9e381292f1df900348793ac9297eaa4e.ppt

- Количество слайдов: 37

Food Safety Management Systems HACCP Clare Millar , FTDB, Loughry Campus

Food Safety Management Systems HACCP Clare Millar , FTDB, Loughry Campus

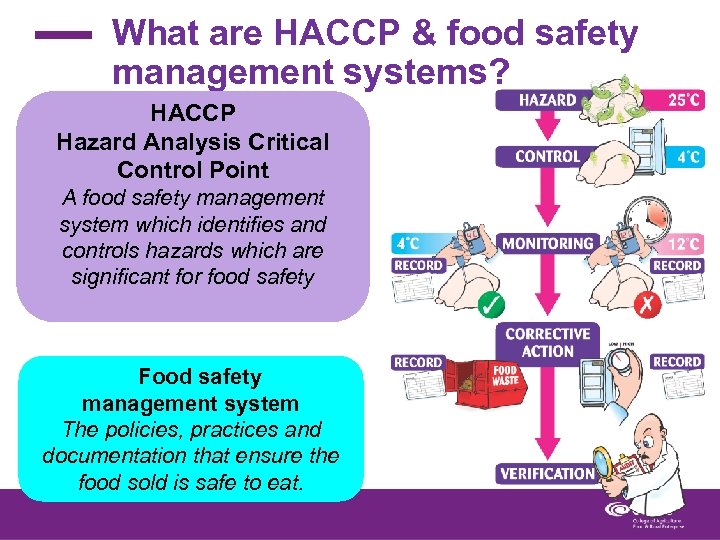

What are HACCP & food safety management systems? HACCP Hazard Analysis Critical Control Point A food safety management system which identifies and controls hazards which are significant for food safety Food safety management system The policies, practices and documentation that ensure the food sold is safe to eat.

What are HACCP & food safety management systems? HACCP Hazard Analysis Critical Control Point A food safety management system which identifies and controls hazards which are significant for food safety Food safety management system The policies, practices and documentation that ensure the food sold is safe to eat.

HACCP Background 1960’s originated by collaboration between NASA and Pillsbury Company 1970’s Introduced to Food Industry 1997 Codex Alimentarius Commission (Codex) set out guidelines for implementing HACCP 2006 Regulation (EC) No. 852/2004 made Codex HACCP a legal requirement for all food businesses

HACCP Background 1960’s originated by collaboration between NASA and Pillsbury Company 1970’s Introduced to Food Industry 1997 Codex Alimentarius Commission (Codex) set out guidelines for implementing HACCP 2006 Regulation (EC) No. 852/2004 made Codex HACCP a legal requirement for all food businesses

Legal requirement for HACCP – Regulation (EC)852/2004) Article 5 Food business operators to implement a food safety management system based on HACCP principles: a) Identify hazards b) Identify critical control points (CCPs) c) Establish critical limits d) Implement monitoring at CCPs e) Establish corrective actions f) Establish verification procedures g) Establish documentation h) Review if changes NB. Hazard analysis, the first principle of HACCP includes control measures.

Legal requirement for HACCP – Regulation (EC)852/2004) Article 5 Food business operators to implement a food safety management system based on HACCP principles: a) Identify hazards b) Identify critical control points (CCPs) c) Establish critical limits d) Implement monitoring at CCPs e) Establish corrective actions f) Establish verification procedures g) Establish documentation h) Review if changes NB. Hazard analysis, the first principle of HACCP includes control measures.

Regulation EC no. 852/2004 on the hygiene of foodstuffs • Annex 11 Chap XII • Food handlers should be trained commensurate with their work activities • Persons responsible for HACCP should receive HACCP training.

Regulation EC no. 852/2004 on the hygiene of foodstuffs • Annex 11 Chap XII • Food handlers should be trained commensurate with their work activities • Persons responsible for HACCP should receive HACCP training.

7 Principles of HACCP 1. 2. 3. 4. 5. 6. Conduct a hazard analysis Determine critical control points Establish critical limits Establish monitoring procedures Establish corrective actions Establish procedures for verification and review of HACCP plan 7. Establish record keeping & documentation

7 Principles of HACCP 1. 2. 3. 4. 5. 6. Conduct a hazard analysis Determine critical control points Establish critical limits Establish monitoring procedures Establish corrective actions Establish procedures for verification and review of HACCP plan 7. Establish record keeping & documentation

12 steps of HACCP • • • Step 1: The HACCP team Step 2: Describe the product Step 3: Identify intended use Step 4: Process flow diagram Step 5: Verify flow diagram Step 6: Conduct a hazard analysis

12 steps of HACCP • • • Step 1: The HACCP team Step 2: Describe the product Step 3: Identify intended use Step 4: Process flow diagram Step 5: Verify flow diagram Step 6: Conduct a hazard analysis

12 steps of HACCP • • • Step 7 Determine critical control points Step 8 Establish critical limits Step 9 Establish monitoring procedures Step 10 Establish corrective actions Step 11 Establish procedures for verification and review of HACCP plan Step 12 Establish record keeping & documentation

12 steps of HACCP • • • Step 7 Determine critical control points Step 8 Establish critical limits Step 9 Establish monitoring procedures Step 10 Establish corrective actions Step 11 Establish procedures for verification and review of HACCP plan Step 12 Establish record keeping & documentation

What are prerequisite programmes? Prerequisite programmes Are the good hygiene practices a business must have in place before implementing HACCP Prerequisite programmes ensure the HACCP plan concentrates on the most significant hazards.

What are prerequisite programmes? Prerequisite programmes Are the good hygiene practices a business must have in place before implementing HACCP Prerequisite programmes ensure the HACCP plan concentrates on the most significant hazards.

What are the prerequisites for HACCP? Management commitment/adequate resources Prerequisite programmes • Approved suppliers • Good design • Equipment calibration • Preventive maintenance • Personal hygiene/competency • Stock rotation • Cleaning and disinfection • Pest management • Good housekeeping • Waste management • Labelling and traceability • Contingency plans.

What are the prerequisites for HACCP? Management commitment/adequate resources Prerequisite programmes • Approved suppliers • Good design • Equipment calibration • Preventive maintenance • Personal hygiene/competency • Stock rotation • Cleaning and disinfection • Pest management • Good housekeeping • Waste management • Labelling and traceability • Contingency plans.

Principle 1 Conduct a hazard analysis

Principle 1 Conduct a hazard analysis

Scope of HACCP plan • what product, or group of products, are to be included in the plan? • where will the plan start and end? • which class of hazard, or classes of hazards, are to be included?

Scope of HACCP plan • what product, or group of products, are to be included in the plan? • where will the plan start and end? • which class of hazard, or classes of hazards, are to be included?

Step 1 - The HACCP team • • Multi – disciplinary Inter – hierarchical - different levels of personnel Workable size – usually 4 – 6 Expertise needed from – technical/microbial, production, maintenance, purchasing, development, distribution, service

Step 1 - The HACCP team • • Multi – disciplinary Inter – hierarchical - different levels of personnel Workable size – usually 4 – 6 Expertise needed from – technical/microbial, production, maintenance, purchasing, development, distribution, service

Step 2 Product description • • • ingredients and formulation raw materials storage conditions processing conditions packaging shelf life consumer instructions distribution methods microbiological data physical/chemical parameters (e. g. p. H, aw)

Step 2 Product description • • • ingredients and formulation raw materials storage conditions processing conditions packaging shelf life consumer instructions distribution methods microbiological data physical/chemical parameters (e. g. p. H, aw)

Step 3 Intended use • Will the product be consumed by any vulnerable groups? • What is its shelf life? • Will it need to be refrigerated, frozen or can it be stored at ambient temperatures? • Are there any special requirements?

Step 3 Intended use • Will the product be consumed by any vulnerable groups? • What is its shelf life? • Will it need to be refrigerated, frozen or can it be stored at ambient temperatures? • Are there any special requirements?

Step 4 – The process flow diagram A flow diagram Is a pictorial representation of the steps involved in a particular process Consider: • • • raw materials – list separately Don’t forget: Packaging Water/air Rework Transfer stages

Step 4 – The process flow diagram A flow diagram Is a pictorial representation of the steps involved in a particular process Consider: • • • raw materials – list separately Don’t forget: Packaging Water/air Rework Transfer stages

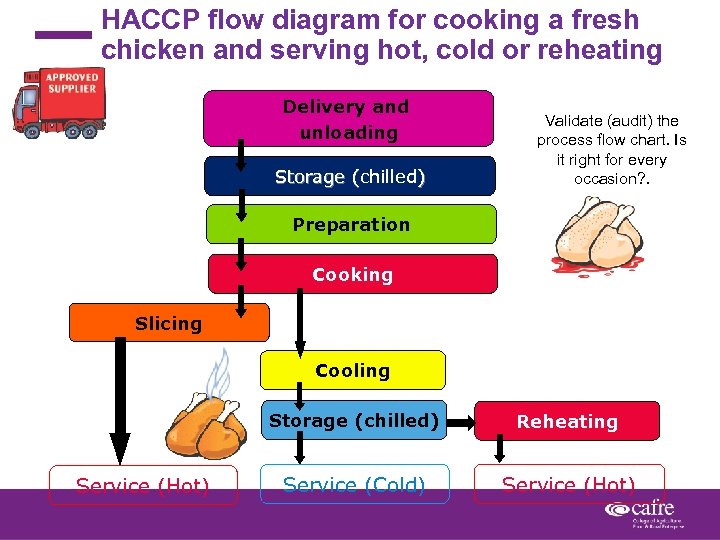

HACCP flow diagram for cooking a fresh chicken and serving hot, cold or reheating Delivery and unloading Storage (chilled) ( Validate (audit) the process flow chart. Is it right for every occasion? . Preparation Cooking Slicing Cooling Storage (chilled) Service (Hot) Reheating Service (Cold) Service (Hot)

HACCP flow diagram for cooking a fresh chicken and serving hot, cold or reheating Delivery and unloading Storage (chilled) ( Validate (audit) the process flow chart. Is it right for every occasion? . Preparation Cooking Slicing Cooling Storage (chilled) Service (Hot) Reheating Service (Cold) Service (Hot)

Step 5 - On site confirmation • Accuracy is essential as the process flow diagram forms the basis of the HACCP plan • “Walk the line” to confirm detail • Usually carried out by someone not involved in the design • Carries out at different times/shifts • Amend where necessary, record changes

Step 5 - On site confirmation • Accuracy is essential as the process flow diagram forms the basis of the HACCP plan • “Walk the line” to confirm detail • Usually carried out by someone not involved in the design • Carries out at different times/shifts • Amend where necessary, record changes

Step 6 - Hazard analysis “The process of collecting & evaluating information on hazards & conditions leading to their presence to decide which are significant for food safety & therefore should be addressed in the HACCP plan. “ Codex 2001

Step 6 - Hazard analysis “The process of collecting & evaluating information on hazards & conditions leading to their presence to decide which are significant for food safety & therefore should be addressed in the HACCP plan. “ Codex 2001

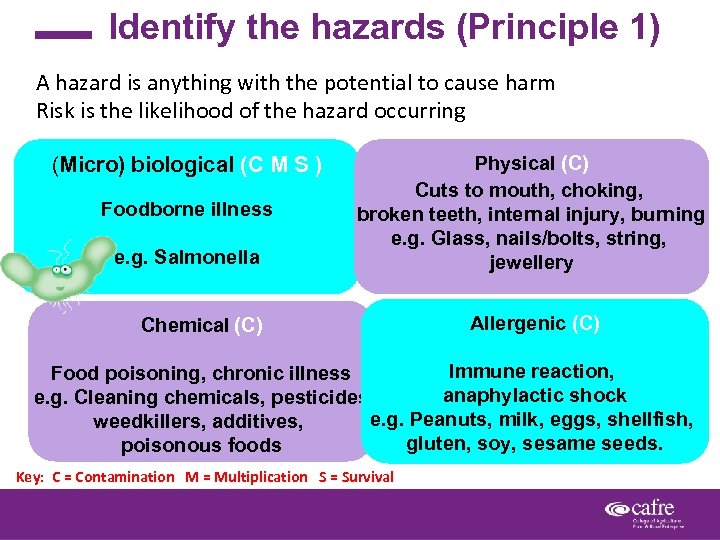

Identify the hazards (Principle 1) A hazard is anything with the potential to cause harm Risk is the likelihood of the hazard occurring (Micro) biological (C M S ) Foodborne illness e. g. Salmonella Physical (C) Cuts to mouth, choking, broken teeth, internal injury, burning e. g. Glass, nails/bolts, string, jewellery Chemical (C) Allergenic (C) Immune reaction, Food poisoning, chronic illness anaphylactic shock e. g. Cleaning chemicals, pesticides e. g. Peanuts, milk, eggs, shellfish, weedkillers, additives, gluten, soy, sesame seeds. poisonous foods Key: C = Contamination M = Multiplication S = Survival

Identify the hazards (Principle 1) A hazard is anything with the potential to cause harm Risk is the likelihood of the hazard occurring (Micro) biological (C M S ) Foodborne illness e. g. Salmonella Physical (C) Cuts to mouth, choking, broken teeth, internal injury, burning e. g. Glass, nails/bolts, string, jewellery Chemical (C) Allergenic (C) Immune reaction, Food poisoning, chronic illness anaphylactic shock e. g. Cleaning chemicals, pesticides e. g. Peanuts, milk, eggs, shellfish, weedkillers, additives, gluten, soy, sesame seeds. poisonous foods Key: C = Contamination M = Multiplication S = Survival

Identify control measures Any action or activity that can be used to prevent or eliminate a food safety hazard or reduce it to an acceptable level. Remember: • More than one hazard may be controlled by a particular control measure • An individual hazard may require more than one control measure

Identify control measures Any action or activity that can be used to prevent or eliminate a food safety hazard or reduce it to an acceptable level. Remember: • More than one hazard may be controlled by a particular control measure • An individual hazard may require more than one control measure

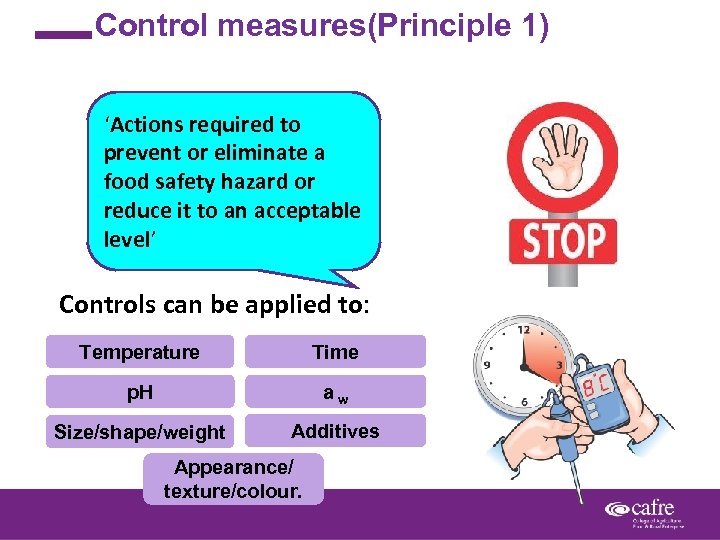

Control measures(Principle 1) ‘Actions required to prevent or eliminate a food safety hazard or reduce it to an acceptable level’ Controls can be applied to: Temperature Time p. H aw Size/shape/weight Additives Appearance/ texture/colour.

Control measures(Principle 1) ‘Actions required to prevent or eliminate a food safety hazard or reduce it to an acceptable level’ Controls can be applied to: Temperature Time p. H aw Size/shape/weight Additives Appearance/ texture/colour.

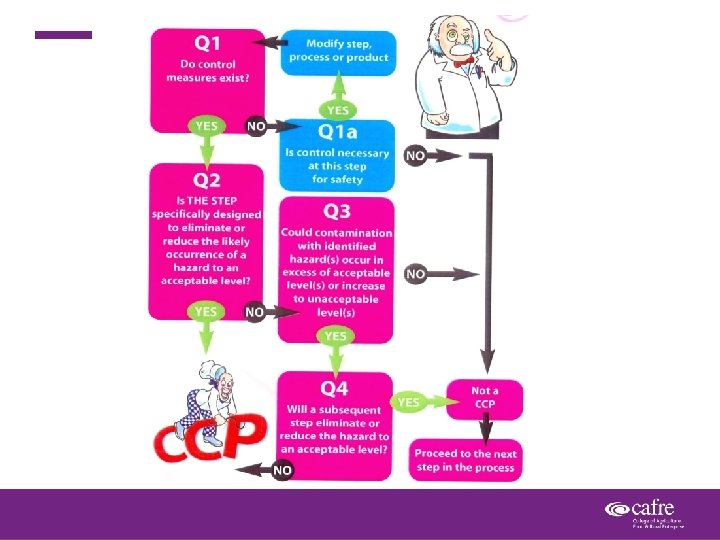

Principle 2 – Determine critical control points Critical control point ‘A step in a process where control is essential to prevent or eliminate a food safety hazard, or reduce it to an acceptable level’. Effective control procedures must be provided at all CCPs

Principle 2 – Determine critical control points Critical control point ‘A step in a process where control is essential to prevent or eliminate a food safety hazard, or reduce it to an acceptable level’. Effective control procedures must be provided at all CCPs

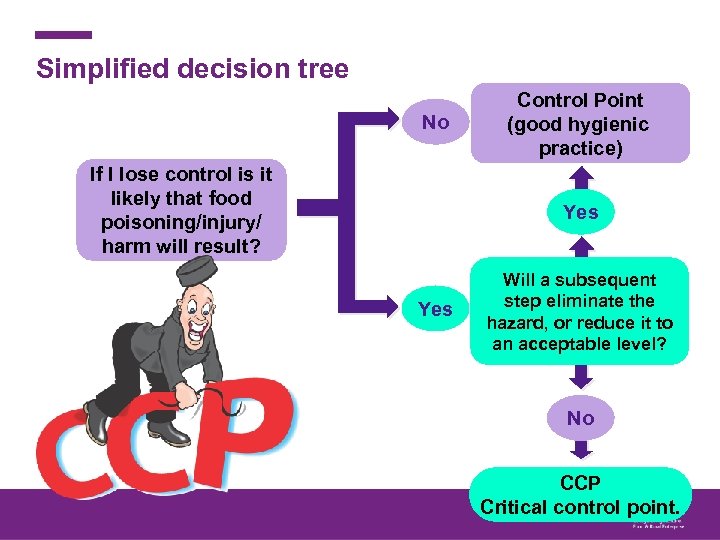

Simplified decision tree No If I lose control is it likely that food poisoning/injury/ harm will result? Control Point (good hygienic practice) Yes Will a subsequent step eliminate the hazard, or reduce it to an acceptable level? No CCP Critical control point.

Simplified decision tree No If I lose control is it likely that food poisoning/injury/ harm will result? Control Point (good hygienic practice) Yes Will a subsequent step eliminate the hazard, or reduce it to an acceptable level? No CCP Critical control point.

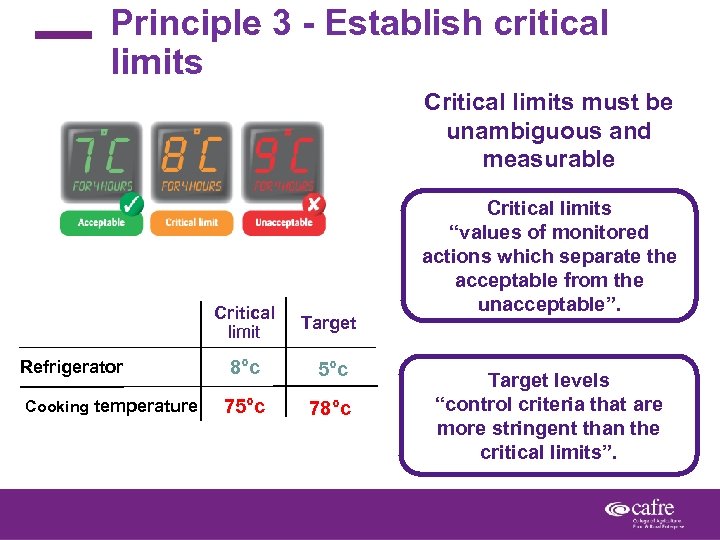

Principle 3 - Establish critical limits Critical limits must be unambiguous and measurable Critical limit Refrigerator Cooking temperature Target 8°c 5°c 78°c Critical limits “values of monitored actions which separate the acceptable from the unacceptable”. Target levels “control criteria that are more stringent than the critical limits”.

Principle 3 - Establish critical limits Critical limits must be unambiguous and measurable Critical limit Refrigerator Cooking temperature Target 8°c 5°c 78°c Critical limits “values of monitored actions which separate the acceptable from the unacceptable”. Target levels “control criteria that are more stringent than the critical limits”.

Principle 4 – Establish monitoring procedures Monitoring “The planned observations and measurements of control parameters to confirm the process is under control and critical limits are not exceeded”. Rapid detection and correction Automatic or manual

Principle 4 – Establish monitoring procedures Monitoring “The planned observations and measurements of control parameters to confirm the process is under control and critical limits are not exceeded”. Rapid detection and correction Automatic or manual

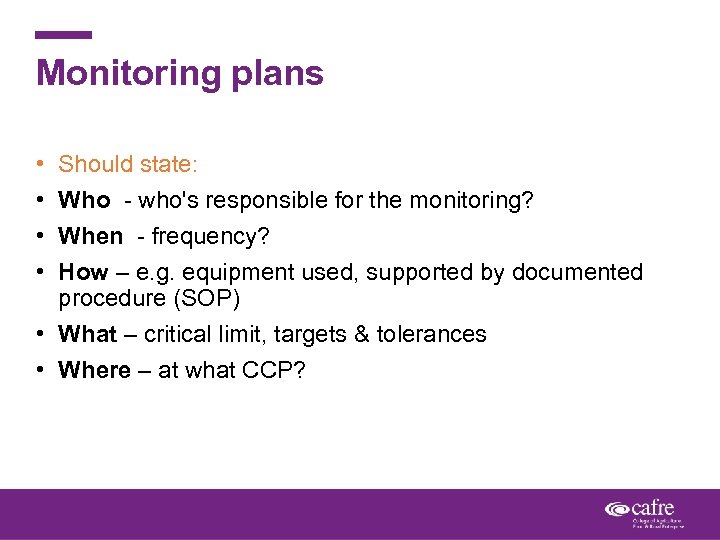

Monitoring plans • • Should state: Who - who's responsible for the monitoring? When - frequency? How – e. g. equipment used, supported by documented procedure (SOP) • What – critical limit, targets & tolerances • Where – at what CCP?

Monitoring plans • • Should state: Who - who's responsible for the monitoring? When - frequency? How – e. g. equipment used, supported by documented procedure (SOP) • What – critical limit, targets & tolerances • Where – at what CCP?

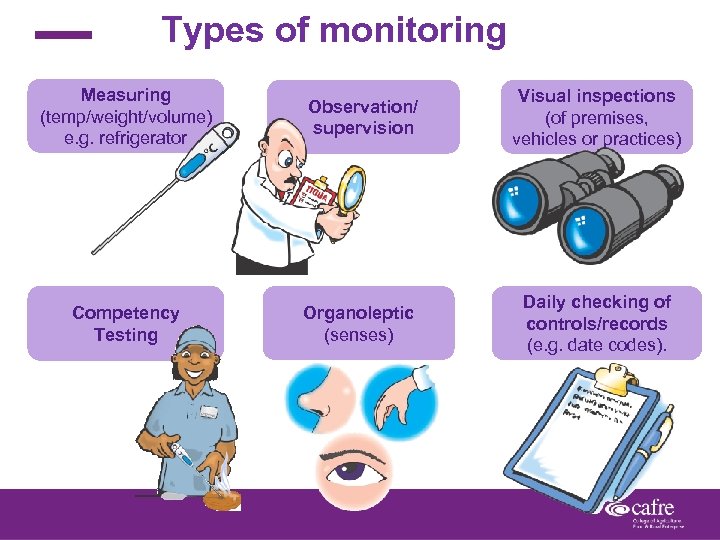

Types of monitoring Measuring (temp/weight/volume) e. g. refrigerator Observation/ supervision Visual inspections (of premises, vehicles or practices) Competency Testing Organoleptic (senses) Daily checking of controls/records (e. g. date codes).

Types of monitoring Measuring (temp/weight/volume) e. g. refrigerator Observation/ supervision Visual inspections (of premises, vehicles or practices) Competency Testing Organoleptic (senses) Daily checking of controls/records (e. g. date codes).

Principle 5 -Establish corrective action Corrective action The action to be taken when a critical limit is breached Remedial action should be taken before a critical limit is breached Corrective action should bring the CCP under control and deal with any affected product.

Principle 5 -Establish corrective action Corrective action The action to be taken when a critical limit is breached Remedial action should be taken before a critical limit is breached Corrective action should bring the CCP under control and deal with any affected product.

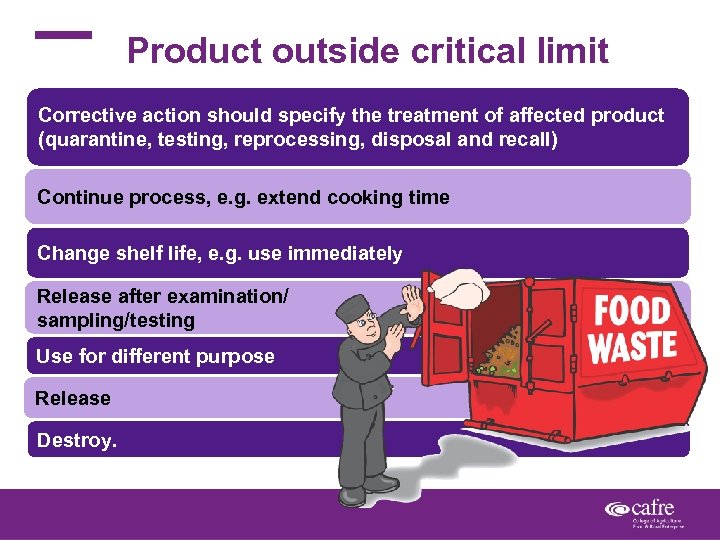

Product outside critical limit Corrective action should specify the treatment of affected product (quarantine, testing, reprocessing, disposal and recall) Continue process, e. g. extend cooking time Change shelf life, e. g. use immediately Release after examination/ sampling/testing Use for different purpose Release Destroy.

Product outside critical limit Corrective action should specify the treatment of affected product (quarantine, testing, reprocessing, disposal and recall) Continue process, e. g. extend cooking time Change shelf life, e. g. use immediately Release after examination/ sampling/testing Use for different purpose Release Destroy.

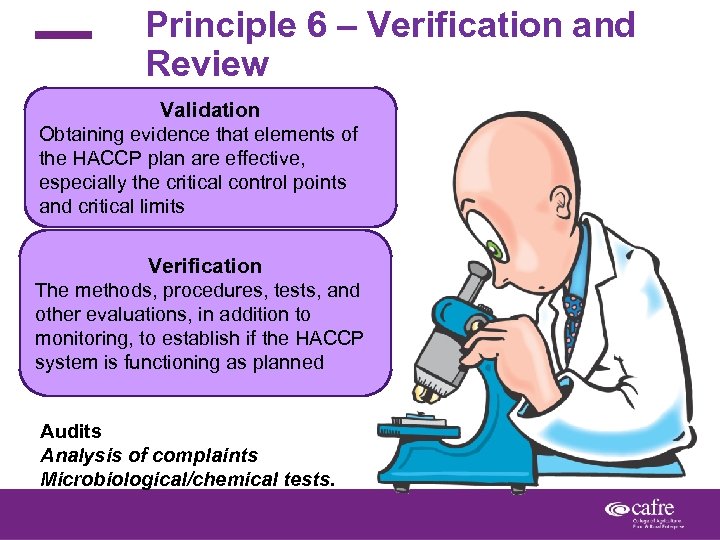

Principle 6 – Verification and Review Validation Obtaining evidence that elements of the HACCP plan are effective, especially the critical control points and critical limits Verification The methods, procedures, tests, and other evaluations, in addition to monitoring, to establish if the HACCP system is functioning as planned Audits Analysis of complaints Microbiological/chemical tests.

Principle 6 – Verification and Review Validation Obtaining evidence that elements of the HACCP plan are effective, especially the critical control points and critical limits Verification The methods, procedures, tests, and other evaluations, in addition to monitoring, to establish if the HACCP system is functioning as planned Audits Analysis of complaints Microbiological/chemical tests.

What is review? A reassessment of the HACCP system to ensure its continued validity. The HACCP system should be reviewed: • If things go wrong, e. g. food poisoning • If there are significant changes, e. g. new ingredients, law, process or product.

What is review? A reassessment of the HACCP system to ensure its continued validity. The HACCP system should be reviewed: • If things go wrong, e. g. food poisoning • If there are significant changes, e. g. new ingredients, law, process or product.

Principle 7 - Establish Documentation • Essential to the application of the HACCP system • Appropriate to the size and nature of the business • Demonstrates importance of CCP monitoring to staff Why is it required? • • Company policy Verification/internal audits Complaint/illness investigation Due-diligence defence Legal compliance External auditors/EHO/EHP Prove business is well managed.

Principle 7 - Establish Documentation • Essential to the application of the HACCP system • Appropriate to the size and nature of the business • Demonstrates importance of CCP monitoring to staff Why is it required? • • Company policy Verification/internal audits Complaint/illness investigation Due-diligence defence Legal compliance External auditors/EHO/EHP Prove business is well managed.

What are the benefits of HACCP? • • • Reduces the risk of food poisoning and food complaints Compliance with the law (due-diligence defence) Resources concentrated at critical points Reduced costs, e. g. waste/recall Generates a food safety culture/all staff involved Proactive not reactive Safety introduced in product development Demonstrates management commitment More effective than end-product testing

What are the benefits of HACCP? • • • Reduces the risk of food poisoning and food complaints Compliance with the law (due-diligence defence) Resources concentrated at critical points Reduced costs, e. g. waste/recall Generates a food safety culture/all staff involved Proactive not reactive Safety introduced in product development Demonstrates management commitment More effective than end-product testing

Problems implementing HACCP • • • Over complicated Lack of management commitment Lack of training = lack of understanding Lack of resources Poor communication

Problems implementing HACCP • • • Over complicated Lack of management commitment Lack of training = lack of understanding Lack of resources Poor communication

European Food Safety Authority https: //www. efsa. europa. eu/

European Food Safety Authority https: //www. efsa. europa. eu/