a17a37f3d1b56855bf9a194443030eda.ppt

- Количество слайдов: 82

Galvanize It! Seminar American Galvanizing Association

Galvanize It! Seminar American Galvanizing Association

American Galvanizers Association The American Galvanizers Association (AGA) is a non-profit trade association dedicated to serving the needs of afterfabrication galvanizers, fabricators, architects, specifiers, and engineers The AGA provides technical support on today's innovative applications and state-of -the-art technological developments in hotdip galvanizing for corrosion control 2

American Galvanizers Association The American Galvanizers Association (AGA) is a non-profit trade association dedicated to serving the needs of afterfabrication galvanizers, fabricators, architects, specifiers, and engineers The AGA provides technical support on today's innovative applications and state-of -the-art technological developments in hotdip galvanizing for corrosion control 2

Continuing Education Credit American Institute of Architects Learning Units (HSW) National Council of Examiners for Engineering & Surveying Professional Development Hours 3

Continuing Education Credit American Institute of Architects Learning Units (HSW) National Council of Examiners for Engineering & Surveying Professional Development Hours 3

Continuing Education AIA/CES Policy on Endorsement: The following program is registered with the AIA/CES and does not include content that may be deemed or construed to be an approval, sponsorship, or endorsement of any material of construction or any method or manner of handling, using, distributing, or dealing in any material or product. 4

Continuing Education AIA/CES Policy on Endorsement: The following program is registered with the AIA/CES and does not include content that may be deemed or construed to be an approval, sponsorship, or endorsement of any material of construction or any method or manner of handling, using, distributing, or dealing in any material or product. 4

Continuing Education The American Galvanizers Association has met the standards and requirements of the Registered Continuing Education Providers Program. Credit earned upon completion of this program will be reported to RCEPP. A certificate of completion will be issued to each participant. As such, it does not include content that may be deemed or construed to be an approval or endorsement by NCEES or RCEPP. 5

Continuing Education The American Galvanizers Association has met the standards and requirements of the Registered Continuing Education Providers Program. Credit earned upon completion of this program will be reported to RCEPP. A certificate of completion will be issued to each participant. As such, it does not include content that may be deemed or construed to be an approval or endorsement by NCEES or RCEPP. 5

Purpose of this Seminar The purpose of this seminar is to inform and educate architects, engineers, and other specifiers about hot-dip galvanized steel and how it can address the growing corrosion problem throughout North America. 6

Purpose of this Seminar The purpose of this seminar is to inform and educate architects, engineers, and other specifiers about hot-dip galvanized steel and how it can address the growing corrosion problem throughout North America. 6

Learning Objectives At the end of this presentation you will be able to: • Recognize the corrosion issues confronting the United States • Describe how zinc coatings, specifically hot-dip galvanizing, can protect against steel corrosion • Incorporate sound corrosion protection into the design of steel products that can significantly decrease maintenance costs over the life of a structure 7

Learning Objectives At the end of this presentation you will be able to: • Recognize the corrosion issues confronting the United States • Describe how zinc coatings, specifically hot-dip galvanizing, can protect against steel corrosion • Incorporate sound corrosion protection into the design of steel products that can significantly decrease maintenance costs over the life of a structure 7

Tour of the City

Tour of the City

The Corrosion Problem 9

The Corrosion Problem 9

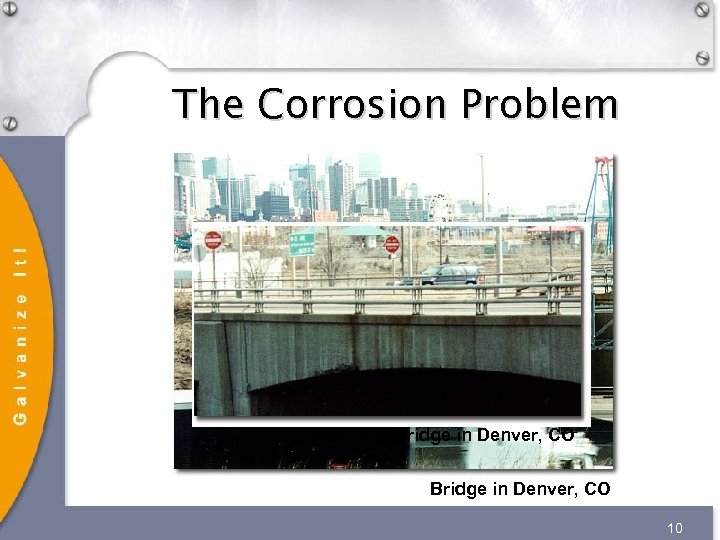

The Corrosion Problem Bridge in Denver, CO 10

The Corrosion Problem Bridge in Denver, CO 10

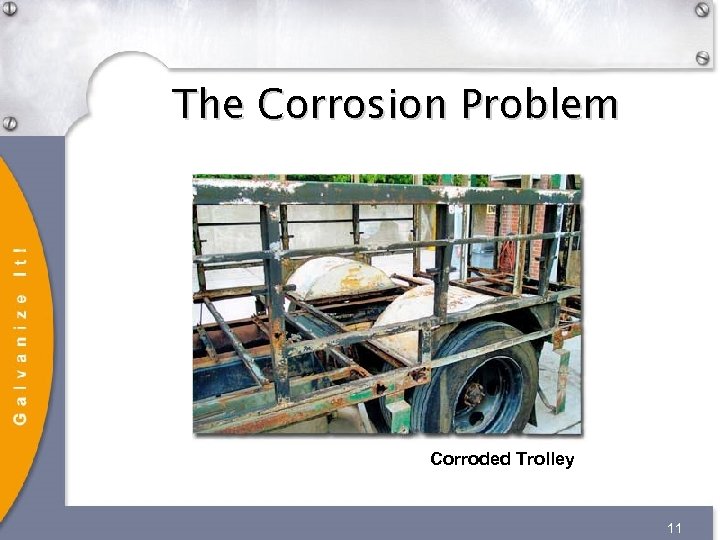

The Corrosion Problem Corroded Trolley 11

The Corrosion Problem Corroded Trolley 11

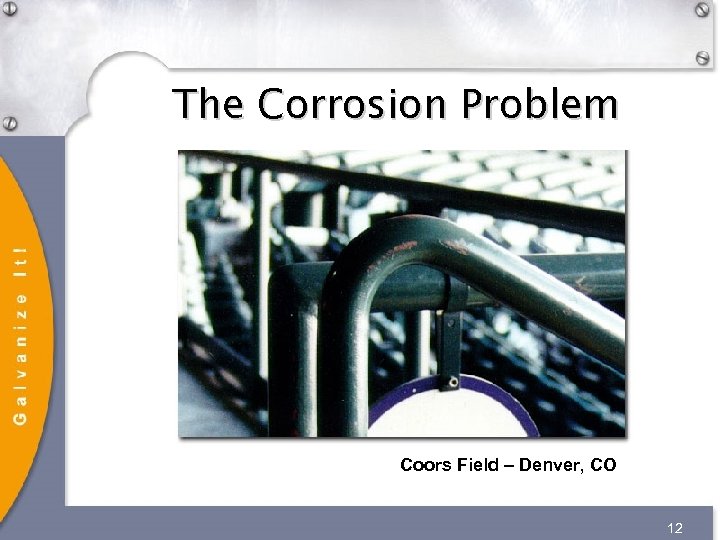

The Corrosion Problem Coors Field – Denver, CO 12

The Corrosion Problem Coors Field – Denver, CO 12

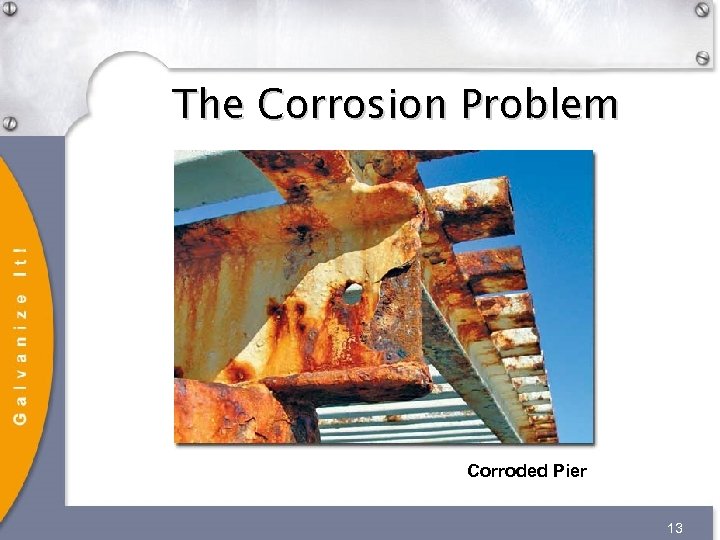

The Corrosion Problem Corroded Pier 13

The Corrosion Problem Corroded Pier 13

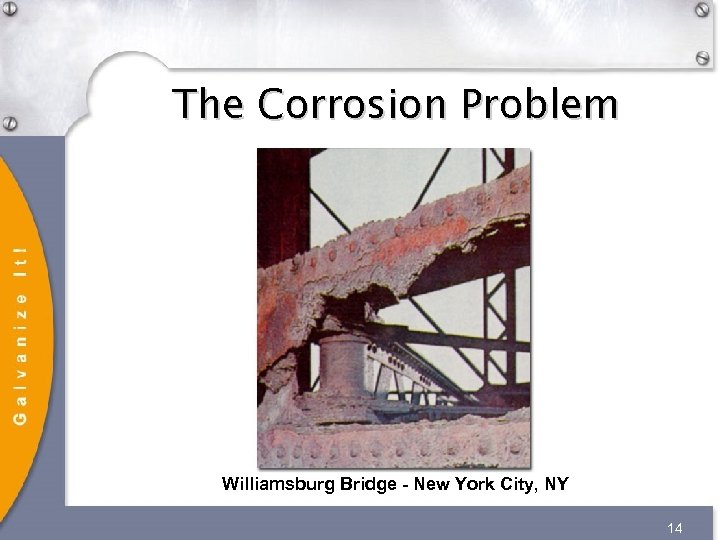

The Corrosion Problem Williamsburg Bridge - New York City, NY 14

The Corrosion Problem Williamsburg Bridge - New York City, NY 14

Corrosion Costs NACE, CC Technologies, & FHWA jointly produced a report in 2001 detailing the costs of corrosion • $297 billion USD annually • 3. 1% of US GDP (1998) Hazardous • Public safety, property damage, environmental contamination Natural Resources • Waste production, increased energy consumption Public Outcry • Traffic, inconvenience 15

Corrosion Costs NACE, CC Technologies, & FHWA jointly produced a report in 2001 detailing the costs of corrosion • $297 billion USD annually • 3. 1% of US GDP (1998) Hazardous • Public safety, property damage, environmental contamination Natural Resources • Waste production, increased energy consumption Public Outcry • Traffic, inconvenience 15

The Solution: Hot-Dip Galvanizing

The Solution: Hot-Dip Galvanizing

Barrier Protection Weathered Guardrail 17

Barrier Protection Weathered Guardrail 17

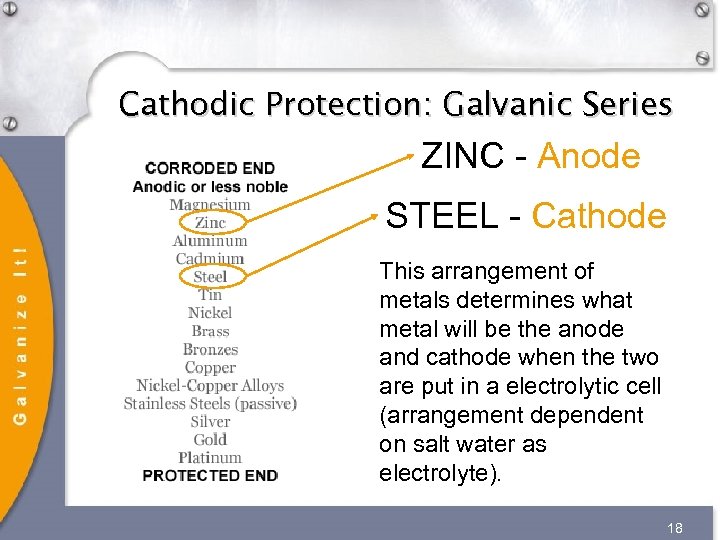

Cathodic Protection: Galvanic Series ZINC - Anode STEEL - Cathode This arrangement of metals determines what metal will be the anode and cathode when the two are put in a electrolytic cell (arrangement dependent on salt water as electrolyte). 18

Cathodic Protection: Galvanic Series ZINC - Anode STEEL - Cathode This arrangement of metals determines what metal will be the anode and cathode when the two are put in a electrolytic cell (arrangement dependent on salt water as electrolyte). 18

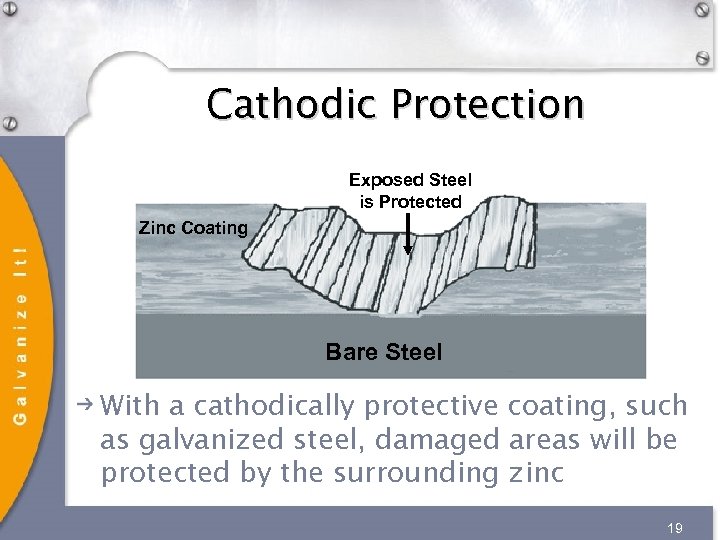

Cathodic Protection Exposed Steel is Protected Zinc Coating Bare Steel With a cathodically protective coating, such as galvanized steel, damaged areas will be protected by the surrounding zinc 19

Cathodic Protection Exposed Steel is Protected Zinc Coating Bare Steel With a cathodically protective coating, such as galvanized steel, damaged areas will be protected by the surrounding zinc 19

HDG Process Steel is dipped in a series of tanks including solutions that remove impurities from the steel surface. The galvanizing reaction only occurs on perfectly clean steel. The steel is inspected after galvanizing to ensure conformance to the appropriate specifications. 20

HDG Process Steel is dipped in a series of tanks including solutions that remove impurities from the steel surface. The galvanizing reaction only occurs on perfectly clean steel. The steel is inspected after galvanizing to ensure conformance to the appropriate specifications. 20

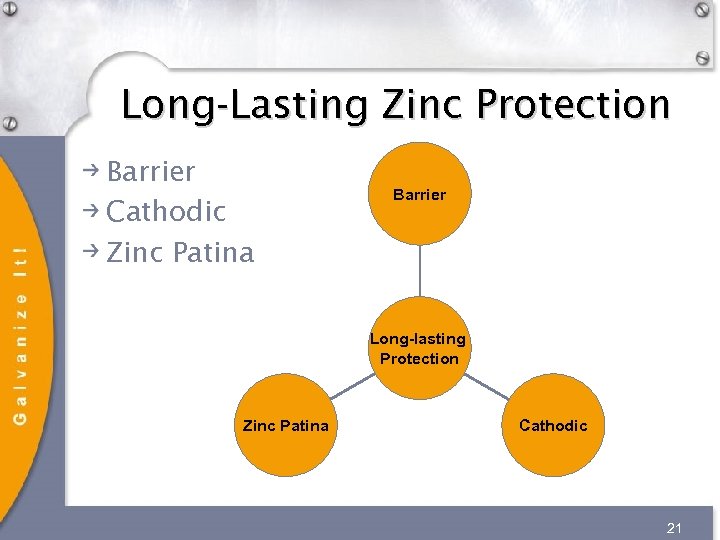

Long-Lasting Zinc Protection Barrier Cathodic Zinc Patina Barrier Long-lasting Protection Zinc Patina Cathodic 21

Long-Lasting Zinc Protection Barrier Cathodic Zinc Patina Barrier Long-lasting Protection Zinc Patina Cathodic 21

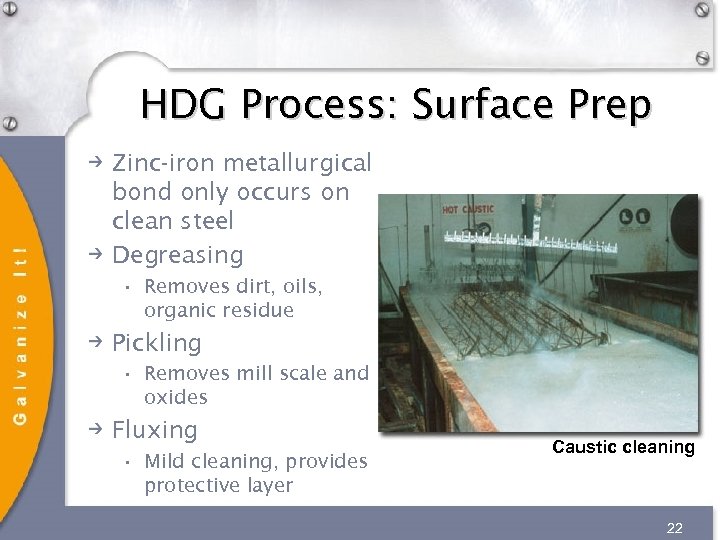

HDG Process: Surface Prep Zinc-iron metallurgical bond only occurs on clean steel Degreasing • Removes dirt, oils, organic residue Pickling • Removes mill scale and oxides Fluxing • Mild cleaning, provides protective layer Caustic cleaning 22

HDG Process: Surface Prep Zinc-iron metallurgical bond only occurs on clean steel Degreasing • Removes dirt, oils, organic residue Pickling • Removes mill scale and oxides Fluxing • Mild cleaning, provides protective layer Caustic cleaning 22

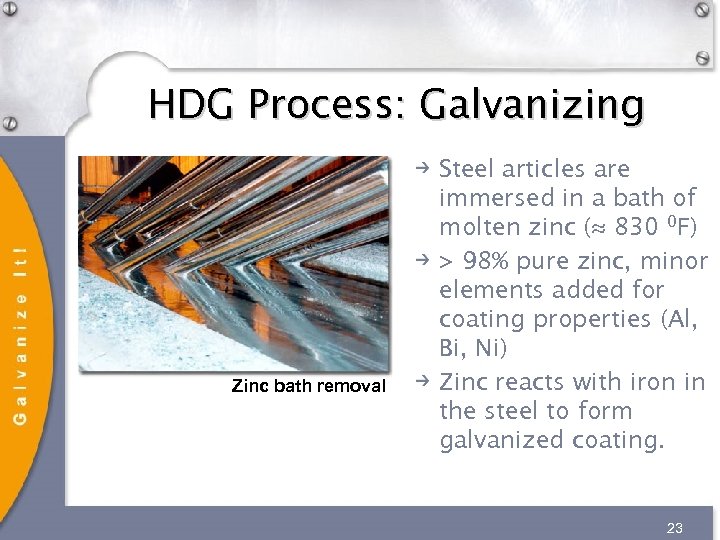

HDG Process: Galvanizing Zinc bath removal Steel articles are immersed in a bath of molten zinc (≈ 830 0 F) > 98% pure zinc, minor elements added for coating properties (Al, Bi, Ni) Zinc reacts with iron in the steel to form galvanized coating. 23

HDG Process: Galvanizing Zinc bath removal Steel articles are immersed in a bath of molten zinc (≈ 830 0 F) > 98% pure zinc, minor elements added for coating properties (Al, Bi, Ni) Zinc reacts with iron in the steel to form galvanized coating. 23

HDG Process: Inspection Steel articles are inspected after galvanizing to verify conformance to appropriate specs. Surface defects easily identified through visual inspection. Coating thickness verified through magnetic thickness gauge readings. 24

HDG Process: Inspection Steel articles are inspected after galvanizing to verify conformance to appropriate specs. Surface defects easily identified through visual inspection. Coating thickness verified through magnetic thickness gauge readings. 24

Hot-Dip Galvanized Coating Properties

Hot-Dip Galvanized Coating Properties

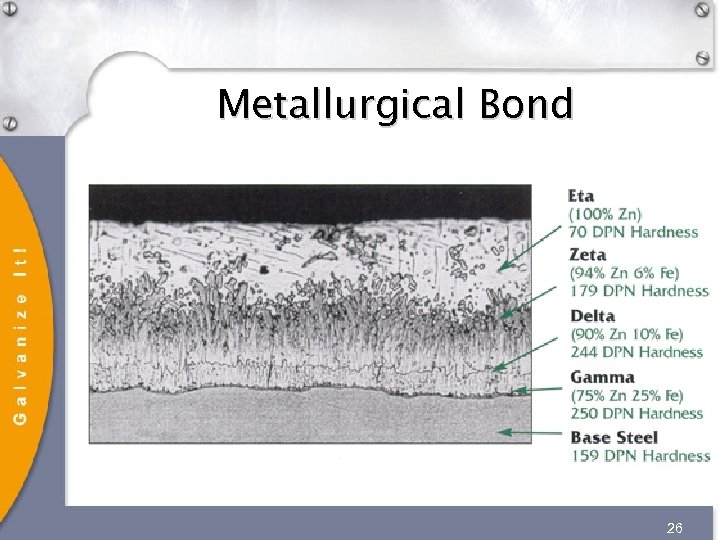

Metallurgical Bond 26

Metallurgical Bond 26

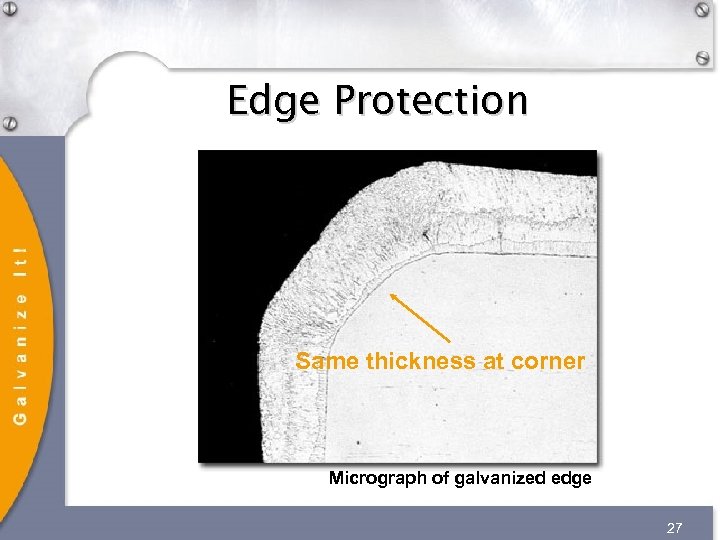

Edge Protection Same thickness at corner Micrograph of galvanized edge 27

Edge Protection Same thickness at corner Micrograph of galvanized edge 27

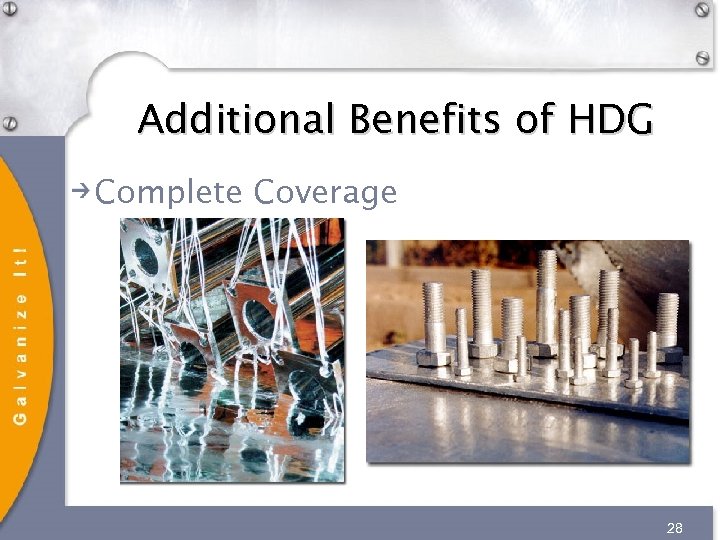

Additional Benefits of HDG Complete Coverage 28

Additional Benefits of HDG Complete Coverage 28

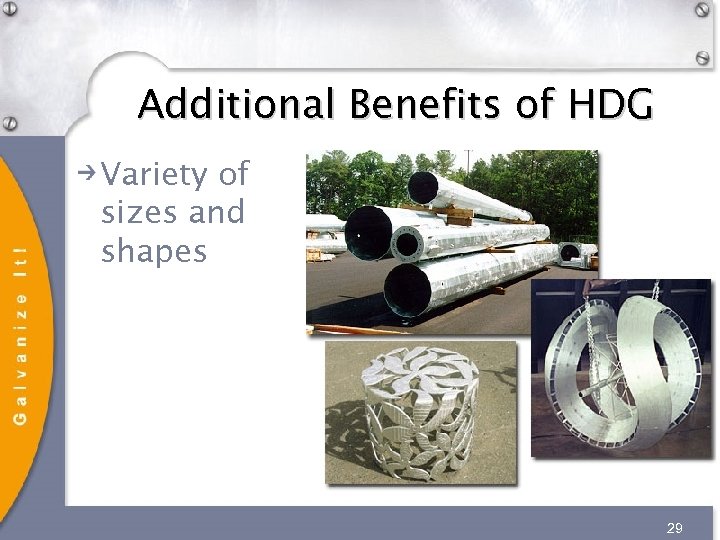

Additional Benefits of HDG Variety of sizes and shapes 29

Additional Benefits of HDG Variety of sizes and shapes 29

Additional Benefits of HDG Availability 30

Additional Benefits of HDG Availability 30

Galvanizing is Green Zinc is 100% recyclable as is the steel • Properties of zinc do not degrade w/ reprocessing • Zinc is a natural element in the Earth’s crust The longevity of galvanizing means no additional energy exerted or waste created maintaining galvanized structures 31

Galvanizing is Green Zinc is 100% recyclable as is the steel • Properties of zinc do not degrade w/ reprocessing • Zinc is a natural element in the Earth’s crust The longevity of galvanizing means no additional energy exerted or waste created maintaining galvanized structures 31

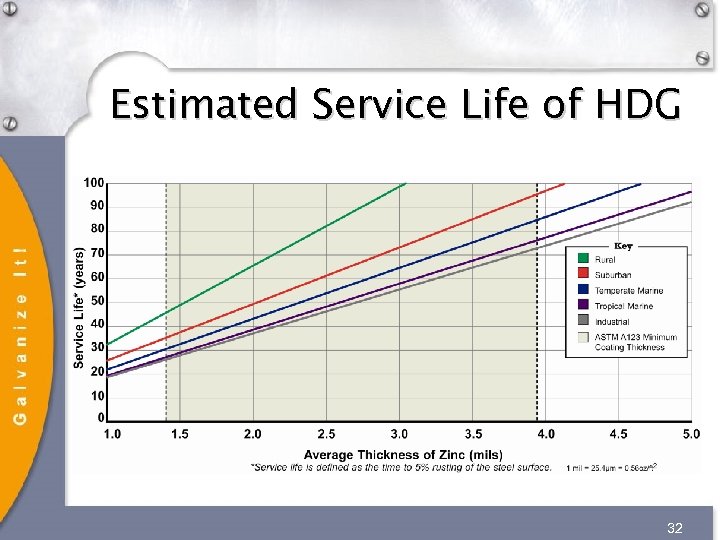

Estimated Service Life of HDG 32

Estimated Service Life of HDG 32

Other Zinc Coatings for Corrosion Protection

Other Zinc Coatings for Corrosion Protection

Metallizing Shop or in-field application Suitable for very large pieces Coating Properties: • Thick coating • Mechanical bond • Less dense than HDG zinc layers • No interior coverage Metallizing Appliation 34

Metallizing Shop or in-field application Suitable for very large pieces Coating Properties: • Thick coating • Mechanical bond • Less dense than HDG zinc layers • No interior coverage Metallizing Appliation 34

Zinc Rich Paint Metallic zinc dust • Inorganic • Organic Barrier protection Cathodic protection • Limited • Dependent on % Zn Zinc Rich Paint Application Use salt spray data to make performance claims 35

Zinc Rich Paint Metallic zinc dust • Inorganic • Organic Barrier protection Cathodic protection • Limited • Dependent on % Zn Zinc Rich Paint Application Use salt spray data to make performance claims 35

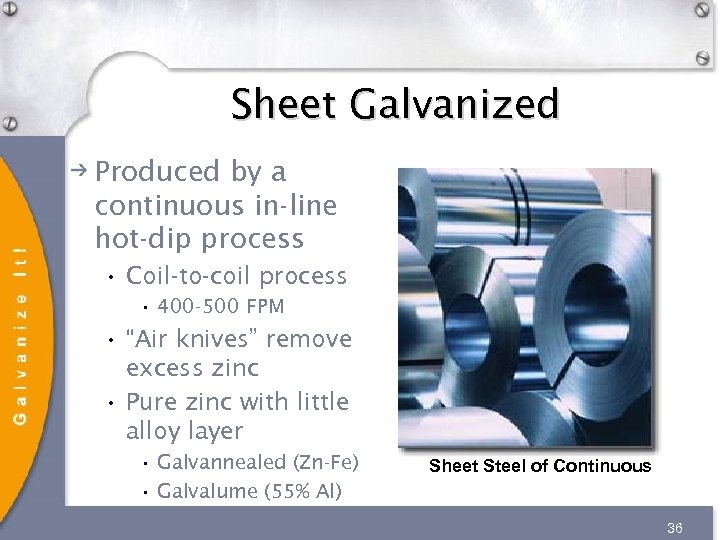

Sheet Galvanized Produced by a continuous in-line hot-dip process • Coil-to-coil process • 400 -500 FPM • “Air knives” remove excess zinc • Pure zinc with little alloy layer • Galvannealed (Zn-Fe) • Galvalume (55% Al) Sheet Steel of Continuous 36

Sheet Galvanized Produced by a continuous in-line hot-dip process • Coil-to-coil process • 400 -500 FPM • “Air knives” remove excess zinc • Pure zinc with little alloy layer • Galvannealed (Zn-Fe) • Galvalume (55% Al) Sheet Steel of Continuous 36

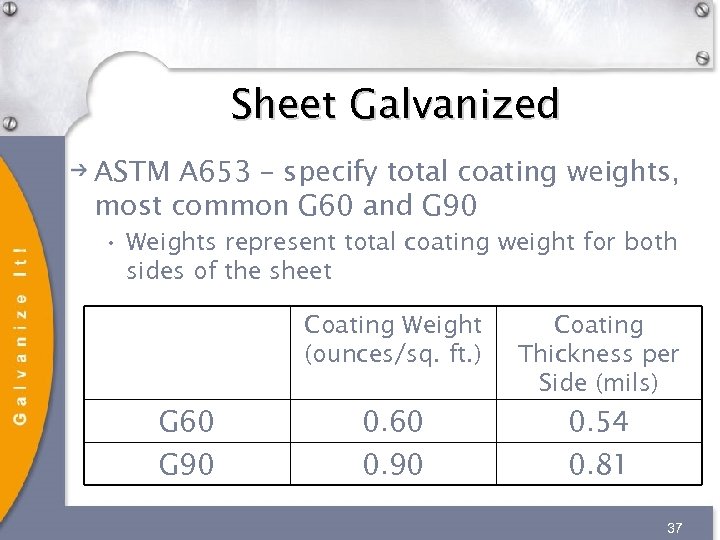

Sheet Galvanized ASTM A 653 – specify total coating weights, most common G 60 and G 90 • Weights represent total coating weight for both sides of the sheet Coating Weight (ounces/sq. ft. ) Coating Thickness per Side (mils) G 60 0. 54 G 90 0. 81 37

Sheet Galvanized ASTM A 653 – specify total coating weights, most common G 60 and G 90 • Weights represent total coating weight for both sides of the sheet Coating Weight (ounces/sq. ft. ) Coating Thickness per Side (mils) G 60 0. 54 G 90 0. 81 37

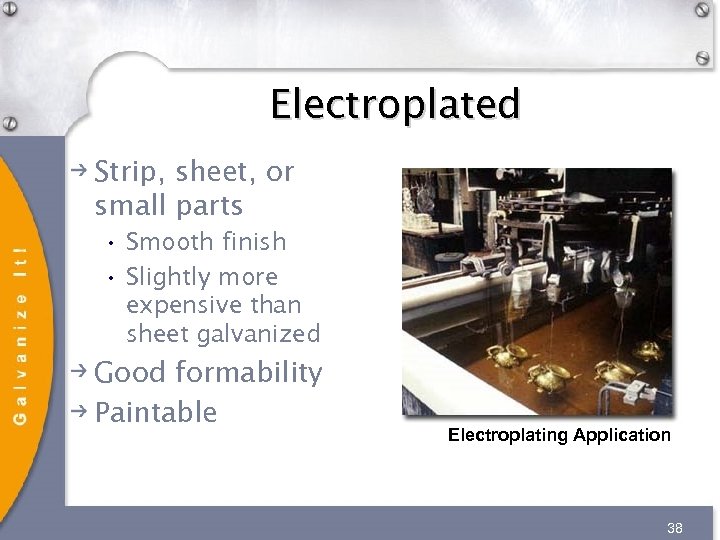

Electroplated Strip, sheet, or small parts • Smooth finish • Slightly more expensive than sheet galvanized Good formability Paintable Electroplating Application 38

Electroplated Strip, sheet, or small parts • Smooth finish • Slightly more expensive than sheet galvanized Good formability Paintable Electroplating Application 38

Zinc (Mechanical) Plating Similar to electroplating • used for fasteners and small parts Parts are tumbled in drum with zinc powder and glass beads • mechanically bonded zinc Mechanical Plating Application 39

Zinc (Mechanical) Plating Similar to electroplating • used for fasteners and small parts Parts are tumbled in drum with zinc powder and glass beads • mechanically bonded zinc Mechanical Plating Application 39

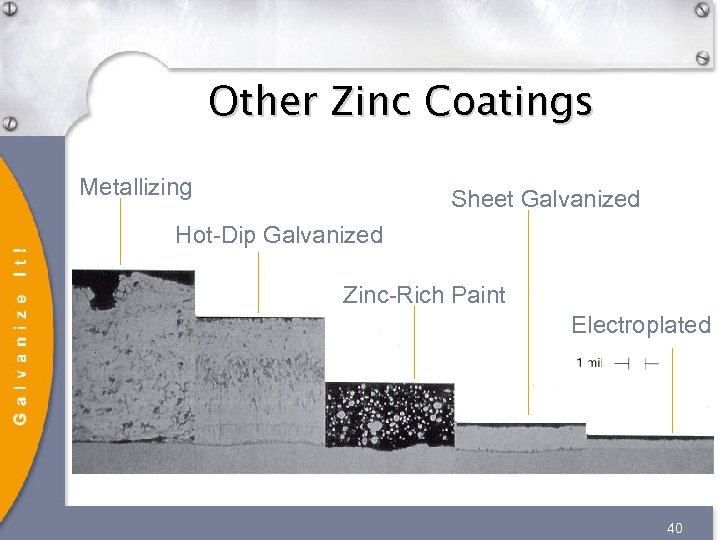

Other Zinc Coatings Metallizing Sheet Galvanized Hot-Dip Galvanized Zinc-Rich Paint Electroplated 40

Other Zinc Coatings Metallizing Sheet Galvanized Hot-Dip Galvanized Zinc-Rich Paint Electroplated 40

Design & Fabrication

Design & Fabrication

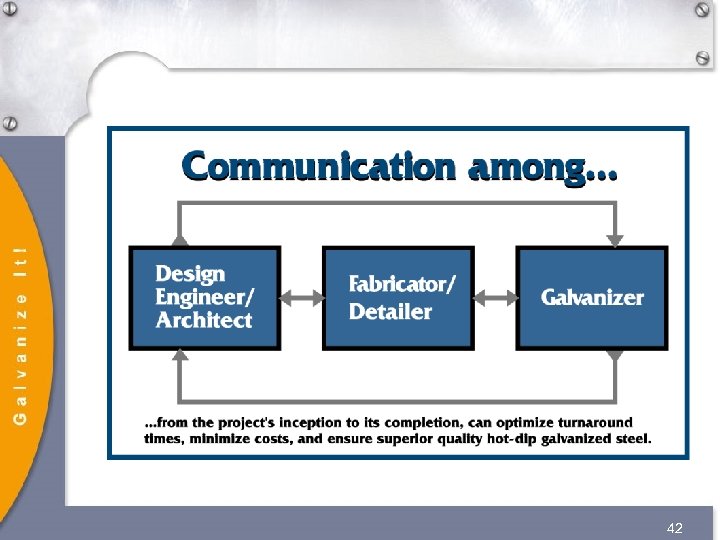

42

42

Materials Suitable for Hot-Dip Galvanizing 43

Materials Suitable for Hot-Dip Galvanizing 43

Hot-Dip Galvanized Fasteners Hot-dip galvanized fasteners are recommended for joining HDG structurals 44

Hot-Dip Galvanized Fasteners Hot-dip galvanized fasteners are recommended for joining HDG structurals 44

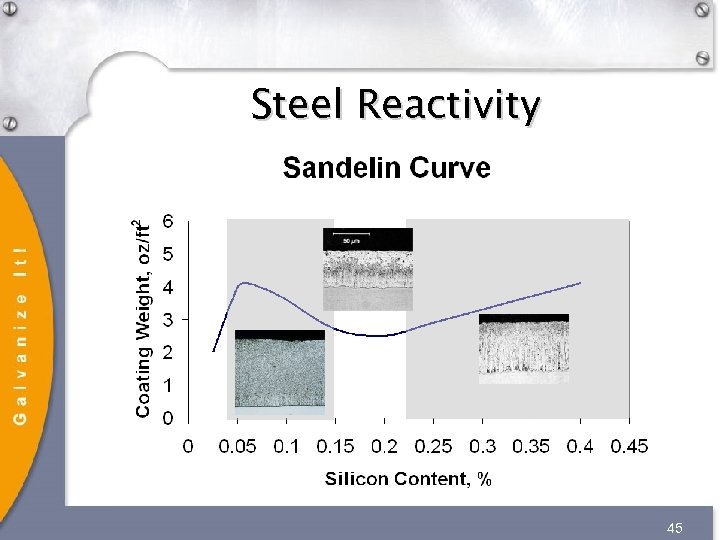

Steel Reactivity 45

Steel Reactivity 45

Coating Appearance Newly Galvanized Dull Coating No Spangle Newly Galvanized Newly Installed Highly Spangle Shiny & Dull Coating 46

Coating Appearance Newly Galvanized Dull Coating No Spangle Newly Galvanized Newly Installed Highly Spangle Shiny & Dull Coating 46

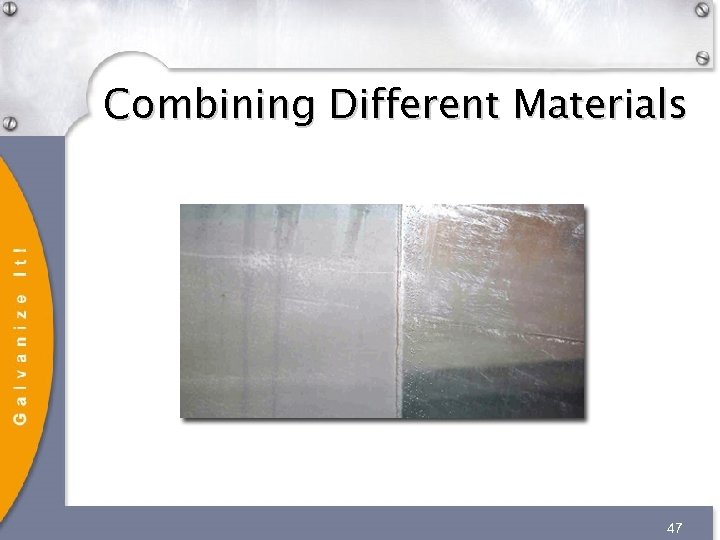

Combining Different Materials 47

Combining Different Materials 47

Weathering of Galvanized Steel Photo taken: 12/18/02 Photo taken: 03/28/03 48

Weathering of Galvanized Steel Photo taken: 12/18/02 Photo taken: 03/28/03 48

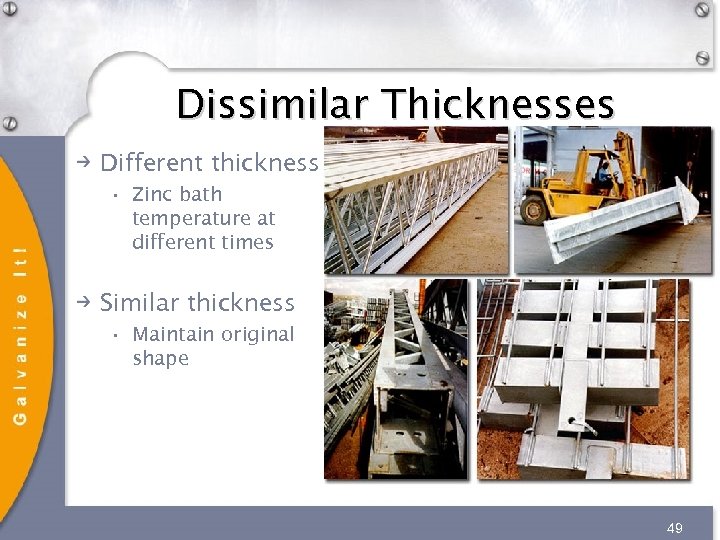

Dissimilar Thicknesses Different thickness • Zinc bath temperature at different times Similar thickness • Maintain original shape 49

Dissimilar Thicknesses Different thickness • Zinc bath temperature at different times Similar thickness • Maintain original shape 49

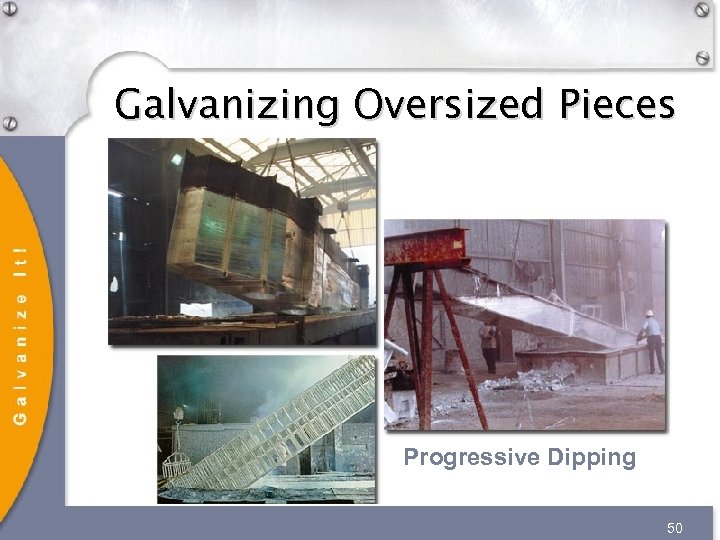

Galvanizing Oversized Pieces Progressive Dipping 50

Galvanizing Oversized Pieces Progressive Dipping 50

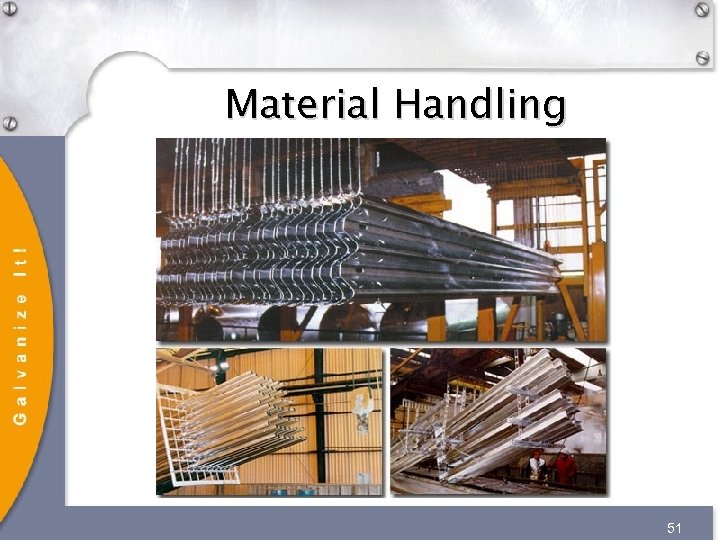

Material Handling 51

Material Handling 51

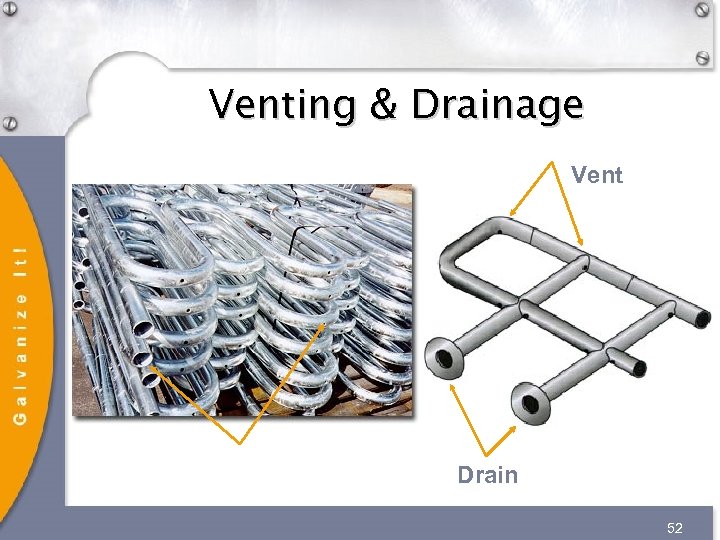

Venting & Drainage Vent Drain 52

Venting & Drainage Vent Drain 52

Specifications & Inspection

Specifications & Inspection

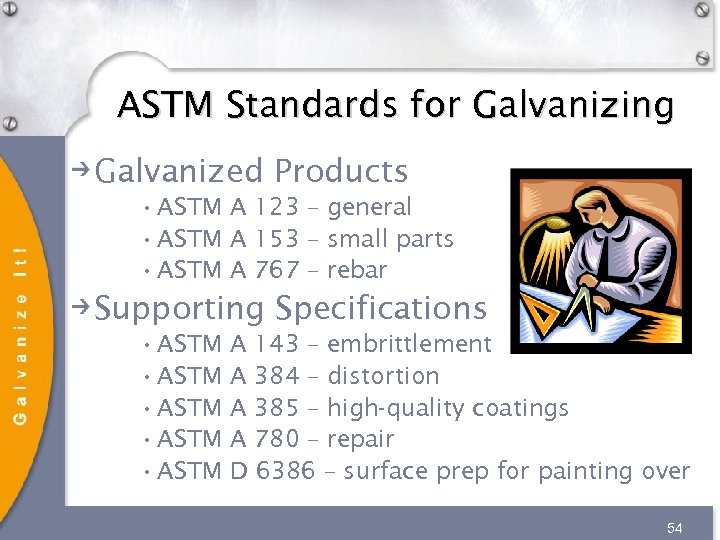

ASTM Standards for Galvanizing Galvanized Products • ASTM A 123 – general • ASTM A 153 – small parts • ASTM A 767 – rebar Supporting Specifications • ASTM • ASTM A 143 – embrittlement A 384 – distortion A 385 – high-quality coatings A 780 – repair D 6386 – surface prep for painting over 54

ASTM Standards for Galvanizing Galvanized Products • ASTM A 123 – general • ASTM A 153 – small parts • ASTM A 767 – rebar Supporting Specifications • ASTM • ASTM A 143 – embrittlement A 384 – distortion A 385 – high-quality coatings A 780 – repair D 6386 – surface prep for painting over 54

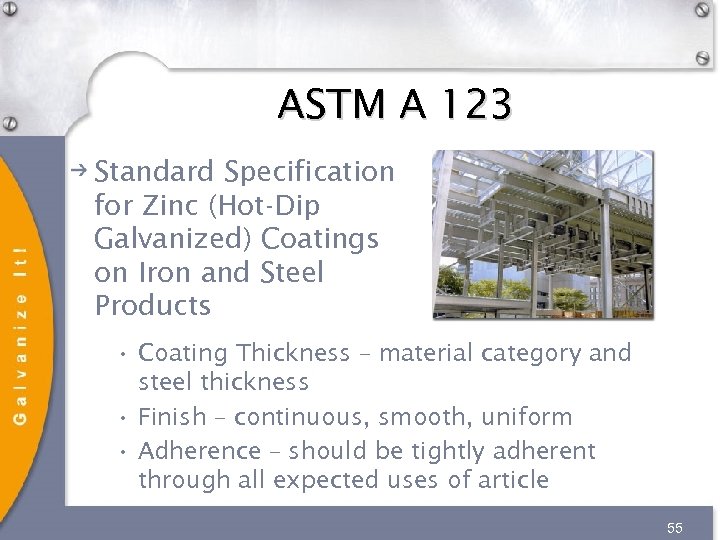

ASTM A 123 Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products • Coating Thickness – material category and steel thickness • Finish – continuous, smooth, uniform • Adherence – should be tightly adherent through all expected uses of article 55

ASTM A 123 Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products • Coating Thickness – material category and steel thickness • Finish – continuous, smooth, uniform • Adherence – should be tightly adherent through all expected uses of article 55

ASTM A 153 Standard Specification for Zinc Coating (Hot. Dip) on Iron and Steel Hardware • Coating Thickness – material category, steel thickness, length • Finish – continuous, smooth, uniform • Adherence – should be tightly adherent through all expected uses of article 56

ASTM A 153 Standard Specification for Zinc Coating (Hot. Dip) on Iron and Steel Hardware • Coating Thickness – material category, steel thickness, length • Finish – continuous, smooth, uniform • Adherence – should be tightly adherent through all expected uses of article 56

ASTM A 767 Standard Specification for Zinc-Coated (Galvanized) Steel Bars for Concrete Reinforcement • Coating Thickness – smooth or deformed (no wire), bar size • Chromating –prevent reaction between fresh cement and recently galvanized material • Bend Diameters – flaking and cracking due to fabrication are not rejectable. 57

ASTM A 767 Standard Specification for Zinc-Coated (Galvanized) Steel Bars for Concrete Reinforcement • Coating Thickness – smooth or deformed (no wire), bar size • Chromating –prevent reaction between fresh cement and recently galvanized material • Bend Diameters – flaking and cracking due to fabrication are not rejectable. 57

ASTM A 780 Standard Practice for Repair of Damaged and Uncoated Areas of Hot-Dip Galvanized Coatings • Zinc-rich paint, zinc-based solder, or metallizing • Zinc-rich paint- most common but must have certain amounts of zinc dust as required by spec • Zinc-based solder– good for small areas, closely mirrors typical HDG coating appearance • Metallizing– excellent corrosion protection 58

ASTM A 780 Standard Practice for Repair of Damaged and Uncoated Areas of Hot-Dip Galvanized Coatings • Zinc-rich paint, zinc-based solder, or metallizing • Zinc-rich paint- most common but must have certain amounts of zinc dust as required by spec • Zinc-based solder– good for small areas, closely mirrors typical HDG coating appearance • Metallizing– excellent corrosion protection 58

Hot-Dip Galvanizing Costs Less & Lasts Longer

Hot-Dip Galvanizing Costs Less & Lasts Longer

Quantitative Analysis Initial cost vs. Life-cycle cost • Based on 2006 galvanizing industry survey -nationwide • 2006 KTA-Tator paper paint industry survey – nationwide • Standard mix of steel products (structural, tubing, plate) • 10, 000 ft 2 project 60

Quantitative Analysis Initial cost vs. Life-cycle cost • Based on 2006 galvanizing industry survey -nationwide • 2006 KTA-Tator paper paint industry survey – nationwide • Standard mix of steel products (structural, tubing, plate) • 10, 000 ft 2 project 60

www. galvanizingcost. com Survey data organized in a database Based on specific project data input by the user, (job size & location, coating type, expected service life, etc. ) The web site automatically calculates initial and life-cycle cost for the specified paint systems and hot-dip galvanizing 61

www. galvanizingcost. com Survey data organized in a database Based on specific project data input by the user, (job size & location, coating type, expected service life, etc. ) The web site automatically calculates initial and life-cycle cost for the specified paint systems and hot-dip galvanizing 61

Initial Cost Material Shop cleaning labor Shop application Field labor Pneumatic Bulk Trailers 62

Initial Cost Material Shop cleaning labor Shop application Field labor Pneumatic Bulk Trailers 62

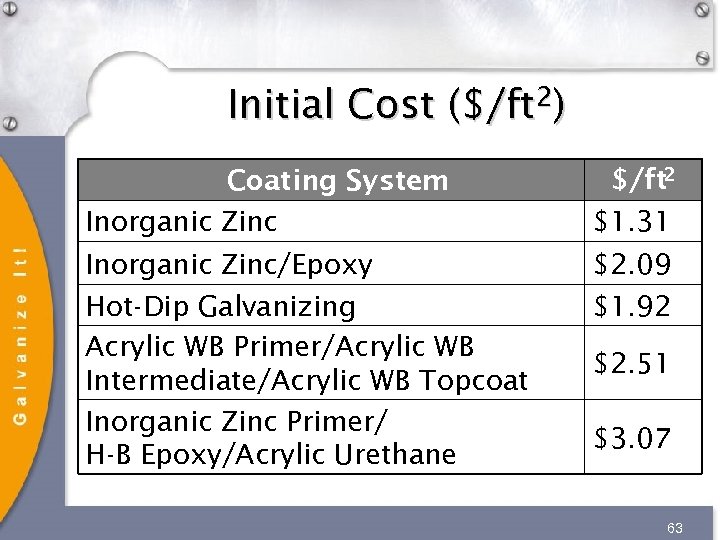

Initial Cost ($/ft 2) Coating System Inorganic Zinc $/ft 2 $1. 31 Inorganic Zinc/Epoxy $2. 09 Hot-Dip Galvanizing Acrylic WB Primer/Acrylic WB Intermediate/Acrylic WB Topcoat Inorganic Zinc Primer/ H-B Epoxy/Acrylic Urethane $1. 92 $2. 51 $3. 07 63

Initial Cost ($/ft 2) Coating System Inorganic Zinc $/ft 2 $1. 31 Inorganic Zinc/Epoxy $2. 09 Hot-Dip Galvanizing Acrylic WB Primer/Acrylic WB Intermediate/Acrylic WB Topcoat Inorganic Zinc Primer/ H-B Epoxy/Acrylic Urethane $1. 92 $2. 51 $3. 07 63

Life-cycle Cost Maintenance on a ‘practical’ (vs. ideal) cycle - unique to each paint system, as recommended by paint manufacturers NACE Model for NFV and NPV calculations • 4% inflation • 7% interest Maintenance repaint at 5% rust in a moderately industrial environment 30 -Year Project Performance 64

Life-cycle Cost Maintenance on a ‘practical’ (vs. ideal) cycle - unique to each paint system, as recommended by paint manufacturers NACE Model for NFV and NPV calculations • 4% inflation • 7% interest Maintenance repaint at 5% rust in a moderately industrial environment 30 -Year Project Performance 64

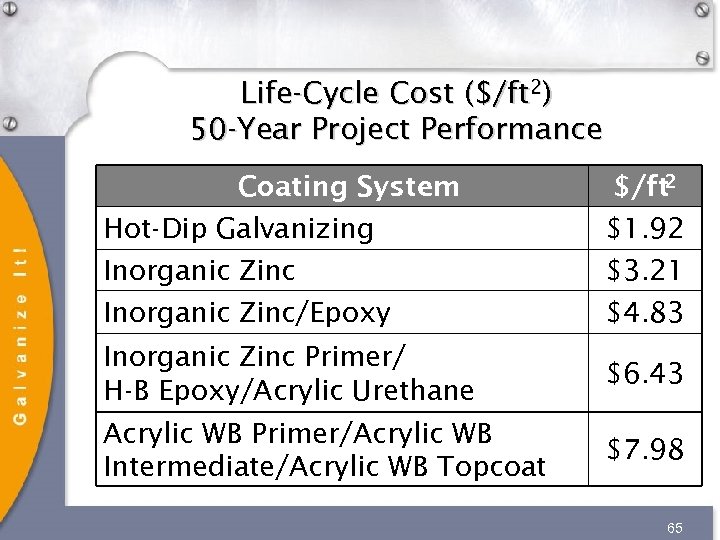

Life-Cycle Cost ($/ft 2) 50 -Year Project Performance $/ft 2 Coating System Hot-Dip Galvanizing $1. 92 Inorganic Zinc/Epoxy $3. 21 $4. 83 Inorganic Zinc Primer/ H-B Epoxy/Acrylic Urethane $6. 43 Acrylic WB Primer/Acrylic WB Intermediate/Acrylic WB Topcoat $7. 98 65

Life-Cycle Cost ($/ft 2) 50 -Year Project Performance $/ft 2 Coating System Hot-Dip Galvanizing $1. 92 Inorganic Zinc/Epoxy $3. 21 $4. 83 Inorganic Zinc Primer/ H-B Epoxy/Acrylic Urethane $6. 43 Acrylic WB Primer/Acrylic WB Intermediate/Acrylic WB Topcoat $7. 98 65

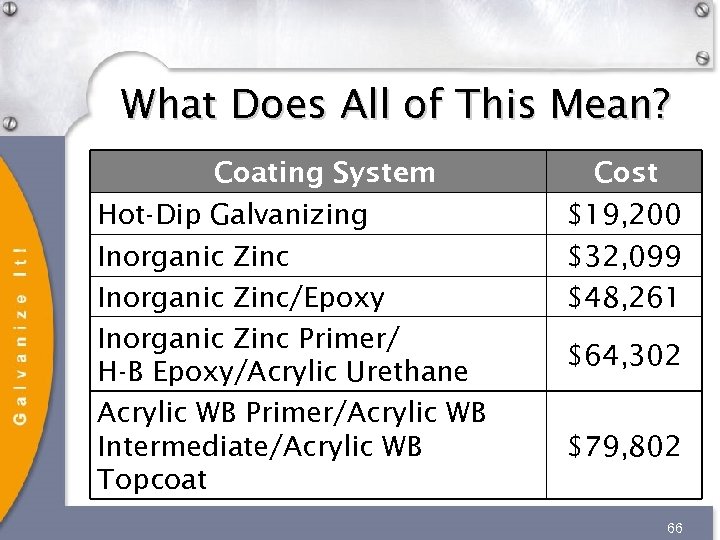

What Does All of This Mean? Coating System Hot-Dip Galvanizing Inorganic Zinc/Epoxy Inorganic Zinc Primer/ H-B Epoxy/Acrylic Urethane Acrylic WB Primer/Acrylic WB Intermediate/Acrylic WB Topcoat Cost $19, 200 $32, 099 $48, 261 $64, 302 $79, 802 66

What Does All of This Mean? Coating System Hot-Dip Galvanizing Inorganic Zinc/Epoxy Inorganic Zinc Primer/ H-B Epoxy/Acrylic Urethane Acrylic WB Primer/Acrylic WB Intermediate/Acrylic WB Topcoat Cost $19, 200 $32, 099 $48, 261 $64, 302 $79, 802 66

Duplex Systems: Painting & Powder Coating Hot-Dip Galvanized Steel

Duplex Systems: Painting & Powder Coating Hot-Dip Galvanized Steel

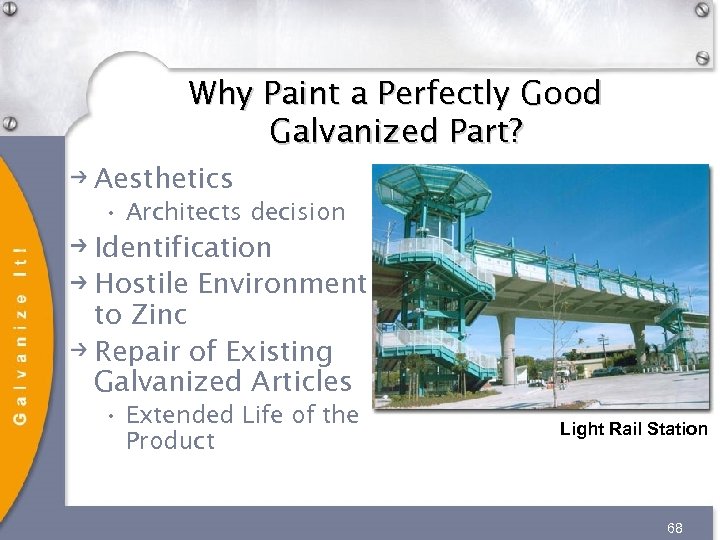

Why Paint a Perfectly Good Galvanized Part? Aesthetics • Architects decision Identification Hostile Environment to Zinc Repair of Existing Galvanized Articles • Extended Life of the Product Light Rail Station 68

Why Paint a Perfectly Good Galvanized Part? Aesthetics • Architects decision Identification Hostile Environment to Zinc Repair of Existing Galvanized Articles • Extended Life of the Product Light Rail Station 68

Galvanized Surface Coating Condition Newly Galvanized Steel Partially Weathered Galvanized Steel Fully Weathered Galvanized Steel Painted Bridge Rail 69

Galvanized Surface Coating Condition Newly Galvanized Steel Partially Weathered Galvanized Steel Fully Weathered Galvanized Steel Painted Bridge Rail 69

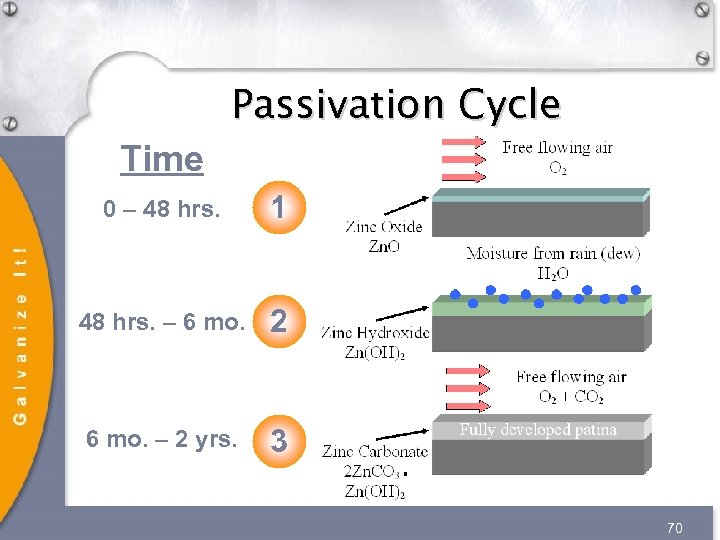

Passivation Cycle Time 0 – 48 hrs. 1 48 hrs. – 6 mo. 2 6 mo. – 2 yrs. 3 70

Passivation Cycle Time 0 – 48 hrs. 1 48 hrs. – 6 mo. 2 6 mo. – 2 yrs. 3 70

Sweep Blasting 71

Sweep Blasting 71

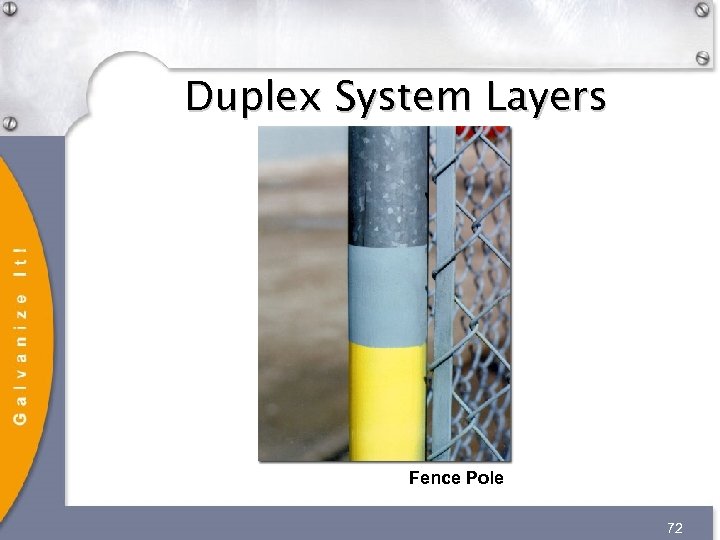

Duplex System Layers Fence Pole 72

Duplex System Layers Fence Pole 72

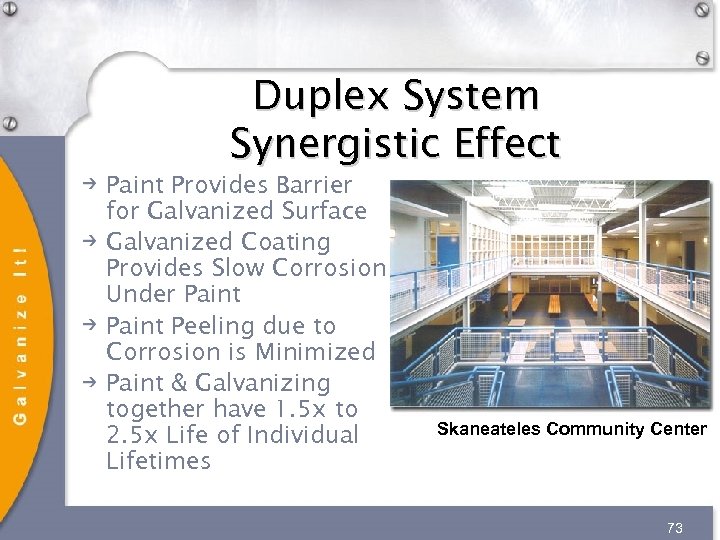

Duplex System Synergistic Effect Paint Provides Barrier for Galvanized Surface Galvanized Coating Provides Slow Corrosion Under Paint Peeling due to Corrosion is Minimized Paint & Galvanizing together have 1. 5 x to 2. 5 x Life of Individual Lifetimes Skaneateles Community Center 73

Duplex System Synergistic Effect Paint Provides Barrier for Galvanized Surface Galvanized Coating Provides Slow Corrosion Under Paint Peeling due to Corrosion is Minimized Paint & Galvanizing together have 1. 5 x to 2. 5 x Life of Individual Lifetimes Skaneateles Community Center 73

Galvanized Steel Project Applications

Galvanized Steel Project Applications

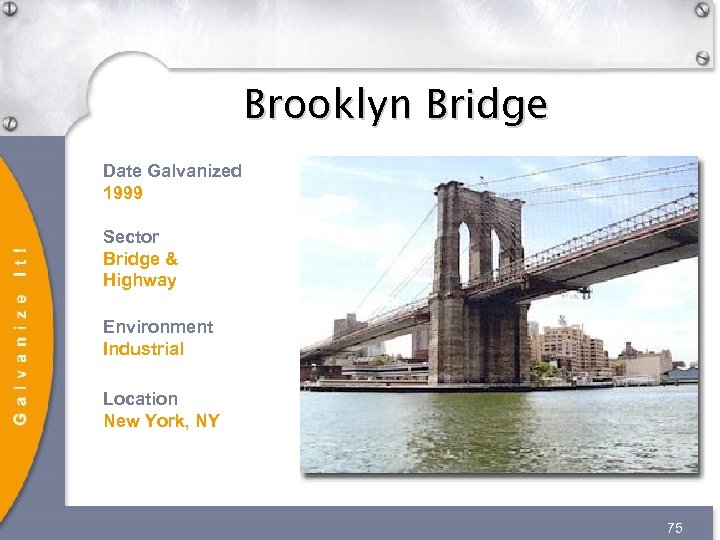

Brooklyn Bridge Date Galvanized 1999 Sector Bridge & Highway Environment Industrial Location New York, NY 75

Brooklyn Bridge Date Galvanized 1999 Sector Bridge & Highway Environment Industrial Location New York, NY 75

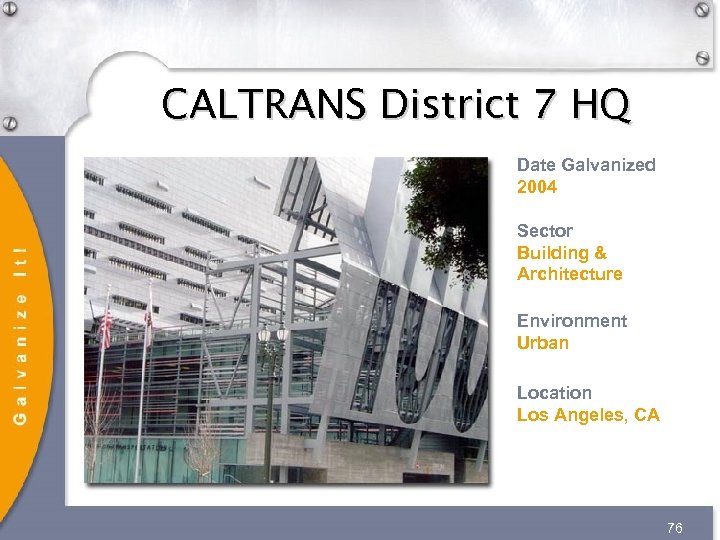

CALTRANS District 7 HQ Date Galvanized 2004 Sector Building & Architecture Environment Urban Location Los Angeles, CA 76

CALTRANS District 7 HQ Date Galvanized 2004 Sector Building & Architecture Environment Urban Location Los Angeles, CA 76

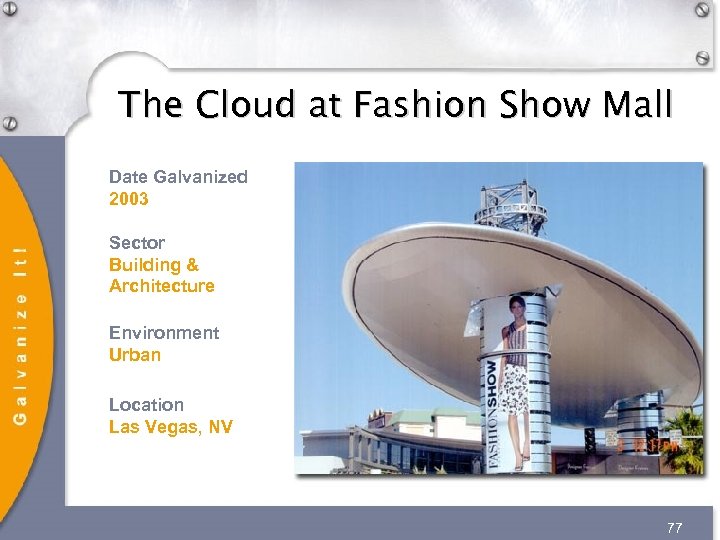

The Cloud at Fashion Show Mall Date Galvanized 2003 Sector Building & Architecture Environment Urban Location Las Vegas, NV 77

The Cloud at Fashion Show Mall Date Galvanized 2003 Sector Building & Architecture Environment Urban Location Las Vegas, NV 77

Harrisburg Airport Transportation Facility Date Galvanized 2004 Sector Building & Architecture Environment Urban Location Harrisburg, PA 78

Harrisburg Airport Transportation Facility Date Galvanized 2004 Sector Building & Architecture Environment Urban Location Harrisburg, PA 78

Cell Towers – Tree Application Date Galvanized 2004 Sector Electrical, Utility & Communication Environment Rural Location California 79

Cell Towers – Tree Application Date Galvanized 2004 Sector Electrical, Utility & Communication Environment Rural Location California 79

Leprino Foods Date Galvanized Unknown Sector Food & Agriculture Environment Rural Location Waverly, NY 80

Leprino Foods Date Galvanized Unknown Sector Food & Agriculture Environment Rural Location Waverly, NY 80

Piers 1 & 21 Replacement Date Galvanized 2002 Sector Water & Marine Environment Marine Location Norfolk, VA 81

Piers 1 & 21 Replacement Date Galvanized 2002 Sector Water & Marine Environment Marine Location Norfolk, VA 81

AGA Resources 1 -800 -HOT-SPEC (800. 468. 7732) aga@galvanizeit. org www. galvanizeit. org Technical Library Galvanizing Insights e-Newsletter 82

AGA Resources 1 -800 -HOT-SPEC (800. 468. 7732) aga@galvanizeit. org www. galvanizeit. org Technical Library Galvanizing Insights e-Newsletter 82