d891a648bc01695e130500fd0804c57f.ppt

- Количество слайдов: 16

Forecasting and Minimizing Field Rework Effects of Field Rework Research Team Jim Atkinson U. S. Steel Effects of Field Rework Research Team 2000 CII Annual Conference Nashville, Tennessee

Forecasting and Minimizing Field Rework Effects of Field Rework Research Team Jim Atkinson U. S. Steel Effects of Field Rework Research Team 2000 CII Annual Conference Nashville, Tennessee

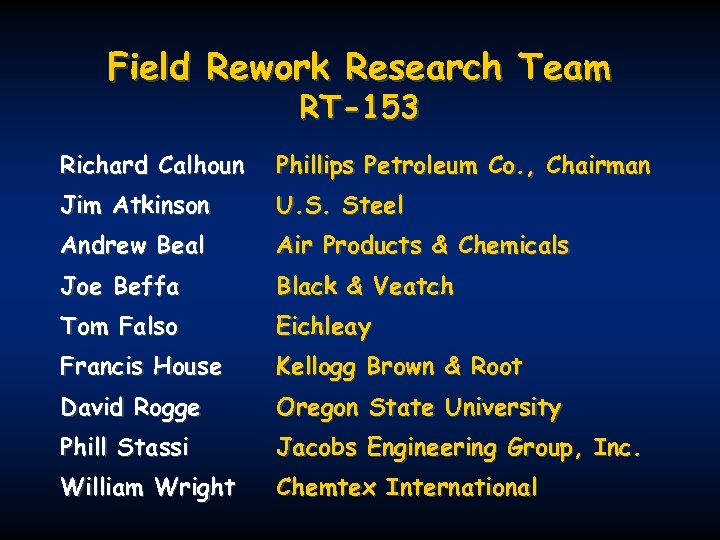

Field Rework Research Team RT-153 Richard Calhoun Phillips Petroleum Co. , Chairman Jim Atkinson U. S. Steel Andrew Beal Air Products & Chemicals Joe Beffa Black & Veatch Tom Falso Eichleay Francis House Kellogg Brown & Root David Rogge Oregon State University Phill Stassi Jacobs Engineering Group, Inc. William Wright Chemtex International

Field Rework Research Team RT-153 Richard Calhoun Phillips Petroleum Co. , Chairman Jim Atkinson U. S. Steel Andrew Beal Air Products & Chemicals Joe Beffa Black & Veatch Tom Falso Eichleay Francis House Kellogg Brown & Root David Rogge Oregon State University Phill Stassi Jacobs Engineering Group, Inc. William Wright Chemtex International

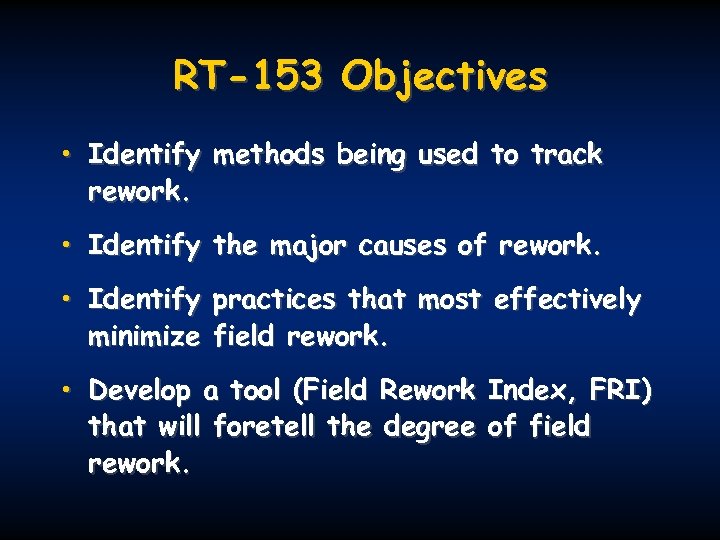

RT-153 Objectives • Identify methods being used to track rework. • Identify the major causes of rework. • Identify practices that most effectively minimize field rework. • Develop a tool (Field Rework Index, FRI) that will foretell the degree of field rework.

RT-153 Objectives • Identify methods being used to track rework. • Identify the major causes of rework. • Identify practices that most effectively minimize field rework. • Develop a tool (Field Rework Index, FRI) that will foretell the degree of field rework.

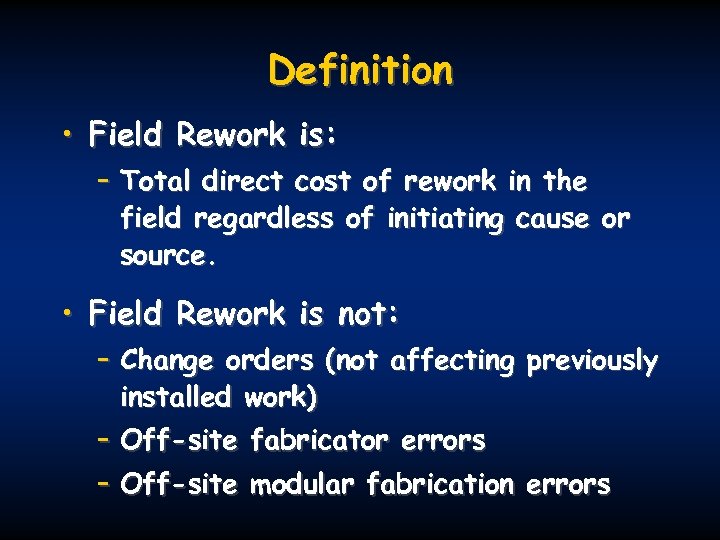

Definition • Field Rework is: – Total direct cost of rework in the field regardless of initiating cause or source. • Field Rework is not: – Change orders (not affecting previously installed work) – Off-site fabricator errors – Off-site modular fabrication errors

Definition • Field Rework is: – Total direct cost of rework in the field regardless of initiating cause or source. • Field Rework is not: – Change orders (not affecting previously installed work) – Off-site fabricator errors – Off-site modular fabrication errors

Calculation % Field Rework = Total direct cost of rework performed in field Total field construction phase cost

Calculation % Field Rework = Total direct cost of rework performed in field Total field construction phase cost

How BIG is the Problem? CII Survey Data • CII Research Summary 10 -2 12% rework on nine industrial projects • 1997 Benchmarking & Metrics Data Report 3. 4% for 19 industrial projects • CII Effects of Field Rework Research Team 5. 8% for 78 industrial projects Ranges between 0% and 27%

How BIG is the Problem? CII Survey Data • CII Research Summary 10 -2 12% rework on nine industrial projects • 1997 Benchmarking & Metrics Data Report 3. 4% for 19 industrial projects • CII Effects of Field Rework Research Team 5. 8% for 78 industrial projects Ranges between 0% and 27%

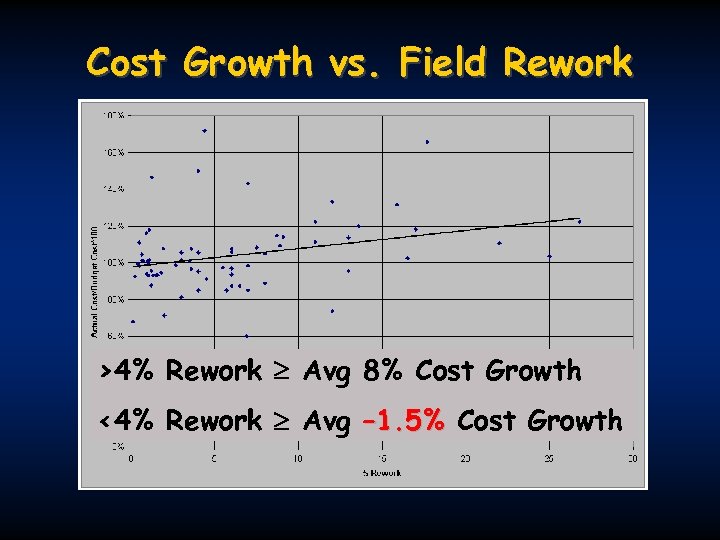

Cost Growth vs. Field Rework >4% Rework Avg 8% Cost Growth <4% Rework Avg – 1. 5% Cost Growth

Cost Growth vs. Field Rework >4% Rework Avg 8% Cost Growth <4% Rework Avg – 1. 5% Cost Growth

How Is Field Rework Tracked? Objective 1 • CII Quality Performance Management System (QPMS) – Adaptations of QPMS elements – Company internal systems Research Report 153 -11 will present a simplified system for field rework tracking only.

How Is Field Rework Tracked? Objective 1 • CII Quality Performance Management System (QPMS) – Adaptations of QPMS elements – Company internal systems Research Report 153 -11 will present a simplified system for field rework tracking only.

Rework Causes and Cures Objectives 2 & 3 • Analysis shows strongest relationships between: – Engineering rework and field rework – Owner organization alignment and field rework • Conclusion: Improve upstream processes (pre -project planning and engineering) and downstream processes (construction) will improve. Not Rocket Science

Rework Causes and Cures Objectives 2 & 3 • Analysis shows strongest relationships between: – Engineering rework and field rework – Owner organization alignment and field rework • Conclusion: Improve upstream processes (pre -project planning and engineering) and downstream processes (construction) will improve. Not Rocket Science

Predicting Field Rework Objective 4 • Project team answers 16 questions. • Scores are tabulated and multiplied by a factor and summed. A 1(X 1) + A 2(X 2) … A 13(X 13) + Constant = FRI An = Factor Xn = Team score for a question

Predicting Field Rework Objective 4 • Project team answers 16 questions. • Scores are tabulated and multiplied by a factor and summed. A 1(X 1) + A 2(X 2) … A 13(X 13) + Constant = FRI An = Factor Xn = Team score for a question

What Are the Questions? • Three categories of questions: – Team planning and organization – Information availability – Staffing or schedule constraints

What Are the Questions? • Three categories of questions: – Team planning and organization – Information availability – Staffing or schedule constraints

Team Planning and Organization • Alignment within owner organization • Owner’s attitude on scope change • Degree of use of project execution planning • Change of design discipline leaders • Commitment to using constructability by design and construction contractors

Team Planning and Organization • Alignment within owner organization • Owner’s attitude on scope change • Degree of use of project execution planning • Change of design discipline leaders • Commitment to using constructability by design and construction contractors

Information Availability • Design firm’s qualifications • Field verification of conditions by engineering • Quality of interdisciplinary design coordination • Availability of supplier information • Level of design rework

Information Availability • Design firm’s qualifications • Field verification of conditions by engineering • Quality of interdisciplinary design coordination • Availability of supplier information • Level of design rework

Staffing or Schedule Constraints • Compression of design schedule • Design overtime • Quality of supplier pre-qualification • Availability of skilled craftworkers • Construction contractor shift work • Construction contractor overtime

Staffing or Schedule Constraints • Compression of design schedule • Design overtime • Quality of supplier pre-qualification • Availability of skilled craftworkers • Construction contractor shift work • Construction contractor overtime

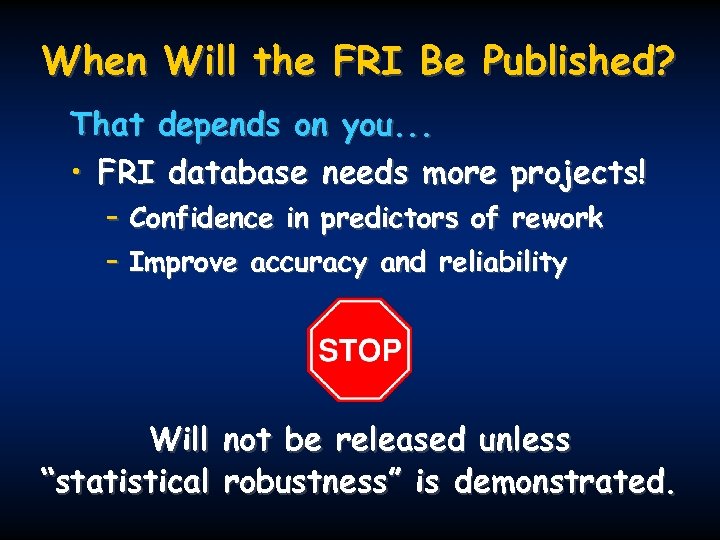

When Will the FRI Be Published? That depends on you. . . • FRI database needs more projects! – Confidence in predictors of rework – Improve accuracy and reliability Will not be released unless “statistical robustness” is demonstrated.

When Will the FRI Be Published? That depends on you. . . • FRI database needs more projects! – Confidence in predictors of rework – Improve accuracy and reliability Will not be released unless “statistical robustness” is demonstrated.

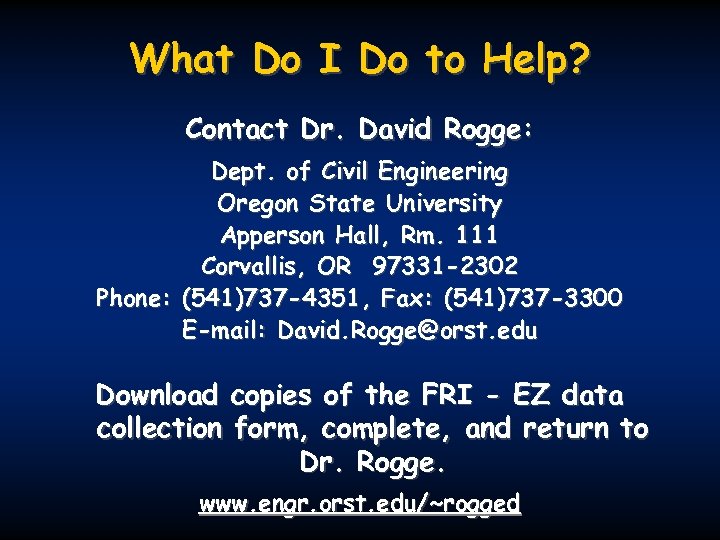

What Do I Do to Help? Contact Dr. David Rogge: Dept. of Civil Engineering Oregon State University Apperson Hall, Rm. 111 Corvallis, OR 97331 -2302 Phone: (541)737 -4351, Fax: (541)737 -3300 E-mail: David. Rogge@orst. edu Download copies of the FRI - EZ data collection form, complete, and return to Dr. Rogge. www. engr. orst. edu/~rogged

What Do I Do to Help? Contact Dr. David Rogge: Dept. of Civil Engineering Oregon State University Apperson Hall, Rm. 111 Corvallis, OR 97331 -2302 Phone: (541)737 -4351, Fax: (541)737 -3300 E-mail: David. Rogge@orst. edu Download copies of the FRI - EZ data collection form, complete, and return to Dr. Rogge. www. engr. orst. edu/~rogged