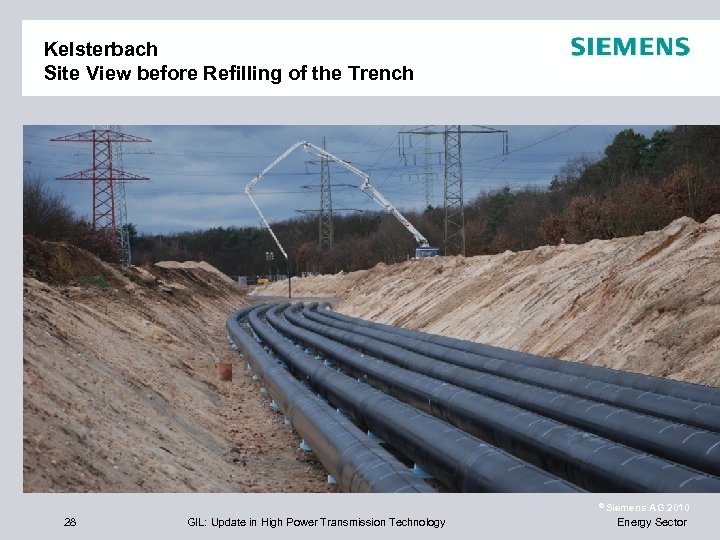

Kelsterbach Site View before Refilling of the Trench © Siemens 28 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

Kelsterbach Site View before Refilling of the Trench © Siemens 28 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

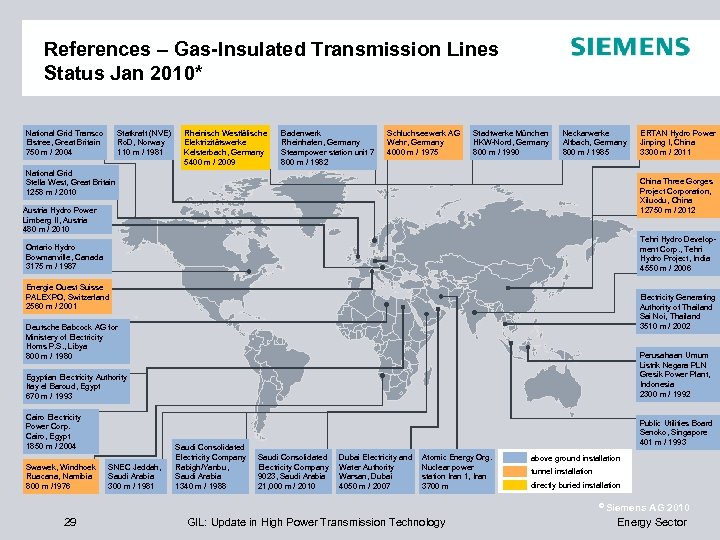

References – Gas-Insulated Transmission Lines Status Jan 2010* National Grid Transco Elstree, Great Britain 750 m / 2004 Statkraft (NVE) Ro. D, Norway 110 m / 1981 Rheinisch Westfälische Elektrizitätswerke Kelsterbach, Germany 5400 m / 2009 Badenwerk Rheinhafen, Germany Steampower station unit 7 800 m / 1982 Schluchseewerk AG Wehr, Germany 4000 m / 1975 Stadtwerke München HKW-Nord, Germany 800 m / 1990 Neckarwerke Altbach, Germany 800 m / 1985 National Grid Stella West, Great Britain 1258 m / 2010 ERTAN Hydro Power Jinping I, China 3300 m / 2011 China Three Gorges Project Corporation, Xiluodu, China 12750 m / 2012 Austria Hydro Power Limberg II, Austria 480 m / 2010 Tehri Hydro Development Corp. , Tehri Hydro Project, India 4550 m / 2006 Ontario Hydro Bowmanville, Canada 3175 m / 1987 Energie Ouest Suisse PALEXPO, Switzerland 2560 m / 2001 Electricity Generating Authority of Thailand Sai Noi, Thailand 3510 m / 2002 Deutsche Babcock AG for Ministery of Electricity Homs P. S. , Libya 800 m / 1980 Egyptian Electricity Authority Itay el Baroud, Egypt 670 m / 1993 Perusahaan Umum Listrik Negara PLN Gresik Power Plant, Indonesia 2300 m / 1992 Cairo Electricity Power Corp. Cairo, Egypt 1850 m / 2004 Public Utilities Board Senoko, Singapore 401 m / 1993 Swawek, Windhoek Ruacana, Namibia 800 m /1976 SNEC Jeddah, Saudi Arabia 300 m / 1981 Saudi Consolidated Electricity Company Rabigh/Yanbu, Saudi Arabia 1340 m / 1988 Saudi Consolidated Electricity Company 9023, Saudi Arabia 21, 000 m / 2010 Dubai Electricity and Water Authority Warsan, Dubai 4050 m / 2007 Atomic Energy Org. Nuclear power station Iran 1, Iran 3700 m above ground installation tunnel installation directly buried installation © Siemens 29 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

References – Gas-Insulated Transmission Lines Status Jan 2010* National Grid Transco Elstree, Great Britain 750 m / 2004 Statkraft (NVE) Ro. D, Norway 110 m / 1981 Rheinisch Westfälische Elektrizitätswerke Kelsterbach, Germany 5400 m / 2009 Badenwerk Rheinhafen, Germany Steampower station unit 7 800 m / 1982 Schluchseewerk AG Wehr, Germany 4000 m / 1975 Stadtwerke München HKW-Nord, Germany 800 m / 1990 Neckarwerke Altbach, Germany 800 m / 1985 National Grid Stella West, Great Britain 1258 m / 2010 ERTAN Hydro Power Jinping I, China 3300 m / 2011 China Three Gorges Project Corporation, Xiluodu, China 12750 m / 2012 Austria Hydro Power Limberg II, Austria 480 m / 2010 Tehri Hydro Development Corp. , Tehri Hydro Project, India 4550 m / 2006 Ontario Hydro Bowmanville, Canada 3175 m / 1987 Energie Ouest Suisse PALEXPO, Switzerland 2560 m / 2001 Electricity Generating Authority of Thailand Sai Noi, Thailand 3510 m / 2002 Deutsche Babcock AG for Ministery of Electricity Homs P. S. , Libya 800 m / 1980 Egyptian Electricity Authority Itay el Baroud, Egypt 670 m / 1993 Perusahaan Umum Listrik Negara PLN Gresik Power Plant, Indonesia 2300 m / 1992 Cairo Electricity Power Corp. Cairo, Egypt 1850 m / 2004 Public Utilities Board Senoko, Singapore 401 m / 1993 Swawek, Windhoek Ruacana, Namibia 800 m /1976 SNEC Jeddah, Saudi Arabia 300 m / 1981 Saudi Consolidated Electricity Company Rabigh/Yanbu, Saudi Arabia 1340 m / 1988 Saudi Consolidated Electricity Company 9023, Saudi Arabia 21, 000 m / 2010 Dubai Electricity and Water Authority Warsan, Dubai 4050 m / 2007 Atomic Energy Org. Nuclear power station Iran 1, Iran 3700 m above ground installation tunnel installation directly buried installation © Siemens 29 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

Content Challenges in Mega Cities Data, Site Works & Laying Methods of GIL Technical Advantages of GIL EMV Radiation Transmission Losses Auto Reclosure Functionality Innovative Arc Location References Summary © Siemens 30 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

Content Challenges in Mega Cities Data, Site Works & Laying Methods of GIL Technical Advantages of GIL EMV Radiation Transmission Losses Auto Reclosure Functionality Innovative Arc Location References Summary © Siemens 30 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

GIL Summary Sealed for lifetime Continuous welded High ampacity Low losses Long lifetime through particle trap No reactive compensation (<100 km) No ageing of insulating gas Automatic reclosure functionality Low external electromagnetic fields High safety (no fire hazard) © Siemens 31 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

GIL Summary Sealed for lifetime Continuous welded High ampacity Low losses Long lifetime through particle trap No reactive compensation (<100 km) No ageing of insulating gas Automatic reclosure functionality Low external electromagnetic fields High safety (no fire hazard) © Siemens 31 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

Thank you ! © Siemens 32 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector

Thank you ! © Siemens 32 GIL: Update in High Power Transmission Technology AG 2010 Energy Sector