03dd3a150e2eba011b28d50056a3397d.ppt

- Количество слайдов: 1

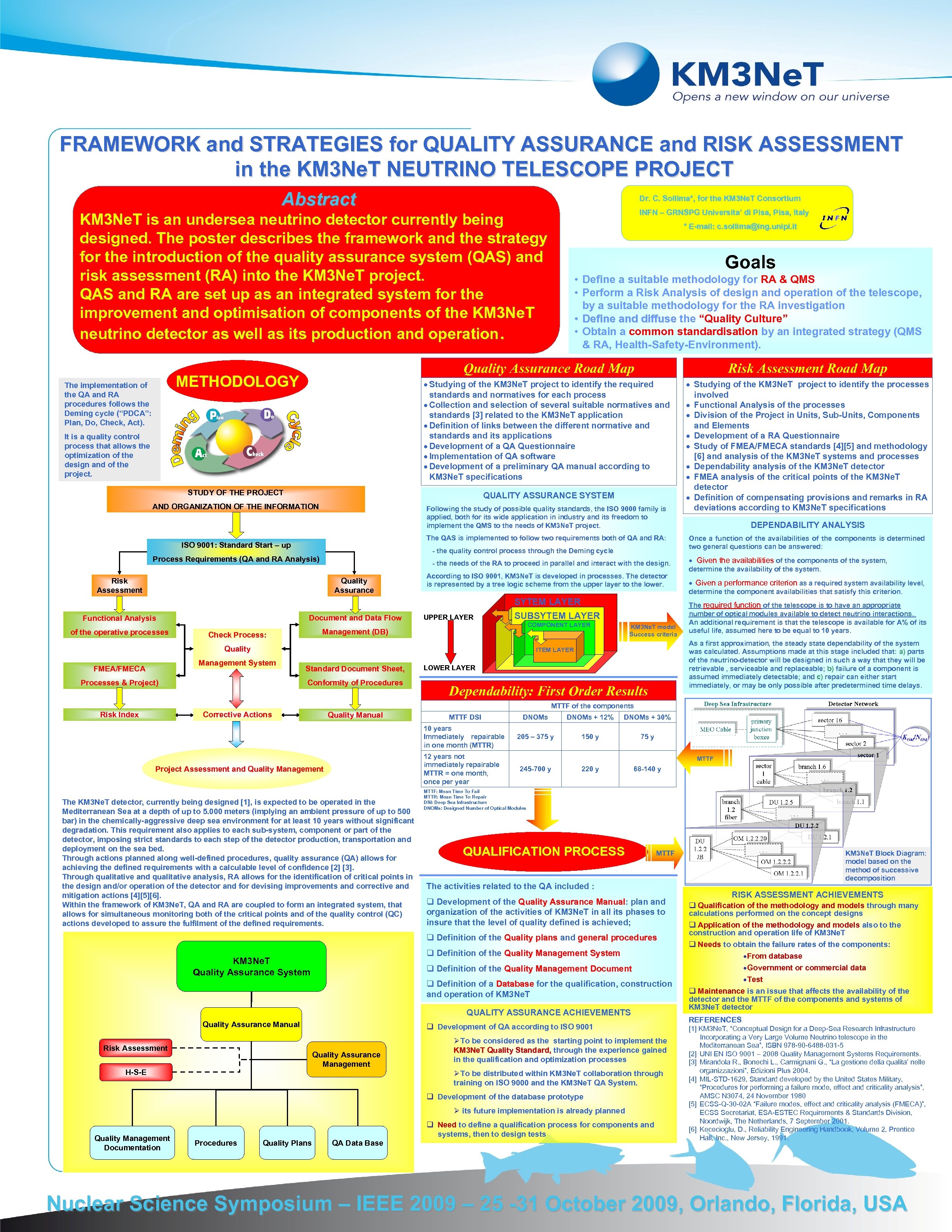

FRAMEWORK and STRATEGIES for QUALITY ASSURANCE and RISK ASSESSMENT in the KM 3 Ne. T NEUTRINO TELESCOPE PROJECT Abstract Dr. C. Sollima*, for the KM 3 Ne. T Consortium INFN – GRNSPG Universita’ di Pisa, Italy KM 3 Ne. T is an undersea neutrino detector currently being designed. The poster describes the framework and the strategy for the introduction of the quality assurance system (QAS) and risk assessment (RA) into the KM 3 Ne. T project. QAS and RA are set up as an integrated system for the improvement and optimisation of components of the KM 3 Ne. T neutrino detector as well as its production and operation. Goals • Define a suitable methodology for RA & QMS • Perform a Risk Analysis of design and operation of the telescope, by a suitable methodology for the RA investigation • Define and diffuse the “Quality Culture” • Obtain a common standardisation by an integrated strategy (QMS & RA, Health-Safety-Environment). Quality Assurance Road Map It is a quality control process that allows the optimization of the design and of the project. Risk Assessment Road Map Studying of the KM 3 Ne. T project to identify the required standards and normatives for each process Collection and selection of several suitable normatives and standards [3] related to the KM 3 Ne. T application Definition of links between the different normative and standards and its applications Development of a QA Questionnaire Implementation of QA software Development of a preliminary QA manual according to KM 3 Ne. T specifications METHODOLOGY The implementation of the QA and RA procedures follows the Deming cycle (“PDCA”: Plan, Do, Check, Act). * E-mail: c. sollima@ing. unipi. it Studying of the KM 3 Ne. T project to identify the processes involved Functional Analysis of the processes Division of the Project in Units, Sub-Units, Components and Elements Development of a RA Questionnaire Study of FMEA/FMECA standards [4][5] and methodology [6] and analysis of the KM 3 Ne. T systems and processes Dependability analysis of the KM 3 Ne. T detector FMEA analysis of the critical points of the KM 3 Ne. T detector Definition of compensating provisions and remarks in RA deviations according to KM 3 Ne. T specifications STUDY OF THE PROJECT QUALITY ASSURANCE SYSTEM AND ORGANIZATION OF THE INFORMATION Following the study of possible quality standards, the ISO 9000 family is applied, both for its wide application in industry and its freedom to implement the QMS to the needs of KM 3 Ne. T project. The QAS is implemented to follow two requirements both of QA and RA: ISO 9001: Standard Start – up - the quality control process through the Deming cycle Process Requirements (QA and RA Analysis) - the needs of the RA to proceed in parallel and interact with the design. Risk Assessment Quality Assurance According to ISO 9001, KM 3 Ne. T is developed in processes. The detector is represented by a tree logic scheme from the upper layer to the lower. SYTEM LAYER Document and Data Flow Functional Analysis of the operative processes UPPER LAYER SUBSYTEM LAYER COMPONENT LAYER Management (DB) Check Process: Quality Processes & Project) Standard Document Sheet, Conformity of Procedures Once a function of the availabilities of the components is determined two general questions can be answered: Given the availabilities of the components of the system, determine the availability of the system. Given a performance criterion as a required system availability level, determine the component availabilities that satisfy this criterion. The required function of the telescope is to have an appropriate number of optical modules available to detect neutrino interactions. An additional requirement is that the telescope is available for A% of its useful life, assumed here to be equal to 10 years. As a first approximation, the steady state dependability of the system was calculated. Assumptions made at this stage included that: a) parts of the neutrino-detector will be designed in such a way that they will be retrievable , serviceable and replaceable; b) failure of a component is assumed immediately detectable; and c) repair can either start immediately, or may be only possible after predetermined time delays. ITEM LAYER Management System FMEA/FMECA KM 3 Ne. T model Success criteria DEPENDABILITY ANALYSIS LOWER LAYER Dependability: First Order Results MTTF of the components Corrective Actions Risk Index Quality Manual MTTF DSI DNOMs + 12% DNOMs + 30% 10 years Immediately repairable in one month (MTTR) 205 – 375 y 150 y 75 y 12 years not immediately repairable MTTR = one month, once per year Project Assessment and Quality Management The KM 3 Ne. T detector, currently being designed [1], is expected to be operated in the Mediterranean Sea at a depth of up to 5. 000 meters (implying an ambient pressure of up to 500 bar) in the chemically-aggressive deep sea environment for at least 10 years without significant degradation. This requirement also applies to each sub-system, component or part of the detector, imposing strict standards to each step of the detector production, transportation and deployment on the sea bed. Through actions planned along well-defined procedures, quality assurance (QA) allows for achieving the defined requirements with a calculable level of confidence [2] [3]. Through qualitative and qualitative analysis, RA allows for the identification of critical points in the design and/or operation of the detector and for devising improvements and corrective and mitigation actions [4][5][6]. Within the framework of KM 3 Ne. T, QA and RA are coupled to form an integrated system, that allows for simultaneous monitoring both of the critical points and of the quality control (QC) actions developed to assure the fulfilment of the defined requirements. MTTF 245 -700 y 220 y 68 -140 y MTTF: Mean Time To Fail MTTR: Mean Time To Repair DSI: Deep Sea Infrastructure DNOMs: Designed Number of Optical Modules QUALIFICATION PROCESS The activities related to the QA included : q Development of the Quality Assurance Manual: plan and Manual organization of the activities of KM 3 Ne. T in all its phases to insure that the level of quality defined is achieved; q Definition of the Quality plans and general procedures q Definition of the Quality Management System KM 3 Ne. T Quality Assurance System q Definition of the Quality Management Document q Definition of a Database for the qualification, construction and operation of KM 3 Ne. T QUALITY ASSURANCE ACHIEVEMENTS Quality Assurance Manual Risk Assessment q Development of QA according to ISO 9001 Quality Assurance Management H-S-E ØTo be considered as the starting point to implement the KM 3 Ne. T Quality Standard, through the experience gained in the qualification and optimization processes ØTo be distributed within KM 3 Ne. T collaboration through training on ISO 9000 and the KM 3 Ne. T QA System. q Development of the database prototype Ø its future implementation is already planned Quality Management Documentation q Need to define a qualification process for components and systems, then to design tests Procedures Quality Plans QA Data Base KM 3 Ne. T Block Diagram: model based on the method of successive decomposition MTTF RISK ASSESSMENT ACHIEVEMENTS q Qualification of the methodology and models through many calculations performed on the concept designs q Application of the methodology and models also to the construction and operation life of KM 3 Ne. T q Needs to obtain the failure rates of the components: From database Government or commercial data Test q Maintenance is an issue that affects the availability of the detector and the MTTF of the components and systems of KM 3 Ne. T detector REFERENCES [1] KM 3 Ne. T, “Conceptual Design for a Deep-Sea Research Infrastructure Incorporating a Very Large Volume Neutrino telescope in the Mediterranean Sea”, ISBN 978 -90 -6488 -031 -5 [2] UNI EN ISO 9001 – 2008 Quality Management Systems Requirements. [3] Mirandola R. , Bonechi L. , Carmignani G. , “La gestione della qualita’ nelle organizzazioni”, Edizioni Plus 2004. [4] MIL-STD-1629, Standard developed by the United States Military, “Procedures for performing a failure mode, effect and criticality analysis”, AMSC N 3074, 24 November 1980 [5] ECSS-Q-30 -02 A “Failure modes, effect and criticality analysis (FMECA)”, ECSS Secretariat, ESA-ESTEC Requirements & Standards Division, Noordwijk, The Netherlands, 7 September 2001. [6] Kececioglu, D. , Reliability Engineering Handbook, Volume 2, Prentice Hall, Inc. , New Jersey, 1991. Nuclear Science Symposium – IEEE 2009 – 25 -31 October 2009, Orlando, Florida, USA

FRAMEWORK and STRATEGIES for QUALITY ASSURANCE and RISK ASSESSMENT in the KM 3 Ne. T NEUTRINO TELESCOPE PROJECT Abstract Dr. C. Sollima*, for the KM 3 Ne. T Consortium INFN – GRNSPG Universita’ di Pisa, Italy KM 3 Ne. T is an undersea neutrino detector currently being designed. The poster describes the framework and the strategy for the introduction of the quality assurance system (QAS) and risk assessment (RA) into the KM 3 Ne. T project. QAS and RA are set up as an integrated system for the improvement and optimisation of components of the KM 3 Ne. T neutrino detector as well as its production and operation. Goals • Define a suitable methodology for RA & QMS • Perform a Risk Analysis of design and operation of the telescope, by a suitable methodology for the RA investigation • Define and diffuse the “Quality Culture” • Obtain a common standardisation by an integrated strategy (QMS & RA, Health-Safety-Environment). Quality Assurance Road Map It is a quality control process that allows the optimization of the design and of the project. Risk Assessment Road Map Studying of the KM 3 Ne. T project to identify the required standards and normatives for each process Collection and selection of several suitable normatives and standards [3] related to the KM 3 Ne. T application Definition of links between the different normative and standards and its applications Development of a QA Questionnaire Implementation of QA software Development of a preliminary QA manual according to KM 3 Ne. T specifications METHODOLOGY The implementation of the QA and RA procedures follows the Deming cycle (“PDCA”: Plan, Do, Check, Act). * E-mail: c. sollima@ing. unipi. it Studying of the KM 3 Ne. T project to identify the processes involved Functional Analysis of the processes Division of the Project in Units, Sub-Units, Components and Elements Development of a RA Questionnaire Study of FMEA/FMECA standards [4][5] and methodology [6] and analysis of the KM 3 Ne. T systems and processes Dependability analysis of the KM 3 Ne. T detector FMEA analysis of the critical points of the KM 3 Ne. T detector Definition of compensating provisions and remarks in RA deviations according to KM 3 Ne. T specifications STUDY OF THE PROJECT QUALITY ASSURANCE SYSTEM AND ORGANIZATION OF THE INFORMATION Following the study of possible quality standards, the ISO 9000 family is applied, both for its wide application in industry and its freedom to implement the QMS to the needs of KM 3 Ne. T project. The QAS is implemented to follow two requirements both of QA and RA: ISO 9001: Standard Start – up - the quality control process through the Deming cycle Process Requirements (QA and RA Analysis) - the needs of the RA to proceed in parallel and interact with the design. Risk Assessment Quality Assurance According to ISO 9001, KM 3 Ne. T is developed in processes. The detector is represented by a tree logic scheme from the upper layer to the lower. SYTEM LAYER Document and Data Flow Functional Analysis of the operative processes UPPER LAYER SUBSYTEM LAYER COMPONENT LAYER Management (DB) Check Process: Quality Processes & Project) Standard Document Sheet, Conformity of Procedures Once a function of the availabilities of the components is determined two general questions can be answered: Given the availabilities of the components of the system, determine the availability of the system. Given a performance criterion as a required system availability level, determine the component availabilities that satisfy this criterion. The required function of the telescope is to have an appropriate number of optical modules available to detect neutrino interactions. An additional requirement is that the telescope is available for A% of its useful life, assumed here to be equal to 10 years. As a first approximation, the steady state dependability of the system was calculated. Assumptions made at this stage included that: a) parts of the neutrino-detector will be designed in such a way that they will be retrievable , serviceable and replaceable; b) failure of a component is assumed immediately detectable; and c) repair can either start immediately, or may be only possible after predetermined time delays. ITEM LAYER Management System FMEA/FMECA KM 3 Ne. T model Success criteria DEPENDABILITY ANALYSIS LOWER LAYER Dependability: First Order Results MTTF of the components Corrective Actions Risk Index Quality Manual MTTF DSI DNOMs + 12% DNOMs + 30% 10 years Immediately repairable in one month (MTTR) 205 – 375 y 150 y 75 y 12 years not immediately repairable MTTR = one month, once per year Project Assessment and Quality Management The KM 3 Ne. T detector, currently being designed [1], is expected to be operated in the Mediterranean Sea at a depth of up to 5. 000 meters (implying an ambient pressure of up to 500 bar) in the chemically-aggressive deep sea environment for at least 10 years without significant degradation. This requirement also applies to each sub-system, component or part of the detector, imposing strict standards to each step of the detector production, transportation and deployment on the sea bed. Through actions planned along well-defined procedures, quality assurance (QA) allows for achieving the defined requirements with a calculable level of confidence [2] [3]. Through qualitative and qualitative analysis, RA allows for the identification of critical points in the design and/or operation of the detector and for devising improvements and corrective and mitigation actions [4][5][6]. Within the framework of KM 3 Ne. T, QA and RA are coupled to form an integrated system, that allows for simultaneous monitoring both of the critical points and of the quality control (QC) actions developed to assure the fulfilment of the defined requirements. MTTF 245 -700 y 220 y 68 -140 y MTTF: Mean Time To Fail MTTR: Mean Time To Repair DSI: Deep Sea Infrastructure DNOMs: Designed Number of Optical Modules QUALIFICATION PROCESS The activities related to the QA included : q Development of the Quality Assurance Manual: plan and Manual organization of the activities of KM 3 Ne. T in all its phases to insure that the level of quality defined is achieved; q Definition of the Quality plans and general procedures q Definition of the Quality Management System KM 3 Ne. T Quality Assurance System q Definition of the Quality Management Document q Definition of a Database for the qualification, construction and operation of KM 3 Ne. T QUALITY ASSURANCE ACHIEVEMENTS Quality Assurance Manual Risk Assessment q Development of QA according to ISO 9001 Quality Assurance Management H-S-E ØTo be considered as the starting point to implement the KM 3 Ne. T Quality Standard, through the experience gained in the qualification and optimization processes ØTo be distributed within KM 3 Ne. T collaboration through training on ISO 9000 and the KM 3 Ne. T QA System. q Development of the database prototype Ø its future implementation is already planned Quality Management Documentation q Need to define a qualification process for components and systems, then to design tests Procedures Quality Plans QA Data Base KM 3 Ne. T Block Diagram: model based on the method of successive decomposition MTTF RISK ASSESSMENT ACHIEVEMENTS q Qualification of the methodology and models through many calculations performed on the concept designs q Application of the methodology and models also to the construction and operation life of KM 3 Ne. T q Needs to obtain the failure rates of the components: From database Government or commercial data Test q Maintenance is an issue that affects the availability of the detector and the MTTF of the components and systems of KM 3 Ne. T detector REFERENCES [1] KM 3 Ne. T, “Conceptual Design for a Deep-Sea Research Infrastructure Incorporating a Very Large Volume Neutrino telescope in the Mediterranean Sea”, ISBN 978 -90 -6488 -031 -5 [2] UNI EN ISO 9001 – 2008 Quality Management Systems Requirements. [3] Mirandola R. , Bonechi L. , Carmignani G. , “La gestione della qualita’ nelle organizzazioni”, Edizioni Plus 2004. [4] MIL-STD-1629, Standard developed by the United States Military, “Procedures for performing a failure mode, effect and criticality analysis”, AMSC N 3074, 24 November 1980 [5] ECSS-Q-30 -02 A “Failure modes, effect and criticality analysis (FMECA)”, ECSS Secretariat, ESA-ESTEC Requirements & Standards Division, Noordwijk, The Netherlands, 7 September 2001. [6] Kececioglu, D. , Reliability Engineering Handbook, Volume 2, Prentice Hall, Inc. , New Jersey, 1991. Nuclear Science Symposium – IEEE 2009 – 25 -31 October 2009, Orlando, Florida, USA