7c177aaa5b65def590c4ef91d935b5a2.ppt

- Количество слайдов: 43

Fortune Favours the Bold ~ Creating a mining company using proprietary mineral processing technology ~ FINEX ´ 08 23 -24 September 2008

AGM Presentation June 2008 2 Disclaimer THIS DOCUMENT IS BEING SUPPLIED TO YOU SOLELY FOR YOUR INFORMATION AND MAY NOT BE REPRODUCED, FURTHER DISTRIBUTED TO ANY OTHER PERSON OR PUBLISHED, IN WHOLE OR IN PART, FOR ANY PURPOSE. This document is being communicated in the United Kingdom only to (a) persons who have professional experience in matters relating to investments falling within Article 19(1) of the Financial Services and Markets Act 2000 (Financial Promotion) Order 2001 (the “Order”) or (b) High Net Worth Entities within Article 49(2) of the Order (all such persons being referred to as “relevant persons”). This document is only directed at relevant persons, and any investment or investment activity to which this presentation relates is only available to relevant persons or will be engaged in only with relevant persons. Solicitations resulting from this document will only be responded to if the person concerned is a relevant person. Other persons should not act upon this document or any of its contents. The distribution of this document in other jurisdictions may be restricted by law, and persons into whose possession this document comes should inform themselves about, and observe, any such restrictions. The information in this document, is subject to updating, completion and revision, further verification and amendment. No representation is made by Alexander Mining plc or any of their principals, advisers, representatives, agents, officers, directors or employees as to, and no responsibility, warranty or liability is accepted for, the accuracy, reliability, or reasonableness or completeness of the contents in this document. No responsibility is accepted by any of them for any errors, mis-statements in, or omissions from, this document, nor for any direct or consequential loss howsoever arising from any use of, or reliance on, this document or otherwise in connection with it. The information in this document is confidential and must not be copied, reproduced or distributed to others at any time. This document does not constitute an invitation to buy shares in Alexander Mining plc. This document is not an offer of securities for sale in the United States of America. Securities may not be offered or sold in the United States of America absent registration or an exemption from registration. Safe Harbour statement: this document may contain forwardlooking statements that reflect the Company's current expectations regarding future events, including the development of the Company's projects, as well as the Company's working capital requirements and future capital raising activities. Forward-looking statements involve risks and uncertainties. Actual events could differ materially from those projected herein and depend on a number of factors, including the success of the Company's development strategies, and the successful and timely completion of clinical studies, the ability of the Company to obtain additional financing for its operations and the market conditions affecting the availability and terms of such financing.

AGM Presentation June 2008 Introduction • LSE-AIM quoted mining company • Admitted to AIM 4 April 2005, AIM ticker: AXM • Experienced board and senior management team • Initial portfolio of copper, gold and silver properties in South America • Fortuitous development of proprietary mineral processing technology • New focus on growth by building a mining company using innovative and proprietary mineral processing technology 3

AGM Presentation June 2008 Mining Companies’ Raison d'être 1. Survival 2. Profitability: Stable earnings Earnings growth Disposals 3. Growth 4

AGM Presentation June 2008 Mining Basics - Theory • Turnings rock in the ground into profits! • Or more eloquently The fundamental value of a mineral deposit ultimately depends entirely on its capacity to support an economically viable mining operation in the future 5

AGM Presentation June 2008 The best route to create shareholder value? 1. Through exploration? 2. Mine development? A combination? 3. Project acquisition? 4. Corporate M&A? 6

AGM Presentation June 2008 A Risky Business in a Risky World • Macro risks: Country, commodity price, global economics • Micro risks: from exploration concept to mine production: Exploration – tenement acquisition, target concept, reconnaissance, anomalies, targets, detailed exploration, discovery, resource delineation/definition Project – scoping study, pre-feasibility, bankable feasibility study, permitting, financing, construction, commissioning Mining – technical, geotechnical, economics 7

AGM Presentation June 2008 Mining Industry Reality • Statistically it’s a tough business and getting harder • Out of thousands of grass roots exploration prospects only a few ever make it to become mines with a satisfactory return on capital • Constant pressure on the industry to improve the odds of success and to lower costs • Environmental obligations for higher standards • Notwithstanding industry’s inherent conservatism, technology has a significant role 8

AGM Presentation June 2008 9 Mining Industry & Technology • Buoyant international mining industry, plus upwards operating cost pressures, means desire to embrace new technologies will intensify. • Major technology breakthroughs in the last few decades: Exploration (geophysics/remote sensing), Mineral processing (gold & copper heap leaching, smelting and HPAL) and Mining (explosives, underground mechanisation, open pit excavators and haulage trucks, and computer control). • Deposits are becoming harder to find and mine – more underground mines • Arguably, most potential for technical innovation is in mineral processing.

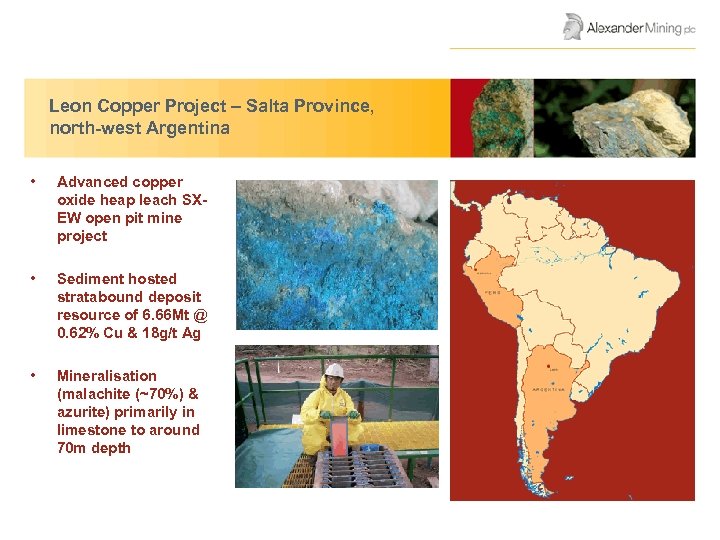

AGM Presentation June 2008 Leon Copper Project – Salta Province, north-west Argentina • Advanced copper oxide heap leach SXEW open pit mine project • Sediment hosted stratabound deposit resource of 6. 66 Mt @ 0. 62% Cu & 18 g/t Ag • Mineralisation (malachite (~70%) & azurite) primarily in limestone to around 70 m depth

AGM Presentation June 2008 Leon Project The processing problem: Very high acid consumption (up to 1, 000 kg/t of ore) 11

AGM Presentation June 2008 Leon Project • Necessity is the mother of invention – Socrates • Necessity is the mother of taking chances - Mark Twain Heath Robinson’s view 12

AGM Presentation June 2008 Leon Project The solution: Ammonia as the leachant and the development of the Amm. Leach® process. Successfully demonstrated in the Leon pilot plant. 13

AGM Presentation June 2008 Leon – Amm. Leach® pilot plant First 500 t heap test leached ore on pad SX-EW pilot plant

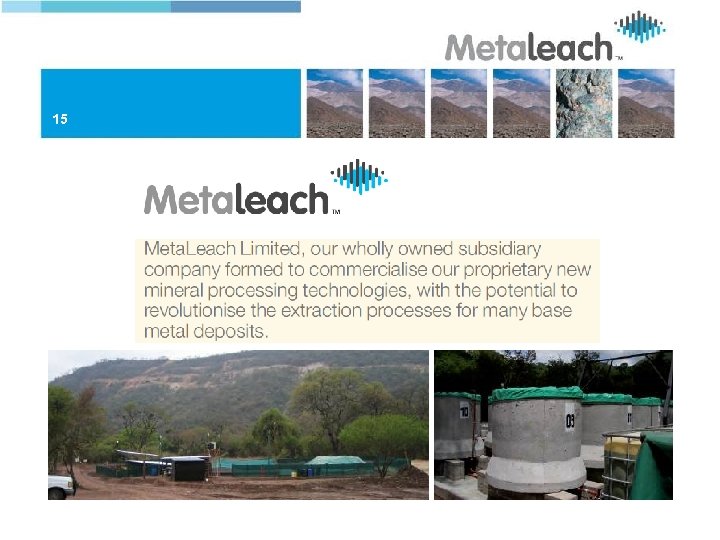

15

16 Meta. Leach owns the intellectual property to two hydrometallurgical technologies where provisional patents have been filed, namely:

17 Key personnel Garry Johnston - Technical Director • B. Sc. Chemistry, University of Western Australia • M. Sc. (dist. ), Mineral Economics, Curtin University and University Medal • 11 years with BHP/Newcrest as Manager • 4 years as CEO and Director of Gold Mines of Sardinia • 5 years as MD/Principal of junior explorer and innovative exploration project generator • 3 years as a consultant • 2 provisional patents

18 Key personnel Associate Professor Nicholas Welham - Principal Technological Consultant • B. Eng. (Hons) in Minerals Engineering, University of Leeds, Ph. D. Royal School of Mines, Imperial College, London • 8 years as researcher at Australian National University • 6 years, Senior Lecturer in Hydrometallurgy at Murdoch University • Currently, Xstrata Zinc Alliance Associate Professor at University of Ballarat • Two edited proceedings, >70 journal papers, R. W. Raymond Award for best paper published by AIME in 2003 plenary conference • Over 30 conference presentations and Editor-in-Chief of the journal Hydrometallurgy

19 Background • Favourable environment to embrace new technologies. • Focused on hydrometallurgical solutions that add value at the mine site. • Cost effective ambient whole ore leaching process using either agitated tanks or heaps. • Conventional and marketable intermediate products • Purification and concentration using SX-EW.

20 Copper extractive metallurgy • Global mined copper production is around 16. 5 Mtpa ……. …. . Approx. a quarter produced using hydrometallurgy and rising. Main process is copper acid leaching and SX-EW of oxides and secondary sulphide ores but acid prices have risen sharply. • Heap and dump leaching dominates as the leaching process. • Chalcopyrite (Cu. Fe. S 2) concentrates are invariably smelted and account for around three-quarters of global copper produced

21 Copper heap leach, SX-EW • Production using leaching recorded in 17/18 th century at Rio Tinto mine in southern Spain • First commercial leach SX-EW plant started in late 1960’ s in Arizona @ 6 ktpa • First large plant in 1973 in Zambia @ 100 ktpa • By 1980’s major plants in USA, Mexico and Chile • Now accounts for ~ 3. 5 Mtpa (~21%) of world copper production

22 Zinc extractive metallurgy • Global mined zinc production is around 12. 7 Mtpa • Most world zinc metal production uses smelting to recover and refine zinc metal from zinc concentrates or zinc oxides. • A new hydrometallurgical process route for zinc oxides has the potential to simplify zinc refining.

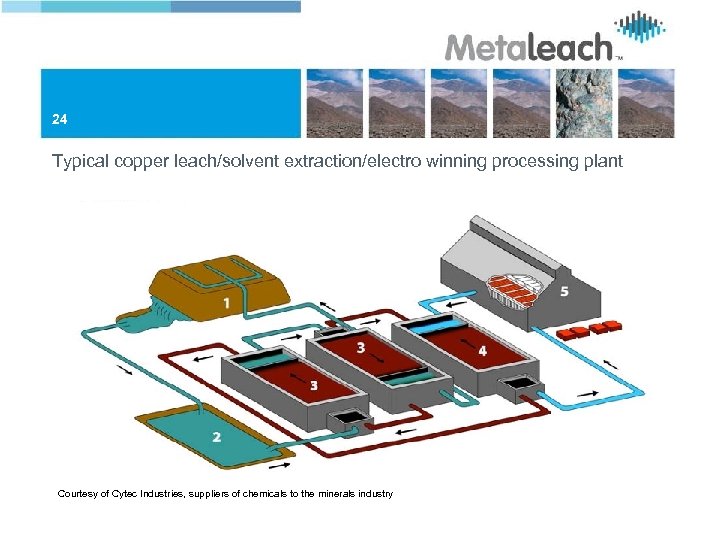

23 Schematic hydrometallurgical recovery flow sheet

24 Typical copper leach/solvent extraction/electro winning processing plant Courtesy of Cytec Industries, suppliers of chemicals to the minerals industry

25

26 Notable historical use, with mixed results, of ammonia as a leaching agent: • 1916 - Kennecott Copper and Hecla Mining plant to precipitate copper oxide • 1950 s - Sherritt Gordon developed a process to recover Ni, Cu & Co from a complex sulphide flotation concentrate using autoclave leaching • 1970’s - Anaconda’s Arbiter process for dissolution of copper sulphides with ammonia and oxygen • 1980 s - Adelaide Chemical company ammonia leach plant, stripping with steam to precipitate copper oxide product • 1990 s – Escondida process

27 Amm. Leach® • • • Alkaline/ammonia leach process at ambient pressure and temperature Proprietary two stage leaching process – Ore specific cure/pre-treatment stage – Heap or tank leaching Proprietary solvent extraction step to avoid ammonia carry-over into electrolyte Uses conventional equipment – Electro-winning is identical to conventional acid circuits – Direct replacement for acid leaching in current operations – Minimal changes to plant – Higher organic transfer efficiencies requires smaller plant Environmental benefits – a ‘green’ process for a ‘green’ metal: – Reduced transport/shipping impact and costs – Minimal likelihood of Acid Mine Drainage (AMD)

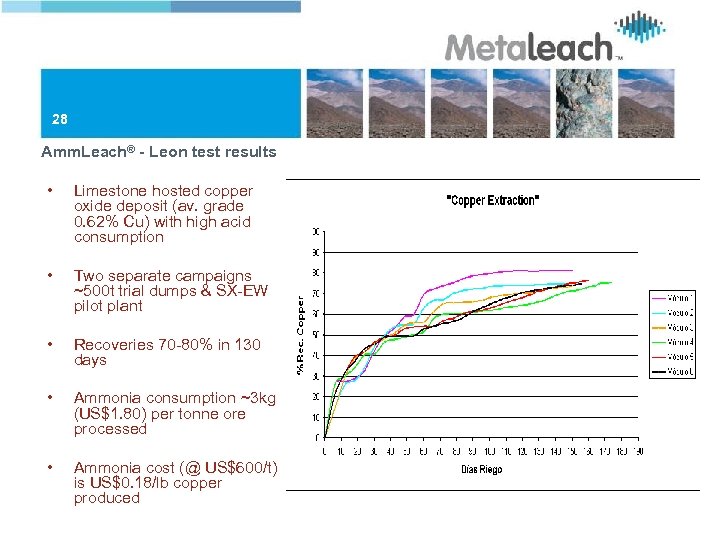

28 Amm. Leach® - Leon test results • Limestone hosted copper oxide deposit (av. grade 0. 62% Cu) with high acid consumption • Two separate campaigns ~500 t trial dumps & SX-EW pilot plant • Recoveries 70 -80% in 130 days • Ammonia consumption ~3 kg (US$1. 80) per tonne ore processed • Ammonia cost (@ US$600/t) is US$0. 18/lb copper produced

29 Amm. Leach® extraction from ammonia more efficient than extraction from acid and needs half as many extraction stages c. f. acid system to get the same metal concentration

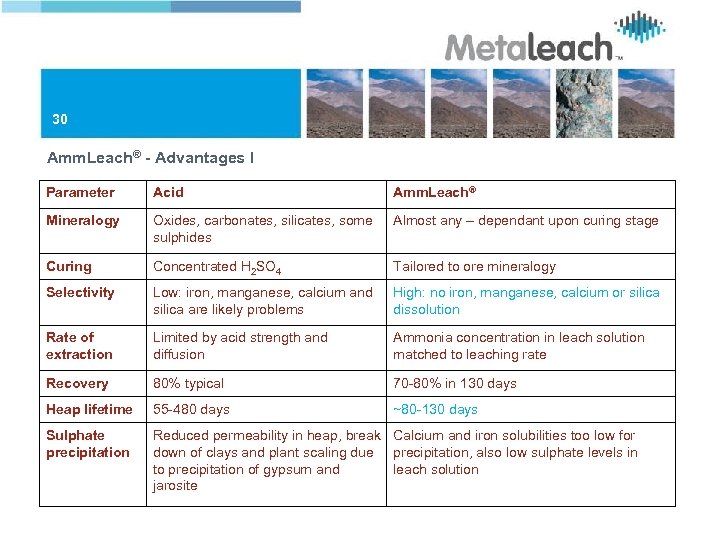

30 Amm. Leach® - Advantages I Parameter Acid Amm. Leach® Mineralogy Oxides, carbonates, silicates, some sulphides Almost any – dependant upon curing stage Curing Concentrated H 2 SO 4 Tailored to ore mineralogy Selectivity Low: iron, manganese, calcium and silica are likely problems High: no iron, manganese, calcium or silica dissolution Rate of extraction Limited by acid strength and diffusion Ammonia concentration in leach solution matched to leaching rate Recovery 80% typical 70 -80% in 130 days Heap lifetime 55 -480 days ~80 -130 days Sulphate precipitation Reduced permeability in heap, break Calcium and iron solubilities too low for down of clays and plant scaling due precipitation, also low sulphate levels in to precipitation of gypsum and leach solution jarosite

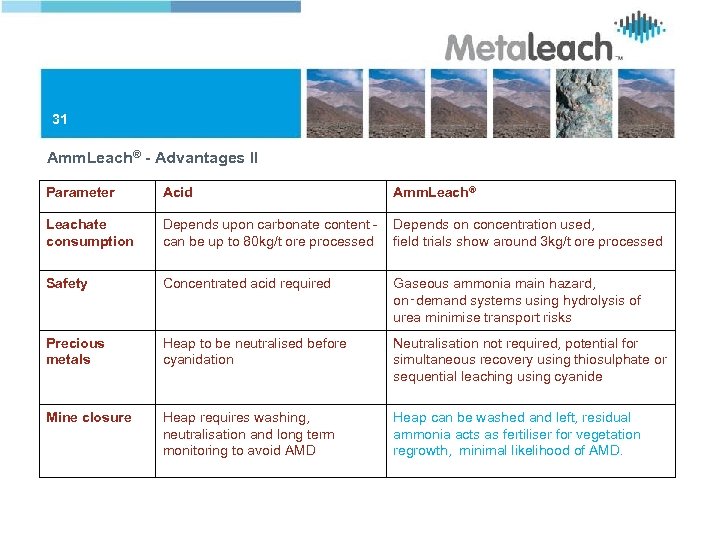

31 Amm. Leach® - Advantages II Parameter Acid Amm. Leach® Leachate consumption Depends upon carbonate content can be up to 80 kg/t ore processed Depends on concentration used, field trials show around 3 kg/t ore processed Safety Concentrated acid required Gaseous ammonia main hazard, on‑demand systems using hydrolysis of urea minimise transport risks Precious metals Heap to be neutralised before cyanidation Neutralisation not required, potential for simultaneous recovery using thiosulphate or sequential leaching using cyanide Mine closure Heap requires washing, neutralisation and long term monitoring to avoid AMD Heap can be washed and left, residual ammonia acts as fertiliser for vegetation regrowth, minimal likelihood of AMD.

32 Amm. Leach® - Potential applications • Demonstrated at pilot heap scale: Ø Copper from strata-bound carbonate and weathered oxide deposits • Demonstrated at laboratory scale: Ø Zinc from mixed oxide/carbonate/silicate deposits right through to metal Ø Zinc from roaster calcine • Under investigation at laboratory scale: Ø Pre-leaching copper from copper-gold ores, oxide molybdenum, oxide nickel and polymetallic oxides

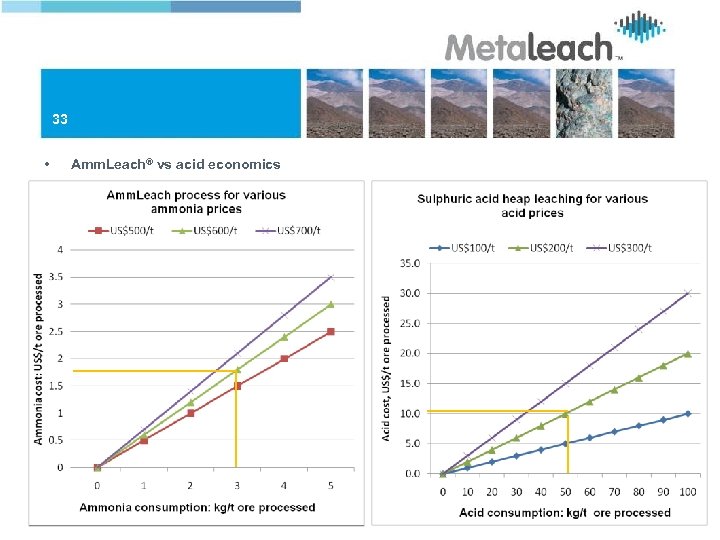

33 • Amm. Leach® vs acid economics

34

35 Hyper. Leach™ - New sulphide leaching technology Because most base metal sulphides are processed to produce a concentrate at the mine site, with the associated selling costs and payment terms involved, there is considerable scope to do more on site processing to generate higher returns for mine owners. Indeed, in many cases miners may receive payment for as little as 60% of the in situ metal content of the concentrate.

36 Hyper. Leach™ - New sulphide leaching technology • Leaches base metal sulphides including chalcopyrite, bornite, chalcocite, millerite, pentlandite, pyrrhotite, violarite, sphalerite, molybdenite and enargite • Provisional patents filed. • Major technological advance, with significant market potential and opportunities to add value at the mine gate. • Potential to safely dispose of arsenic from dissolution of arsenopyrite and enargite. • Environmentally better; 1 t of copper from smelting produces >1. 6 t slag and >2 t SO 2

37 Hyper. Leach™ - Key Features • Unlike previous chlorine based processes, Hyper. Leach™ does not require chlorine gas to operate. • The oxidant can be generated on‑site via industry standard chlor‑alkali technology; low reagent consumption. • Operates at ambient temperatures and pressure and is eminently suitable for heap leaching as well as tank leaching; rapid kinetics. • Suitable for both low grade heap leaching and higher grade tank leaching; the choice is dictated by the grade and deposit economics. • Polymetallic deposits can be readily handled using standard solvent extraction and solution purification techniques.

38 Hyper. Leach™ - The technology and how it works • Three major stages; leaching, separation/concentration and recovery. • Lab scale >95% recovery from >1 mm nickel sulphide in 72 h • Leaching either in a heap or tank by contacting the ore/concentrate with a solution at an appropriate concentration. • SX is used to separate and concentrate the metal(s) from solution whilst also changing from a mixed chloride/sulphate media to acid sulphate media. • Most metals can either be directly electrowon using industry standard unit operations or produce marketable intermediates to reduce CAPEX. • Key benefits are no special purpose plant required, operates under ambient conditions, and relatively coarse grinds and amenable to heap leaching

39 Hyper. Leach™ - Potential applications HEAP LEACHING • Nickel sulphide ores • Copper sulphide ores • Native copper ores • Mixed copper sulphide / oxide ores • Copper-gold ores • Uranium • Molybdenum sulphide / oxide • Polymetallic ores and concentrates TANK LEACHING • Nickel sulphide concentrates • Nickel mattes • Copper flotation concentrates • Arsenical copper ores • Arsenical gold ores • Gold bearing sulphides • Concentrate cleaning • PGM bearing sulphides / matte • Molybdenum sulphide • Polymetallic ores and concentrates

40 Meta. Leach™ - Focused on commercialisation and revenue generation • Two pronged approach to commercialise the Meta. Leach. TM technologies. • Firstly, third parties to use technology in exchange for a royalty and/or under a licence fee structure, or indeed a minority project interest. • Secondly, by identifying and securing direct equity interests in amenable base metals deposits. • Discussions with over thirty five companies: Ø Confidentiality agreements with several majors and juniors signed. Ø Negotiations in progress about potential specific projects/deposits amenable to processing with Amm. Leach® and Hyper. Leach™ technologies. • Eight companies have committed to carry out metallurgical testwork programmes.

AGM Presentation June 2008 Summary • Serendipity saw Alexander develop two proprietary hydrometallurgical ambient temperature and pressure processes. • Amm. Leach® has significant economic and environmental benefits cf. acid. • Main Amm. Leach® use is for high acid consuming copper oxides and zinc oxides. • Sister Hyper. Leach™ technology for sulphides adding value at mine site. • Commercialisation and revenue generation via two pronged approach – Firstly, third parties users in exchange for a royalty and/or a licence fee – Secondly, direct equity interests in amenable base metals deposits. 41

Enquiries: Alexander Mining plc: Martin Rosser and Matthew Sutcliffe 1 st Floor 35 Piccadilly London, W 1 J 0 DW Tel: Fax: Email: Web: +44 (0) 20 7292 1300 +44 (0) 20 7292 1313 mail@alexandermining. com Britton Financial PR: Tim Blackstone, tel: +44 (0) 20 7251 2544 +44 (0) 7957 140 416

AGM Presentation June 2008 Discovering value

7c177aaa5b65def590c4ef91d935b5a2.ppt