183aa37a5b167d8833e31b2fe07cf2a5.ppt

- Количество слайдов: 65

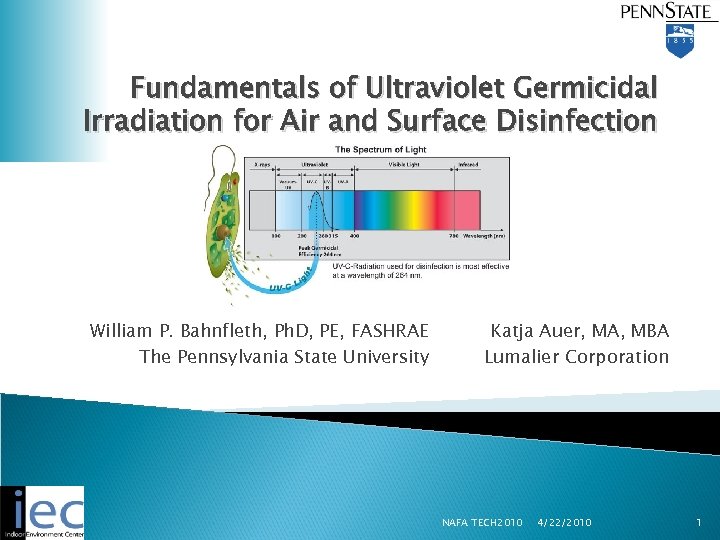

Fundamentals of Ultraviolet Germicidal Irradiation for Air and Surface Disinfection William P. Bahnfleth, Ph. D, PE, FASHRAE The Pennsylvania State University Katja Auer, MA, MBA Lumalier Corporation NAFA TECH 2010 4/22/2010 1

Fundamentals of Ultraviolet Germicidal Irradiation for Air and Surface Disinfection William P. Bahnfleth, Ph. D, PE, FASHRAE The Pennsylvania State University Katja Auer, MA, MBA Lumalier Corporation NAFA TECH 2010 4/22/2010 1

Outline Introduction UVGI Fundamentals Application Issues UVGI System Types Upper Air vs. In-Duct Economics In-duct system performance Summary NAFA TECH 2010 4/22/2010 2

Outline Introduction UVGI Fundamentals Application Issues UVGI System Types Upper Air vs. In-Duct Economics In-duct system performance Summary NAFA TECH 2010 4/22/2010 2

Introduction • Microorganisms • Microbial control alternatives • UVGI history • Evidence for UVGI effectiveness NAFA TECH 2010 4/22/2010 3

Introduction • Microorganisms • Microbial control alternatives • UVGI history • Evidence for UVGI effectiveness NAFA TECH 2010 4/22/2010 3

Indoor Microorganisms-Pathogens Bacteria ◦ Tuberculosis ◦ Anthrax ◦ MRSA Virus ◦ Rhinovirus ◦ SARS ◦ Influenza Sources Characteristics ◦ m and sub- m ◦ Carrier particles Droplet residue Dust Transmission ◦ Airborne ◦ Fomite ◦ Infected humans ◦ Biological warfare/ terrorism NAFA TECH 2010 4/22/2010 4

Indoor Microorganisms-Pathogens Bacteria ◦ Tuberculosis ◦ Anthrax ◦ MRSA Virus ◦ Rhinovirus ◦ SARS ◦ Influenza Sources Characteristics ◦ m and sub- m ◦ Carrier particles Droplet residue Dust Transmission ◦ Airborne ◦ Fomite ◦ Infected humans ◦ Biological warfare/ terrorism NAFA TECH 2010 4/22/2010 4

Indoor Microorganisms-Fungi Cause/aggravate ◦ Allergies ◦ Asthma ◦ Opportunistic infections Grow in presence of food (organic material) and water Types Characteristics ◦ Surface growth— mycelium ◦ Spores, O(1 -10 m) ◦ VOCs ◦ Mycotoxins In HVAC systems ◦ Cooling coils ◦ Damp filter media ◦ Aspergillus ◦ Stachybotris ◦ Penicillium NAFA TECH 2010 4/22/2010 5

Indoor Microorganisms-Fungi Cause/aggravate ◦ Allergies ◦ Asthma ◦ Opportunistic infections Grow in presence of food (organic material) and water Types Characteristics ◦ Surface growth— mycelium ◦ Spores, O(1 -10 m) ◦ VOCs ◦ Mycotoxins In HVAC systems ◦ Cooling coils ◦ Damp filter media ◦ Aspergillus ◦ Stachybotris ◦ Penicillium NAFA TECH 2010 4/22/2010 5

Indoor Microbial Control Approaches All ◦ ◦ Filter Dilute in air Clean from surfaces Inactivate Pathogens ◦ Limit person to person transmission with good hygiene Fungi ◦ Control sources of moisture ◦ Treat surfaces that cannot be kept dry NAFA TECH 2010 4/22/2010 6

Indoor Microbial Control Approaches All ◦ ◦ Filter Dilute in air Clean from surfaces Inactivate Pathogens ◦ Limit person to person transmission with good hygiene Fungi ◦ Control sources of moisture ◦ Treat surfaces that cannot be kept dry NAFA TECH 2010 4/22/2010 6

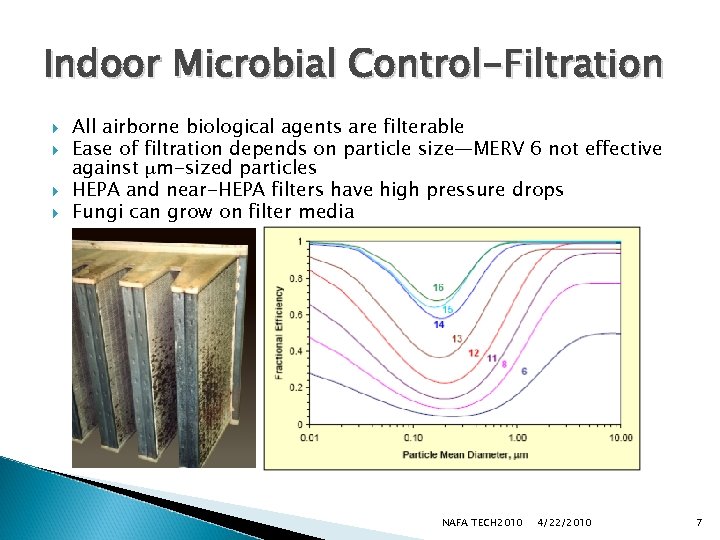

Indoor Microbial Control-Filtration All airborne biological agents are filterable Ease of filtration depends on particle size—MERV 6 not effective against m-sized particles HEPA and near-HEPA filters have high pressure drops Fungi can grow on filter media NAFA TECH 2010 4/22/2010 7

Indoor Microbial Control-Filtration All airborne biological agents are filterable Ease of filtration depends on particle size—MERV 6 not effective against m-sized particles HEPA and near-HEPA filters have high pressure drops Fungi can grow on filter media NAFA TECH 2010 4/22/2010 7

Indoor Microbial Control-Dilution Outside air can be used to dilute any airborne indoor contaminant Conditioning of outside air is a major energy consumer Large amounts of outside air conditioning in hot/humid climates may lead to moisture control problems NAFA TECH 2010 4/22/2010 8

Indoor Microbial Control-Dilution Outside air can be used to dilute any airborne indoor contaminant Conditioning of outside air is a major energy consumer Large amounts of outside air conditioning in hot/humid climates may lead to moisture control problems NAFA TECH 2010 4/22/2010 8

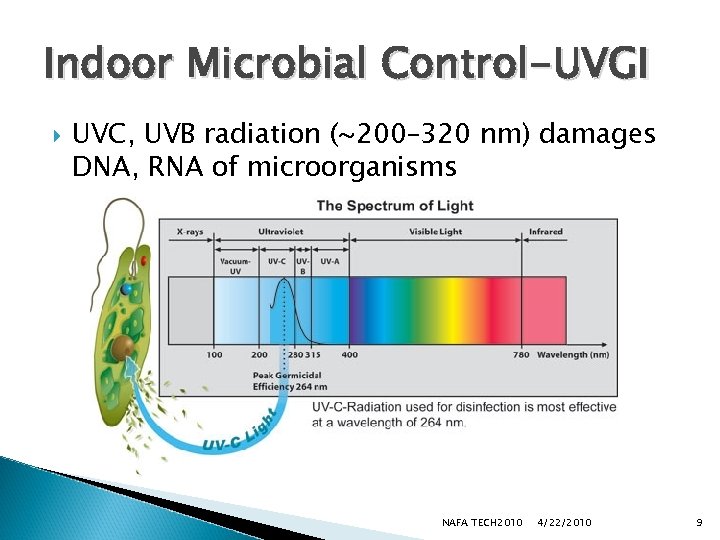

Indoor Microbial Control-UVGI UVC, UVB radiation (~200– 320 nm) damages DNA, RNA of microorganisms NAFA TECH 2010 4/22/2010 9

Indoor Microbial Control-UVGI UVC, UVB radiation (~200– 320 nm) damages DNA, RNA of microorganisms NAFA TECH 2010 4/22/2010 9

History 1880 s Finsen uses UVB to treat skin diseases 1920 s Studies of UV effect on microorganisms 1930 s First air treatment applications-Wells, et al. m Multi-year PA school study shows upper room highly effective against measles 1940 s Studies of surface mold disinfection 1950 s Use of UV in A/C described as “standard” application in GE literature 1980 s First cooling coil disinfection Philips UV lamp application guidance 1990 s Growth of commercial UVGI, renewed scientific interest in UVGI 2005 ASHRAE TG 2. UVAS formed 2007 TG 2. UVAS becomes TC 2. 9 Ultraviolet Air and Surface Treatment 2008 ASHRAE Handbook-S&E chapter on UV 2009 ASHRAE Position Document on Airborne Infectious Diseases identifies UVGI as a proven technique for airborne infection control 2009 NIOSH guidelines for control of tuberculosis with upper room UVGI 2009 Formation of ISO working group on “UV devices” NAFA TECH 2010 4/22/2010 10

History 1880 s Finsen uses UVB to treat skin diseases 1920 s Studies of UV effect on microorganisms 1930 s First air treatment applications-Wells, et al. m Multi-year PA school study shows upper room highly effective against measles 1940 s Studies of surface mold disinfection 1950 s Use of UV in A/C described as “standard” application in GE literature 1980 s First cooling coil disinfection Philips UV lamp application guidance 1990 s Growth of commercial UVGI, renewed scientific interest in UVGI 2005 ASHRAE TG 2. UVAS formed 2007 TG 2. UVAS becomes TC 2. 9 Ultraviolet Air and Surface Treatment 2008 ASHRAE Handbook-S&E chapter on UV 2009 ASHRAE Position Document on Airborne Infectious Diseases identifies UVGI as a proven technique for airborne infection control 2009 NIOSH guidelines for control of tuberculosis with upper room UVGI 2009 Formation of ISO working group on “UV devices” NAFA TECH 2010 4/22/2010 10

Recent Evidence of UVGI Efficacy Major laboratory study documents ability to deactivate microorganisms in moving air (RTI, 2002) EPA ETV tests of nine commercial products show effectiveness against 3 standard microorganisms Double blind office building study shows reduction of sick building symptoms and sampled microbial levels (Menzies, et al. Lancet 2003) More evidence of impact on outcomes is needed NAFA TECH 2010 4/22/2010 11

Recent Evidence of UVGI Efficacy Major laboratory study documents ability to deactivate microorganisms in moving air (RTI, 2002) EPA ETV tests of nine commercial products show effectiveness against 3 standard microorganisms Double blind office building study shows reduction of sick building symptoms and sampled microbial levels (Menzies, et al. Lancet 2003) More evidence of impact on outcomes is needed NAFA TECH 2010 4/22/2010 11

ASHRAE Position Document – Airborne Infectious Diseases Airborne infectious disease transmission can be reduced using UVGI (and other modalities) Research that shows UVGI can inactivate some disease transmitting organisms and that it can affect disease transmission rates. Additional research is needed showing clinical efficacy specifically in occupancies with highrisk sources Top three research priorities are UVGI-related NAFA TECH 2010 4/22/2010 12

ASHRAE Position Document – Airborne Infectious Diseases Airborne infectious disease transmission can be reduced using UVGI (and other modalities) Research that shows UVGI can inactivate some disease transmitting organisms and that it can affect disease transmission rates. Additional research is needed showing clinical efficacy specifically in occupancies with highrisk sources Top three research priorities are UVGI-related NAFA TECH 2010 4/22/2010 12

Fundamentals • History • Microbial response • UV sources NAFA TECH 2010 4/22/2010 13

Fundamentals • History • Microbial response • UV sources NAFA TECH 2010 4/22/2010 13

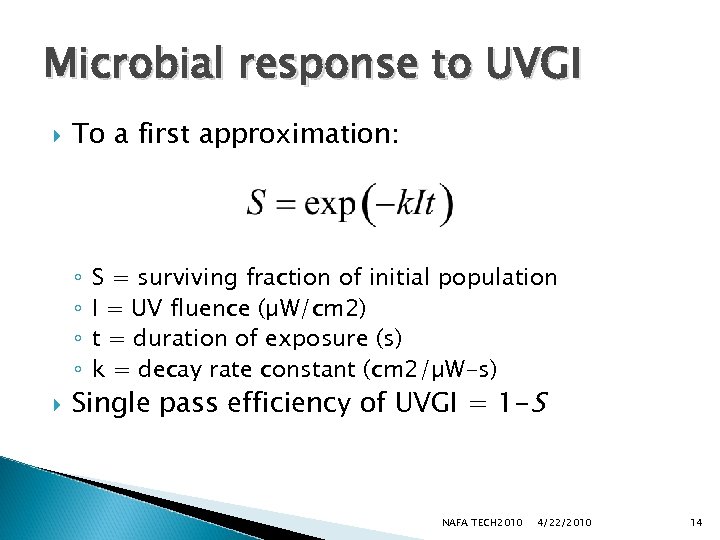

Microbial response to UVGI To a first approximation: ◦ ◦ S = surviving fraction of initial population I = UV fluence (µW/cm 2) t = duration of exposure (s) k = decay rate constant (cm 2/µW-s) Single pass efficiency of UVGI = 1 -S NAFA TECH 2010 4/22/2010 14

Microbial response to UVGI To a first approximation: ◦ ◦ S = surviving fraction of initial population I = UV fluence (µW/cm 2) t = duration of exposure (s) k = decay rate constant (cm 2/µW-s) Single pass efficiency of UVGI = 1 -S NAFA TECH 2010 4/22/2010 14

Microbial Response to UVGI k varies widely for different microorganisms Representative values (cm 2/ W-s) ◦ ◦ Bacillus anthracis 0. 000031 Influenza A 0. 0019 Mycobacterium tuberculosis 0. 002132 Streptococcus pneumoniae 0. 006161 Accurate measurement of k is difficult and a weakness of existing design data NAFA TECH 2010 4/22/2010 15

Microbial Response to UVGI k varies widely for different microorganisms Representative values (cm 2/ W-s) ◦ ◦ Bacillus anthracis 0. 000031 Influenza A 0. 0019 Mycobacterium tuberculosis 0. 002132 Streptococcus pneumoniae 0. 006161 Accurate measurement of k is difficult and a weakness of existing design data NAFA TECH 2010 4/22/2010 15

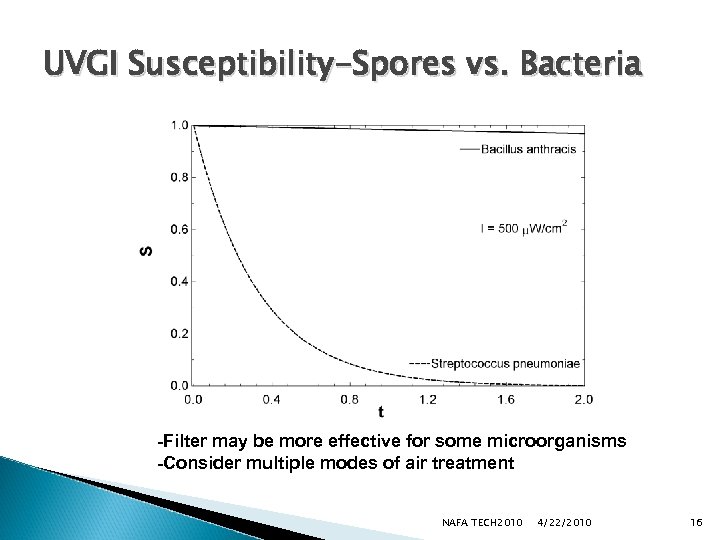

UVGI Susceptibility-Spores vs. Bacteria -Filter may be more effective for some microorganisms -Consider multiple modes of air treatment NAFA TECH 2010 4/22/2010 16

UVGI Susceptibility-Spores vs. Bacteria -Filter may be more effective for some microorganisms -Consider multiple modes of air treatment NAFA TECH 2010 4/22/2010 16

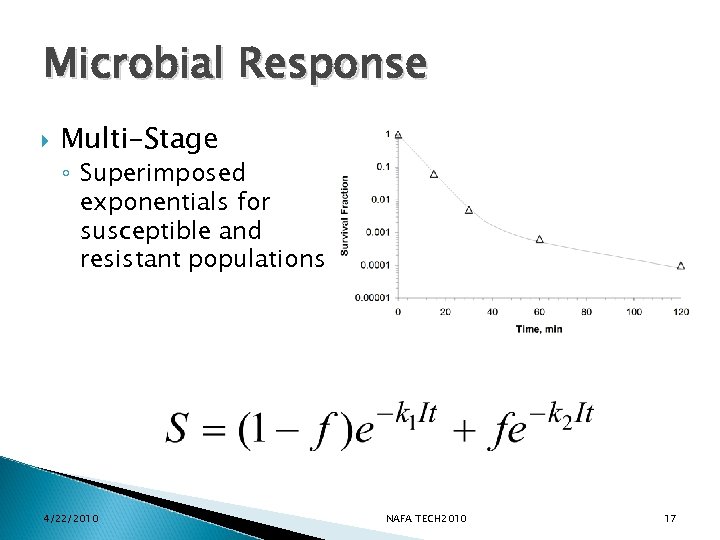

Microbial Response Multi-Stage ◦ Superimposed exponentials for susceptible and resistant populations 4/22/2010 NAFA TECH 2010 17

Microbial Response Multi-Stage ◦ Superimposed exponentials for susceptible and resistant populations 4/22/2010 NAFA TECH 2010 17

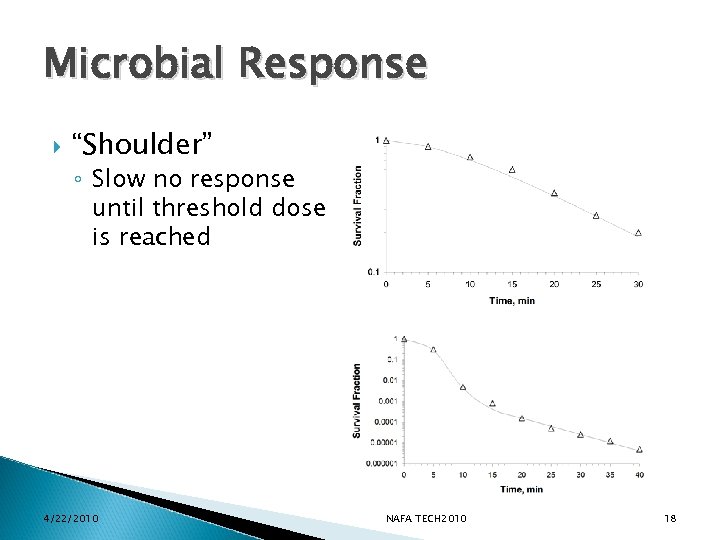

Microbial Response “Shoulder” ◦ Slow no response until threshold dose is reached 4/22/2010 NAFA TECH 2010 18

Microbial Response “Shoulder” ◦ Slow no response until threshold dose is reached 4/22/2010 NAFA TECH 2010 18

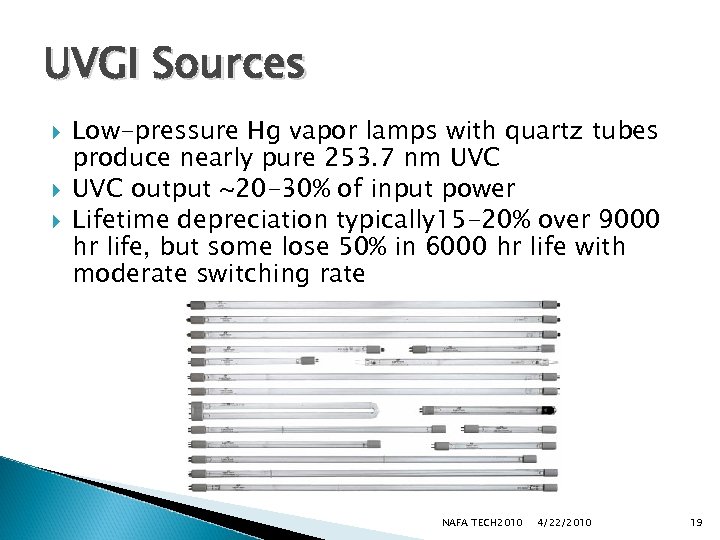

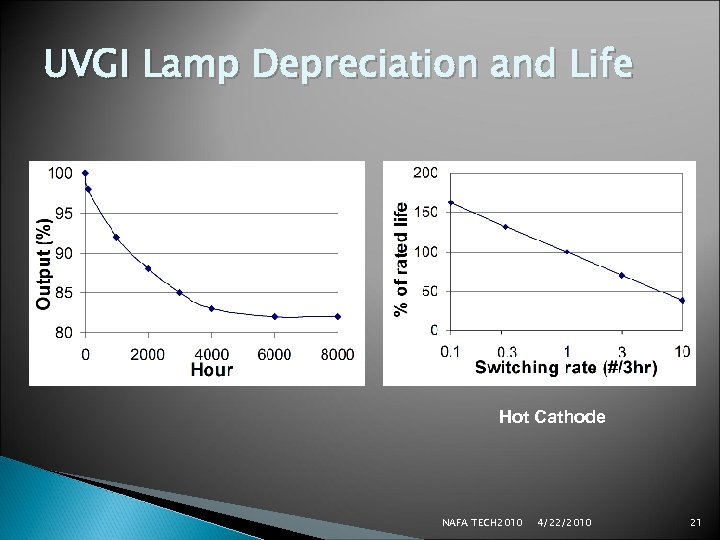

UVGI Sources Low-pressure Hg vapor lamps with quartz tubes produce nearly pure 253. 7 nm UVC output ~20 -30% of input power Lifetime depreciation typically 15 -20% over 9000 hr life, but some lose 50% in 6000 hr life with moderate switching rate NAFA TECH 2010 4/22/2010 19

UVGI Sources Low-pressure Hg vapor lamps with quartz tubes produce nearly pure 253. 7 nm UVC output ~20 -30% of input power Lifetime depreciation typically 15 -20% over 9000 hr life, but some lose 50% in 6000 hr life with moderate switching rate NAFA TECH 2010 4/22/2010 19

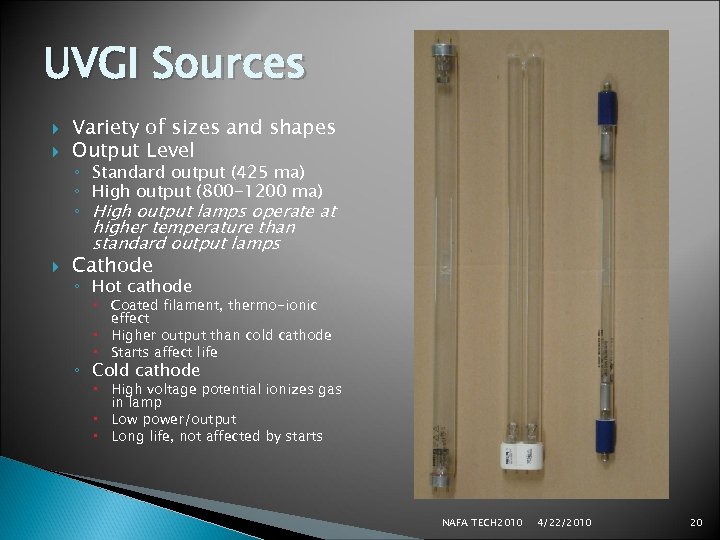

UVGI Sources Variety of sizes and shapes Output Level Cathode ◦ Standard output (425 ma) ◦ High output (800 -1200 ma) ◦ High output lamps operate at higher temperature than standard output lamps ◦ Hot cathode Coated filament, thermo-ionic effect Higher output than cold cathode Starts affect life ◦ Cold cathode High voltage potential ionizes gas in lamp Low power/output Long life, not affected by starts NAFA TECH 2010 4/22/2010 20

UVGI Sources Variety of sizes and shapes Output Level Cathode ◦ Standard output (425 ma) ◦ High output (800 -1200 ma) ◦ High output lamps operate at higher temperature than standard output lamps ◦ Hot cathode Coated filament, thermo-ionic effect Higher output than cold cathode Starts affect life ◦ Cold cathode High voltage potential ionizes gas in lamp Low power/output Long life, not affected by starts NAFA TECH 2010 4/22/2010 20

UVGI Lamp Depreciation and Life Hot Cathode NAFA TECH 2010 4/22/2010 21

UVGI Lamp Depreciation and Life Hot Cathode NAFA TECH 2010 4/22/2010 21

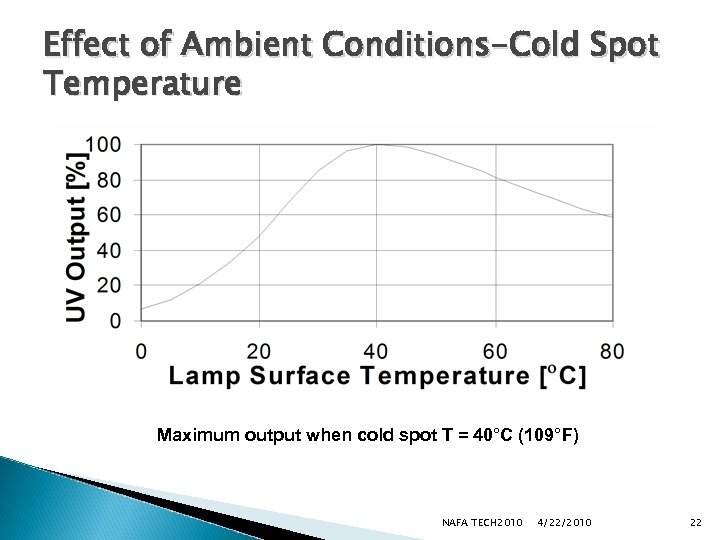

Effect of Ambient Conditions-Cold Spot Temperature Maximum output when cold spot T = 40°C (109°F) NAFA TECH 2010 4/22/2010 22

Effect of Ambient Conditions-Cold Spot Temperature Maximum output when cold spot T = 40°C (109°F) NAFA TECH 2010 4/22/2010 22

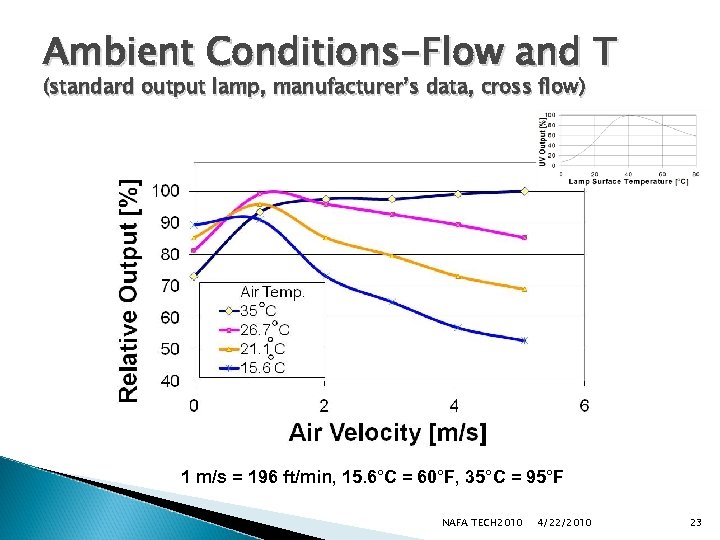

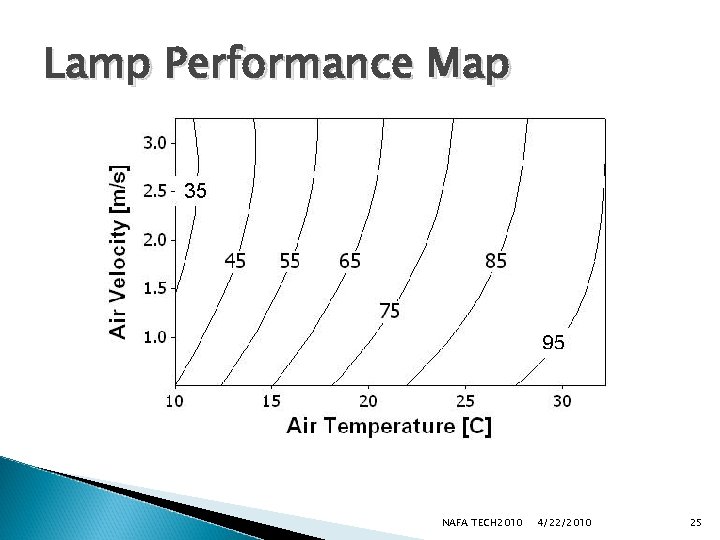

Ambient Conditions-Flow and T (standard output lamp, manufacturer’s data, cross flow) 1 m/s = 196 ft/min, 15. 6°C = 60°F, 35°C = 95°F NAFA TECH 2010 4/22/2010 23

Ambient Conditions-Flow and T (standard output lamp, manufacturer’s data, cross flow) 1 m/s = 196 ft/min, 15. 6°C = 60°F, 35°C = 95°F NAFA TECH 2010 4/22/2010 23

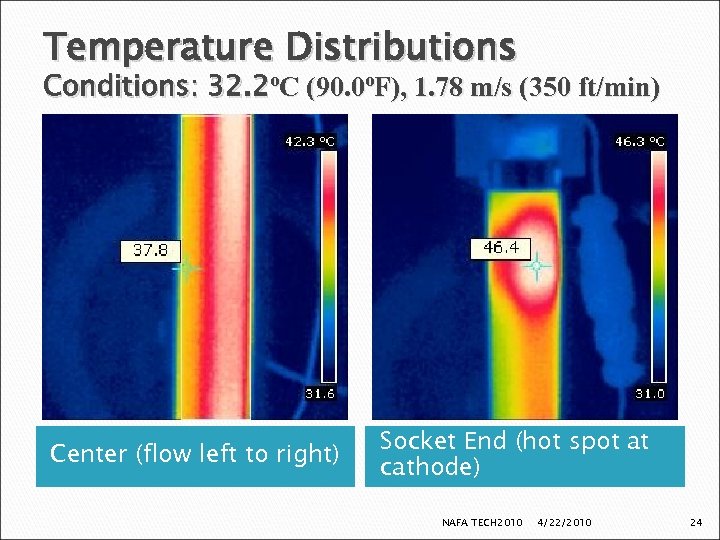

Temperature Distributions Conditions: 32. 2ºC (90. 0ºF), 1. 78 m/s (350 ft/min) Center (flow left to right) Socket End (hot spot at cathode) NAFA TECH 2010 4/22/2010 24

Temperature Distributions Conditions: 32. 2ºC (90. 0ºF), 1. 78 m/s (350 ft/min) Center (flow left to right) Socket End (hot spot at cathode) NAFA TECH 2010 4/22/2010 24

Lamp Performance Map NAFA TECH 2010 4/22/2010 25

Lamp Performance Map NAFA TECH 2010 4/22/2010 25

Application Issues • Lamp output variation • Humidity • Safety • Material degradation • Mixed mode air treatment NAFA TECH 2010 4/22/2010 26

Application Issues • Lamp output variation • Humidity • Safety • Material degradation • Mixed mode air treatment NAFA TECH 2010 4/22/2010 26

Lamp Output Rated capacity measured after 100 hr burn-in under favorable environmental conditions— may not be representative Depreciation and convective effects are independent, multiplicative Lamp selection should be based on worst case temperature/velocity combination and end-of-life depreciated lamp output NAFA TECH 2010 4/22/2010 27

Lamp Output Rated capacity measured after 100 hr burn-in under favorable environmental conditions— may not be representative Depreciation and convective effects are independent, multiplicative Lamp selection should be based on worst case temperature/velocity combination and end-of-life depreciated lamp output NAFA TECH 2010 4/22/2010 27

Humidity Negligible effect on ◦ Lamp output (heat transfer) ◦ Attenuation of UVGI in air Possibly significant effect on microbial susceptibility to UVGI—may increase or decrease, depending on the organism NAFA TECH 2010 4/22/2010 28

Humidity Negligible effect on ◦ Lamp output (heat transfer) ◦ Attenuation of UVGI in air Possibly significant effect on microbial susceptibility to UVGI—may increase or decrease, depending on the organism NAFA TECH 2010 4/22/2010 28

Material Compatibility UVC can degrade organic materials commonly found in HVAC systems ◦ ◦ Synthetic filter media Gaskets Electrical insulation Plastic pipe Potential problem for retrofits Rule of thumb-shield all organic components within 4 -5 ft (1. 5 m) of UV lamps ASHRAE 1509 -RP, "Study the Degradation of Typical HVAC Materials, Filters and Components Irradiated by UVC Energy” in progress – report due completed Jan 2011 NAFA TECH 2010 4/22/2010 29

Material Compatibility UVC can degrade organic materials commonly found in HVAC systems ◦ ◦ Synthetic filter media Gaskets Electrical insulation Plastic pipe Potential problem for retrofits Rule of thumb-shield all organic components within 4 -5 ft (1. 5 m) of UV lamps ASHRAE 1509 -RP, "Study the Degradation of Typical HVAC Materials, Filters and Components Irradiated by UVC Energy” in progress – report due completed Jan 2011 NAFA TECH 2010 4/22/2010 29

Safety UVB and UVC cause skin and eye irritation Overexposure is a concern NIOSH RELs for 253. 7 nm UVC ◦ Due to leakage from imperfectly sealed devices ◦ Improper maintenance procedures and/or malfunction of safeties ◦ Upper room systems ◦ 1 min: 100 W/cm 2 ◦ 1 hour: 1. 7 W/cm 2 ◦ 8 hours: 0. 2 W/cm 2 Incorporate safeties in fixed systems Train maintenance staff Maintain equipment NAFA TECH 2010 4/22/2010 30

Safety UVB and UVC cause skin and eye irritation Overexposure is a concern NIOSH RELs for 253. 7 nm UVC ◦ Due to leakage from imperfectly sealed devices ◦ Improper maintenance procedures and/or malfunction of safeties ◦ Upper room systems ◦ 1 min: 100 W/cm 2 ◦ 1 hour: 1. 7 W/cm 2 ◦ 8 hours: 0. 2 W/cm 2 Incorporate safeties in fixed systems Train maintenance staff Maintain equipment NAFA TECH 2010 4/22/2010 30

UVGI, Filters, Ventilation UVGI is complementary to ventilation and particle filtration Smaller microorganisms (viruses, bacteria) are generally difficult to filter but relatively easy to deactivate with UVGI Larger microorganisms (spores) are relatively easy to filter and hard to deactivate. Moderately high efficiency filtration + UVGI with minimum OA may be optimal NAFA TECH 2010 4/22/2010 31

UVGI, Filters, Ventilation UVGI is complementary to ventilation and particle filtration Smaller microorganisms (viruses, bacteria) are generally difficult to filter but relatively easy to deactivate with UVGI Larger microorganisms (spores) are relatively easy to filter and hard to deactivate. Moderately high efficiency filtration + UVGI with minimum OA may be optimal NAFA TECH 2010 4/22/2010 31

System Types • Room surface treatment • Self-contained air treatment • Upper room air treatment • In-duct air and air/surface treatment NAFA TECH 2010 4/22/2010 32

System Types • Room surface treatment • Self-contained air treatment • Upper room air treatment • In-duct air and air/surface treatment NAFA TECH 2010 4/22/2010 32

Room Decontamination Standalone, portable Surface and air Small unoccupied rooms Used in EMS vehicles between patient transports NAFA TECH 2010 4/22/2010 33

Room Decontamination Standalone, portable Surface and air Small unoccupied rooms Used in EMS vehicles between patient transports NAFA TECH 2010 4/22/2010 33

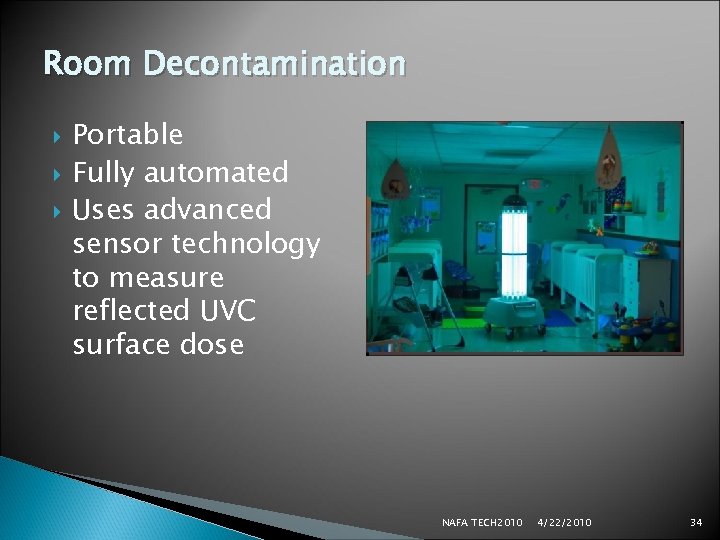

Room Decontamination Portable Fully automated Uses advanced sensor technology to measure reflected UVC surface dose NAFA TECH 2010 4/22/2010 34

Room Decontamination Portable Fully automated Uses advanced sensor technology to measure reflected UVC surface dose NAFA TECH 2010 4/22/2010 34

Room Decontamination Automated and self calibrating system Remote controlled Can be set to dose for specific pathogens including MRSA, VRE, C-Diff, Acinetobacter NAFA TECH 2010 4/22/2010 35

Room Decontamination Automated and self calibrating system Remote controlled Can be set to dose for specific pathogens including MRSA, VRE, C-Diff, Acinetobacter NAFA TECH 2010 4/22/2010 35

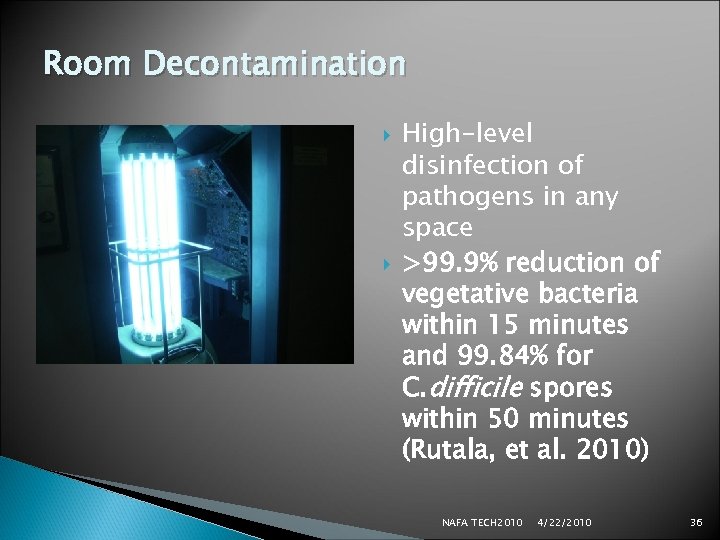

Room Decontamination High-level disinfection of pathogens in any space >99. 9% reduction of vegetative bacteria within 15 minutes and 99. 84% for C. difficile spores within 50 minutes (Rutala, et al. 2010) NAFA TECH 2010 4/22/2010 36

Room Decontamination High-level disinfection of pathogens in any space >99. 9% reduction of vegetative bacteria within 15 minutes and 99. 84% for C. difficile spores within 50 minutes (Rutala, et al. 2010) NAFA TECH 2010 4/22/2010 36

Self-Contained Air Treatment Lamps and fan in a module Combines performance issues of in-duct device and portable air cleaner (i. e. , ability to turn over air in treated space) NAFA TECH 2010 4/22/2010 37

Self-Contained Air Treatment Lamps and fan in a module Combines performance issues of in-duct device and portable air cleaner (i. e. , ability to turn over air in treated space) NAFA TECH 2010 4/22/2010 37

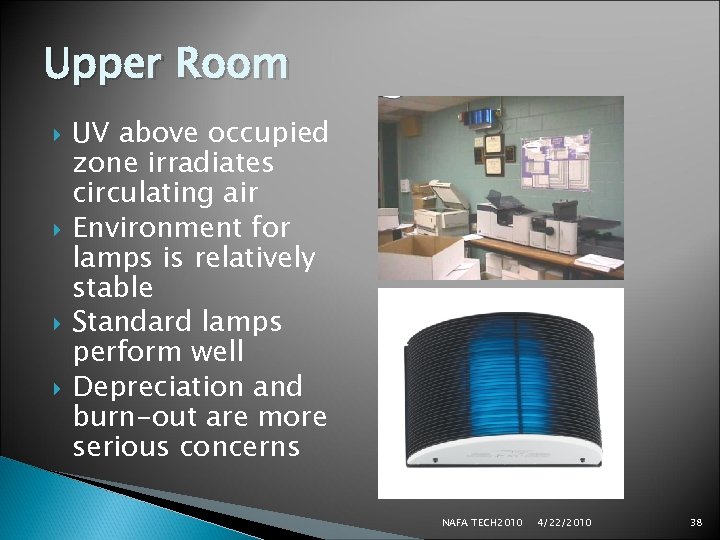

Upper Room UV above occupied zone irradiates circulating air Environment for lamps is relatively stable Standard lamps perform well Depreciation and burn-out are more serious concerns NAFA TECH 2010 4/22/2010 38

Upper Room UV above occupied zone irradiates circulating air Environment for lamps is relatively stable Standard lamps perform well Depreciation and burn-out are more serious concerns NAFA TECH 2010 4/22/2010 38

Upper Room Long approved for control of disease transmission by CDC/NIOSH (2009): Environmental Control for Tuberculosis: Basic Upper-Room Ultraviolet Germicidal Irradiation Guidelines for Healthcare Settings. NAFA TECH 2010 4/22/2010 39

Upper Room Long approved for control of disease transmission by CDC/NIOSH (2009): Environmental Control for Tuberculosis: Basic Upper-Room Ultraviolet Germicidal Irradiation Guidelines for Healthcare Settings. NAFA TECH 2010 4/22/2010 39

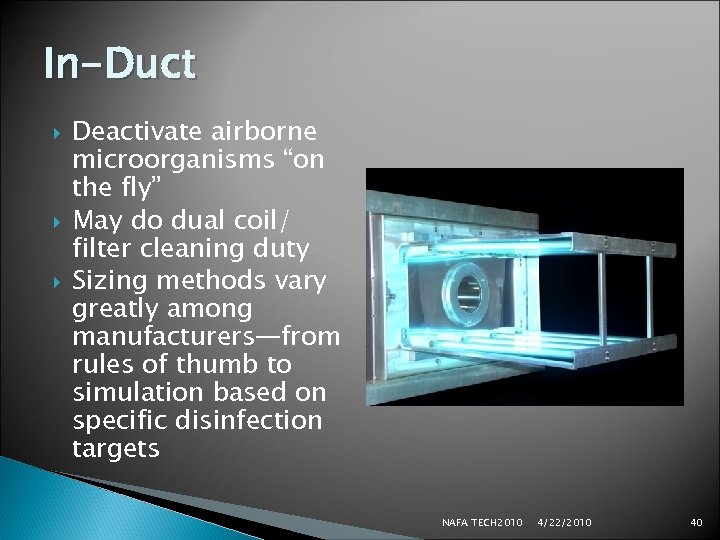

In-Duct Deactivate airborne microorganisms “on the fly” May do dual coil/ filter cleaning duty Sizing methods vary greatly among manufacturers—from rules of thumb to simulation based on specific disinfection targets NAFA TECH 2010 4/22/2010 40

In-Duct Deactivate airborne microorganisms “on the fly” May do dual coil/ filter cleaning duty Sizing methods vary greatly among manufacturers—from rules of thumb to simulation based on specific disinfection targets NAFA TECH 2010 4/22/2010 40

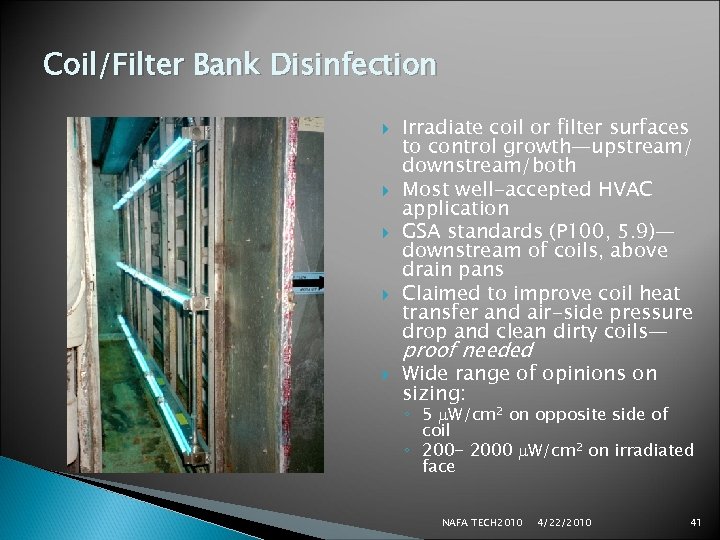

Coil/Filter Bank Disinfection Irradiate coil or filter surfaces to control growth—upstream/ downstream/both Most well-accepted HVAC application GSA standards (P 100, 5. 9)— downstream of coils, above drain pans Claimed to improve coil heat transfer and air-side pressure drop and clean dirty coils— proof needed Wide range of opinions on sizing: ◦ 5 W/cm 2 on opposite side of coil ◦ 200 - 2000 W/cm 2 on irradiated face NAFA TECH 2010 4/22/2010 41

Coil/Filter Bank Disinfection Irradiate coil or filter surfaces to control growth—upstream/ downstream/both Most well-accepted HVAC application GSA standards (P 100, 5. 9)— downstream of coils, above drain pans Claimed to improve coil heat transfer and air-side pressure drop and clean dirty coils— proof needed Wide range of opinions on sizing: ◦ 5 W/cm 2 on opposite side of coil ◦ 200 - 2000 W/cm 2 on irradiated face NAFA TECH 2010 4/22/2010 41

In-Duct Commercial Downstream coil surface/air installations NAFA TECH 2010 4/22/2010 42

In-Duct Commercial Downstream coil surface/air installations NAFA TECH 2010 4/22/2010 42

In-Duct Residential NAFA TECH 2010 4/22/2010 43

In-Duct Residential NAFA TECH 2010 4/22/2010 43

Upper Air vs. In-Duct Economics NAFA TECH 2010 4/22/2010 44

Upper Air vs. In-Duct Economics NAFA TECH 2010 4/22/2010 44

Upper Room Economics • Common rule of thumb for sizing (Riley, HSPH): 30 W per 200 ft 2 • Modern fixtures are 36 W (12 UV W) and cost ~$600 • First cost: $2. 50/ft 2 • Operating cost: $0. 13/ft 2 -yr for continuous operation @ $0. 10/k. Wh NAFA TECH 2010 4/22/2010 45

Upper Room Economics • Common rule of thumb for sizing (Riley, HSPH): 30 W per 200 ft 2 • Modern fixtures are 36 W (12 UV W) and cost ~$600 • First cost: $2. 50/ft 2 • Operating cost: $0. 13/ft 2 -yr for continuous operation @ $0. 10/k. Wh NAFA TECH 2010 4/22/2010 45

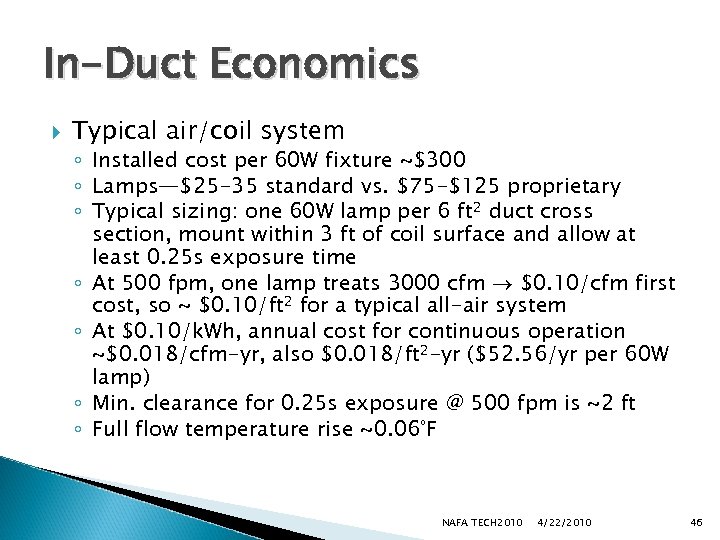

In-Duct Economics Typical air/coil system ◦ Installed cost per 60 W fixture ~$300 ◦ Lamps—$25 -35 standard vs. $75 -$125 proprietary ◦ Typical sizing: one 60 W lamp per 6 ft 2 duct cross section, mount within 3 ft of coil surface and allow at least 0. 25 s exposure time ◦ At 500 fpm, one lamp treats 3000 cfm $0. 10/cfm first cost, so ~ $0. 10/ft 2 for a typical all-air system ◦ At $0. 10/k. Wh, annual cost for continuous operation ~$0. 018/cfm-yr, also $0. 018/ft 2 -yr ($52. 56/yr per 60 W lamp) ◦ Min. clearance for 0. 25 s exposure @ 500 fpm is ~2 ft ◦ Full flow temperature rise ~0. 06°F NAFA TECH 2010 4/22/2010 46

In-Duct Economics Typical air/coil system ◦ Installed cost per 60 W fixture ~$300 ◦ Lamps—$25 -35 standard vs. $75 -$125 proprietary ◦ Typical sizing: one 60 W lamp per 6 ft 2 duct cross section, mount within 3 ft of coil surface and allow at least 0. 25 s exposure time ◦ At 500 fpm, one lamp treats 3000 cfm $0. 10/cfm first cost, so ~ $0. 10/ft 2 for a typical all-air system ◦ At $0. 10/k. Wh, annual cost for continuous operation ~$0. 018/cfm-yr, also $0. 018/ft 2 -yr ($52. 56/yr per 60 W lamp) ◦ Min. clearance for 0. 25 s exposure @ 500 fpm is ~2 ft ◦ Full flow temperature rise ~0. 06°F NAFA TECH 2010 4/22/2010 46

In-Duct System Performance Analysis • Efficiency • Energy use • Economics NAFA TECH 2010 4/22/2010 47

In-Duct System Performance Analysis • Efficiency • Energy use • Economics NAFA TECH 2010 4/22/2010 47

Simulation-Based LCC Analysis Performance simulation ◦ Thermal/energy (whole-building—e. QUEST) ◦ IAQ control (components, system—custom MATLAB) Economic analysis ◦ ◦ First cost Annual labor and equipment cost Energy cost (direct/indirect) Benefit? If benefit cannot be quantified with sufficient accuracy, an alternative approach is to compare with cost of alternative methods (e. g. , filtration, dilution) to achieve the same level of contaminant control

Simulation-Based LCC Analysis Performance simulation ◦ Thermal/energy (whole-building—e. QUEST) ◦ IAQ control (components, system—custom MATLAB) Economic analysis ◦ ◦ First cost Annual labor and equipment cost Energy cost (direct/indirect) Benefit? If benefit cannot be quantified with sufficient accuracy, an alternative approach is to compare with cost of alternative methods (e. g. , filtration, dilution) to achieve the same level of contaminant control

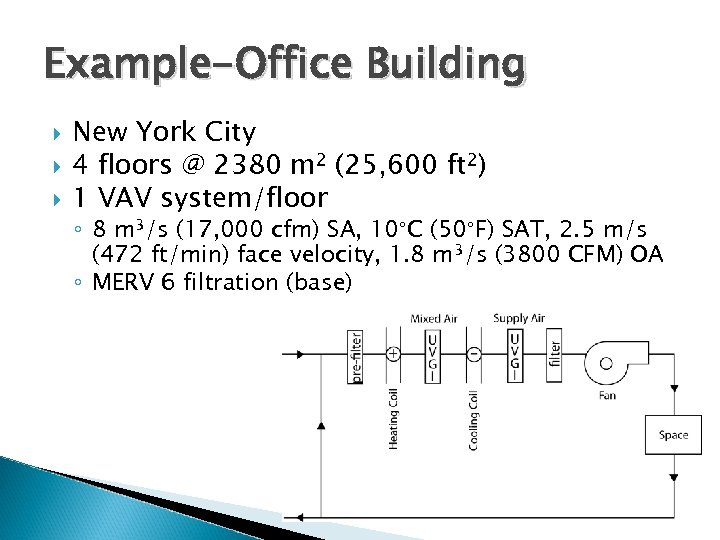

Example-Office Building New York City 4 floors @ 2380 m 2 (25, 600 ft 2) 1 VAV system/floor ◦ 8 m 3/s (17, 000 cfm) SA, 10°C (50°F) SAT, 2. 5 m/s (472 ft/min) face velocity, 1. 8 m 3/s (3800 CFM) OA ◦ MERV 6 filtration (base)

Example-Office Building New York City 4 floors @ 2380 m 2 (25, 600 ft 2) 1 VAV system/floor ◦ 8 m 3/s (17, 000 cfm) SA, 10°C (50°F) SAT, 2. 5 m/s (472 ft/min) face velocity, 1. 8 m 3/s (3800 CFM) OA ◦ MERV 6 filtration (base)

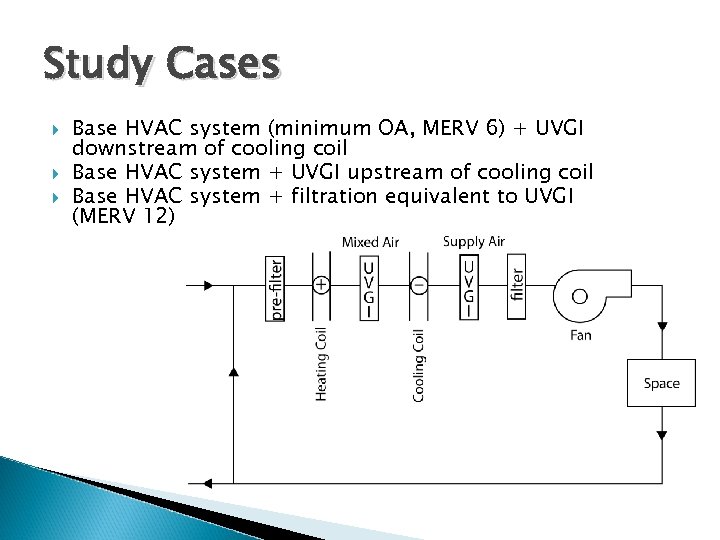

Study Cases Base HVAC system (minimum OA, MERV 6) + UVGI downstream of cooling coil Base HVAC system + UVGI upstream of cooling coil Base HVAC system + filtration equivalent to UVGI (MERV 12)

Study Cases Base HVAC system (minimum OA, MERV 6) + UVGI downstream of cooling coil Base HVAC system + UVGI upstream of cooling coil Base HVAC system + filtration equivalent to UVGI (MERV 12)

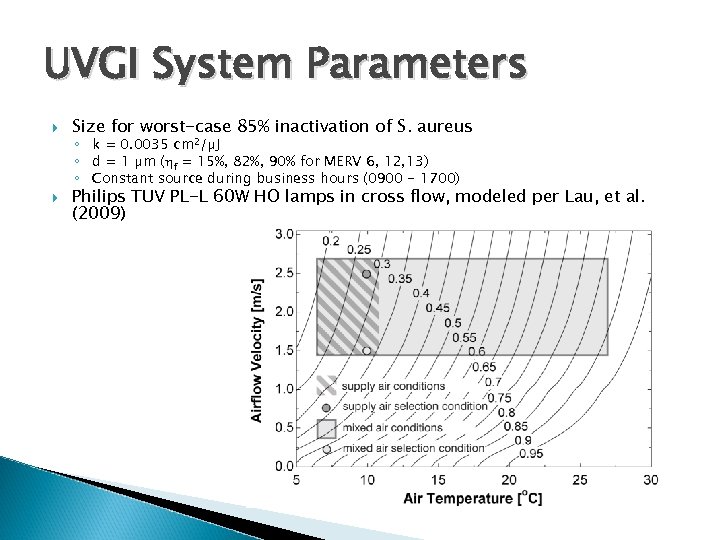

UVGI System Parameters Size for worst-case 85% inactivation of S. aureus ◦ k = 0. 0035 cm 2/µJ ◦ d = 1 µm ( f = 15%, 82%, 90% for MERV 6, 12, 13) ◦ Constant source during business hours (0900 - 1700) Philips TUV PL-L 60 W HO lamps in cross flow, modeled per Lau, et al. (2009)

UVGI System Parameters Size for worst-case 85% inactivation of S. aureus ◦ k = 0. 0035 cm 2/µJ ◦ d = 1 µm ( f = 15%, 82%, 90% for MERV 6, 12, 13) ◦ Constant source during business hours (0900 - 1700) Philips TUV PL-L 60 W HO lamps in cross flow, modeled per Lau, et al. (2009)

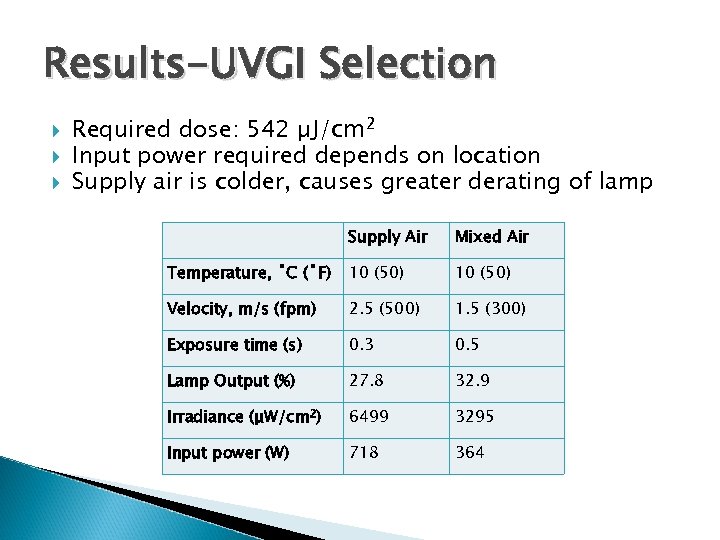

Results-UVGI Selection Required dose: 542 µJ/cm 2 Input power required depends on location Supply air is colder, causes greater derating of lamp Supply Air Mixed Air Temperature, ˚C (˚F) 10 (50) Velocity, m/s (fpm) 2. 5 (500) 1. 5 (300) Exposure time (s) 0. 3 0. 5 Lamp Output (%) 27. 8 32. 9 Irradiance (μW/cm 2) 6499 3295 Input power (W) 718 364

Results-UVGI Selection Required dose: 542 µJ/cm 2 Input power required depends on location Supply air is colder, causes greater derating of lamp Supply Air Mixed Air Temperature, ˚C (˚F) 10 (50) Velocity, m/s (fpm) 2. 5 (500) 1. 5 (300) Exposure time (s) 0. 3 0. 5 Lamp Output (%) 27. 8 32. 9 Irradiance (μW/cm 2) 6499 3295 Input power (W) 718 364

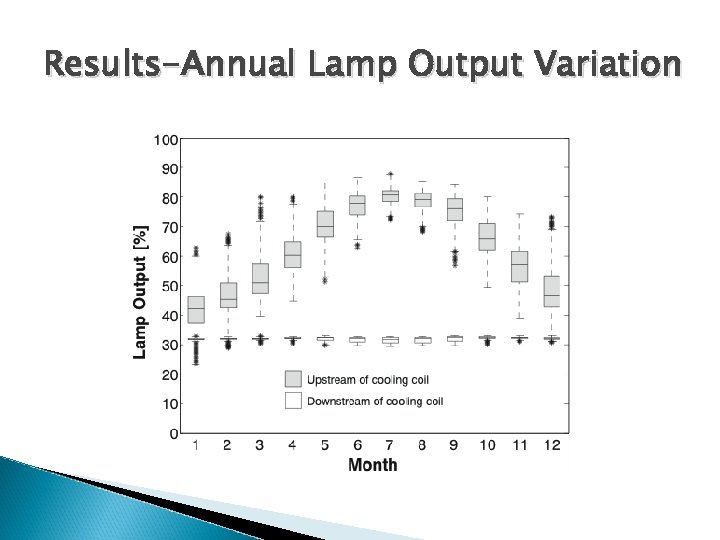

Results-Annual Lamp Output Variation

Results-Annual Lamp Output Variation

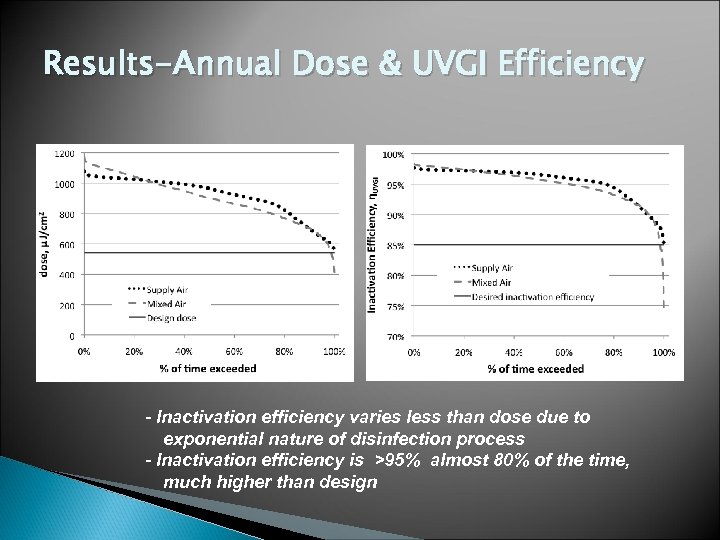

Results-Annual Dose & UVGI Efficiency - Inactivation efficiency varies less than dose due to exponential nature of disinfection process - Inactivation efficiency is >95% almost 80% of the time, much higher than design

Results-Annual Dose & UVGI Efficiency - Inactivation efficiency varies less than dose due to exponential nature of disinfection process - Inactivation efficiency is >95% almost 80% of the time, much higher than design

UVGI Economics First cost and operating cost of IAQ control equipment can be estimated reasonably well Benefits of good IAQ are not well quantified ◦ “ 10, 000 m” (30, 000 ft) view: $17 -48 billion per year impact in US (Fisk 2002) ◦ Detailed models based on uncertain dose-response models and cost assumptions (Fisk, et al. 2005) Application of IAQ technology is limited by underdeveloped economic case

UVGI Economics First cost and operating cost of IAQ control equipment can be estimated reasonably well Benefits of good IAQ are not well quantified ◦ “ 10, 000 m” (30, 000 ft) view: $17 -48 billion per year impact in US (Fisk 2002) ◦ Detailed models based on uncertain dose-response models and cost assumptions (Fisk, et al. 2005) Application of IAQ technology is limited by underdeveloped economic case

UVGI Economics Costs ◦ Initial costs: design, installation of fixtures, initial lamping ◦ Recurring costs: lamp replacement, cleaning ◦ Energy cost: lamps, heating/cooling, fan Sizing affects all of the above

UVGI Economics Costs ◦ Initial costs: design, installation of fixtures, initial lamping ◦ Recurring costs: lamp replacement, cleaning ◦ Energy cost: lamps, heating/cooling, fan Sizing affects all of the above

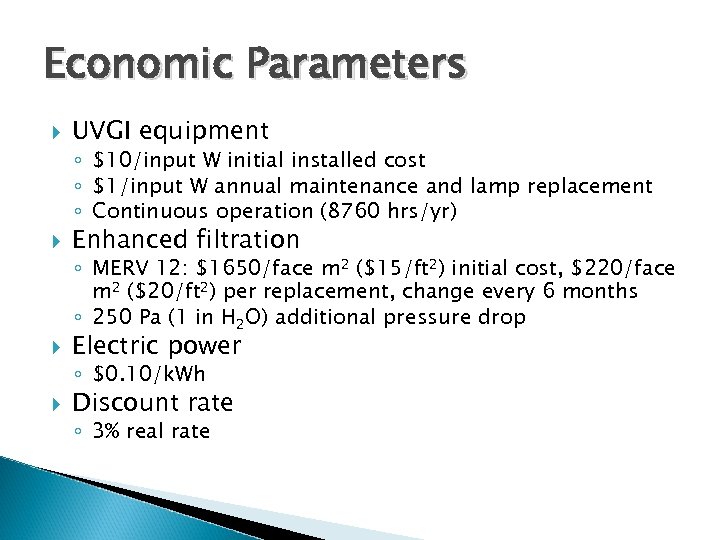

Economic Parameters UVGI equipment ◦ $10/input W initial installed cost ◦ $1/input W annual maintenance and lamp replacement ◦ Continuous operation (8760 hrs/yr) Enhanced filtration ◦ MERV 12: $1650/face m 2 ($15/ft 2) initial cost, $220/face m 2 ($20/ft 2) per replacement, change every 6 months ◦ 250 Pa (1 in H 2 O) additional pressure drop Electric power ◦ $0. 10/k. Wh Discount rate ◦ 3% real rate

Economic Parameters UVGI equipment ◦ $10/input W initial installed cost ◦ $1/input W annual maintenance and lamp replacement ◦ Continuous operation (8760 hrs/yr) Enhanced filtration ◦ MERV 12: $1650/face m 2 ($15/ft 2) initial cost, $220/face m 2 ($20/ft 2) per replacement, change every 6 months ◦ 250 Pa (1 in H 2 O) additional pressure drop Electric power ◦ $0. 10/k. Wh Discount rate ◦ 3% real rate

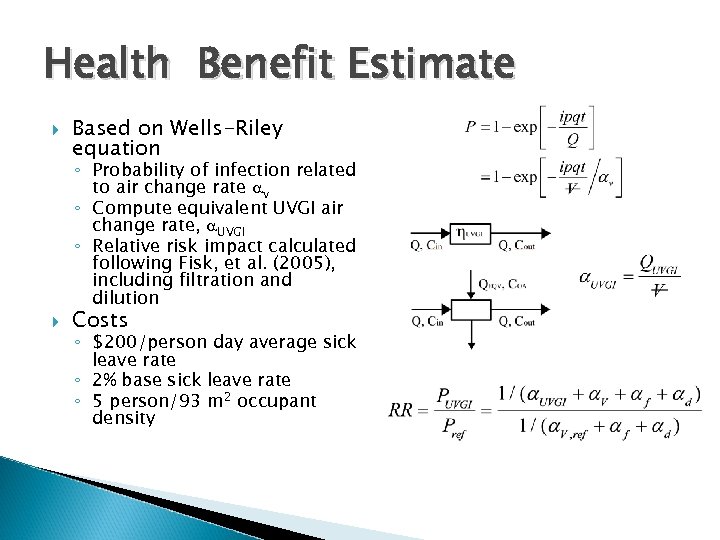

Health Benefit Estimate Based on Wells-Riley equation ◦ Probability of infection related to air change rate v ◦ Compute equivalent UVGI air change rate, UVGI ◦ Relative risk impact calculated following Fisk, et al. (2005), including filtration and dilution Costs ◦ $200/person day average sick leave rate ◦ 2% base sick leave rate ◦ 5 person/93 m 2 occupant density

Health Benefit Estimate Based on Wells-Riley equation ◦ Probability of infection related to air change rate v ◦ Compute equivalent UVGI air change rate, UVGI ◦ Relative risk impact calculated following Fisk, et al. (2005), including filtration and dilution Costs ◦ $200/person day average sick leave rate ◦ 2% base sick leave rate ◦ 5 person/93 m 2 occupant density

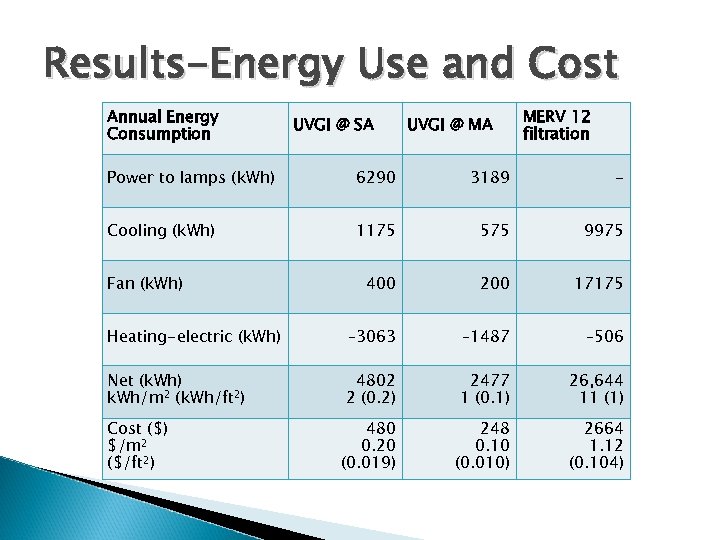

Results-Energy Use and Cost Annual Energy Consumption UVGI @ SA UVGI @ MA MERV 12 filtration Power to lamps (k. Wh) 6290 3189 - Cooling (k. Wh) 1175 575 9975 400 200 17175 Heating-electric (k. Wh) – 3063 – 1487 – 506 Net (k. Wh) k. Wh/m 2 (k. Wh/ft 2) 4802 2 (0. 2) 2477 1 (0. 1) 26, 644 11 (1) 480 0. 20 (0. 019) 248 0. 10 (0. 010) 2664 1. 12 (0. 104) Fan (k. Wh) Cost ($) $/m 2 ($/ft 2)

Results-Energy Use and Cost Annual Energy Consumption UVGI @ SA UVGI @ MA MERV 12 filtration Power to lamps (k. Wh) 6290 3189 - Cooling (k. Wh) 1175 575 9975 400 200 17175 Heating-electric (k. Wh) – 3063 – 1487 – 506 Net (k. Wh) k. Wh/m 2 (k. Wh/ft 2) 4802 2 (0. 2) 2477 1 (0. 1) 26, 644 11 (1) 480 0. 20 (0. 019) 248 0. 10 (0. 010) 2664 1. 12 (0. 104) Fan (k. Wh) Cost ($) $/m 2 ($/ft 2)

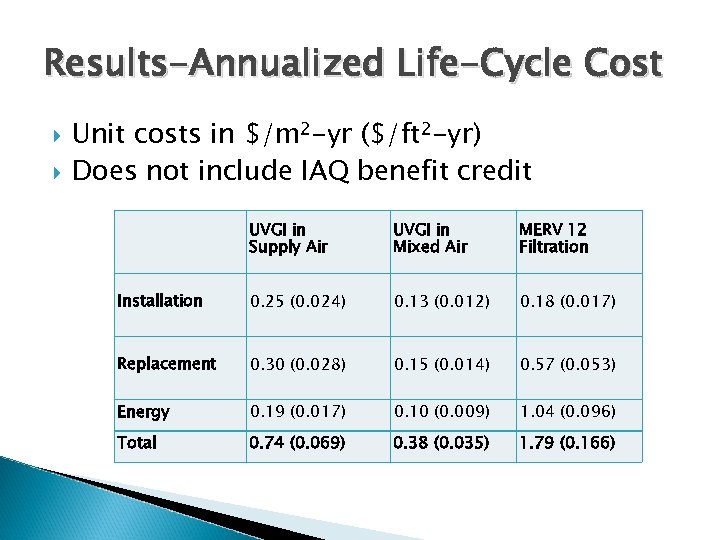

Results-Annualized Life-Cycle Cost Unit costs in $/m 2 -yr ($/ft 2 -yr) Does not include IAQ benefit credit UVGI in Supply Air UVGI in Mixed Air MERV 12 Filtration Installation 0. 25 (0. 024) 0. 13 (0. 012) 0. 18 (0. 017) Replacement 0. 30 (0. 028) 0. 15 (0. 014) 0. 57 (0. 053) Energy 0. 19 (0. 017) 0. 10 (0. 009) 1. 04 (0. 096) Total 0. 74 (0. 069) 0. 38 (0. 035) 1. 79 (0. 166)

Results-Annualized Life-Cycle Cost Unit costs in $/m 2 -yr ($/ft 2 -yr) Does not include IAQ benefit credit UVGI in Supply Air UVGI in Mixed Air MERV 12 Filtration Installation 0. 25 (0. 024) 0. 13 (0. 012) 0. 18 (0. 017) Replacement 0. 30 (0. 028) 0. 15 (0. 014) 0. 57 (0. 053) Energy 0. 19 (0. 017) 0. 10 (0. 009) 1. 04 (0. 096) Total 0. 74 (0. 069) 0. 38 (0. 035) 1. 79 (0. 166)

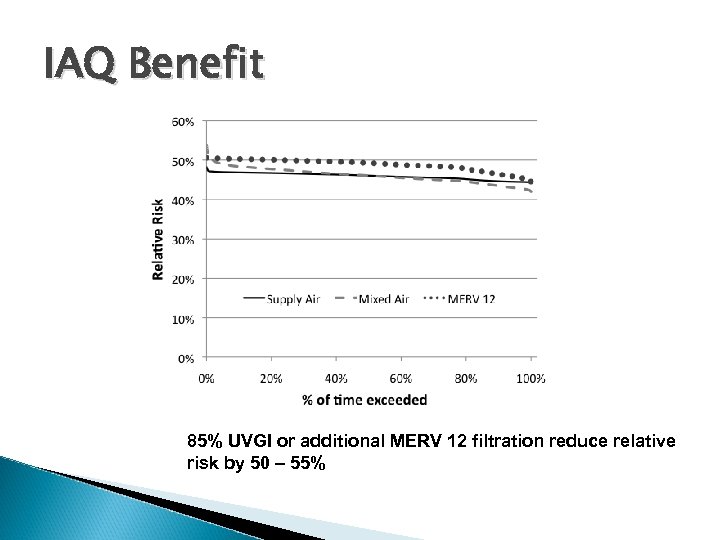

IAQ Benefit 85% UVGI or additional MERV 12 filtration reduce relative risk by 50 – 55%

IAQ Benefit 85% UVGI or additional MERV 12 filtration reduce relative risk by 50 – 55%

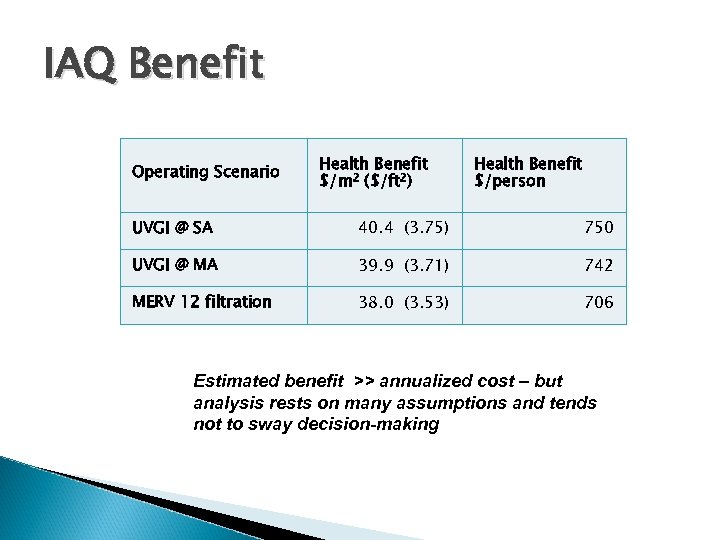

IAQ Benefit Operating Scenario Health Benefit $/m 2 ($/ft 2) Health Benefit $/person UVGI @ SA 40. 4 (3. 75) 750 UVGI @ MA 39. 9 (3. 71) 742 MERV 12 filtration 38. 0 (3. 53) 706 Estimated benefit >> annualized cost – but analysis rests on many assumptions and tends not to sway decision-making

IAQ Benefit Operating Scenario Health Benefit $/m 2 ($/ft 2) Health Benefit $/person UVGI @ SA 40. 4 (3. 75) 750 UVGI @ MA 39. 9 (3. 71) 742 MERV 12 filtration 38. 0 (3. 53) 706 Estimated benefit >> annualized cost – but analysis rests on many assumptions and tends not to sway decision-making

Summary UVGI is not new and there is a pile of evidence to support its effectiveness As an industry, UVGI is still developing, needs more standardization and openness, but that is not a reason to avoid using it today As with any IAQ technology, UVGI is most effective when applied in an environment where benefits can be quantified (e. g. , healthcare) NAFA TECH 2010 4/22/2010 63

Summary UVGI is not new and there is a pile of evidence to support its effectiveness As an industry, UVGI is still developing, needs more standardization and openness, but that is not a reason to avoid using it today As with any IAQ technology, UVGI is most effective when applied in an environment where benefits can be quantified (e. g. , healthcare) NAFA TECH 2010 4/22/2010 63

Needs Standards for rating components and assemblies ◦ ASHRAE SPC 185 - Method of Testing UVC Lights for Use in Air Handling Units or Air Ducts to Inactivate Airborne Microorganisms ◦ ISO TC 142 WG 2 - UVC Devices Rigorous sizing methods Design and application guidance Equipment data to support selection and design More and better k value data More field studies to establish practical performance and identify problems NAFA TECH 2010 4/22/2010 64

Needs Standards for rating components and assemblies ◦ ASHRAE SPC 185 - Method of Testing UVC Lights for Use in Air Handling Units or Air Ducts to Inactivate Airborne Microorganisms ◦ ISO TC 142 WG 2 - UVC Devices Rigorous sizing methods Design and application guidance Equipment data to support selection and design More and better k value data More field studies to establish practical performance and identify problems NAFA TECH 2010 4/22/2010 64

Resources ASHRAE. 2009. ASHRAE Position Document on Airborne Infectious Diseases. Atlanta: American Society of Heating, Refrigerating and Air-Conditioning Engineers. www. ashrae. org/doc. Lib/20090901_Airborne. Infex. Diseases. PDFrev. pdf ASHRAE. 2008. Ultraviolet Lamp Systems. 2008 ASHRAE Handbook – HVAC Systems and Equipment. Atlanta: American Society of Heating, Refrigerating and Air-Conditioning Engineers. Martin, S. , C. Dunn, F. Freihaut, W. Bahnfleth, J. Lau, A. Nedeljkovic-Davidovic. 2008. Ultraviolet germicidal irradiation: current best practices. ASHRAE Journal 50(8): 28 -36. Kowalski, W. 2009. Ultraviolet Germicidal Irradiation Handbook. Heidelberg: Springer. ISBN 879 -3 -642 -019998 -2. NIOSH. 2009. Environmental Control for Tuberculosis: Basic Upper-Room Ultraviolet Germicidal Irradiation Guidelines for Healthcare Settings. DHHS (NIOSH) Publication No. 2009– 105. www. cdc. gov/niosh/docs/2009 -105/pdfs/2009 -105. pdf NAFA TECH 2010 4/22/2010 65

Resources ASHRAE. 2009. ASHRAE Position Document on Airborne Infectious Diseases. Atlanta: American Society of Heating, Refrigerating and Air-Conditioning Engineers. www. ashrae. org/doc. Lib/20090901_Airborne. Infex. Diseases. PDFrev. pdf ASHRAE. 2008. Ultraviolet Lamp Systems. 2008 ASHRAE Handbook – HVAC Systems and Equipment. Atlanta: American Society of Heating, Refrigerating and Air-Conditioning Engineers. Martin, S. , C. Dunn, F. Freihaut, W. Bahnfleth, J. Lau, A. Nedeljkovic-Davidovic. 2008. Ultraviolet germicidal irradiation: current best practices. ASHRAE Journal 50(8): 28 -36. Kowalski, W. 2009. Ultraviolet Germicidal Irradiation Handbook. Heidelberg: Springer. ISBN 879 -3 -642 -019998 -2. NIOSH. 2009. Environmental Control for Tuberculosis: Basic Upper-Room Ultraviolet Germicidal Irradiation Guidelines for Healthcare Settings. DHHS (NIOSH) Publication No. 2009– 105. www. cdc. gov/niosh/docs/2009 -105/pdfs/2009 -105. pdf NAFA TECH 2010 4/22/2010 65