398cff13213f362285dd713f0694123f.ppt

- Количество слайдов: 48

FUTURE AEROSPCAE MANUFACTURE AND TECHNOLOGY INTRODUCTION. FUTURE AEROSPCAE INDUSTRY LLC.

FUTURE AEROSPCAE MANUFACTURE AND TECHNOLOGY INTRODUCTION. FUTURE AEROSPCAE INDUSTRY LLC.

Main Content 01 Company Profile Project Management 02 Technology R&D 03 Production Capacity 04 Quality Assurance 05 06 Investment Field Plan 02

Main Content 01 Company Profile Project Management 02 Technology R&D 03 Production Capacity 04 Quality Assurance 05 06 Investment Field Plan 02

01 PART ONE Company Profile

01 PART ONE Company Profile

Company Profile Established on 22 th, Dec. 2009, Sichuan Future Aerospace LLC have one legal entity with two manufacturing sites, of which the headquarter is located in the economic development zone Shifang city, Sichuan province and the branch is located in Changping district, Beijing, (Zhongguancun Science Park). Our company covers an area of more than 1000 mu, including R&D office area of more than 20000 square meters and production area of more than 80000 square meters(6000 square meters for the air-conditioning workshop). Besides, the staff number is 750, including 155 employees for R&D. The total investment reached 3 billion in the end of 2015. 04

Company Profile Established on 22 th, Dec. 2009, Sichuan Future Aerospace LLC have one legal entity with two manufacturing sites, of which the headquarter is located in the economic development zone Shifang city, Sichuan province and the branch is located in Changping district, Beijing, (Zhongguancun Science Park). Our company covers an area of more than 1000 mu, including R&D office area of more than 20000 square meters and production area of more than 80000 square meters(6000 square meters for the air-conditioning workshop). Besides, the staff number is 750, including 155 employees for R&D. The total investment reached 3 billion in the end of 2015. 04

Company Profile Future Aerospace, as a technology-led enterprise, focusing on the development and application of the weight reduction technology of aircraft structural parts and components, makes research and development of a wide range of complex large thinwalled aircraft parts and components, the involved technologies including: application and research of the materials used by Future Aerospace, tooling design, sheet metal forming, CNC processing, special welding, heat treatment, surface treatment, components assembly, comprehensive test. More than 6000 kinds of products have been developed and in batch production. 05

Company Profile Future Aerospace, as a technology-led enterprise, focusing on the development and application of the weight reduction technology of aircraft structural parts and components, makes research and development of a wide range of complex large thinwalled aircraft parts and components, the involved technologies including: application and research of the materials used by Future Aerospace, tooling design, sheet metal forming, CNC processing, special welding, heat treatment, surface treatment, components assembly, comprehensive test. More than 6000 kinds of products have been developed and in batch production. 05

Company Profile CHAIRMAN Mr. Han Hua, as the chairman and CEO of Future Aerospace, who set up two companies, Beijing Asia Titanium Company and Sichuan Future Aerospace Industry LLC, always devotes himself to the aerospace business. Obtaining many national patents and getting the third prize for China innovation and entrepreneurship competition in 2014, Mr. Han has made a big contribution to the local economy of the two regions. 06

Company Profile CHAIRMAN Mr. Han Hua, as the chairman and CEO of Future Aerospace, who set up two companies, Beijing Asia Titanium Company and Sichuan Future Aerospace Industry LLC, always devotes himself to the aerospace business. Obtaining many national patents and getting the third prize for China innovation and entrepreneurship competition in 2014, Mr. Han has made a big contribution to the local economy of the two regions. 06

Company Profile EVENT CHRONICLE 2010 > Broke ground in Shifang Economic Development Zone, Sichuan Province, China. 2011 > Passed AS 9100/C quality system certificate 2011 > Obtained high-tech enterprise certificate of Sichuan province. 2012 > Obtained Nadcap authentication certificates (special welding and heat treatment). 2015 > Our technology center was identified as a national technology center. 2015 > Our asset reconstruction program was approved by CSRC without strings and the transaction values reached 3. 6 billion RMB, which marked we formally accessed to the capital market. 07

Company Profile EVENT CHRONICLE 2010 > Broke ground in Shifang Economic Development Zone, Sichuan Province, China. 2011 > Passed AS 9100/C quality system certificate 2011 > Obtained high-tech enterprise certificate of Sichuan province. 2012 > Obtained Nadcap authentication certificates (special welding and heat treatment). 2015 > Our technology center was identified as a national technology center. 2015 > Our asset reconstruction program was approved by CSRC without strings and the transaction values reached 3. 6 billion RMB, which marked we formally accessed to the capital market. 07

Company Profile EVENT CHRONICLE 2010 > Broke ground in Shifang Economic Development Zone, Sichuan Province, China. 2011 > Passed AS 9100/C quality system certificate 2011 > Obtained high-tech enterprise certificate of Sichuan province. 2012 > Obtained Nadcap authentication certificates (special welding and heat treatment). 2015 > Our technology center was identified as a national technology center. 2015 > Our asset reconstruction program was approved by CSRC without strings and the transaction values reached 3. 6 billion RMB, which marked we formally accessed to the capital market. 07

Company Profile EVENT CHRONICLE 2010 > Broke ground in Shifang Economic Development Zone, Sichuan Province, China. 2011 > Passed AS 9100/C quality system certificate 2011 > Obtained high-tech enterprise certificate of Sichuan province. 2012 > Obtained Nadcap authentication certificates (special welding and heat treatment). 2015 > Our technology center was identified as a national technology center. 2015 > Our asset reconstruction program was approved by CSRC without strings and the transaction values reached 3. 6 billion RMB, which marked we formally accessed to the capital market. 07

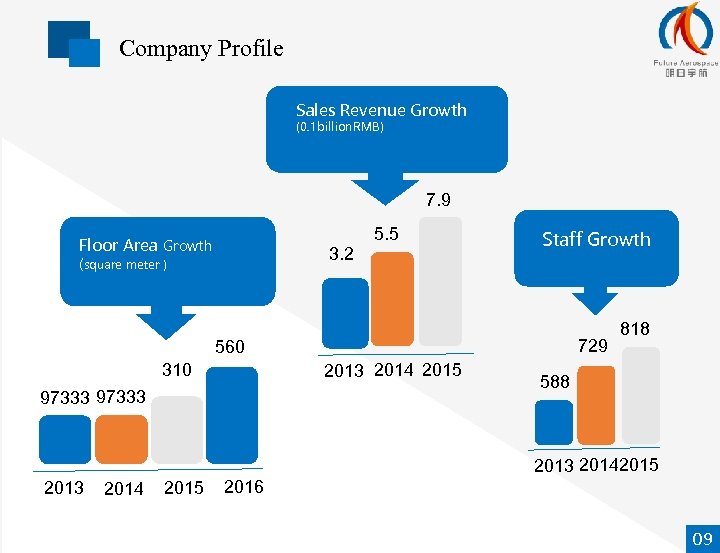

Company Profile Sales Revenue Growth (0. 1 billion. RMB) 7. 9 Floor Area Growth 3. 2 (square meter ) 5. 5 Staff Growth 729 560 2013 2014 2015 310 97333 818 588 2013 20142015 2013 2014 2015 2016 09

Company Profile Sales Revenue Growth (0. 1 billion. RMB) 7. 9 Floor Area Growth 3. 2 (square meter ) 5. 5 Staff Growth 729 560 2013 2014 2015 310 97333 818 588 2013 20142015 2013 2014 2015 2016 09

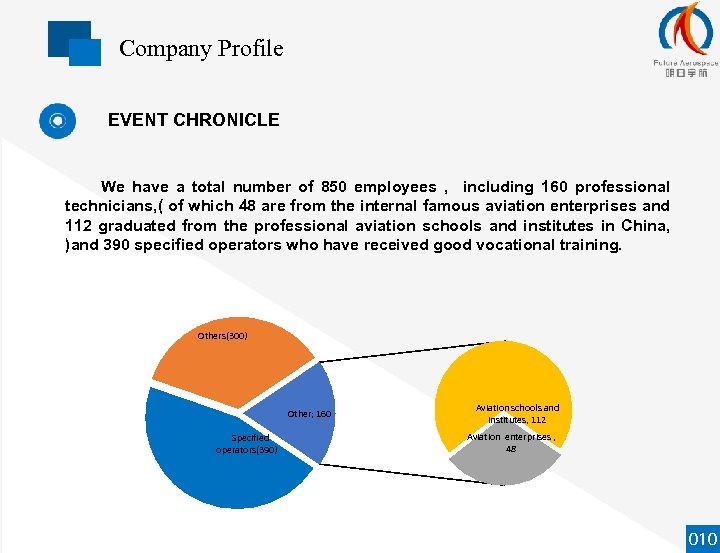

Company Profile EVENT CHRONICLE We have a total number of 850 employees , including 160 professional technicians, ( of which 48 are from the internal famous aviation enterprises and 112 graduated from the professional aviation schools and institutes in China, )and 390 specified operators who have received good vocational training. Others(300) Other; 160 Specified operators(390) Aviation schools and institutes, 112 Aviation enterprises , 48 010

Company Profile EVENT CHRONICLE We have a total number of 850 employees , including 160 professional technicians, ( of which 48 are from the internal famous aviation enterprises and 112 graduated from the professional aviation schools and institutes in China, )and 390 specified operators who have received good vocational training. Others(300) Other; 160 Specified operators(390) Aviation schools and institutes, 112 Aviation enterprises , 48 010

Company Profile MAJOR PRODUCT Aircraft Structural Parts Frame, beam, rib, joint, panel, stringer,edge strip and landing gear. Engine Structural Parts Engine casing, blisk, blade, thrust reverser,vectored nozzle and gas combustion parts Tooling Design and manufacturing of forming mold, vacuum fixture, special gauge, welding tool, machining tool and assembly jig. New Materials Light high-strength titanium alloy with melting point of 700 degrees, refractory alloy and surface modification material. 11

Company Profile MAJOR PRODUCT Aircraft Structural Parts Frame, beam, rib, joint, panel, stringer,edge strip and landing gear. Engine Structural Parts Engine casing, blisk, blade, thrust reverser,vectored nozzle and gas combustion parts Tooling Design and manufacturing of forming mold, vacuum fixture, special gauge, welding tool, machining tool and assembly jig. New Materials Light high-strength titanium alloy with melting point of 700 degrees, refractory alloy and surface modification material. 11

02 PART TWO Project Management

02 PART TWO Project Management

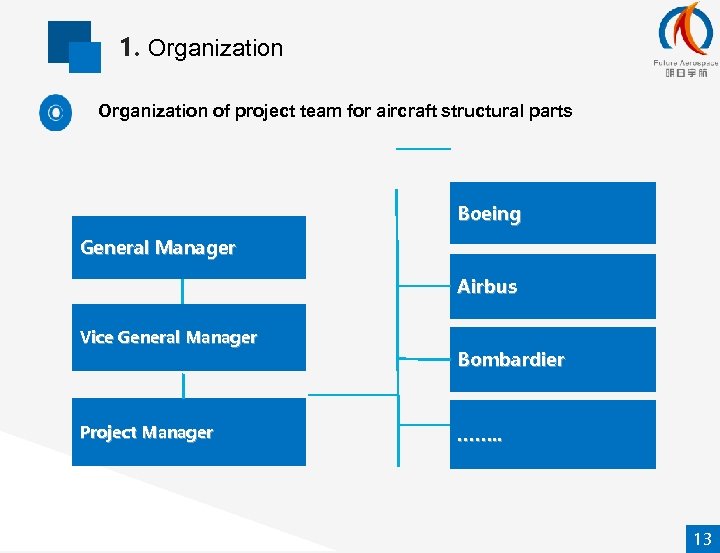

1. Organization of project team for aircraft structural parts Boeing General Manager Airbus Vice General Manager Project Manager Bombardier ……. . 13

1. Organization of project team for aircraft structural parts Boeing General Manager Airbus Vice General Manager Project Manager Bombardier ……. . 13

2、Management Platform Adoption: With MES and CAPP, the advanced manufacturing execution systems , have been found as the basic operation and controlling platform of project management procedure. Execution: □project planning □cost analysis □ automatic scheduling of work plans □ equipment management □ management of fixture and tool Realization: project management of low cost, high quality and JIT. 14

2、Management Platform Adoption: With MES and CAPP, the advanced manufacturing execution systems , have been found as the basic operation and controlling platform of project management procedure. Execution: □project planning □cost analysis □ automatic scheduling of work plans □ equipment management □ management of fixture and tool Realization: project management of low cost, high quality and JIT. 14

3. Project Management Concept STRONG COMPETITIVENESS Modern and effective production equipment organized , professional team and technology, cooperative resources. RELIABLE ORGANISATION which guarantees the processes implemented and the quality of the delivered products. 15

3. Project Management Concept STRONG COMPETITIVENESS Modern and effective production equipment organized , professional team and technology, cooperative resources. RELIABLE ORGANISATION which guarantees the processes implemented and the quality of the delivered products. 15

3. Project Management Concept A POLIVY OF PERMANENT INNOVATION investment is human and material resources , allowing us to adapt according to our customers needs. A CULTURE OF CONTINUOUS IMPROVEMENT through technical innovation and management innovation , to ensure that enterprises in the industry’s leading position. 16

3. Project Management Concept A POLIVY OF PERMANENT INNOVATION investment is human and material resources , allowing us to adapt according to our customers needs. A CULTURE OF CONTINUOUS IMPROVEMENT through technical innovation and management innovation , to ensure that enterprises in the industry’s leading position. 16

03 PART THREE Technology R&D

03 PART THREE Technology R&D

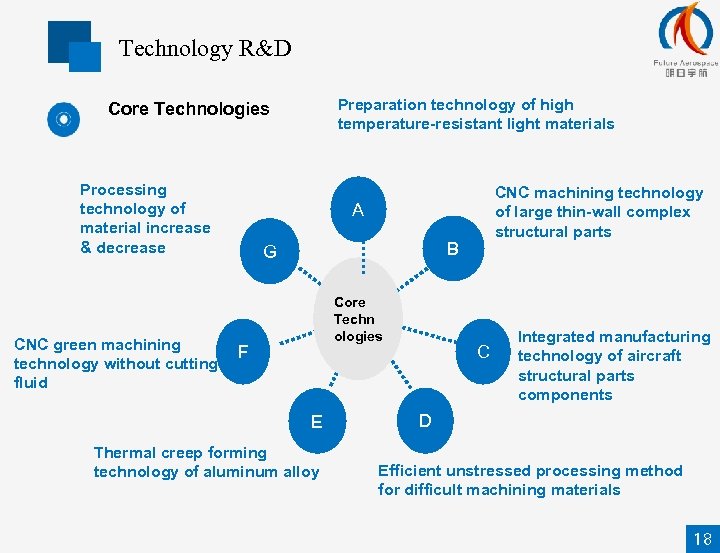

Technology R&D Preparation technology of high temperature-resistant light materials Core Technologies Processing technology of material increase & decrease CNC green machining technology without cutting fluid CNC machining technology of large thin-wall complex structural parts A B G Core Techn ologies F E Thermal creep forming technology of aluminum alloy C Integrated manufacturing technology of aircraft structural parts components D Efficient unstressed processing method for difficult machining materials 18

Technology R&D Preparation technology of high temperature-resistant light materials Core Technologies Processing technology of material increase & decrease CNC green machining technology without cutting fluid CNC machining technology of large thin-wall complex structural parts A B G Core Techn ologies F E Thermal creep forming technology of aluminum alloy C Integrated manufacturing technology of aircraft structural parts components D Efficient unstressed processing method for difficult machining materials 18

Technology R&D method and work process Based on CATIA/UG/CIMATRONE/HYPERMILL found digital model structure & engineering application program. Through VERICUT physical and geometrical simulations verify processing and detection procedures. realize According to CAPP system instruction, digitalized information transfer, receiving and engineering modification. 19

Technology R&D method and work process Based on CATIA/UG/CIMATRONE/HYPERMILL found digital model structure & engineering application program. Through VERICUT physical and geometrical simulations verify processing and detection procedures. realize According to CAPP system instruction, digitalized information transfer, receiving and engineering modification. 19

04 PART FOUR Production Capacity

04 PART FOUR Production Capacity

Production Capacity Engine production line 21

Production Capacity Engine production line 21

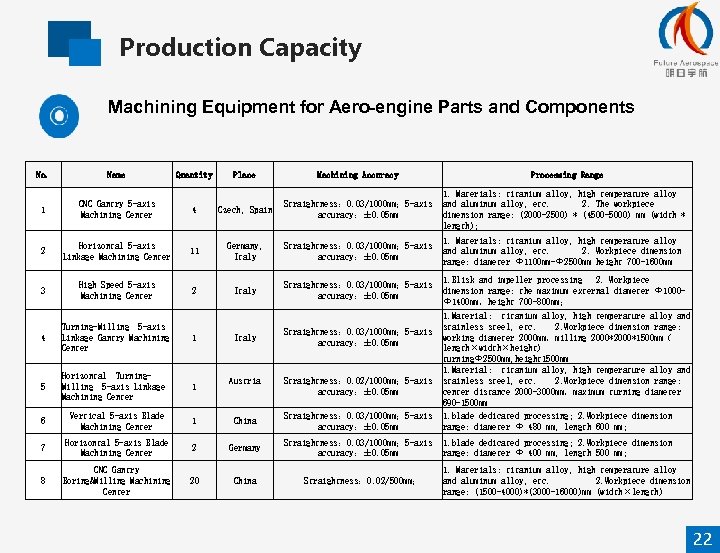

Production Capacity Machining Equipment for Aero-engine Parts and Components No. Name 1 CNC Gantry 5 -axis Machining Center 2 Quantity Place Machining Accuracy 4 Czech, Spain Straightness: 0. 03/1000 mm; 5 -axis accuracy:± 0. 05 mm 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. The workpiece dimension range: (2000 -2500) * (4500 -5000) mm (width * length); Horizontal 5 -axis Linkage Machining Center 11 Germany, Italy Straightness: 0. 03/1000 mm; 5 -axis accuracy:± 0. 05 mm 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. Workpiece dimension range: diameter Ф 1100 mm-Ф 2500 mm height 700 -1600 mm 3 High Speed 5 -axis Machining Center 2 Italy Straightness: 0. 03/1000 mm; 5 -axis accuracy:± 0. 05 mm 1. Blisk and impeller processing 2. Workpiece dimension range: the maximum external diameter Ф 1000 Ф 1400 mm,height 700 -800 mm; 4 Turning-Milling 5 -axis Linkage Gantry Machining Center 1 5 Horizontal Turning. Milling 5 -axis Linkage Machining Center 1 6 Vertical 5 -axis Blade Machining Center 1 China Straightness: 0. 03/1000 mm; 5 -axis accuracy:± 0. 05 mm 1. Material: titanium alloy, high temperature alloy and stainless steel, etc. 2. Workpiece dimension range: working diameter 2000 mm,milling 2000*1500 mm( length×width×height) turning. Ф 2500 mm, height 1500 mm 1. Material: titanium alloy, high temperature alloy and stainless steel, etc. 2. Workpiece dimension range: center distance 2000 -3000 mm,maximum turning diameter 690 -1500 mm 1. blade dedicated processing; 2. Workpiece dimension range: diameter Ф 480 mm, length 600 mm; 7 Horizontal 5 -axis Blade Machining Center 2 Germany Straightness: 0. 03/1000 mm; 5 -axis accuracy:± 0. 05 mm 1. blade dedicated processing; 2. Workpiece dimension range: diameter Ф 400 mm, length 500 mm; 8 CNC Gantry Boring&Milling Machining Center 20 China Italy Austria Straightness: 0. 03/1000 mm; 5 -axis accuracy:± 0. 05 mm Straightness: 0. 02/500 mm; Processing Range 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. Workpiece dimension range: (1500 -4000)*(3000 -16000)mm (width×length) 22

Production Capacity Machining Equipment for Aero-engine Parts and Components No. Name 1 CNC Gantry 5 -axis Machining Center 2 Quantity Place Machining Accuracy 4 Czech, Spain Straightness: 0. 03/1000 mm; 5 -axis accuracy:± 0. 05 mm 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. The workpiece dimension range: (2000 -2500) * (4500 -5000) mm (width * length); Horizontal 5 -axis Linkage Machining Center 11 Germany, Italy Straightness: 0. 03/1000 mm; 5 -axis accuracy:± 0. 05 mm 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. Workpiece dimension range: diameter Ф 1100 mm-Ф 2500 mm height 700 -1600 mm 3 High Speed 5 -axis Machining Center 2 Italy Straightness: 0. 03/1000 mm; 5 -axis accuracy:± 0. 05 mm 1. Blisk and impeller processing 2. Workpiece dimension range: the maximum external diameter Ф 1000 Ф 1400 mm,height 700 -800 mm; 4 Turning-Milling 5 -axis Linkage Gantry Machining Center 1 5 Horizontal Turning. Milling 5 -axis Linkage Machining Center 1 6 Vertical 5 -axis Blade Machining Center 1 China Straightness: 0. 03/1000 mm; 5 -axis accuracy:± 0. 05 mm 1. Material: titanium alloy, high temperature alloy and stainless steel, etc. 2. Workpiece dimension range: working diameter 2000 mm,milling 2000*1500 mm( length×width×height) turning. Ф 2500 mm, height 1500 mm 1. Material: titanium alloy, high temperature alloy and stainless steel, etc. 2. Workpiece dimension range: center distance 2000 -3000 mm,maximum turning diameter 690 -1500 mm 1. blade dedicated processing; 2. Workpiece dimension range: diameter Ф 480 mm, length 600 mm; 7 Horizontal 5 -axis Blade Machining Center 2 Germany Straightness: 0. 03/1000 mm; 5 -axis accuracy:± 0. 05 mm 1. blade dedicated processing; 2. Workpiece dimension range: diameter Ф 400 mm, length 500 mm; 8 CNC Gantry Boring&Milling Machining Center 20 China Italy Austria Straightness: 0. 03/1000 mm; 5 -axis accuracy:± 0. 05 mm Straightness: 0. 02/500 mm; Processing Range 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. Workpiece dimension range: (1500 -4000)*(3000 -16000)mm (width×length) 22

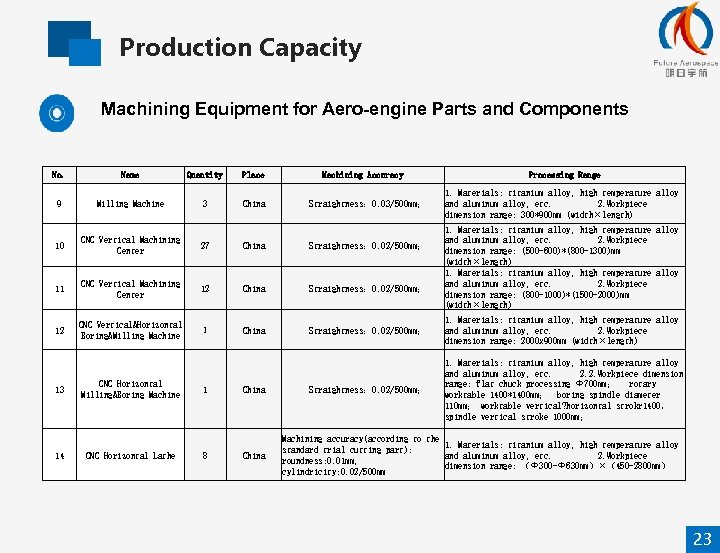

Production Capacity Machining Equipment for Aero-engine Parts and Components No. Name Quantity Place 9 Milling Machine 3 China 10 CNC Vertical Machining Center 27 China Straightness: 0. 02/500 mm; 11 CNC Vertical Machining Center 12 China Straightness: 0. 02/500 mm; 12 CNC Vertical&Horizontal Boring&Milling Machine 1 China Straightness: 0. 02/500 mm; 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. Workpiece dimension range: 2000 x 900 mm (width×length) Straightness: 0. 02/500 mm; 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. 2. Workpiece dimension range: flat chuck processing Ф 700 mm; rotary worktable 1400*1400 mm; boring spindle diameter 110 mm; worktable vertical? horizontal strokr 1400, spindle vertical stroke 1000 mm; 13 14 CNC Horizontal Milling&Boring Machine CNC Horizontal Lathe 1 8 China Machining Accuracy Straightness: 0. 03/500 mm; Processing Range 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. Workpiece dimension range: 300*900 mm (width×length) 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. Workpiece dimension range: (500 -600)*(800 -1300)mm (width×length) 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. Workpiece dimension range: (800 -1000)*(1500 -2000)mm (width×length) Machining accuracy(according to the 1. Materials: titanium alloy, high temperature alloy standard trial cutting part): and aluminum alloy, etc. 2. Workpiece roundness: 0. 01 mm, dimension range: (Ф 300 -Ф 630 mm)×(450 -2800 mm) cylindricity: 0. 02/500 mm 23

Production Capacity Machining Equipment for Aero-engine Parts and Components No. Name Quantity Place 9 Milling Machine 3 China 10 CNC Vertical Machining Center 27 China Straightness: 0. 02/500 mm; 11 CNC Vertical Machining Center 12 China Straightness: 0. 02/500 mm; 12 CNC Vertical&Horizontal Boring&Milling Machine 1 China Straightness: 0. 02/500 mm; 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. Workpiece dimension range: 2000 x 900 mm (width×length) Straightness: 0. 02/500 mm; 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. 2. Workpiece dimension range: flat chuck processing Ф 700 mm; rotary worktable 1400*1400 mm; boring spindle diameter 110 mm; worktable vertical? horizontal strokr 1400, spindle vertical stroke 1000 mm; 13 14 CNC Horizontal Milling&Boring Machine CNC Horizontal Lathe 1 8 China Machining Accuracy Straightness: 0. 03/500 mm; Processing Range 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. Workpiece dimension range: 300*900 mm (width×length) 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. Workpiece dimension range: (500 -600)*(800 -1300)mm (width×length) 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. Workpiece dimension range: (800 -1000)*(1500 -2000)mm (width×length) Machining accuracy(according to the 1. Materials: titanium alloy, high temperature alloy standard trial cutting part): and aluminum alloy, etc. 2. Workpiece roundness: 0. 01 mm, dimension range: (Ф 300 -Ф 630 mm)×(450 -2800 mm) cylindricity: 0. 02/500 mm 23

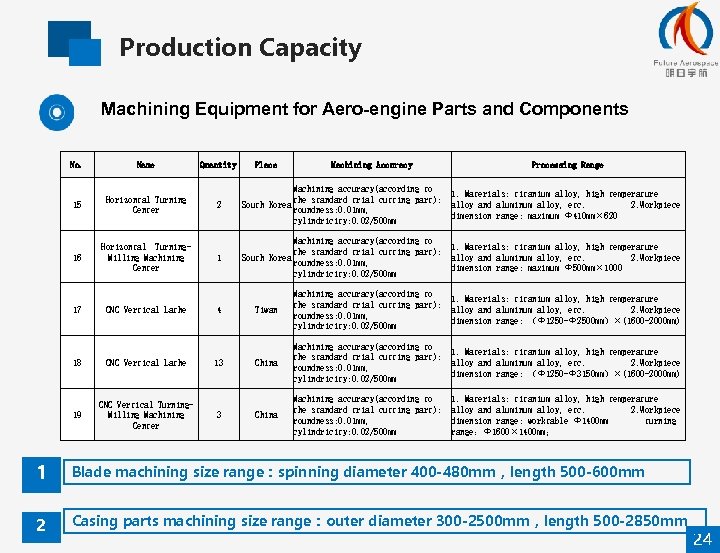

Production Capacity Machining Equipment for Aero-engine Parts and Components No. Name 15 Horizontal Turning Center 16 Horizontal Turning. Milling Machining Center 17 CNC Vertical Lathe 18 CNC Vertical Lathe 19 CNC Vertical Turning. Milling Machining Center Quantity Place Machining Accuracy Processing Range 2 Machining accuracy(according to the standard trial cutting part): South Korea roundness: 0. 01 mm, cylindricity: 0. 02/500 mm 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. Workpiece dimension range: maximum Ф 410 mm× 620 1 Machining accuracy(according to the standard trial cutting part): South Korea roundness: 0. 01 mm, cylindricity: 0. 02/500 mm 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. Workpiece dimension range: maximum Ф 500 mm× 1000 4 Tiwan Machining accuracy(according to the standard trial cutting part): roundness: 0. 01 mm, cylindricity: 0. 02/500 mm 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. Workpiece dimension range: (Ф 1250 -Ф 2500 mm)×(1600 -2000 mm) China Machining accuracy(according to the standard trial cutting part): roundness: 0. 01 mm, cylindricity: 0. 02/500 mm 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. Workpiece dimension range: (Ф 1250 -Ф 3150 mm)×(1600 -2000 mm) China Machining accuracy(according to the standard trial cutting part): roundness: 0. 01 mm, cylindricity: 0. 02/500 mm 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. Workpiece dimension range: worktable Ф 1400 mm turning range:Ф 1600× 1400 mm; 13 3 1 Blade machining size range:spinning diameter 400 -480 mm,length 500 -600 mm 2 Casing parts machining size range:outer diameter 300 -2500 mm,length 500 -2850 mm 24

Production Capacity Machining Equipment for Aero-engine Parts and Components No. Name 15 Horizontal Turning Center 16 Horizontal Turning. Milling Machining Center 17 CNC Vertical Lathe 18 CNC Vertical Lathe 19 CNC Vertical Turning. Milling Machining Center Quantity Place Machining Accuracy Processing Range 2 Machining accuracy(according to the standard trial cutting part): South Korea roundness: 0. 01 mm, cylindricity: 0. 02/500 mm 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. Workpiece dimension range: maximum Ф 410 mm× 620 1 Machining accuracy(according to the standard trial cutting part): South Korea roundness: 0. 01 mm, cylindricity: 0. 02/500 mm 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. Workpiece dimension range: maximum Ф 500 mm× 1000 4 Tiwan Machining accuracy(according to the standard trial cutting part): roundness: 0. 01 mm, cylindricity: 0. 02/500 mm 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. Workpiece dimension range: (Ф 1250 -Ф 2500 mm)×(1600 -2000 mm) China Machining accuracy(according to the standard trial cutting part): roundness: 0. 01 mm, cylindricity: 0. 02/500 mm 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. Workpiece dimension range: (Ф 1250 -Ф 3150 mm)×(1600 -2000 mm) China Machining accuracy(according to the standard trial cutting part): roundness: 0. 01 mm, cylindricity: 0. 02/500 mm 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. Workpiece dimension range: worktable Ф 1400 mm turning range:Ф 1600× 1400 mm; 13 3 1 Blade machining size range:spinning diameter 400 -480 mm,length 500 -600 mm 2 Casing parts machining size range:outer diameter 300 -2500 mm,length 500 -2850 mm 24

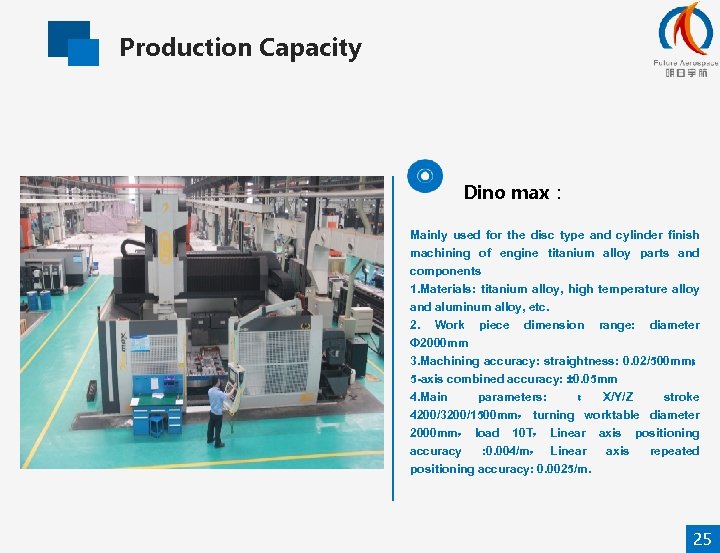

Production Capacity Dino max: Mainly used for the disc type and cylinder finish machining of engine titanium alloy parts and components 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. Work piece dimension range: diameter Ф 2000 mm 3. Machining accuracy: straightness: 0. 02/500 mm; 5 -axis combined accuracy: ± 0. 05 mm 4. Main parameters: : X/Y/Z stroke 4200/3200/1500 mm, turning worktable diameter 2000 mm, load 10 T, Linear axis positioning accuracy : 0. 004/m, Linear axis repeated positioning accuracy: 0. 0025/m. 25

Production Capacity Dino max: Mainly used for the disc type and cylinder finish machining of engine titanium alloy parts and components 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. Work piece dimension range: diameter Ф 2000 mm 3. Machining accuracy: straightness: 0. 02/500 mm; 5 -axis combined accuracy: ± 0. 05 mm 4. Main parameters: : X/Y/Z stroke 4200/3200/1500 mm, turning worktable diameter 2000 mm, load 10 T, Linear axis positioning accuracy : 0. 004/m, Linear axis repeated positioning accuracy: 0. 0025/m. 25

Production Capacity THS-X-TILT 2500 : Mainly used for heavy cutting and finish machining of the titanium alloy rotational parts like blisk, impeller, disc part, and casing part. 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. Work piece dimension range: diameter 2500 mm 3. Main parameters: X/Y/Z stroke 2500/1600/ 2000 mm,maximum work piece processing range 2500 mm,rotary table size. Ф 1600 mm, rotating speed 30 rpm, X/Y/Z repeated positioning accuracy < 0. 003 mm 26

Production Capacity THS-X-TILT 2500 : Mainly used for heavy cutting and finish machining of the titanium alloy rotational parts like blisk, impeller, disc part, and casing part. 1. Materials: titanium alloy, high temperature alloy and aluminum alloy, etc. 2. Work piece dimension range: diameter 2500 mm 3. Main parameters: X/Y/Z stroke 2500/1600/ 2000 mm,maximum work piece processing range 2500 mm,rotary table size. Ф 1600 mm, rotating speed 30 rpm, X/Y/Z repeated positioning accuracy < 0. 003 mm 26

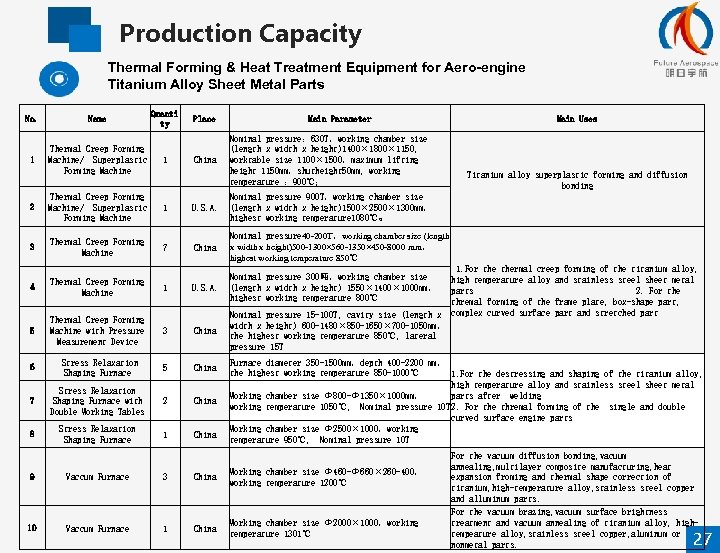

Production Capacity Thermal Forming & Heat Treatment Equipment for Aero-engine Titanium Alloy Sheet Metal Parts Quanti ty No. Name 1 Thermal Creep Forming Machine/ Superplastic Forming Machine 1 2 Thermal Creep Forming Machine/ Superplastic Forming Machine 1 U. S. A. Nominal pressure 900 T,working chamber size (length x width x height)1500× 2500× 1300 mm, highest working temperature 1080℃。 3 Thermal Creep Forming Machine 7 China Nominal pressure 40 -200 T,working chamber size (length x width x height)500 -1300× 560 -1350× 450 -8000 mm, highest working temperature 850℃ 4 Thermal Creep Forming Machine U. S. A. Nominal pressure 300吨,working chamber size (length x width x height) 1550× 1400× 1000 mm, highest working temperature 800℃ 5 Thermal Creep Forming Machine with Pressure Measurement Device 3 China Nominal pressure 15 -100 T, cavity size (length x width x height) 600 -1480× 850 -1650× 700 -1050 mm, the highest working temperature 850℃, lateral pressure 15 T 6 Stress Relaxation Shaping Furnace 5 China 7 Stress Relaxation Shaping Furnace with Double Working Tables 2 China 8 Stress Relaxation Shaping Furnace 1 China 1 Place China Main Parameter Nominal pressure: 630 T,working chamber size (length x width x height)1400× 1800× 1150, worktable size 1100× 1500,maximum lifting height 1150 mm,shutheight 50 mm, working temperature : 900℃; Main Uses Titanium alloy superplastic forming and diffusion bonding 1. For thermal creep forming of the titanium alloy, high temperature alloy and stainless steel sheet metal parts 2. For the thremal forming of the frame plate, box-shape part, complex curved surface part and stretched part Furnace diameter 350 -1500 mm,depth 400 -2200 mm, the highest working temperature 850 -1000℃ 1. For the destressing and shaping of the titanium alloy, high temperature alloy and stainless steel sheet metal Working chamber size Φ 800 -Φ 1350× 1000 mm, parts after welding working temperature 1050℃, Nominal pressure 10 T 2. For the thremal forming of the single and double curved surface engine parts Working chamber size Φ 2500× 1000,working temperature 950℃, Nominal pressure 10 T 9 Vaccum Furnace 3 China Working chamber size Φ 460 -Φ 660× 260 -400, working temperature 1200℃ 10 Vaccum Furnace 1 China Working chamber size Φ 2000× 1000,working temperature 1301℃ For the vacuum diffusion bonding, vacuum annealing, multilayer composite manufacturing, heat expansion froming and thermal shape correction of titanium, high-temperature alloy, stainless steel copper and alluminum parts. For the vacuum brazing, vacuum surface brightness treatment and vacuum annealing of titanium alloy, hightempeature alloy, stainless steel copper, aluminum or nonmetal parts. 27

Production Capacity Thermal Forming & Heat Treatment Equipment for Aero-engine Titanium Alloy Sheet Metal Parts Quanti ty No. Name 1 Thermal Creep Forming Machine/ Superplastic Forming Machine 1 2 Thermal Creep Forming Machine/ Superplastic Forming Machine 1 U. S. A. Nominal pressure 900 T,working chamber size (length x width x height)1500× 2500× 1300 mm, highest working temperature 1080℃。 3 Thermal Creep Forming Machine 7 China Nominal pressure 40 -200 T,working chamber size (length x width x height)500 -1300× 560 -1350× 450 -8000 mm, highest working temperature 850℃ 4 Thermal Creep Forming Machine U. S. A. Nominal pressure 300吨,working chamber size (length x width x height) 1550× 1400× 1000 mm, highest working temperature 800℃ 5 Thermal Creep Forming Machine with Pressure Measurement Device 3 China Nominal pressure 15 -100 T, cavity size (length x width x height) 600 -1480× 850 -1650× 700 -1050 mm, the highest working temperature 850℃, lateral pressure 15 T 6 Stress Relaxation Shaping Furnace 5 China 7 Stress Relaxation Shaping Furnace with Double Working Tables 2 China 8 Stress Relaxation Shaping Furnace 1 China 1 Place China Main Parameter Nominal pressure: 630 T,working chamber size (length x width x height)1400× 1800× 1150, worktable size 1100× 1500,maximum lifting height 1150 mm,shutheight 50 mm, working temperature : 900℃; Main Uses Titanium alloy superplastic forming and diffusion bonding 1. For thermal creep forming of the titanium alloy, high temperature alloy and stainless steel sheet metal parts 2. For the thremal forming of the frame plate, box-shape part, complex curved surface part and stretched part Furnace diameter 350 -1500 mm,depth 400 -2200 mm, the highest working temperature 850 -1000℃ 1. For the destressing and shaping of the titanium alloy, high temperature alloy and stainless steel sheet metal Working chamber size Φ 800 -Φ 1350× 1000 mm, parts after welding working temperature 1050℃, Nominal pressure 10 T 2. For the thremal forming of the single and double curved surface engine parts Working chamber size Φ 2500× 1000,working temperature 950℃, Nominal pressure 10 T 9 Vaccum Furnace 3 China Working chamber size Φ 460 -Φ 660× 260 -400, working temperature 1200℃ 10 Vaccum Furnace 1 China Working chamber size Φ 2000× 1000,working temperature 1301℃ For the vacuum diffusion bonding, vacuum annealing, multilayer composite manufacturing, heat expansion froming and thermal shape correction of titanium, high-temperature alloy, stainless steel copper and alluminum parts. For the vacuum brazing, vacuum surface brightness treatment and vacuum annealing of titanium alloy, hightempeature alloy, stainless steel copper, aluminum or nonmetal parts. 27

Production Capacity HT-ER 200 Thermal Forming Machine: Furnace chamber size 1280× 1350× 850, working temperature: 850℃, nominal pressure: 200 T , used for thermal forming, thermal stretch, and thermal lateral pressure forming of titanium alloy, high temperature alloy and stainless steel parts 28

Production Capacity HT-ER 200 Thermal Forming Machine: Furnace chamber size 1280× 1350× 850, working temperature: 850℃, nominal pressure: 200 T , used for thermal forming, thermal stretch, and thermal lateral pressure forming of titanium alloy, high temperature alloy and stainless steel parts 28

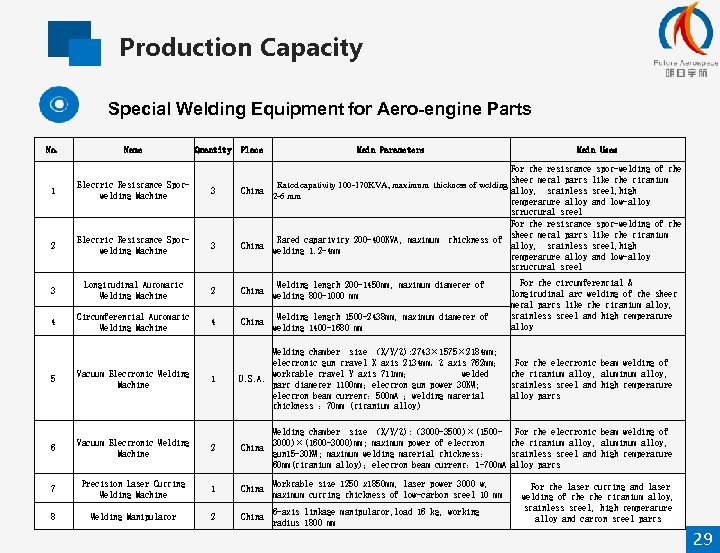

Production Capacity Special Welding Equipment for Aero-engine Parts No. Name Quantity Place Main Parameters Main Uses For the resistance spot-welding of the sheet metal parts like the titanium Rated capativity 100 -170 KVA, maximum thickness of welding China alloy, stainless steel, high 2 -6 mm temperature alloy and low-alloy structural steel For the resistance spot-welding of the sheet metal parts like the titanium Rated capativity 200 -400 KVA, maximum thickness of China alloy, stainless steel, high welding 1. 2 -4 mm temperature alloy and low-alloy structural steel 1 Electric Resistance Spotwelding Machine 3 2 Electric Resistance Spotwelding Machine 3 3 Longitudinal Automatic Welding Machine 2 China Welding length 200 -1450 mm, maximum diameter of welding 800 -1000 mm 4 Circumferential Automatic Welding Machine 4 China Welding length 1500 -2438 mm, maximum diameter of welding 1400 -1680 mm 1 Welding chamber size (X/Y/Z): 2743× 1575× 2184 mm; electronic gun travel X axis 2134 mm,Z axis 762 mm; For the electronic beam welding of worktable travel Y axis 711 mm; welded the titanium alloy, aluminum alloy, U. S. A. part diameter 1100 mm;electron gun power 30 KW; stainless steel and high temperature electron beam current: 500 m. A ;welding material alloy parts thickness : 70 mm (titanium alloy) 5 Vacuum Electronic Welding Machine 6 Vacuum Electronic Welding Machine 2 Welding chamber size (X/Y/Z): (3000 -3500)×(15003000)×(1600 -3000)mm; maximum power of electron China gun 15 -30 KW; maximum welding material thickness: 60 mm(titanium alloy);electron beam current: 1 -700 m. A 7 Precision Laser Cutting Welding Machine 1 China Worktable size 1250 x 1850 mm, laser power 3000 w, maximum cutting thickness of low-carbon steel 10 mm 8 Welding Manipulator 2 China 6 -axis linkage manipulator, load 16 kg, working radius 1800 mm For the circumferential & longitudinal arc welding of the sheet metal parts like the titanium alloy, stainless steel and high temperature alloy For the electronic beam welding of the titanium alloy, aluminum alloy, stainless steel and high temperature alloy parts For the laser cutting and laser welding of the titanium alloy, stainless steel, high temperature alloy and carton steel parts 29

Production Capacity Special Welding Equipment for Aero-engine Parts No. Name Quantity Place Main Parameters Main Uses For the resistance spot-welding of the sheet metal parts like the titanium Rated capativity 100 -170 KVA, maximum thickness of welding China alloy, stainless steel, high 2 -6 mm temperature alloy and low-alloy structural steel For the resistance spot-welding of the sheet metal parts like the titanium Rated capativity 200 -400 KVA, maximum thickness of China alloy, stainless steel, high welding 1. 2 -4 mm temperature alloy and low-alloy structural steel 1 Electric Resistance Spotwelding Machine 3 2 Electric Resistance Spotwelding Machine 3 3 Longitudinal Automatic Welding Machine 2 China Welding length 200 -1450 mm, maximum diameter of welding 800 -1000 mm 4 Circumferential Automatic Welding Machine 4 China Welding length 1500 -2438 mm, maximum diameter of welding 1400 -1680 mm 1 Welding chamber size (X/Y/Z): 2743× 1575× 2184 mm; electronic gun travel X axis 2134 mm,Z axis 762 mm; For the electronic beam welding of worktable travel Y axis 711 mm; welded the titanium alloy, aluminum alloy, U. S. A. part diameter 1100 mm;electron gun power 30 KW; stainless steel and high temperature electron beam current: 500 m. A ;welding material alloy parts thickness : 70 mm (titanium alloy) 5 Vacuum Electronic Welding Machine 6 Vacuum Electronic Welding Machine 2 Welding chamber size (X/Y/Z): (3000 -3500)×(15003000)×(1600 -3000)mm; maximum power of electron China gun 15 -30 KW; maximum welding material thickness: 60 mm(titanium alloy);electron beam current: 1 -700 m. A 7 Precision Laser Cutting Welding Machine 1 China Worktable size 1250 x 1850 mm, laser power 3000 w, maximum cutting thickness of low-carbon steel 10 mm 8 Welding Manipulator 2 China 6 -axis linkage manipulator, load 16 kg, working radius 1800 mm For the circumferential & longitudinal arc welding of the sheet metal parts like the titanium alloy, stainless steel and high temperature alloy For the electronic beam welding of the titanium alloy, aluminum alloy, stainless steel and high temperature alloy parts For the laser cutting and laser welding of the titanium alloy, stainless steel, high temperature alloy and carton steel parts 29

Production Capacity SCIAKY MODEL VX 4. 108 X 62 X 84: Used for the electronic beam welding of the welded parts like titanium alloy part, aluminum alloy part and stainless steel part, etc. Welding chamber size(X/Y/Z): 2743× 1575× 2184 mm; Electronic stroke X axis 2134 mm,Z axis 762 mm; Worktable stroke Y axis 711 mm, Welded part diameter 1100 mm, Electronic gun power 30 KW; electronic beam current: 500 m. A ,Material thickness: 70 mm(titanium alloy). 30

Production Capacity SCIAKY MODEL VX 4. 108 X 62 X 84: Used for the electronic beam welding of the welded parts like titanium alloy part, aluminum alloy part and stainless steel part, etc. Welding chamber size(X/Y/Z): 2743× 1575× 2184 mm; Electronic stroke X axis 2134 mm,Z axis 762 mm; Worktable stroke Y axis 711 mm, Welded part diameter 1100 mm, Electronic gun power 30 KW; electronic beam current: 500 m. A ,Material thickness: 70 mm(titanium alloy). 30

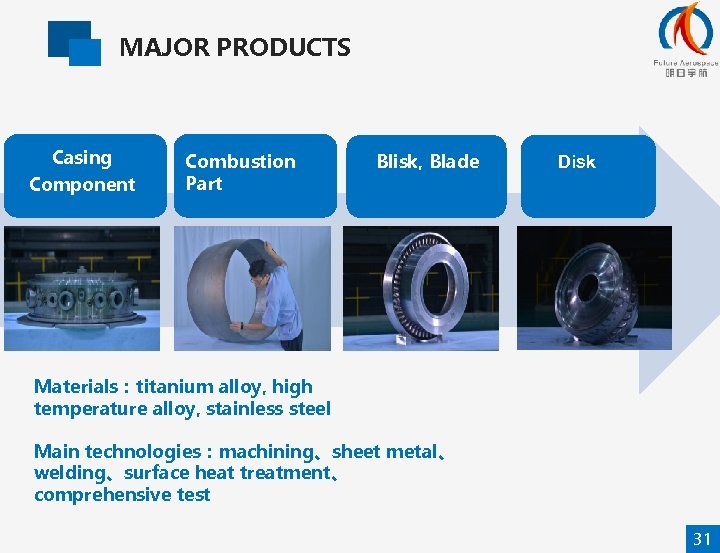

MAJOR PRODUCTS Casing Component Combustion Part Blisk, Blade Disk Materials:titanium alloy, high temperature alloy, stainless steel Main technologies:machining、sheet metal、 welding、surface heat treatment、 comprehensive test 31

MAJOR PRODUCTS Casing Component Combustion Part Blisk, Blade Disk Materials:titanium alloy, high temperature alloy, stainless steel Main technologies:machining、sheet metal、 welding、surface heat treatment、 comprehensive test 31

MAJOR PRODUCTS upper flange panel casing component lower flange 32

MAJOR PRODUCTS upper flange panel casing component lower flange 32

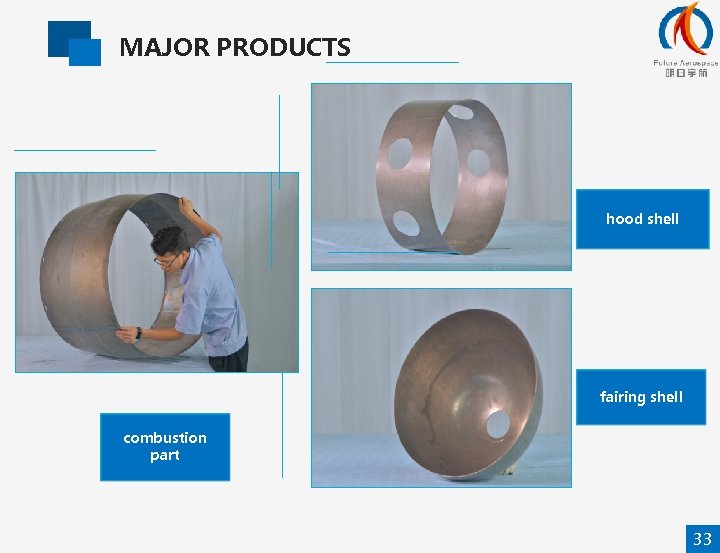

MAJOR PRODUCTS hood shell fairing shell combustion part 33

MAJOR PRODUCTS hood shell fairing shell combustion part 33

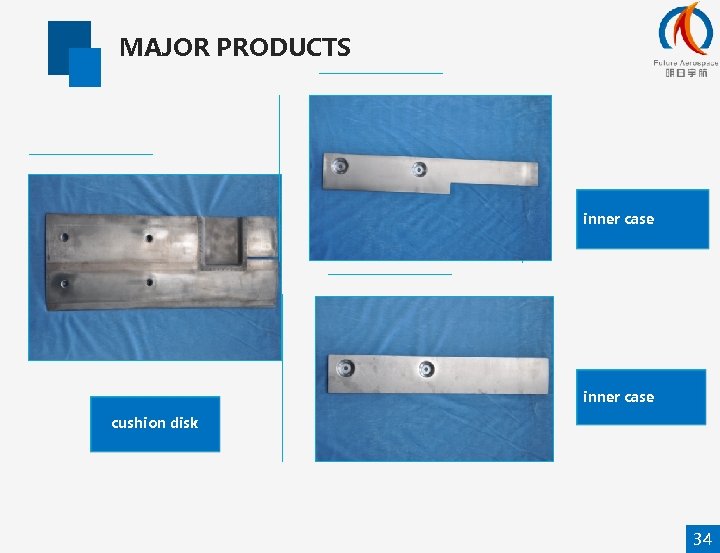

MAJOR PRODUCTS inner case cushion disk 34

MAJOR PRODUCTS inner case cushion disk 34

MAJOR PRODUCTS integral impeller Size: Ø 400 -Ø 800, Blade quantity: 47 -96 Material: titanium alloy, high temperature alloy Processing time: 120 -220 H Main programming software: HYPERMILLUGNX Main equipment: DMG Detection equipment: 35

MAJOR PRODUCTS integral impeller Size: Ø 400 -Ø 800, Blade quantity: 47 -96 Material: titanium alloy, high temperature alloy Processing time: 120 -220 H Main programming software: HYPERMILLUGNX Main equipment: DMG Detection equipment: 35

MAJOR PRODUCTS Disk: five-drum gas compressor disk 36

MAJOR PRODUCTS Disk: five-drum gas compressor disk 36

MAJOR PRODUCTS outer ring inner ring blade Stator blade ring component 37

MAJOR PRODUCTS outer ring inner ring blade Stator blade ring component 37

MAJOR PRODUCTS impeller disk rotary guide shell diffusion casing slot ring 38

MAJOR PRODUCTS impeller disk rotary guide shell diffusion casing slot ring 38

MAJOR PRODUCTS third level guide apparatus front casing diffuser outer panel anti-surge casing 39

MAJOR PRODUCTS third level guide apparatus front casing diffuser outer panel anti-surge casing 39

MAJOR PRODUCTS low pressure inner casing distribution panel diffusion casing 40

MAJOR PRODUCTS low pressure inner casing distribution panel diffusion casing 40

05 PART FIVE Quality Assurance

05 PART FIVE Quality Assurance

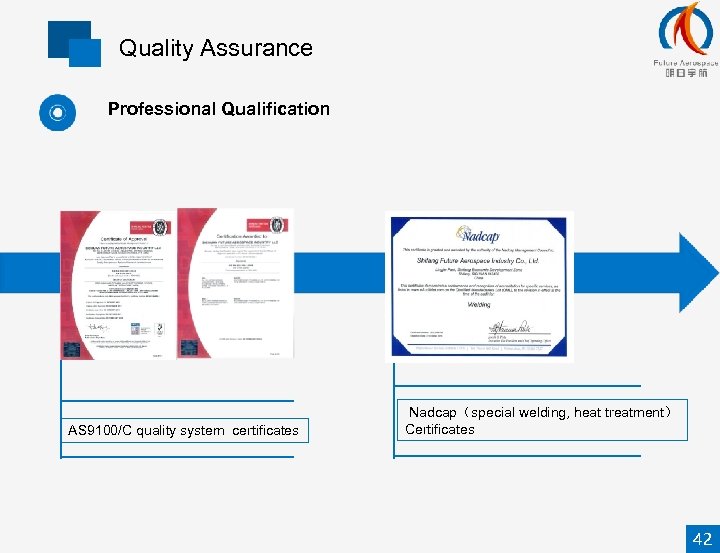

Quality Assurance Professional Qualification AS 9100/C quality system certificates Nadcap(special welding, heat treatment) Certificates 42

Quality Assurance Professional Qualification AS 9100/C quality system certificates Nadcap(special welding, heat treatment) Certificates 42

Quality Assurance Product realization of the whole process of quality Validation of the processes: qualification of special processes, Fist Article Inspection (FAI) report, quality plans. . Control processes integrated into manufacture 43

Quality Assurance Product realization of the whole process of quality Validation of the processes: qualification of special processes, Fist Article Inspection (FAI) report, quality plans. . Control processes integrated into manufacture 43

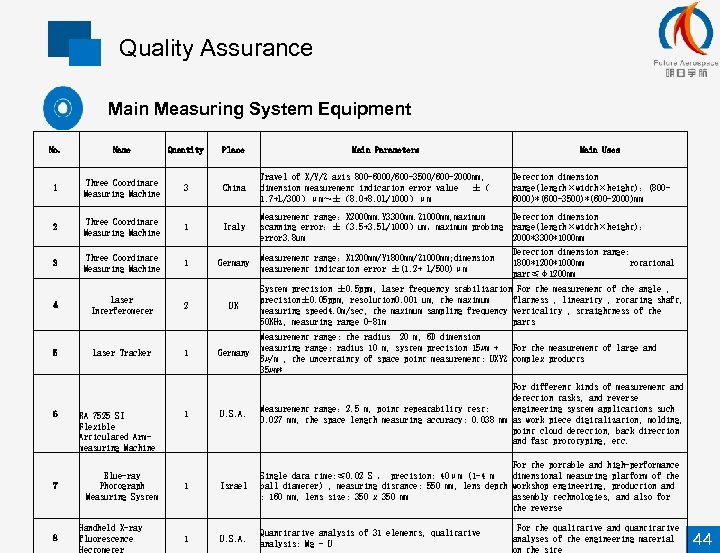

Quality Assurance Main Measuring System Equipment No. Name Quantity Place 1 Three Coordinate Measuring Machine 3 China Travel of X/Y/Z axis 800 -6000/600 -3500/600 -2000 mm, dimension measurement indication error value ±( 1. 7+L/300)μm~±(8. 0+8. 0 L/1000)μm Detection dimension range(length×width×height):(8006000)*(600 -3500)*(600 -2000)mm 2 Three Coordinate Measuring Machine 1 Italy Measurement range:X 2000 mm. Y 3300 mm. Z 1000 mm, maximum scanning error:±(3. 5+3. 5 L/1000)um,maximum probing error 3. 8 um Detection dimension range(length×width×height): 2000*3300*1000 mm 3 Three Coordinate Measuring Machine 1 Germany Measurement range:X 1200 mm/Y 1800 mm/Z 1000 mm; dimension measurement indication error ±(1. 2+ L/500)μm Detection dimension range: 1800*1200*1000 mm rotational part≤φ1200 mm 4 Laser Interferometer 5 6 7 8 Laser Tracker RA 7525 SI Flexible Articulated Armmeasuring Machine Blue-ray Photograph Measuring System Handheld X-ray fluorescence Hectometer 2 UK Main Parameters Main Uses System precision ± 0. 5 ppm, Laser frequency stabilization For the measurement of the angle , precision± 0. 05 ppm, resolution 0. 001 um, the maximum flatness , linearity , rotating shaft, measuring speed 4. 0 m/sec, the maximum sampling frequency verticality , straightness of the 50 KHz, measuring range 0 -81 m parts Germany Measurement range: the radius 20 m, 6 D dimension measuring range: radius 10 m, system precision 15µm + For the measurement of large and 6µ/m , the uncertainty of space point measurement: UXYZ complex products 35µm* U. S. A. For different kinds of measurement and detection tasks, and reverse Measurement range: 2. 5 m, point repeatability test: engineering system applications such 0. 027 mm, the space length measuring accuracy: 0. 038 mm as work piece digitalization, molding, point cloud detection, back direction and fast prototyping, etc. 1 Israel For the portable and high-performance Single data time: ≤ 0. 02 S , precision: 40μm (1 -4 m dimensional measuring platform of the ball diameter) , measuring distance: 550 mm, lens depth workshop engineering, production and : 160 mm, lens size: 350 x 350 mm assembly technologies, and also for the reverse 1 U. S. A. Quantitative analysis of 31 elements, qualitative analysis: Mg - U 1 1 For the qualitative and quantitative analyses of the engineering material on the site 44

Quality Assurance Main Measuring System Equipment No. Name Quantity Place 1 Three Coordinate Measuring Machine 3 China Travel of X/Y/Z axis 800 -6000/600 -3500/600 -2000 mm, dimension measurement indication error value ±( 1. 7+L/300)μm~±(8. 0+8. 0 L/1000)μm Detection dimension range(length×width×height):(8006000)*(600 -3500)*(600 -2000)mm 2 Three Coordinate Measuring Machine 1 Italy Measurement range:X 2000 mm. Y 3300 mm. Z 1000 mm, maximum scanning error:±(3. 5+3. 5 L/1000)um,maximum probing error 3. 8 um Detection dimension range(length×width×height): 2000*3300*1000 mm 3 Three Coordinate Measuring Machine 1 Germany Measurement range:X 1200 mm/Y 1800 mm/Z 1000 mm; dimension measurement indication error ±(1. 2+ L/500)μm Detection dimension range: 1800*1200*1000 mm rotational part≤φ1200 mm 4 Laser Interferometer 5 6 7 8 Laser Tracker RA 7525 SI Flexible Articulated Armmeasuring Machine Blue-ray Photograph Measuring System Handheld X-ray fluorescence Hectometer 2 UK Main Parameters Main Uses System precision ± 0. 5 ppm, Laser frequency stabilization For the measurement of the angle , precision± 0. 05 ppm, resolution 0. 001 um, the maximum flatness , linearity , rotating shaft, measuring speed 4. 0 m/sec, the maximum sampling frequency verticality , straightness of the 50 KHz, measuring range 0 -81 m parts Germany Measurement range: the radius 20 m, 6 D dimension measuring range: radius 10 m, system precision 15µm + For the measurement of large and 6µ/m , the uncertainty of space point measurement: UXYZ complex products 35µm* U. S. A. For different kinds of measurement and detection tasks, and reverse Measurement range: 2. 5 m, point repeatability test: engineering system applications such 0. 027 mm, the space length measuring accuracy: 0. 038 mm as work piece digitalization, molding, point cloud detection, back direction and fast prototyping, etc. 1 Israel For the portable and high-performance Single data time: ≤ 0. 02 S , precision: 40μm (1 -4 m dimensional measuring platform of the ball diameter) , measuring distance: 550 mm, lens depth workshop engineering, production and : 160 mm, lens size: 350 x 350 mm assembly technologies, and also for the reverse 1 U. S. A. Quantitative analysis of 31 elements, qualitative analysis: Mg - U 1 1 For the qualitative and quantitative analyses of the engineering material on the site 44

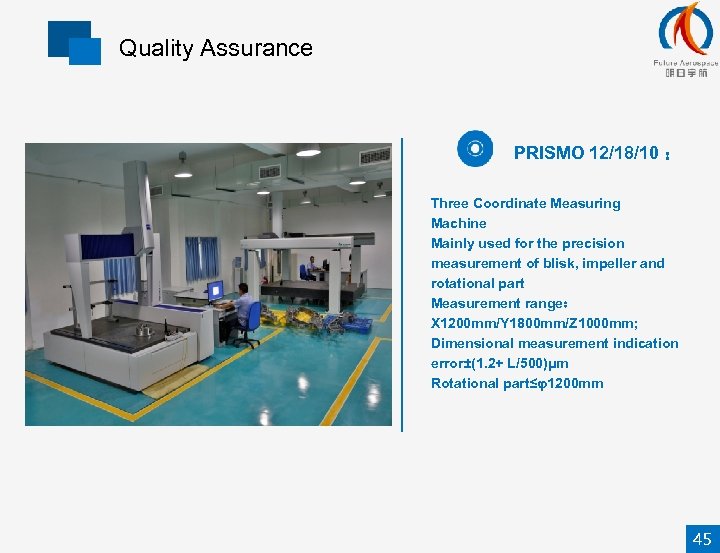

Quality Assurance PRISMO 12/18/10 : Three Coordinate Measuring Machine Mainly used for the precision measurement of blisk, impeller and rotational part Measurement range: X 1200 mm/Y 1800 mm/Z 1000 mm; Dimensional measurement indication error±(1. 2+ L/500)μm Rotational part≤φ1200 mm 45

Quality Assurance PRISMO 12/18/10 : Three Coordinate Measuring Machine Mainly used for the precision measurement of blisk, impeller and rotational part Measurement range: X 1200 mm/Y 1800 mm/Z 1000 mm; Dimensional measurement indication error±(1. 2+ L/500)μm Rotational part≤φ1200 mm 45

Quality Assurance Blue-ray scanner RS integrated laser probe of RA 7525 SI flexible Articulated Arm-measuring Machine Portable laser scanner On-line measuring device 5 -axis linkage machine and CNC vertical lathe are equipped with On-line measuring system, for realizing real-time online measurement, and improving product quality. 46

Quality Assurance Blue-ray scanner RS integrated laser probe of RA 7525 SI flexible Articulated Arm-measuring Machine Portable laser scanner On-line measuring device 5 -axis linkage machine and CNC vertical lathe are equipped with On-line measuring system, for realizing real-time online measurement, and improving product quality. 46

47

47

Thanks for Listening FUTURE AEROSPCAE INDUSTRY LLC.

Thanks for Listening FUTURE AEROSPCAE INDUSTRY LLC.