45af9c17d7ae0cec645b782eeaf7b40b.ppt

- Количество слайдов: 18

Flame brazing machinery (PP-tech, s. r. o. ) Mr. Pavel PROCHÁZKA – founder, owner and CEO of PP-tech, s. r. o. , Hutisko 761, CZ-756 62 Hutisko-Solanec, Czech Republic, www. pp-tech. eu

Foreword The paper introduces PP-tech, s. r. o. as a brazing machinery renowned supplier, outlines background to staff and an extensive knowledge and, of course, presents advanced methods of brazing process control and their recent refinements.

Contents 2 Foreword 3 Contents 4 PP-tech introduction 5 PP-tech in CZ/EU 6 Brazing facilities 8 Brazing machinery by PP-tech 9 Accessories to brazing machinery 10 Brazing machinery customised package philosophy 11 Flame brazing process specifics and demands 12 Flame brazing process control 13 „Intelligent“ wire feeder – fig. 14 CCD camera – fig. 15 New concept – comparison 16 Showcases 18 Conclusion

PP-tech - introduction PP-tech, s. r. o. was founded, acquired technical know-how (archive) and accommodated former technical staff of Themis/Thevia in June, 2009. Since then we at PP-tech, s. r. o. have delivered 60+ flame brazing machines of various designs, added to some 125 Themis’s machines we now service and maintain. www. pp-tech. eu

PP-tech in CZ/EU PP-tech, s. r. o. , Hutisko 761, CZ-756 62 Hutisko-Solanec, Czech Rep.

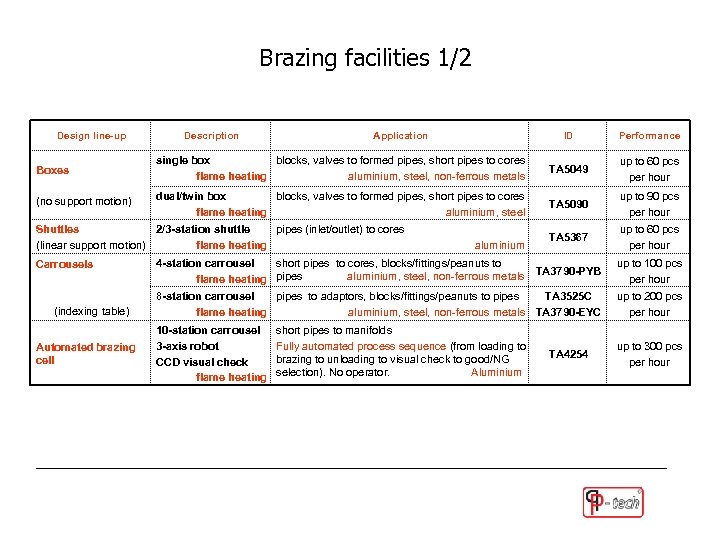

Brazing facilities 1/2 Design line-up Description Application ID Performance Boxes single box blocks, valves to formed pipes, short pipes to cores flame heating aluminium, steel, non-ferrous metals TA 5049 up to 60 pcs per hour (no support motion) dual/twin box blocks, valves to formed pipes, short pipes to cores flame heating aluminium, steel TA 5090 up to 90 pcs per hour TA 5367 up to 60 pcs per hour Shuttles 2/3 -station shuttle pipes (inlet/outlet) to cores (linear support motion) flame heating Carrousels (indexing table) Automated brazing cell aluminium 4 -station carrousel short pipes to cores, blocks/fittings/peanuts to aluminium, steel, non-ferrous metals TA 3790 -PYB flame heating pipes up to 100 pcs per hour 8 -station carrousel pipes to adaptors, blocks/fittings/peanuts to pipes TA 3525 C flame heating aluminium, steel, non-ferrous metals TA 3790 -EYC up to 200 pcs per hour 10 -station carrousel 3 -axis robot CCD visual check flame heating up to 300 pcs per hour short pipes to manifolds Fully automated process sequence (from loading to brazing to unloading to visual check to good/NG selection). No operator. Aluminium TA 4254

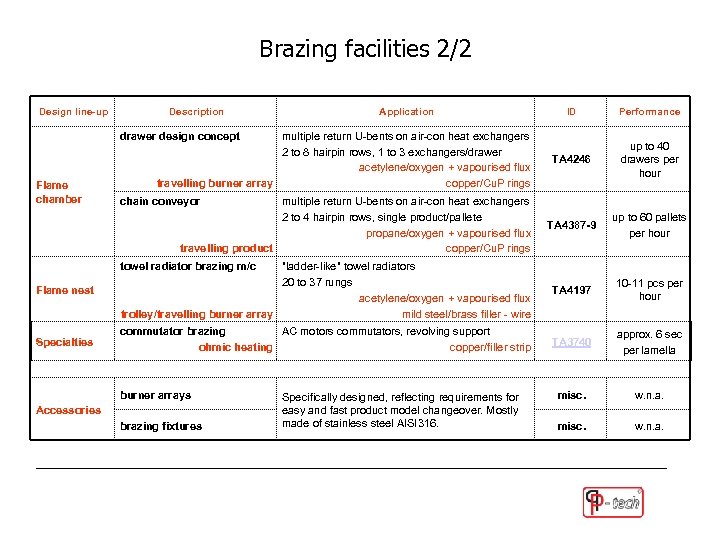

Brazing facilities 2/2 Design line-up Description Application ID Performance TA 4246 up to 40 drawers per hour TA 4387 -9 up to 60 pallets per hour Flame nest "ladder-like" towel radiators 20 to 37 rungs acetylene/oxygen + vapourised flux trolley/travelling burner array mild steel/brass filler - wire TA 4197 10 -11 pcs per hour Specialties commutator brazing AC motors commutators, revolving support ohmic heating copper/filler strip TA 3740 approx. 6 sec per lamella misc. w. n. a. drawer design concept Flame chamber multiple return U-bents on air-con heat exchangers 2 to 8 hairpin rows, 1 to 3 exchangers/drawer acetylene/oxygen + vapourised flux travelling burner array copper/Cu. P rings chain conveyor multiple return U-bents on air-con heat exchangers 2 to 4 hairpin rows, single product/pallete propane/oxygen + vapourised flux travelling product copper/Cu. P rings towel radiator brazing m/c burner arrays Accessories brazing fixtures Specifically designed, reflecting requirements for easy and fast product model changeover. Mostly made of stainless steel AISI 316.

Brazing machinery by PP-tech

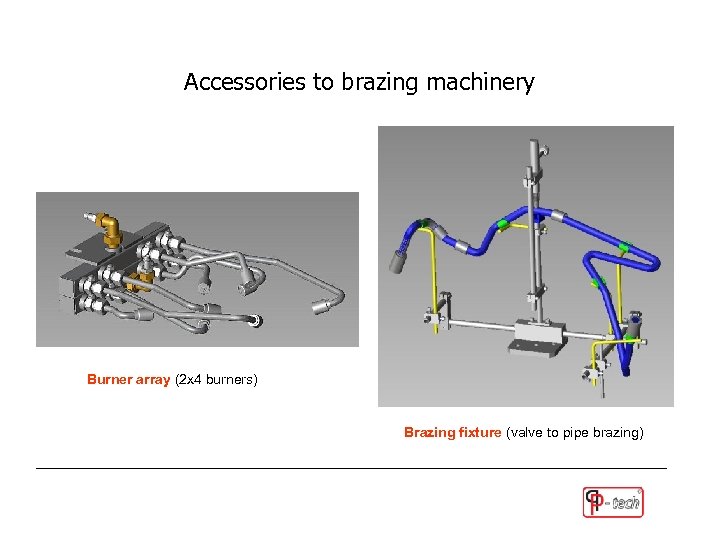

Accessories to brazing machinery Burner array (2 x 4 burners) Brazing fixture (valve to pipe brazing)

Brazing machinery customised package philosophy Client‘s requirements (as to the process features, characteristics, specifications, particularities and limitations) are always carefully consulted, evaluated and followed throughout all design stages (i. e. from conceptual sketches through 3 D modelling to manufacturing drawings), thus resulting in a unique, customised machine, nonetheless typically built upon our „standard-modularized“ line-up of boxes and carrousels. We always aim to deliver a turn-key package to our Clients, i. e. customised machine with fitted accessory and functional process settings (set and verified during brazing trials preceeding a machine overhaul).

Flame brazing process specifics and demands Flame brazing alternates and/or substitutes brazing in furnaces when: • Brazed parts are of complicated shape (e. g. heat exchangers and pipe manifolds for car air-con systems) • Easy and fast job-change is needed • Small-lot production is being run (batches not justifiable for costly CABs) But, due its principle of localised (spot) flame heating, it faces following challenges: • Changing environment around the machine (temperature, humidity, air draught) • Gas quality (calorific capacity) fluctuations • Human (error) factor Better process stability and costs/yield ratio of flame brazing can be achieved by: • Higher level of brazing process control • Reduction of human error

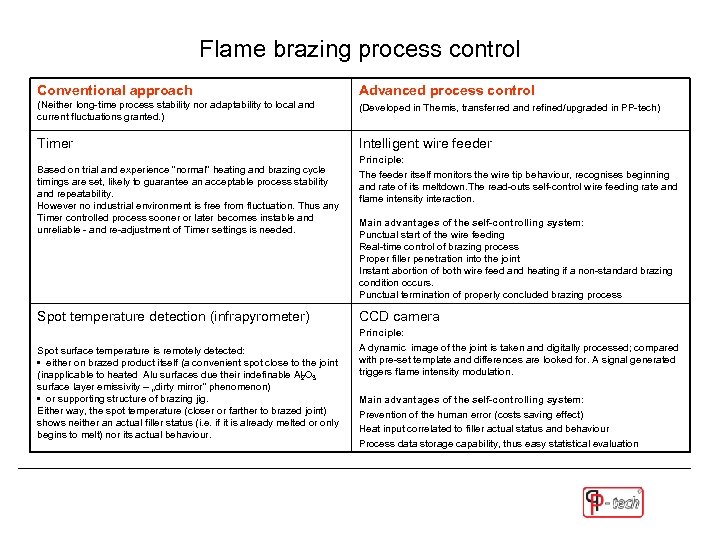

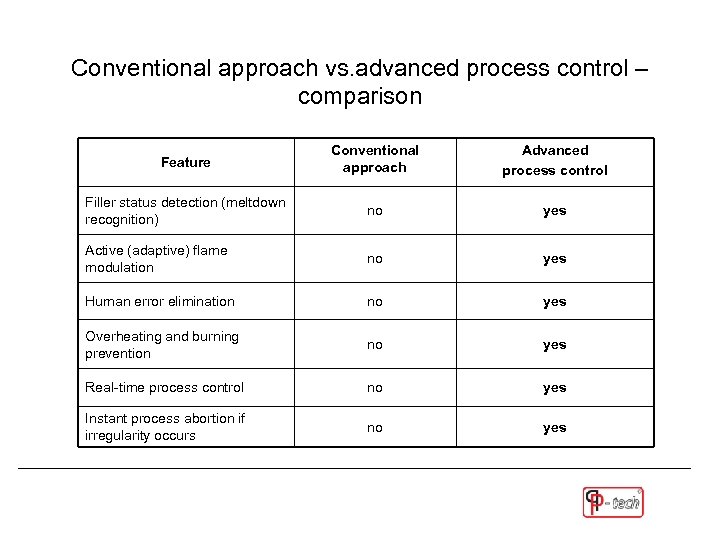

Flame brazing process control Conventional approach Advanced process control (Neither long-time process stability nor adaptability to local and current fluctuations granted. ) (Developed in Themis, transferred and refined/upgraded in PP-tech) Timer Intelligent wire feeder Based on trial and experience "normal" heating and brazing cycle timings are set, likely to guarantee an acceptable process stability and repeatability. However no industrial environment is free from fluctuation. Thus any Timer controlled process sooner or later becomes instable and unreliable - and re-adjustment of Timer settings is needed. Spot temperature detection (infrapyrometer) Spot surface temperature is remotely detected: • either on brazed product itself (a convenient spot close to the joint (inapplicable to heated Alu surfaces due their indefinable Al 2 O 3 surface layer emissivity – „dirty mirror“ phenomenon) • or supporting structure of brazing jig. Either way, the spot temperature (closer or farther to brazed joint) shows neither an actual filler status (i. e. if it is already melted or only begins to melt) nor its actual behaviour. Principle: The feeder itself monitors the wire tip behaviour, recognises beginning and rate of its meltdown. The read-outs self-control wire feeding rate and flame intensity interaction. Main advantages of the self-controlling system: Punctual start of the wire feeding Real-time control of brazing process Proper filler penetration into the joint Instant abortion of both wire feed and heating if a non-standard brazing condition occurs. Punctual termination of properly concluded brazing process CCD camera Principle: A dynamic image of the joint is taken and digitally processed; compared with pre-set template and differences are looked for. A signal generated triggers flame intensity modulation. Main advantages of the self-controlling system: Prevention of the human error (costs saving effect) Heat input correlated to filler actual status and behaviour Process data storage capability, thus easy statistical evaluation

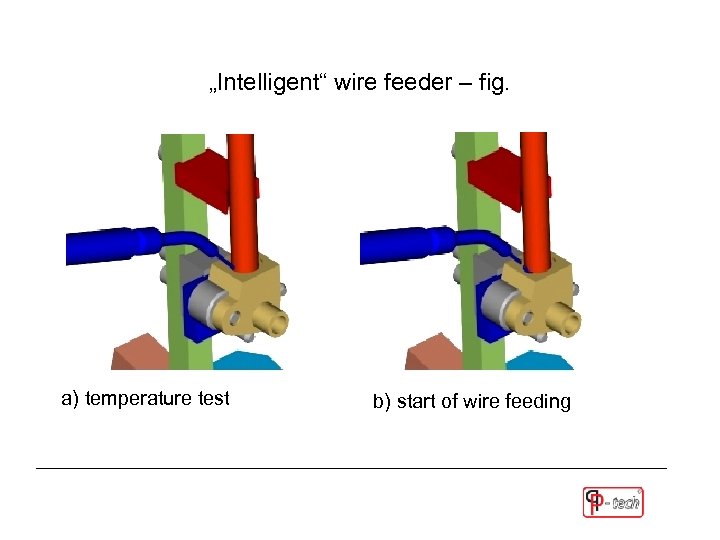

„Intelligent“ wire feeder – fig. a) temperature test b) start of wire feeding

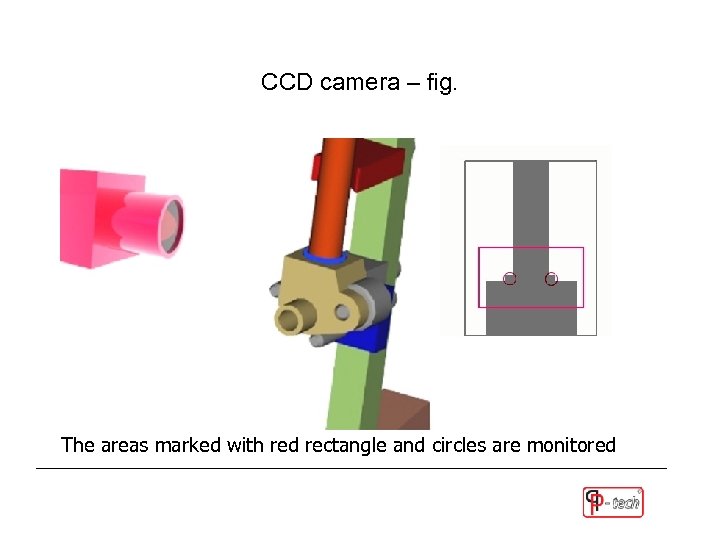

CCD camera – fig. The areas marked with red rectangle and circles are monitored

Conventional approach vs. advanced process control – comparison Feature Conventional approach Advanced process control Filler status detection (meltdown recognition) no yes Active (adaptive) flame modulation no yes Human error elimination no yes Overheating and burning prevention no yes Real-time process control no yes Instant process abortion if irregularity occurs no yes

Showcase – intelligent wire feeder

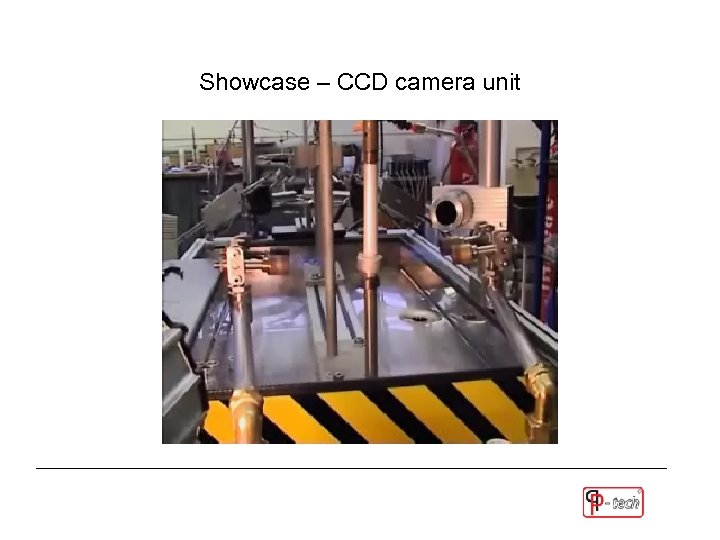

Showcase – CCD camera unit

Conclusion Seven years into my own business (nonethleless preceeded by a decade in the field under the flag of Themis) I dare to believe PP-tech, s. r. o. already established its position on the market. We not only simply go on with the machine designs inherited from Themis, surely we cultivate them, reflecting latest developments in legislation as well as design trends, nevertheless always bearing in mind the golden „KISS“ design principle. Both advanced methods of flame brazing process control mentioned have been proved in long-time industrial environment in brazing of Aluminum components of HVAC applications as well as domestic Air-conditioning units. At PP-tech, we turned the single-purpose custom made unique applications of CCD camera and Intelligent wire feeder into widely used versatile tools based on common industrialgrade systems such as Omron, Siemens, Allen Bradley etc.

45af9c17d7ae0cec645b782eeaf7b40b.ppt