3e9be4684a8df6e6ea46a6e7ed52ddcf.ppt

- Количество слайдов: 51

Future Wood Products Technology June 22 nd 2009 Western Hardwoods Association Annual Meeting Sunriver, OR Scott Leavengood Oregon State University

Future Wood Products Technology June 22 nd 2009 Western Hardwoods Association Annual Meeting Sunriver, OR Scott Leavengood Oregon State University

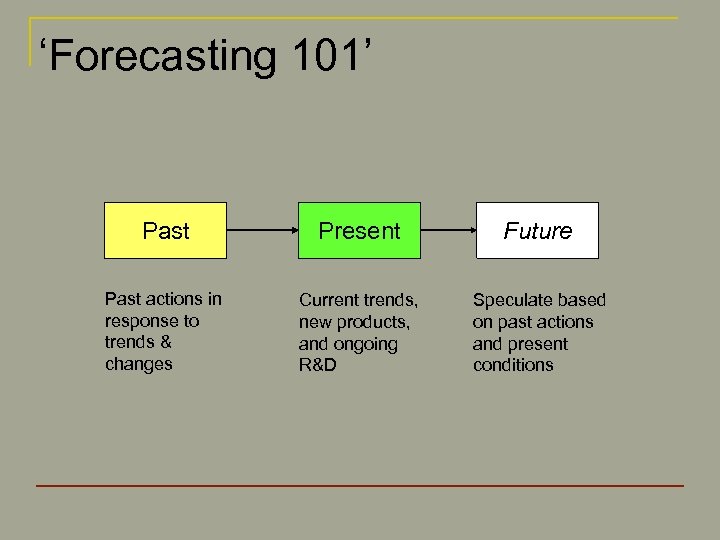

‘Forecasting 101’ Past Present Future Past actions in response to trends & changes Current trends, new products, and ongoing R&D Speculate based on past actions and present conditions

‘Forecasting 101’ Past Present Future Past actions in response to trends & changes Current trends, new products, and ongoing R&D Speculate based on past actions and present conditions

Outline • Past & Present - Industry trends • Present - New product/process examples • Implications for western hardwoods

Outline • Past & Present - Industry trends • Present - New product/process examples • Implications for western hardwoods

Industry Trends • Consolidation & restructuring • Market shifts – – Shifts in channel power Environmental pressure Substitute products Interest in ‘decoupling’ from housing • Globalization • All things ‘Bio’ • Green building

Industry Trends • Consolidation & restructuring • Market shifts – – Shifts in channel power Environmental pressure Substitute products Interest in ‘decoupling’ from housing • Globalization • All things ‘Bio’ • Green building

Globalization

Globalization

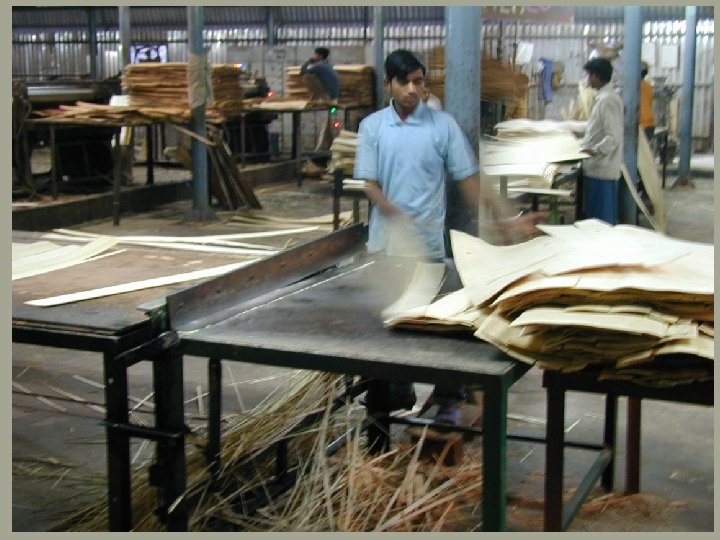

India – hardwood plywood

India – hardwood plywood

They have labor, but we have quality Right?

They have labor, but we have quality Right?

Vietnam – furniture

Vietnam – furniture

Industry Trends • • • Consolidation Restructuring Market shifts Globalization All things ‘Bio’ Green building

Industry Trends • • • Consolidation Restructuring Market shifts Globalization All things ‘Bio’ Green building

All Things ‘Bio’ • • • Biomass University of Minnesota's Bioenergy Department of Wood & Paper Science changed name to Biofuels Department of Bio-based Products Biorefining Bio-based products Bio-economy

All Things ‘Bio’ • • • Biomass University of Minnesota's Bioenergy Department of Wood & Paper Science changed name to Biofuels Department of Bio-based Products Biorefining Bio-based products Bio-economy

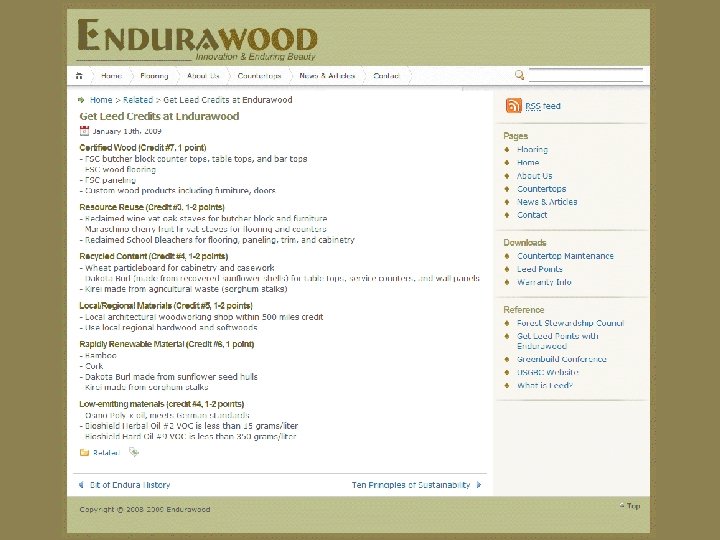

Green Building • Variety of programs – National: LEED, Green Globes – State & Local: CA (Green Builder), WI, CO, King County (WA), Austin (TX) • Credits for environmental-friendliness – For example, LEED-NC: 69 possible credits in 6 categories • • • Sustainable Sites Water Efficiency Energy & Atmosphere Materials & Resources Indoor Air Quality Innovation & Design Process

Green Building • Variety of programs – National: LEED, Green Globes – State & Local: CA (Green Builder), WI, CO, King County (WA), Austin (TX) • Credits for environmental-friendliness – For example, LEED-NC: 69 possible credits in 6 categories • • • Sustainable Sites Water Efficiency Energy & Atmosphere Materials & Resources Indoor Air Quality Innovation & Design Process

Green Building • For LEED-NC, approx. 19% of credits related to Materials & Resources – – – – Reduction of construction waste Use of salvaged/reused materials Materials w/ recycled content Local/regional materials (harvest & manufacture) FSC certified Rapidly renewable Low-emitting materials • Biased against wood? – Supply is a significant challenge – Commercial construction - building codes may be most limiting factor

Green Building • For LEED-NC, approx. 19% of credits related to Materials & Resources – – – – Reduction of construction waste Use of salvaged/reused materials Materials w/ recycled content Local/regional materials (harvest & manufacture) FSC certified Rapidly renewable Low-emitting materials • Biased against wood? – Supply is a significant challenge – Commercial construction - building codes may be most limiting factor

The future? I just want to say one word to you — just one word. Plastics. There's a great future in plastics. The Graduate

The future? I just want to say one word to you — just one word. Plastics. There's a great future in plastics. The Graduate

The future? "I just want to say one word to you — just one word. Glue. There's a great future in glue. " The Graduate

The future? "I just want to say one word to you — just one word. Glue. There's a great future in glue. " The Graduate

The future? "I just want to say one word to you — just one word. Chemistry. There's a great future in chemistry. " The Graduate

The future? "I just want to say one word to you — just one word. Chemistry. There's a great future in chemistry. " The Graduate

New Product/Process Examples • “Better living through chemistry” – Wood-Plastic Composites – “Green” adhesives – Chemical (& ‘mechanical’) modification – Biorefining – Nanotechnology

New Product/Process Examples • “Better living through chemistry” – Wood-Plastic Composites – “Green” adhesives – Chemical (& ‘mechanical’) modification – Biorefining – Nanotechnology

Wood Plastic Composites www. altree. com

Wood Plastic Composites www. altree. com

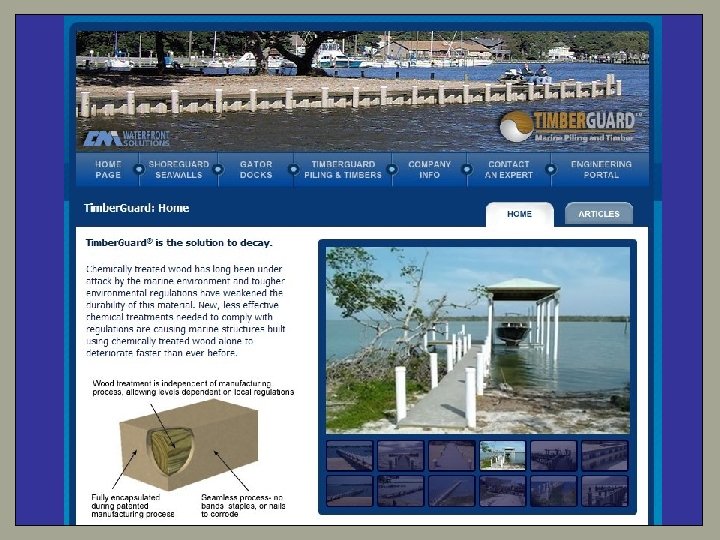

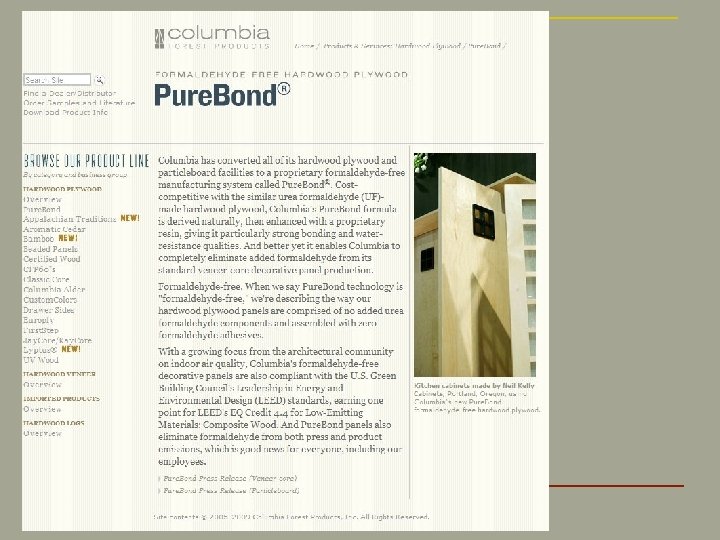

“Green Adhesives”

“Green Adhesives”

Chemical Modification • Polymer-Impregnation • Furfurylation

Chemical Modification • Polymer-Impregnation • Furfurylation

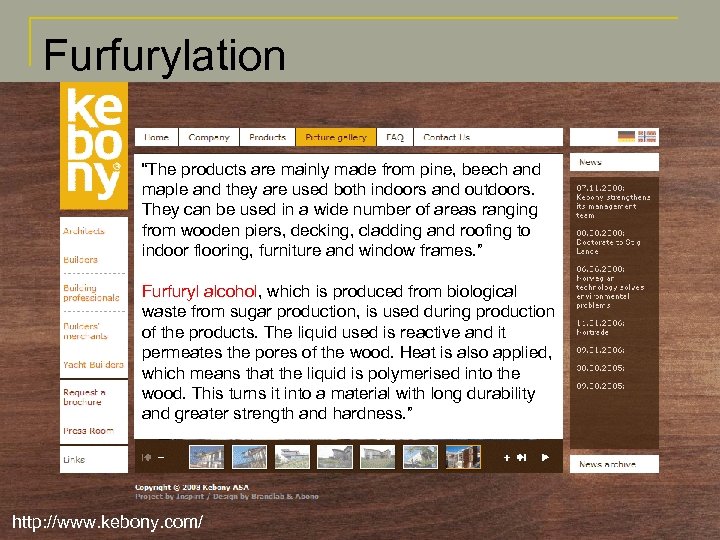

Furfurylation “The products are mainly made from pine, beech and maple and they are used both indoors and outdoors. They can be used in a wide number of areas ranging from wooden piers, decking, cladding and roofing to indoor flooring, furniture and window frames. ” Furfuryl alcohol, which is produced from biological waste from sugar production, is used during production of the products. The liquid used is reactive and it permeates the pores of the wood. Heat is also applied, which means that the liquid is polymerised into the wood. This turns it into a material with long durability and greater strength and hardness. ” http: //www. kebony. com/

Furfurylation “The products are mainly made from pine, beech and maple and they are used both indoors and outdoors. They can be used in a wide number of areas ranging from wooden piers, decking, cladding and roofing to indoor flooring, furniture and window frames. ” Furfuryl alcohol, which is produced from biological waste from sugar production, is used during production of the products. The liquid used is reactive and it permeates the pores of the wood. Heat is also applied, which means that the liquid is polymerised into the wood. This turns it into a material with long durability and greater strength and hardness. ” http: //www. kebony. com/

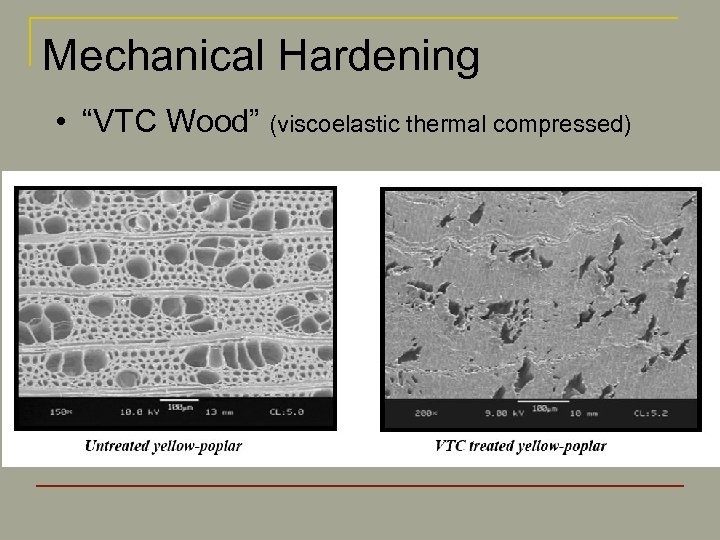

Mechanical Hardening • “VTC Wood” (viscoelastic thermal compressed)

Mechanical Hardening • “VTC Wood” (viscoelastic thermal compressed)

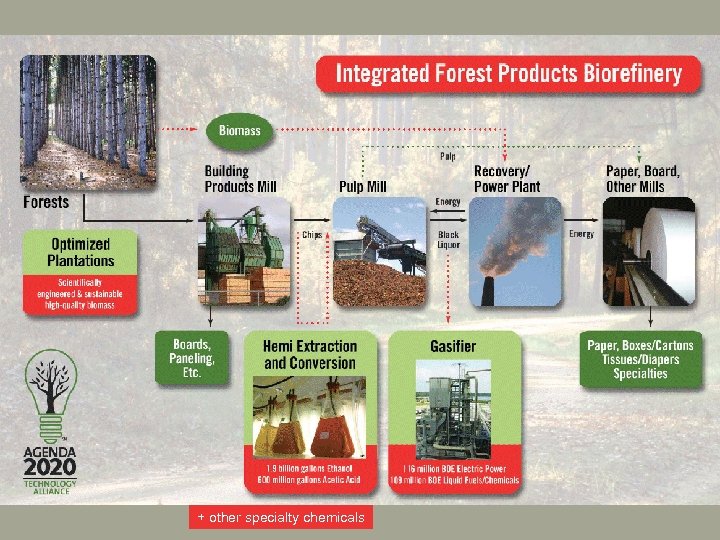

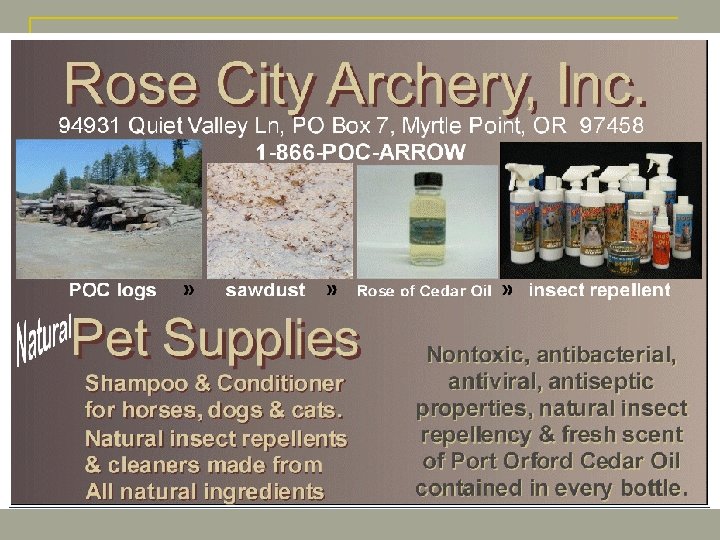

+ other specialty chemicals

+ other specialty chemicals

Products from the biorefinery? • Moulded plastics • Specialty chemicals

Products from the biorefinery? • Moulded plastics • Specialty chemicals

Products from the biorefinery? • Moulded plastics • Specialty chemicals

Products from the biorefinery? • Moulded plastics • Specialty chemicals

Nanotechnology http: //www. nanovations. com. au/Wood. htm

Nanotechnology http: //www. nanovations. com. au/Wood. htm

Implications for Western Hardwoods

Implications for Western Hardwoods

Implications • Key (relevant) trends – Green building & sustainability – Climate change – Energy costs

Implications • Key (relevant) trends – Green building & sustainability – Climate change – Energy costs

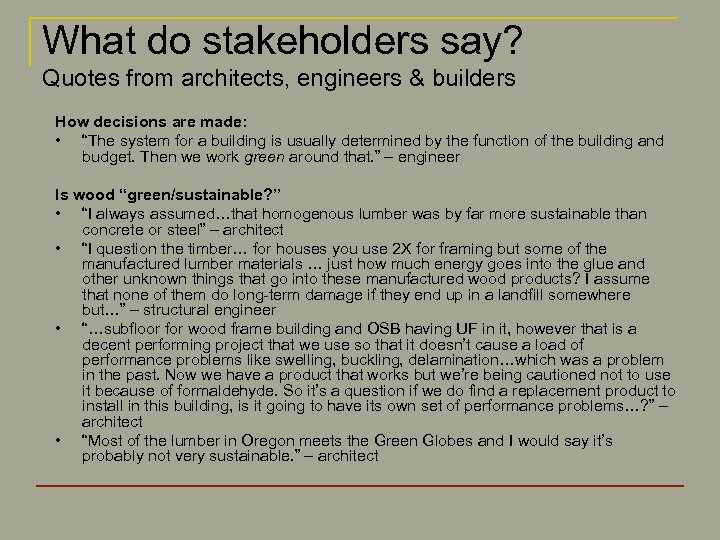

What do stakeholders say? Quotes from architects, engineers & builders How decisions are made: • “The system for a building is usually determined by the function of the building and budget. Then we work green around that. ” – engineer Is wood “green/sustainable? ” • “I always assumed…that homogenous lumber was by far more sustainable than concrete or steel” – architect • “I question the timber… for houses you use 2 X for framing but some of the manufactured lumber materials … just how much energy goes into the glue and other unknown things that go into these manufactured wood products? I assume that none of them do long-term damage if they end up in a landfill somewhere but…” – structural engineer • “…subfloor for wood frame building and OSB having UF in it, however that is a decent performing project that we use so that it doesn’t cause a load of performance problems like swelling, buckling, delamination…which was a problem in the past. Now we have a product that works but we’re being cautioned not to use it because of formaldehyde. So it’s a question if we do find a replacement product to install in this building, is it going to have its own set of performance problems…? ” – architect • “Most of the lumber in Oregon meets the Green Globes and I would say it’s probably not very sustainable. ” – architect

What do stakeholders say? Quotes from architects, engineers & builders How decisions are made: • “The system for a building is usually determined by the function of the building and budget. Then we work green around that. ” – engineer Is wood “green/sustainable? ” • “I always assumed…that homogenous lumber was by far more sustainable than concrete or steel” – architect • “I question the timber… for houses you use 2 X for framing but some of the manufactured lumber materials … just how much energy goes into the glue and other unknown things that go into these manufactured wood products? I assume that none of them do long-term damage if they end up in a landfill somewhere but…” – structural engineer • “…subfloor for wood frame building and OSB having UF in it, however that is a decent performing project that we use so that it doesn’t cause a load of performance problems like swelling, buckling, delamination…which was a problem in the past. Now we have a product that works but we’re being cautioned not to use it because of formaldehyde. So it’s a question if we do find a replacement product to install in this building, is it going to have its own set of performance problems…? ” – architect • “Most of the lumber in Oregon meets the Green Globes and I would say it’s probably not very sustainable. ” – architect

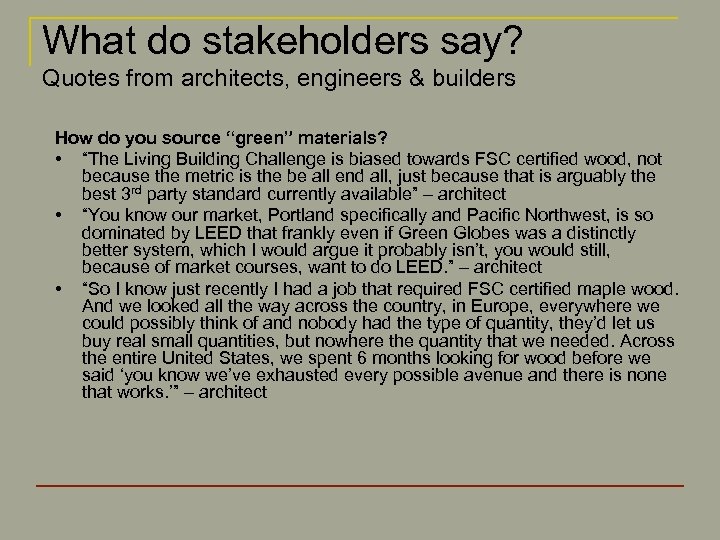

What do stakeholders say? Quotes from architects, engineers & builders How do you source “green” materials? • “The Living Building Challenge is biased towards FSC certified wood, not because the metric is the be all end all, just because that is arguably the best 3 rd party standard currently available” – architect • “You know our market, Portland specifically and Pacific Northwest, is so dominated by LEED that frankly even if Green Globes was a distinctly better system, which I would argue it probably isn’t, you would still, because of market courses, want to do LEED. ” – architect • “So I know just recently I had a job that required FSC certified maple wood. And we looked all the way across the country, in Europe, everywhere we could possibly think of and nobody had the type of quantity, they’d let us buy real small quantities, but nowhere the quantity that we needed. Across the entire United States, we spent 6 months looking for wood before we said ‘you know we’ve exhausted every possible avenue and there is none that works. ’” – architect

What do stakeholders say? Quotes from architects, engineers & builders How do you source “green” materials? • “The Living Building Challenge is biased towards FSC certified wood, not because the metric is the be all end all, just because that is arguably the best 3 rd party standard currently available” – architect • “You know our market, Portland specifically and Pacific Northwest, is so dominated by LEED that frankly even if Green Globes was a distinctly better system, which I would argue it probably isn’t, you would still, because of market courses, want to do LEED. ” – architect • “So I know just recently I had a job that required FSC certified maple wood. And we looked all the way across the country, in Europe, everywhere we could possibly think of and nobody had the type of quantity, they’d let us buy real small quantities, but nowhere the quantity that we needed. Across the entire United States, we spent 6 months looking for wood before we said ‘you know we’ve exhausted every possible avenue and there is none that works. ’” – architect

Implications for Western Hardwoods • “The message”: – Local – Legally harvested from regulated forests – Solid wood • or formaldehyde-free, even ‘resin free’ – Carbon neutral/low-carbon footprint – Renewable

Implications for Western Hardwoods • “The message”: – Local – Legally harvested from regulated forests – Solid wood • or formaldehyde-free, even ‘resin free’ – Carbon neutral/low-carbon footprint – Renewable

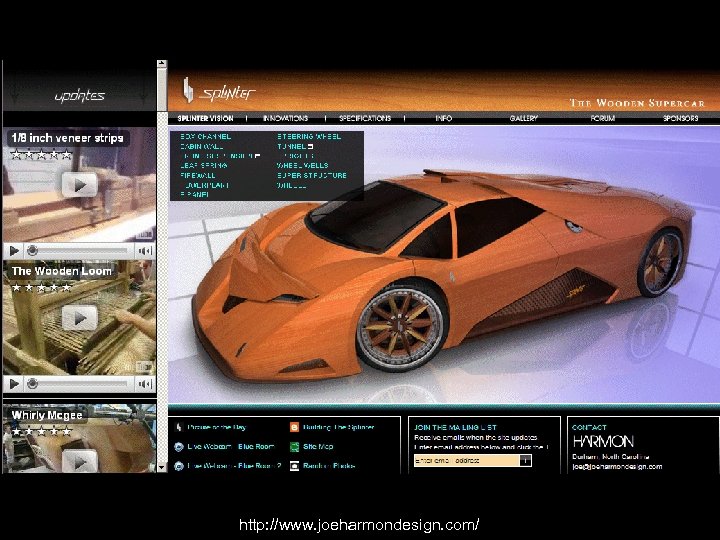

And if that doesn’t rev your engines… http: //www. joeharmondesign. com/

And if that doesn’t rev your engines… http: //www. joeharmondesign. com/

Contact Information Scott Leavengood Director, Oregon Wood Innovation Center Oregon State University 119 Richardson Hall Corvallis, OR 97331 (541) 737 -4212 Scott. Leavengood@oregonstate. edu http: //owic. oregonstate. edu

Contact Information Scott Leavengood Director, Oregon Wood Innovation Center Oregon State University 119 Richardson Hall Corvallis, OR 97331 (541) 737 -4212 Scott. Leavengood@oregonstate. edu http: //owic. oregonstate. edu

Additional Materials

Additional Materials

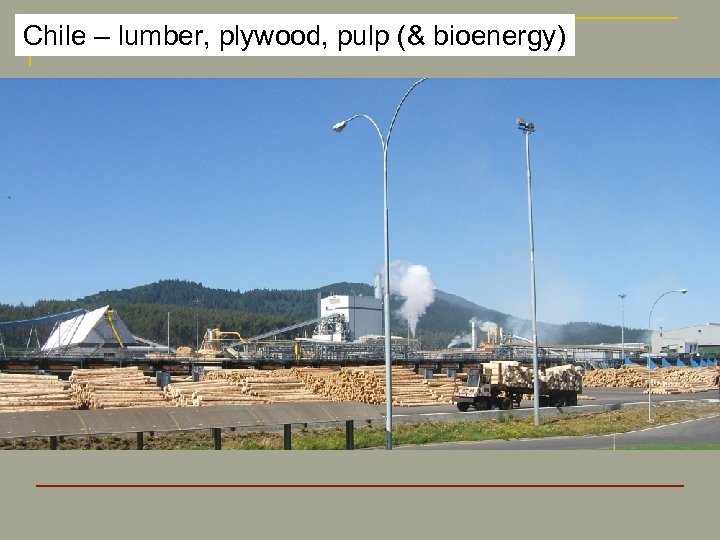

Chile – lumber, plywood, pulp (& bioenergy)

Chile – lumber, plywood, pulp (& bioenergy)

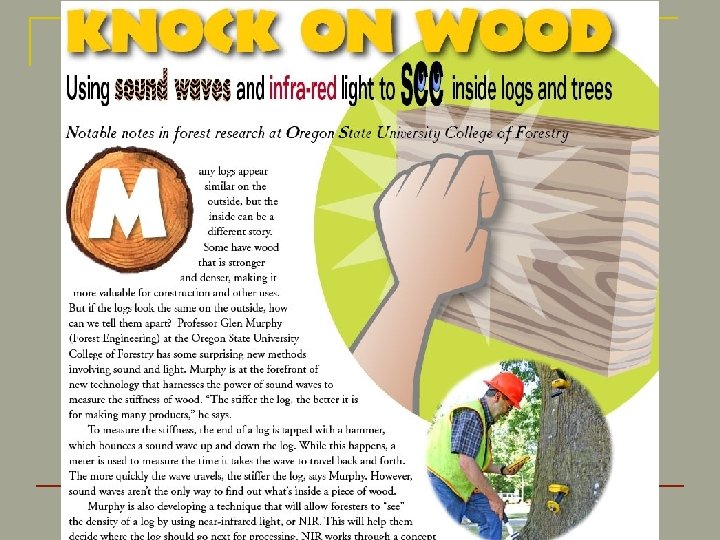

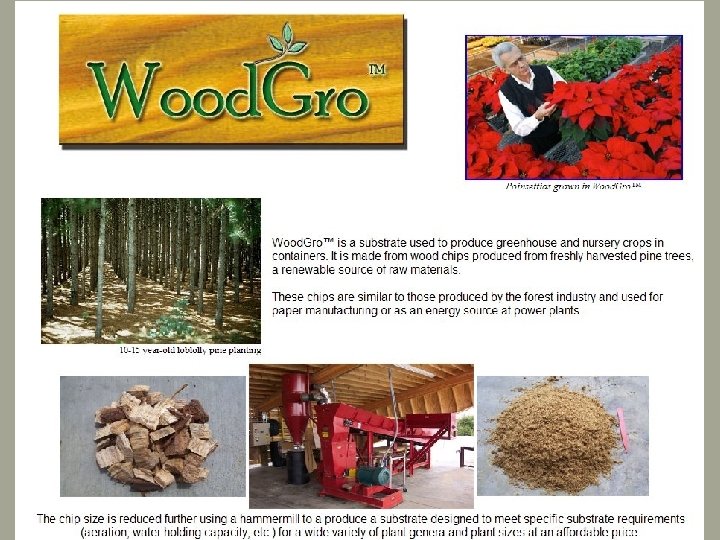

Other ‘technologies’ to watch • Hybrid poplar • Ultrasound and NIR • Biomass for container growing medium

Other ‘technologies’ to watch • Hybrid poplar • Ultrasound and NIR • Biomass for container growing medium

Hybrid Poplar

Hybrid Poplar