718ac3a87f38e8088d6dd01c038c6ff0.ppt

- Количество слайдов: 54

"FOUNDRIES IN NORTHERN CALIFORNIA? ? " An Overview of Your Neighborhood Aluminum, Brass, Iron, and Steel Foundries (and Why We’re Here).

"FOUNDRIES IN NORTHERN CALIFORNIA? ? " An Overview of Your Neighborhood Aluminum, Brass, Iron, and Steel Foundries (and Why We’re Here).

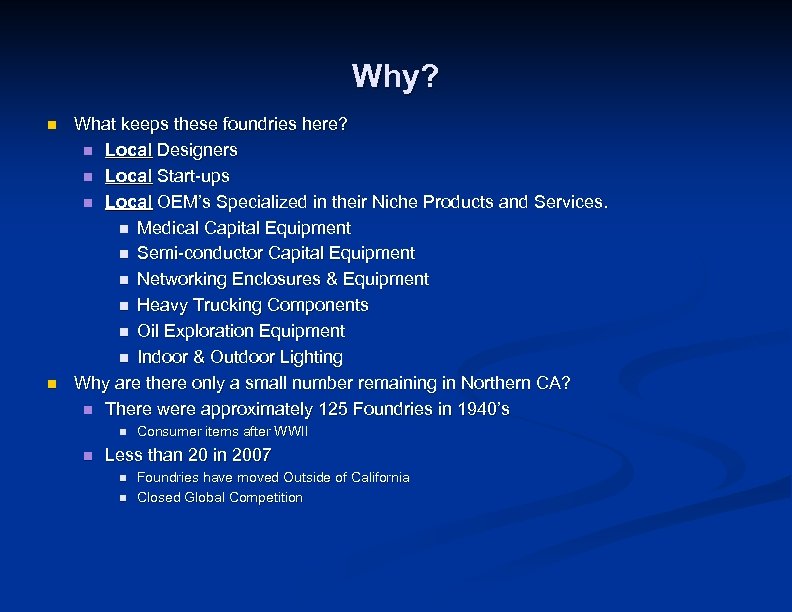

Why? n n What keeps these foundries here? n Local Designers n Local Start-ups n Local OEM’s Specialized in their Niche Products and Services. n Medical Capital Equipment n Semi-conductor Capital Equipment n Networking Enclosures & Equipment n Heavy Trucking Components n Oil Exploration Equipment n Indoor & Outdoor Lighting Why are there only a small number remaining in Northern CA? n There were approximately 125 Foundries in 1940’s n n Consumer items after WWII Less than 20 in 2007 n n Foundries have moved Outside of California Closed Global Competition

Why? n n What keeps these foundries here? n Local Designers n Local Start-ups n Local OEM’s Specialized in their Niche Products and Services. n Medical Capital Equipment n Semi-conductor Capital Equipment n Networking Enclosures & Equipment n Heavy Trucking Components n Oil Exploration Equipment n Indoor & Outdoor Lighting Why are there only a small number remaining in Northern CA? n There were approximately 125 Foundries in 1940’s n n Consumer items after WWII Less than 20 in 2007 n n Foundries have moved Outside of California Closed Global Competition

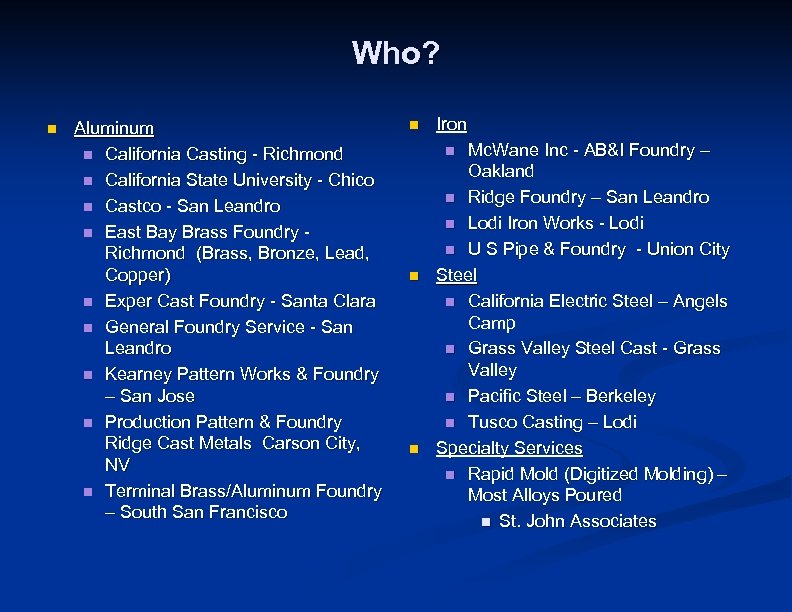

Who? n Aluminum n California Casting - Richmond n California State University - Chico n Castco - San Leandro n East Bay Brass Foundry - Richmond (Brass, Bronze, Lead, Copper) n Exper Cast Foundry - Santa Clara n General Foundry Service - San Leandro n Kearney Pattern Works & Foundry – San Jose n Production Pattern & Foundry Ridge Cast Metals Carson City, NV n Terminal Brass/Aluminum Foundry – South San Francisco n n n Iron n Mc. Wane Inc - AB&I Foundry – Oakland n Ridge Foundry – San Leandro n Lodi Iron Works - Lodi n U S Pipe & Foundry - Union City Steel n California Electric Steel – Angels Camp n Grass Valley Steel Cast - Grass Valley n Pacific Steel – Berkeley n Tusco Casting – Lodi Specialty Services n Rapid Mold (Digitized Molding) – Most Alloys Poured n St. John Associates

Who? n Aluminum n California Casting - Richmond n California State University - Chico n Castco - San Leandro n East Bay Brass Foundry - Richmond (Brass, Bronze, Lead, Copper) n Exper Cast Foundry - Santa Clara n General Foundry Service - San Leandro n Kearney Pattern Works & Foundry – San Jose n Production Pattern & Foundry Ridge Cast Metals Carson City, NV n Terminal Brass/Aluminum Foundry – South San Francisco n n n Iron n Mc. Wane Inc - AB&I Foundry – Oakland n Ridge Foundry – San Leandro n Lodi Iron Works - Lodi n U S Pipe & Foundry - Union City Steel n California Electric Steel – Angels Camp n Grass Valley Steel Cast - Grass Valley n Pacific Steel – Berkeley n Tusco Casting – Lodi Specialty Services n Rapid Mold (Digitized Molding) – Most Alloys Poured n St. John Associates

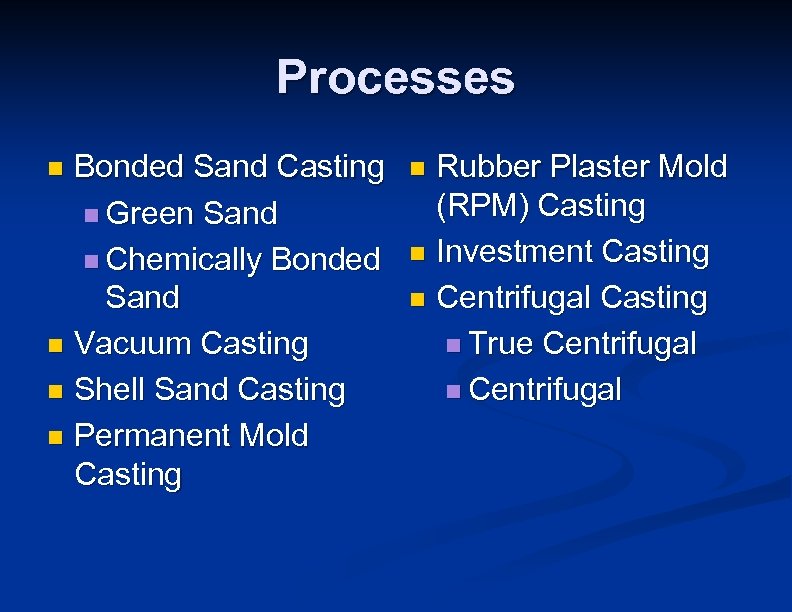

Processes Bonded Sand Casting n Green Sand n Chemically Bonded Sand n Vacuum Casting n Shell Sand Casting n Permanent Mold Casting n Rubber Plaster Mold (RPM) Casting n Investment Casting n Centrifugal Casting n True Centrifugal n

Processes Bonded Sand Casting n Green Sand n Chemically Bonded Sand n Vacuum Casting n Shell Sand Casting n Permanent Mold Casting n Rubber Plaster Mold (RPM) Casting n Investment Casting n Centrifugal Casting n True Centrifugal n

Bonded Sand Processes n. Green Sand n. Chemically Bonded Sand – “No Bake”

Bonded Sand Processes n. Green Sand n. Chemically Bonded Sand – “No Bake”

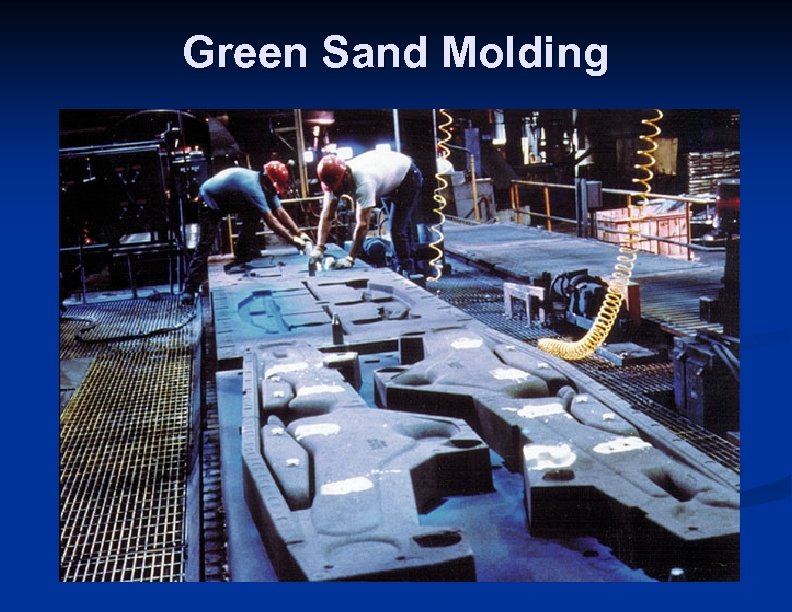

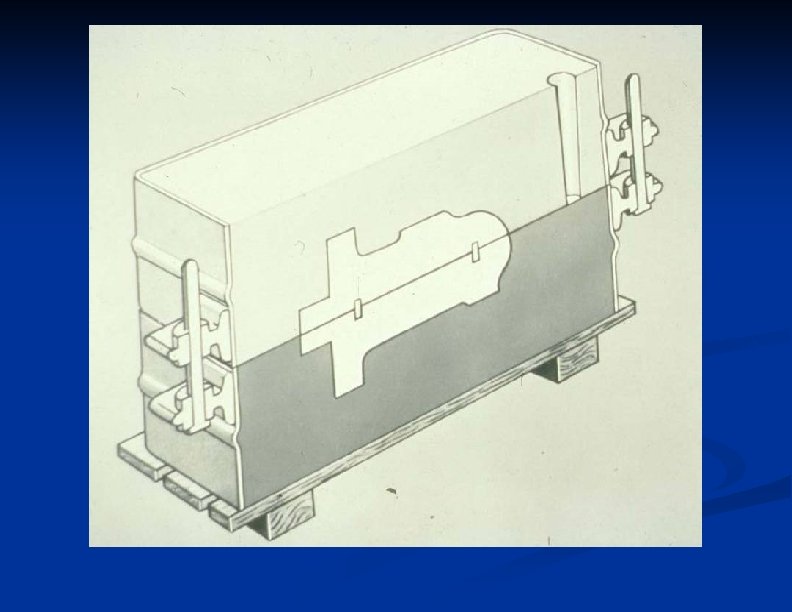

Green Sand Molding

Green Sand Molding

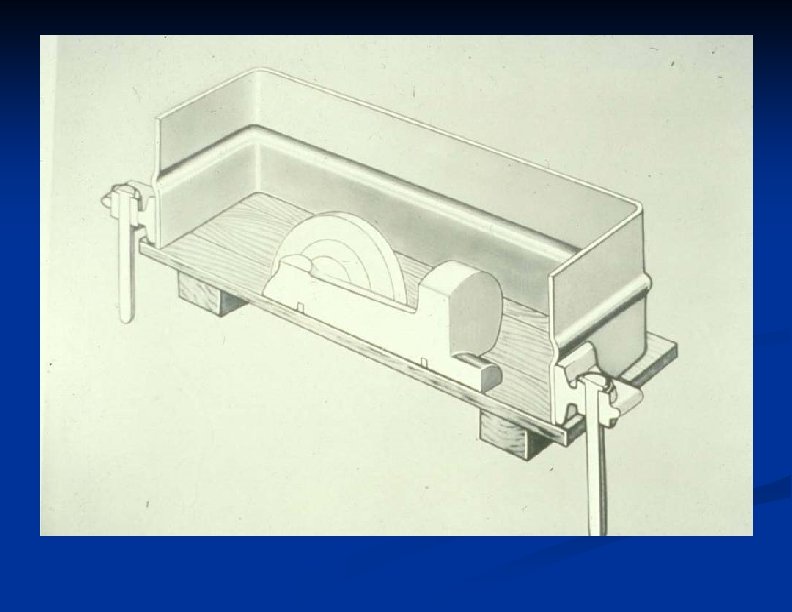

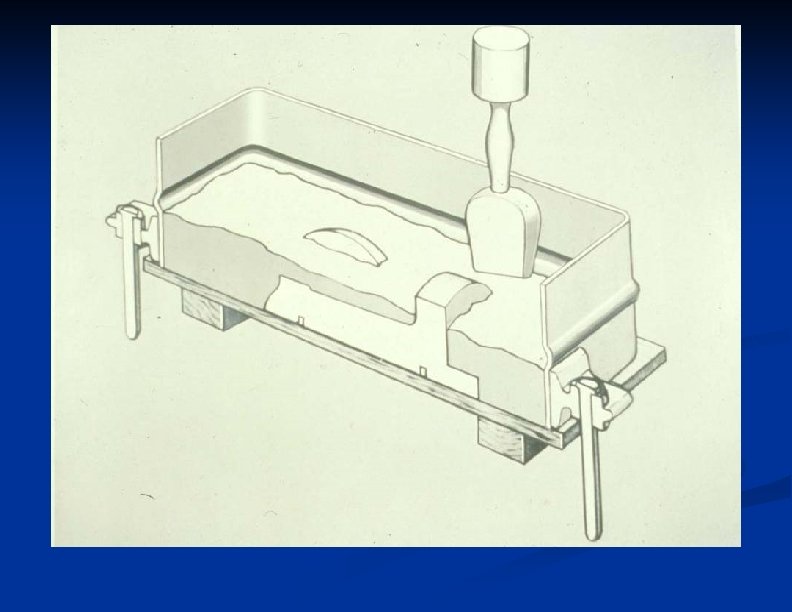

Green Sand Components Sand n Clay n Water n Additives n Carbons n Cellulose n Cereals n

Green Sand Components Sand n Clay n Water n Additives n Carbons n Cellulose n Cereals n

Green Sand Molding

Green Sand Molding

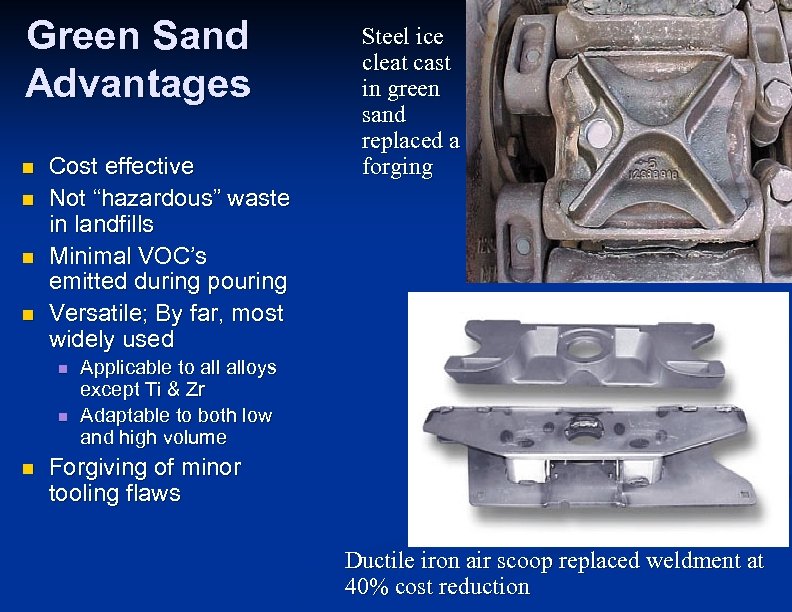

Green Sand Advantages n n Cost effective Not “hazardous” waste in landfills Minimal VOC’s emitted during pouring Versatile; By far, most widely used n n n Steel ice cleat cast in green sand replaced a forging Applicable to alloys except Ti & Zr Adaptable to both low and high volume Forgiving of minor tooling flaws Ductile iron air scoop replaced weldment at 40% cost reduction

Green Sand Advantages n n Cost effective Not “hazardous” waste in landfills Minimal VOC’s emitted during pouring Versatile; By far, most widely used n n n Steel ice cleat cast in green sand replaced a forging Applicable to alloys except Ti & Zr Adaptable to both low and high volume Forgiving of minor tooling flaws Ductile iron air scoop replaced weldment at 40% cost reduction

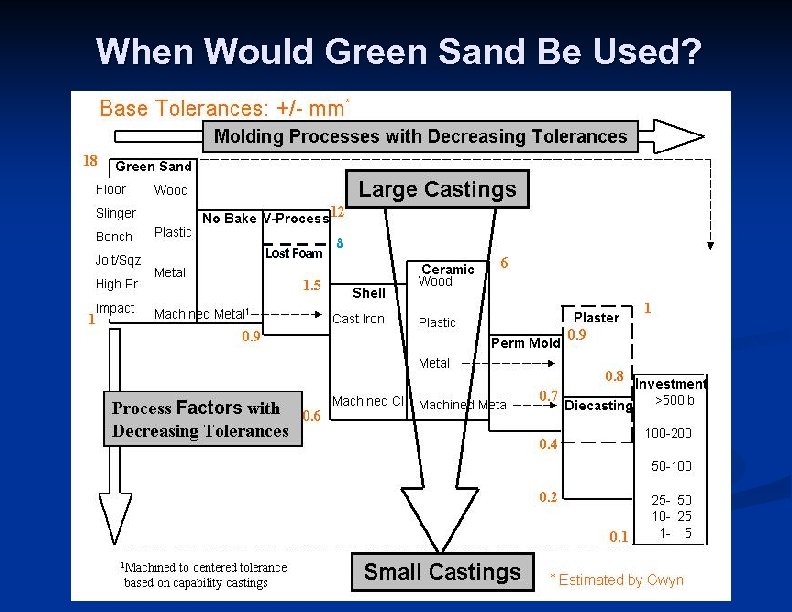

When Would Green Sand Be Used? Lost Foam 8

When Would Green Sand Be Used? Lost Foam 8

No Bake Molding

No Bake Molding

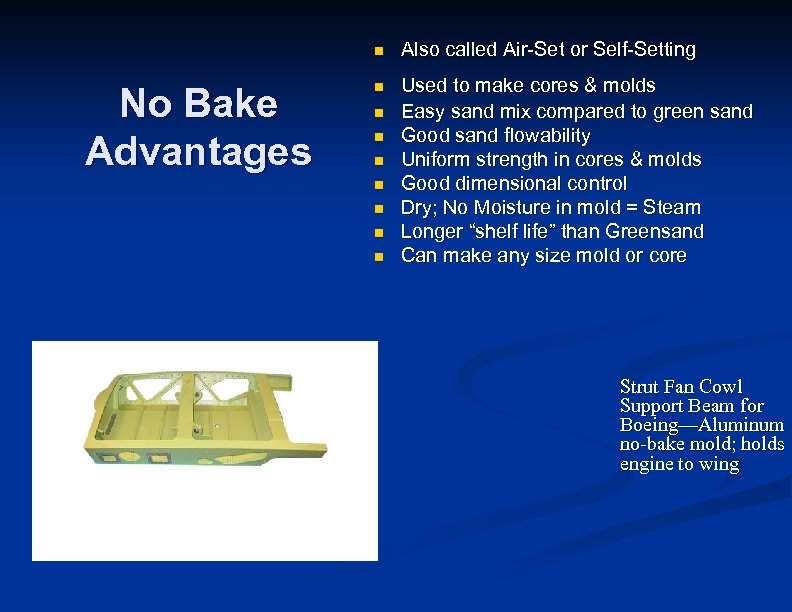

n No Bake Advantages Also called Air-Set or Self-Setting n Used to make cores & molds Easy sand mix compared to green sand Good sand flowability Uniform strength in cores & molds Good dimensional control Dry; No Moisture in mold = Steam Longer “shelf life” than Greensand Can make any size mold or core n n n n Strut Fan Cowl Support Beam for Boeing—Aluminum no-bake mold; holds engine to wing

n No Bake Advantages Also called Air-Set or Self-Setting n Used to make cores & molds Easy sand mix compared to green sand Good sand flowability Uniform strength in cores & molds Good dimensional control Dry; No Moisture in mold = Steam Longer “shelf life” than Greensand Can make any size mold or core n n n n Strut Fan Cowl Support Beam for Boeing—Aluminum no-bake mold; holds engine to wing

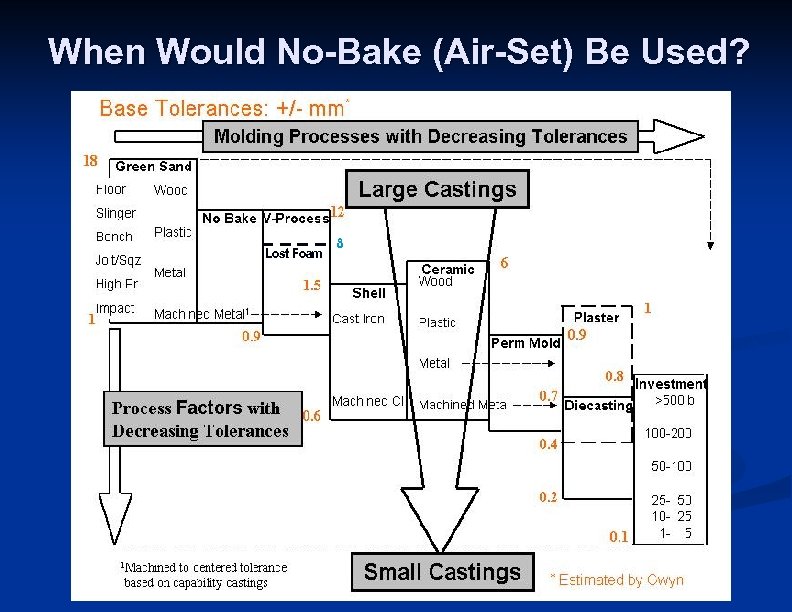

When Would No-Bake (Air-Set) Be Used? Lost Foam 8

When Would No-Bake (Air-Set) Be Used? Lost Foam 8

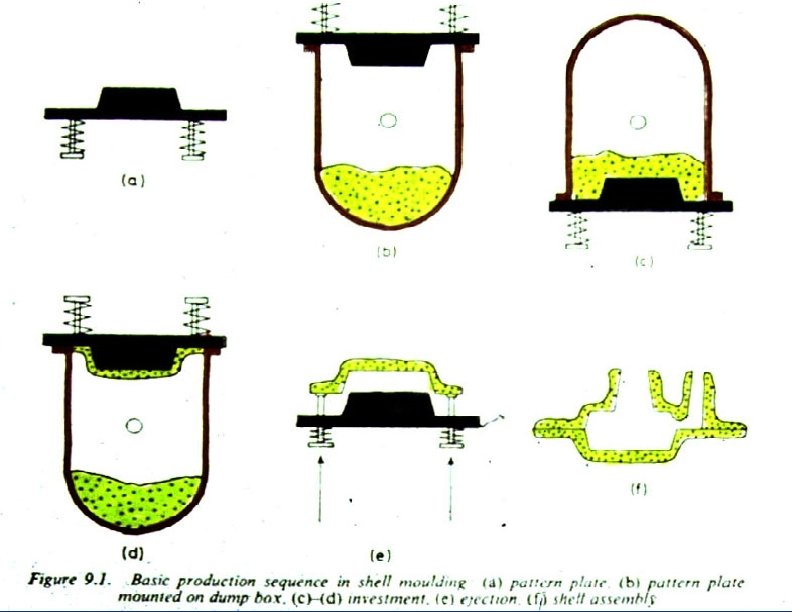

Shell Sand Process

Shell Sand Process

Shell Sand Advantages n Holds tight tolerances n Less draft required n Very thin walled sections possible n Small cored holes easily cast n Excellent surface finish n Excellent dimensional capability n Excellent dimensional stability

Shell Sand Advantages n Holds tight tolerances n Less draft required n Very thin walled sections possible n Small cored holes easily cast n Excellent surface finish n Excellent dimensional capability n Excellent dimensional stability

Shell Sand Drawbacks Special pattern equipment required n Capital outlay for machinery n Size limits - small to medium sized molds & cores n Resin level is slightly higher than other chemically bonded sands n High casting volume needed for cost efficiency n

Shell Sand Drawbacks Special pattern equipment required n Capital outlay for machinery n Size limits - small to medium sized molds & cores n Resin level is slightly higher than other chemically bonded sands n High casting volume needed for cost efficiency n

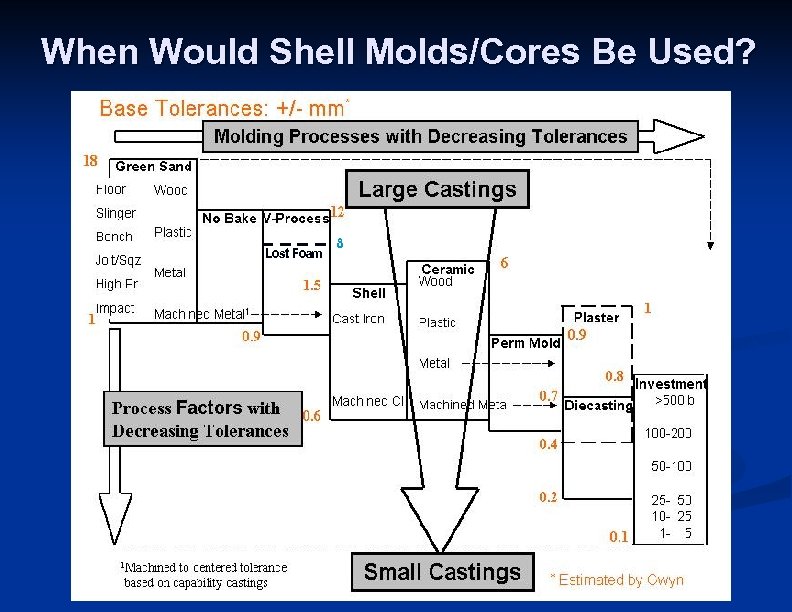

When Would Shell Molds/Cores Be Used? Lost Foam 8

When Would Shell Molds/Cores Be Used? Lost Foam 8

Permanent Molding n. Permanent Mold n. Semi-Permanent Mold n. Low-Pressure Die Casting

Permanent Molding n. Permanent Mold n. Semi-Permanent Mold n. Low-Pressure Die Casting

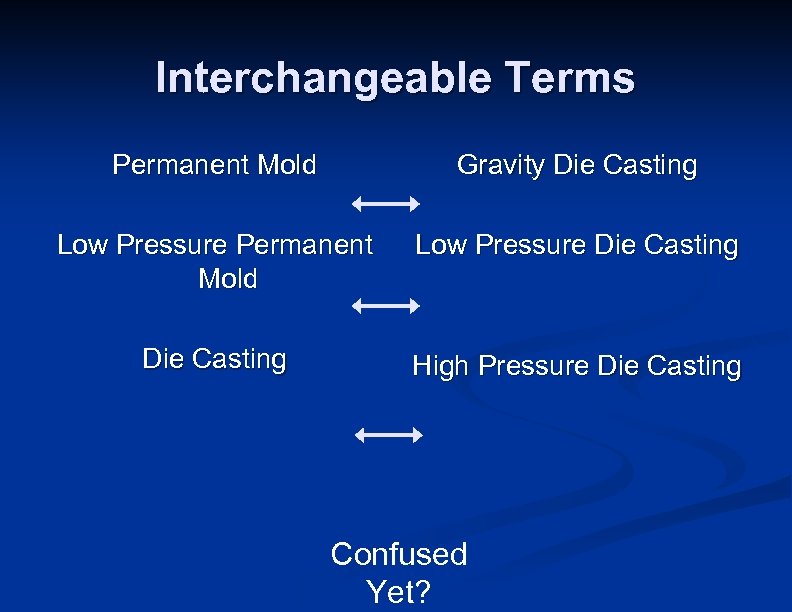

Interchangeable Terms Permanent Mold Gravity Die Casting Low Pressure Permanent Mold Low Pressure Die Casting High Pressure Die Casting Confused Yet?

Interchangeable Terms Permanent Mold Gravity Die Casting Low Pressure Permanent Mold Low Pressure Die Casting High Pressure Die Casting Confused Yet?

Permanent Mold Casting

Permanent Mold Casting

Types of Permanent Mold Casting n Static Pouring n n Tilt Pouring n n similar to sand casting metal is poured into a basin while mold is horizontal and flows into the mold cavity as the mold is gradually tilted to a vertical position Low Pressure or Vacuum n metal is drawn from below the mold up into the mold (counter gravity ) via a vacuum or pressure

Types of Permanent Mold Casting n Static Pouring n n Tilt Pouring n n similar to sand casting metal is poured into a basin while mold is horizontal and flows into the mold cavity as the mold is gradually tilted to a vertical position Low Pressure or Vacuum n metal is drawn from below the mold up into the mold (counter gravity ) via a vacuum or pressure

Permanent Mold Advantages n n n Oscar-Copperbased alloy Good dimensional accuracy Consistent quality Metal fill can be controlled (tilt-pour) Suitable for fairly complex castings Multiple alloys castable Expendable cores can be used n Process is then called Semi-Permanent mold Corvette Brake Pedal-converted from steel to aluminum

Permanent Mold Advantages n n n Oscar-Copperbased alloy Good dimensional accuracy Consistent quality Metal fill can be controlled (tilt-pour) Suitable for fairly complex castings Multiple alloys castable Expendable cores can be used n Process is then called Semi-Permanent mold Corvette Brake Pedal-converted from steel to aluminum

Permanent Mold Drawbacks n High cost of tooling n Limited casting size

Permanent Mold Drawbacks n High cost of tooling n Limited casting size

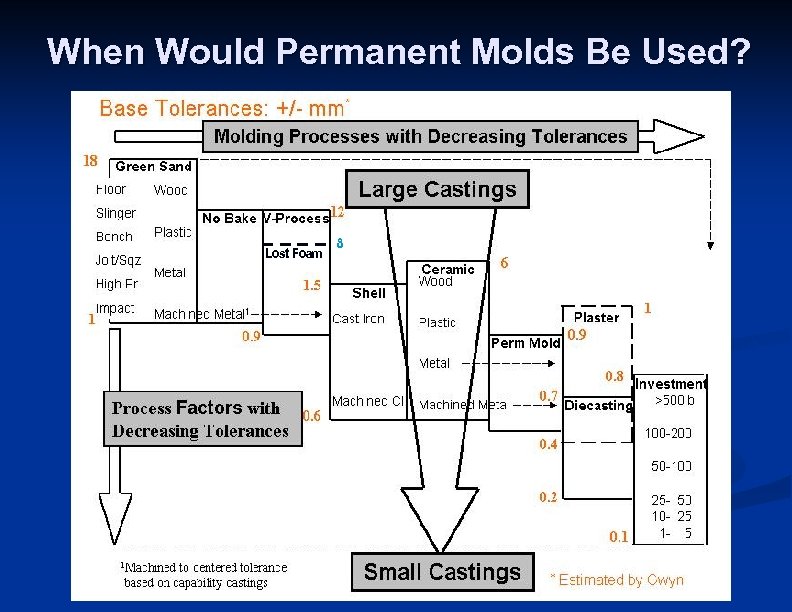

When Would Permanent Molds Be Used? Lost Foam 8

When Would Permanent Molds Be Used? Lost Foam 8

Plaster Molding

Plaster Molding

Plaster Molding Process n Mold is made from a mixture of plaster, talc, other refractory materials and water n Slurry is poured or piped into a flask containing the pattern n Mold is dried in a circulating air oven until no moisture is present

Plaster Molding Process n Mold is made from a mixture of plaster, talc, other refractory materials and water n Slurry is poured or piped into a flask containing the pattern n Mold is dried in a circulating air oven until no moisture is present

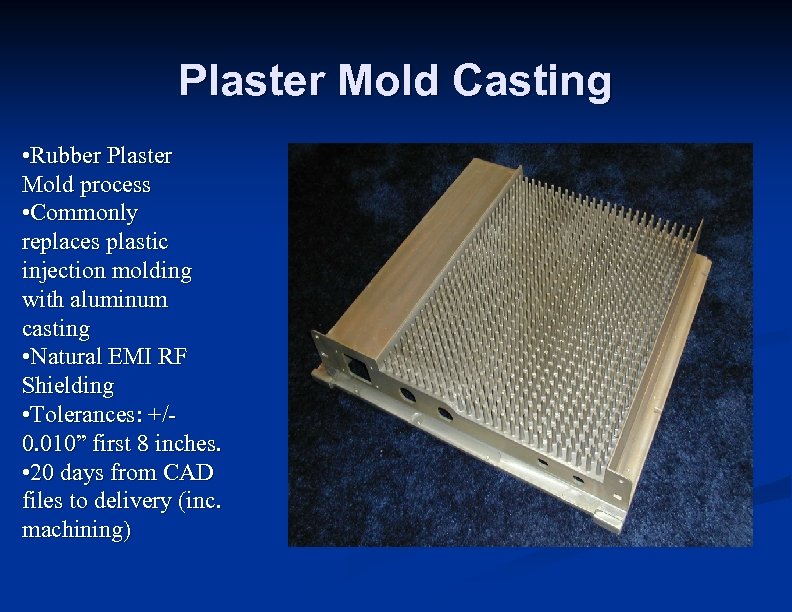

Plaster Mold Casting • Rubber Plaster Mold process • Commonly replaces plastic injection molding with aluminum casting • Natural EMI RF Shielding • Tolerances: +/- 0. 010” first 8 inches. • 20 days from CAD files to delivery (inc. machining)

Plaster Mold Casting • Rubber Plaster Mold process • Commonly replaces plastic injection molding with aluminum casting • Natural EMI RF Shielding • Tolerances: +/- 0. 010” first 8 inches. • 20 days from CAD files to delivery (inc. machining)

Plaster Advantages n High casting yield n no gas or steam produced when metal is poured n Fine detail & intricate thin sections possible n Very little cleaning, if any, needed

Plaster Advantages n High casting yield n no gas or steam produced when metal is poured n Fine detail & intricate thin sections possible n Very little cleaning, if any, needed

Plaster Drawbacks n Drying time can take hours and can cause warpage or shrinkage of the mold n Low to medium volume production capabilities n Limited alloys - usually nonferrous

Plaster Drawbacks n Drying time can take hours and can cause warpage or shrinkage of the mold n Low to medium volume production capabilities n Limited alloys - usually nonferrous

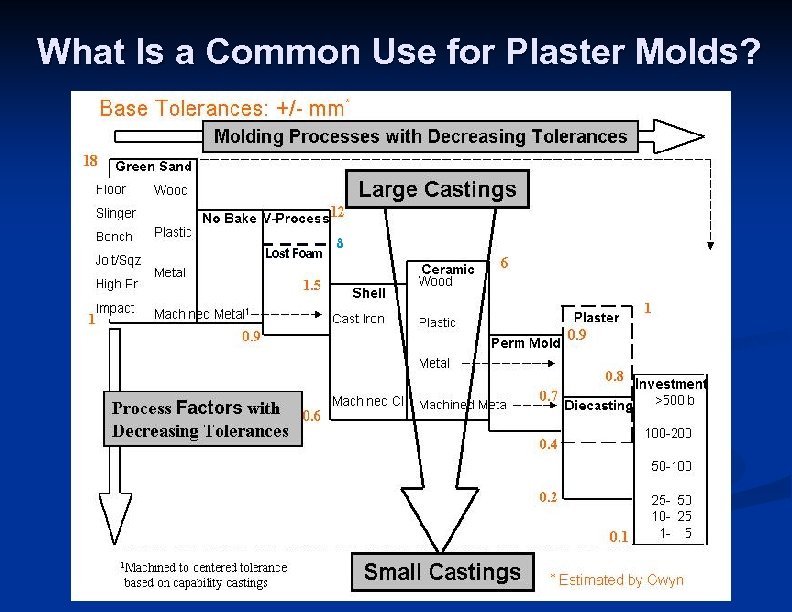

What Is a Common Use for Plaster Molds? Lost Foam 8

What Is a Common Use for Plaster Molds? Lost Foam 8

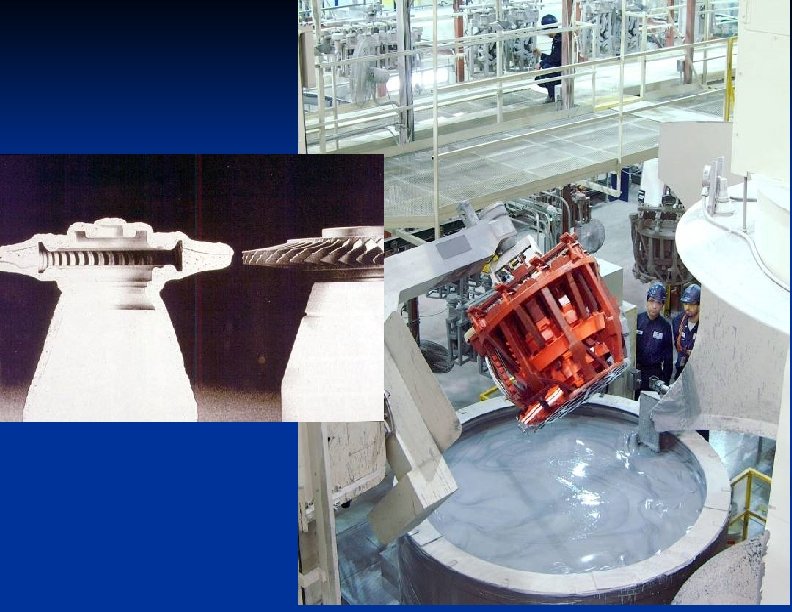

Investment Casting

Investment Casting

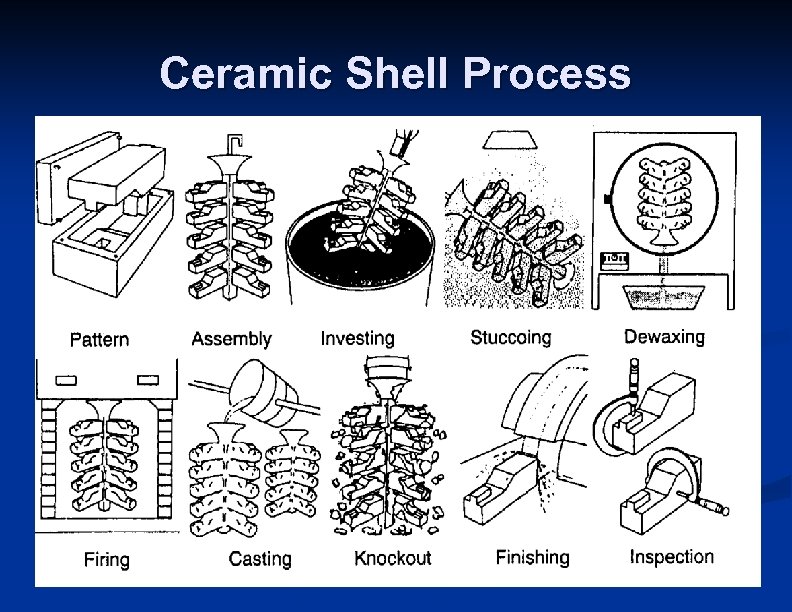

Ceramic Shell Process

Ceramic Shell Process

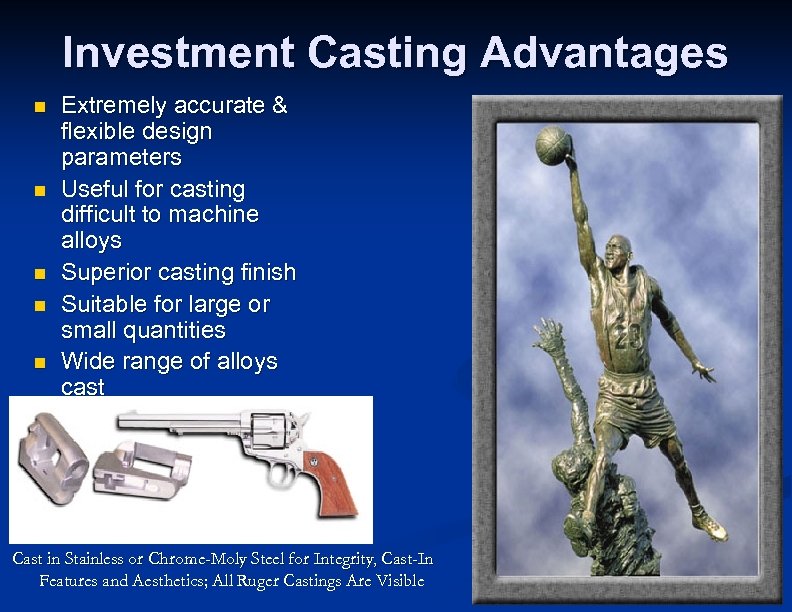

Investment Casting Advantages n n n Extremely accurate & flexible design parameters Useful for casting difficult to machine alloys Superior casting finish Suitable for large or small quantities Wide range of alloys cast Cast in Stainless or Chrome-Moly Steel for Integrity, Cast-In Features and Aesthetics; All Ruger Castings Are Visible

Investment Casting Advantages n n n Extremely accurate & flexible design parameters Useful for casting difficult to machine alloys Superior casting finish Suitable for large or small quantities Wide range of alloys cast Cast in Stainless or Chrome-Moly Steel for Integrity, Cast-In Features and Aesthetics; All Ruger Castings Are Visible

Investment Casting Drawbacks n Casting size is limited n Costly process n Equipment n Patterns n Process components very important n Additional quality checks required

Investment Casting Drawbacks n Casting size is limited n Costly process n Equipment n Patterns n Process components very important n Additional quality checks required

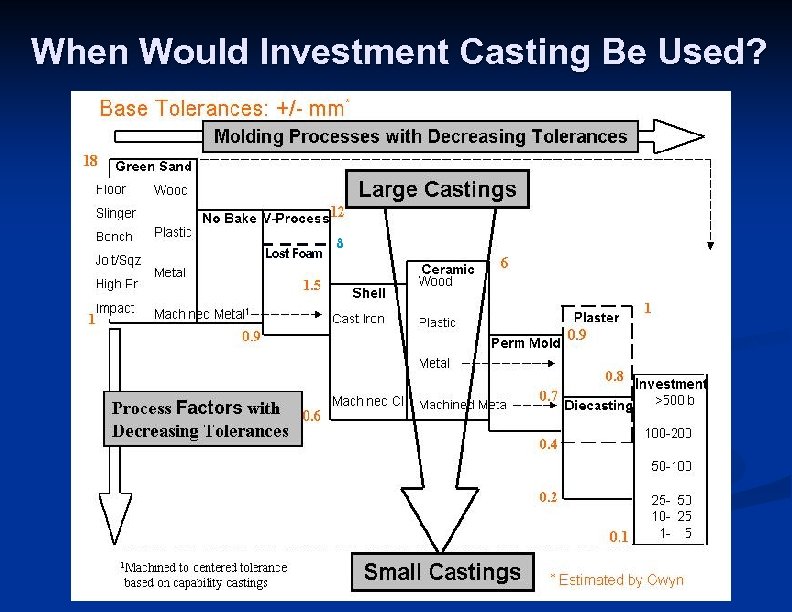

When Would Investment Casting Be Used? Lost Foam 8

When Would Investment Casting Be Used? Lost Foam 8

Centrifugal Casting

Centrifugal Casting

“True” Centrifugal Casting n Casting is spun on its own axis n No risers are required n No center core is needed

“True” Centrifugal Casting n Casting is spun on its own axis n No risers are required n No center core is needed

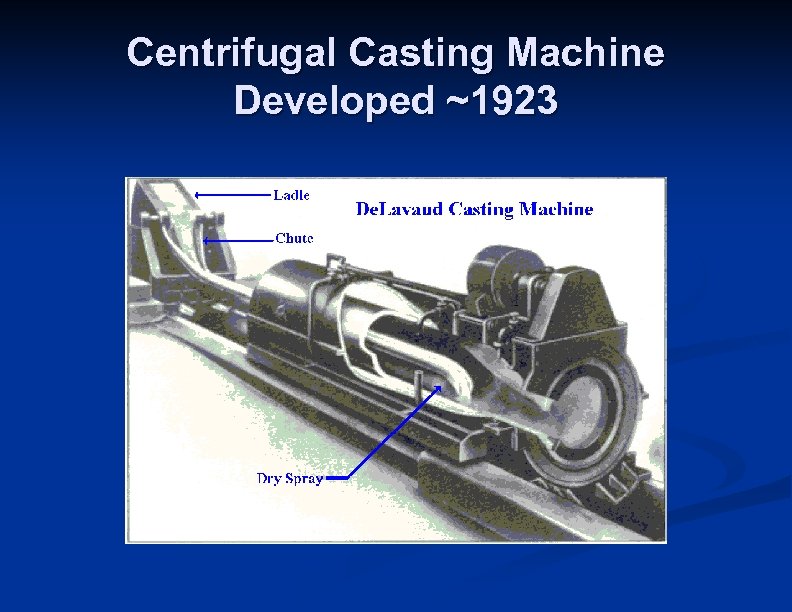

Centrifugal Casting Machine Developed ~1923

Centrifugal Casting Machine Developed ~1923

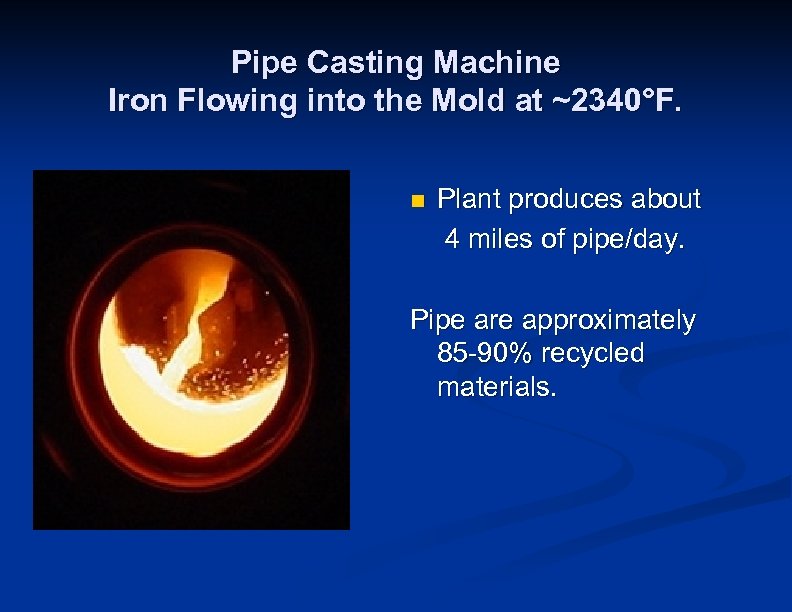

Pipe Casting Machine Iron Flowing into the Mold at ~2340°F. n Plant produces about 4 miles of pipe/day. Pipe are approximately 85 -90% recycled materials.

Pipe Casting Machine Iron Flowing into the Mold at ~2340°F. n Plant produces about 4 miles of pipe/day. Pipe are approximately 85 -90% recycled materials.

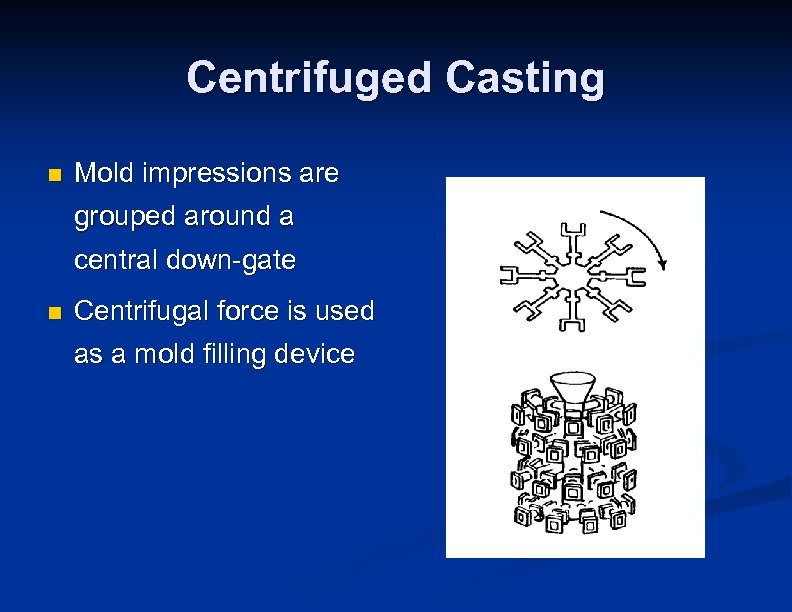

Centrifuged Casting n Mold impressions are grouped around a central down-gate n Centrifugal force is used as a mold filling device

Centrifuged Casting n Mold impressions are grouped around a central down-gate n Centrifugal force is used as a mold filling device

Centrifugal Casting Advantages n Improved homogeneity n Improved accuracy in special circumstances

Centrifugal Casting Advantages n Improved homogeneity n Improved accuracy in special circumstances

Centrifugal Casting Drawback Limitations on casting shape

Centrifugal Casting Drawback Limitations on casting shape

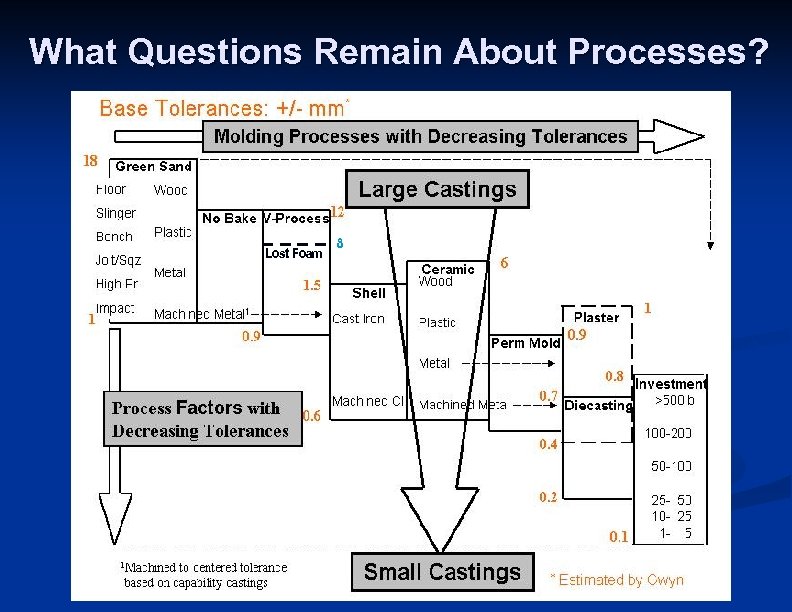

What Questions Remain About Processes? Lost Foam 8

What Questions Remain About Processes? Lost Foam 8

n Value to both the manufacturer and the end user, is for the engineer to communicate with the foundry, fabricator, or whomever during the design process. If the drawing calls for a fabricated piece they may have missed an opportunity for a cast part that may have done a superior job, may have cost less, may have been quicker. n Or if a casting was called for maybe they designed in such a way that the part is 3 times as expensive as it would have been had they not added an undercut that required extra tooling via inserts or multiple core boxes. We love it when we get an email from an engineer asking for input during part design. - East Bay Brass

n Value to both the manufacturer and the end user, is for the engineer to communicate with the foundry, fabricator, or whomever during the design process. If the drawing calls for a fabricated piece they may have missed an opportunity for a cast part that may have done a superior job, may have cost less, may have been quicker. n Or if a casting was called for maybe they designed in such a way that the part is 3 times as expensive as it would have been had they not added an undercut that required extra tooling via inserts or multiple core boxes. We love it when we get an email from an engineer asking for input during part design. - East Bay Brass

www. Lodiiron. com n Lodi Iron works has been making quality Iron and Steel castings for over 60 years. Centrally located in the San Joaquin Valley, LIW is capable of pouring 1 pound to 1000 pound castings in any Ferrous alloy including Cast Iron or Ductile Iron in our Lodi Foundry, and any Steel, Stainless Steel or various specialty alloy such as 17 -4 PH & Monel in our Galt Foundry, 10 miles away. We have a Pattern Shop on site and are willing to help our customers in the design phase of projects in order to develop the best combination of quality and cost efficiency in the final product. We are happy to quote projects of as few as one casting but we are also set up to run volumes of 1000's of castings on our 3 automated production lines. If you need high quality sand castings and want to work with a foundry that cares about your success, give us a call. Barron Gage - Sales Manager Lodi Iron Works 209 -368 -5395 x 4

www. Lodiiron. com n Lodi Iron works has been making quality Iron and Steel castings for over 60 years. Centrally located in the San Joaquin Valley, LIW is capable of pouring 1 pound to 1000 pound castings in any Ferrous alloy including Cast Iron or Ductile Iron in our Lodi Foundry, and any Steel, Stainless Steel or various specialty alloy such as 17 -4 PH & Monel in our Galt Foundry, 10 miles away. We have a Pattern Shop on site and are willing to help our customers in the design phase of projects in order to develop the best combination of quality and cost efficiency in the final product. We are happy to quote projects of as few as one casting but we are also set up to run volumes of 1000's of castings on our 3 automated production lines. If you need high quality sand castings and want to work with a foundry that cares about your success, give us a call. Barron Gage - Sales Manager Lodi Iron Works 209 -368 -5395 x 4

Digital Mold and Core Printing System n Technikon is advancing rapid prototyping technologies, such as digital manufacturing. . . n n n Production digital mold and core printing system Prototype casting capability – CAD file to finish castings without tooling Development of superior binder technologies are being tested to advance digital manufacturing mold and core packages Jay S. St. John ST. JOHN ASSOCIATES P. O. Box 323 Diablo, CA 94528 (925) 984 -4677 jsstjohn@hotmail. com

Digital Mold and Core Printing System n Technikon is advancing rapid prototyping technologies, such as digital manufacturing. . . n n n Production digital mold and core printing system Prototype casting capability – CAD file to finish castings without tooling Development of superior binder technologies are being tested to advance digital manufacturing mold and core packages Jay S. St. John ST. JOHN ASSOCIATES P. O. Box 323 Diablo, CA 94528 (925) 984 -4677 jsstjohn@hotmail. com

Local Foundries n Aluminum n California Casting - Richmond n California State University - Chico n Castco - San Leandro n East Bay Brass Foundry - Richmond (Brass, Bronze, Lead, Copper) n Exper Cast Foundry - Santa Clara n General Foundry Service - San Leandro n Kearney Pattern Works & Foundry – San Jose n Production Pattern & Foundry Ridge Cast Metals Carson City, NV n Terminal Brass/Aluminum Foundry – South San Francisco n n Cast Iron n Ridge Foundry – San Leandro n Lodi Iron Works - Lodi Centrifugal Iron n Mc. Wane Inc - AB&I Foundry – Oakland n U S Pipe & Foundry - Union City Steel n California Electric Steel – Angels Camp n Grass Valley Steel Cast - Grass Valley n Pacific Steel – Berkeley n Tusco Casting – Lodi Specialty Services n Rapid Mold (Digitized Molding) – (Pouring Most Alloys) n St. John Associates

Local Foundries n Aluminum n California Casting - Richmond n California State University - Chico n Castco - San Leandro n East Bay Brass Foundry - Richmond (Brass, Bronze, Lead, Copper) n Exper Cast Foundry - Santa Clara n General Foundry Service - San Leandro n Kearney Pattern Works & Foundry – San Jose n Production Pattern & Foundry Ridge Cast Metals Carson City, NV n Terminal Brass/Aluminum Foundry – South San Francisco n n Cast Iron n Ridge Foundry – San Leandro n Lodi Iron Works - Lodi Centrifugal Iron n Mc. Wane Inc - AB&I Foundry – Oakland n U S Pipe & Foundry - Union City Steel n California Electric Steel – Angels Camp n Grass Valley Steel Cast - Grass Valley n Pacific Steel – Berkeley n Tusco Casting – Lodi Specialty Services n Rapid Mold (Digitized Molding) – (Pouring Most Alloys) n St. John Associates