4c7d2055e0bc47a19417f7af5924fcfa.ppt

- Количество слайдов: 65

Flow Overview January 2000

Flow Overview January 2000

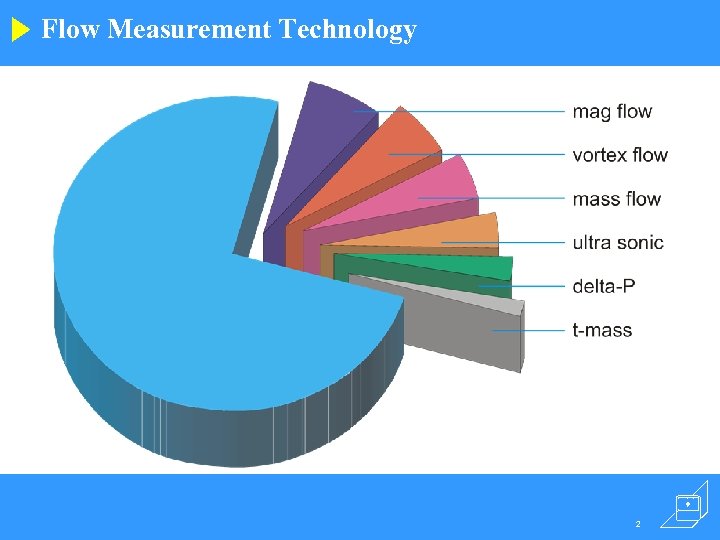

Flow Measurement Technology 2

Flow Measurement Technology 2

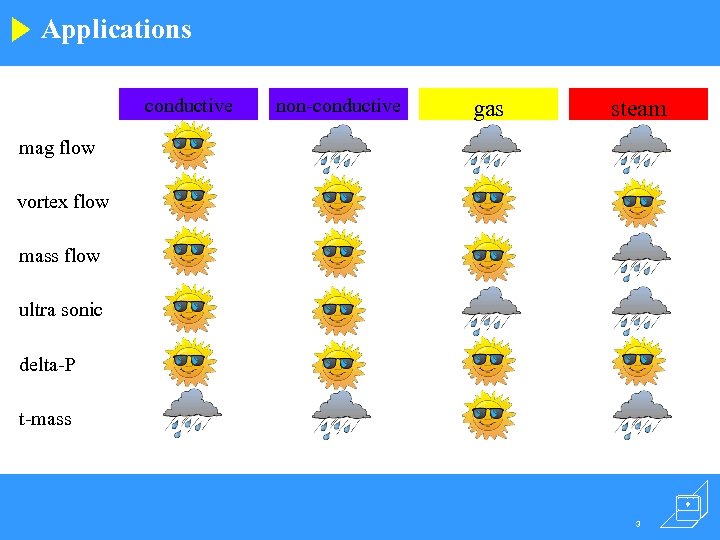

Applications conductive non-conductive gas steam mag flow vortex flow mass flow ultra sonic delta-P t-mass 3

Applications conductive non-conductive gas steam mag flow vortex flow mass flow ultra sonic delta-P t-mass 3

![Conductive liquids mag flow vortexflow mass flow ultra sonic Delta-P [mm] 2 - 2000 Conductive liquids mag flow vortexflow mass flow ultra sonic Delta-P [mm] 2 - 2000](https://present5.com/presentation/4c7d2055e0bc47a19417f7af5924fcfa/image-4.jpg) Conductive liquids mag flow vortexflow mass flow ultra sonic Delta-P [mm] 2 - 2000 15 - 300 1 - 100 50 - 3000 4 - 5000 pressure [bar] Up to 40 Up to 250 Up to 400 temp. [°C] -40. . . +180 -200. . . +400 -50. . . +200 -40. . . +170 . . . 1000°C accuracy* [%] 0. 26/ 0. 53 0. 75 0. 16/0. 11 typ. 0. 5. . . 2. 0 171 138 1: 286 Dp* [mbar] turndown* 1: 350 1: 17 remarks >5 µS/cm >20 µS/cm low viscous no gas Up to 420 160 1: 12 1: 18 <1% gas <5% solids (for H 2 O) *water at 20°C, 10 bar, DN 100 and 100 m³/h 4

Conductive liquids mag flow vortexflow mass flow ultra sonic Delta-P [mm] 2 - 2000 15 - 300 1 - 100 50 - 3000 4 - 5000 pressure [bar] Up to 40 Up to 250 Up to 400 temp. [°C] -40. . . +180 -200. . . +400 -50. . . +200 -40. . . +170 . . . 1000°C accuracy* [%] 0. 26/ 0. 53 0. 75 0. 16/0. 11 typ. 0. 5. . . 2. 0 171 138 1: 286 Dp* [mbar] turndown* 1: 350 1: 17 remarks >5 µS/cm >20 µS/cm low viscous no gas Up to 420 160 1: 12 1: 18 <1% gas <5% solids (for H 2 O) *water at 20°C, 10 bar, DN 100 and 100 m³/h 4

![Non-conductive liquids mag flow vortexflow mass flow ultra sonic Delta-P [mm] 2 - 2000 Non-conductive liquids mag flow vortexflow mass flow ultra sonic Delta-P [mm] 2 - 2000](https://present5.com/presentation/4c7d2055e0bc47a19417f7af5924fcfa/image-5.jpg) Non-conductive liquids mag flow vortexflow mass flow ultra sonic Delta-P [mm] 2 - 2000 15 - 300 1 - 100 50 - 3000 4 - 5000 pressure [bar] Up to 40 Up to 250 Up to 400 temp. [°C] -40. . . +180 -200. . . +400 -50. . . +200 -40. . . +170 accuracy* [%] 0. 26/ 0. 53 0. 75 0. 16/0. 11 typ. 0. 5. . . 2. 0 171 138 1: 286 Dp* [mbar] turndown* 1: 350 1: 17 remarks >5 µS/cm >20 µS/cm low viscous no gas Up to 420. . . 1000°C 160 1: 12 1: 18 <1% gas <5% solids (for H 2 O) *water at 20°C, 10 bar, DN 100 and 100 m³/h 5

Non-conductive liquids mag flow vortexflow mass flow ultra sonic Delta-P [mm] 2 - 2000 15 - 300 1 - 100 50 - 3000 4 - 5000 pressure [bar] Up to 40 Up to 250 Up to 400 temp. [°C] -40. . . +180 -200. . . +400 -50. . . +200 -40. . . +170 accuracy* [%] 0. 26/ 0. 53 0. 75 0. 16/0. 11 typ. 0. 5. . . 2. 0 171 138 1: 286 Dp* [mbar] turndown* 1: 350 1: 17 remarks >5 µS/cm >20 µS/cm low viscous no gas Up to 420. . . 1000°C 160 1: 12 1: 18 <1% gas <5% solids (for H 2 O) *water at 20°C, 10 bar, DN 100 and 100 m³/h 5

![Gas vortex flow mass flow tmass Delta-P [mm] 15 - 300 1 - 100 Gas vortex flow mass flow tmass Delta-P [mm] 15 - 300 1 - 100](https://present5.com/presentation/4c7d2055e0bc47a19417f7af5924fcfa/image-6.jpg) Gas vortex flow mass flow tmass Delta-P [mm] 15 - 300 1 - 100 15 - 1000 4 - 5000 pressure [bar] Up to 250 Up to 40 Up to 420 bar temp. [°C] -200. . . +400 -50. . . +200 -10. . . +100 . . 1000°C accuracy* [%] 1. 0 0. 63 2. 0 1. 0 Dp* [mbar] 220. 6 163. 5 . . . 10 175 turndown* 1: 19 1: 40 1: 100 1: 20 remarks DN 200 *Air at 20°C, 10 bar, g, DN 80 and 600 m³/h 6

Gas vortex flow mass flow tmass Delta-P [mm] 15 - 300 1 - 100 15 - 1000 4 - 5000 pressure [bar] Up to 250 Up to 40 Up to 420 bar temp. [°C] -200. . . +400 -50. . . +200 -10. . . +100 . . 1000°C accuracy* [%] 1. 0 0. 63 2. 0 1. 0 Dp* [mbar] 220. 6 163. 5 . . . 10 175 turndown* 1: 19 1: 40 1: 100 1: 20 remarks DN 200 *Air at 20°C, 10 bar, g, DN 80 and 600 m³/h 6

![Steam vortex flow mass flow tmass Delta-P [mm] 15 - 300 1 - 100 Steam vortex flow mass flow tmass Delta-P [mm] 15 - 300 1 - 100](https://present5.com/presentation/4c7d2055e0bc47a19417f7af5924fcfa/image-7.jpg) Steam vortex flow mass flow tmass Delta-P [mm] 15 - 300 1 - 100 15 - 1000 4 - 5000 pressure [bar] Up to 250 Up to 40 Up to 420 bar temp. [°C] -200. . . +400 -50. . . +200 -10. . . +100 . . 1000°C accuracy* [%] 1. 0 0. 63 2. 0 1. 0 Dp* [mbar] 220. 6 163. 5 . . . 10 175 turndown* 1: 19 1: 40 1: 100 1: 20 remarks DN 200 *Air at 20°C, 10 bar, g, DN 80 and 600 m³/h 7

Steam vortex flow mass flow tmass Delta-P [mm] 15 - 300 1 - 100 15 - 1000 4 - 5000 pressure [bar] Up to 250 Up to 40 Up to 420 bar temp. [°C] -200. . . +400 -50. . . +200 -10. . . +100 . . 1000°C accuracy* [%] 1. 0 0. 63 2. 0 1. 0 Dp* [mbar] 220. 6 163. 5 . . . 10 175 turndown* 1: 19 1: 40 1: 100 1: 20 remarks DN 200 *Air at 20°C, 10 bar, g, DN 80 and 600 m³/h 7

Endress+Hauser Promag Product Presentation January 2000

Endress+Hauser Promag Product Presentation January 2000

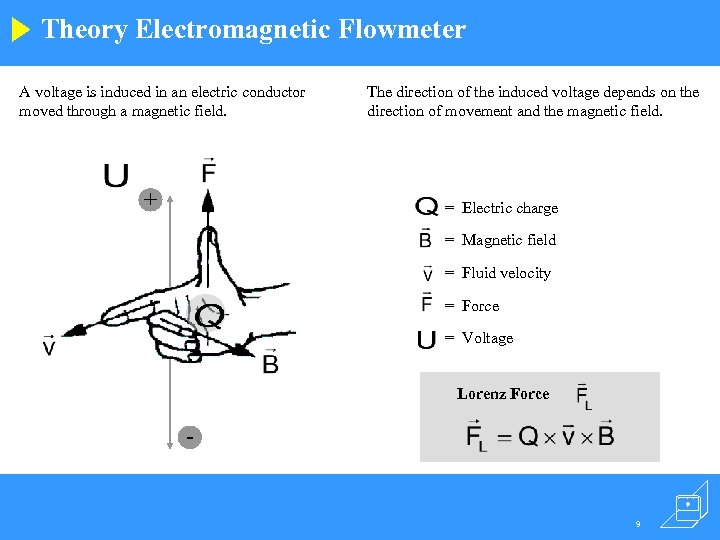

Theory Electromagnetic Flowmeter A voltage is induced in an electric conductor moved through a magnetic field. + The direction of the induced voltage depends on the direction of movement and the magnetic field. = Electric charge = Magnetic field = Fluid velocity = Force = Voltage Lorenz Force - 9

Theory Electromagnetic Flowmeter A voltage is induced in an electric conductor moved through a magnetic field. + The direction of the induced voltage depends on the direction of movement and the magnetic field. = Electric charge = Magnetic field = Fluid velocity = Force = Voltage Lorenz Force - 9

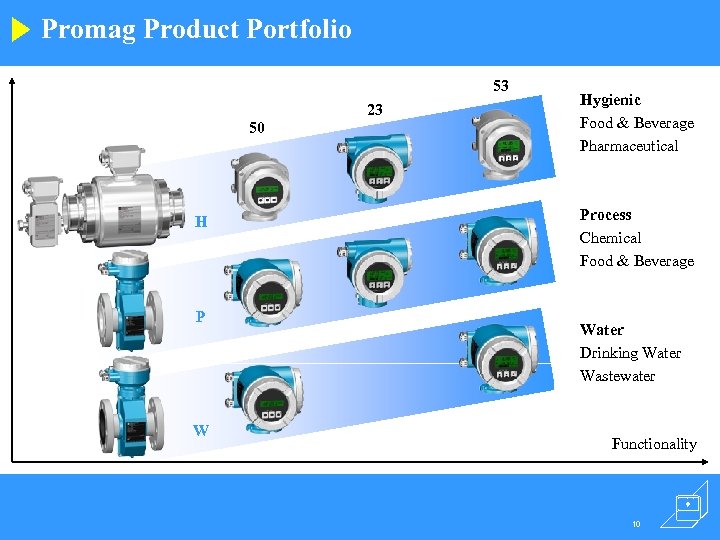

Promag Product Portfolio 53 23 50 H P W Hygienic Food & Beverage Pharmaceutical Process Chemical Food & Beverage Water Drinking Water Wastewater Functionality 10

Promag Product Portfolio 53 23 50 H P W Hygienic Food & Beverage Pharmaceutical Process Chemical Food & Beverage Water Drinking Water Wastewater Functionality 10

Promag 50 Transmitter Communication 0/4. . . 20 m. A 0. . . 1 k. Hz Operation Quick Setup for rapid and easy commissioning Push-button operation 2 -line display, illuminated Accuracy max 0. 5% measuring error (max. 0. 2% as option) Data Management S-DAT™ 11

Promag 50 Transmitter Communication 0/4. . . 20 m. A 0. . . 1 k. Hz Operation Quick Setup for rapid and easy commissioning Push-button operation 2 -line display, illuminated Accuracy max 0. 5% measuring error (max. 0. 2% as option) Data Management S-DAT™ 11

Promag 53 Transmitter Communication Flexible I/O-modules Operation Application-specific software modules (F-Chip™) Quick Setups for rapid, easy and application-specific commissioning Touch Control operation 4 -line display, illuminated Accuracy max 0. 2% measuring error Data Management T-DAT™, S-DAT™ 12

Promag 53 Transmitter Communication Flexible I/O-modules Operation Application-specific software modules (F-Chip™) Quick Setups for rapid, easy and application-specific commissioning Touch Control operation 4 -line display, illuminated Accuracy max 0. 2% measuring error Data Management T-DAT™, S-DAT™ 12

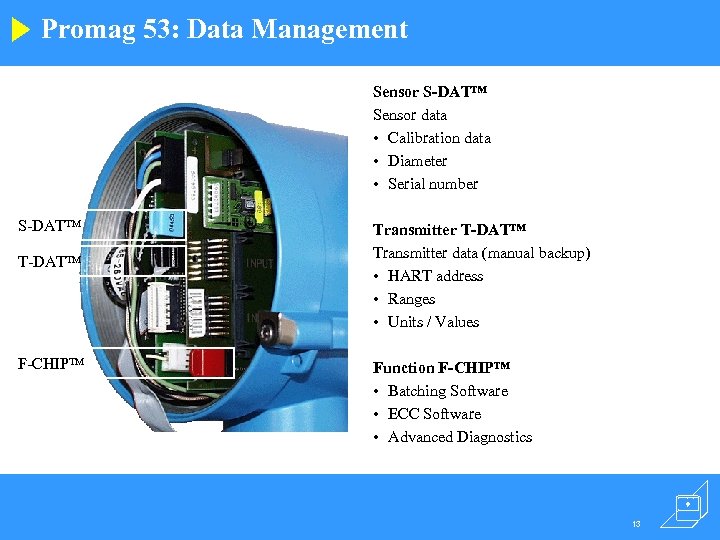

Promag 53: Data Management Sensor S-DAT™ Sensor data • Calibration data • Diameter • Serial number S-DATTM T-DATTM F-CHIPTM Transmitter T-DAT™ Transmitter data (manual backup) • HART address • Ranges • Units / Values Function F-CHIP™ • Batching Software • ECC Software • Advanced Diagnostics 13

Promag 53: Data Management Sensor S-DAT™ Sensor data • Calibration data • Diameter • Serial number S-DATTM T-DATTM F-CHIPTM Transmitter T-DAT™ Transmitter data (manual backup) • HART address • Ranges • Units / Values Function F-CHIP™ • Batching Software • ECC Software • Advanced Diagnostics 13

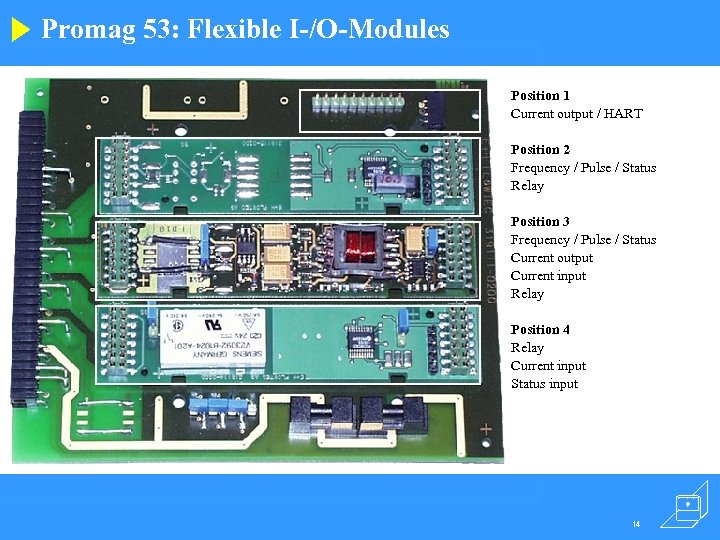

Promag 53: Flexible I-/O-Modules Position 1 Current output / HART Position 2 Frequency / Pulse / Status Relay Position 3 Frequency / Pulse / Status Current output Current input Relay Position 4 Relay Current input Status input 14

Promag 53: Flexible I-/O-Modules Position 1 Current output / HART Position 2 Frequency / Pulse / Status Relay Position 3 Frequency / Pulse / Status Current output Current input Relay Position 4 Relay Current input Status input 14

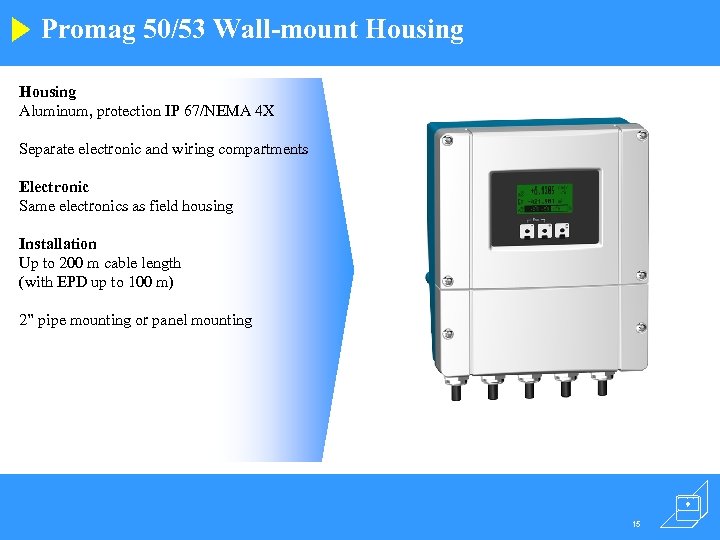

Promag 50/53 Wall-mount Housing Aluminum, protection IP 67/NEMA 4 X Separate electronic and wiring compartments Electronic Same electronics as field housing Installation Up to 200 m cable length (with EPD up to 100 m) 2” pipe mounting or panel mounting 15

Promag 50/53 Wall-mount Housing Aluminum, protection IP 67/NEMA 4 X Separate electronic and wiring compartments Electronic Same electronics as field housing Installation Up to 200 m cable length (with EPD up to 100 m) 2” pipe mounting or panel mounting 15

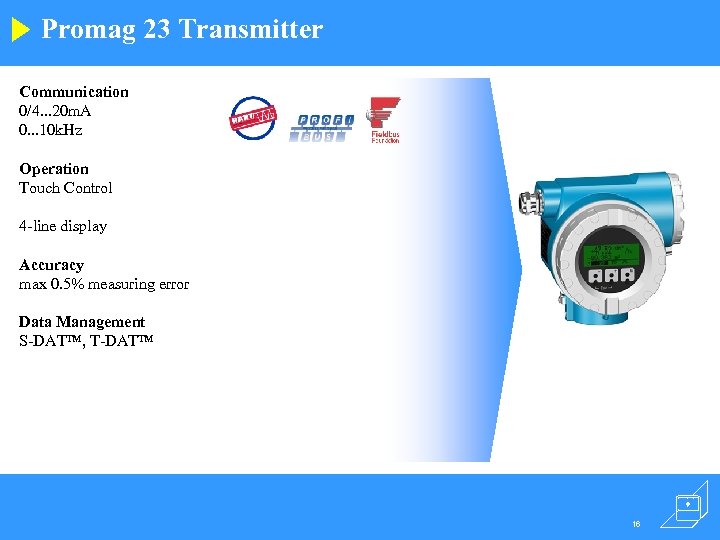

Promag 23 Transmitter Communication 0/4. . . 20 m. A 0. . . 10 k. Hz Operation Touch Control 4 -line display Accuracy max 0. 5% measuring error Data Management S-DAT™, T-DAT™ 16

Promag 23 Transmitter Communication 0/4. . . 20 m. A 0. . . 10 k. Hz Operation Touch Control 4 -line display Accuracy max 0. 5% measuring error Data Management S-DAT™, T-DAT™ 16

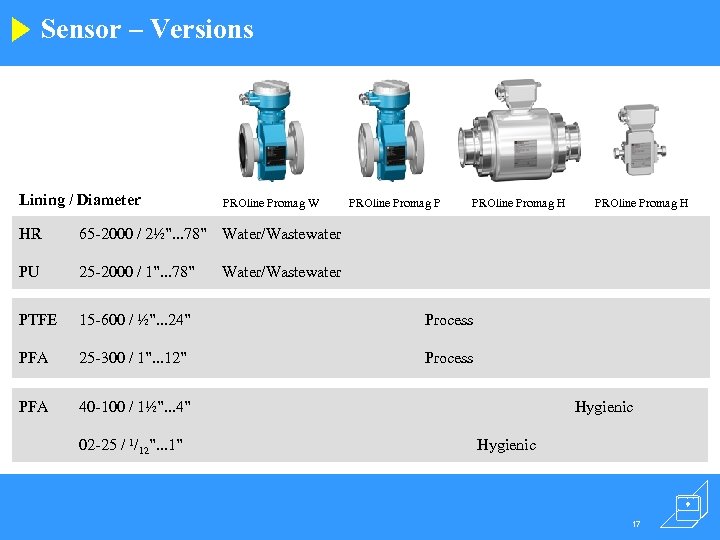

Sensor – Versions Lining / Diameter PROline Promag W PROline Promag P PROline Promag H HR 65 -2000 / 2½”. . . 78” Water/Wastewater PU 25 -2000 / 1”. . . 78” PTFE 15 -600 / ½”. . . 24” Process PFA 25 -300 / 1”. . . 12” Process PFA 40 -100 / 1½”. . . 4” PROline Promag H 02 -25 / 1/12”. . . 1” Water/Wastewater Hygienic 17

Sensor – Versions Lining / Diameter PROline Promag W PROline Promag P PROline Promag H HR 65 -2000 / 2½”. . . 78” Water/Wastewater PU 25 -2000 / 1”. . . 78” PTFE 15 -600 / ½”. . . 24” Process PFA 25 -300 / 1”. . . 12” Process PFA 40 -100 / 1½”. . . 4” PROline Promag H 02 -25 / 1/12”. . . 1” Water/Wastewater Hygienic 17

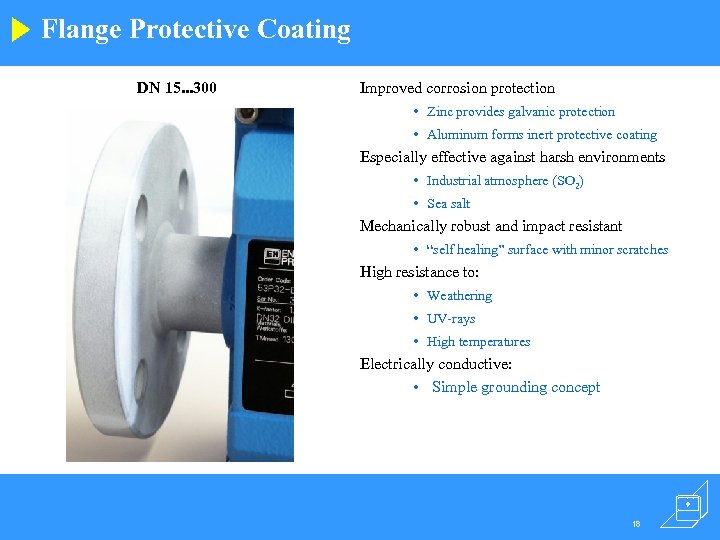

Flange Protective Coating DN 15. . . 300 Improved corrosion protection • Zinc provides galvanic protection • Aluminum forms inert protective coating Especially effective against harsh environments • Industrial atmosphere (SO 2) • Sea salt Mechanically robust and impact resistant • “self healing” surface with minor scratches High resistance to: • Weathering • UV-rays • High temperatures Electrically conductive: • Simple grounding concept 18

Flange Protective Coating DN 15. . . 300 Improved corrosion protection • Zinc provides galvanic protection • Aluminum forms inert protective coating Especially effective against harsh environments • Industrial atmosphere (SO 2) • Sea salt Mechanically robust and impact resistant • “self healing” surface with minor scratches High resistance to: • Weathering • UV-rays • High temperatures Electrically conductive: • Simple grounding concept 18

Modularity Promag 50 Promag 53 Promag 23 — — — W P H 19

Modularity Promag 50 Promag 53 Promag 23 — — — W P H 19

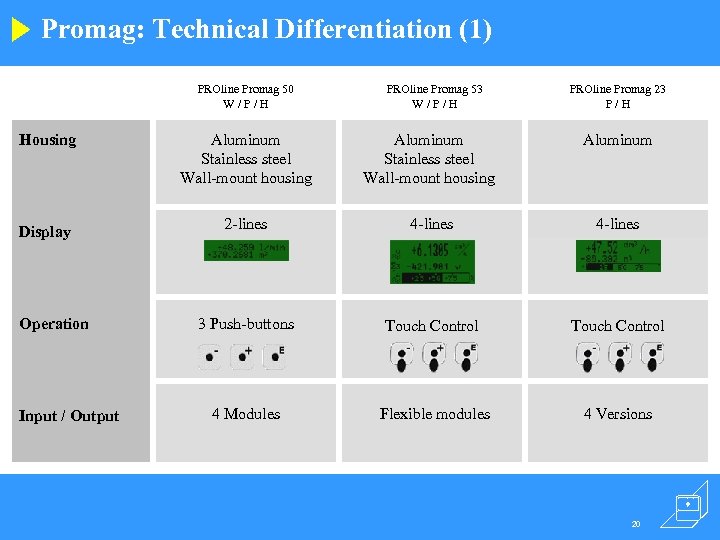

Promag: Technical Differentiation (1) PROline Promag 50 W/P/H PROline Promag 53 W/P/H PROline Promag 23 P/H Housing Aluminum Stainless steel Wall-mount housing Aluminum Display 2 -lines 4 -lines 3 Push-buttons Touch Control 4 Modules Flexible modules 4 Versions Operation Input / Output 20

Promag: Technical Differentiation (1) PROline Promag 50 W/P/H PROline Promag 53 W/P/H PROline Promag 23 P/H Housing Aluminum Stainless steel Wall-mount housing Aluminum Display 2 -lines 4 -lines 3 Push-buttons Touch Control 4 Modules Flexible modules 4 Versions Operation Input / Output 20

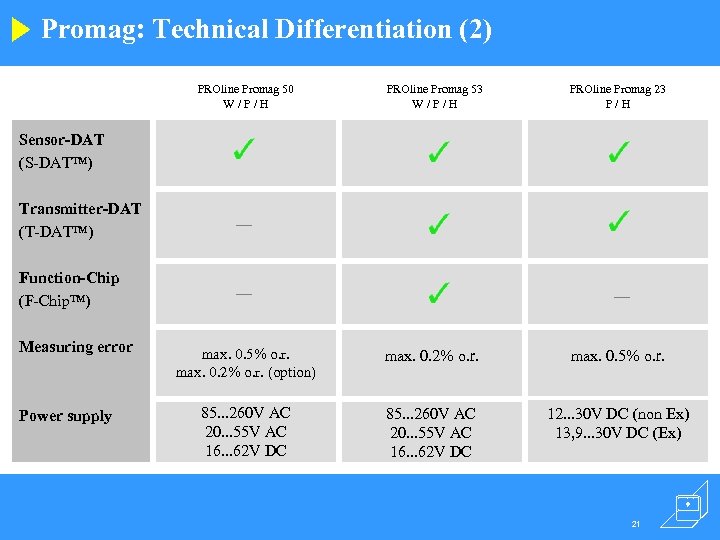

Promag: Technical Differentiation (2) PROline Promag 50 W/P/H PROline Promag 53 W/P/H PROline Promag 23 P/H Sensor-DAT (S-DAT™) Transmitter-DAT (T-DAT™) — Function-Chip (F-Chip™) — Measuring error Power supply — max. 0. 5% o. r. max. 0. 2% o. r. (option) max. 0. 2% o. r. max. 0. 5% o. r. 85. . . 260 V AC 20. . . 55 V AC 16. . . 62 V DC 12. . . 30 V DC (non Ex) 13, 9. . . 30 V DC (Ex) 21

Promag: Technical Differentiation (2) PROline Promag 50 W/P/H PROline Promag 53 W/P/H PROline Promag 23 P/H Sensor-DAT (S-DAT™) Transmitter-DAT (T-DAT™) — Function-Chip (F-Chip™) — Measuring error Power supply — max. 0. 5% o. r. max. 0. 2% o. r. (option) max. 0. 2% o. r. max. 0. 5% o. r. 85. . . 260 V AC 20. . . 55 V AC 16. . . 62 V DC 12. . . 30 V DC (non Ex) 13, 9. . . 30 V DC (Ex) 21

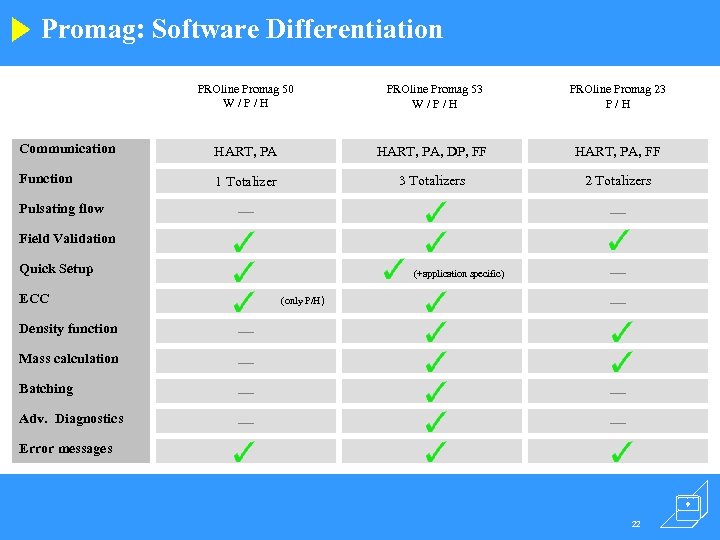

Promag: Software Differentiation PROline Promag 50 W/P/H PROline Promag 53 W/P/H PROline Promag 23 P/H Communication HART, PA, DP, FF HART, PA, FF Function 1 Totalizer 3 Totalizers 2 Totalizers Pulsating flow — — Field Validation Quick Setup (+application specific) ECC (only P/H) — — Density function — Mass calculation — Batching — — Adv. Diagnostics — — Error messages 22

Promag: Software Differentiation PROline Promag 50 W/P/H PROline Promag 53 W/P/H PROline Promag 23 P/H Communication HART, PA, DP, FF HART, PA, FF Function 1 Totalizer 3 Totalizers 2 Totalizers Pulsating flow — — Field Validation Quick Setup (+application specific) ECC (only P/H) — — Density function — Mass calculation — Batching — — Adv. Diagnostics — — Error messages 22

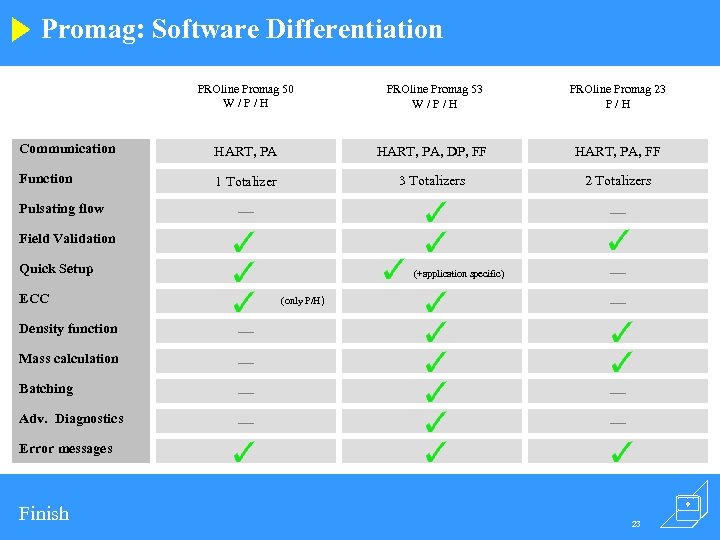

Promag: Software Differentiation PROline Promag 50 W/P/H PROline Promag 53 W/P/H PROline Promag 23 P/H Communication HART, PA, DP, FF HART, PA, FF Function 1 Totalizer 3 Totalizers 2 Totalizers Pulsating flow — — Field Validation Quick Setup (+application specific) ECC (only P/H) — — Density function — Mass calculation — Batching — — Adv. Diagnostics — — Error messages Finish 23

Promag: Software Differentiation PROline Promag 50 W/P/H PROline Promag 53 W/P/H PROline Promag 23 P/H Communication HART, PA, DP, FF HART, PA, FF Function 1 Totalizer 3 Totalizers 2 Totalizers Pulsating flow — — Field Validation Quick Setup (+application specific) ECC (only P/H) — — Density function — Mass calculation — Batching — — Adv. Diagnostics — — Error messages Finish 23

Endress+Hauser Promass Product Presentation January 2000

Endress+Hauser Promass Product Presentation January 2000

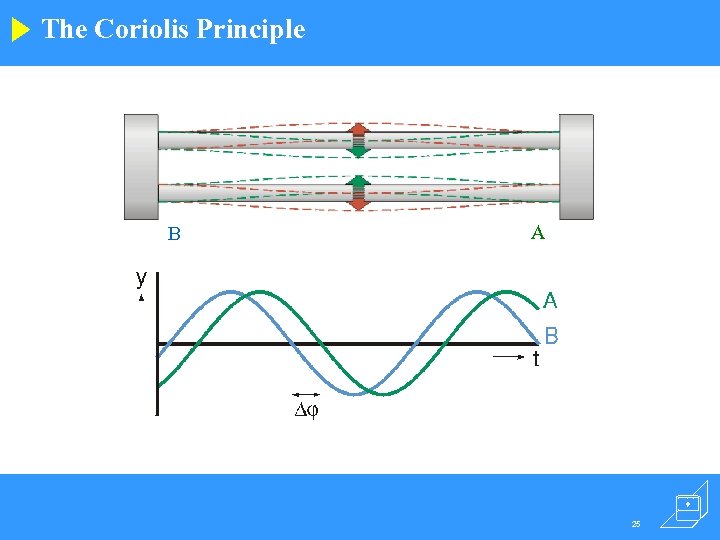

The Coriolis Principle B A 25

The Coriolis Principle B A 25

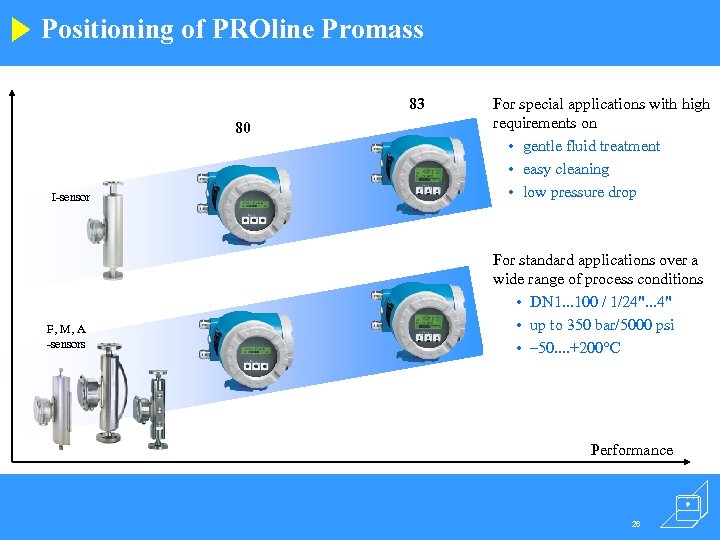

Positioning of PROline Promass 83 80 I-sensor F, M, A -sensors For special applications with high requirements on • gentle fluid treatment • easy cleaning • low pressure drop For standard applications over a wide range of process conditions • DN 1. . . 100 / 1/24". . . 4" • up to 350 bar/5000 psi • – 50. . +200°C Performance 26

Positioning of PROline Promass 83 80 I-sensor F, M, A -sensors For special applications with high requirements on • gentle fluid treatment • easy cleaning • low pressure drop For standard applications over a wide range of process conditions • DN 1. . . 100 / 1/24". . . 4" • up to 350 bar/5000 psi • – 50. . +200°C Performance 26

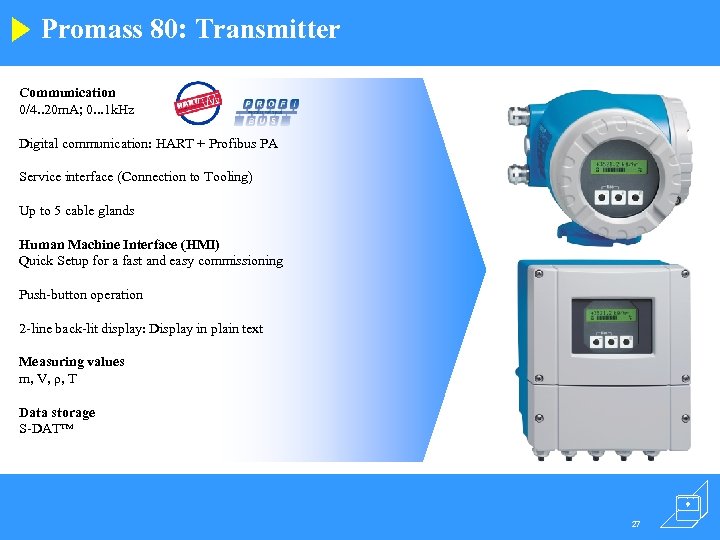

Promass 80: Transmitter Communication 0/4. . 20 m. A; 0. . . 1 k. Hz Digital communication: HART + Profibus PA Service interface (Connection to Tooling) Up to 5 cable glands Human Machine Interface (HMI) Quick Setup for a fast and easy commissioning Push-button operation 2 -line back-lit display: Display in plain text Measuring values m, V, ρ, T Data storage S-DAT™ 27

Promass 80: Transmitter Communication 0/4. . 20 m. A; 0. . . 1 k. Hz Digital communication: HART + Profibus PA Service interface (Connection to Tooling) Up to 5 cable glands Human Machine Interface (HMI) Quick Setup for a fast and easy commissioning Push-button operation 2 -line back-lit display: Display in plain text Measuring values m, V, ρ, T Data storage S-DAT™ 27

Promass 83: Transmitter Communication Flexible I/O-Modules HART, Profibus PA and DP, FF Service interface (connection to Tooling) Human Machine Interface (HMI) Quick Setup for a fast and easy commissioning Touch Control operation allows programming without opening of electronics 4 -line back-lit display Modular Software concept Concentration calculation, batching functions and advanced diagnostics Data storage S-DAT™, T-DAT™, F-CHIP™ 28

Promass 83: Transmitter Communication Flexible I/O-Modules HART, Profibus PA and DP, FF Service interface (connection to Tooling) Human Machine Interface (HMI) Quick Setup for a fast and easy commissioning Touch Control operation allows programming without opening of electronics 4 -line back-lit display Modular Software concept Concentration calculation, batching functions and advanced diagnostics Data storage S-DAT™, T-DAT™, F-CHIP™ 28

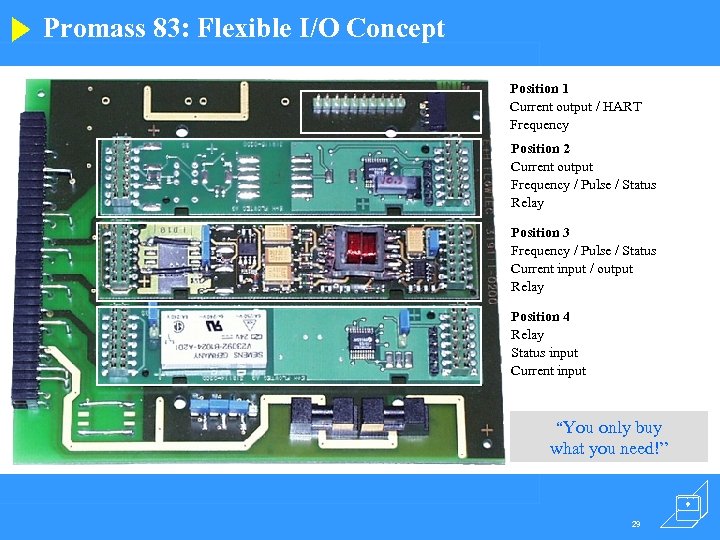

Promass 83: Flexible I/O Concept Position 1 Current output / HART Frequency Position 2 Current output Frequency / Pulse / Status Relay Position 3 Frequency / Pulse / Status Current input / output Relay Position 4 Relay Status input Current input “You only buy what you need!” 29

Promass 83: Flexible I/O Concept Position 1 Current output / HART Frequency Position 2 Current output Frequency / Pulse / Status Relay Position 3 Frequency / Pulse / Status Current input / output Relay Position 4 Relay Status input Current input “You only buy what you need!” 29

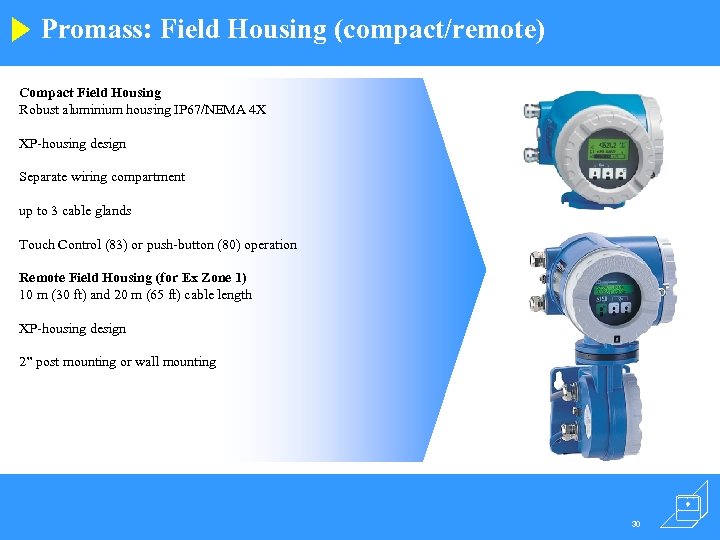

Promass: Field Housing (compact/remote) Compact Field Housing Robust aluminium housing IP 67/NEMA 4 X XP-housing design Separate wiring compartment up to 3 cable glands Touch Control (83) or push-button (80) operation Remote Field Housing (for Ex Zone 1) 10 m (30 ft) and 20 m (65 ft) cable length XP-housing design 2” post mounting or wall mounting 30

Promass: Field Housing (compact/remote) Compact Field Housing Robust aluminium housing IP 67/NEMA 4 X XP-housing design Separate wiring compartment up to 3 cable glands Touch Control (83) or push-button (80) operation Remote Field Housing (for Ex Zone 1) 10 m (30 ft) and 20 m (65 ft) cable length XP-housing design 2” post mounting or wall mounting 30

Promass: Wall Mount Housing Robust aluminium housing, IP 67/NEMA 4 X Separate wiring compartment Electronics Same electronics as for aluminium field housing • Simple spare parts handling Connection 10 m (30 ft) and 20 m (65 ft) cable length 2” post mounting or panel mounting 31

Promass: Wall Mount Housing Robust aluminium housing, IP 67/NEMA 4 X Separate wiring compartment Electronics Same electronics as for aluminium field housing • Simple spare parts handling Connection 10 m (30 ft) and 20 m (65 ft) cable length 2” post mounting or panel mounting 31

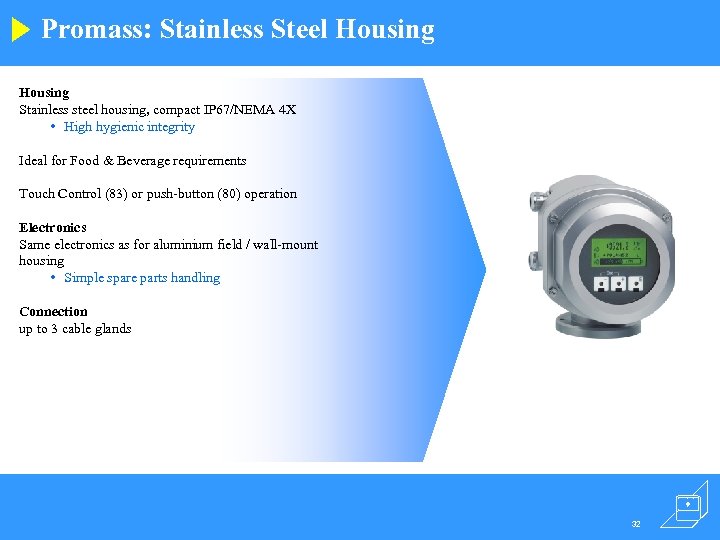

Promass: Stainless Steel Housing Stainless steel housing, compact IP 67/NEMA 4 X • High hygienic integrity Ideal for Food & Beverage requirements Touch Control (83) or push-button (80) operation Electronics Same electronics as for aluminium field / wall-mount housing • Simple spare parts handling Connection up to 3 cable glands 32

Promass: Stainless Steel Housing Stainless steel housing, compact IP 67/NEMA 4 X • High hygienic integrity Ideal for Food & Beverage requirements Touch Control (83) or push-button (80) operation Electronics Same electronics as for aluminium field / wall-mount housing • Simple spare parts handling Connection up to 3 cable glands 32

Promass 80/83 F: Universal Solution Measurement • Low pressure gases (e. g. natural gas, air) • LPG (e. g. butane, propane) • Fuel oils and gasoline • Fruit concentrates • Vegetable oils, animal fats • • Alcohol Detergents and solvents Latex, Silicon oil Toluene, Benzene “The standard for almost every application!” 33

Promass 80/83 F: Universal Solution Measurement • Low pressure gases (e. g. natural gas, air) • LPG (e. g. butane, propane) • Fuel oils and gasoline • Fruit concentrates • Vegetable oils, animal fats • • Alcohol Detergents and solvents Latex, Silicon oil Toluene, Benzene “The standard for almost every application!” 33

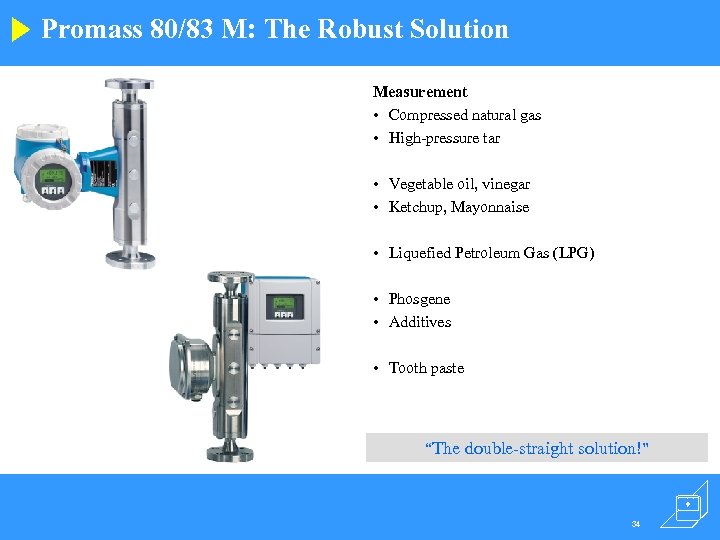

Promass 80/83 M: The Robust Solution Measurement • Compressed natural gas • High-pressure tar • Vegetable oil, vinegar • Ketchup, Mayonnaise • Liquefied Petroleum Gas (LPG) • Phosgene • Additives • Tooth paste “The double-straight solution!” 34

Promass 80/83 M: The Robust Solution Measurement • Compressed natural gas • High-pressure tar • Vegetable oil, vinegar • Ketchup, Mayonnaise • Liquefied Petroleum Gas (LPG) • Phosgene • Additives • Tooth paste “The double-straight solution!” 34

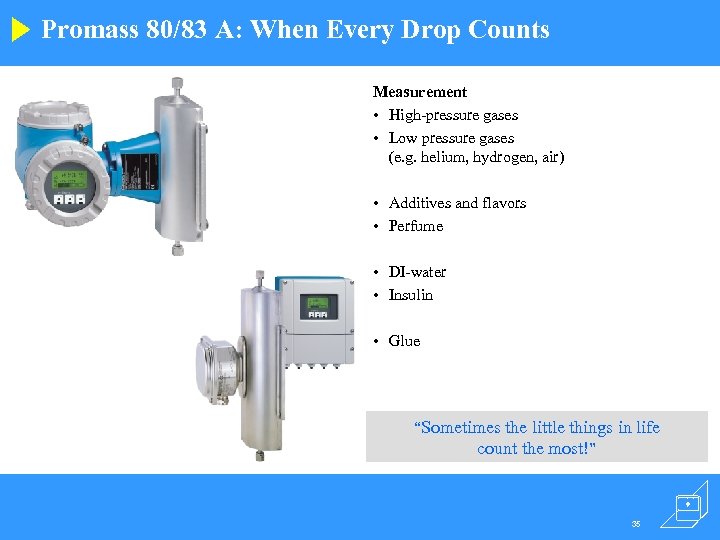

Promass 80/83 A: When Every Drop Counts Measurement • High-pressure gases • Low pressure gases (e. g. helium, hydrogen, air) • Additives and flavors • Perfume • DI-water • Insulin • Glue “Sometimes the little things in life count the most!” 35

Promass 80/83 A: When Every Drop Counts Measurement • High-pressure gases • Low pressure gases (e. g. helium, hydrogen, air) • Additives and flavors • Perfume • DI-water • Insulin • Glue “Sometimes the little things in life count the most!” 35

Promass 80/83 I: The Specialist Measurement • Yogurt with fruit pieces • Syrup/Molasses • Chocolate with nut pieces • Blood plasma (sterile) • Detergents, solvents • Colors • Liquefied gases • Cosmetics “The straight design for a straight measurement!” 36

Promass 80/83 I: The Specialist Measurement • Yogurt with fruit pieces • Syrup/Molasses • Chocolate with nut pieces • Blood plasma (sterile) • Detergents, solvents • Colors • Liquefied gases • Cosmetics “The straight design for a straight measurement!” 36

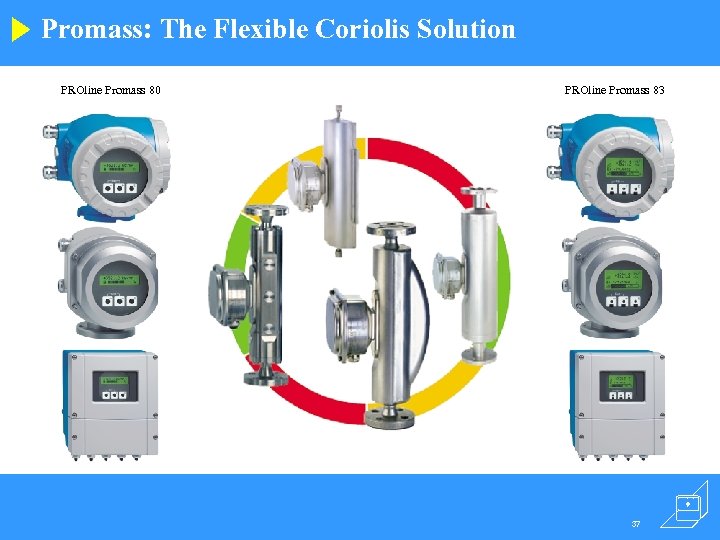

Promass: The Flexible Coriolis Solution PROline Promass 80 PROline Promass 83 37

Promass: The Flexible Coriolis Solution PROline Promass 80 PROline Promass 83 37

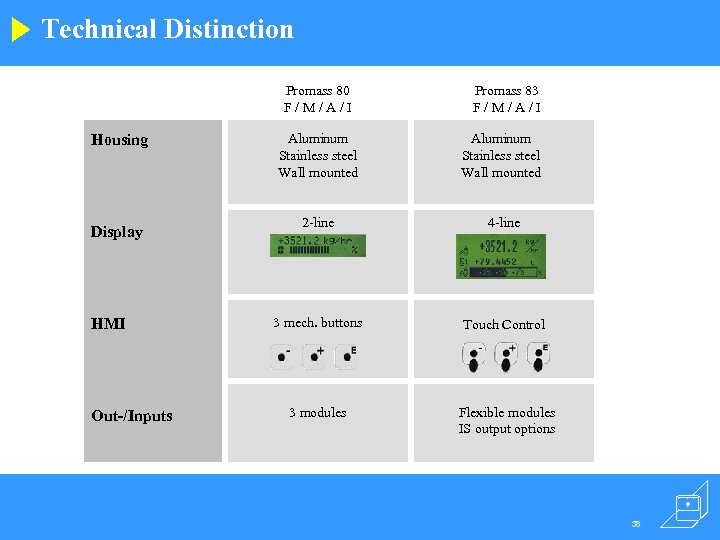

Technical Distinction Promass 80 F/M/A/I Housing Display HMI Out-/Inputs Promass 83 F/M/A/I Aluminum Stainless steel Wall mounted 2 -line 4 -line 3 mech. buttons Touch Control 3 modules Flexible modules IS output options 38

Technical Distinction Promass 80 F/M/A/I Housing Display HMI Out-/Inputs Promass 83 F/M/A/I Aluminum Stainless steel Wall mounted 2 -line 4 -line 3 mech. buttons Touch Control 3 modules Flexible modules IS output options 38

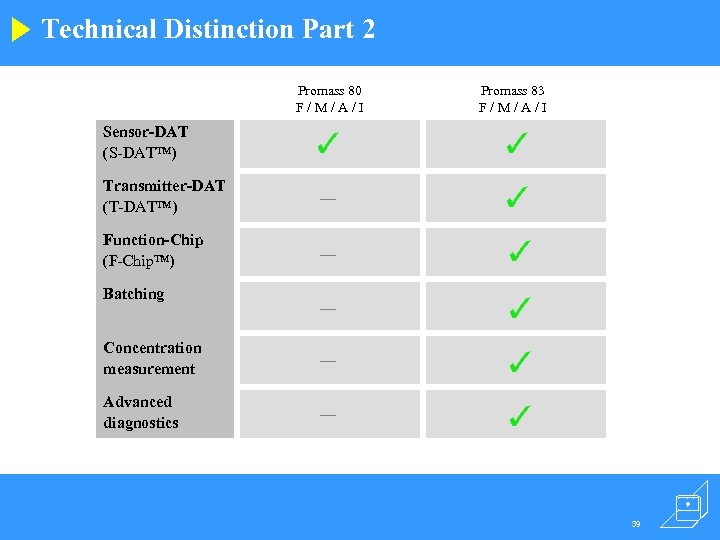

Technical Distinction Part 2 Promass 80 F/M/A/I Promass 83 F/M/A/I Sensor-DAT (S-DAT™) Transmitter-DAT (T-DAT™) — Function-Chip (F-Chip™) — Batching — Concentration measurement — Advanced diagnostics — 39

Technical Distinction Part 2 Promass 80 F/M/A/I Promass 83 F/M/A/I Sensor-DAT (S-DAT™) Transmitter-DAT (T-DAT™) — Function-Chip (F-Chip™) — Batching — Concentration measurement — Advanced diagnostics — 39

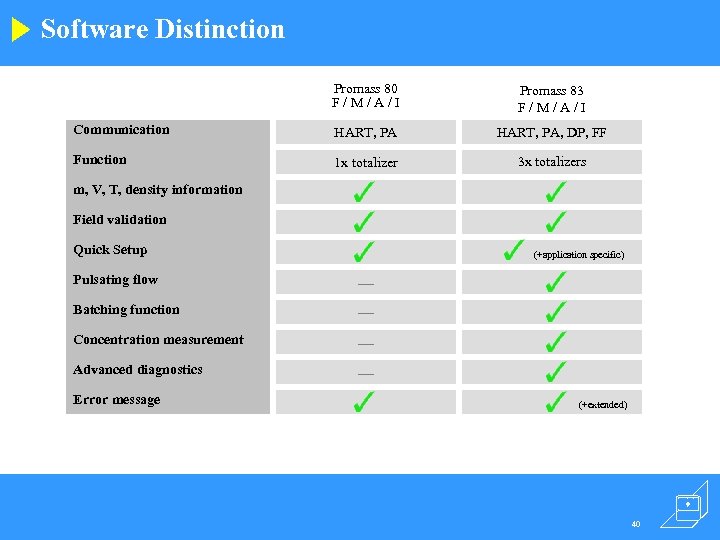

Software Distinction Promass 80 F/M/A/I Promass 83 F/M/A/I Communication HART, PA, DP, FF Function 1 x totalizer 3 x totalizers m, V, T, density information Field validation Quick Setup (+application specific) Pulsating flow — Batching function — Concentration measurement — Advanced diagnostics — Error message (+extended) 40

Software Distinction Promass 80 F/M/A/I Promass 83 F/M/A/I Communication HART, PA, DP, FF Function 1 x totalizer 3 x totalizers m, V, T, density information Field validation Quick Setup (+application specific) Pulsating flow — Batching function — Concentration measurement — Advanced diagnostics — Error message (+extended) 40

Promass 40 E: The Gateway to New Markets Flow meters: • PD-meters • Turbine meter • DP-meters The Market: • Huge installed base • Conservative • Requirements for reduced cost of ownership 41

Promass 40 E: The Gateway to New Markets Flow meters: • PD-meters • Turbine meter • DP-meters The Market: • Huge installed base • Conservative • Requirements for reduced cost of ownership 41

Promass 40 E: Sensor Technical data Measured Variables: Mass or volumetric flow rate Fluids: Liquids and gases Nominal diameter: 3/8". . . 2" (DN 8. . . DN 50) Temperature: -40. . . 256°F (-40. . . 125°C) Pressure: Up to 1450 psi (100 bar) Material: Stainless steel Connections: Flanges DIN, ANSI, JIS, sanitary connections 42

Promass 40 E: Sensor Technical data Measured Variables: Mass or volumetric flow rate Fluids: Liquids and gases Nominal diameter: 3/8". . . 2" (DN 8. . . DN 50) Temperature: -40. . . 256°F (-40. . . 125°C) Pressure: Up to 1450 psi (100 bar) Material: Stainless steel Connections: Flanges DIN, ANSI, JIS, sanitary connections 42

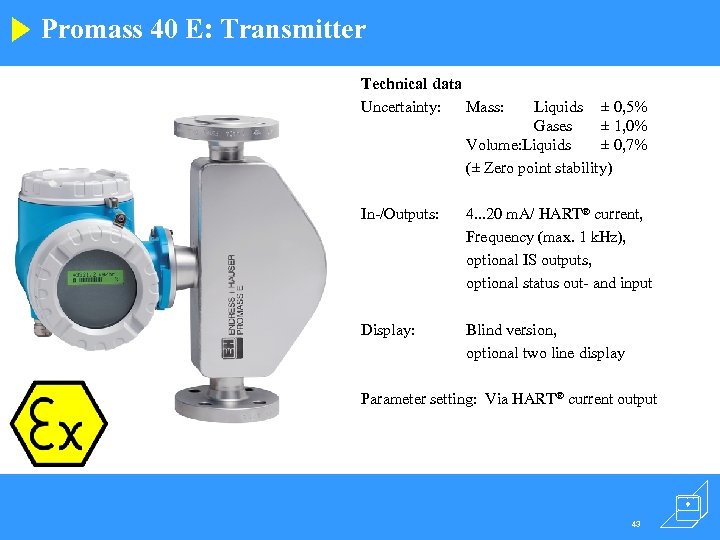

Promass 40 E: Transmitter Technical data Uncertainty: Mass: Liquids ± 0, 5% Gases ± 1, 0% Volume: Liquids ± 0, 7% (± Zero point stability) In-/Outputs: 4. . . 20 m. A/ HART® current, Frequency (max. 1 k. Hz), optional IS outputs, optional status out- and input Display: Blind version, optional two line display Parameter setting: Via HART® current output 43

Promass 40 E: Transmitter Technical data Uncertainty: Mass: Liquids ± 0, 5% Gases ± 1, 0% Volume: Liquids ± 0, 7% (± Zero point stability) In-/Outputs: 4. . . 20 m. A/ HART® current, Frequency (max. 1 k. Hz), optional IS outputs, optional status out- and input Display: Blind version, optional two line display Parameter setting: Via HART® current output 43

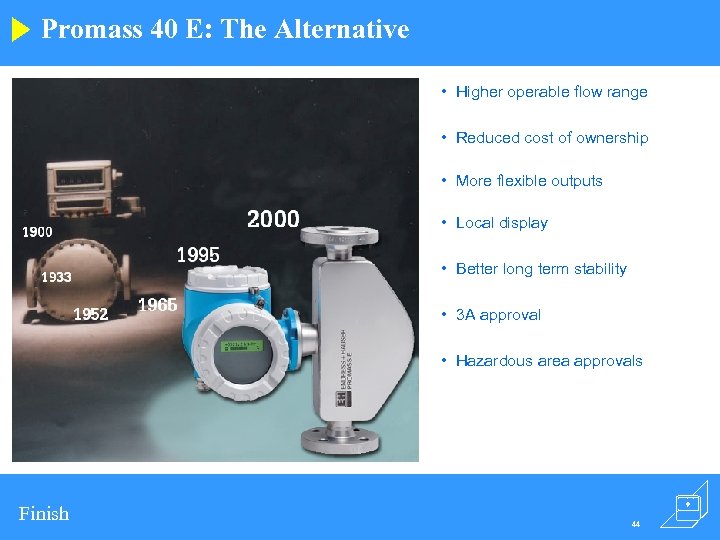

Promass 40 E: The Alternative • Higher operable flow range • Reduced cost of ownership • More flexible outputs • Local display • Better long term stability • 3 A approval • Hazardous area approvals Finish 44

Promass 40 E: The Alternative • Higher operable flow range • Reduced cost of ownership • More flexible outputs • Local display • Better long term stability • 3 A approval • Hazardous area approvals Finish 44

Endress+Hauser Prowirl Product Presentation January 2000

Endress+Hauser Prowirl Product Presentation January 2000

Vortex Product Overview 46

Vortex Product Overview 46

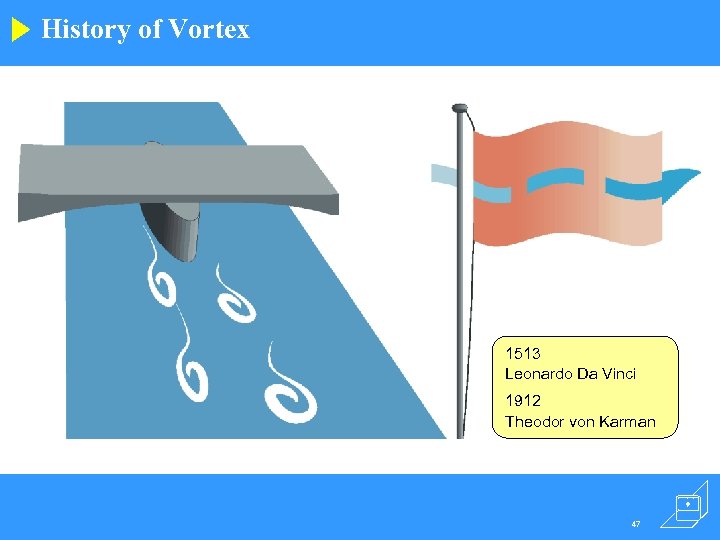

History of Vortex 1513 Leonardo Da Vinci 1912 Theodor von Karman 47

History of Vortex 1513 Leonardo Da Vinci 1912 Theodor von Karman 47

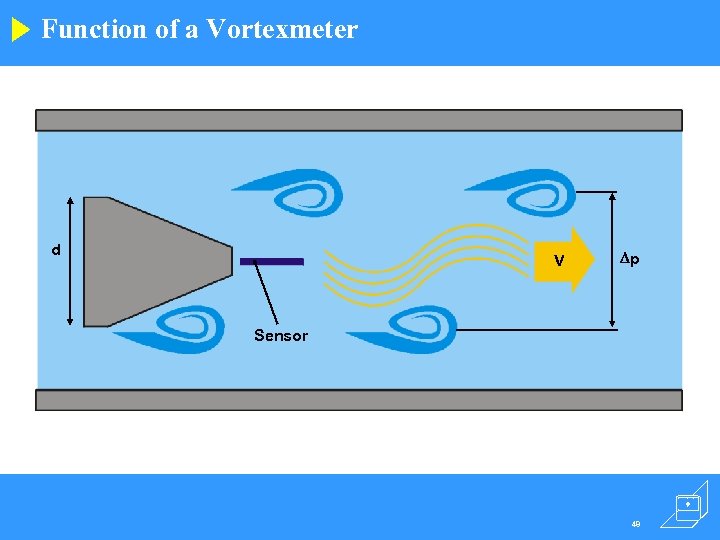

Function of a Vortexmeter d V p Sensor 48

Function of a Vortexmeter d V p Sensor 48

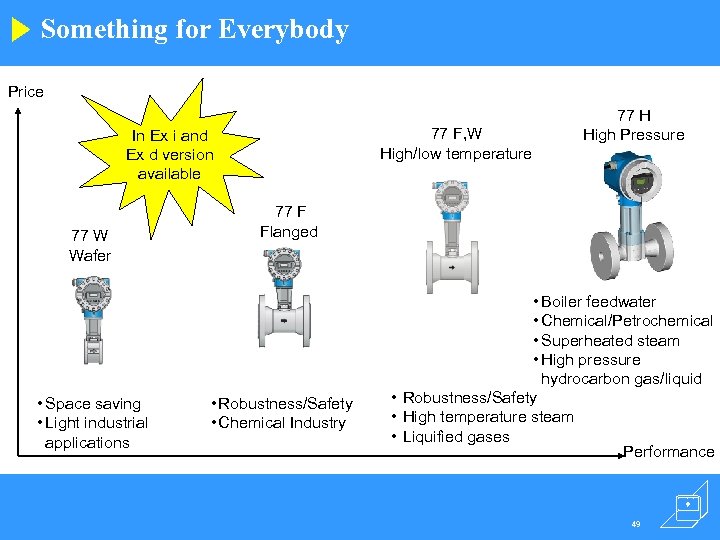

Something for Everybody Price 77 F, W High/low temperature In Ex i and Ex d version available 77 W Wafer • Space saving • Light industrial applications 77 H High Pressure 77 F Flanged • Robustness/Safety • Chemical Industry • Boiler feedwater • Chemical/Petrochemical • Superheated steam • High pressure hydrocarbon gas/liquid • Robustness/Safety • High temperature steam • Liquified gases Performance 49

Something for Everybody Price 77 F, W High/low temperature In Ex i and Ex d version available 77 W Wafer • Space saving • Light industrial applications 77 H High Pressure 77 F Flanged • Robustness/Safety • Chemical Industry • Boiler feedwater • Chemical/Petrochemical • Superheated steam • High pressure hydrocarbon gas/liquid • Robustness/Safety • High temperature steam • Liquified gases Performance 49

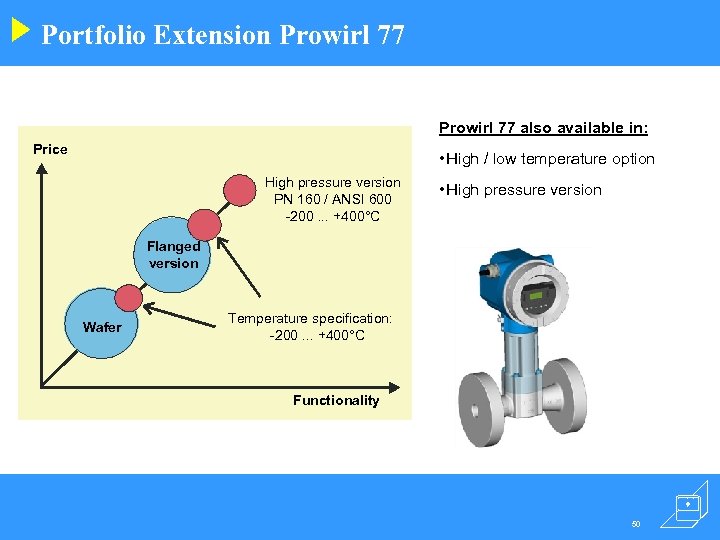

Portfolio Extension Prowirl 77 also available in: Price • High / low temperature option High pressure version PN 160 / ANSI 600 -200. . . +400°C • High pressure version Flanged version Wafer Temperature specification: -200. . . +400°C Functionality 50

Portfolio Extension Prowirl 77 also available in: Price • High / low temperature option High pressure version PN 160 / ANSI 600 -200. . . +400°C • High pressure version Flanged version Wafer Temperature specification: -200. . . +400°C Functionality 50

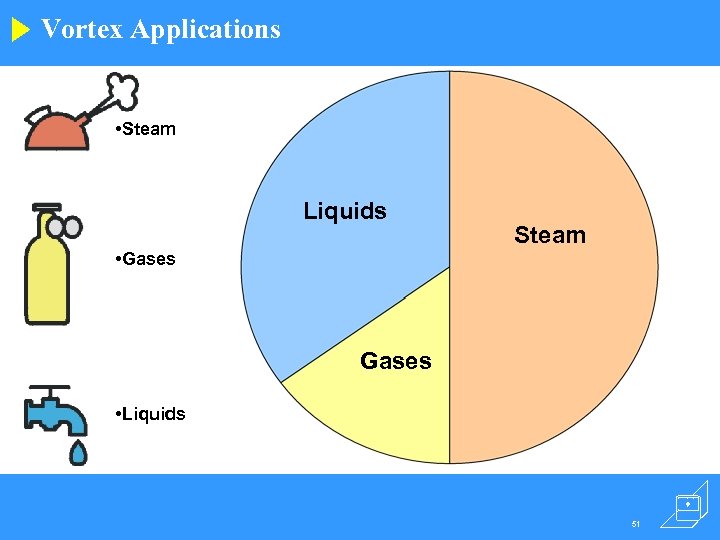

Vortex Applications • Steam Liquids • Gases Steam Gases • Liquids 51

Vortex Applications • Steam Liquids • Gases Steam Gases • Liquids 51

Vortex Steam Applications • Saturated steam • Superheated steam • Heat • Delta heat • Mass Finish 52

Vortex Steam Applications • Saturated steam • Superheated steam • Heat • Delta heat • Mass Finish 52

Endress+Hauser Prosonic Flow Product Presentation January 2000

Endress+Hauser Prosonic Flow Product Presentation January 2000

Economical, Innovative and Flexible · Non-contact measurement · Non-invasive · No moving parts · No electrical conductivity required · Same parts from DN 50 / 2” to 3000 mm / 120” 54

Economical, Innovative and Flexible · Non-contact measurement · Non-invasive · No moving parts · No electrical conductivity required · Same parts from DN 50 / 2” to 3000 mm / 120” 54

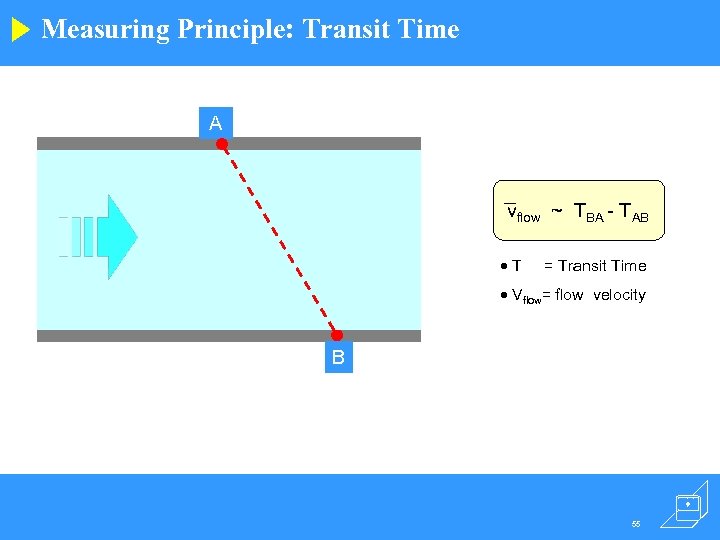

Measuring Principle: Transit Time A vflow ~ TBA - TAB ·T = Transit Time · Vflow= flow velocity B 55

Measuring Principle: Transit Time A vflow ~ TBA - TAB ·T = Transit Time · Vflow= flow velocity B 55

Prosonic Flow Product Overview DDU 15 DMU 93 DDU 10 56

Prosonic Flow Product Overview DDU 15 DMU 93 DDU 10 56

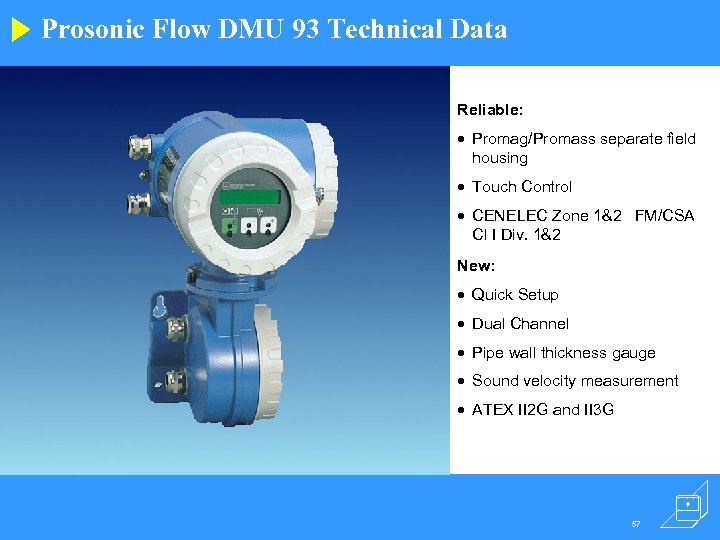

Prosonic Flow DMU 93 Technical Data Reliable: · Promag/Promass separate field housing · Touch Control · CENELEC Zone 1&2 FM/CSA Cl I Div. 1&2 New: · Quick Setup · Dual Channel · Pipe wall thickness gauge · Sound velocity measurement · ATEX II 2 G and II 3 G 57

Prosonic Flow DMU 93 Technical Data Reliable: · Promag/Promass separate field housing · Touch Control · CENELEC Zone 1&2 FM/CSA Cl I Div. 1&2 New: · Quick Setup · Dual Channel · Pipe wall thickness gauge · Sound velocity measurement · ATEX II 2 G and II 3 G 57

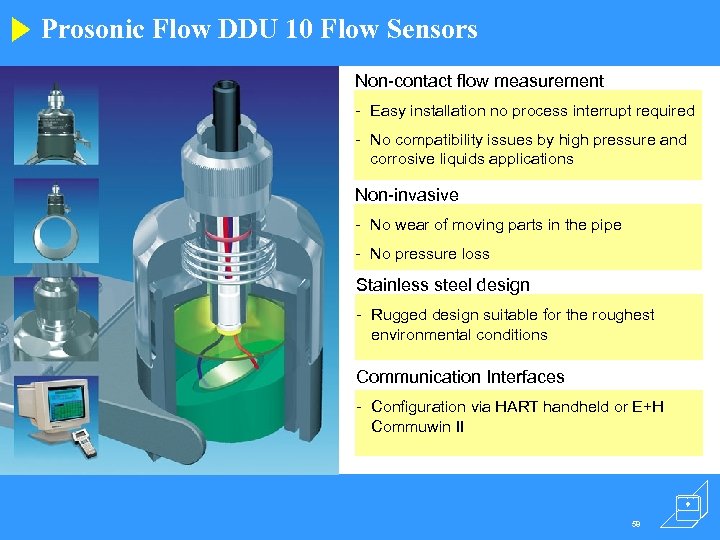

Prosonic Flow DDU 10 Flow Sensors Non-contact flow measurement - Easy installation no process interrupt required - No compatibility issues by high pressure and corrosive liquids applications Non-invasive - No wear of moving parts in the pipe - No pressure loss Stainless steel design - Rugged design suitable for the roughest environmental conditions Communication Interfaces - Configuration via HART handheld or E+H Commuwin II 58

Prosonic Flow DDU 10 Flow Sensors Non-contact flow measurement - Easy installation no process interrupt required - No compatibility issues by high pressure and corrosive liquids applications Non-invasive - No wear of moving parts in the pipe - No pressure loss Stainless steel design - Rugged design suitable for the roughest environmental conditions Communication Interfaces - Configuration via HART handheld or E+H Commuwin II 58

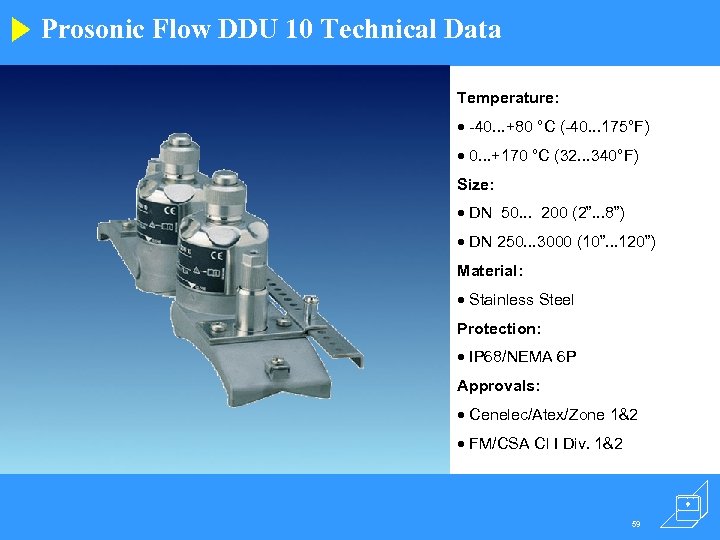

Prosonic Flow DDU 10 Technical Data Temperature: · -40. . . +80 °C (-40. . . 175°F) · 0. . . +170 °C (32. . . 340°F) Size: · DN 50. . . 200 (2”. . . 8”) · DN 250. . . 3000 (10”. . . 120”) Material: · Stainless Steel Protection: · IP 68/NEMA 6 P Approvals: · Cenelec/Atex/Zone 1&2 · FM/CSA Cl I Div. 1&2 59

Prosonic Flow DDU 10 Technical Data Temperature: · -40. . . +80 °C (-40. . . 175°F) · 0. . . +170 °C (32. . . 340°F) Size: · DN 50. . . 200 (2”. . . 8”) · DN 250. . . 3000 (10”. . . 120”) Material: · Stainless Steel Protection: · IP 68/NEMA 6 P Approvals: · Cenelec/Atex/Zone 1&2 · FM/CSA Cl I Div. 1&2 59

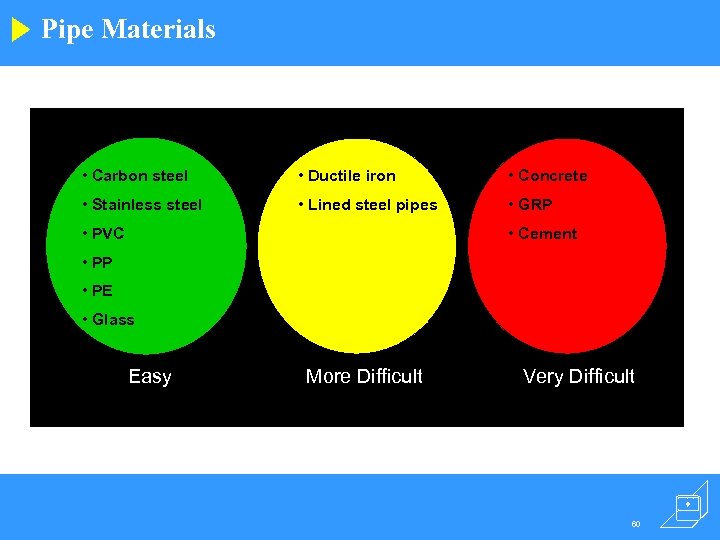

Pipe Materials • Carbon steel • Ductile iron • Concrete • Stainless steel • Lined steel pipes • GRP • PVC • Cement • PP • PE • Glass Easy More Difficult Very Difficult 60

Pipe Materials • Carbon steel • Ductile iron • Concrete • Stainless steel • Lined steel pipes • GRP • PVC • Cement • PP • PE • Glass Easy More Difficult Very Difficult 60

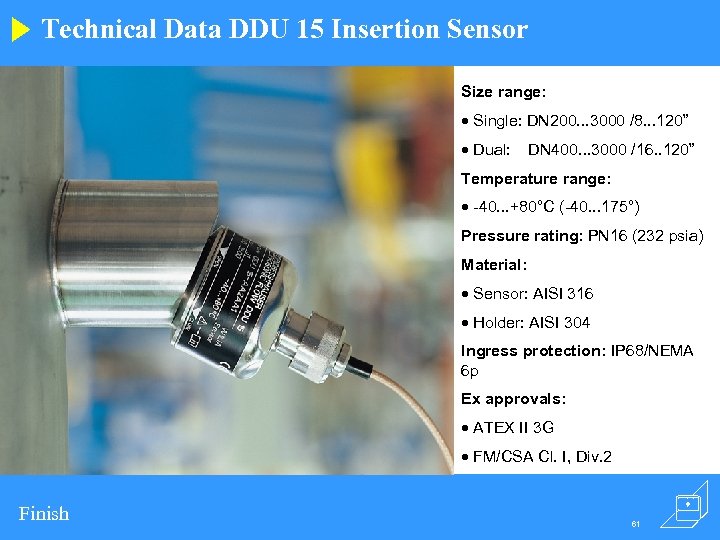

Technical Data DDU 15 Insertion Sensor Size range: · Single: DN 200. . . 3000 /8. . . 120” · Dual: DN 400. . . 3000 /16. . 120” Temperature range: · -40. . . +80°C (-40. . . 175°) Pressure rating: PN 16 (232 psia) Material: · Sensor: AISI 316 · Holder: AISI 304 Ingress protection: IP 68/NEMA 6 p Ex approvals: · ATEX II 3 G · FM/CSA Cl. I, Div. 2 Finish 61

Technical Data DDU 15 Insertion Sensor Size range: · Single: DN 200. . . 3000 /8. . . 120” · Dual: DN 400. . . 3000 /16. . 120” Temperature range: · -40. . . +80°C (-40. . . 175°) Pressure rating: PN 16 (232 psia) Material: · Sensor: AISI 316 · Holder: AISI 304 Ingress protection: IP 68/NEMA 6 p Ex approvals: · ATEX II 3 G · FM/CSA Cl. I, Div. 2 Finish 61

Endress+Hauser tmass Product Presentation January 2000

Endress+Hauser tmass Product Presentation January 2000

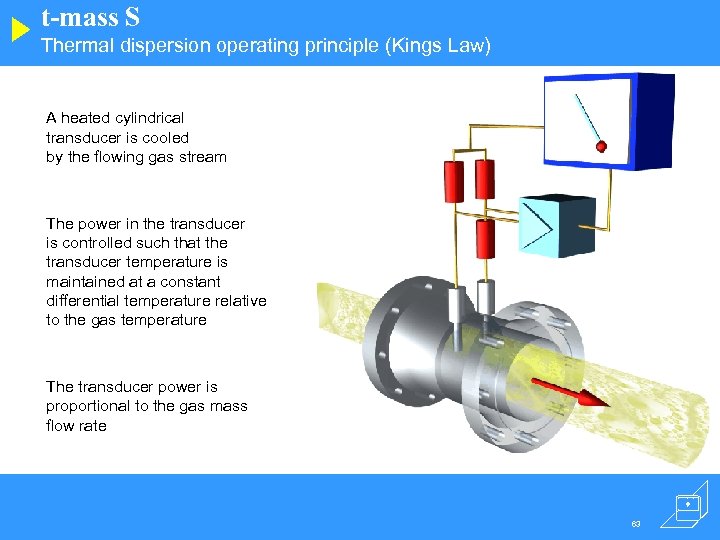

t-mass S Thermal dispersion operating principle (Kings Law) A heated cylindrical transducer is cooled by the flowing gas stream The power in the transducer is controlled such that the transducer temperature is maintained at a constant differential temperature relative to the gas temperature The transducer power is proportional to the gas mass flow rate 63

t-mass S Thermal dispersion operating principle (Kings Law) A heated cylindrical transducer is cooled by the flowing gas stream The power in the transducer is controlled such that the transducer temperature is maintained at a constant differential temperature relative to the gas temperature The transducer power is proportional to the gas mass flow rate 63

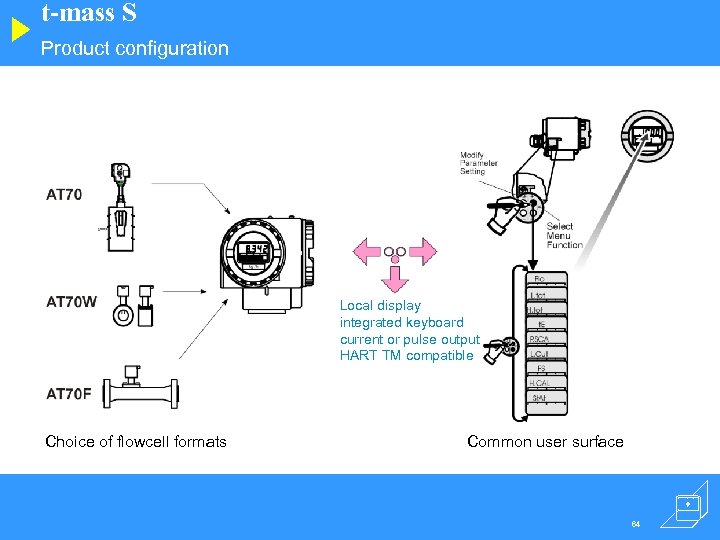

t-mass S Product configuration Local display integrated keyboard current or pulse output HART TM compatible Choice of flowcell formats Common user surface 64

t-mass S Product configuration Local display integrated keyboard current or pulse output HART TM compatible Choice of flowcell formats Common user surface 64

The t-mass family 65

The t-mass family 65