ed94d1225f5b7315785d25be96db5c50.ppt

- Количество слайдов: 17

FP 420 Infrastructure in LHC FP 420 @ UTA 27 -Mar-2007 27 March 2007 D. Swoboda FP 420 @ UTA

FP 420 Infrastructure in LHC FP 420 @ UTA 27 -Mar-2007 27 March 2007 D. Swoboda FP 420 @ UTA

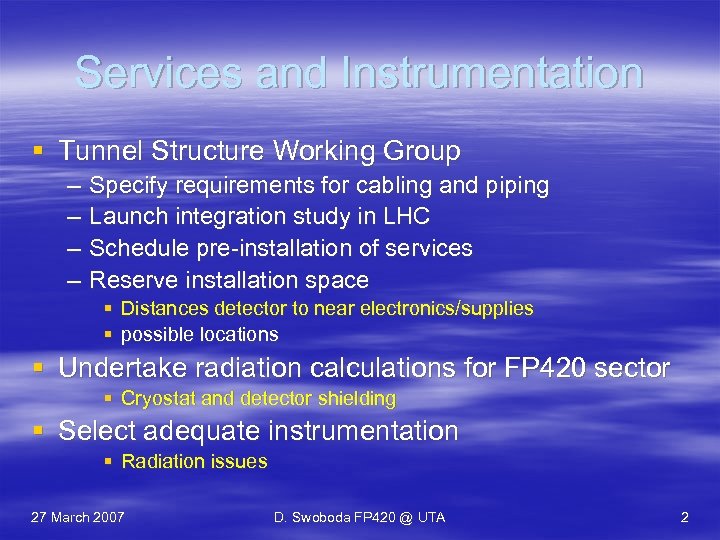

Services and Instrumentation § Tunnel Structure Working Group – – Specify requirements for cabling and piping Launch integration study in LHC Schedule pre-installation of services Reserve installation space § Distances detector to near electronics/supplies § possible locations § Undertake radiation calculations for FP 420 sector § Cryostat and detector shielding § Select adequate instrumentation § Radiation issues 27 March 2007 D. Swoboda FP 420 @ UTA 2

Services and Instrumentation § Tunnel Structure Working Group – – Specify requirements for cabling and piping Launch integration study in LHC Schedule pre-installation of services Reserve installation space § Distances detector to near electronics/supplies § possible locations § Undertake radiation calculations for FP 420 sector § Cryostat and detector shielding § Select adequate instrumentation § Radiation issues 27 March 2007 D. Swoboda FP 420 @ UTA 2

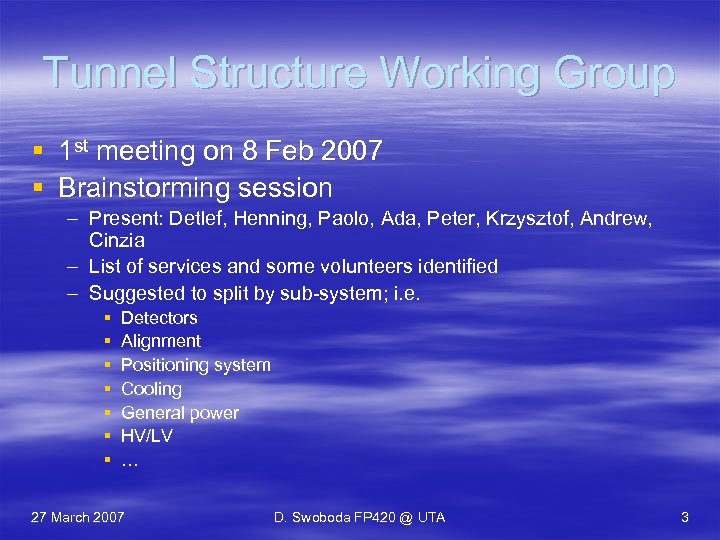

Tunnel Structure Working Group § 1 st meeting on 8 Feb 2007 § Brainstorming session – Present: Detlef, Henning, Paolo, Ada, Peter, Krzysztof, Andrew, Cinzia – List of services and some volunteers identified – Suggested to split by sub-system; i. e. § § § § Detectors Alignment Positioning system Cooling General power HV/LV … 27 March 2007 D. Swoboda FP 420 @ UTA 3

Tunnel Structure Working Group § 1 st meeting on 8 Feb 2007 § Brainstorming session – Present: Detlef, Henning, Paolo, Ada, Peter, Krzysztof, Andrew, Cinzia – List of services and some volunteers identified – Suggested to split by sub-system; i. e. § § § § Detectors Alignment Positioning system Cooling General power HV/LV … 27 March 2007 D. Swoboda FP 420 @ UTA 3

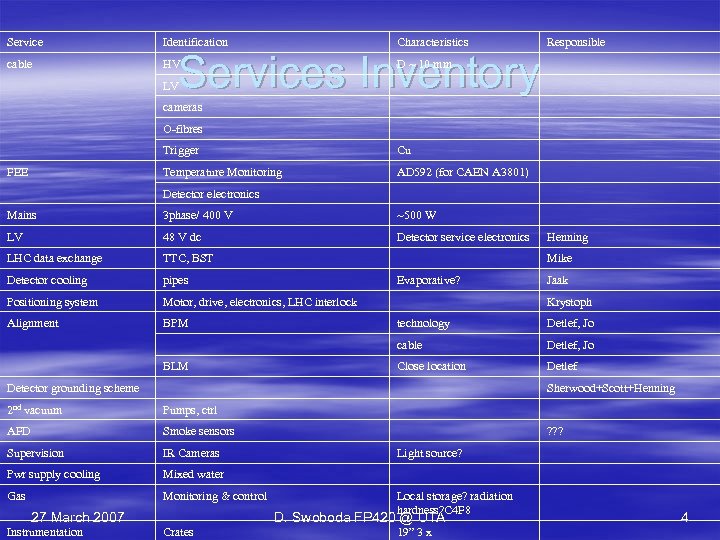

Service Identification Characteristics cable HV D ~ 10 mm Services Inventory Responsible LV cameras O-fibres Trigger Temperature Monitoring FEE Cu AD 592 (for CAEN A 3801) Detector electronics Mains 3 phase/ 400 V ~500 W LV 48 V dc Detector service electronics LHC data exchange TTC, BST Detector cooling pipes Positioning system Motor, drive, electronics, LHC interlock Alignment BPM Henning Mike Evaporative? Jaak Krystoph Detlef, Jo cable BLM technology Detlef, Jo Close location Detlef Detector grounding scheme Sherwood+Scott+Henning 2 nd vacuum Pumps, ctrl AFD Smoke sensors Supervision IR Cameras Pwr supply cooling Mixed water Gas Monitoring & control 27 March 2007 Instrumentation Crates ? ? ? Light source? Local storage? radiation hardness? C 4 F 8 D. Swoboda FP 420 @ UTA 19” 3 x 4

Service Identification Characteristics cable HV D ~ 10 mm Services Inventory Responsible LV cameras O-fibres Trigger Temperature Monitoring FEE Cu AD 592 (for CAEN A 3801) Detector electronics Mains 3 phase/ 400 V ~500 W LV 48 V dc Detector service electronics LHC data exchange TTC, BST Detector cooling pipes Positioning system Motor, drive, electronics, LHC interlock Alignment BPM Henning Mike Evaporative? Jaak Krystoph Detlef, Jo cable BLM technology Detlef, Jo Close location Detlef Detector grounding scheme Sherwood+Scott+Henning 2 nd vacuum Pumps, ctrl AFD Smoke sensors Supervision IR Cameras Pwr supply cooling Mixed water Gas Monitoring & control 27 March 2007 Instrumentation Crates ? ? ? Light source? Local storage? radiation hardness? C 4 F 8 D. Swoboda FP 420 @ UTA 19” 3 x 4

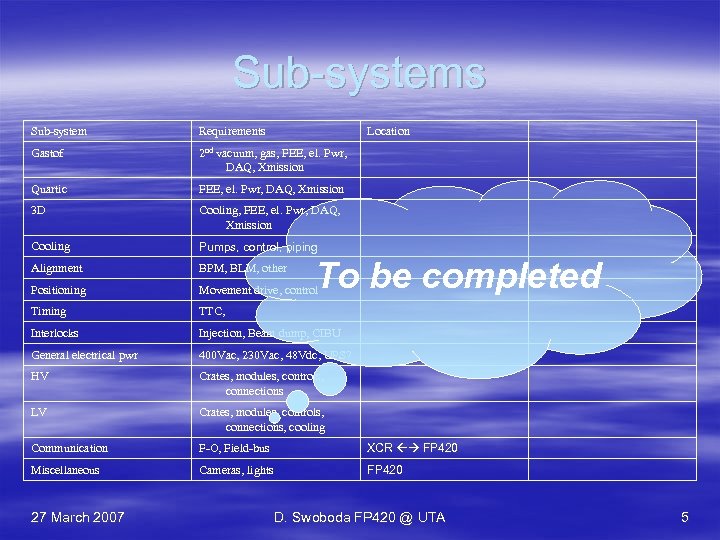

Sub-systems Sub-system Requirements Gastof 2 nd vacuum, gas, FEE, el. Pwr, DAQ, Xmission Quartic FEE, el. Pwr, DAQ, Xmission 3 D Cooling, FEE, el. Pwr, DAQ, Xmission Cooling Pumps, control, piping Alignment BPM, BLM, other Positioning Movement drive, control Timing TTC, Interlocks Injection, Beam dump, CIBU General electrical pwr 400 Vac, 230 Vac, 48 Vdc, UPS? HV Crates, modules, controls, connections LV Crates, modules, controls, connections, cooling Communication F-O, Field-bus XCR FP 420 Miscellaneous Cameras, lights FP 420 27 March 2007 Location To be completed D. Swoboda FP 420 @ UTA 5

Sub-systems Sub-system Requirements Gastof 2 nd vacuum, gas, FEE, el. Pwr, DAQ, Xmission Quartic FEE, el. Pwr, DAQ, Xmission 3 D Cooling, FEE, el. Pwr, DAQ, Xmission Cooling Pumps, control, piping Alignment BPM, BLM, other Positioning Movement drive, control Timing TTC, Interlocks Injection, Beam dump, CIBU General electrical pwr 400 Vac, 230 Vac, 48 Vdc, UPS? HV Crates, modules, controls, connections LV Crates, modules, controls, connections, cooling Communication F-O, Field-bus XCR FP 420 Miscellaneous Cameras, lights FP 420 27 March 2007 Location To be completed D. Swoboda FP 420 @ UTA 5

Service locations near FP 420 1. Tunnel wall above the QRL. The space reserved for electronic boxes could eventually be used for electronics/power supplies. The reserved cross-section is 400 x 320 mm (H x W). However, additional radiation shielding would certainly be required in these locations. 2. Underneath adjacent magnets. Throughout the LHC tunnel the space underneath the magnets, mainly in the arc regions has already been reserved for electronics instrumentation because of the relatively low radiation dose. 3. Tunnel wall inside. A proposed alternative is the excavation of cavities on the tunnel wall on the “transport” side. A 1 st inquiry has shown that holes of 75 cm diameter and 100 cm depth could be drilled [ ]. This solution seems to be theoretically feasible but would also require a good understanding of the radiation level at this location. 4. Support beams of cryostat. Support beams could receive openings to house custom electronics. Probably adequate for trigger devices requiring very short cable length. 27 March 2007 D. Swoboda FP 420 @ UTA 6

Service locations near FP 420 1. Tunnel wall above the QRL. The space reserved for electronic boxes could eventually be used for electronics/power supplies. The reserved cross-section is 400 x 320 mm (H x W). However, additional radiation shielding would certainly be required in these locations. 2. Underneath adjacent magnets. Throughout the LHC tunnel the space underneath the magnets, mainly in the arc regions has already been reserved for electronics instrumentation because of the relatively low radiation dose. 3. Tunnel wall inside. A proposed alternative is the excavation of cavities on the tunnel wall on the “transport” side. A 1 st inquiry has shown that holes of 75 cm diameter and 100 cm depth could be drilled [ ]. This solution seems to be theoretically feasible but would also require a good understanding of the radiation level at this location. 4. Support beams of cryostat. Support beams could receive openings to house custom electronics. Probably adequate for trigger devices requiring very short cable length. 27 March 2007 D. Swoboda FP 420 @ UTA 6

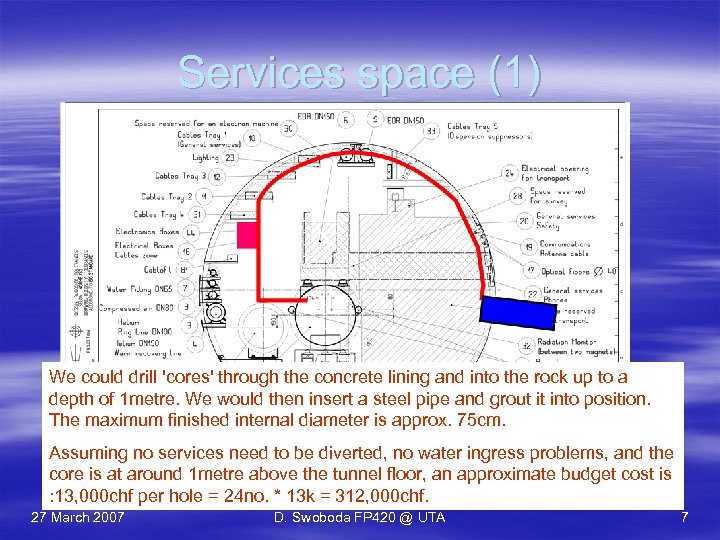

Services space (1) We could drill 'cores' through the concrete lining and into the rock up to a depth of 1 metre. We would then insert a steel pipe and grout it into position. The maximum finished internal diameter is approx. 75 cm. Assuming no services need to be diverted, no water ingress problems, and the core is at around 1 metre above the tunnel floor, an approximate budget cost is : 13, 000 chf per hole = 24 no. * 13 k = 312, 000 chf. 27 March 2007 D. Swoboda FP 420 @ UTA 7

Services space (1) We could drill 'cores' through the concrete lining and into the rock up to a depth of 1 metre. We would then insert a steel pipe and grout it into position. The maximum finished internal diameter is approx. 75 cm. Assuming no services need to be diverted, no water ingress problems, and the core is at around 1 metre above the tunnel floor, an approximate budget cost is : 13, 000 chf per hole = 24 no. * 13 k = 312, 000 chf. 27 March 2007 D. Swoboda FP 420 @ UTA 7

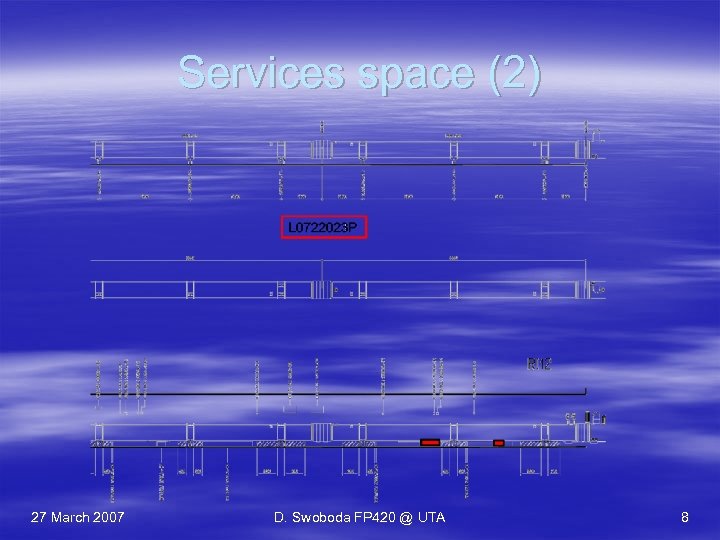

Services space (2) 27 March 2007 D. Swoboda FP 420 @ UTA 8

Services space (2) 27 March 2007 D. Swoboda FP 420 @ UTA 8

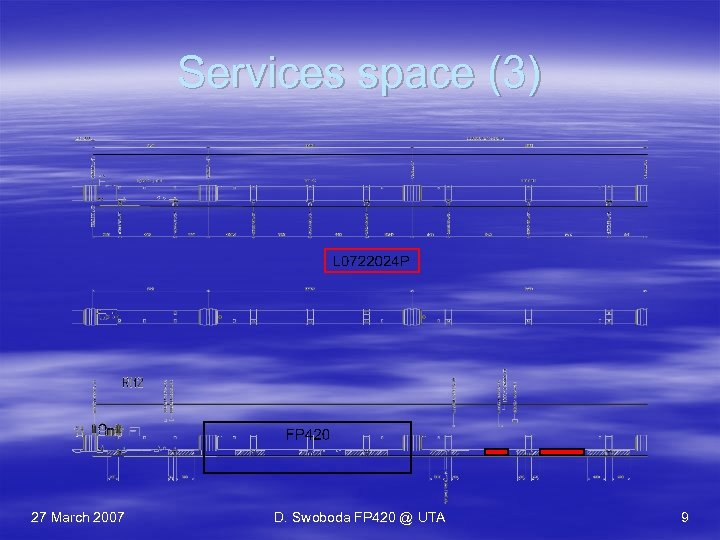

Services space (3) 27 March 2007 D. Swoboda FP 420 @ UTA 9

Services space (3) 27 March 2007 D. Swoboda FP 420 @ UTA 9

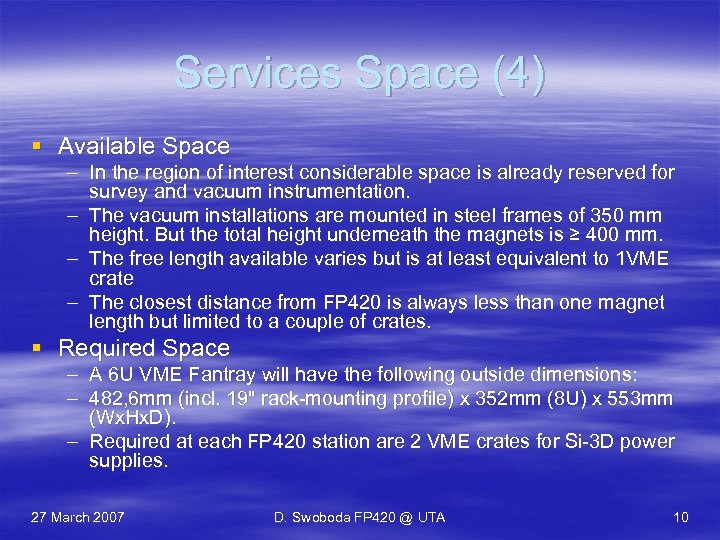

Services Space (4) § Available Space – In the region of interest considerable space is already reserved for survey and vacuum instrumentation. – The vacuum installations are mounted in steel frames of 350 mm height. But the total height underneath the magnets is ≥ 400 mm. – The free length available varies but is at least equivalent to 1 VME crate – The closest distance from FP 420 is always less than one magnet length but limited to a couple of crates. § Required Space – A 6 U VME Fantray will have the following outside dimensions: – 482, 6 mm (incl. 19" rack-mounting profile) x 352 mm (8 U) x 553 mm (Wx. Hx. D). – Required at each FP 420 station are 2 VME crates for Si-3 D power supplies. 27 March 2007 D. Swoboda FP 420 @ UTA 10

Services Space (4) § Available Space – In the region of interest considerable space is already reserved for survey and vacuum instrumentation. – The vacuum installations are mounted in steel frames of 350 mm height. But the total height underneath the magnets is ≥ 400 mm. – The free length available varies but is at least equivalent to 1 VME crate – The closest distance from FP 420 is always less than one magnet length but limited to a couple of crates. § Required Space – A 6 U VME Fantray will have the following outside dimensions: – 482, 6 mm (incl. 19" rack-mounting profile) x 352 mm (8 U) x 553 mm (Wx. Hx. D). – Required at each FP 420 station are 2 VME crates for Si-3 D power supplies. 27 March 2007 D. Swoboda FP 420 @ UTA 10

FP 420 Services Routing LHCf implementation 27 March 2007 D. Swoboda FP 420 @ UTA 11

FP 420 Services Routing LHCf implementation 27 March 2007 D. Swoboda FP 420 @ UTA 11

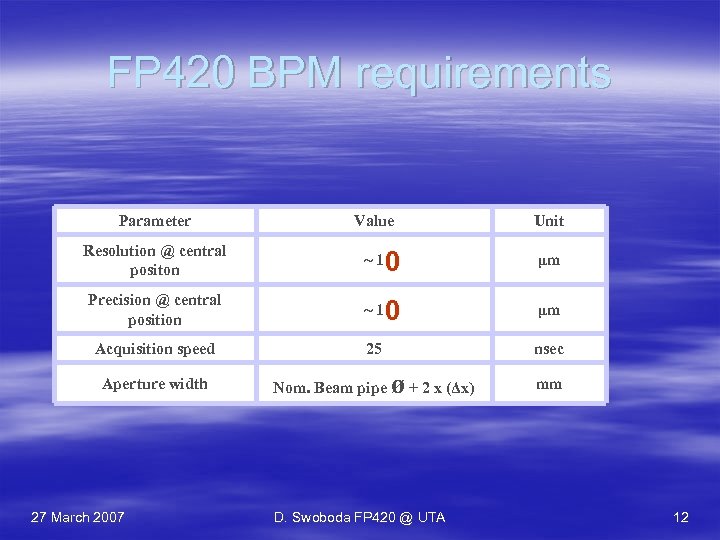

FP 420 BPM requirements Parameter Value Resolution @ central positon ~1 0 μm Precision @ central position ~1 0 μm Acquisition speed 25 Aperture width 27 March 2007 Nom. Beam pipe Unit nsec ø + 2 x (Δx) D. Swoboda FP 420 @ UTA mm 12

FP 420 BPM requirements Parameter Value Resolution @ central positon ~1 0 μm Precision @ central position ~1 0 μm Acquisition speed 25 Aperture width 27 March 2007 Nom. Beam pipe Unit nsec ø + 2 x (Δx) D. Swoboda FP 420 @ UTA mm 12

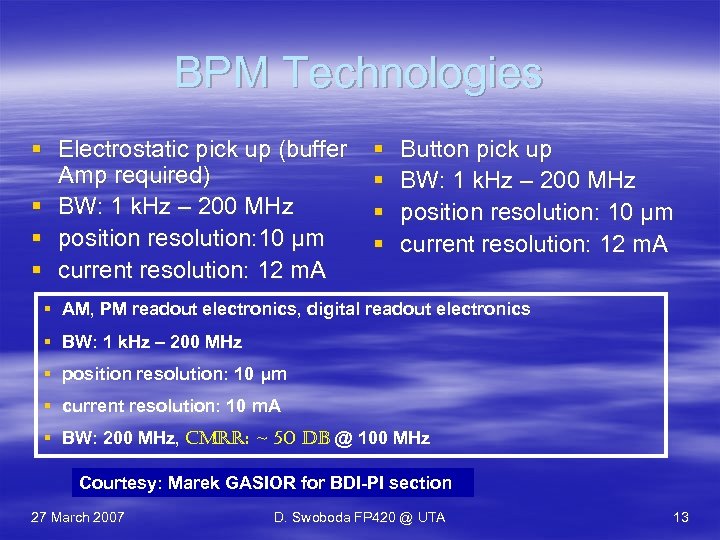

BPM Technologies § Electrostatic pick up (buffer Amp required) § BW: 1 k. Hz – 200 MHz § position resolution: 10 μm § current resolution: 12 m. A § § Button pick up BW: 1 k. Hz – 200 MHz position resolution: 10 μm current resolution: 12 m. A § AM, PM readout electronics, digital readout electronics § BW: 1 k. Hz – 200 MHz § position resolution: 10 μm § current resolution: 10 m. A § BW: 200 MHz, CMRR: ~ 50 d. B @ 100 MHz Courtesy: Marek GASIOR for BDI-PI section 27 March 2007 D. Swoboda FP 420 @ UTA 13

BPM Technologies § Electrostatic pick up (buffer Amp required) § BW: 1 k. Hz – 200 MHz § position resolution: 10 μm § current resolution: 12 m. A § § Button pick up BW: 1 k. Hz – 200 MHz position resolution: 10 μm current resolution: 12 m. A § AM, PM readout electronics, digital readout electronics § BW: 1 k. Hz – 200 MHz § position resolution: 10 μm § current resolution: 10 m. A § BW: 200 MHz, CMRR: ~ 50 d. B @ 100 MHz Courtesy: Marek GASIOR for BDI-PI section 27 March 2007 D. Swoboda FP 420 @ UTA 13

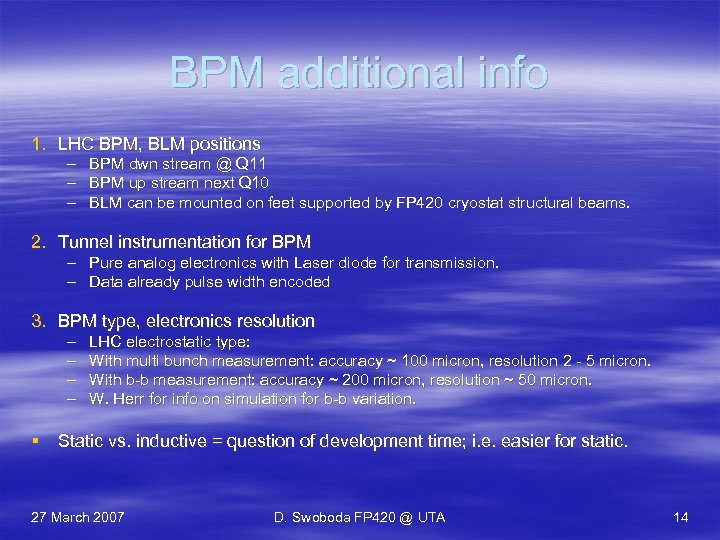

BPM additional info 1. LHC BPM, BLM positions – – – BPM dwn stream @ Q 11 BPM up stream next Q 10 BLM can be mounted on feet supported by FP 420 cryostat structural beams. 2. Tunnel instrumentation for BPM – Pure analog electronics with Laser diode for transmission. – Data already pulse width encoded 3. BPM type, electronics resolution – – LHC electrostatic type: With multi bunch measurement: accuracy ~ 100 micron, resolution 2 - 5 micron. With b-b measurement: accuracy ~ 200 micron, resolution ~ 50 micron. W. Herr for info on simulation for b-b variation. § Static vs. inductive = question of development time; i. e. easier for static. 27 March 2007 D. Swoboda FP 420 @ UTA 14

BPM additional info 1. LHC BPM, BLM positions – – – BPM dwn stream @ Q 11 BPM up stream next Q 10 BLM can be mounted on feet supported by FP 420 cryostat structural beams. 2. Tunnel instrumentation for BPM – Pure analog electronics with Laser diode for transmission. – Data already pulse width encoded 3. BPM type, electronics resolution – – LHC electrostatic type: With multi bunch measurement: accuracy ~ 100 micron, resolution 2 - 5 micron. With b-b measurement: accuracy ~ 200 micron, resolution ~ 50 micron. W. Herr for info on simulation for b-b variation. § Static vs. inductive = question of development time; i. e. easier for static. 27 March 2007 D. Swoboda FP 420 @ UTA 14

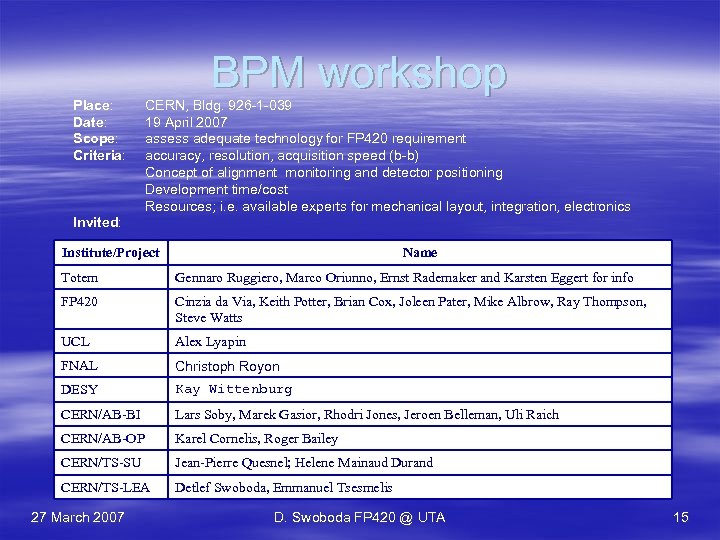

Place: Date: Scope: Criteria: BPM workshop CERN, Bldg. 926 -1 -039 19 April 2007 assess adequate technology for FP 420 requirement accuracy, resolution, acquisition speed (b-b) Concept of alignment monitoring and detector positioning Development time/cost Resources; i. e. available experts for mechanical layout, integration, electronics Invited: Institute/Project Name Totem Gennaro Ruggiero, Marco Oriunno, Ernst Rademaker and Karsten Eggert for info FP 420 Cinzia da Via, Keith Potter, Brian Cox, Joleen Pater, Mike Albrow, Ray Thompson, Steve Watts UCL Alex Lyapin FNAL Christoph Royon DESY Kay Wittenburg CERN/AB-BI Lars Soby, Marek Gasior, Rhodri Jones, Jeroen Belleman, Uli Raich CERN/AB-OP Karel Cornelis, Roger Bailey CERN/TS-SU Jean-Pierre Quesnel; Helene Mainaud Durand CERN/TS-LEA Detlef Swoboda, Emmanuel Tsesmelis 27 March 2007 D. Swoboda FP 420 @ UTA 15

Place: Date: Scope: Criteria: BPM workshop CERN, Bldg. 926 -1 -039 19 April 2007 assess adequate technology for FP 420 requirement accuracy, resolution, acquisition speed (b-b) Concept of alignment monitoring and detector positioning Development time/cost Resources; i. e. available experts for mechanical layout, integration, electronics Invited: Institute/Project Name Totem Gennaro Ruggiero, Marco Oriunno, Ernst Rademaker and Karsten Eggert for info FP 420 Cinzia da Via, Keith Potter, Brian Cox, Joleen Pater, Mike Albrow, Ray Thompson, Steve Watts UCL Alex Lyapin FNAL Christoph Royon DESY Kay Wittenburg CERN/AB-BI Lars Soby, Marek Gasior, Rhodri Jones, Jeroen Belleman, Uli Raich CERN/AB-OP Karel Cornelis, Roger Bailey CERN/TS-SU Jean-Pierre Quesnel; Helene Mainaud Durand CERN/TS-LEA Detlef Swoboda, Emmanuel Tsesmelis 27 March 2007 D. Swoboda FP 420 @ UTA 15

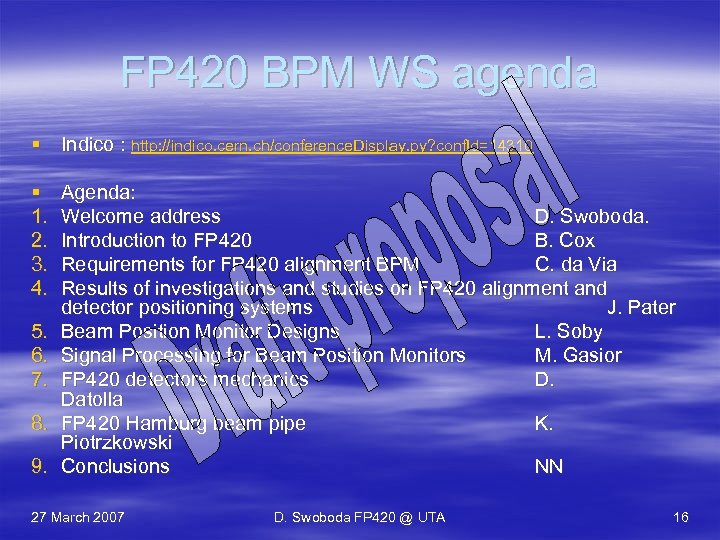

FP 420 BPM WS agenda § Indico : http: //indico. cern. ch/conference. Display. py? conf. Id=14310 § 1. 2. 3. 4. 5. 6. 7. 8. 9. Agenda: Welcome address D. Swoboda. Introduction to FP 420 B. Cox Requirements for FP 420 alignment BPM C. da Via Results of investigations and studies on FP 420 alignment and detector positioning systems J. Pater Beam Position Monitor Designs L. Soby Signal Processing for Beam Position Monitors M. Gasior FP 420 detectors mechanics D. Datolla FP 420 Hamburg beam pipe K. Piotrzkowski Conclusions NN 27 March 2007 D. Swoboda FP 420 @ UTA 16

FP 420 BPM WS agenda § Indico : http: //indico. cern. ch/conference. Display. py? conf. Id=14310 § 1. 2. 3. 4. 5. 6. 7. 8. 9. Agenda: Welcome address D. Swoboda. Introduction to FP 420 B. Cox Requirements for FP 420 alignment BPM C. da Via Results of investigations and studies on FP 420 alignment and detector positioning systems J. Pater Beam Position Monitor Designs L. Soby Signal Processing for Beam Position Monitors M. Gasior FP 420 detectors mechanics D. Datolla FP 420 Hamburg beam pipe K. Piotrzkowski Conclusions NN 27 March 2007 D. Swoboda FP 420 @ UTA 16

Interlocks § Risk analysis for beam accident scenarios § Fast movement of closed orbit § Control failure of detector positioning system § Discussion launched for all LHC experiments with LHC machine § WS planned for June 2007 27 March 2007 D. Swoboda FP 420 @ UTA 17

Interlocks § Risk analysis for beam accident scenarios § Fast movement of closed orbit § Control failure of detector positioning system § Discussion launched for all LHC experiments with LHC machine § WS planned for June 2007 27 March 2007 D. Swoboda FP 420 @ UTA 17