6a62d21e05888743faac9221d11d11f7.ppt

- Количество слайдов: 14

Fluidised powder target research A potential target technology for both a Superbeam and a neutrino factory CJ Densham, O Caretta, P Loveridge STFC Rutherford Appleton Laboratory

Fluidised powder target research A potential target technology for both a Superbeam and a neutrino factory CJ Densham, O Caretta, P Loveridge STFC Rutherford Appleton Laboratory

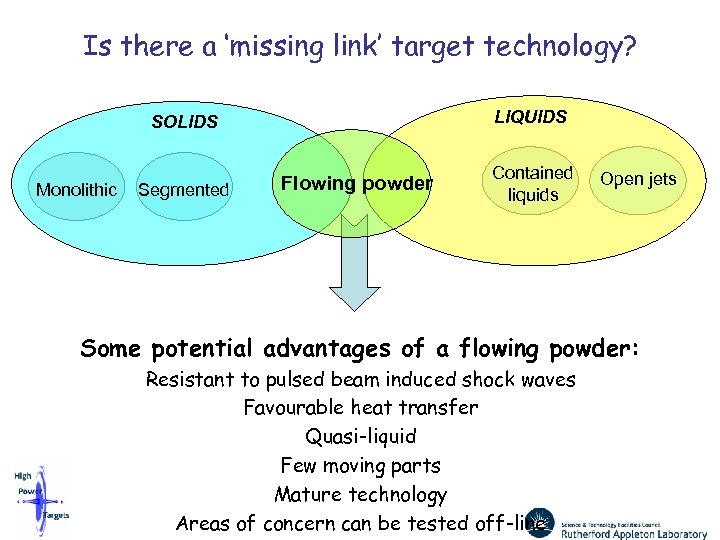

Is there a ‘missing link’ target technology? LIQUIDS SOLIDS Monolithic Segmented Flowing powder Contained liquids Open jets Some potential advantages of a flowing powder: Resistant to pulsed beam induced shock waves Favourable heat transfer Quasi-liquid Few moving parts Mature technology Areas of concern can be tested off-line

Is there a ‘missing link’ target technology? LIQUIDS SOLIDS Monolithic Segmented Flowing powder Contained liquids Open jets Some potential advantages of a flowing powder: Resistant to pulsed beam induced shock waves Favourable heat transfer Quasi-liquid Few moving parts Mature technology Areas of concern can be tested off-line

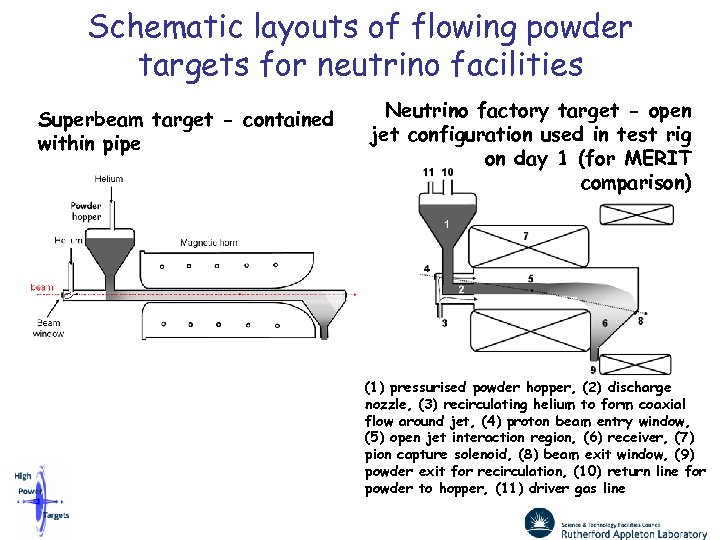

Schematic layouts of flowing powder targets for neutrino facilities Superbeam target - contained within pipe Neutrino factory target - open jet configuration used in test rig on day 1 (for MERIT comparison) (1) pressurised powder hopper, (2) discharge nozzle, (3) recirculating helium to form coaxial flow around jet, (4) proton beam entry window, (5) open jet interaction region, (6) receiver, (7) pion capture solenoid, (8) beam exit window, (9) powder exit for recirculation, (10) return line for powder to hopper, (11) driver gas line

Schematic layouts of flowing powder targets for neutrino facilities Superbeam target - contained within pipe Neutrino factory target - open jet configuration used in test rig on day 1 (for MERIT comparison) (1) pressurised powder hopper, (2) discharge nozzle, (3) recirculating helium to form coaxial flow around jet, (4) proton beam entry window, (5) open jet interaction region, (6) receiver, (7) pion capture solenoid, (8) beam exit window, (9) powder exit for recirculation, (10) return line for powder to hopper, (11) driver gas line

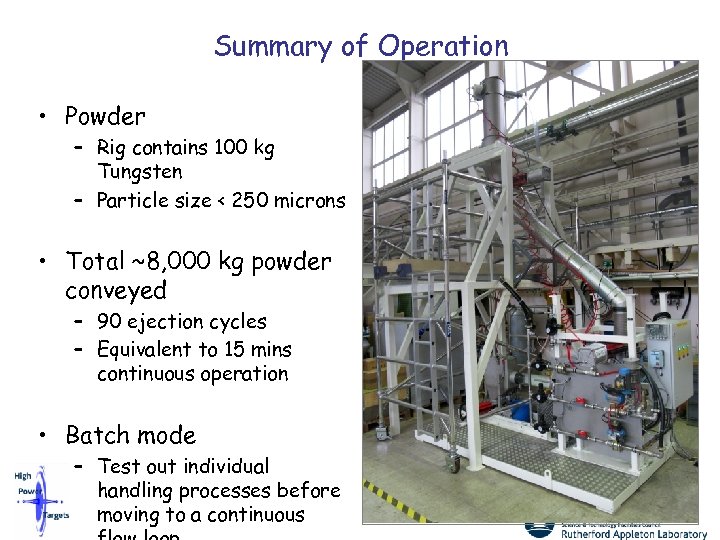

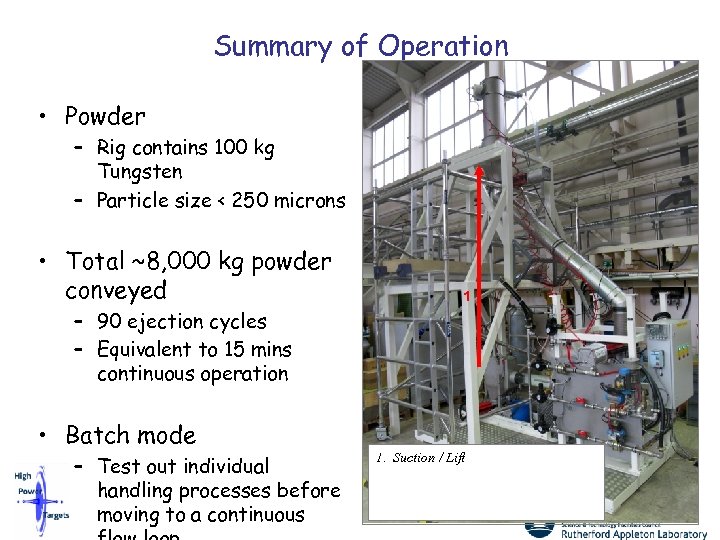

Summary of Operation • Powder – Rig contains 100 kg Tungsten – Particle size < 250 microns • Total ~8, 000 kg powder conveyed – 90 ejection cycles – Equivalent to 15 mins continuous operation • Batch mode – Test out individual handling processes before moving to a continuous

Summary of Operation • Powder – Rig contains 100 kg Tungsten – Particle size < 250 microns • Total ~8, 000 kg powder conveyed – 90 ejection cycles – Equivalent to 15 mins continuous operation • Batch mode – Test out individual handling processes before moving to a continuous

Summary of Operation • Powder – Rig contains 100 kg Tungsten – Particle size < 250 microns • Total ~8, 000 kg powder conveyed 1 – 90 ejection cycles – Equivalent to 15 mins continuous operation • Batch mode – Test out individual handling processes before moving to a continuous 1. Suction / Lift

Summary of Operation • Powder – Rig contains 100 kg Tungsten – Particle size < 250 microns • Total ~8, 000 kg powder conveyed 1 – 90 ejection cycles – Equivalent to 15 mins continuous operation • Batch mode – Test out individual handling processes before moving to a continuous 1. Suction / Lift

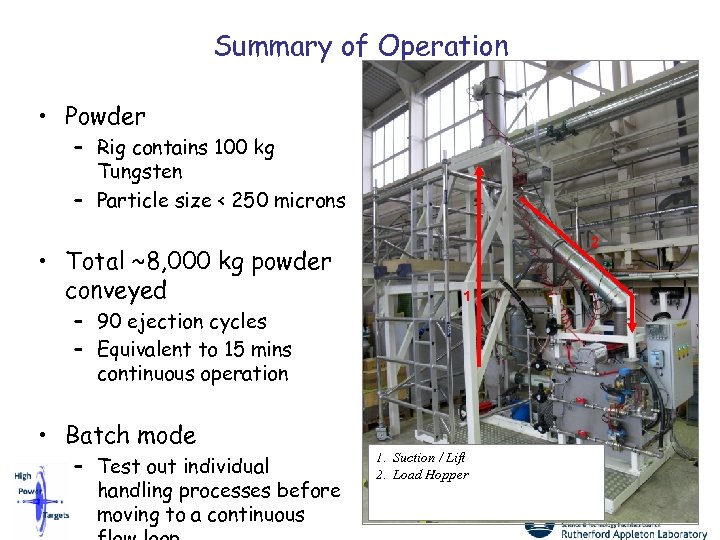

Summary of Operation • Powder – Rig contains 100 kg Tungsten – Particle size < 250 microns • Total ~8, 000 kg powder conveyed 2 1 – 90 ejection cycles – Equivalent to 15 mins continuous operation • Batch mode – Test out individual handling processes before moving to a continuous 1. Suction / Lift 2. Load Hopper

Summary of Operation • Powder – Rig contains 100 kg Tungsten – Particle size < 250 microns • Total ~8, 000 kg powder conveyed 2 1 – 90 ejection cycles – Equivalent to 15 mins continuous operation • Batch mode – Test out individual handling processes before moving to a continuous 1. Suction / Lift 2. Load Hopper

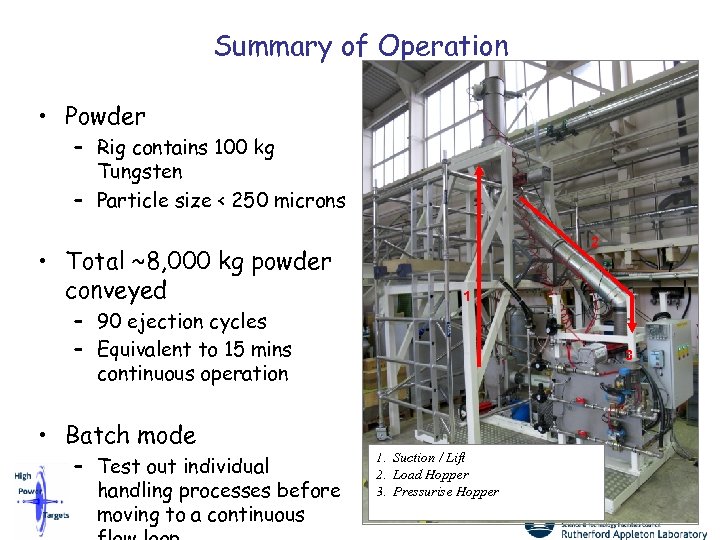

Summary of Operation • Powder – Rig contains 100 kg Tungsten – Particle size < 250 microns • Total ~8, 000 kg powder conveyed 2 1 – 90 ejection cycles – Equivalent to 15 mins continuous operation • Batch mode – Test out individual handling processes before moving to a continuous 3 1. Suction / Lift 2. Load Hopper 3. Pressurise Hopper

Summary of Operation • Powder – Rig contains 100 kg Tungsten – Particle size < 250 microns • Total ~8, 000 kg powder conveyed 2 1 – 90 ejection cycles – Equivalent to 15 mins continuous operation • Batch mode – Test out individual handling processes before moving to a continuous 3 1. Suction / Lift 2. Load Hopper 3. Pressurise Hopper

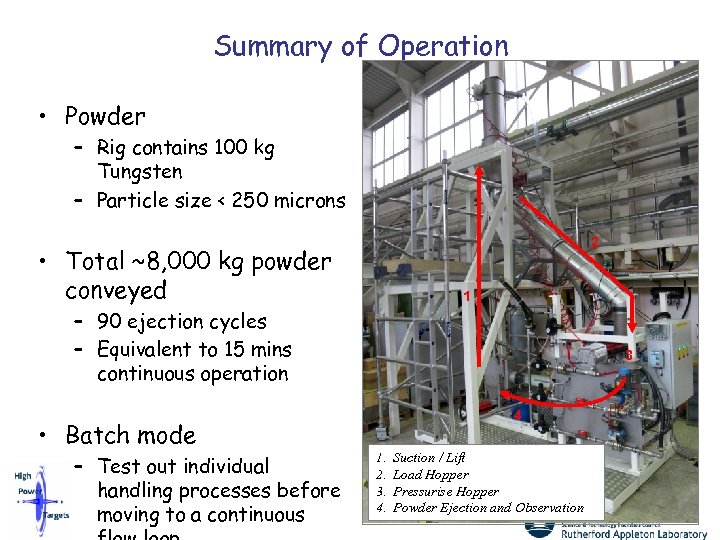

Summary of Operation • Powder – Rig contains 100 kg Tungsten – Particle size < 250 microns 2 • Total ~8, 000 kg powder conveyed 1 – 90 ejection cycles – Equivalent to 15 mins continuous operation • Batch mode – Test out individual handling processes before moving to a continuous 3 4 1. 2. 3. 4. Suction / Lift Load Hopper Pressurise Hopper Powder Ejection and Observation

Summary of Operation • Powder – Rig contains 100 kg Tungsten – Particle size < 250 microns 2 • Total ~8, 000 kg powder conveyed 1 – 90 ejection cycles – Equivalent to 15 mins continuous operation • Batch mode – Test out individual handling processes before moving to a continuous 3 4 1. 2. 3. 4. Suction / Lift Load Hopper Pressurise Hopper Powder Ejection and Observation

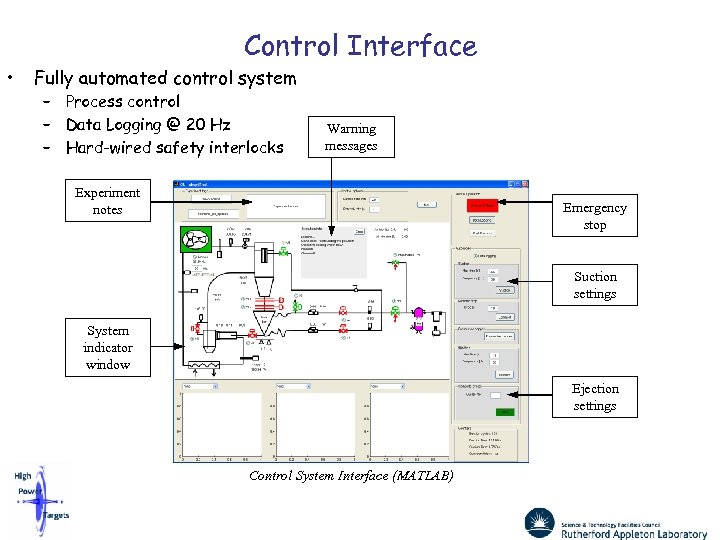

Control Interface • Fully automated control system – Process control – Data Logging @ 20 Hz – Hard-wired safety interlocks Warning messages Experiment notes Emergency stop Suction settings System indicator window Ejection settings Control System Interface (MATLAB)

Control Interface • Fully automated control system – Process control – Data Logging @ 20 Hz – Hard-wired safety interlocks Warning messages Experiment notes Emergency stop Suction settings System indicator window Ejection settings Control System Interface (MATLAB)

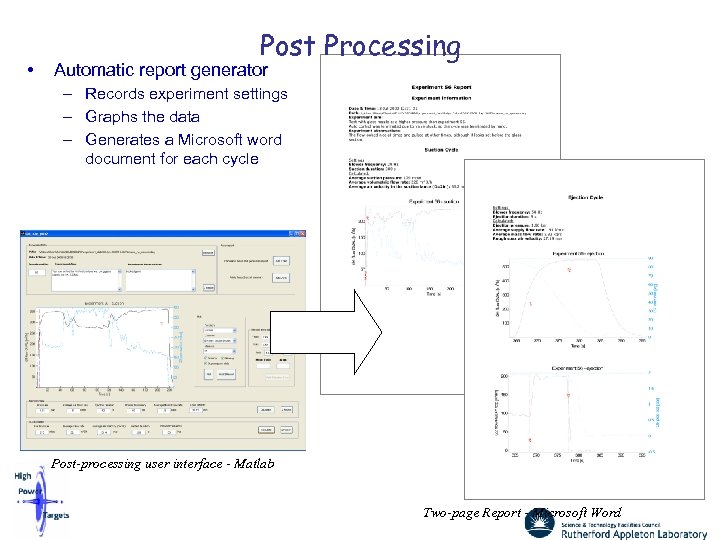

• Post Processing Automatic report generator – Records experiment settings – Graphs the data – Generates a Microsoft word document for each cycle Post-processing user interface - Matlab Two-page Report - Microsoft Word

• Post Processing Automatic report generator – Records experiment settings – Graphs the data – Generates a Microsoft word document for each cycle Post-processing user interface - Matlab Two-page Report - Microsoft Word

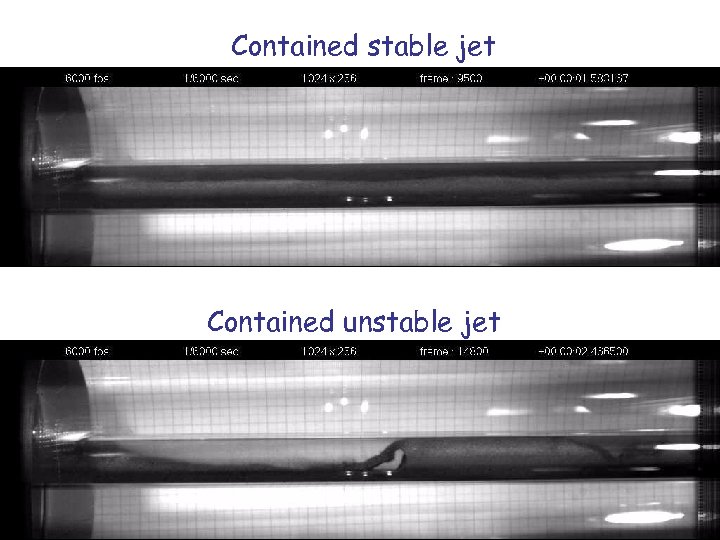

Contained stable jet Contained unstable jet

Contained stable jet Contained unstable jet

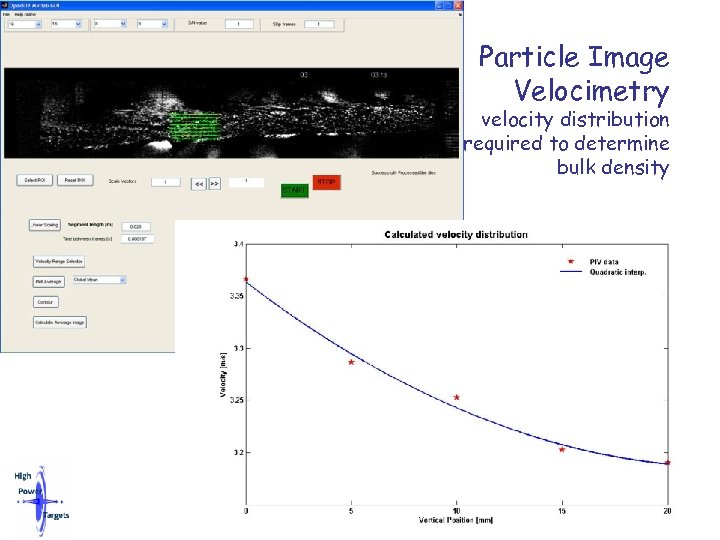

Particle Image Velocimetry velocity distribution required to determine bulk density Ottone Caretta, Oxford, Nov 09

Particle Image Velocimetry velocity distribution required to determine bulk density Ottone Caretta, Oxford, Nov 09

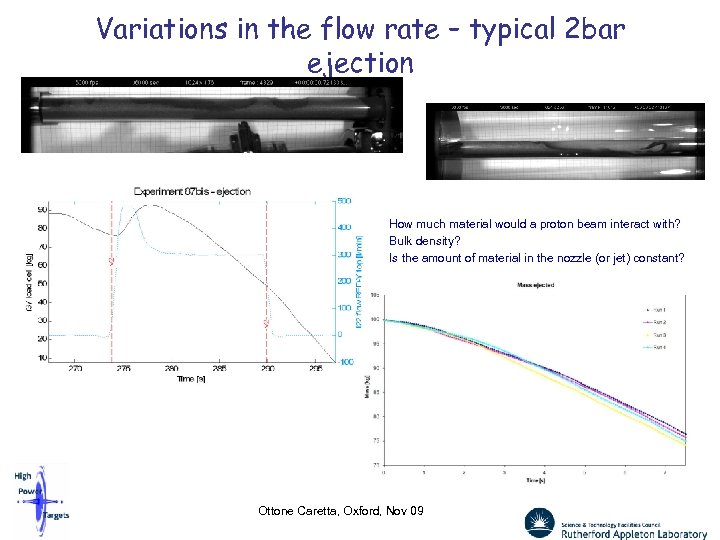

Variations in the flow rate – typical 2 bar ejection How much material would a proton beam interact with? Bulk density? Is the amount of material in the nozzle (or jet) constant? Ottone Caretta, Oxford, Nov 09

Variations in the flow rate – typical 2 bar ejection How much material would a proton beam interact with? Bulk density? Is the amount of material in the nozzle (or jet) constant? Ottone Caretta, Oxford, Nov 09

Flowing powder target: next stages • • • Optimise gas lift system for CW operation Carry out long term erosion tests and study mitigation Investigate low-flow limit Study heat transfer between pipe wall and powder Demonstrate shock waves are not a problem – Use of CERN test facility for shock wave experiment on a powder sample in helium environment • Demonstrate magnetic fields/eddy currents are not a problem – Use of high field solenoid? • Investigate active powder handling issues (cf mercury? )

Flowing powder target: next stages • • • Optimise gas lift system for CW operation Carry out long term erosion tests and study mitigation Investigate low-flow limit Study heat transfer between pipe wall and powder Demonstrate shock waves are not a problem – Use of CERN test facility for shock wave experiment on a powder sample in helium environment • Demonstrate magnetic fields/eddy currents are not a problem – Use of high field solenoid? • Investigate active powder handling issues (cf mercury? )