c821637d50db6126d2e5c9d07021927b.ppt

- Количество слайдов: 71

FIRES IN THE OIL & GAS INDUSTRY CASE STUDY – THE PETROTRIN OIL REFINERY by Dr. Victor Coombs Chief Medical Officer, Petrotrin Consultant Occupational & Environmental Health

FIRES IN THE OIL & GAS INDUSTRY CASE STUDY – THE PETROTRIN OIL REFINERY by Dr. Victor Coombs Chief Medical Officer, Petrotrin Consultant Occupational & Environmental Health

Greatest Fire in History 1991 During the Gulf War 640 -odd wells ignited in Kuwait. Fires raged for more than eight months, consumed 2 billion barrels of oil and cost Kuwait $100 billion. . Oil wells, refineries, pipelines and harbours were destroyed. Economist 11/9/91; Vol 321 Issue 7732; p 84.

Greatest Fire in History 1991 During the Gulf War 640 -odd wells ignited in Kuwait. Fires raged for more than eight months, consumed 2 billion barrels of oil and cost Kuwait $100 billion. . Oil wells, refineries, pipelines and harbours were destroyed. Economist 11/9/91; Vol 321 Issue 7732; p 84.

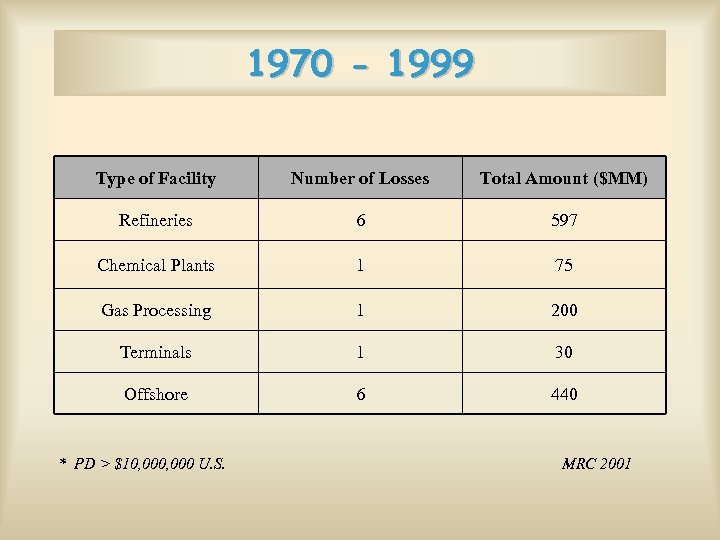

1970 - 1999 Type of Facility Number of Losses Total Amount ($MM) Refineries 6 597 Chemical Plants 1 75 Gas Processing 1 200 Terminals 1 30 Offshore 6 440 * PD > $10, 000 U. S. MRC 2001

1970 - 1999 Type of Facility Number of Losses Total Amount ($MM) Refineries 6 597 Chemical Plants 1 75 Gas Processing 1 200 Terminals 1 30 Offshore 6 440 * PD > $10, 000 U. S. MRC 2001

Oil Refinery Bombing/Fire • • Oil products releases Pollutants released Groundwater pollution Soil pollution Chemical Emission Injuries Death

Oil Refinery Bombing/Fire • • Oil products releases Pollutants released Groundwater pollution Soil pollution Chemical Emission Injuries Death

Industrial Disasters • Fire • Explosion • Toxic Release

Industrial Disasters • Fire • Explosion • Toxic Release

Piper Alpha Disaster • North Sea 88. 07. 06. 165 fatalities from 226 on board • Death toll highest in oil an gas offshore operations • 109 died from smoke inhalation and fire, 14 died while escaping. Few died from actual burns.

Piper Alpha Disaster • North Sea 88. 07. 06. 165 fatalities from 226 on board • Death toll highest in oil an gas offshore operations • 109 died from smoke inhalation and fire, 14 died while escaping. Few died from actual burns.

FCCU FIRE/EXPLOSION 91. 06. 05 Equipment Damaged/Destroyed • • • The slurry settler (completely destroyed) Slurry Pumps Steam blowdown drum Steam Superheater exchanger Piping

FCCU FIRE/EXPLOSION 91. 06. 05 Equipment Damaged/Destroyed • • • The slurry settler (completely destroyed) Slurry Pumps Steam blowdown drum Steam Superheater exchanger Piping

FCCU FIRE/EXPLOSION 91. 06. 05 Equipment Damaged/Destroyed (cont’d) • • Structures Instrumentation Buildings Electrical equipment

FCCU FIRE/EXPLOSION 91. 06. 05 Equipment Damaged/Destroyed (cont’d) • • Structures Instrumentation Buildings Electrical equipment

Documents Requested by Insurers • Preliminary report by Accident Investigation Team • Medical Report and Injury List • Interviews • Photographs • Measurements and Weights of fragments • Engineering Report • Engineering data on by-pass valve around slurry settler

Documents Requested by Insurers • Preliminary report by Accident Investigation Team • Medical Report and Injury List • Interviews • Photographs • Measurements and Weights of fragments • Engineering Report • Engineering data on by-pass valve around slurry settler

Preliminary Report I • An explosion and fire occurred at the FCCU at 2. 53 am on Wednesday June 05, 1991. The fire was brought under control by Company Fire Services, TT Fire Services and TT Methanol Company Fire Services

Preliminary Report I • An explosion and fire occurred at the FCCU at 2. 53 am on Wednesday June 05, 1991. The fire was brought under control by Company Fire Services, TT Fire Services and TT Methanol Company Fire Services

Preliminary Report II • There was one fatality, 12 injuries of which 2 were very serious and 10 were relatively minor. Several workers suffered Post Traumatic Stress Disorder (PTSD).

Preliminary Report II • There was one fatality, 12 injuries of which 2 were very serious and 10 were relatively minor. Several workers suffered Post Traumatic Stress Disorder (PTSD).

Explosion Damage I • The Fire of the explosion at the slurry settler caused extensive damage to N-S piperacks and nearby equipment east of the FCCU.

Explosion Damage I • The Fire of the explosion at the slurry settler caused extensive damage to N-S piperacks and nearby equipment east of the FCCU.

Explosion Damage II • Much of this ancillary damage was apparently due to the “shrapnel” effect of the slurry settler and was concentrated in the NE the path of trajectory.

Explosion Damage II • Much of this ancillary damage was apparently due to the “shrapnel” effect of the slurry settler and was concentrated in the NE the path of trajectory.

Explosion Damage III • At FCCU and Gas Control Rooms the blast damaged roofs, ceiling, and windows. Adjacent structures were relatively intact. But breakage of windows occurred 200 metres away.

Explosion Damage III • At FCCU and Gas Control Rooms the blast damaged roofs, ceiling, and windows. Adjacent structures were relatively intact. But breakage of windows occurred 200 metres away.

Fire Damage I • Near the base of the main fractionator the slurry pumps were destroyed by fire. Intense heat and flames damaged adjacent equipment such as lines, heat exchangers and the blower house roof.

Fire Damage I • Near the base of the main fractionator the slurry pumps were destroyed by fire. Intense heat and flames damaged adjacent equipment such as lines, heat exchangers and the blower house roof.

Fire Damage II • On the FCCU main structure there was fire damage mainly on the north side of the reactor where the steam drum is located.

Fire Damage II • On the FCCU main structure there was fire damage mainly on the north side of the reactor where the steam drum is located.

Fire Damage III • The FCCU charge pre-heater and related piping suffered damage due to fire caused by a ruptured feed line. The East Area Guard Basin became ignited from flying debris.

Fire Damage III • The FCCU charge pre-heater and related piping suffered damage due to fire caused by a ruptured feed line. The East Area Guard Basin became ignited from flying debris.

Some Findings • The slurry settler vessel showed tensile failure typical of internal explosion. • Failure of the head in the area adjacent to the reinforcing pad around the 18” manway nozzle.

Some Findings • The slurry settler vessel showed tensile failure typical of internal explosion. • Failure of the head in the area adjacent to the reinforcing pad around the 18” manway nozzle.

Some Findings (cont’d) • The manway nozzle complete with bolted over was found about 200 m north east of the vessel’s original location.

Some Findings (cont’d) • The manway nozzle complete with bolted over was found about 200 m north east of the vessel’s original location.

Engineering Findings I • 480 – 565 psi pressure in slurry settler was required for rupture. • Vessel operating temperature was 610 o. F. • Calculations on blast effect was equivalent to 120 -200 pounds of TNT.

Engineering Findings I • 480 – 565 psi pressure in slurry settler was required for rupture. • Vessel operating temperature was 610 o. F. • Calculations on blast effect was equivalent to 120 -200 pounds of TNT.

Engineering Findings II • A vapour space was most likely present in the vessel. (compressible gas bubble) 420 to 1000 cu ft. • Energy required to fracture or deform the slurry settler vessel was about 70 million ftlbs of energy 40 to 47 pounds of TNT.

Engineering Findings II • A vapour space was most likely present in the vessel. (compressible gas bubble) 420 to 1000 cu ft. • Energy required to fracture or deform the slurry settler vessel was about 70 million ftlbs of energy 40 to 47 pounds of TNT.

Engineering Findings III • After the slurry settler pressure vessel exploded, there was instantaneous fire (I. e. auto-ignition) from the hot slurry oil released into the atmosphere.

Engineering Findings III • After the slurry settler pressure vessel exploded, there was instantaneous fire (I. e. auto-ignition) from the hot slurry oil released into the atmosphere.

Engineering Findings IV • “Air was most likely trapped inside the vessel during start up. ” • No evidence of an external explosive device was found.

Engineering Findings IV • “Air was most likely trapped inside the vessel during start up. ” • No evidence of an external explosive device was found.

Personal Injuries • SR, age 22. Fatality • WM, age 35. Severe burns and shock. • RS, age 39. Severe burns, fracture right arm, right foot and right hip, shock. • KL, age 44. Minor burns and shock.

Personal Injuries • SR, age 22. Fatality • WM, age 35. Severe burns and shock. • RS, age 39. Severe burns, fracture right arm, right foot and right hip, shock. • KL, age 44. Minor burns and shock.

Personal Injuries cont’d) • HK, age 35. Injuries to right ear and right shoulder. • KJ, age 36. Foreign body in eyes. • FH, age 28. Minor burns to both forearms. • RR, age 37. Minor burns and abrasions from fall.

Personal Injuries cont’d) • HK, age 35. Injuries to right ear and right shoulder. • KJ, age 36. Foreign body in eyes. • FH, age 28. Minor burns to both forearms. • RR, age 37. Minor burns and abrasions from fall.

Personal Injuries (cont’d) • RR, age 22. Minor burns and strained neck muscles. • OJ, age 37. Muscular injury right thigh. • SB, age 39. Splinter in arms. • TT, age 46. ‘Shock’ and elevated BP “malignant”. • FA, age 32. Sprained ankle.

Personal Injuries (cont’d) • RR, age 22. Minor burns and strained neck muscles. • OJ, age 37. Muscular injury right thigh. • SB, age 39. Splinter in arms. • TT, age 46. ‘Shock’ and elevated BP “malignant”. • FA, age 32. Sprained ankle.

Fortunate Events I • Damage was mitigated because the predominantly ballistic or impact type of damage was confined to the NE direction which was unoccupied hillside.

Fortunate Events I • Damage was mitigated because the predominantly ballistic or impact type of damage was confined to the NE direction which was unoccupied hillside.

Fortunate Events II • Damage was mitigated by the fact that several workers had gone to the canteen to eat.

Fortunate Events II • Damage was mitigated by the fact that several workers had gone to the canteen to eat.

Fortunate Events III • Some rainfall occurred 20 minutes before the explosion which resulted in several workers delaying in returning to the FCCU.

Fortunate Events III • Some rainfall occurred 20 minutes before the explosion which resulted in several workers delaying in returning to the FCCU.

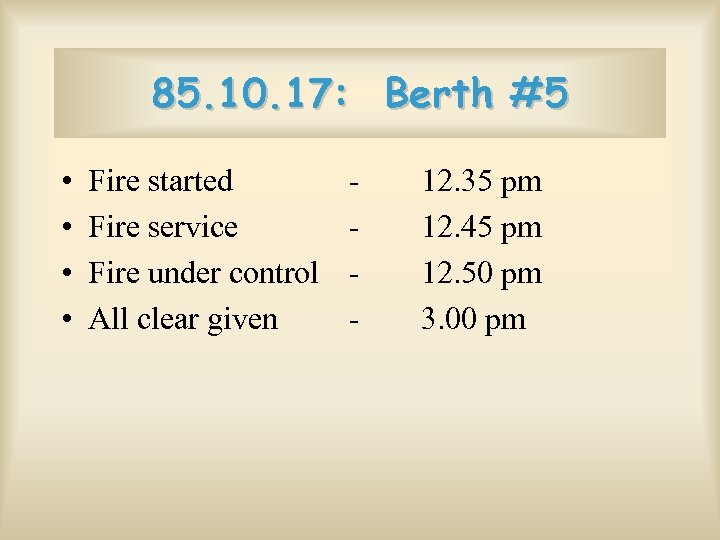

85. 10. 17: Berth #5 • • Fire started Fire service Fire under control All clear given - 12. 35 pm 12. 45 pm 12. 50 pm 3. 00 pm

85. 10. 17: Berth #5 • • Fire started Fire service Fire under control All clear given - 12. 35 pm 12. 45 pm 12. 50 pm 3. 00 pm

Background to Fire I • In June 1985 a decision was taken to recommission the entire length of the 30 inch diameter sealine (S/L No. 33) running from the Pile Bent 80 manifold to No. 5 berth and terminating at No. 6 Berth.

Background to Fire I • In June 1985 a decision was taken to recommission the entire length of the 30 inch diameter sealine (S/L No. 33) running from the Pile Bent 80 manifold to No. 5 berth and terminating at No. 6 Berth.

Background II • The section of the line between No. 5 and No. 6 Berths (length 1200 ft) was the only inoperative part and was positively isolated from the rest of the line in 1975. This section had to be tested and repaired before being brought back into service.

Background II • The section of the line between No. 5 and No. 6 Berths (length 1200 ft) was the only inoperative part and was positively isolated from the rest of the line in 1975. This section had to be tested and repaired before being brought back into service.

Background III • Between July and October 1985, the other portion of the line was in crude oil service, the last being the receipt of 319, 000 bbls of Algerian Condensate on September 1.

Background III • Between July and October 1985, the other portion of the line was in crude oil service, the last being the receipt of 319, 000 bbls of Algerian Condensate on September 1.

Background IV • By October 11, all activities related to the repairs of the disused section were completed.

Background IV • By October 11, all activities related to the repairs of the disused section were completed.

Background V • On October 17, equipment was mobilized and manpower allocated to the task of completing the final job to allow the recommissioning of the entire length of S/L 33.

Background V • On October 17, equipment was mobilized and manpower allocated to the task of completing the final job to allow the recommissioning of the entire length of S/L 33.

Background VI • The last task was to remove the 30 inch diameter slip blind installed in 1975, from between the bolted flanges on the riser section of the line at No. 5 berth, located approximately 22 inches above sea water level at noon on the day of the fire.

Background VI • The last task was to remove the 30 inch diameter slip blind installed in 1975, from between the bolted flanges on the riser section of the line at No. 5 berth, located approximately 22 inches above sea water level at noon on the day of the fire.

Background VII • A Maintenance Work Permit was prepared and signed off by (1) Assistant Area Maintenance Superintendent West; (2) Port Captain; (3) Oil Stocks Superintendent and delivered on site just prior to start of the job.

Background VII • A Maintenance Work Permit was prepared and signed off by (1) Assistant Area Maintenance Superintendent West; (2) Port Captain; (3) Oil Stocks Superintendent and delivered on site just prior to start of the job.

The Fire I • Around 12 noon after the flange was loosened on S/L 33, heavy crude trapped in the dead leg followed by light hydrocarbons (Algerian Condensate API 64. 9 and vapour Pressure 9. 1 psig) flowed at an estimated rate of 40 barrels per minute for 8 -9 minutes.

The Fire I • Around 12 noon after the flange was loosened on S/L 33, heavy crude trapped in the dead leg followed by light hydrocarbons (Algerian Condensate API 64. 9 and vapour Pressure 9. 1 psig) flowed at an estimated rate of 40 barrels per minute for 8 -9 minutes.

The Fire II • This line was under a positive pressure from an operating crude transfer system in the foreshore area. During the 8 to 9 minutes period, the 30 -inch slip blind, weighing 250 lbs was removed by the crew.

The Fire II • This line was under a positive pressure from an operating crude transfer system in the foreshore area. During the 8 to 9 minutes period, the 30 -inch slip blind, weighing 250 lbs was removed by the crew.

The Fire III • At 12. 33 pm vapours from the light hydrocarbons, which had surrounded all floating craft were ignited by an open flame or spark, resulting in a muffled explosion. Flames were driven by strong winds over 20 knots and engulfed all men and equipment on the job.

The Fire III • At 12. 33 pm vapours from the light hydrocarbons, which had surrounded all floating craft were ignited by an open flame or spark, resulting in a muffled explosion. Flames were driven by strong winds over 20 knots and engulfed all men and equipment on the job.

The Fire IV • The fire raged for 15 minutes after which it was brought under control, but in all lasted about one hour and forty-five minutes.

The Fire IV • The fire raged for 15 minutes after which it was brought under control, but in all lasted about one hour and forty-five minutes.

The Fire V • When the crude transfer operations at the foreshore area were isolated from the sea line the fire was finally extinguished.

The Fire V • When the crude transfer operations at the foreshore area were isolated from the sea line the fire was finally extinguished.

Search and Rescue I • Soon after the outbreak of the fire two men in a contractor’s pirogue arrived on the east of No. 5 berth and rescued three contractor’s painters who were clinging to the east breasting dolphin clear of the water.

Search and Rescue I • Soon after the outbreak of the fire two men in a contractor’s pirogue arrived on the east of No. 5 berth and rescued three contractor’s painters who were clinging to the east breasting dolphin clear of the water.

Search and Rescue II • Launches “Star Fish” and “Flying Fish” were involved in the retrieval of victims. Seven were recovered from the sea; three charred bodies were collected from the deck of the Pile Driver.

Search and Rescue II • Launches “Star Fish” and “Flying Fish” were involved in the retrieval of victims. Seven were recovered from the sea; three charred bodies were collected from the deck of the Pile Driver.

Fire Fighting Operations • Tug “Plaisance” arrived at 12. 45 pm and Tug “Plein Palais” arrived at 1. 28 pm both were engaged in fire fighting activity. Foam was used to contain the fire.

Fire Fighting Operations • Tug “Plaisance” arrived at 12. 45 pm and Tug “Plein Palais” arrived at 1. 28 pm both were engaged in fire fighting activity. Foam was used to contain the fire.

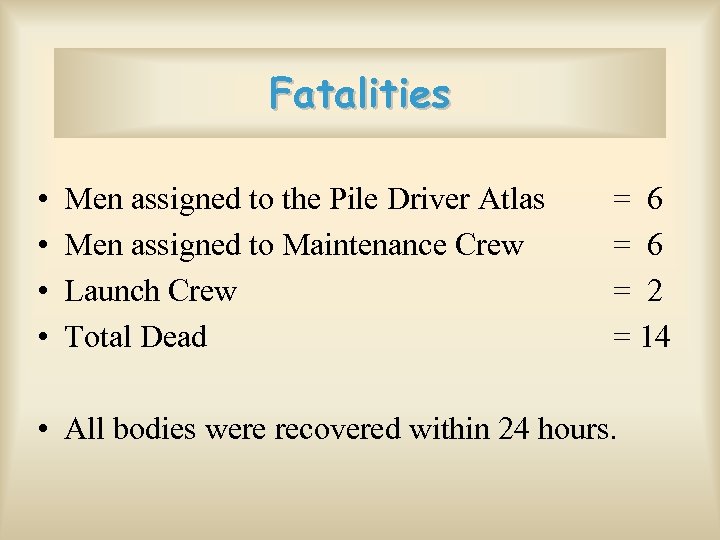

Fatalities • • Men assigned to the Pile Driver Atlas Men assigned to Maintenance Crew Launch Crew Total Dead = 6 = 2 = 14 • All bodies were recovered within 24 hours.

Fatalities • • Men assigned to the Pile Driver Atlas Men assigned to Maintenance Crew Launch Crew Total Dead = 6 = 2 = 14 • All bodies were recovered within 24 hours.

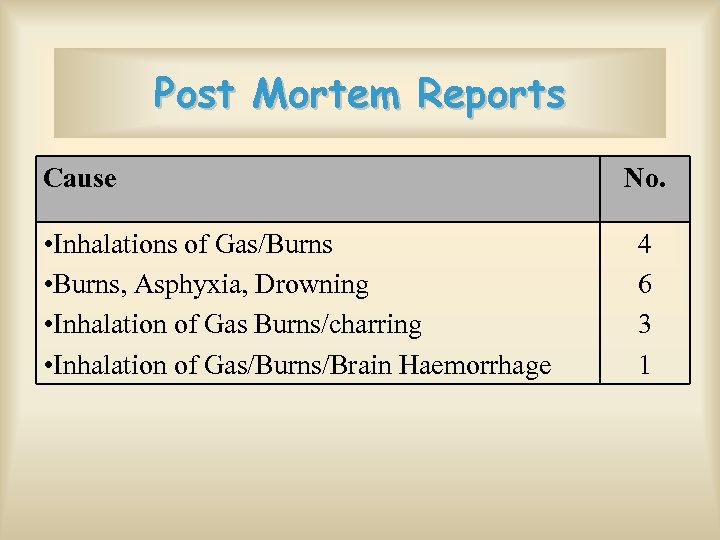

Post Mortem Reports Cause • Inhalations of Gas/Burns • Burns, Asphyxia, Drowning • Inhalation of Gas Burns/charring • Inhalation of Gas/Burns/Brain Haemorrhage No. 4 6 3 1

Post Mortem Reports Cause • Inhalations of Gas/Burns • Burns, Asphyxia, Drowning • Inhalation of Gas Burns/charring • Inhalation of Gas/Burns/Brain Haemorrhage No. 4 6 3 1

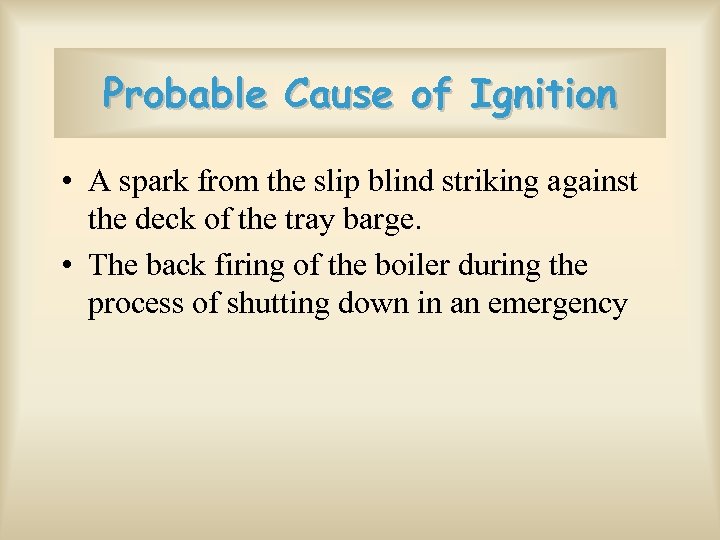

Probable Cause of Ignition • A spark from the slip blind striking against the deck of the tray barge. • The back firing of the boiler during the process of shutting down in an emergency

Probable Cause of Ignition • A spark from the slip blind striking against the deck of the tray barge. • The back firing of the boiler during the process of shutting down in an emergency

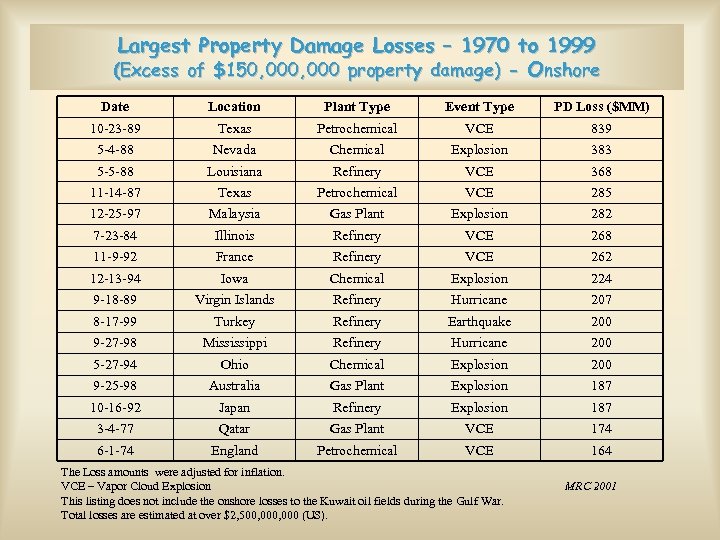

Largest Property Damage Losses – 1970 to 1999 (Excess of $150, 000 property damage) - Onshore Date Location Plant Type Event Type PD Loss ($MM) 10 -23 -89 Texas Petrochemical VCE 839 5 -4 -88 Nevada Chemical Explosion 383 5 -5 -88 Louisiana Refinery VCE 368 11 -14 -87 Texas Petrochemical VCE 285 12 -25 -97 Malaysia Gas Plant Explosion 282 7 -23 -84 Illinois Refinery VCE 268 11 -9 -92 France Refinery VCE 262 12 -13 -94 Iowa Chemical Explosion 224 9 -18 -89 Virgin Islands Refinery Hurricane 207 8 -17 -99 Turkey Refinery Earthquake 200 9 -27 -98 Mississippi Refinery Hurricane 200 5 -27 -94 Ohio Chemical Explosion 200 9 -25 -98 Australia Gas Plant Explosion 187 10 -16 -92 Japan Refinery Explosion 187 3 -4 -77 Qatar Gas Plant VCE 174 6 -1 -74 England Petrochemical VCE 164 The Loss amounts were adjusted for inflation. VCE – Vapor Cloud Explosion This listing does not include the onshore losses to the Kuwait oil fields during the Gulf War. Total losses are estimated at over $2, 500, 000 (US). MRC 2001

Largest Property Damage Losses – 1970 to 1999 (Excess of $150, 000 property damage) - Onshore Date Location Plant Type Event Type PD Loss ($MM) 10 -23 -89 Texas Petrochemical VCE 839 5 -4 -88 Nevada Chemical Explosion 383 5 -5 -88 Louisiana Refinery VCE 368 11 -14 -87 Texas Petrochemical VCE 285 12 -25 -97 Malaysia Gas Plant Explosion 282 7 -23 -84 Illinois Refinery VCE 268 11 -9 -92 France Refinery VCE 262 12 -13 -94 Iowa Chemical Explosion 224 9 -18 -89 Virgin Islands Refinery Hurricane 207 8 -17 -99 Turkey Refinery Earthquake 200 9 -27 -98 Mississippi Refinery Hurricane 200 5 -27 -94 Ohio Chemical Explosion 200 9 -25 -98 Australia Gas Plant Explosion 187 10 -16 -92 Japan Refinery Explosion 187 3 -4 -77 Qatar Gas Plant VCE 174 6 -1 -74 England Petrochemical VCE 164 The Loss amounts were adjusted for inflation. VCE – Vapor Cloud Explosion This listing does not include the onshore losses to the Kuwait oil fields during the Gulf War. Total losses are estimated at over $2, 500, 000 (US). MRC 2001

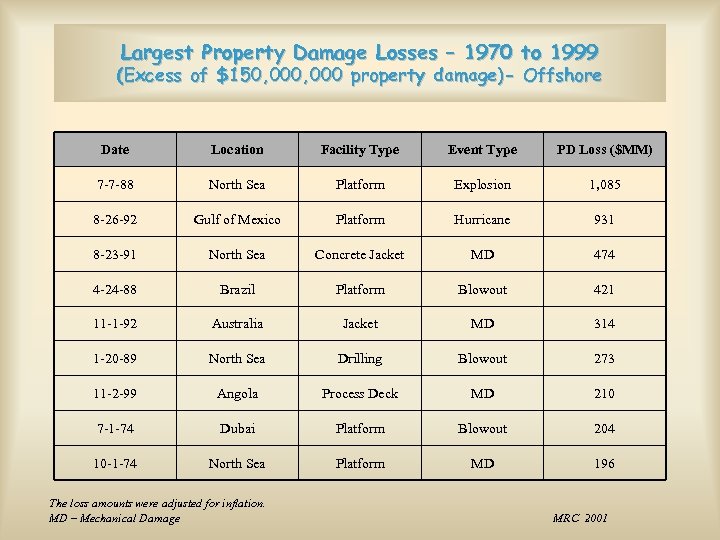

Largest Property Damage Losses – 1970 to 1999 (Excess of $150, 000 property damage)- Offshore Date Location Facility Type Event Type PD Loss ($MM) 7 -7 -88 North Sea Platform Explosion 1, 085 8 -26 -92 Gulf of Mexico Platform Hurricane 931 8 -23 -91 North Sea Concrete Jacket MD 474 4 -24 -88 Brazil Platform Blowout 421 11 -1 -92 Australia Jacket MD 314 1 -20 -89 North Sea Drilling Blowout 273 11 -2 -99 Angola Process Deck MD 210 7 -1 -74 Dubai Platform Blowout 204 10 -1 -74 North Sea Platform MD 196 The loss amounts were adjusted for inflation. MD – Mechanical Damage MRC 2001

Largest Property Damage Losses – 1970 to 1999 (Excess of $150, 000 property damage)- Offshore Date Location Facility Type Event Type PD Loss ($MM) 7 -7 -88 North Sea Platform Explosion 1, 085 8 -26 -92 Gulf of Mexico Platform Hurricane 931 8 -23 -91 North Sea Concrete Jacket MD 474 4 -24 -88 Brazil Platform Blowout 421 11 -1 -92 Australia Jacket MD 314 1 -20 -89 North Sea Drilling Blowout 273 11 -2 -99 Angola Process Deck MD 210 7 -1 -74 Dubai Platform Blowout 204 10 -1 -74 North Sea Platform MD 196 The loss amounts were adjusted for inflation. MD – Mechanical Damage MRC 2001

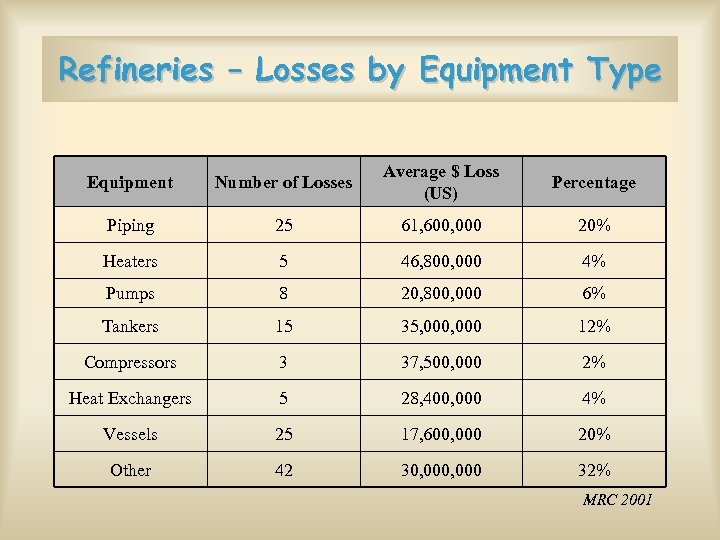

Refineries – Losses by Equipment Type Equipment Number of Losses Average $ Loss (US) Percentage Piping 25 61, 600, 000 20% Heaters 5 46, 800, 000 4% Pumps 8 20, 800, 000 6% Tankers 15 35, 000 12% Compressors 3 37, 500, 000 2% Heat Exchangers 5 28, 400, 000 4% Vessels 25 17, 600, 000 20% Other 42 30, 000 32% MRC 2001

Refineries – Losses by Equipment Type Equipment Number of Losses Average $ Loss (US) Percentage Piping 25 61, 600, 000 20% Heaters 5 46, 800, 000 4% Pumps 8 20, 800, 000 6% Tankers 15 35, 000 12% Compressors 3 37, 500, 000 2% Heat Exchangers 5 28, 400, 000 4% Vessels 25 17, 600, 000 20% Other 42 30, 000 32% MRC 2001

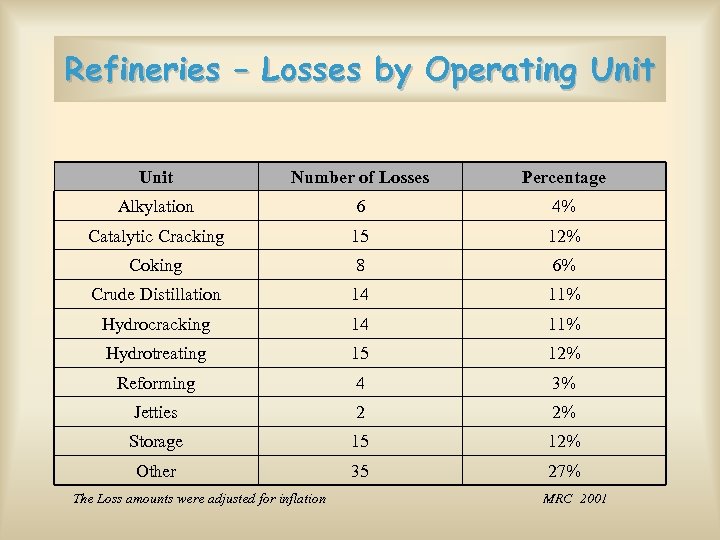

Refineries – Losses by Operating Unit Number of Losses Percentage Alkylation 6 4% Catalytic Cracking 15 12% Coking 8 6% Crude Distillation 14 11% Hydrocracking 14 11% Hydrotreating 15 12% Reforming 4 3% Jetties 2 2% Storage 15 12% Other 35 27% The Loss amounts were adjusted for inflation MRC 2001

Refineries – Losses by Operating Unit Number of Losses Percentage Alkylation 6 4% Catalytic Cracking 15 12% Coking 8 6% Crude Distillation 14 11% Hydrocracking 14 11% Hydrotreating 15 12% Reforming 4 3% Jetties 2 2% Storage 15 12% Other 35 27% The Loss amounts were adjusted for inflation MRC 2001

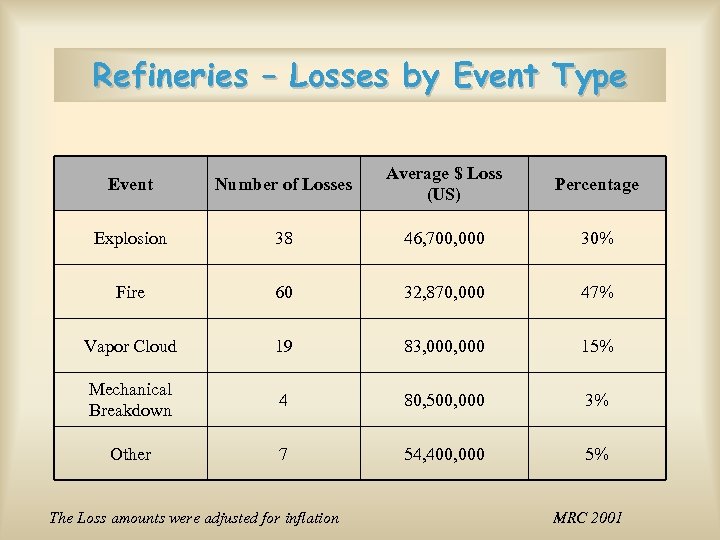

Refineries – Losses by Event Type Event Number of Losses Average $ Loss (US) Percentage Explosion 38 46, 700, 000 30% Fire 60 32, 870, 000 47% Vapor Cloud 19 83, 000 15% Mechanical Breakdown 4 80, 500, 000 3% Other 7 54, 400, 000 5% The Loss amounts were adjusted for inflation MRC 2001

Refineries – Losses by Event Type Event Number of Losses Average $ Loss (US) Percentage Explosion 38 46, 700, 000 30% Fire 60 32, 870, 000 47% Vapor Cloud 19 83, 000 15% Mechanical Breakdown 4 80, 500, 000 3% Other 7 54, 400, 000 5% The Loss amounts were adjusted for inflation MRC 2001

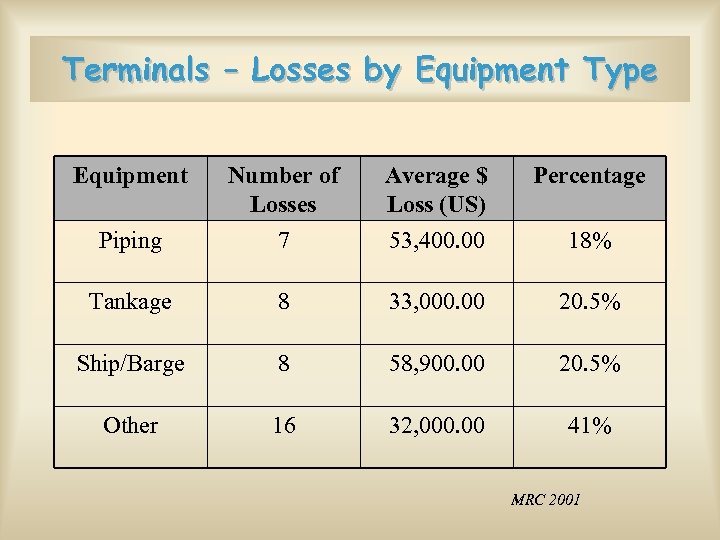

Terminals – Losses by Equipment Type Equipment Number of Losses Average $ Loss (US) Percentage Piping 7 53, 400. 00 18% Tankage 8 33, 000. 00 20. 5% Ship/Barge 8 58, 900. 00 20. 5% Other 16 32, 000. 00 41% MRC 2001

Terminals – Losses by Equipment Type Equipment Number of Losses Average $ Loss (US) Percentage Piping 7 53, 400. 00 18% Tankage 8 33, 000. 00 20. 5% Ship/Barge 8 58, 900. 00 20. 5% Other 16 32, 000. 00 41% MRC 2001

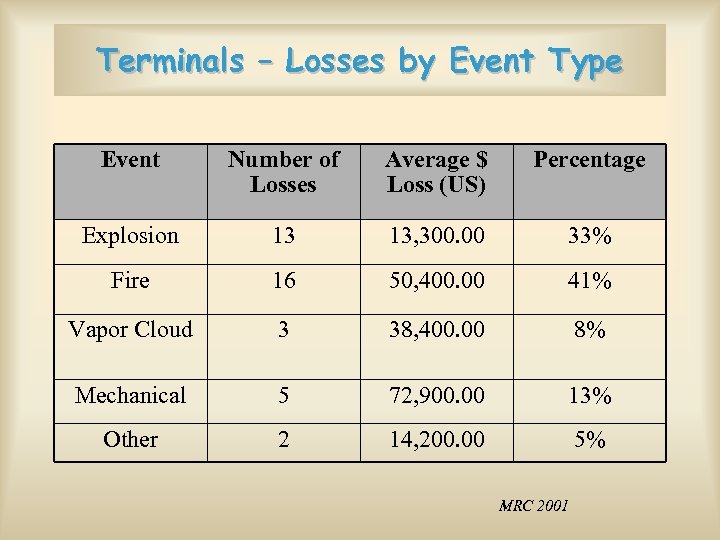

Terminals – Losses by Event Type Event Number of Losses Average $ Loss (US) Percentage Explosion 13 13, 300. 00 33% Fire 16 50, 400. 00 41% Vapor Cloud 3 38, 400. 00 8% Mechanical 5 72, 900. 00 13% Other 2 14, 200. 00 5% MRC 2001

Terminals – Losses by Event Type Event Number of Losses Average $ Loss (US) Percentage Explosion 13 13, 300. 00 33% Fire 16 50, 400. 00 41% Vapor Cloud 3 38, 400. 00 8% Mechanical 5 72, 900. 00 13% Other 2 14, 200. 00 5% MRC 2001

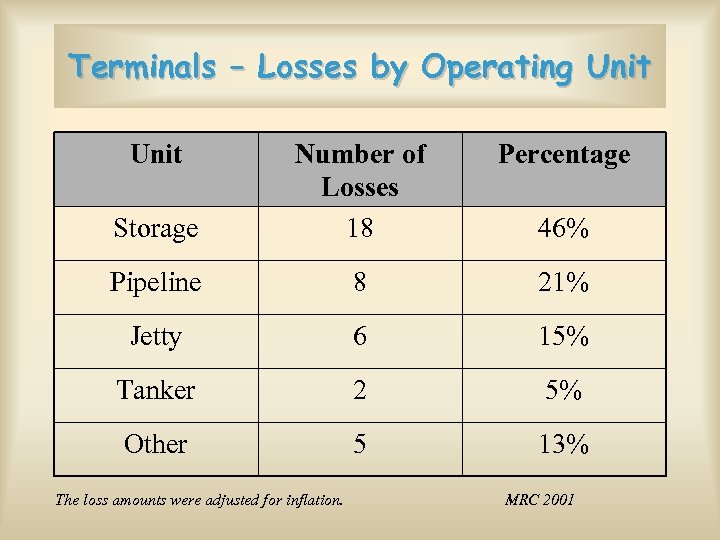

Terminals – Losses by Operating Unit Percentage Storage Number of Losses 18 Pipeline 8 21% Jetty 6 15% Tanker 2 5% Other 5 13% The loss amounts were adjusted for inflation. 46% MRC 2001

Terminals – Losses by Operating Unit Percentage Storage Number of Losses 18 Pipeline 8 21% Jetty 6 15% Tanker 2 5% Other 5 13% The loss amounts were adjusted for inflation. 46% MRC 2001

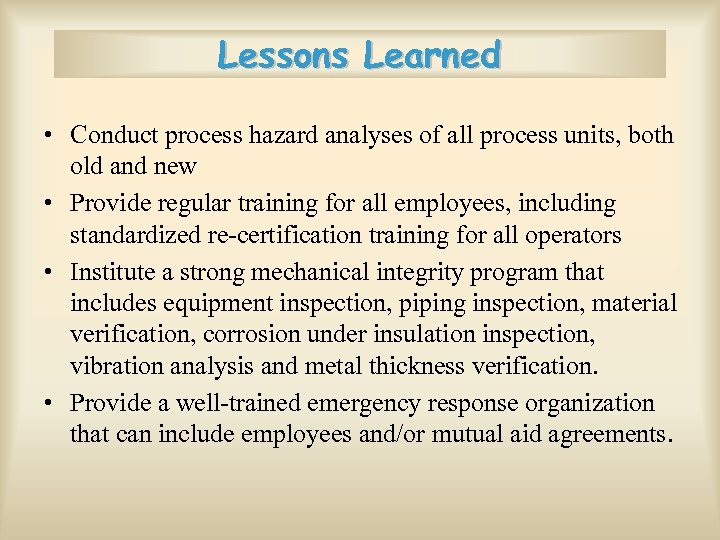

Lessons Learned • Conduct process hazard analyses of all process units, both old and new • Provide regular training for all employees, including standardized re-certification training for all operators • Institute a strong mechanical integrity program that includes equipment inspection, piping inspection, material verification, corrosion under insulation inspection, vibration analysis and metal thickness verification. • Provide a well-trained emergency response organization that can include employees and/or mutual aid agreements.

Lessons Learned • Conduct process hazard analyses of all process units, both old and new • Provide regular training for all employees, including standardized re-certification training for all operators • Institute a strong mechanical integrity program that includes equipment inspection, piping inspection, material verification, corrosion under insulation inspection, vibration analysis and metal thickness verification. • Provide a well-trained emergency response organization that can include employees and/or mutual aid agreements.

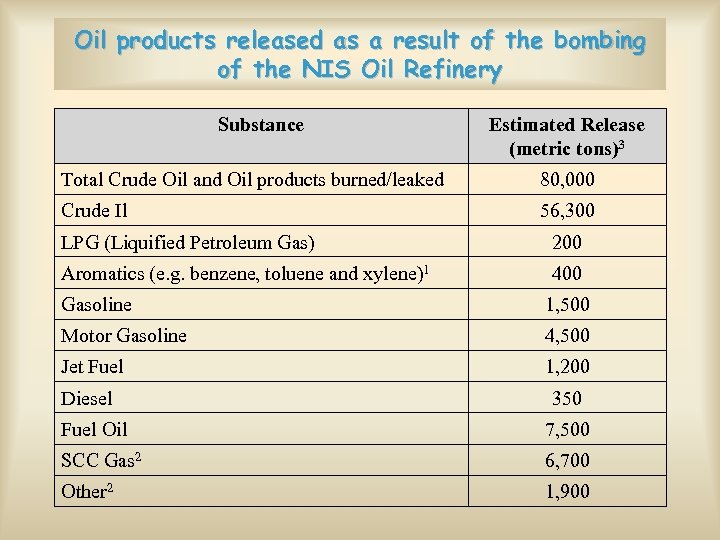

Oil products released as a result of the bombing of the NIS Oil Refinery Substance Estimated Release (metric tons)3 Total Crude Oil and Oil products burned/leaked 80, 000 Crude Il 56, 300 LPG (Liquified Petroleum Gas) 200 Aromatics (e. g. benzene, toluene and xylene)1 400 Gasoline 1, 500 Motor Gasoline 4, 500 Jet Fuel 1, 200 Diesel 350 Fuel Oil 7, 500 SCC Gas 2 6, 700 Other 2 1, 900

Oil products released as a result of the bombing of the NIS Oil Refinery Substance Estimated Release (metric tons)3 Total Crude Oil and Oil products burned/leaked 80, 000 Crude Il 56, 300 LPG (Liquified Petroleum Gas) 200 Aromatics (e. g. benzene, toluene and xylene)1 400 Gasoline 1, 500 Motor Gasoline 4, 500 Jet Fuel 1, 200 Diesel 350 Fuel Oil 7, 500 SCC Gas 2 6, 700 Other 2 1, 900

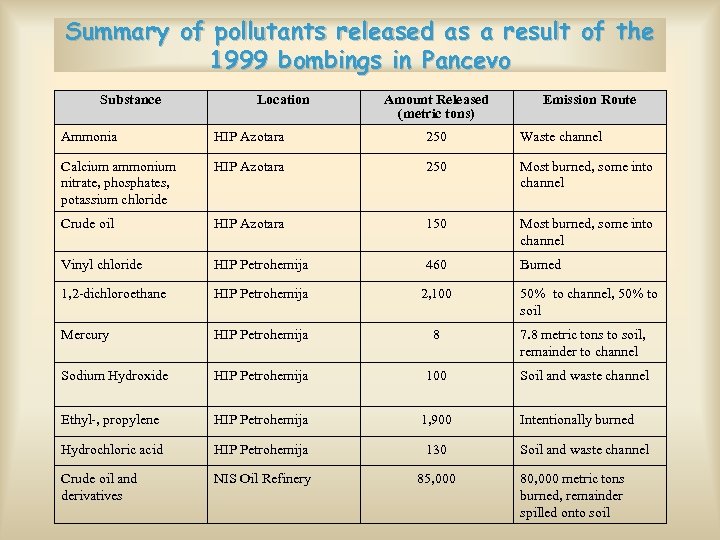

Summary of pollutants released as a result of the 1999 bombings in Pancevo Substance Location Amount Released (metric tons) Emission Route Ammonia HIP Azotara 250 Waste channel Calcium ammonium nitrate, phosphates, potassium chloride HIP Azotara 250 Most burned, some into channel Crude oil HIP Azotara 150 Most burned, some into channel Vinyl chloride HIP Petrohemija 460 Burned 1, 2 -dichloroethane HIP Petrohemija 2, 100 Mercury HIP Petrohemija 8 7. 8 metric tons to soil, remainder to channel Sodium Hydroxide HIP Petrohemija 100 Soil and waste channel Ethyl-, propylene HIP Petrohemija 1, 900 Hydrochloric acid HIP Petrohemija 130 Crude oil and derivatives NIS Oil Refinery 85, 000 50% to channel, 50% to soil Intentionally burned Soil and waste channel 80, 000 metric tons burned, remainder spilled onto soil

Summary of pollutants released as a result of the 1999 bombings in Pancevo Substance Location Amount Released (metric tons) Emission Route Ammonia HIP Azotara 250 Waste channel Calcium ammonium nitrate, phosphates, potassium chloride HIP Azotara 250 Most burned, some into channel Crude oil HIP Azotara 150 Most burned, some into channel Vinyl chloride HIP Petrohemija 460 Burned 1, 2 -dichloroethane HIP Petrohemija 2, 100 Mercury HIP Petrohemija 8 7. 8 metric tons to soil, remainder to channel Sodium Hydroxide HIP Petrohemija 100 Soil and waste channel Ethyl-, propylene HIP Petrohemija 1, 900 Hydrochloric acid HIP Petrohemija 130 Crude oil and derivatives NIS Oil Refinery 85, 000 50% to channel, 50% to soil Intentionally burned Soil and waste channel 80, 000 metric tons burned, remainder spilled onto soil

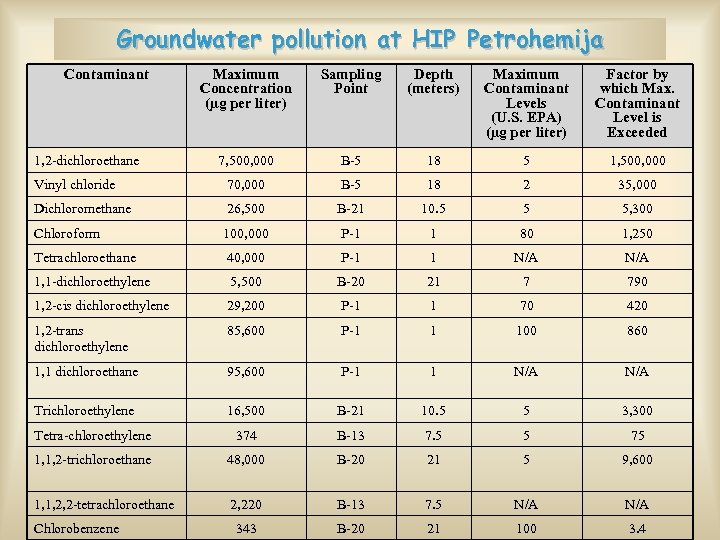

Groundwater pollution at HIP Petrohemija Contaminant Maximum Concentration (µg per liter) Sampling Point Depth (meters) Maximum Contaminant Levels (U. S. EPA) (µg per liter) Factor by which Max. Contaminant Level is Exceeded 7, 500, 000 B-5 18 5 1, 500, 000 Vinyl chloride 70, 000 B-5 18 2 35, 000 Dichloromethane 26, 500 B-21 10. 5 5 5, 300 Chloroform 100, 000 P-1 1 80 1, 250 Tetrachloroethane 40, 000 P-1 1 N/A 1, 1 -dichloroethylene 5, 500 B-20 21 7 790 1, 2 -cis dichloroethylene 29, 200 P-1 1 70 420 1, 2 -trans dichloroethylene 85, 600 P-1 1 100 860 1, 1 dichloroethane 95, 600 P-1 1 N/A Trichloroethylene 16, 500 B-21 10. 5 5 3, 300 Tetra-chloroethylene 374 B-13 7. 5 5 75 1, 1, 2 -trichloroethane 48, 000 B-20 21 5 9, 600 1, 1, 2, 2 -tetrachloroethane 2, 220 B-13 7. 5 N/A 343 B-20 21 100 3. 4 1, 2 -dichloroethane Chlorobenzene

Groundwater pollution at HIP Petrohemija Contaminant Maximum Concentration (µg per liter) Sampling Point Depth (meters) Maximum Contaminant Levels (U. S. EPA) (µg per liter) Factor by which Max. Contaminant Level is Exceeded 7, 500, 000 B-5 18 5 1, 500, 000 Vinyl chloride 70, 000 B-5 18 2 35, 000 Dichloromethane 26, 500 B-21 10. 5 5 5, 300 Chloroform 100, 000 P-1 1 80 1, 250 Tetrachloroethane 40, 000 P-1 1 N/A 1, 1 -dichloroethylene 5, 500 B-20 21 7 790 1, 2 -cis dichloroethylene 29, 200 P-1 1 70 420 1, 2 -trans dichloroethylene 85, 600 P-1 1 100 860 1, 1 dichloroethane 95, 600 P-1 1 N/A Trichloroethylene 16, 500 B-21 10. 5 5 3, 300 Tetra-chloroethylene 374 B-13 7. 5 5 75 1, 1, 2 -trichloroethane 48, 000 B-20 21 5 9, 600 1, 1, 2, 2 -tetrachloroethane 2, 220 B-13 7. 5 N/A 343 B-20 21 100 3. 4 1, 2 -dichloroethane Chlorobenzene

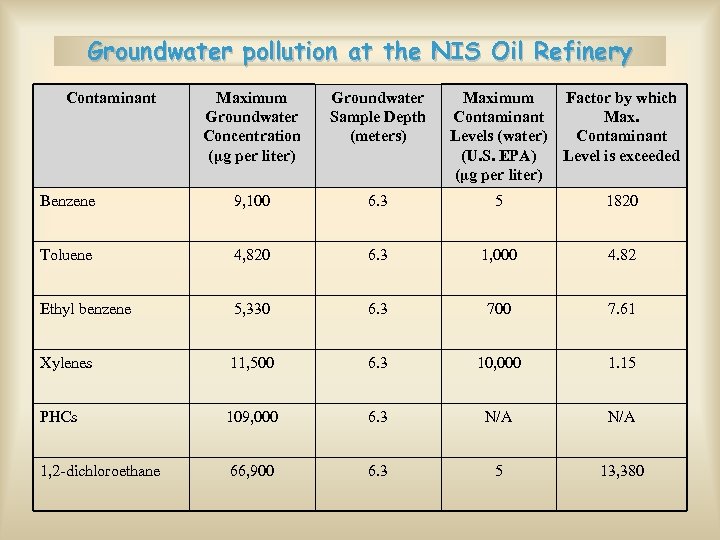

Groundwater pollution at the NIS Oil Refinery Contaminant Maximum Groundwater Concentration (µg per liter) Groundwater Sample Depth (meters) Maximum Factor by which Contaminant Max. Levels (water) Contaminant (U. S. EPA) Level is exceeded (µg per liter) Benzene 9, 100 6. 3 5 1820 Toluene 4, 820 6. 3 1, 000 4. 82 Ethyl benzene 5, 330 6. 3 700 7. 61 Xylenes 11, 500 6. 3 10, 000 1. 15 PHCs 109, 000 6. 3 N/A 1, 2 -dichloroethane 66, 900 6. 3 5 13, 380

Groundwater pollution at the NIS Oil Refinery Contaminant Maximum Groundwater Concentration (µg per liter) Groundwater Sample Depth (meters) Maximum Factor by which Contaminant Max. Levels (water) Contaminant (U. S. EPA) Level is exceeded (µg per liter) Benzene 9, 100 6. 3 5 1820 Toluene 4, 820 6. 3 1, 000 4. 82 Ethyl benzene 5, 330 6. 3 700 7. 61 Xylenes 11, 500 6. 3 10, 000 1. 15 PHCs 109, 000 6. 3 N/A 1, 2 -dichloroethane 66, 900 6. 3 5 13, 380

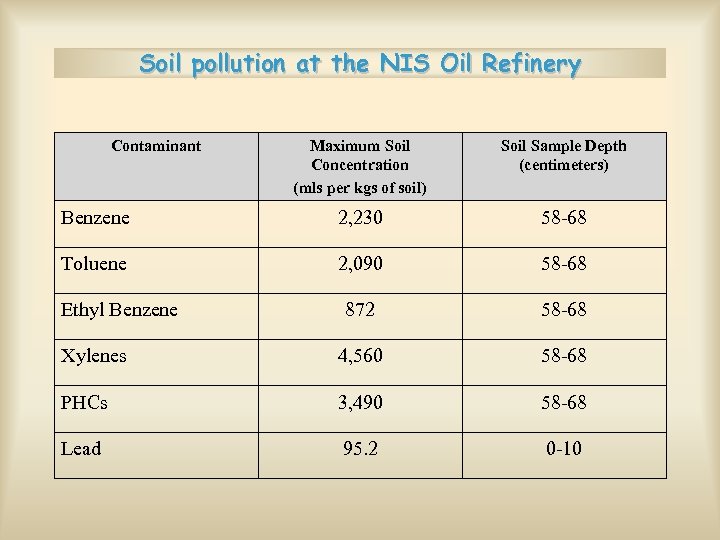

Soil pollution at the NIS Oil Refinery Contaminant Maximum Soil Concentration (mls per kgs of soil) Soil Sample Depth (centimeters) Benzene 2, 230 58 -68 Toluene 2, 090 58 -68 872 58 -68 Xylenes 4, 560 58 -68 PHCs 3, 490 58 -68 Lead 95. 2 0 -10 Ethyl Benzene

Soil pollution at the NIS Oil Refinery Contaminant Maximum Soil Concentration (mls per kgs of soil) Soil Sample Depth (centimeters) Benzene 2, 230 58 -68 Toluene 2, 090 58 -68 872 58 -68 Xylenes 4, 560 58 -68 PHCs 3, 490 58 -68 Lead 95. 2 0 -10 Ethyl Benzene

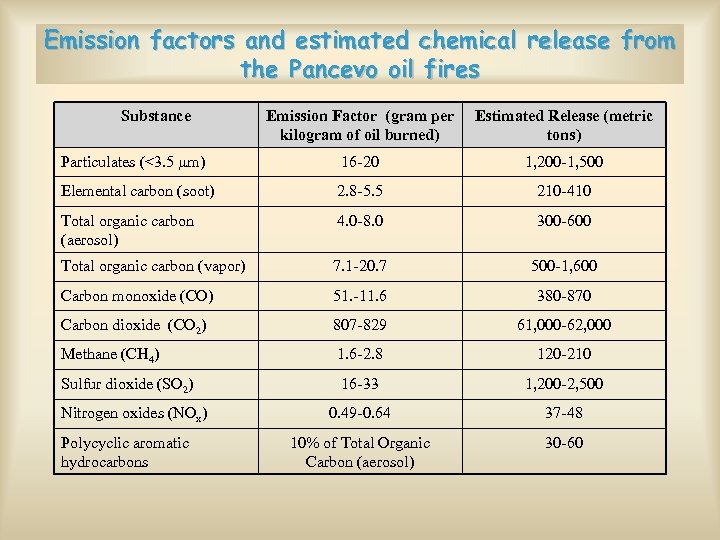

Emission factors and estimated chemical release from the Pancevo oil fires Substance Emission Factor (gram per kilogram of oil burned) Estimated Release (metric tons) Particulates (<3. 5 µm) 16 -20 1, 200 -1, 500 Elemental carbon (soot) 2. 8 -5. 5 210 -410 Total organic carbon (aerosol) 4. 0 -8. 0 300 -600 Total organic carbon (vapor) 7. 1 -20. 7 500 -1, 600 Carbon monoxide (CO) 51. -11. 6 380 -870 Carbon dioxide (CO 2) 807 -829 61, 000 -62, 000 Methane (CH 4) 1. 6 -2. 8 120 -210 Sulfur dioxide (SO 2) 16 -33 1, 200 -2, 500 0. 49 -0. 64 37 -48 10% of Total Organic Carbon (aerosol) 30 -60 Nitrogen oxides (NOx) Polycyclic aromatic hydrocarbons

Emission factors and estimated chemical release from the Pancevo oil fires Substance Emission Factor (gram per kilogram of oil burned) Estimated Release (metric tons) Particulates (<3. 5 µm) 16 -20 1, 200 -1, 500 Elemental carbon (soot) 2. 8 -5. 5 210 -410 Total organic carbon (aerosol) 4. 0 -8. 0 300 -600 Total organic carbon (vapor) 7. 1 -20. 7 500 -1, 600 Carbon monoxide (CO) 51. -11. 6 380 -870 Carbon dioxide (CO 2) 807 -829 61, 000 -62, 000 Methane (CH 4) 1. 6 -2. 8 120 -210 Sulfur dioxide (SO 2) 16 -33 1, 200 -2, 500 0. 49 -0. 64 37 -48 10% of Total Organic Carbon (aerosol) 30 -60 Nitrogen oxides (NOx) Polycyclic aromatic hydrocarbons

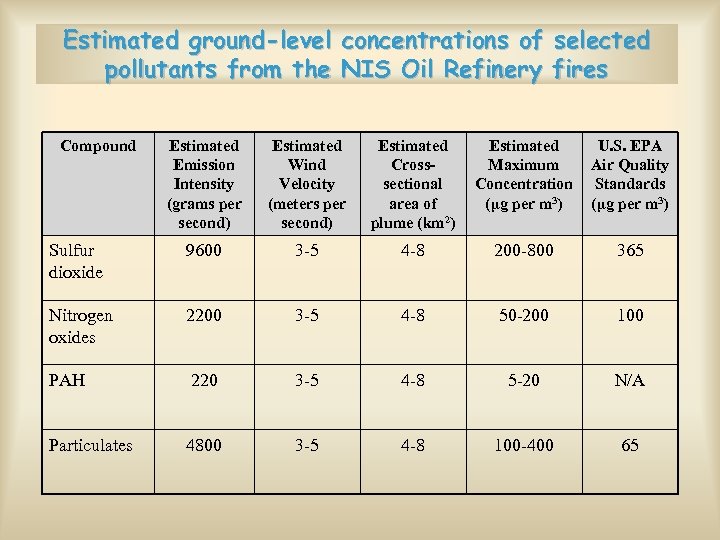

Estimated ground-level concentrations of selected pollutants from the NIS Oil Refinery fires Compound Estimated Emission Intensity (grams per second) Estimated Wind Velocity (meters per second) Estimated Crosssectional area of plume (km 2) Estimated Maximum Concentration (µg per m 3) U. S. EPA Air Quality Standards (µg per m 3) Sulfur dioxide 9600 3 -5 4 -8 200 -800 365 Nitrogen oxides 2200 3 -5 4 -8 50 -200 100 PAH 220 3 -5 4 -8 5 -20 N/A Particulates 4800 3 -5 4 -8 100 -400 65

Estimated ground-level concentrations of selected pollutants from the NIS Oil Refinery fires Compound Estimated Emission Intensity (grams per second) Estimated Wind Velocity (meters per second) Estimated Crosssectional area of plume (km 2) Estimated Maximum Concentration (µg per m 3) U. S. EPA Air Quality Standards (µg per m 3) Sulfur dioxide 9600 3 -5 4 -8 200 -800 365 Nitrogen oxides 2200 3 -5 4 -8 50 -200 100 PAH 220 3 -5 4 -8 5 -20 N/A Particulates 4800 3 -5 4 -8 100 -400 65

Medical Management of Mass Casualty • Search, rescue and first aid. • Transport to health facility and treatment • Redistribution of patients between hospitals

Medical Management of Mass Casualty • Search, rescue and first aid. • Transport to health facility and treatment • Redistribution of patients between hospitals

Definitions Disaster • A Disaster situation may be defined as any emergency that overwhelms the available medical resources. Triage • Triage is a French work meaning “to sort”.

Definitions Disaster • A Disaster situation may be defined as any emergency that overwhelms the available medical resources. Triage • Triage is a French work meaning “to sort”.

Definitions (cont’d) MCI • A Mass Casualty Incident (MCI) is defined as any situation in which the medical care required exceeds the ability to provide that care.

Definitions (cont’d) MCI • A Mass Casualty Incident (MCI) is defined as any situation in which the medical care required exceeds the ability to provide that care.

Scene Evaluation • Safety – evaluation of all possible dangers and assuring that none still exist. • Scene – evaluation of physical site e. g. no of vehicles in crash, fire, explosion or toxic release. • Situation – what really happened here? Why?

Scene Evaluation • Safety – evaluation of all possible dangers and assuring that none still exist. • Scene – evaluation of physical site e. g. no of vehicles in crash, fire, explosion or toxic release. • Situation – what really happened here? Why?

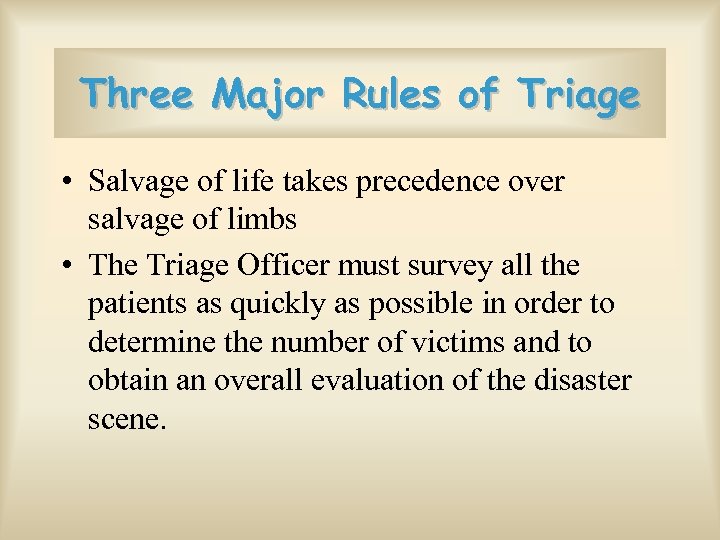

Three Major Rules of Triage • Only immediate life-threatening conditions are identified and treated in the initial triage round: i. e. airway obstruction, open chest injuries or major external haemorrhage.

Three Major Rules of Triage • Only immediate life-threatening conditions are identified and treated in the initial triage round: i. e. airway obstruction, open chest injuries or major external haemorrhage.

Three Major Rules of Triage • Salvage of life takes precedence over salvage of limbs • The Triage Officer must survey all the patients as quickly as possible in order to determine the number of victims and to obtain an overall evaluation of the disaster scene.

Three Major Rules of Triage • Salvage of life takes precedence over salvage of limbs • The Triage Officer must survey all the patients as quickly as possible in order to determine the number of victims and to obtain an overall evaluation of the disaster scene.

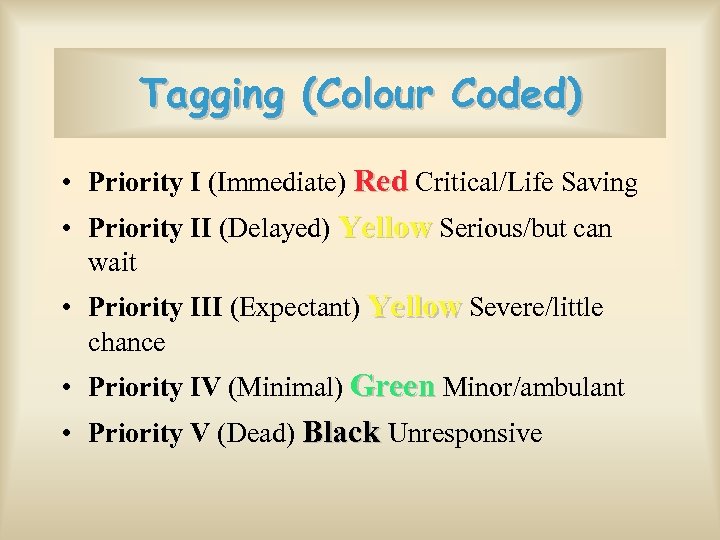

Tagging (Colour Coded) • Priority I (Immediate) Red Critical/Life Saving • Priority II (Delayed) Yellow Serious/but can wait • Priority III (Expectant) Yellow Severe/little chance • Priority IV (Minimal) Green Minor/ambulant • Priority V (Dead) Black Unresponsive

Tagging (Colour Coded) • Priority I (Immediate) Red Critical/Life Saving • Priority II (Delayed) Yellow Serious/but can wait • Priority III (Expectant) Yellow Severe/little chance • Priority IV (Minimal) Green Minor/ambulant • Priority V (Dead) Black Unresponsive