5fe6f0de1955e2b0c99ebcf95b12e5cc.ppt

- Количество слайдов: 23

Fluid Bed Reactors Chapter (Not in book) CH EN 4393 Terry A. Ring

Fluidization • Minimum Fluidization – Void Fraction – Superficial Velocity • Bubbling Bed Expansion • Prevent Slugging – Poor gas/solid contact

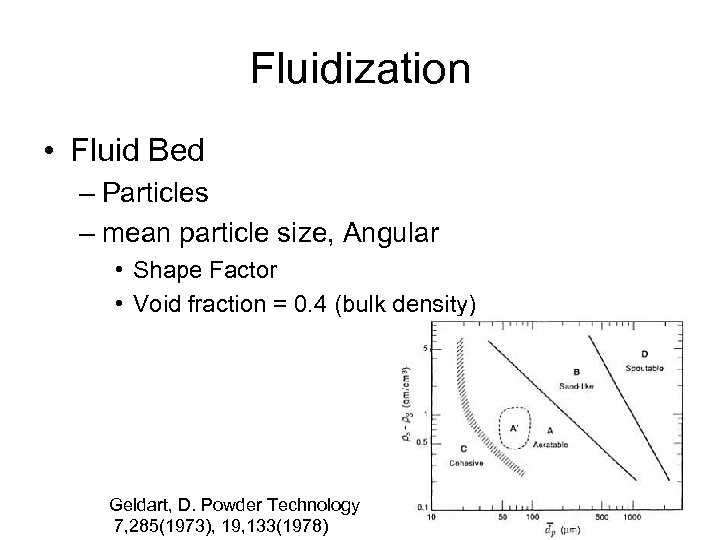

Fluidization • Fluid Bed – Particles – mean particle size, Angular • Shape Factor • Void fraction = 0. 4 (bulk density) Geldart, D. Powder Technology 7, 285(1973), 19, 133(1978)

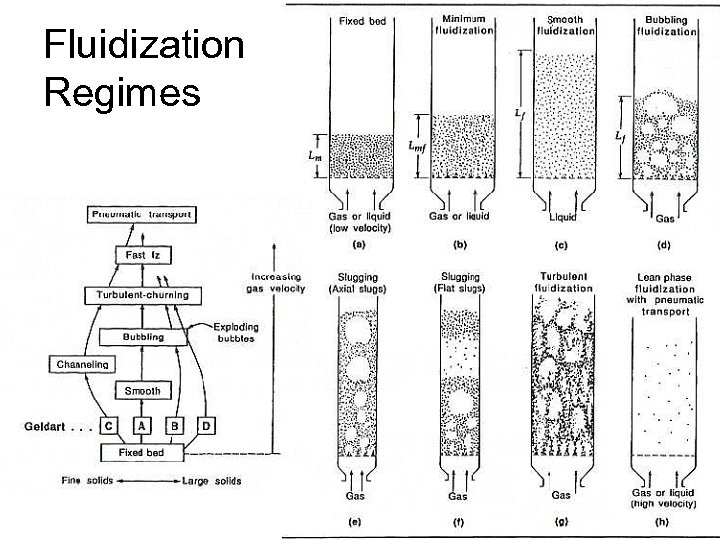

Fluidization Regimes

Fluidization Regimes • • • Packed Bed Minimum Fluidization Bubbling Fluidization Slugging (in some cases) Turbulent Fluidization

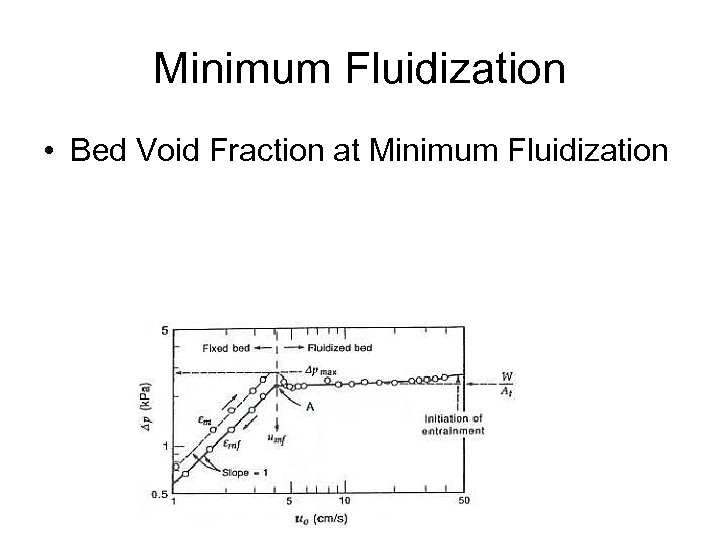

Minimum Fluidization • Bed Void Fraction at Minimum Fluidization

Overlap of phenomenon • Kinetics – Depend upon solid content in bed • Mass Transfer – Depends upon particle Re number • Heat Transfer – Depends upon solid content in bed and gas Re • Fluid Dynamics – Fluidization – function of particle Re – Particle elution rate – terminal settling rate vs gas velocity – Distribution Plate Design to prevent channeling

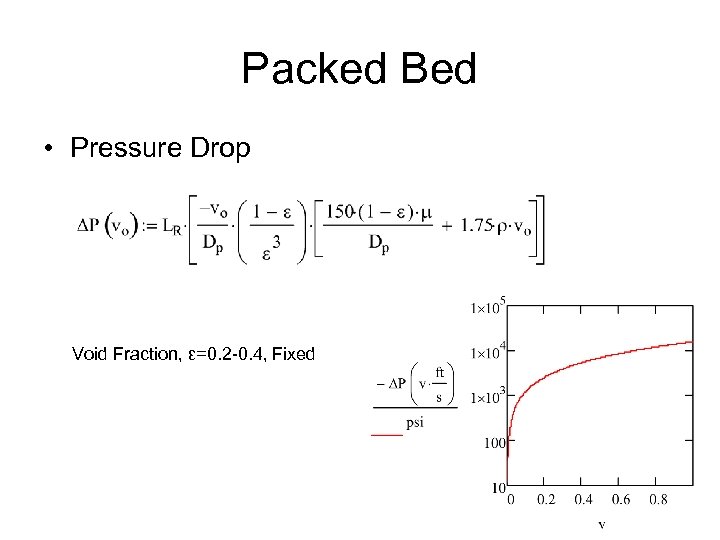

Packed Bed • Pressure Drop Void Fraction, ε=0. 2 -0. 4, Fixed

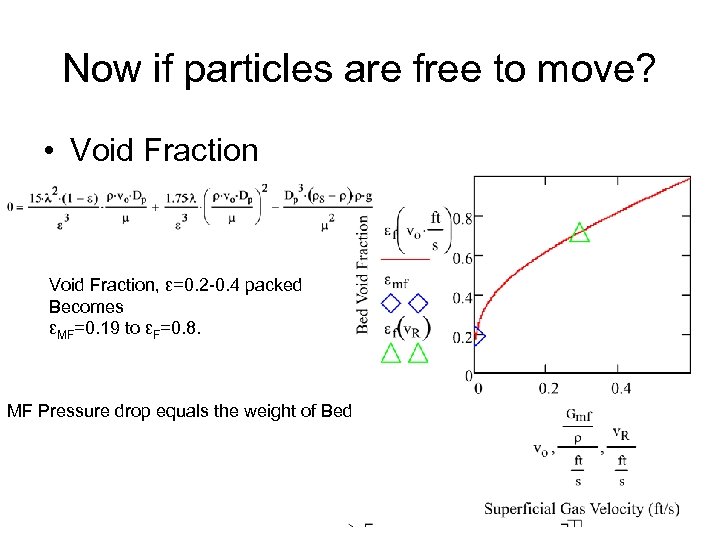

Now if particles are free to move? • Void Fraction, ε=0. 2 -0. 4 packed Becomes εMF=0. 19 to εF=0. 8. MF Pressure drop equals the weight of Bed

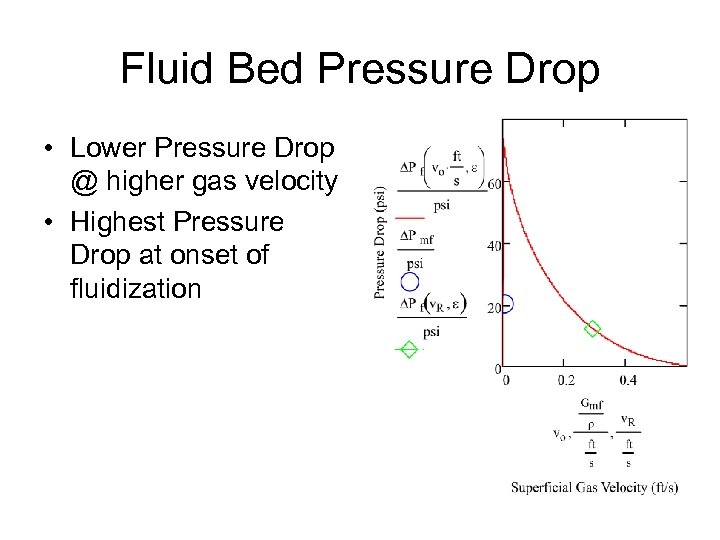

Fluid Bed Pressure Drop • Lower Pressure Drop @ higher gas velocity • Highest Pressure Drop at onset of fluidization

Bed at Fluidization Conditions • • • Void Fraction is High Solids Content is Low Surface Area for Reaction is Low Pressure Drop is Low Good Heat Transfer Good Mass Transfer

Distributor Plate Design • Pressure Drop over the Distributor Plate should be 30% of Total Pressure Drop ( bed and distributor) – Pressure drop at distributor is ½ bed pressure drop. • Bubble Cap Design is often used

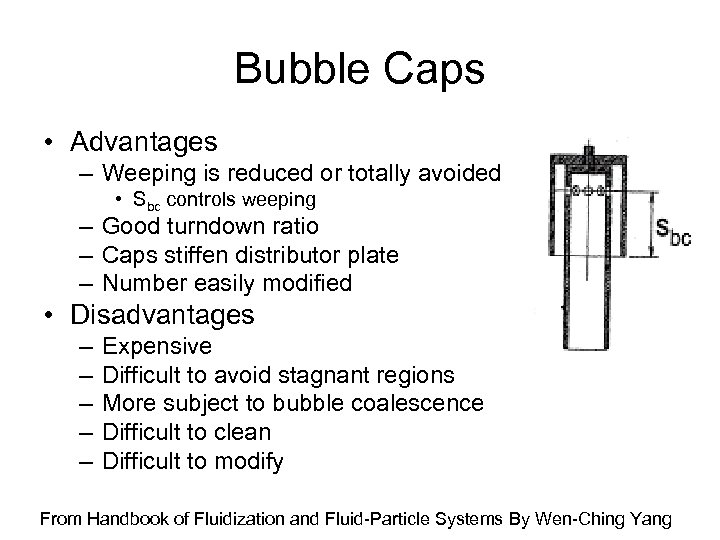

Bubble Caps • Advantages – Weeping is reduced or totally avoided • Sbc controls weeping – Good turndown ratio – Caps stiffen distributor plate – Number easily modified • Disadvantages – – – Expensive Difficult to avoid stagnant regions More subject to bubble coalescence Difficult to clean Difficult to modify From Handbook of Fluidization and Fluid-Particle Systems By Wen-Ching Yang

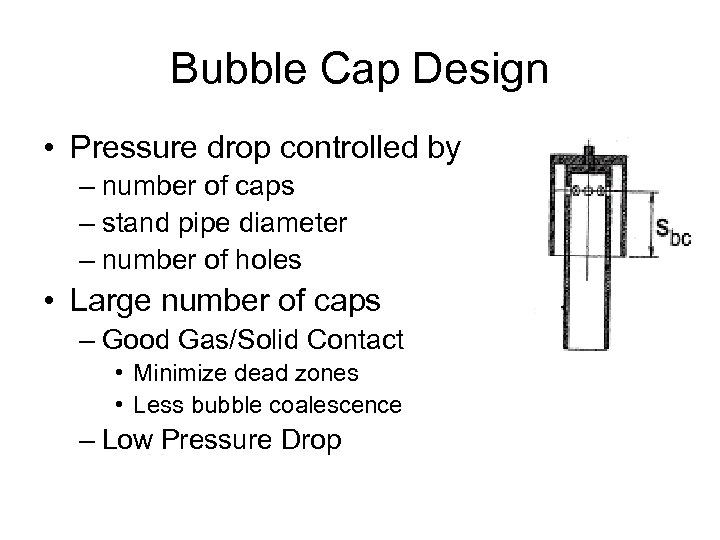

Bubble Cap Design • Pressure drop controlled by – number of caps – stand pipe diameter – number of holes • Large number of caps – Good Gas/Solid Contact • Minimize dead zones • Less bubble coalescence – Low Pressure Drop

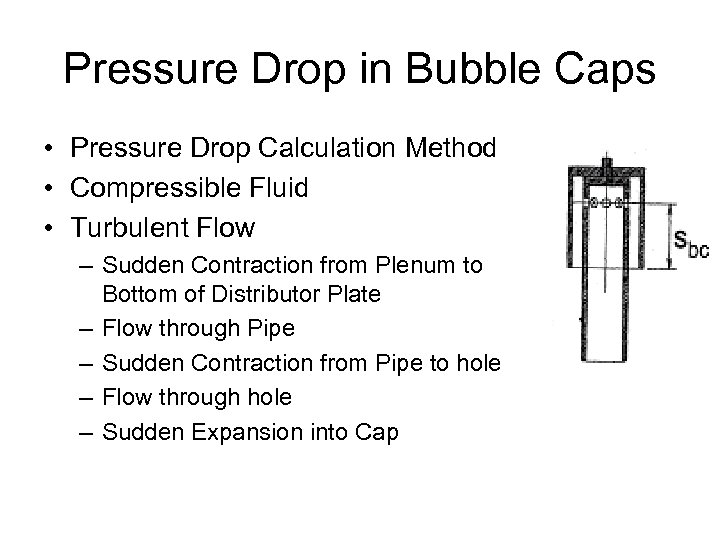

Pressure Drop in Bubble Caps • Pressure Drop Calculation Method • Compressible Fluid • Turbulent Flow – Sudden Contraction from Plenum to Bottom of Distributor Plate – Flow through Pipe – Sudden Contraction from Pipe to hole – Flow through hole – Sudden Expansion into Cap

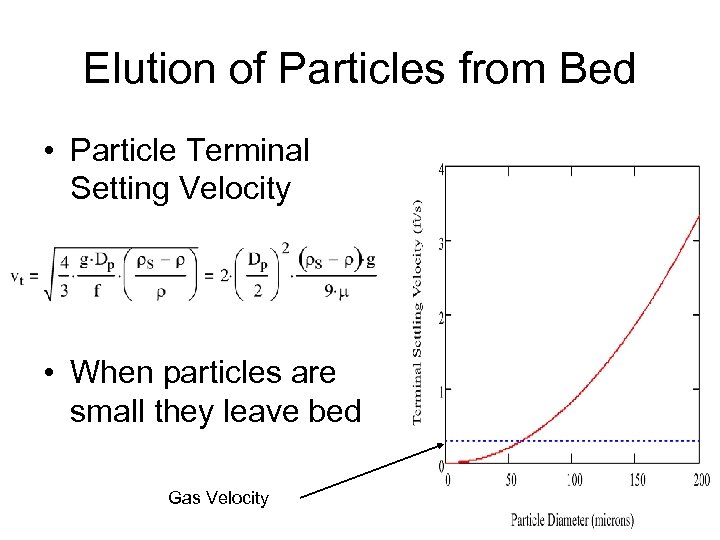

Elution of Particles from Bed • Particle Terminal Setting Velocity • When particles are small they leave bed Gas Velocity

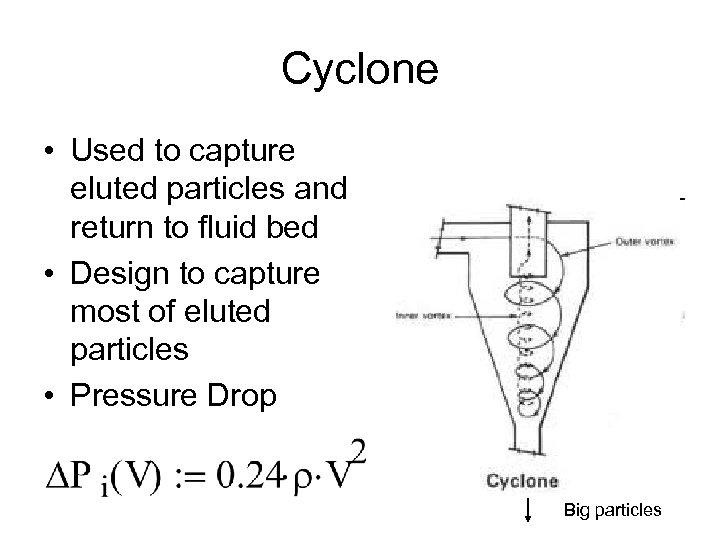

Cyclone • Used to capture eluted particles and return to fluid bed • Design to capture most of eluted particles • Pressure Drop Big particles

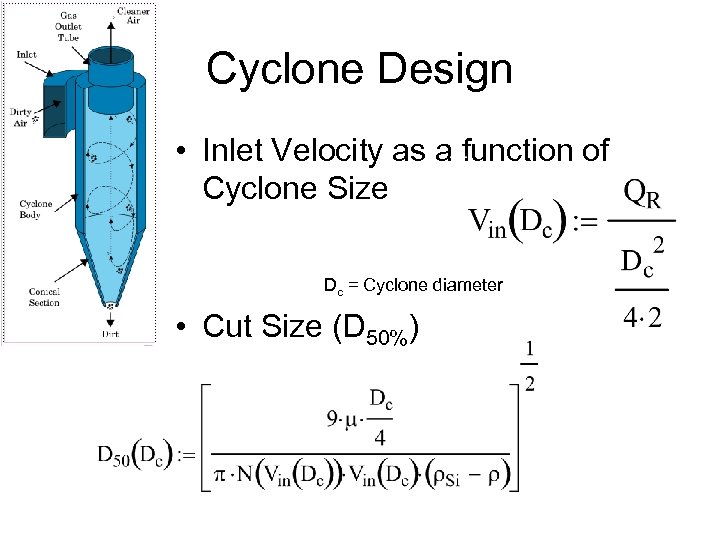

Cyclone Design • Inlet Velocity as a function of Cyclone Size Dc = Cyclone diameter • Cut Size (D 50%)

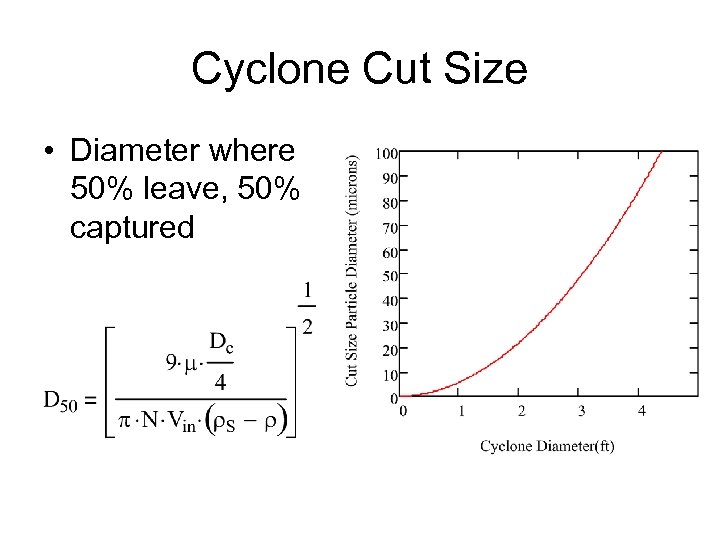

Cyclone Cut Size • Diameter where 50% leave, 50% captured

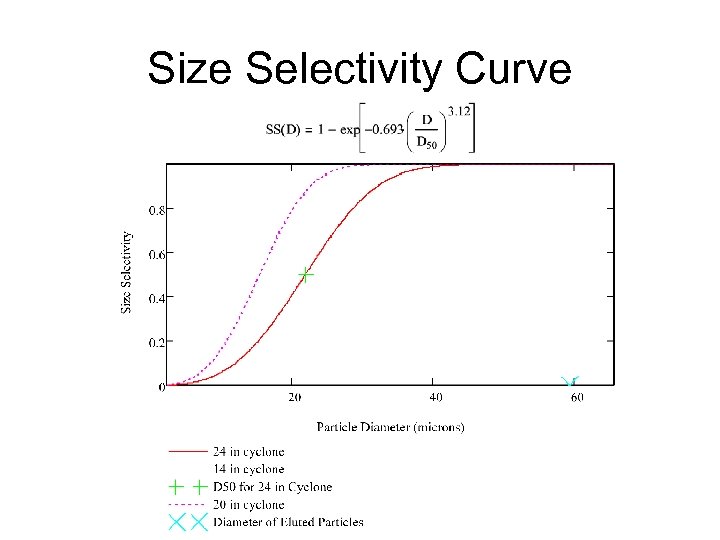

Size Selectivity Curve

Mass Transfer • Particle Mass Transfer – Sh= KMTD/DAB = 2. 0 + 0. 6 Re 1/2 Sc 1/3 • Bed Mass Transfer – Complicated function of • • Gas flow Particles influence turbulence Particles may shorten BL Particles may be inert to MT

Fluid Bed Reactor Conclusions • The hard part is to get the fluid dynamics correct • Kinetics, MT and HT are done within the context of the fluid dynamics

Heat Transfer • Particle Heat Transfer – Nu= h. D/k = 2. 0 + 0. 6 Re 1/2 Pr 1/3 • Bed Heat Transfer – Complicated function of • Gas flow • Particle contacts

5fe6f0de1955e2b0c99ebcf95b12e5cc.ppt