cdcac06b988fc69e2c5424173facbae6.ppt

- Количество слайдов: 30

Five Technologies That Will Drive The Future Of Industrial Automation Sujeet Chand Sr. Vice President & Chief Technical Officer Kenwood Hall Vice President Architecture and Systems Copyright © 2005 Rockwell Automation, Inc. All rights reserved. 1

Five Technologies That Will Drive The Future Of Industrial Automation Sujeet Chand Sr. Vice President & Chief Technical Officer Kenwood Hall Vice President Architecture and Systems Copyright © 2005 Rockwell Automation, Inc. All rights reserved. 1

Outline • Manufacturing Trends • Technology and Architecture Trends • How Will Technology Trends Transform Industrial Automation? • Q&A Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 2

Outline • Manufacturing Trends • Technology and Architecture Trends • How Will Technology Trends Transform Industrial Automation? • Q&A Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 2

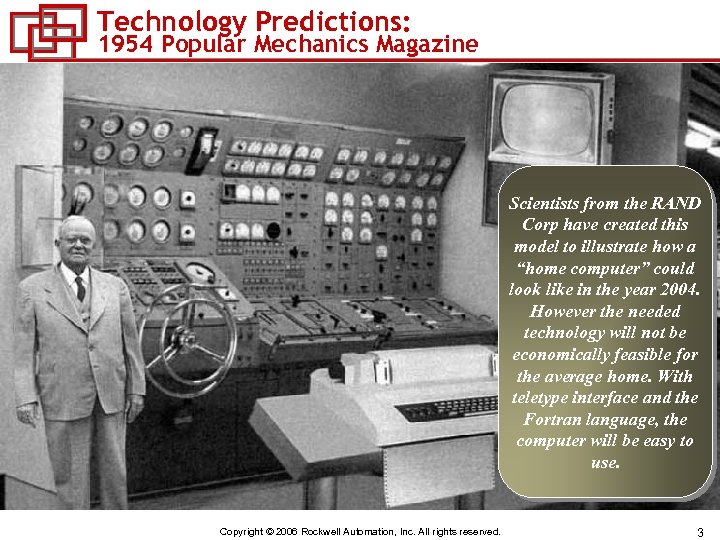

Technology Predictions: 1954 Popular Mechanics Magazine Scientists from the RAND Corp have created this model to illustrate how a “home computer” could look like in the year 2004. However the needed technology will not be economically feasible for the average home. With teletype interface and the Fortran language, the computer will be easy to use. Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 3

Technology Predictions: 1954 Popular Mechanics Magazine Scientists from the RAND Corp have created this model to illustrate how a “home computer” could look like in the year 2004. However the needed technology will not be economically feasible for the average home. With teletype interface and the Fortran language, the computer will be easy to use. Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 3

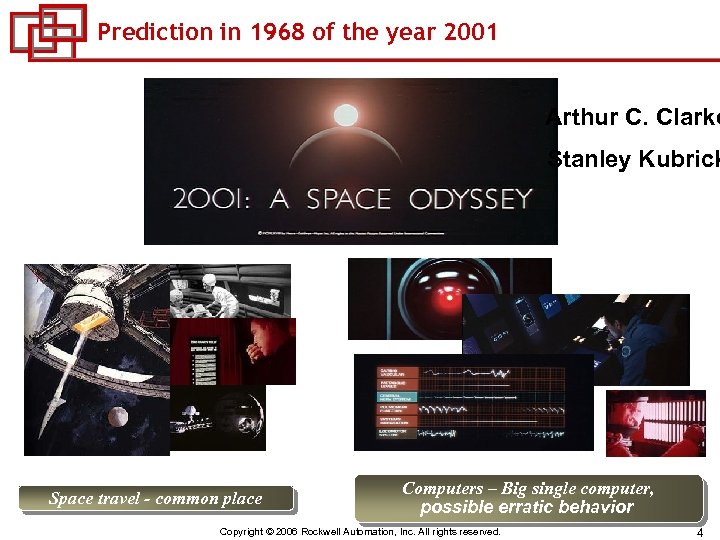

Prediction in 1968 of the year 2001 Arthur C. Clarke Stanley Kubrick Space travel - common place Computers – Big single computer, possible erratic behavior Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 4

Prediction in 1968 of the year 2001 Arthur C. Clarke Stanley Kubrick Space travel - common place Computers – Big single computer, possible erratic behavior Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 4

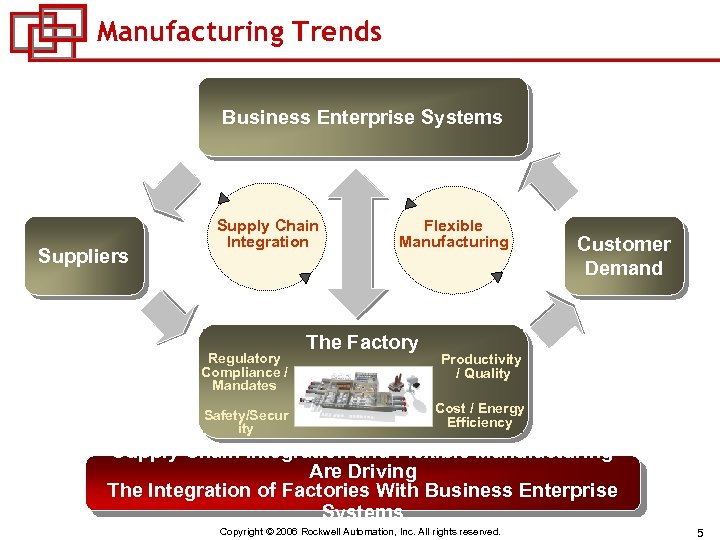

Manufacturing Trends Business Enterprise Systems Suppliers Supply Chain Integration Regulatory Compliance / Mandates Safety/Secur ity Flexible Manufacturing The Factory Customer Demand Productivity / Quality Cost / Energy Efficiency Supply Chain Integration and Flexible Manufacturing Are Driving The Integration of Factories With Business Enterprise Systems Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 5

Manufacturing Trends Business Enterprise Systems Suppliers Supply Chain Integration Regulatory Compliance / Mandates Safety/Secur ity Flexible Manufacturing The Factory Customer Demand Productivity / Quality Cost / Energy Efficiency Supply Chain Integration and Flexible Manufacturing Are Driving The Integration of Factories With Business Enterprise Systems Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 5

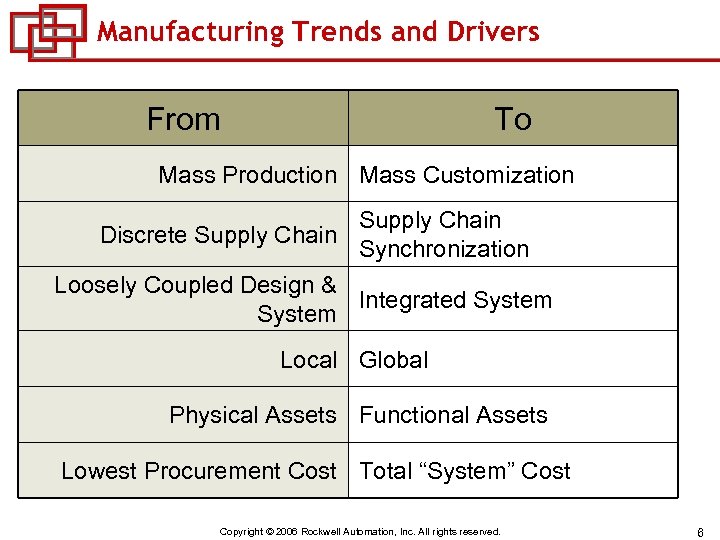

Manufacturing Trends and Drivers From To Mass Production Mass Customization Discrete Supply Chain Synchronization Loosely Coupled Design & Integrated System Local Global Physical Assets Functional Assets Lowest Procurement Cost Total “System” Cost Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 6

Manufacturing Trends and Drivers From To Mass Production Mass Customization Discrete Supply Chain Synchronization Loosely Coupled Design & Integrated System Local Global Physical Assets Functional Assets Lowest Procurement Cost Total “System” Cost Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 6

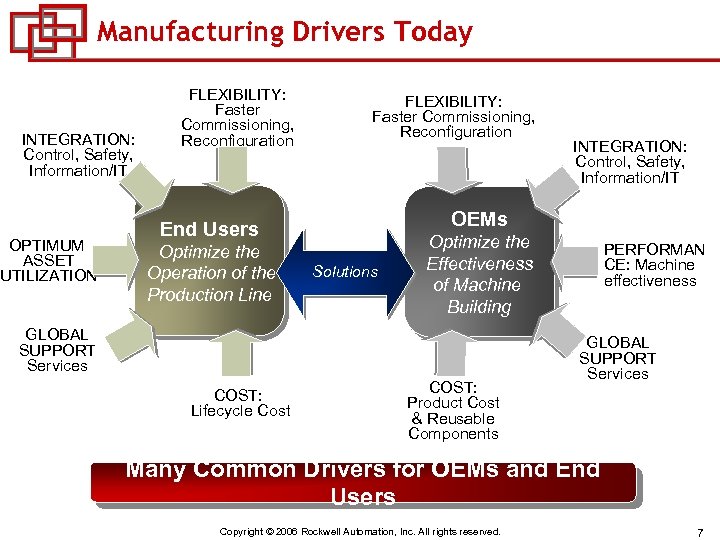

Manufacturing Drivers Today INTEGRATION: Control, Safety, Information/IT OPTIMUM ASSET UTILIZATION FLEXIBILITY: Faster Commissioning, Reconfiguration OEMs End Users Optimize the Operation of the Production Line Solutions Optimize the Effectiveness of Machine Building GLOBAL SUPPORT Services COST: Lifecycle Cost INTEGRATION: Control, Safety, Information/IT COST: Product Cost & Reusable Components PERFORMAN CE: Machine effectiveness GLOBAL SUPPORT Services Many Common Drivers for OEMs and End Users Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 7

Manufacturing Drivers Today INTEGRATION: Control, Safety, Information/IT OPTIMUM ASSET UTILIZATION FLEXIBILITY: Faster Commissioning, Reconfiguration OEMs End Users Optimize the Operation of the Production Line Solutions Optimize the Effectiveness of Machine Building GLOBAL SUPPORT Services COST: Lifecycle Cost INTEGRATION: Control, Safety, Information/IT COST: Product Cost & Reusable Components PERFORMAN CE: Machine effectiveness GLOBAL SUPPORT Services Many Common Drivers for OEMs and End Users Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 7

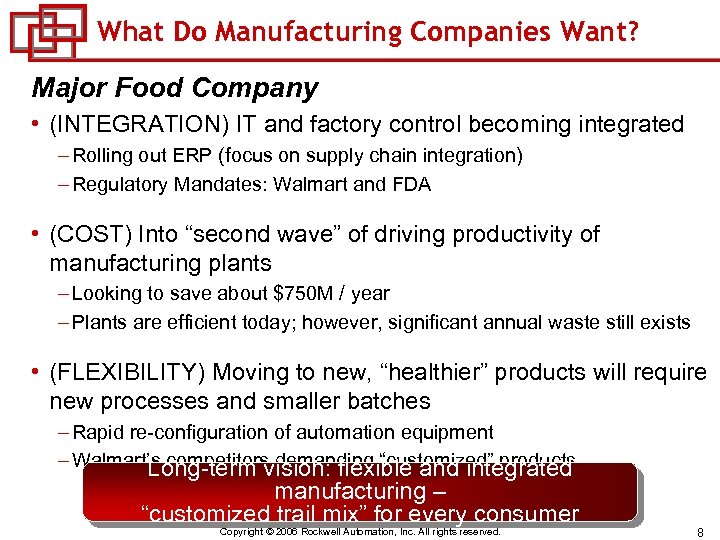

What Do Manufacturing Companies Want? Major Food Company • (INTEGRATION) IT and factory control becoming integrated – Rolling out ERP (focus on supply chain integration) – Regulatory Mandates: Walmart and FDA • (COST) Into “second wave” of driving productivity of manufacturing plants – Looking to save about $750 M / year – Plants are efficient today; however, significant annual waste still exists • (FLEXIBILITY) Moving to new, “healthier” products will require new processes and smaller batches – Rapid re-configuration of automation equipment – Walmart’s competitors demanding “customized” products Long-term vision: flexible and integrated manufacturing – “customized trail mix” for every consumer Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 8

What Do Manufacturing Companies Want? Major Food Company • (INTEGRATION) IT and factory control becoming integrated – Rolling out ERP (focus on supply chain integration) – Regulatory Mandates: Walmart and FDA • (COST) Into “second wave” of driving productivity of manufacturing plants – Looking to save about $750 M / year – Plants are efficient today; however, significant annual waste still exists • (FLEXIBILITY) Moving to new, “healthier” products will require new processes and smaller batches – Rapid re-configuration of automation equipment – Walmart’s competitors demanding “customized” products Long-term vision: flexible and integrated manufacturing – “customized trail mix” for every consumer Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 8

Outline • Manufacturing Megatrends Technology and Architecture Trends • Technology and Architecture Trends • How Will Technology Trends Transform Industrial Automation? • Q&A Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 9

Outline • Manufacturing Megatrends Technology and Architecture Trends • Technology and Architecture Trends • How Will Technology Trends Transform Industrial Automation? • Q&A Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 9

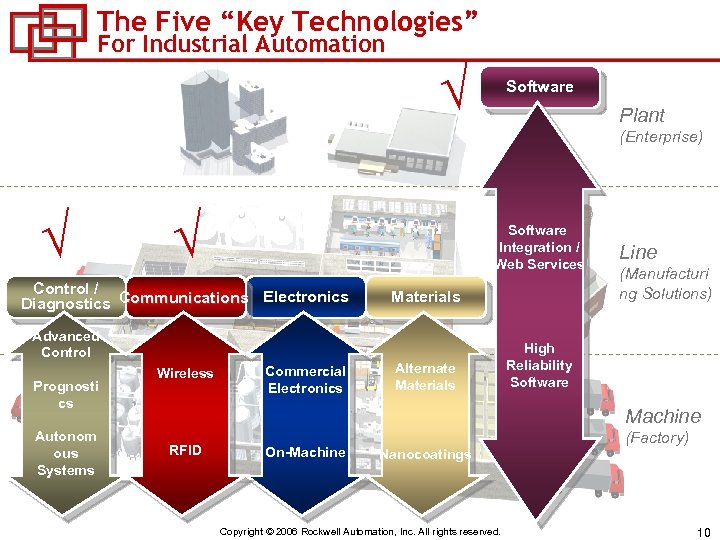

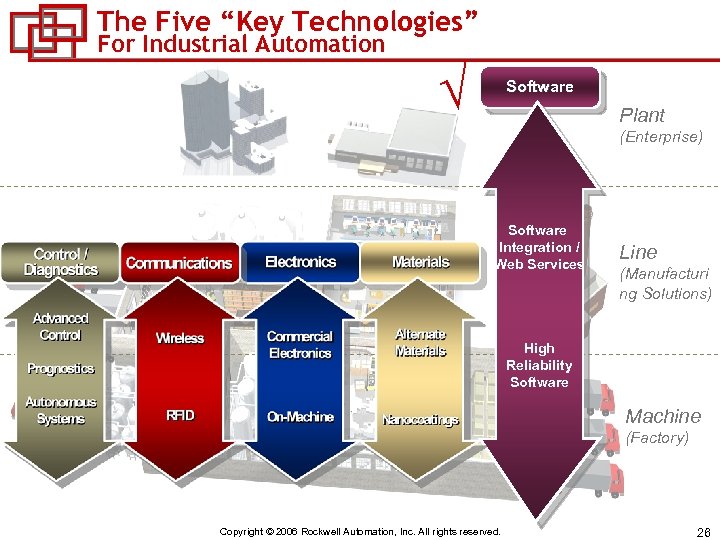

The Five “Key Technologies” For Industrial Automation √ Software Plant (Enterprise) √ √ Software Integration / Web Services Control / Diagnostics Communications Electronics Materials Advanced Control Prognosti cs Autonom ous Systems Wireless Commercial Electronics Alternate Materials Line (Manufacturi ng Solutions) High Reliability Software Machine RFID On-Machine (Factory) Nanocoatings Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 10

The Five “Key Technologies” For Industrial Automation √ Software Plant (Enterprise) √ √ Software Integration / Web Services Control / Diagnostics Communications Electronics Materials Advanced Control Prognosti cs Autonom ous Systems Wireless Commercial Electronics Alternate Materials Line (Manufacturi ng Solutions) High Reliability Software Machine RFID On-Machine (Factory) Nanocoatings Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 10

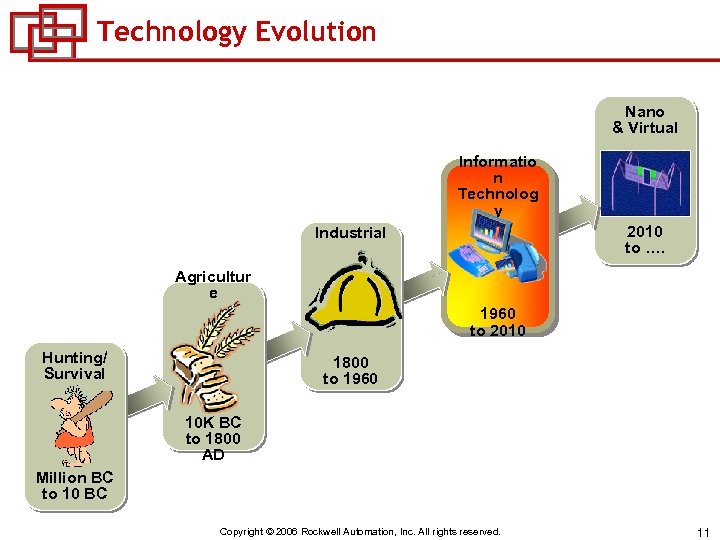

Technology Evolution Nano & Virtual Informatio n Technolog y 2010 to …. Industrial Agricultur e 1960 to 2010 Hunting/ Survival 1800 to 1960 10 K BC to 1800 AD Million BC to 10 BC Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 11

Technology Evolution Nano & Virtual Informatio n Technolog y 2010 to …. Industrial Agricultur e 1960 to 2010 Hunting/ Survival 1800 to 1960 10 K BC to 1800 AD Million BC to 10 BC Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 11

Trends Impacted By Information Technology Evolution • Integrated Control, Safety, Security, and Information – Information-Enabled Control Platforms with Integrated Safety and Security • Ethernet – Industrial Ethernet Becomes the Dominant Network • Adoption of World-Wide Web Software Standards – WWW Data Exchange and Software Integration Standards for Industrial Copyright Automation © 2006 Rockwell Automation, Inc. All rights reserved. 12

Trends Impacted By Information Technology Evolution • Integrated Control, Safety, Security, and Information – Information-Enabled Control Platforms with Integrated Safety and Security • Ethernet – Industrial Ethernet Becomes the Dominant Network • Adoption of World-Wide Web Software Standards – WWW Data Exchange and Software Integration Standards for Industrial Copyright Automation © 2006 Rockwell Automation, Inc. All rights reserved. 12

Outline • Manufacturing Megatrends • Technology and Architecture Trends Will Technology Trends Transform. Industrial • How Will Technology Trends Transform Industrial Automation? • Q&A Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 13

Outline • Manufacturing Megatrends • Technology and Architecture Trends Will Technology Trends Transform. Industrial • How Will Technology Trends Transform Industrial Automation? • Q&A Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 13

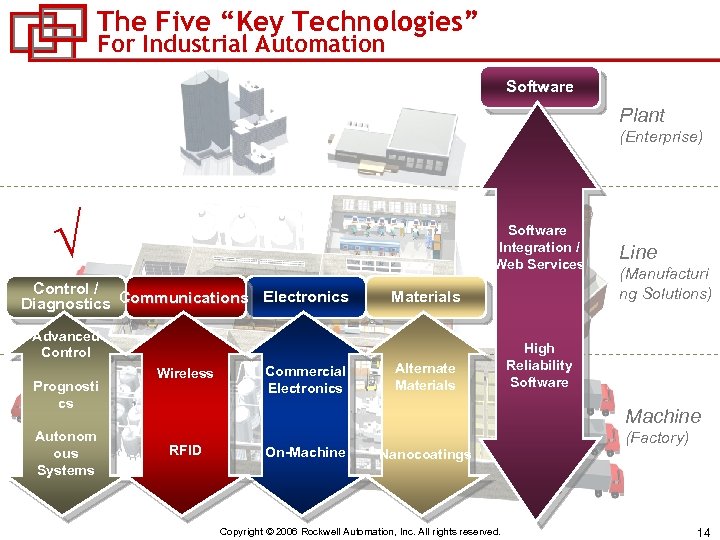

The Five “Key Technologies” For Industrial Automation Software Plant (Enterprise) √ Software Integration / Web Services Control / Diagnostics Communications Electronics Materials Advanced Control Prognosti cs Autonom ous Systems Wireless Commercial Electronics Alternate Materials Line (Manufacturi ng Solutions) High Reliability Software Machine RFID On-Machine (Factory) Nanocoatings Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 14

The Five “Key Technologies” For Industrial Automation Software Plant (Enterprise) √ Software Integration / Web Services Control / Diagnostics Communications Electronics Materials Advanced Control Prognosti cs Autonom ous Systems Wireless Commercial Electronics Alternate Materials Line (Manufacturi ng Solutions) High Reliability Software Machine RFID On-Machine (Factory) Nanocoatings Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 14

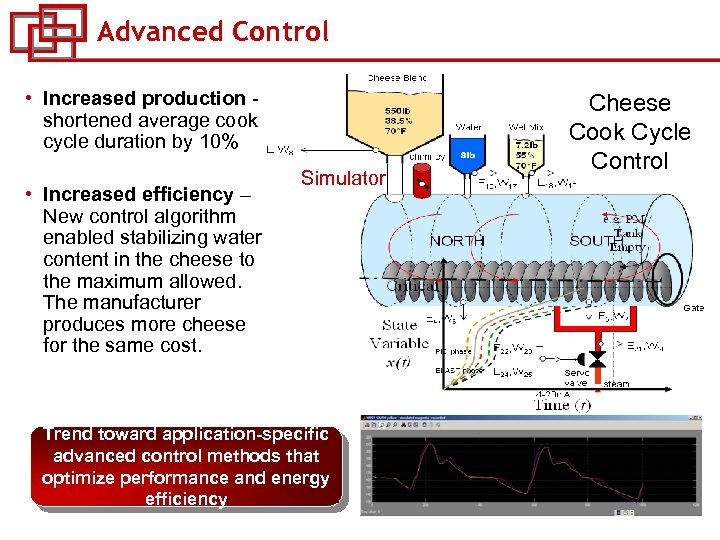

Advanced Control • Increased production shortened average cook cycle duration by 10% • Increased efficiency – New control algorithm enabled stabilizing water content in the cheese to the maximum allowed. The manufacturer produces more cheese for the same cost. Simulator Trend toward application-specific advanced control methods that optimize performance and energy efficiency Cheese Cook Cycle Control

Advanced Control • Increased production shortened average cook cycle duration by 10% • Increased efficiency – New control algorithm enabled stabilizing water content in the cheese to the maximum allowed. The manufacturer produces more cheese for the same cost. Simulator Trend toward application-specific advanced control methods that optimize performance and energy efficiency Cheese Cook Cycle Control

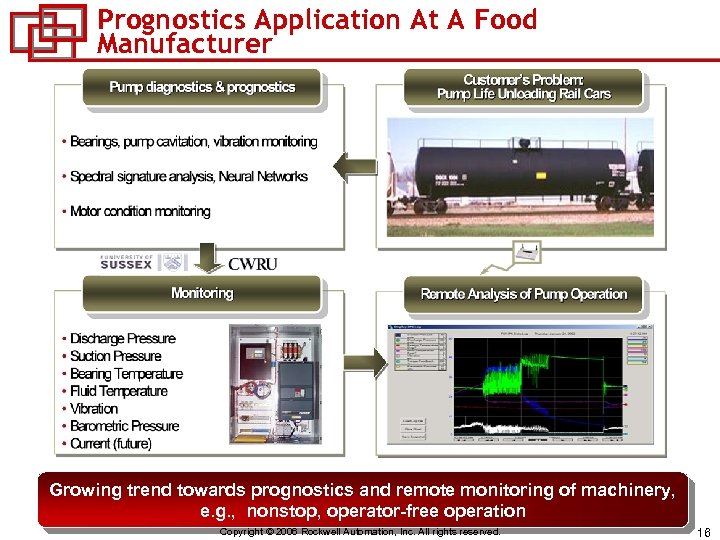

Prognostics Application At A Food Manufacturer Growing trend towards prognostics and remote monitoring of machinery, e. g. , nonstop, operator-free operation Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 16

Prognostics Application At A Food Manufacturer Growing trend towards prognostics and remote monitoring of machinery, e. g. , nonstop, operator-free operation Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 16

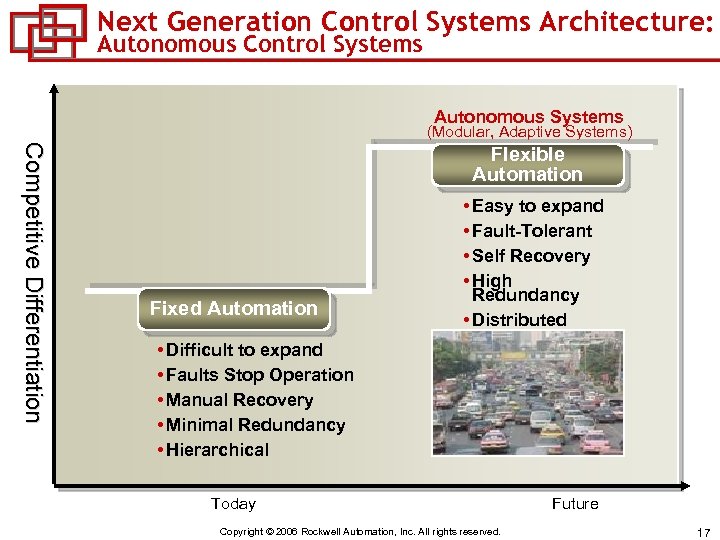

Next Generation Control Systems Architecture: Autonomous Control Systems Autonomous Systems (Modular, Adaptive Systems) Competitive Differentiation Flexible Automation Fixed Automation • Easy to expand • Fault-Tolerant • Self Recovery • High Redundancy • Distributed • Difficult to expand • Faults Stop Operation • Manual Recovery • Minimal Redundancy • Hierarchical Today Copyright © 2006 Rockwell Automation, Inc. All rights reserved. Future 17

Next Generation Control Systems Architecture: Autonomous Control Systems Autonomous Systems (Modular, Adaptive Systems) Competitive Differentiation Flexible Automation Fixed Automation • Easy to expand • Fault-Tolerant • Self Recovery • High Redundancy • Distributed • Difficult to expand • Faults Stop Operation • Manual Recovery • Minimal Redundancy • Hierarchical Today Copyright © 2006 Rockwell Automation, Inc. All rights reserved. Future 17

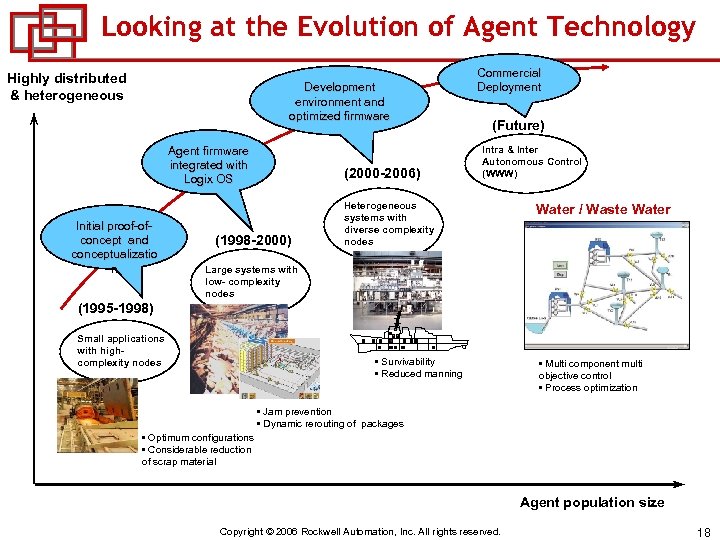

Looking at the Evolution of Agent Technology Highly distributed & heterogeneous Development environment and optimized firmware Agent firmware integrated with Logix OS Initial proof-ofconcept and conceptualizatio n (2000 -2006) (1998 -2000) Commercial Deployment (Future) Intra & Inter Autonomous Control (WWW) Heterogeneous systems with diverse complexity nodes Water / Waste Water Large systems with low- complexity nodes (1995 -1998) Small applications with highcomplexity nodes • Survivability • Reduced manning • Multi component multi objective control • Process optimization • Jam prevention • Dynamic rerouting of packages • Optimum configurations • Considerable reduction of scrap material Agent population size Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 18

Looking at the Evolution of Agent Technology Highly distributed & heterogeneous Development environment and optimized firmware Agent firmware integrated with Logix OS Initial proof-ofconcept and conceptualizatio n (2000 -2006) (1998 -2000) Commercial Deployment (Future) Intra & Inter Autonomous Control (WWW) Heterogeneous systems with diverse complexity nodes Water / Waste Water Large systems with low- complexity nodes (1995 -1998) Small applications with highcomplexity nodes • Survivability • Reduced manning • Multi component multi objective control • Process optimization • Jam prevention • Dynamic rerouting of packages • Optimum configurations • Considerable reduction of scrap material Agent population size Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 18

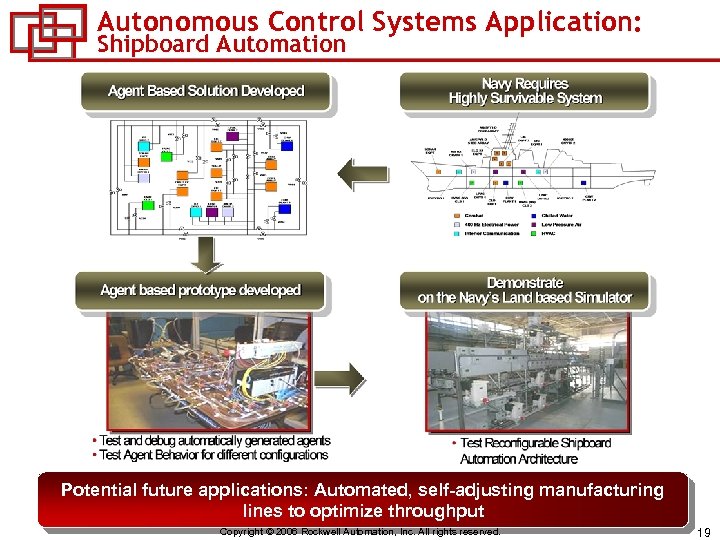

Autonomous Control Systems Application: Shipboard Automation Potential future applications: Automated, self-adjusting manufacturing lines to optimize throughput Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 19

Autonomous Control Systems Application: Shipboard Automation Potential future applications: Automated, self-adjusting manufacturing lines to optimize throughput Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 19

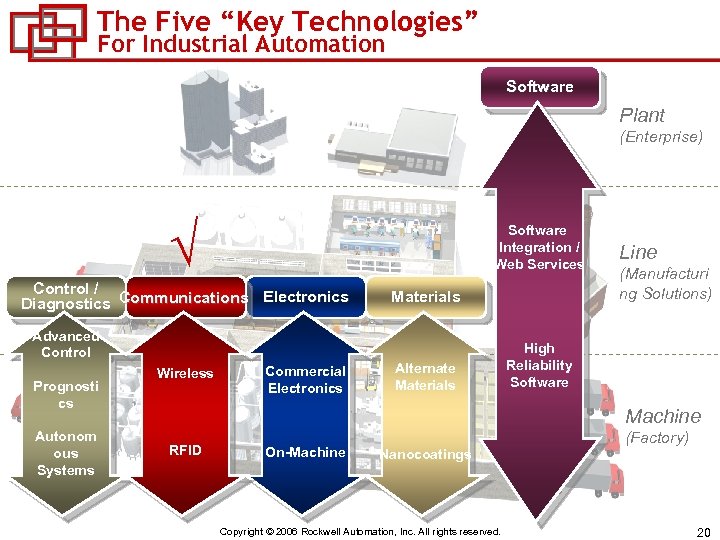

The Five “Key Technologies” For Industrial Automation Software Plant (Enterprise) √ Software Integration / Web Services Control / Diagnostics Communications Electronics Materials Advanced Control Prognosti cs Autonom ous Systems Wireless Commercial Electronics Alternate Materials Line (Manufacturi ng Solutions) High Reliability Software Machine RFID On-Machine (Factory) Nanocoatings Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 20

The Five “Key Technologies” For Industrial Automation Software Plant (Enterprise) √ Software Integration / Web Services Control / Diagnostics Communications Electronics Materials Advanced Control Prognosti cs Autonom ous Systems Wireless Commercial Electronics Alternate Materials Line (Manufacturi ng Solutions) High Reliability Software Machine RFID On-Machine (Factory) Nanocoatings Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 20

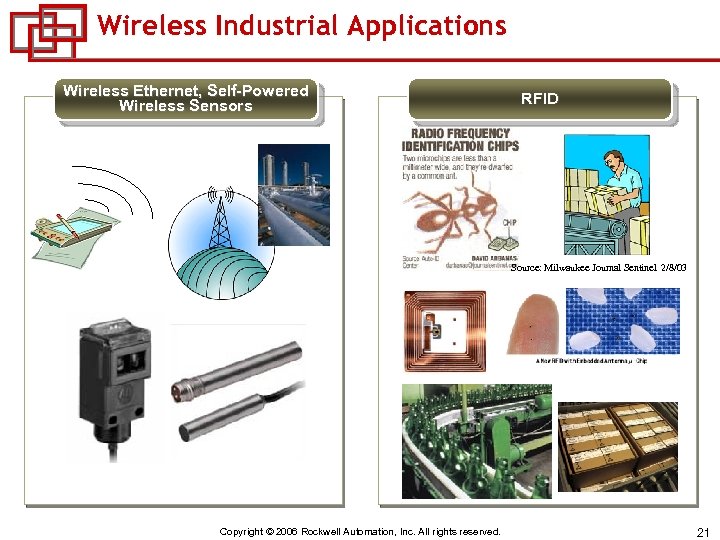

Wireless Industrial Applications Wireless Ethernet, Self-Powered Wireless Sensors RFID Source: Milwaukee Journal Sentinel 2/8/03 Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 21

Wireless Industrial Applications Wireless Ethernet, Self-Powered Wireless Sensors RFID Source: Milwaukee Journal Sentinel 2/8/03 Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 21

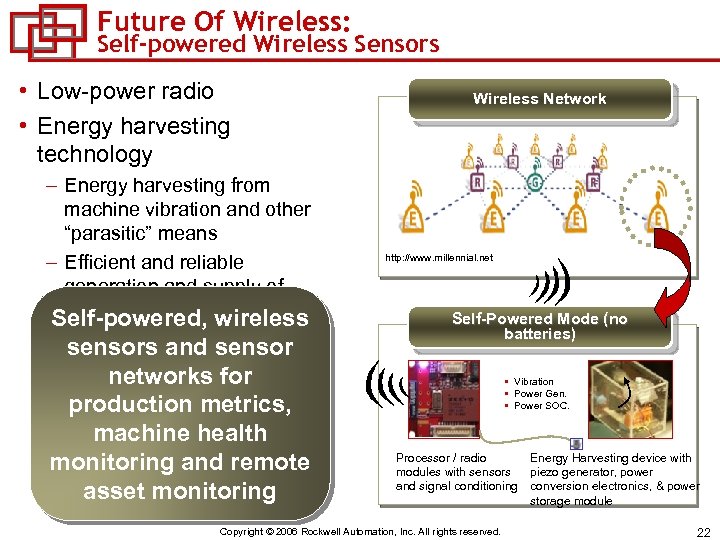

Future Of Wireless: Self-powered Wireless Sensors • Low-power radio • Energy harvesting technology – Energy harvesting from machine vibration and other “parasitic” means – Efficient and reliable generation and supply of energy to power wireless Self-powered, nodes sensors and sensor networks for production metrics, machine health monitoring and remote asset monitoring Wireless Network http: //www. millennial. net Self-Powered Mode (no batteries) • Vibration • Power Gen. • Power SOC. Processor / radio modules with sensors and signal conditioning Copyright © 2006 Rockwell Automation, Inc. All rights reserved. Energy Harvesting device with piezo generator, power conversion electronics, & power storage module 22

Future Of Wireless: Self-powered Wireless Sensors • Low-power radio • Energy harvesting technology – Energy harvesting from machine vibration and other “parasitic” means – Efficient and reliable generation and supply of energy to power wireless Self-powered, nodes sensors and sensor networks for production metrics, machine health monitoring and remote asset monitoring Wireless Network http: //www. millennial. net Self-Powered Mode (no batteries) • Vibration • Power Gen. • Power SOC. Processor / radio modules with sensors and signal conditioning Copyright © 2006 Rockwell Automation, Inc. All rights reserved. Energy Harvesting device with piezo generator, power conversion electronics, & power storage module 22

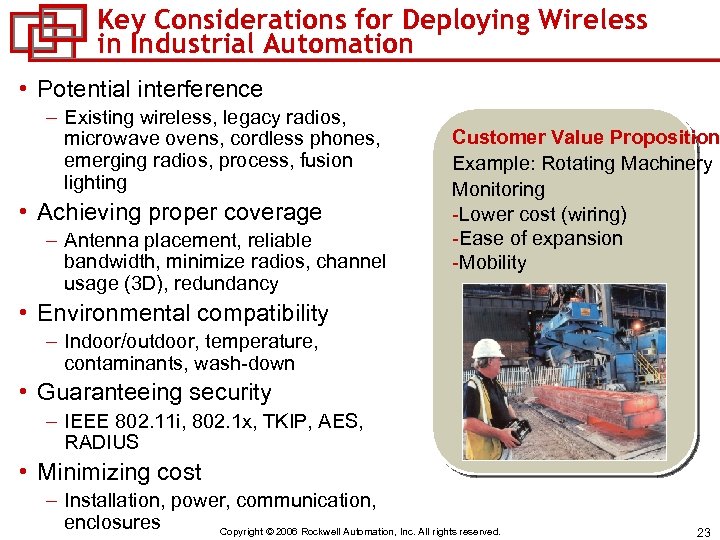

Key Considerations for Deploying Wireless in Industrial Automation • Potential interference – Existing wireless, legacy radios, microwave ovens, cordless phones, emerging radios, process, fusion lighting • Achieving proper coverage – Antenna placement, reliable bandwidth, minimize radios, channel usage (3 D), redundancy Customer Value Proposition Example: Rotating Machinery Monitoring -Lower cost (wiring) -Ease of expansion -Mobility • Environmental compatibility – Indoor/outdoor, temperature, contaminants, wash-down • Guaranteeing security – IEEE 802. 11 i, 802. 1 x, TKIP, AES, RADIUS • Minimizing cost – Installation, power, communication, enclosures Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 23

Key Considerations for Deploying Wireless in Industrial Automation • Potential interference – Existing wireless, legacy radios, microwave ovens, cordless phones, emerging radios, process, fusion lighting • Achieving proper coverage – Antenna placement, reliable bandwidth, minimize radios, channel usage (3 D), redundancy Customer Value Proposition Example: Rotating Machinery Monitoring -Lower cost (wiring) -Ease of expansion -Mobility • Environmental compatibility – Indoor/outdoor, temperature, contaminants, wash-down • Guaranteeing security – IEEE 802. 11 i, 802. 1 x, TKIP, AES, RADIUS • Minimizing cost – Installation, power, communication, enclosures Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 23

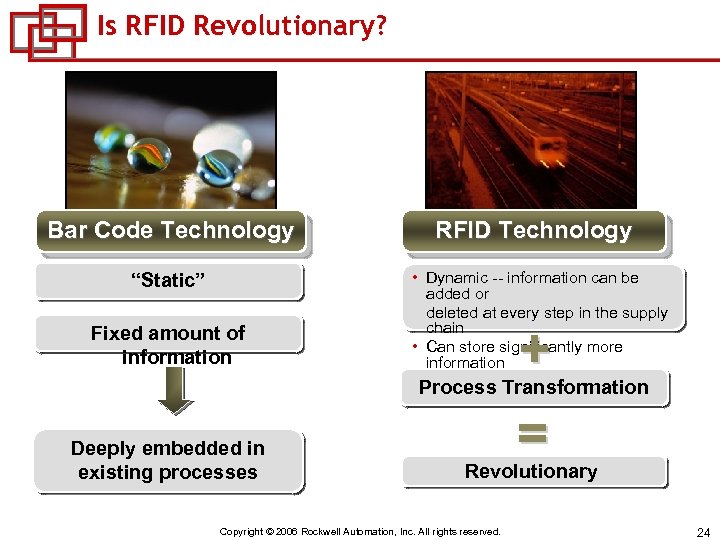

Is RFID Revolutionary? Bar Code Technology “Static” Fixed amount of information RFID Technology • Dynamic -- information can be added or deleted at every step in the supply chain • Can store significantly more information + Process Transformation Deeply embedded in existing processes = Revolutionary Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 24

Is RFID Revolutionary? Bar Code Technology “Static” Fixed amount of information RFID Technology • Dynamic -- information can be added or deleted at every step in the supply chain • Can store significantly more information + Process Transformation Deeply embedded in existing processes = Revolutionary Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 24

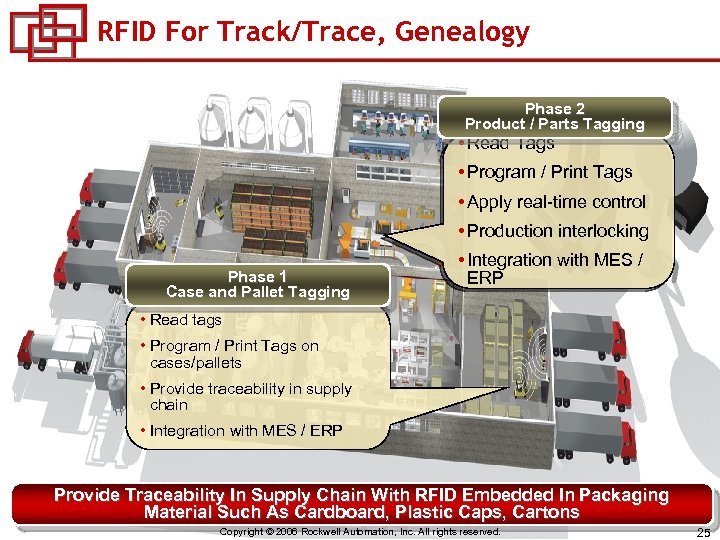

RFID For Track/Trace, Genealogy Phase 2 Product / Parts Tagging • Read Tags • Program / Print Tags • Apply real-time control • Production interlocking Phase 1 Case and Pallet Tagging • Integration with MES / ERP • Read tags • Program / Print Tags on cases/pallets • Provide traceability in supply chain • Integration with MES / ERP Provide Traceability In Supply Chain With RFID Embedded In Packaging Material Such As Cardboard, Plastic Caps, Cartons Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 25

RFID For Track/Trace, Genealogy Phase 2 Product / Parts Tagging • Read Tags • Program / Print Tags • Apply real-time control • Production interlocking Phase 1 Case and Pallet Tagging • Integration with MES / ERP • Read tags • Program / Print Tags on cases/pallets • Provide traceability in supply chain • Integration with MES / ERP Provide Traceability In Supply Chain With RFID Embedded In Packaging Material Such As Cardboard, Plastic Caps, Cartons Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 25

The Five “Key Technologies” For Industrial Automation √ Software Plant (Enterprise) Software Integration / Web Services Line (Manufacturi ng Solutions) High Reliability Software Machine (Factory) Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 26

The Five “Key Technologies” For Industrial Automation √ Software Plant (Enterprise) Software Integration / Web Services Line (Manufacturi ng Solutions) High Reliability Software Machine (Factory) Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 26

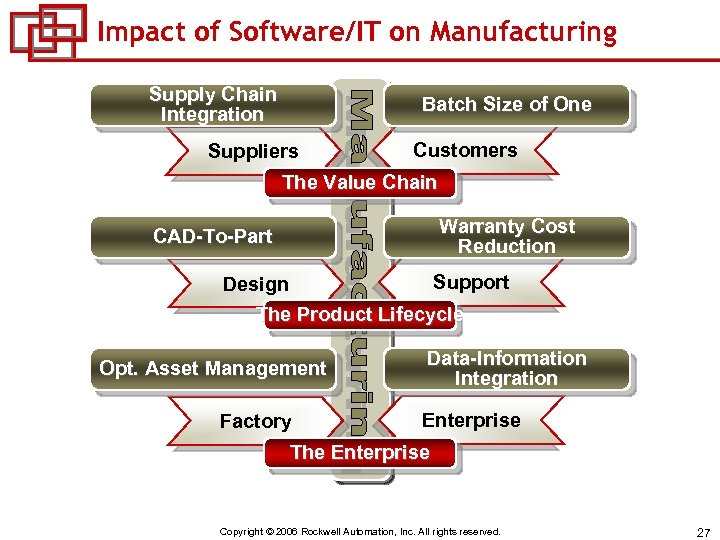

Impact of Software/IT on Manufacturing Supply Chain Integration Batch Size of One Suppliers Customers The Value Chain Warranty Cost Reduction CAD-To-Part Support Design The Product Lifecycle Opt. Asset Management Factory Data-Information Integration Enterprise The Enterprise Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 27

Impact of Software/IT on Manufacturing Supply Chain Integration Batch Size of One Suppliers Customers The Value Chain Warranty Cost Reduction CAD-To-Part Support Design The Product Lifecycle Opt. Asset Management Factory Data-Information Integration Enterprise The Enterprise Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 27

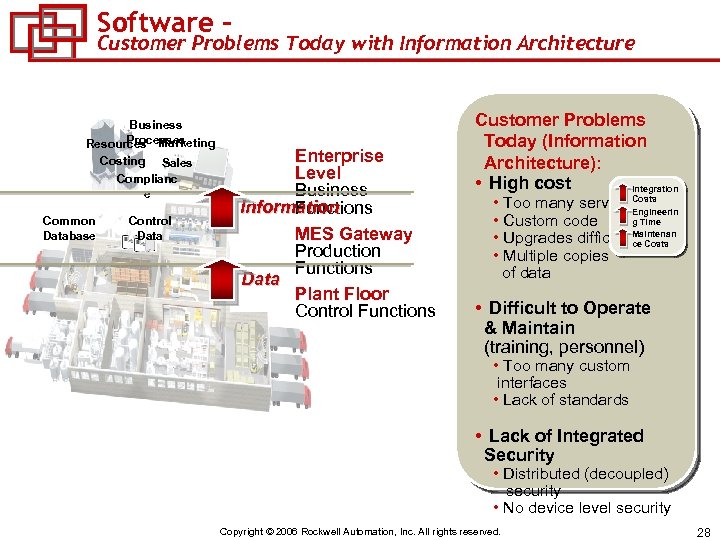

Software – Customer Problems Today with Information Architecture Business Processes Resources Marketing Costing Sales Complianc e Common Database Control Data Enterprise Level Business Information Functions MES Gateway Production Functions Data Plant Floor Control Functions Customer Problems Today (Information Architecture): • High cost Integration • Too many servers. Costs Engineerin g Time • Custom code • Upgrades difficult Maintenan ce Costs • Multiple copies of data • Difficult to Operate & Maintain (training, personnel) • Too many custom interfaces • Lack of standards • Lack of Integrated Security • Distributed (decoupled) security • No device level security Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 28

Software – Customer Problems Today with Information Architecture Business Processes Resources Marketing Costing Sales Complianc e Common Database Control Data Enterprise Level Business Information Functions MES Gateway Production Functions Data Plant Floor Control Functions Customer Problems Today (Information Architecture): • High cost Integration • Too many servers. Costs Engineerin g Time • Custom code • Upgrades difficult Maintenan ce Costs • Multiple copies of data • Difficult to Operate & Maintain (training, personnel) • Too many custom interfaces • Lack of standards • Lack of Integrated Security • Distributed (decoupled) security • No device level security Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 28

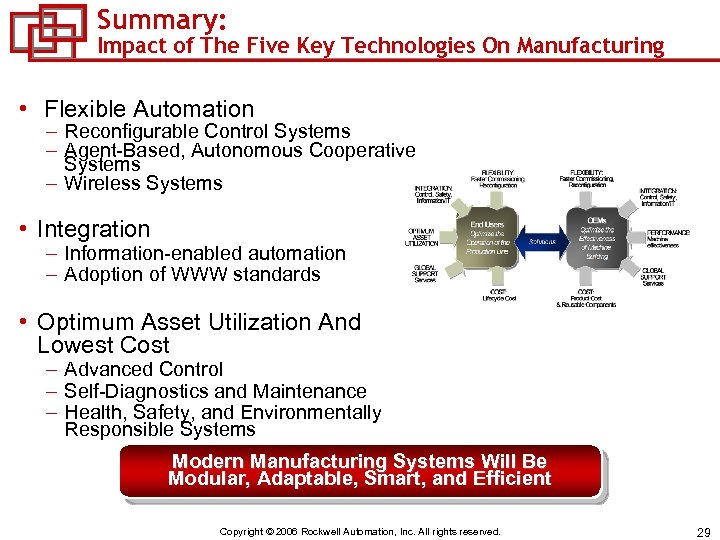

Summary: Impact of The Five Key Technologies On Manufacturing • Flexible Automation – Reconfigurable Control Systems – Agent-Based, Autonomous Cooperative Systems – Wireless Systems • Integration – Information-enabled automation – Adoption of WWW standards • Optimum Asset Utilization And Lowest Cost – Advanced Control – Self-Diagnostics and Maintenance – Health, Safety, and Environmentally Responsible Systems Modern Manufacturing Systems Will Be Modular, Adaptable, Smart, and Efficient Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 29

Summary: Impact of The Five Key Technologies On Manufacturing • Flexible Automation – Reconfigurable Control Systems – Agent-Based, Autonomous Cooperative Systems – Wireless Systems • Integration – Information-enabled automation – Adoption of WWW standards • Optimum Asset Utilization And Lowest Cost – Advanced Control – Self-Diagnostics and Maintenance – Health, Safety, and Environmentally Responsible Systems Modern Manufacturing Systems Will Be Modular, Adaptable, Smart, and Efficient Copyright © 2006 Rockwell Automation, Inc. All rights reserved. 29

Five Technologies That Will Drive The Future Of Industrial Automation Questions Sujeet Chand Sr. Vice President & Chief Technical Officer Kenwood Hall Vice President Architecture and Systems Copyright © 2005 Rockwell Automation, Inc. All rights reserved. 30

Five Technologies That Will Drive The Future Of Industrial Automation Questions Sujeet Chand Sr. Vice President & Chief Technical Officer Kenwood Hall Vice President Architecture and Systems Copyright © 2005 Rockwell Automation, Inc. All rights reserved. 30