5c206cf01cb3407ca83368a2c7479da5.ppt

- Количество слайдов: 42

Flat. Jet Dispensing & Printing Technology Copyright, 2004 © Multimedia Studio Budapest- HUNGARY

Flat. Jet Dispensing & Printing Technology Copyright, 2004 © Multimedia Studio Budapest- HUNGARY

Flat. Jet • Liquid dispensing • High Throughput Printing

Flat. Jet • Liquid dispensing • High Throughput Printing

Objective • The development of the technology is motivated by the gap between production rate of a conventional offset and the digital systems. • Other ink-jet developers are searching solutions to reduce the ejected ink quantity – our aiming was opposite – the high flow rate.

Objective • The development of the technology is motivated by the gap between production rate of a conventional offset and the digital systems. • Other ink-jet developers are searching solutions to reduce the ejected ink quantity – our aiming was opposite – the high flow rate.

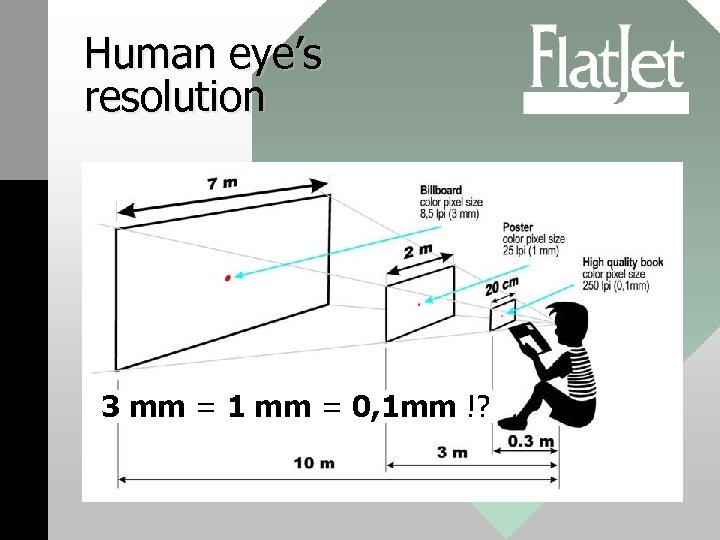

The aimed resolution • The theoretical limit of the human eye’s resolution is 1’ angle – it means that from 3 meter viewing distance, 1 mm size details can hardly be distinguished. • Our basic objective was to find solution to produce images for large distance observation with as high throughput as possible.

The aimed resolution • The theoretical limit of the human eye’s resolution is 1’ angle – it means that from 3 meter viewing distance, 1 mm size details can hardly be distinguished. • Our basic objective was to find solution to produce images for large distance observation with as high throughput as possible.

Human eye’s resolution 3 mm = 1 mm = 0, 1 mm !?

Human eye’s resolution 3 mm = 1 mm = 0, 1 mm !?

The result • simple robust construction, possibility of low production costs • very low & extremely high liquid flow • Possibility of media-wide operating large -format digital systems • Individually replaceable printing elements

The result • simple robust construction, possibility of low production costs • very low & extremely high liquid flow • Possibility of media-wide operating large -format digital systems • Individually replaceable printing elements

Simple and easy to manufacture • Flat. Jet is assembled of a metal plate and tube, and a piezo-ceramic disc • Simple and relatively robust mechanical construction • Conventional materials and manufacturing

Simple and easy to manufacture • Flat. Jet is assembled of a metal plate and tube, and a piezo-ceramic disc • Simple and relatively robust mechanical construction • Conventional materials and manufacturing

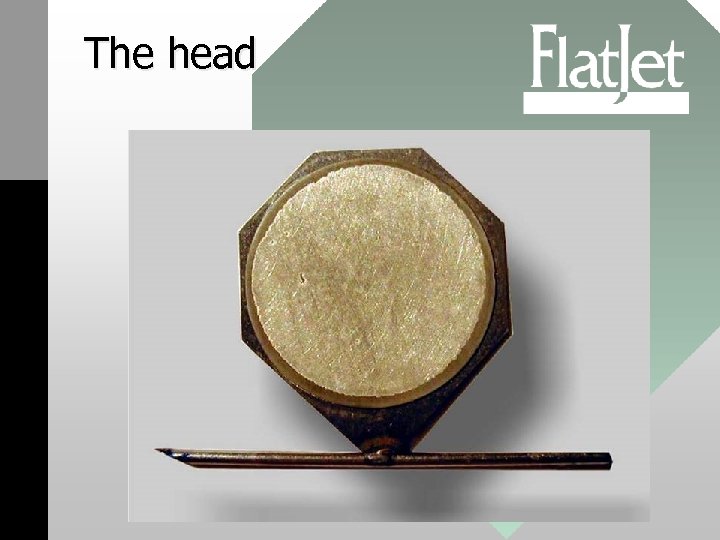

The head

The head

The liquid transfer • From pico-liter range ejection up to 50 microliters/s continuous flow

The liquid transfer • From pico-liter range ejection up to 50 microliters/s continuous flow

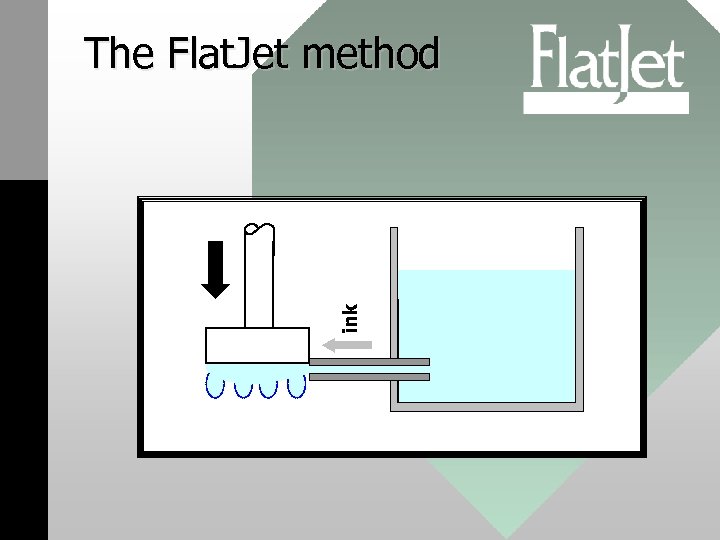

ink The Flat. Jet method

ink The Flat. Jet method

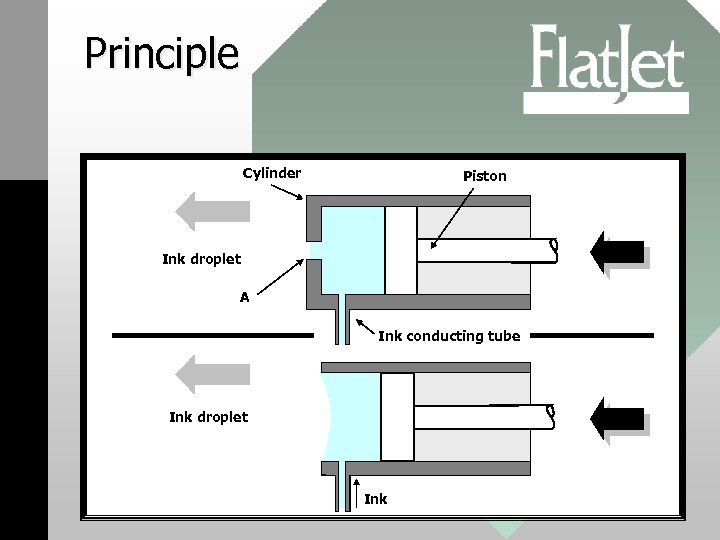

Principle Cylinder Piston Ink droplet A Ink conducting tube Ink droplet Ink

Principle Cylinder Piston Ink droplet A Ink conducting tube Ink droplet Ink

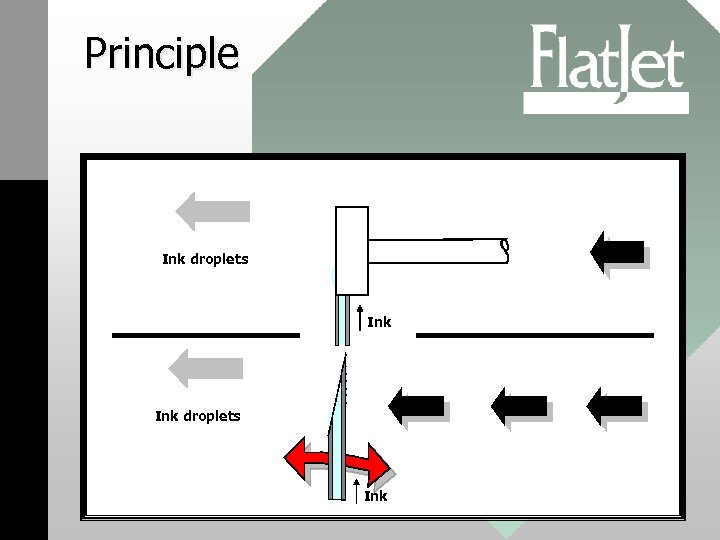

Principle Ink droplets Ink

Principle Ink droplets Ink

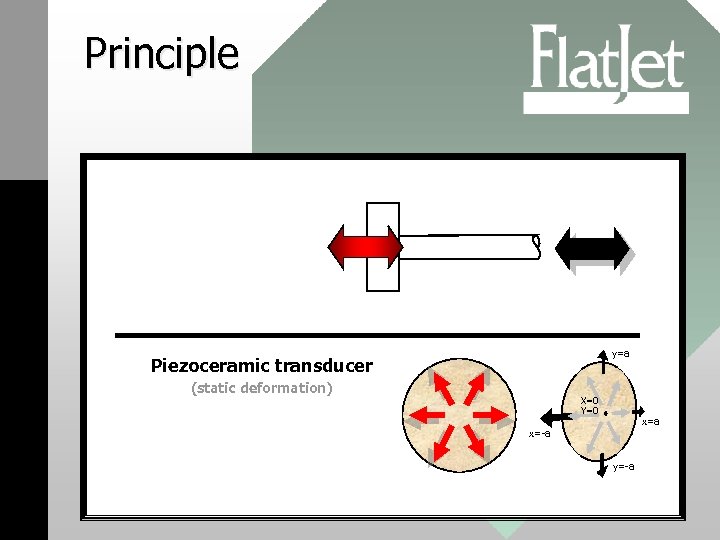

Principle y=a Piezoceramic transducer (static deformation) X=0 Y=0 x=a x=-a y=-a

Principle y=a Piezoceramic transducer (static deformation) X=0 Y=0 x=a x=-a y=-a

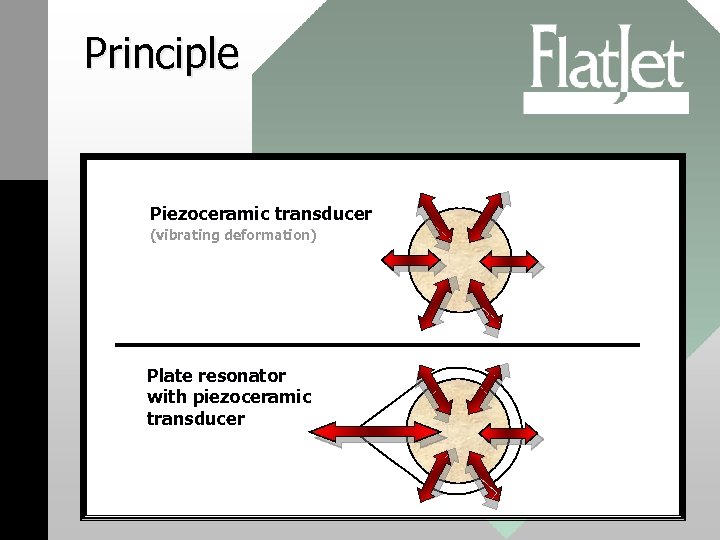

Principle Piezoceramic transducer (vibrating deformation) Plate resonator with piezoceramic transducer

Principle Piezoceramic transducer (vibrating deformation) Plate resonator with piezoceramic transducer

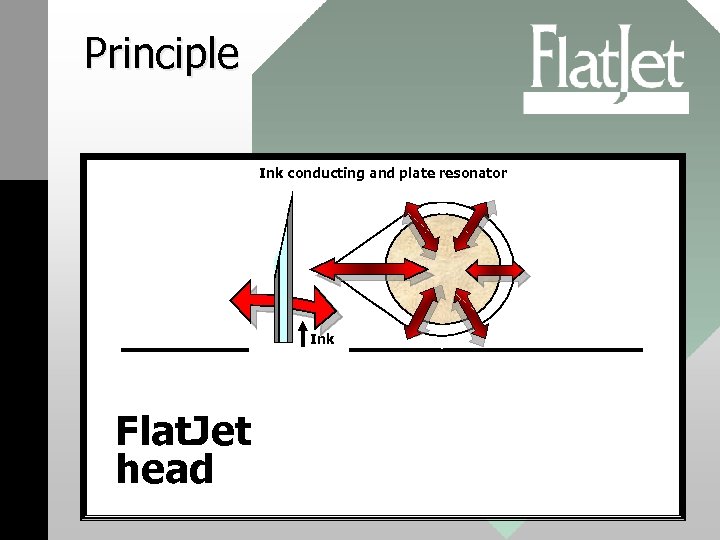

Principle Ink conducting and plate resonator Ink Flat. Jet head

Principle Ink conducting and plate resonator Ink Flat. Jet head

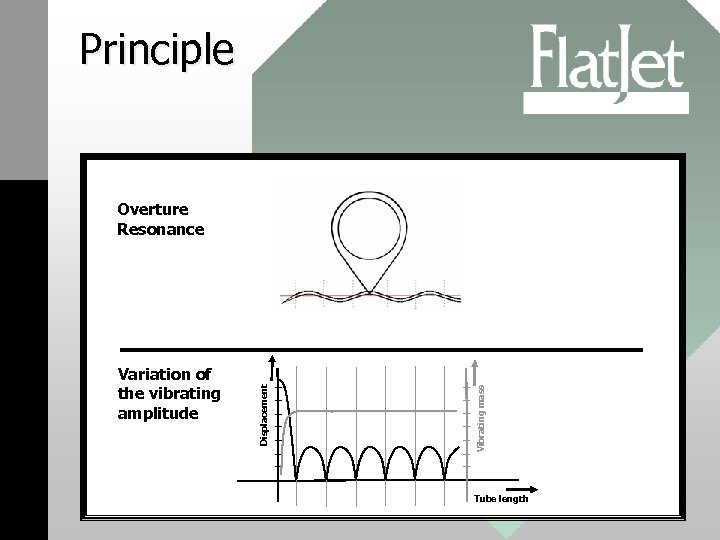

Principle Vibrating mass Variation of the vibrating amplitude Displacement Overture Resonance Tube length

Principle Vibrating mass Variation of the vibrating amplitude Displacement Overture Resonance Tube length

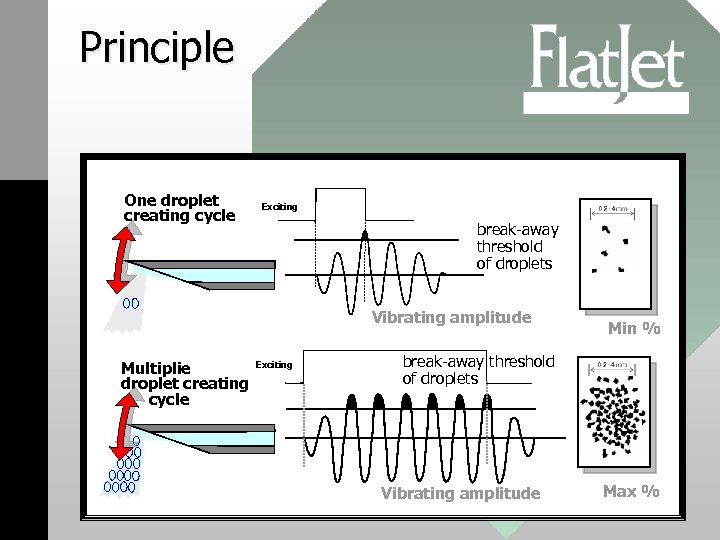

Principle One droplet creating cycle Exciting break-away threshold of droplets Vibrating amplitude Multiplie droplet creating cycle Exciting Min % break-away threshold of droplets Vibrating amplitude Max %

Principle One droplet creating cycle Exciting break-away threshold of droplets Vibrating amplitude Multiplie droplet creating cycle Exciting Min % break-away threshold of droplets Vibrating amplitude Max %

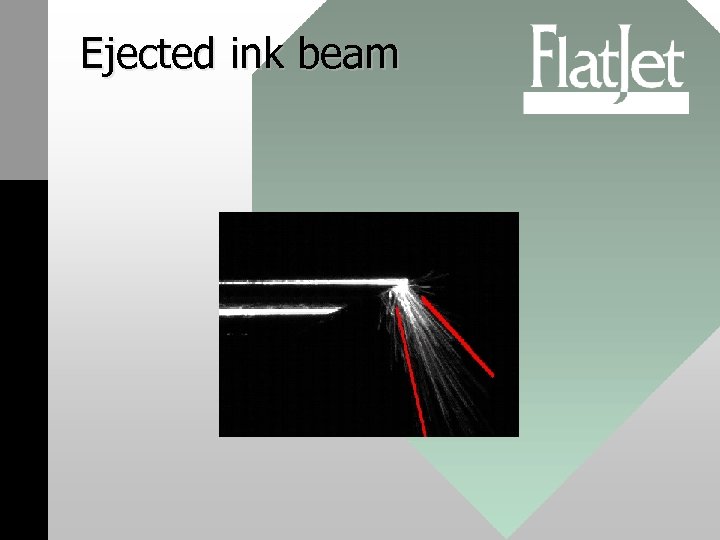

Ejected ink beam

Ejected ink beam

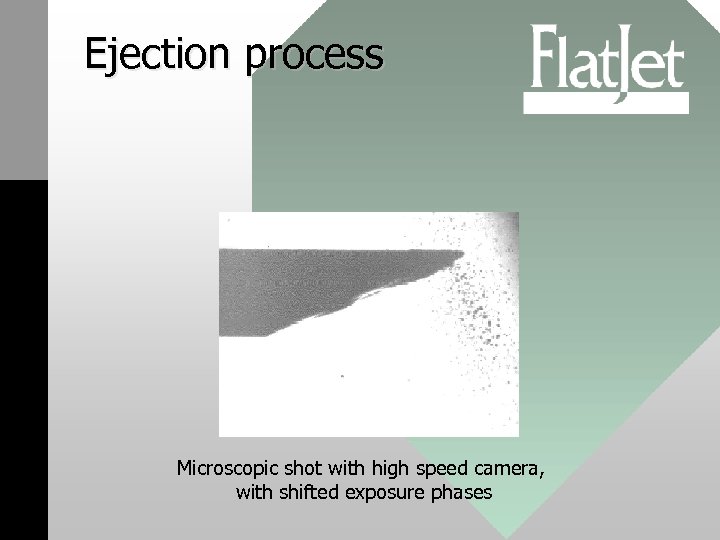

Ejection process Microscopic shot with high speed camera, with shifted exposure phases

Ejection process Microscopic shot with high speed camera, with shifted exposure phases

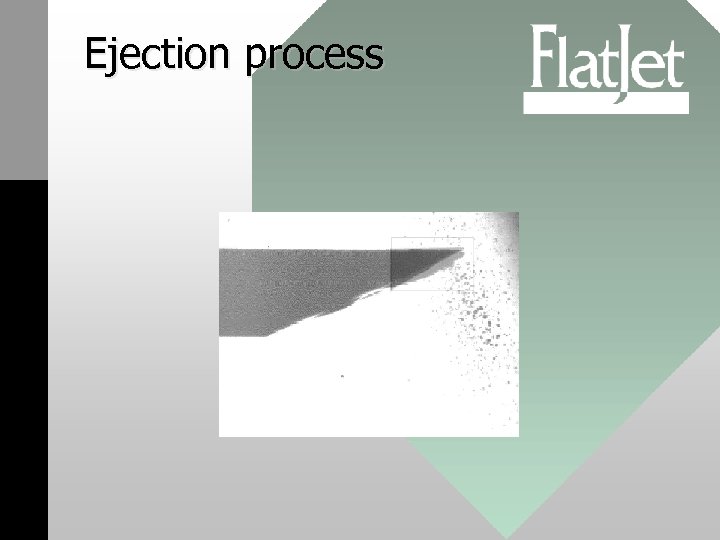

Ejection process

Ejection process

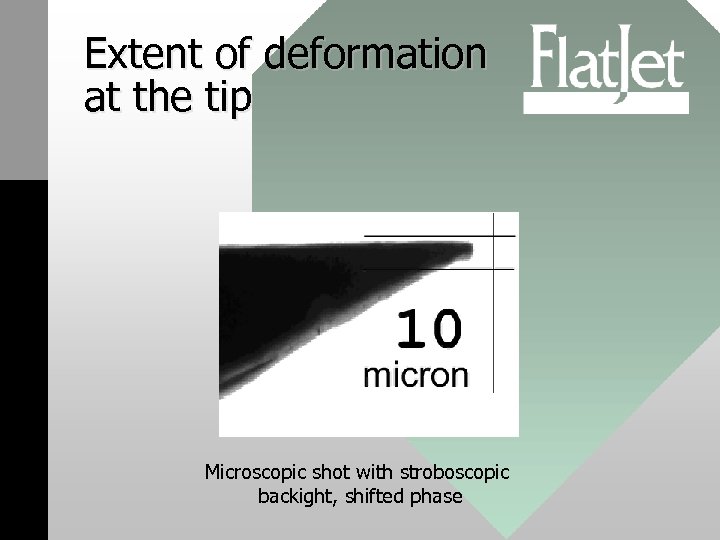

Extent of deformation at the tip Microscopic shot with stroboscopic backight, shifted phase

Extent of deformation at the tip Microscopic shot with stroboscopic backight, shifted phase

Local speed and acceleration at the tip • At 200 k. Hz frequency the periodical speed of the tip surface is about 6 m/s • The acceleration at the dead point exceeds the 1. 000 g

Local speed and acceleration at the tip • At 200 k. Hz frequency the periodical speed of the tip surface is about 6 m/s • The acceleration at the dead point exceeds the 1. 000 g

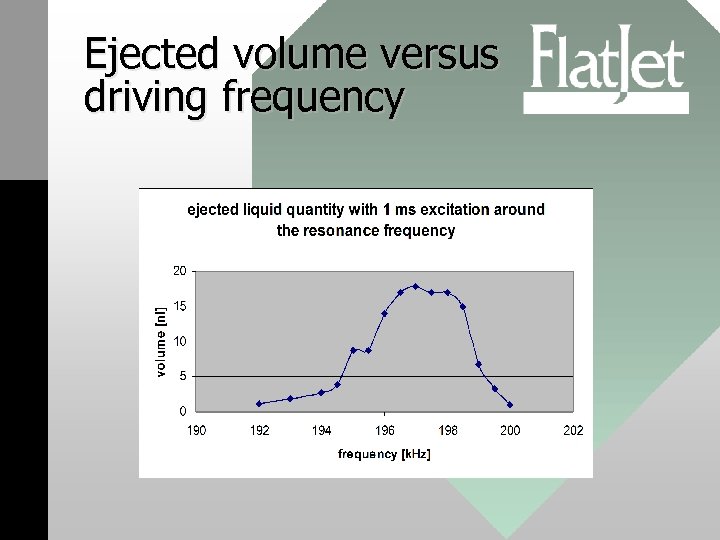

Ejected volume versus driving frequency

Ejected volume versus driving frequency

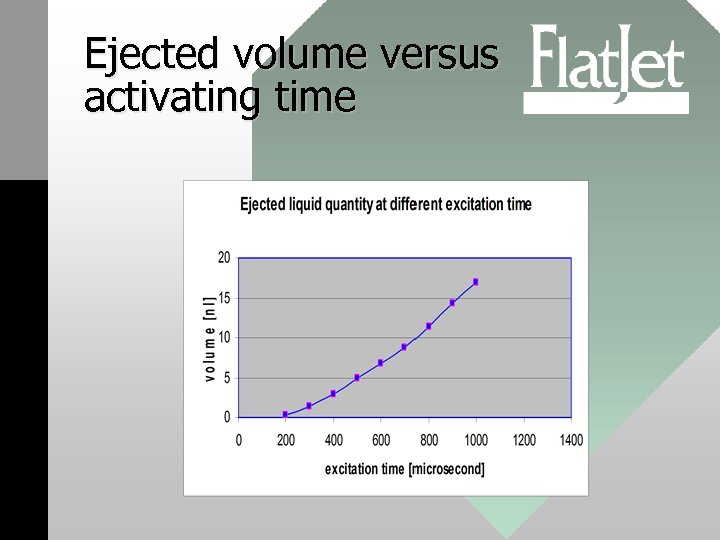

Ejected volume versus activating time

Ejected volume versus activating time

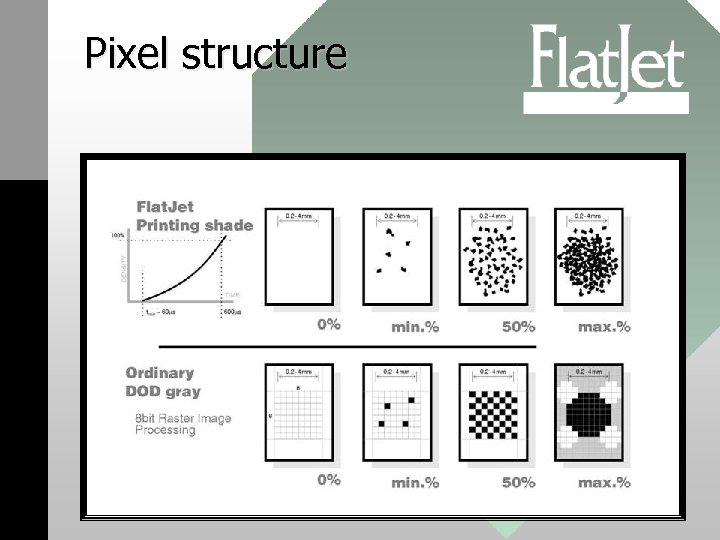

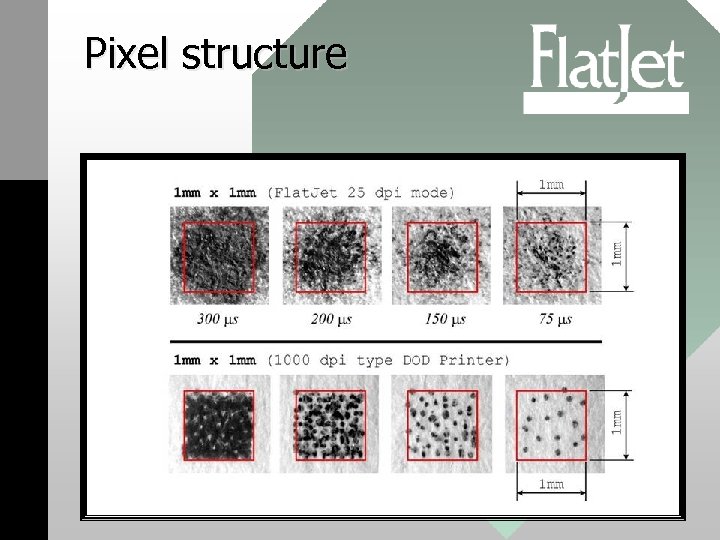

Pixel structure

Pixel structure

Pixel structure

Pixel structure

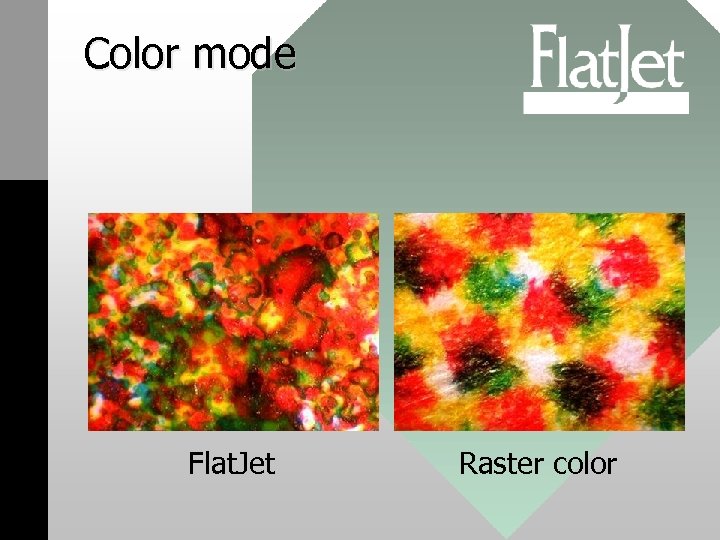

Color mode Flat. Jet Raster color

Color mode Flat. Jet Raster color

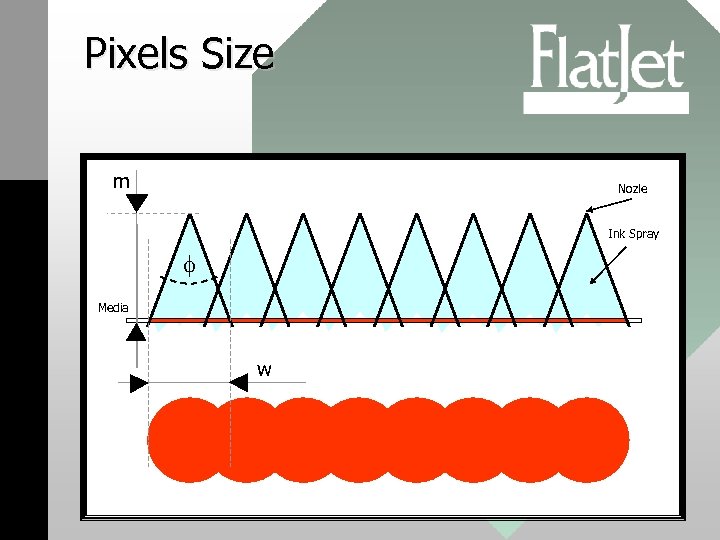

Pixels Size m Nozle Ink Spray f Media w

Pixels Size m Nozle Ink Spray f Media w

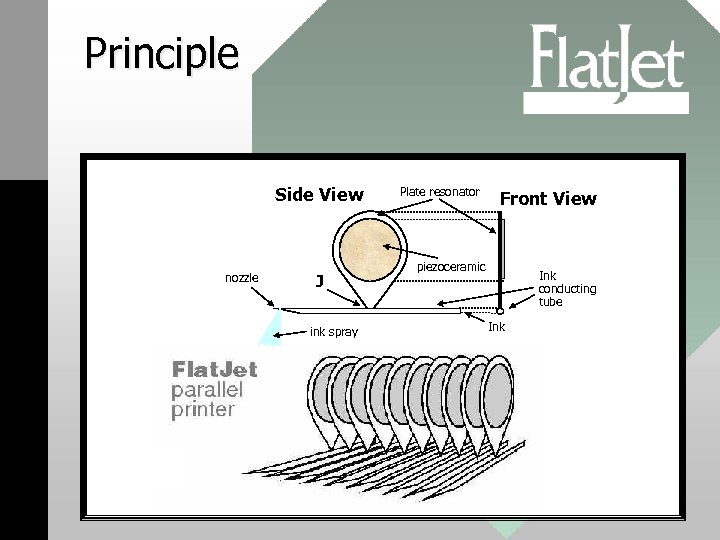

Principle Side View nozzle J ink spray Plate resonator Front View piezoceramic Ink conducting tube Ink

Principle Side View nozzle J ink spray Plate resonator Front View piezoceramic Ink conducting tube Ink

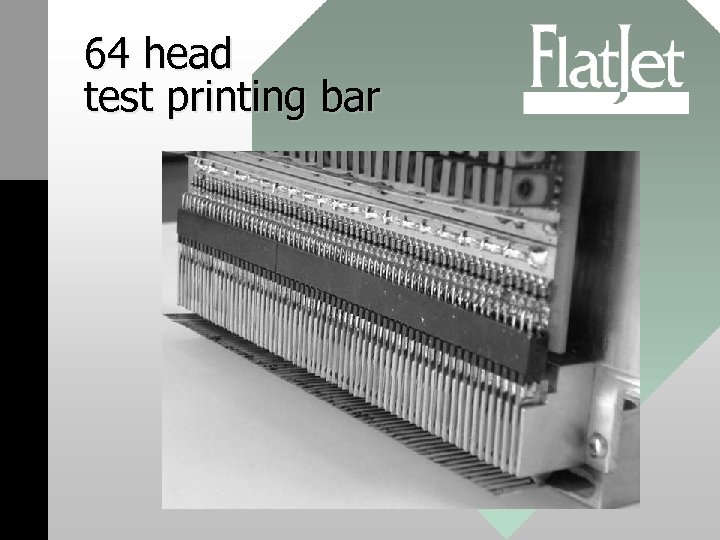

64 head test printing bar

64 head test printing bar

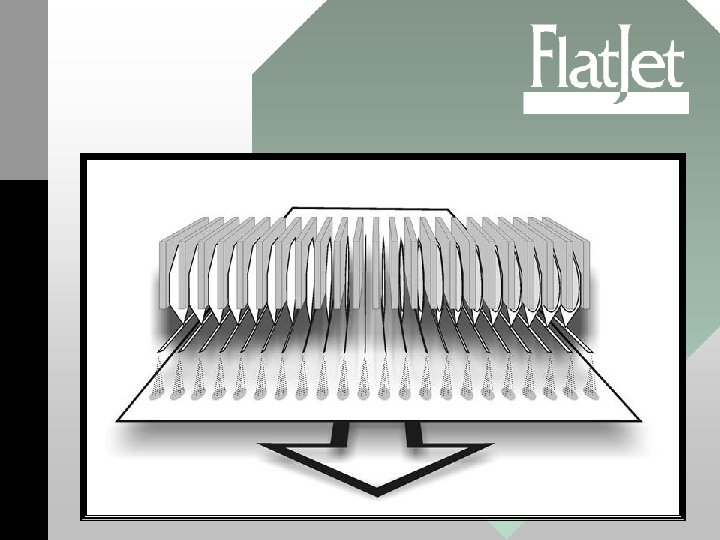

Planed media-wide printer

Planed media-wide printer

Application fields • Printing on ordinary materials • Printing on special materials • Different applications – Chemical, Pharmaceutical or Microbiological dispensers – Moisturizers

Application fields • Printing on ordinary materials • Printing on special materials • Different applications – Chemical, Pharmaceutical or Microbiological dispensers – Moisturizers

Printing on ordinary materials • Industrial media-wide large-format ink-jet printing • Low cost media, low cost inks & low operating costs • Wide variety of media & inks • Computer to print technology

Printing on ordinary materials • Industrial media-wide large-format ink-jet printing • Low cost media, low cost inks & low operating costs • Wide variety of media & inks • Computer to print technology

Printing on special materials • Ceramics • Wallpaper • Glass • Corrugated paper • Wood • Leather • Concrete • Plastics • Metals • …etc.

Printing on special materials • Ceramics • Wallpaper • Glass • Corrugated paper • Wood • Leather • Concrete • Plastics • Metals • …etc.

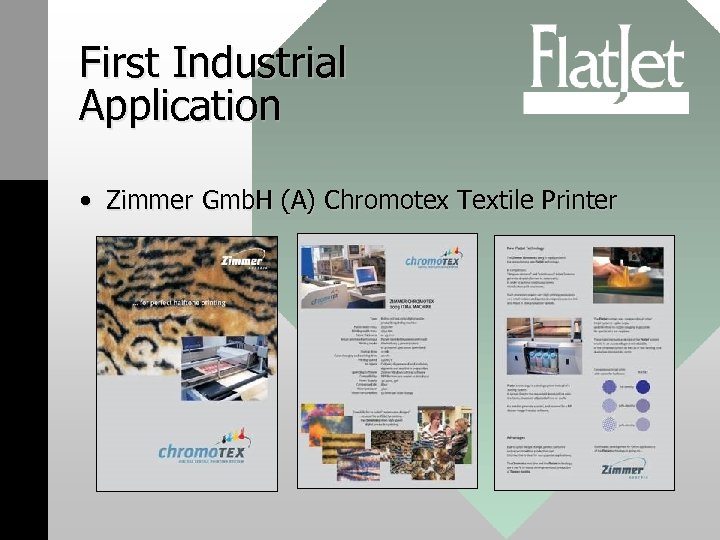

First Industrial Application • Zimmer Gmb. H (A) Chromotex Textile Printer

First Industrial Application • Zimmer Gmb. H (A) Chromotex Textile Printer

First Industrial Application • Zimmer Gmb. H (A) Chromotex Textile Printer

First Industrial Application • Zimmer Gmb. H (A) Chromotex Textile Printer

Patents EU)(DE)(GB)(FR)(AT)(IT)(BE)(NL)(ES)(CH)(CA)(AU)(JP)

Patents EU)(DE)(GB)(FR)(AT)(IT)(BE)(NL)(ES)(CH)(CA)(AU)(JP)

Hopes and Expectations • A NEW TECHNOLOGY CAN SUCCEED IF IT IS QUICKER OR BETTER OR CHEAPER • THE FLATJET CAN BE QUICKER & BETTER & CHEAPER

Hopes and Expectations • A NEW TECHNOLOGY CAN SUCCEED IF IT IS QUICKER OR BETTER OR CHEAPER • THE FLATJET CAN BE QUICKER & BETTER & CHEAPER

QUICKER • Possible 1 sq. meter per second printing speed • The printing width can be increased without limits

QUICKER • Possible 1 sq. meter per second printing speed • The printing width can be increased without limits

BETTER • High tone / color resolution (possibly 256 shade in a pixel) • High color saturation pigmented inks • Environmentally friendly water based inks • High tolerance in ink parameters (viscosity up to 15 m. Pas)

BETTER • High tone / color resolution (possibly 256 shade in a pixel) • High color saturation pigmented inks • Environmentally friendly water based inks • High tolerance in ink parameters (viscosity up to 15 m. Pas)

CHEAPER • Low cost media • Low cost inks • Low operating costs • Quick return of investment

CHEAPER • Low cost media • Low cost inks • Low operating costs • Quick return of investment