794f8acdcc50bb2ddf99c187fe9be48d.ppt

- Количество слайдов: 33

FM Measuring or Measuring FM ? Dr. Doug Aldrich CFM, IFMA Fellow

FM Measuring or Measuring FM ? Dr. Doug Aldrich CFM, IFMA Fellow

Today’s Discussion n n n “Measure for Measurer” Numbers and Words Stakeholders Examples “Packaging” Closing and Q&A

Today’s Discussion n n n “Measure for Measurer” Numbers and Words Stakeholders Examples “Packaging” Closing and Q&A

Introduction n FM Measuring u u n Department Peers Measuring FM u u Customers or Users Leadership

Introduction n FM Measuring u u n Department Peers Measuring FM u u Customers or Users Leadership

Two Sets of Books Set #1 – Within FM n n Efficiency of operations FM measures and judges results I care…. . but they probably don’t Steward Set #2 - Outside FM n n Effectiveness of services Stakeholders measure and judge ___? ____ They care…. . so I must too Stock broker

Two Sets of Books Set #1 – Within FM n n Efficiency of operations FM measures and judges results I care…. . but they probably don’t Steward Set #2 - Outside FM n n Effectiveness of services Stakeholders measure and judge ___? ____ They care…. . so I must too Stock broker

Dr. Doug’s Dilemmas n Precise numbers with effort or simple speedy approximations? n Year-to-year numbers or historical trends? n Quick response or “I’ll get back to you”? n Cheerful supply of data or concerns about what they’re going to do with it? n Careful forecasts or ballpark ranges?

Dr. Doug’s Dilemmas n Precise numbers with effort or simple speedy approximations? n Year-to-year numbers or historical trends? n Quick response or “I’ll get back to you”? n Cheerful supply of data or concerns about what they’re going to do with it? n Careful forecasts or ballpark ranges?

Benefits of FM Measurements n You know how well you are serving your customers; there are few surprises. n You will continually improve your service output for cost, timing, and quality. n You will be the most competitive supplier of products and services to your users. n You will demonstrate your value to the organization, both short and long-term.

Benefits of FM Measurements n You know how well you are serving your customers; there are few surprises. n You will continually improve your service output for cost, timing, and quality. n You will be the most competitive supplier of products and services to your users. n You will demonstrate your value to the organization, both short and long-term.

Numbers and Words - 1 n Accuracy – 104 n Precision - $10, 436 n Significant Figures u $55 M and 3. 4 M gsf u $16. 18 / gsf

Numbers and Words - 1 n Accuracy – 104 n Precision - $10, 436 n Significant Figures u $55 M and 3. 4 M gsf u $16. 18 / gsf

Numbers and Words - 2 n Units u 186, 282 and 1. 803 x 10^12 u 183 and 11, 300 n Averages u Suspicious u Statistics

Numbers and Words - 2 n Units u 186, 282 and 1. 803 x 10^12 u 183 and 11, 300 n Averages u Suspicious u Statistics

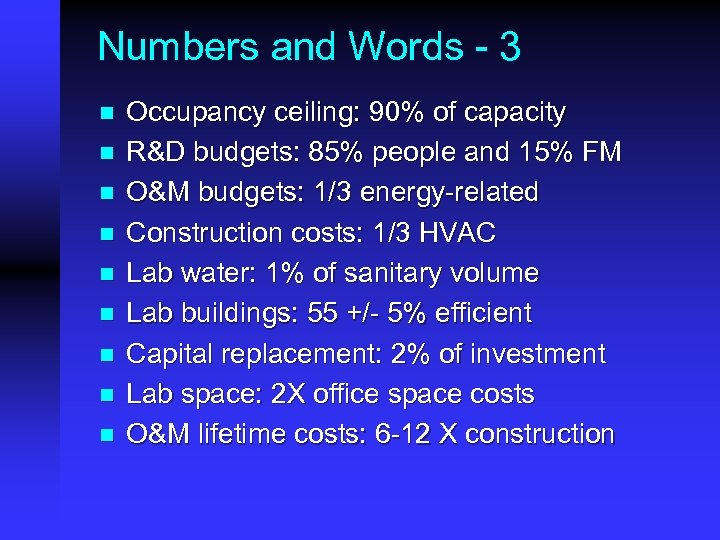

Numbers and Words - 3 n n n n n Occupancy ceiling: 90% of capacity R&D budgets: 85% people and 15% FM O&M budgets: 1/3 energy-related Construction costs: 1/3 HVAC Lab water: 1% of sanitary volume Lab buildings: 55 +/- 5% efficient Capital replacement: 2% of investment Lab space: 2 X office space costs O&M lifetime costs: 6 -12 X construction

Numbers and Words - 3 n n n n n Occupancy ceiling: 90% of capacity R&D budgets: 85% people and 15% FM O&M budgets: 1/3 energy-related Construction costs: 1/3 HVAC Lab water: 1% of sanitary volume Lab buildings: 55 +/- 5% efficient Capital replacement: 2% of investment Lab space: 2 X office space costs O&M lifetime costs: 6 -12 X construction

Numbers and Words - 4 n Data + Context = Information n Information + Seasoning = Knowledge n Knowledge + Reflection = Wisdom*

Numbers and Words - 4 n Data + Context = Information n Information + Seasoning = Knowledge n Knowledge + Reflection = Wisdom*

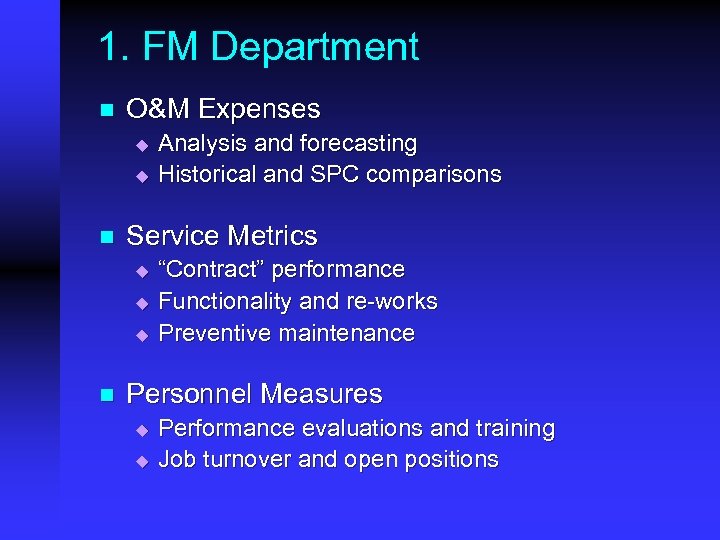

1. FM Department n O&M Expenses u u n Service Metrics u u u n Analysis and forecasting Historical and SPC comparisons “Contract” performance Functionality and re-works Preventive maintenance Personnel Measures u u Performance evaluations and training Job turnover and open positions

1. FM Department n O&M Expenses u u n Service Metrics u u u n Analysis and forecasting Historical and SPC comparisons “Contract” performance Functionality and re-works Preventive maintenance Personnel Measures u u Performance evaluations and training Job turnover and open positions

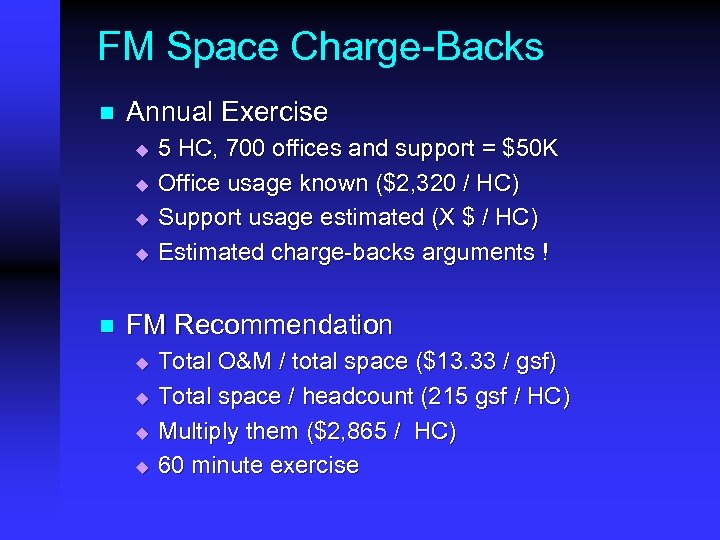

FM Space Charge-Backs n Annual Exercise u u n 5 HC, 700 offices and support = $50 K Office usage known ($2, 320 / HC) Support usage estimated (X $ / HC) Estimated charge-backs arguments ! FM Recommendation u u Total O&M / total space ($13. 33 / gsf) Total space / headcount (215 gsf / HC) Multiply them ($2, 865 / HC) 60 minute exercise

FM Space Charge-Backs n Annual Exercise u u n 5 HC, 700 offices and support = $50 K Office usage known ($2, 320 / HC) Support usage estimated (X $ / HC) Estimated charge-backs arguments ! FM Recommendation u u Total O&M / total space ($13. 33 / gsf) Total space / headcount (215 gsf / HC) Multiply them ($2, 865 / HC) 60 minute exercise

2. FM Peers n Best Practices---qualitative n Benchmarking---quantitative n Denominator u u n Area Easy Numerator u u Costs Difficult

2. FM Peers n Best Practices---qualitative n Benchmarking---quantitative n Denominator u u n Area Easy Numerator u u Costs Difficult

Numerator – Variable Expenses n n n n n Maintenance and Repairs Improvements and Changes Supplies Custodial Roads and Grounds Telecommunications Energy* and Water Waste disposal Recycling

Numerator – Variable Expenses n n n n n Maintenance and Repairs Improvements and Changes Supplies Custodial Roads and Grounds Telecommunications Energy* and Water Waste disposal Recycling

Numerator – Other Expenses n Semi-Fixed u u u n Fixed u u n FM SW&B FM budget support Site Staff Depreciation Insurance Rentals Taxes Allocations

Numerator – Other Expenses n Semi-Fixed u u u n Fixed u u n FM SW&B FM budget support Site Staff Depreciation Insurance Rentals Taxes Allocations

3. FM Customers n n n n Why do things take so long? Are the costs fair? What’s the status of my work request? Why do I have to pay for “X”? Will you be there in emergencies? Why do I have to talk to so many people? Can you let me know when you’re done? Can’t you do it right the first time?

3. FM Customers n n n n Why do things take so long? Are the costs fair? What’s the status of my work request? Why do I have to pay for “X”? Will you be there in emergencies? Why do I have to talk to so many people? Can you let me know when you’re done? Can’t you do it right the first time?

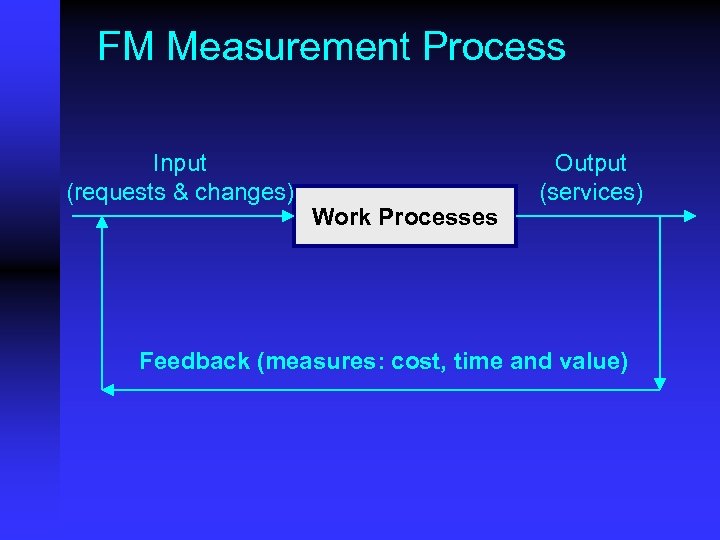

FM Measurement Process Input (requests & changes) Work Processes Output (services) Feedback (measures: cost, time and value)

FM Measurement Process Input (requests & changes) Work Processes Output (services) Feedback (measures: cost, time and value)

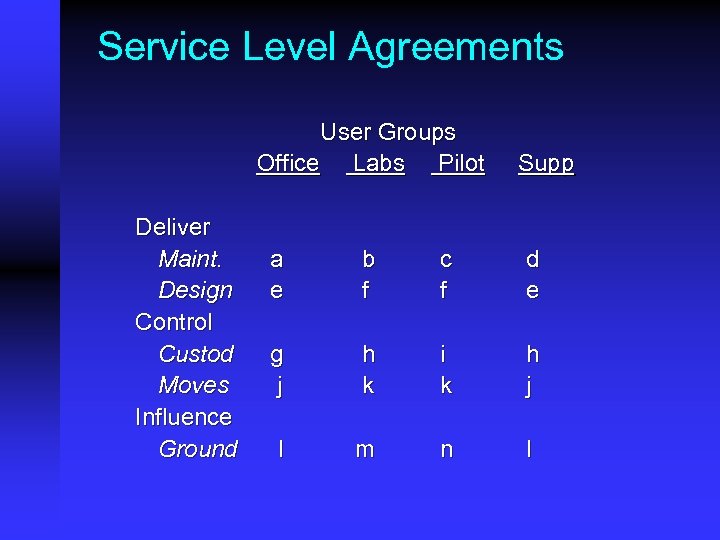

Service Level Agreements User Groups Office Labs Pilot Deliver Maint. Design Control Custod Moves Influence Ground Supp a e b f c f d e g j h k i k h j l m n l

Service Level Agreements User Groups Office Labs Pilot Deliver Maint. Design Control Custod Moves Influence Ground Supp a e b f c f d e g j h k i k h j l m n l

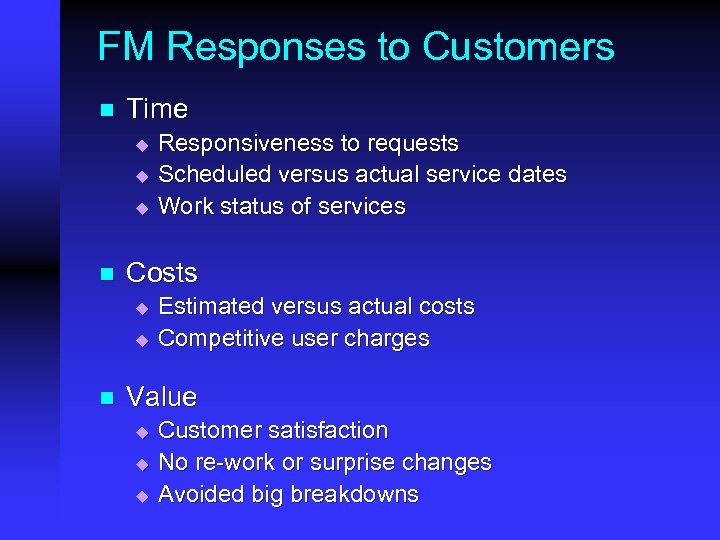

FM Responses to Customers n Time u u u n Costs u u n Responsiveness to requests Scheduled versus actual service dates Work status of services Estimated versus actual costs Competitive user charges Value u u u Customer satisfaction No re-work or surprise changes Avoided big breakdowns

FM Responses to Customers n Time u u u n Costs u u n Responsiveness to requests Scheduled versus actual service dates Work status of services Estimated versus actual costs Competitive user charges Value u u u Customer satisfaction No re-work or surprise changes Avoided big breakdowns

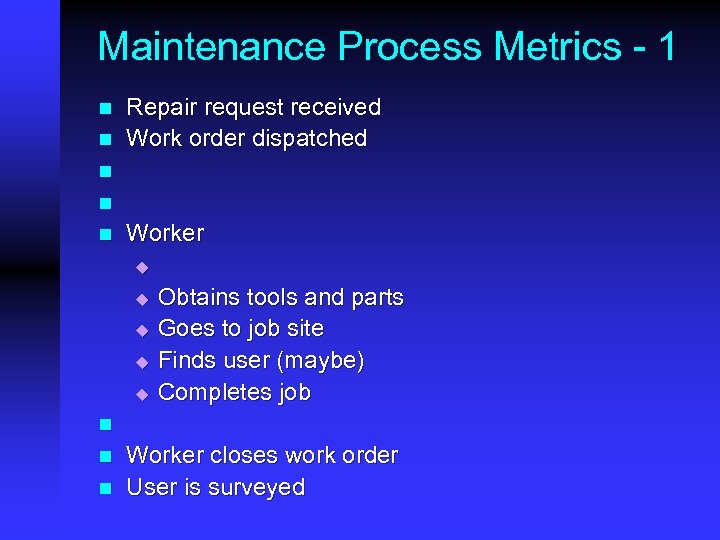

Maintenance Process Metrics - 1 n n Repair request received Work order dispatched n n n Worker u u u Obtains tools and parts Goes to job site Finds user (maybe) Completes job n n n Worker closes work order User is surveyed

Maintenance Process Metrics - 1 n n Repair request received Work order dispatched n n n Worker u u u Obtains tools and parts Goes to job site Finds user (maybe) Completes job n n n Worker closes work order User is surveyed

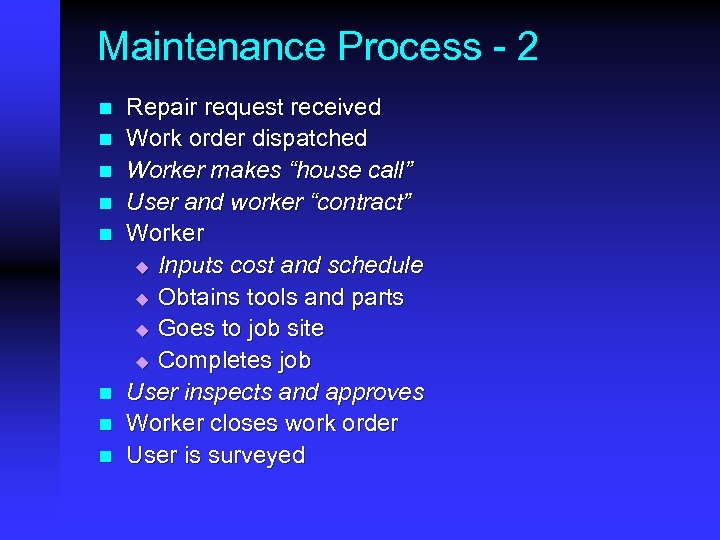

Maintenance Process - 2 n n n n Repair request received Work order dispatched Worker makes “house call” User and worker “contract” Worker u Inputs cost and schedule u Obtains tools and parts u Goes to job site u Completes job User inspects and approves Worker closes work order User is surveyed

Maintenance Process - 2 n n n n Repair request received Work order dispatched Worker makes “house call” User and worker “contract” Worker u Inputs cost and schedule u Obtains tools and parts u Goes to job site u Completes job User inspects and approves Worker closes work order User is surveyed

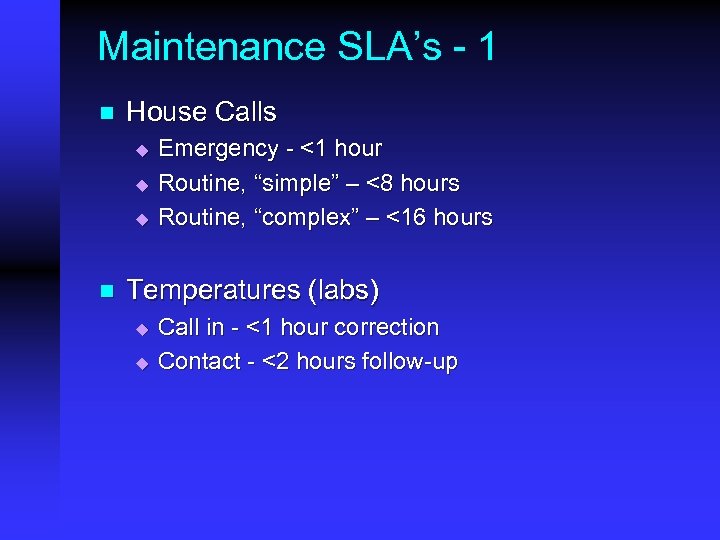

Maintenance SLA’s - 1 n House Calls u u u n Emergency - <1 hour Routine, “simple” – <8 hours Routine, “complex” – <16 hours Temperatures (labs) u u Call in - <1 hour correction Contact - <2 hours follow-up

Maintenance SLA’s - 1 n House Calls u u u n Emergency - <1 hour Routine, “simple” – <8 hours Routine, “complex” – <16 hours Temperatures (labs) u u Call in - <1 hour correction Contact - <2 hours follow-up

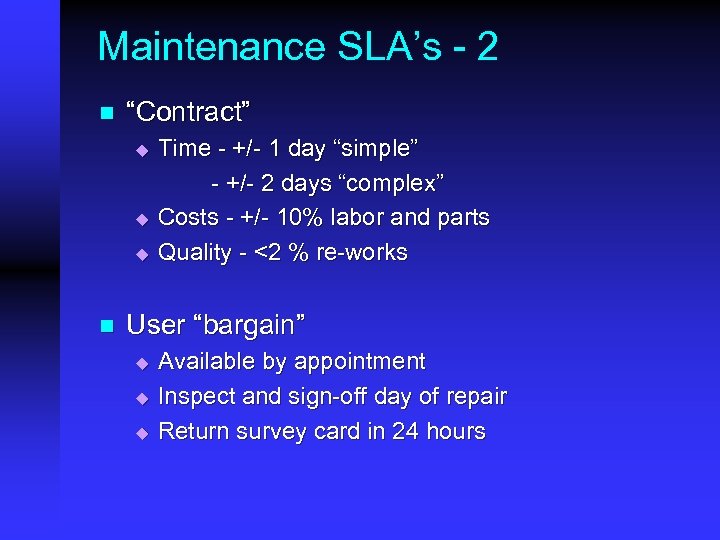

Maintenance SLA’s - 2 n “Contract” u u u n Time - +/- 1 day “simple” - +/- 2 days “complex” Costs - +/- 10% labor and parts Quality - <2 % re-works User “bargain” u u u Available by appointment Inspect and sign-off day of repair Return survey card in 24 hours

Maintenance SLA’s - 2 n “Contract” u u u n Time - +/- 1 day “simple” - +/- 2 days “complex” Costs - +/- 10% labor and parts Quality - <2 % re-works User “bargain” u u u Available by appointment Inspect and sign-off day of repair Return survey card in 24 hours

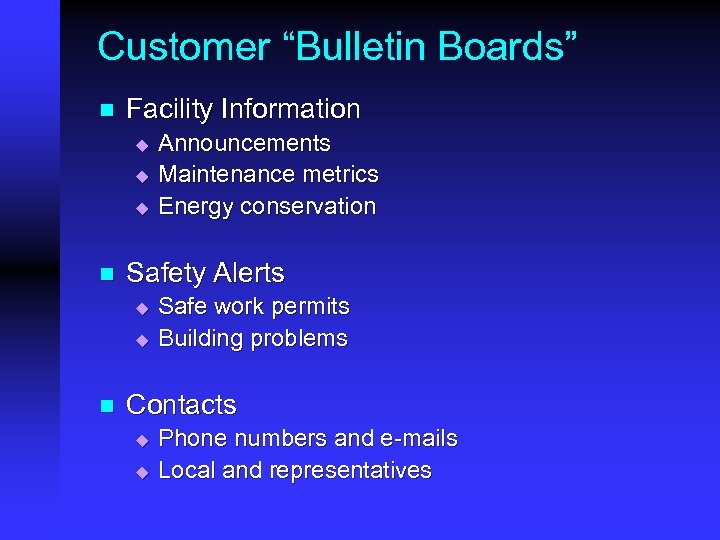

Customer “Bulletin Boards” n Facility Information u u u n Safety Alerts u u n Announcements Maintenance metrics Energy conservation Safe work permits Building problems Contacts u u Phone numbers and e-mails Local and representatives

Customer “Bulletin Boards” n Facility Information u u u n Safety Alerts u u n Announcements Maintenance metrics Energy conservation Safe work permits Building problems Contacts u u Phone numbers and e-mails Local and representatives

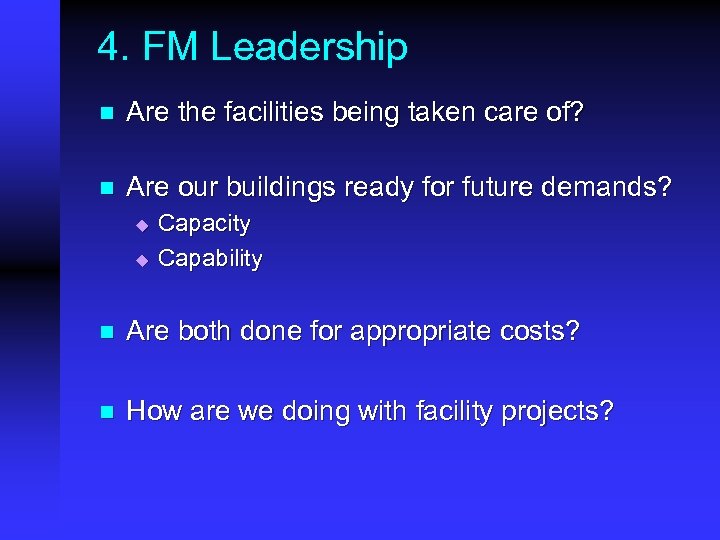

4. FM Leadership n Are the facilities being taken care of? n Are our buildings ready for future demands? u u Capacity Capability n Are both done for appropriate costs? n How are we doing with facility projects?

4. FM Leadership n Are the facilities being taken care of? n Are our buildings ready for future demands? u u Capacity Capability n Are both done for appropriate costs? n How are we doing with facility projects?

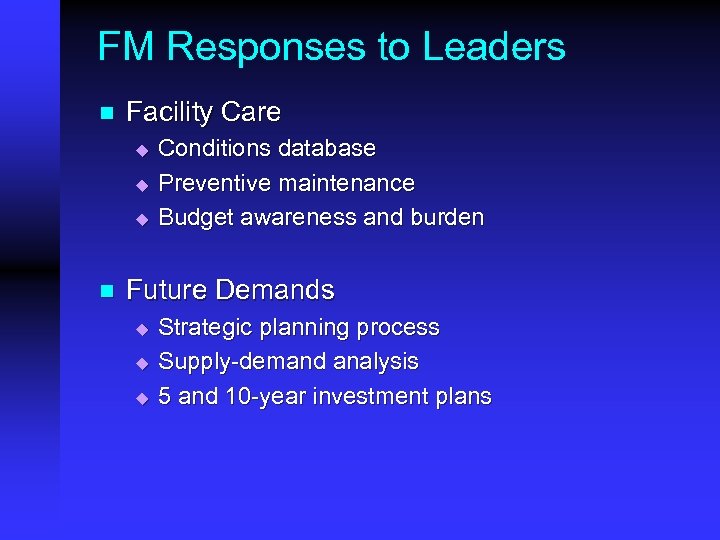

FM Responses to Leaders n Facility Care u u u n Conditions database Preventive maintenance Budget awareness and burden Future Demands u u u Strategic planning process Supply-demand analysis 5 and 10 -year investment plans

FM Responses to Leaders n Facility Care u u u n Conditions database Preventive maintenance Budget awareness and burden Future Demands u u u Strategic planning process Supply-demand analysis 5 and 10 -year investment plans

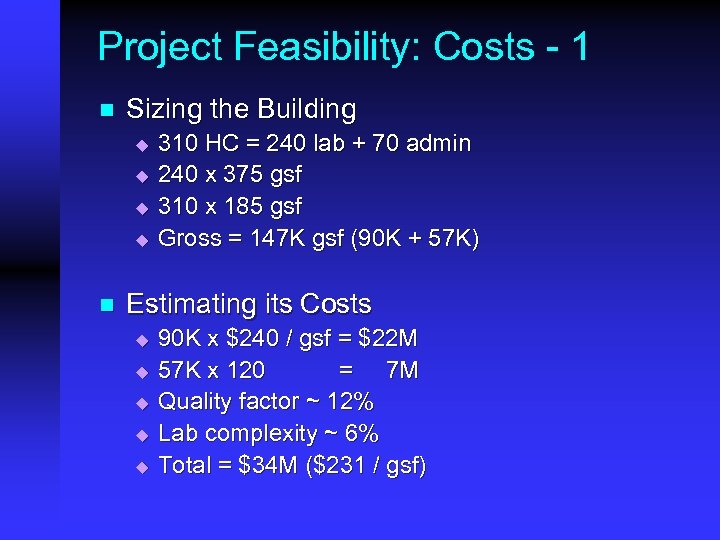

Project Feasibility: Costs - 1 n Sizing the Building u u n 310 HC = 240 lab + 70 admin 240 x 375 gsf 310 x 185 gsf Gross = 147 K gsf (90 K + 57 K) Estimating its Costs u u u 90 K x $240 / gsf = $22 M 57 K x 120 = 7 M Quality factor ~ 12% Lab complexity ~ 6% Total = $34 M ($231 / gsf)

Project Feasibility: Costs - 1 n Sizing the Building u u n 310 HC = 240 lab + 70 admin 240 x 375 gsf 310 x 185 gsf Gross = 147 K gsf (90 K + 57 K) Estimating its Costs u u u 90 K x $240 / gsf = $22 M 57 K x 120 = 7 M Quality factor ~ 12% Lab complexity ~ 6% Total = $34 M ($231 / gsf)

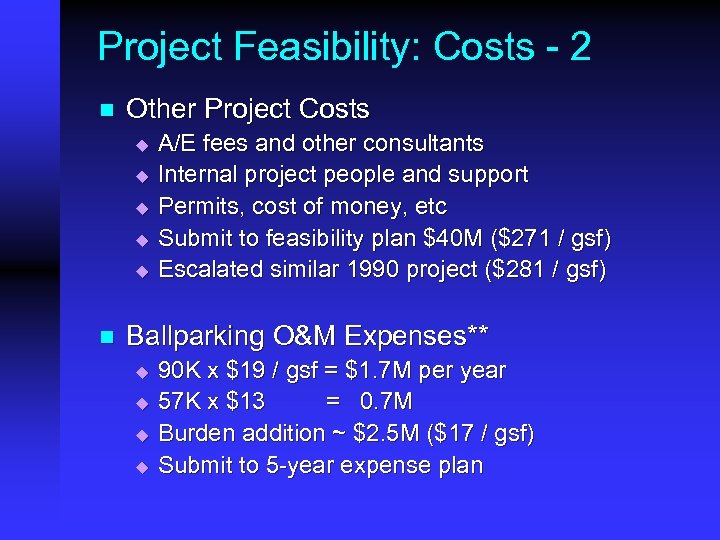

Project Feasibility: Costs - 2 n Other Project Costs u u u n A/E fees and other consultants Internal project people and support Permits, cost of money, etc Submit to feasibility plan $40 M ($271 / gsf) Escalated similar 1990 project ($281 / gsf) Ballparking O&M Expenses** u u 90 K x $19 / gsf = $1. 7 M per year 57 K x $13 = 0. 7 M Burden addition ~ $2. 5 M ($17 / gsf) Submit to 5 -year expense plan

Project Feasibility: Costs - 2 n Other Project Costs u u u n A/E fees and other consultants Internal project people and support Permits, cost of money, etc Submit to feasibility plan $40 M ($271 / gsf) Escalated similar 1990 project ($281 / gsf) Ballparking O&M Expenses** u u 90 K x $19 / gsf = $1. 7 M per year 57 K x $13 = 0. 7 M Burden addition ~ $2. 5 M ($17 / gsf) Submit to 5 -year expense plan

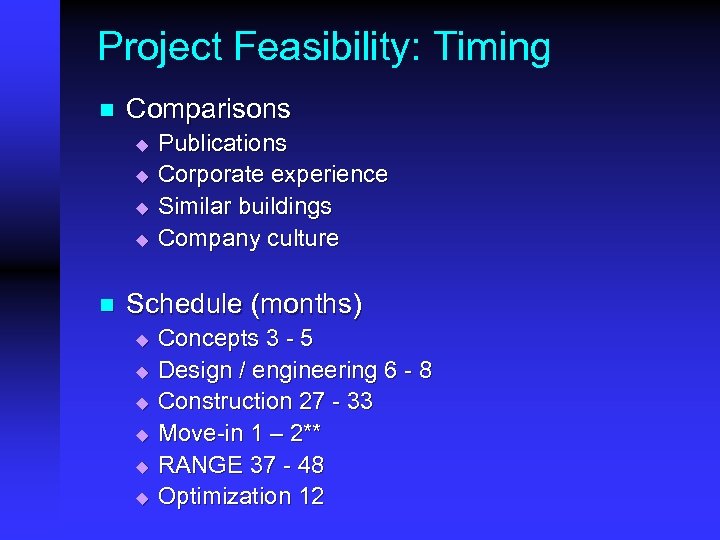

Project Feasibility: Timing n Comparisons u u n Publications Corporate experience Similar buildings Company culture Schedule (months) u u u Concepts 3 - 5 Design / engineering 6 - 8 Construction 27 - 33 Move-in 1 – 2** RANGE 37 - 48 Optimization 12

Project Feasibility: Timing n Comparisons u u n Publications Corporate experience Similar buildings Company culture Schedule (months) u u u Concepts 3 - 5 Design / engineering 6 - 8 Construction 27 - 33 Move-in 1 – 2** RANGE 37 - 48 Optimization 12

“Packaging” - Understanding n n n n Flexibility versus Adaptability Balancing Acts One-Stop Shopping Cost versus Value Baton Hand-Off Competitive Pricing Time Value of Time Ballpark Estimates (+/-)

“Packaging” - Understanding n n n n Flexibility versus Adaptability Balancing Acts One-Stop Shopping Cost versus Value Baton Hand-Off Competitive Pricing Time Value of Time Ballpark Estimates (+/-)

“Packaging” - Analogies n n n n n Home Automobile Airplane Journey Sports Hobbies Pets Vegetables School

“Packaging” - Analogies n n n n n Home Automobile Airplane Journey Sports Hobbies Pets Vegetables School

“Hard Drives Out Soft” n Numbers drive out notions. n Measurements top guesswork. n Knowing trumps hoping.

“Hard Drives Out Soft” n Numbers drive out notions. n Measurements top guesswork. n Knowing trumps hoping.

Closing n What ? It’s the measurement and the understanding. n So What ? They make the difference in your FM world. n Now What ? Use your two sets of books wisely.

Closing n What ? It’s the measurement and the understanding. n So What ? They make the difference in your FM world. n Now What ? Use your two sets of books wisely.